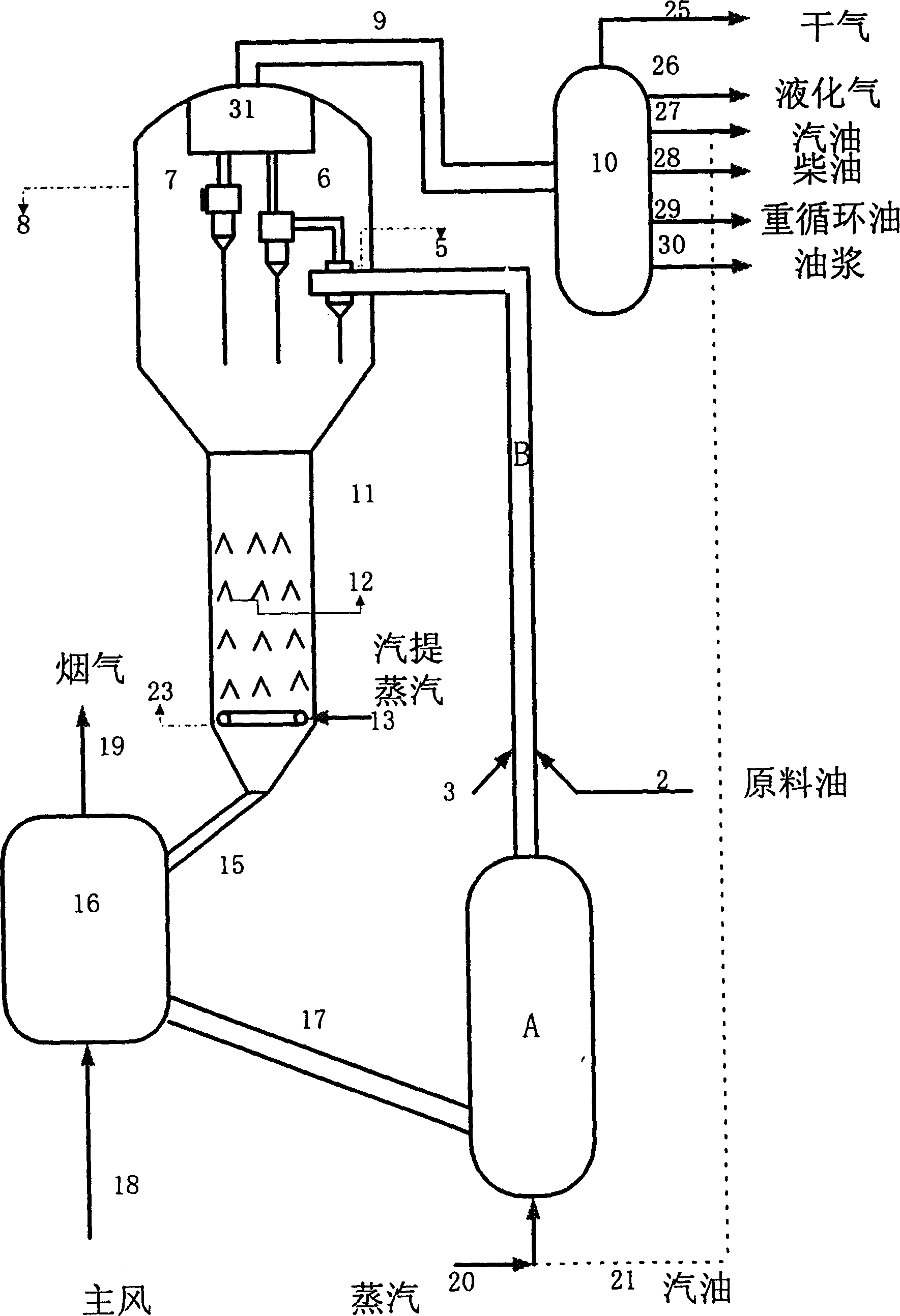

Method for catalyzing and transfering petroleum hydrocarbon compounds by using reactor with dual reacting regions

A technology for reactors and petroleum hydrocarbons, applied in catalytic cracking, petroleum industry, cracking, etc., can solve the problems of high olefin content and the inability to greatly reduce olefin content at the same time, so as to increase octane number and reduce hydrothermal deactivation , Improve the effect of diesel-gas ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example illustrates the situation of gasoline cracking, aromatization, desulfurization, and olefin reduction in a small fixed fluidized bed reactor using the method provided by the present invention and conventional catalysts. The properties of the catalytic gasoline feedstock refer to feedstock A in Table 1.

[0043] The test procedure is the same as that of the conventional catalytic cracking fixed fluidized bed unit. Using catalytic gasoline as raw material, the effect of temperature change on aromatics in product gasoline was investigated using MLC-500 catalyst (commercial brand, industrial production of catalyst factory of Qilu Petrochemical Company). The properties of the catalysts are listed in Table 3. Agent oil ratio is 30, space velocity is 4Hr -1 , and the temperatures were 500°C, 550°C, 600°C, and 650°C, respectively. The test data are listed in Table 4. From the data in Table 4, it can be seen that the content of aromatics in the product gasoline h...

Embodiment 2

[0045] This example illustrates the situation of gasoline cracking, aromatization, desulfurization, and olefin reduction in a small fixed fluidized bed reactor using the method provided by the present invention and using different types of catalysts.

[0046] The test procedure is the same as that of the conventional catalytic cracking fixed fluidized bed unit. See B in Table 1 for the properties of the raw materials. Catalyzed gasoline is used as raw material, conventional MLC-500 + catalyst containing shape-selective molecular sieve additives, conventional LV-23 + catalysts containing shape-selective molecular sieve additives, RAG-6, CRP-1 are used. The properties of the catalyst are shown in Table 2 and Table 3. The test data are listed in Table 5. It can be seen from Table 5 that the content of aromatics in the product gasoline has been greatly increased, reaching over 77.68% by weight; the content of olefins has dropped below 6.67% by weight; the content of sulfur has d...

Embodiment 3

[0048] This example illustrates the situation of gasoline cracking, aromatization, desulfurization, and olefin reduction in a small fixed fluidized bed reactor using the method provided by the invention and using MLC-500+ additives under different operating conditions.

[0049] The test procedure is the same as that of the conventional catalytic cracking fixed fluidized bed unit. The properties of the catalyst are shown in Table 2; the properties of the raw materials are shown in A in Table 1. The test results are listed in Table 6. From the data in Table 6, it can be known that the content of aromatics in the product gasoline has increased significantly, the content of olefins and sulfur has decreased, and the octane number has increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com