Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce forging process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wind-powered main shaft forging method

ActiveCN102806291AEnsure forging quality requirementsReduce fire consumptionMetal-working apparatusFurnace typesElectricityThermal treatment

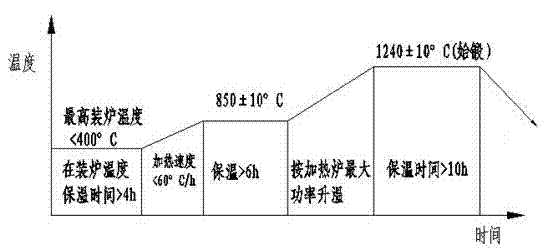

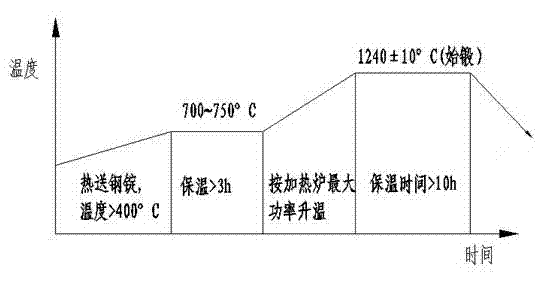

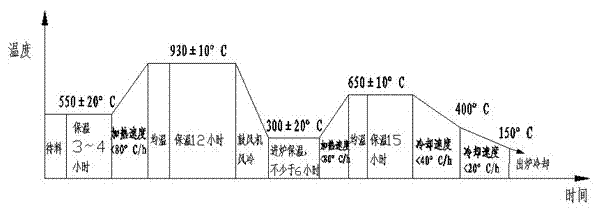

The invention relates to a wind-powered main shaft forging method. The wind-powered main shaft forging method comprises the following steps of inspecting a material; heating the material; taking out a blank which is formed by annealing the material for the first time, pre-forging, upsetting, drawing and printing the blank, performing pre-forging to form the blank, and blanking; finally forging the blank to form a main shaft by annealing for the second time, forging a flange end on a hollow rotary worktable, and drawing the main shaft until a shaft body has forging size; performing re-crystallization normalized tempering thermal treatment by using a one-time thermal loading furnace after forging the wind-powered main shaft; roughly turning the wind-powered main shaft and detecting flaws through ultrasonic wave; hardening and tempering the wind-powered main shaft, and performing nondestructive inspection and physical and chemical inspection on the wind-powered main shaft; finely turning the wind-powered main shaft; and packaging the wind-powered main shaft. The wind-powered main shaft forging method provided by the invention has the characteristics that the efficiency is high, the energy is saved, the cost is reduced, and the forging quality is improved.

Owner:JIANGSU LINGFEI FORGING

Short-flow casting and rolling composite forming method for ferrule piece

The invention relates to a short-flow casting and rolling composite forming method for a ferrule piece, which belongs to a machining and forming method for a large-sized ferrule piece and mainly overcomes the technical difficulty that the conventional rolling method has high material waste and serious energy waste. The invention adopts the technical scheme that the short-flow casting and rolling composite forming method for the ferrule piece comprises the steps of alloy melting, molten steel refining, centrifugal casting of a ring blank, hot rolling and expanding, rough machining, heat treatment and finish machining, wherein the molten steel refining refers to external refining with an LF furnace and argon stirring to obtain high-purity molten steel; the centrifugal casting of the ring blank comprises that the refined molten steel is centrifugally cast at the temperature of 1,600 DEG C to form the ring blank, and meanwhile the cast blank grains are thinned by adopting electromagnetic stirring; and the hot rolling and expanding comprise that when the ring blank casting is solidified and the temperature drops to initial forging temperature of 1,200 DEG C, the rolling and expanding are directly performed on a rolling and expanding machine, the feeding amount is controlled during rolling and expanding, and the rolling-expanding ratio is 2 to 3.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

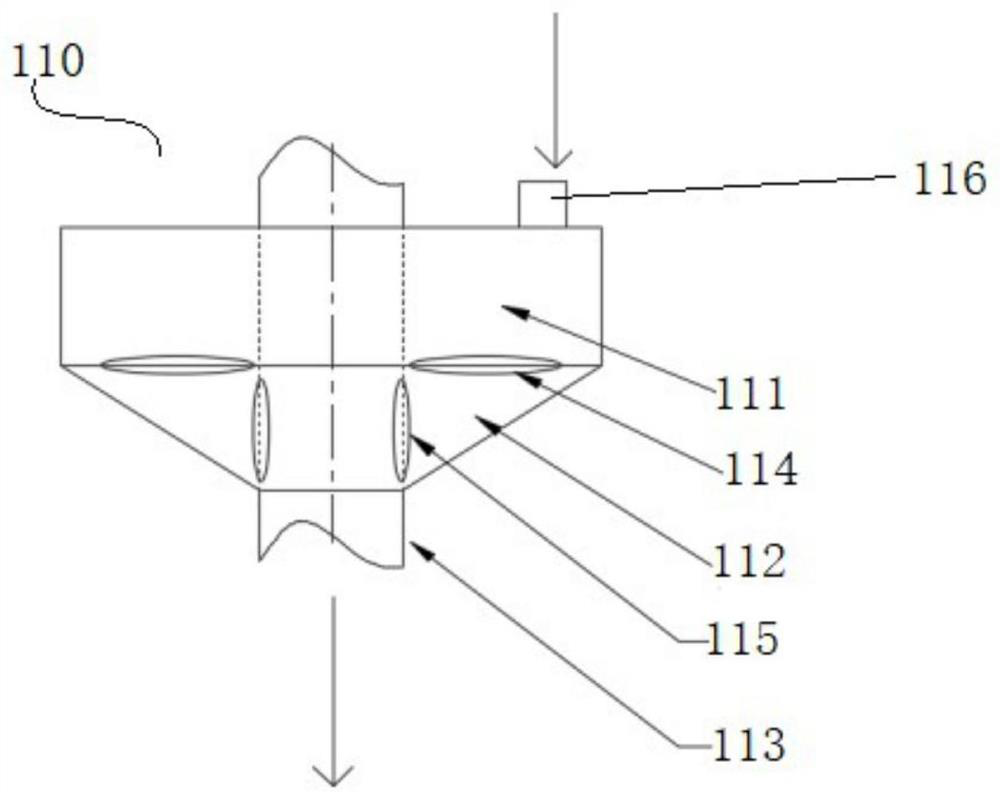

Non-flash groove, non ingot tail smithing method for large-scale wind power principal axle

InactiveCN101293269AGood clamping functionEasy to turn functionForging/hammering/pressing machinesEngine componentsElectricityIngot

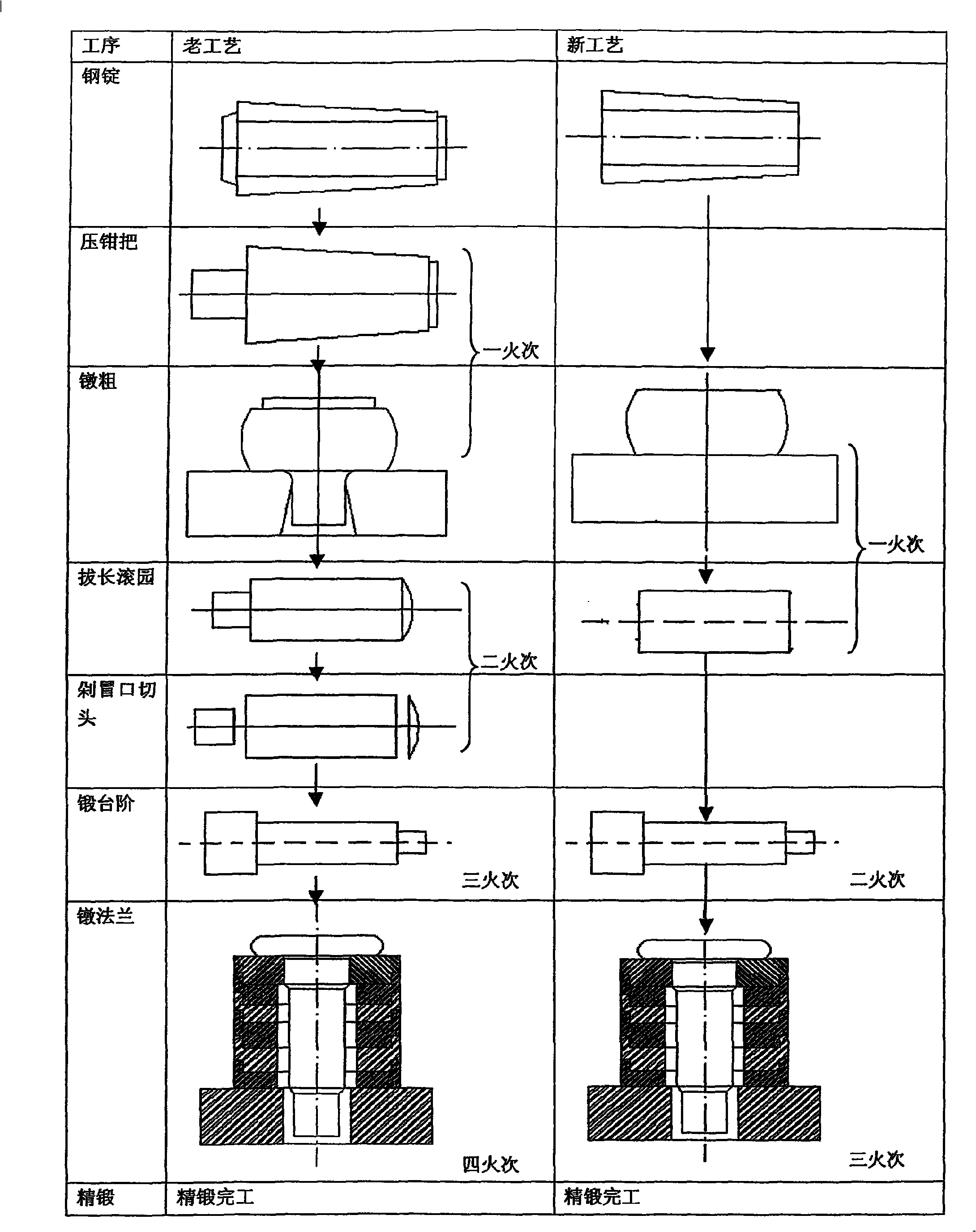

The invention relates to a no-riser and no-ingot tail forging method for a large-scale wind power main shaft; before heating and forging, a riser and a ingot tail of a steel ingot are cut off by a saw, then a jaw of pliers of a manipulator is used for clamping the steel ingot without the riser and the ingot tail, and then the processes of upsetting, drawing out, rolling circle, forging steps and upsetting flange are carried out; the jaw of the pliers of the manipulator includes pliers arms (2), sleeve seats (4) and ball-head cylinders (5); the number of the pliers arms (2), the sleeve seats (4) and the ball-head cylinders (5) is two, one piece is at the left and the other piece is at the right, one end of the left pliers arm (2) is articulated with one end of the right pliers arms (2) by a gemel (1), the other ends thereof are respectively provided with the left sleeve seat (4) and the right sleeve seat (4), the left ball-head cylinder and the right ball-head cylinder (5) are respectively pass through the left sleeve seat (4) and the right sleeve seat (4); the ball-head ends of the left ball-head cylinder and the right ball-head cylinder (5) are arranged at the inner sides of the left sleeve seat (4) and the right sleeve seat (4) in a left and right antithetic manner, and the other ends thereof are provided with a fixed pin (6) by inserting along the radial direction. The method of the invention can reduce forging processes, improve production efficiency, shorten forging time and enhance forging precision and forging quality.

Owner:JIANGYIN LEGAO ENERGY EQUIP

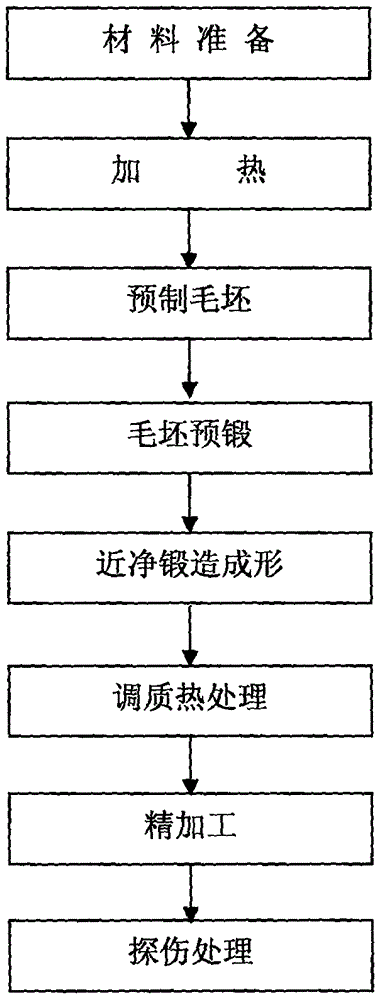

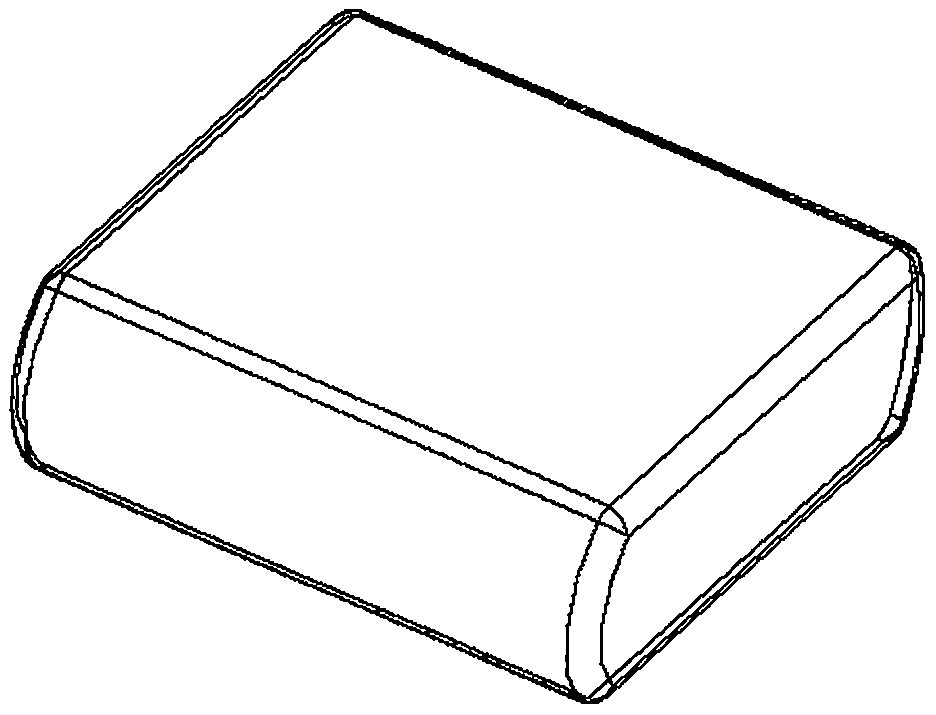

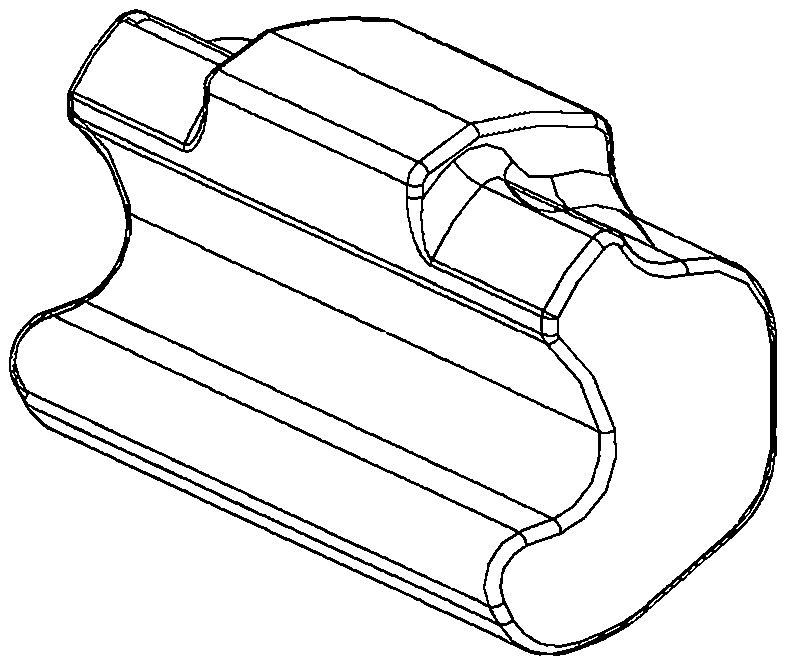

Near-net forging forming method of railway vehicle coupler knuckle

ActiveCN106077380AHigh forming precisionNo machining process requiredMetal-working apparatusMaterials preparationHigh volume manufacturing

The invention discloses a near-net forging forming method of a railway vehicle coupler knuckle. The problems that forging forming of the railway vehicle coupler knuckle is difficult, and the machining and manufacturing process is complex are solved. The near-net forging forming method comprises the steps of material preparation, heating, prefabrication of blanks, preforging, closed die-forging, waste heat quenched-tempered heat treatment, finish machining, flaw detection and the like. A closed die-forging technology is adopted so that near-net forming of the coupler knuckle can be achieved, energy and materials are saved, the outer contour shape and size do not need to be machined, and the utilization ratio of the materials can reach 92% or above. In the whole forming process, workpieces are always in a three-dimensional stress state, and products have a compact structure, high toughness, good fatigue performance and long service life. The defects of air holes, shrinkage porosity, inclusions, cracks and the like in existing casted coupler knuckles are overcome, and the problems of complex process and difficult forming in the existing coupler knuckle forging manufacturing process are solved. The near-net forging forming method is simple in manufacturing process, high in material utilization rate and suitable for mass production and manufacturing of railway vehicle coupler knuckle products of various types.

Owner:JILIN UNIV +1

Method for rapidly forming GH4720Li high-temperature alloy forge piece

ActiveCN112893722AThe grain size is finer and more uniformImprove uniformityMetal-working apparatusIncreasing energy efficiencyFiberAluminum silicate

The invention relates to a method for rapidly forming a GH4720Li high-temperature alloy forge piece, and belongs to the technical field of material forming and control. The method for rapidly forming the GH4720Li high-temperature alloy forge piece comprises the following steps that a, preparation is performed, specifically, a unilateral allowance of 9-12mm is designed for the forge piece; the minimum deformation of a bar in a die cavity in the primary die forging process is 50% or above; the bar is sequentially coated with fiber cloth coated with graphite, aluminum silicate heat preservation cotton and a metal layer at the normal temperature; the bar is preheated through four-section temperature rising; a mold core is preheated to 500-650 DEG C, and a mold sleeve is preheated to 300-400 DEG C; after the mold is prepared, a lower mold cavity is sequentially covered with fiber cloth coated with graphite and aluminum silicate heat preservation cotton, the preheated bar is placed in the mold cavity, and the upper surface of the bar is covered with the fiber cloth coated with the graphite; and b, forging is performed, specifically, after a press makes contact with the bar, forging and forming are performed. According to the method, the forge piece is directly molded from the bar to die forging through one-fire molding, and the forging procedure is shortened by more than 50%.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

Retaining ring short-flow manufacturing process

ActiveCN105903869AIncrease profitReduce forging processMetal-working apparatusElectricityManufacturing technology

The invention relates to a retaining ring short-flow manufacture technology, and belongs to the electroslag technology field. <{EN2}>The method comprises the steps of A) electroslag hollow steel pipe, namely employing electroslag continuous casting mobile core rod production principle, i.e. consumable electrode for continuously uniform fusing, so that a slag surface rises continuously to start an ingot device after reaching a predetermined height, so as to tract the hollow steel ingot move downwards slowly; the tract speed is in direct proportion with the consumable electrode fusing speed, and the two speeds are balanced; after melting, the steel ingot and the core rod are lifted; the core rod is taken out and the hollow steel pipe retaining ring is completed; B) pulling; C) solid melting; D) mechanical processing, namely processing the internal and external surface of a blank and two transverse planes until ho black dots appear; E) cold expansion, namely deforming the retaining ring by means of hydraulic pressure by using a water press over 8000ton through a special die to obtain a retaining ring that has a high strength that is larger than or equal to 1000 Mpa; F) tempering, namely employing insulating the retaining ring between 35- DEG C and 400 DEG C for a long time after cold expansion to eliminate the deformation pressure.

Owner:海南岛隆环保科技有限公司

Method for manufacturing martensitic stainless steel continuous casting billet extruded seamless pipe

The invention discloses a method for manufacturing a martensitic stainless steel continuous casting billet extruded seamless pipe. The method comprises the following steps of firstly, preparing a martensitic stainless steel continuous casting billet; secondly, peeling and segmenting the surface of the continuous casting billet; thirdly, drilling the continuous casting billet and processing a bellmouth on the end face; fourthly, cleaning and preheating the continuous casting billet; fifthly, carrying out induction heating and lubricant rolling on the continuous casting billet; sixthly, addinga lubricant to the bell mouth and expanding the hole; seventhly, carrying out induction heating again, adding lubricant inside and rolling the continuous casting billet with lubricant outside; and eighthly, preparing a tool and a mold and performing extrusion molding. According to the extrusion method for the martensitic stainless steel continuous casting billet provided by the invention, the rawmaterial is the continuous casting round billet, the defects of loose center, shrinkage holes and the like of the continuous casting billet are removed through outside peeling and inside drilling, thecenter quality of the continuous casting billet is improved through hole expanding, and the martensitic stainless steel seamless pipe is produced through an extrusion process. The seamless steel pipeproduced in the invention is low in manufacturing cost and good in inner and outer surface quality, and the size of the steel pipe can meet the requirements of customers.

Owner:江阴华润制钢有限公司

Short-process continuous casting and continuous extrusion equipment for titanium or titanium alloy wires and preparation method for wires

The invention provides short-process continuous casting and continuous extrusion equipment for titanium or titanium alloy wires. The short-process continuous casting and continuous extrusion equipment comprises a mixing and feeding device, a melting and ingot casting device, a pulling device, a continuous rod making device, a continuous wire drawing device and a wire winding device. Different kinds of raw materials enter a cooling bed in the melting and ingot casting device after being fed and mixed, metal liquid is formed through heating and smelting of a plasma gun, the metal liquid overflows into a crystallizer for ingot casting forming, formed ingots enter the continuous rod making device after being pulled out through the pulling device, the structure form needed by wire drawing is obtained through the continuous rod making device, then the ingots enter the continuous wire drawing device for wire drawing to obtain formed wires, and the formed wires are wound into a reel through the wire winding device. The invention further provides a short-process preparation method for the titanium or titanium alloy wires. According to the short-process equipment for the titanium or titanium alloy wires, the machining procedure is shortened through continuous design, and the titanium alloy wires with more uniform components and better structure forms are obtained through the specific structural design of continuous casting and continuous extrusion.

Owner:江苏宇钛新材料有限公司

Production method of L80-9Cr martensitic stainless steel pipe

The invention relates to a production method of an L80-9Cr martensitic stainless steel pipe. The production method comprises the following steps of (1) preparing a blank, specifically, centrifugally casting to produce a hollow pipe blank; (2) blank annealing, specifically, annealing the hollow pipe blank to reduce the hardness of the hollow pipe blank; (3) blank machining, specifically, machiningthe annealed hollow pipe blank, and removing air holes, shrinkage porosity and slag inclusion defects on the inner wall and the outer wall; (4) hot counterboring, specifically, heating to 1120-1160 DEG C, and performing the hot counterboring in a counterboring barrel; (5) hot extrusion, specifically, heating to 1160-1210 DEG C, and carrying out the hot extrusion deformation in an extrusion barrel;and (6) heat treatment, specifically, heating the steel pipe to 970-1000 DEG C, conducting air blowing and rapid cooling, heating again to 680-720 DEG C, and tempering to obtain the finished steel pipe; and the production system involves a centrifugal casting machine, an annealing furnace, blank machining equipment, a counterboring machine, a heat extruding machine and a heat treatment furnace. According to the production method of the L80-9Cr martensitic stainless steel pipe, a process route of centrifugal casting and hot extrusion is adopted, so that a production process is optimized, the loss of a riser is reduced, the metal yield is high, and the cost is low.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Production method of corrosion resistant alloy plates and split type pouring die used by same

ActiveCN102941322AImprove mechanical propertiesMechanical properties unchangedCorrosion resistant alloyEnergy consumption

The invention aims at the defects of complex manufacturing process and large energy consumption for producing plates by using the pouring die and the production method in the prior art and provides a production method of corrosion resistant alloy plates and a split type pouring die used by the same. A die body is composed of a half square cylinder-shaped female die and a half square cylinder-shaped male die, the female die and the male die are combined to form a square cylinder-shaped die cavity by a female die matching surface and a male die matching surface, and the female die and the male die are fastened into a whole by a fastening device. The production method comprises the following steps of: carrying out vacuum pouring to obtain a rough plate blank by adopting the split type pouring die, removing oxide skins and feed heads for the rough plate blank to obtain a plate blank, and rolling the plate blank to obtain the plate. According to the split type pouring die and the production method, because the shape of an inner cavity of the die body is in consistent with the plate blank shape required by the plate, the rough plate blank formed by pouring can become the required plate blank so long as the oxide skins and the feed head are removed, the forging process is saved, and the processing cost is reduced by 20%.

Owner:秦皇岛核诚镍业有限公司

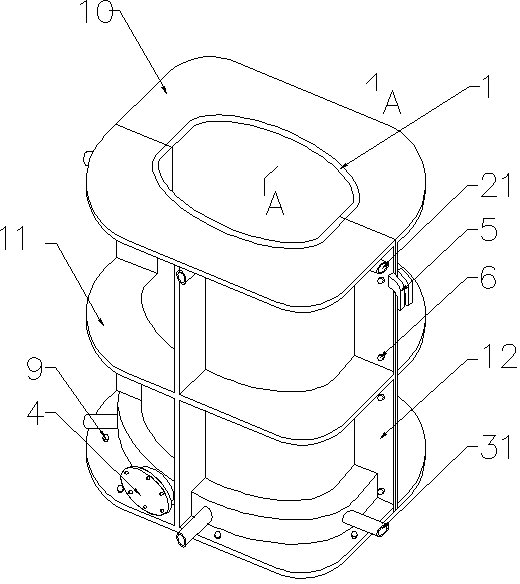

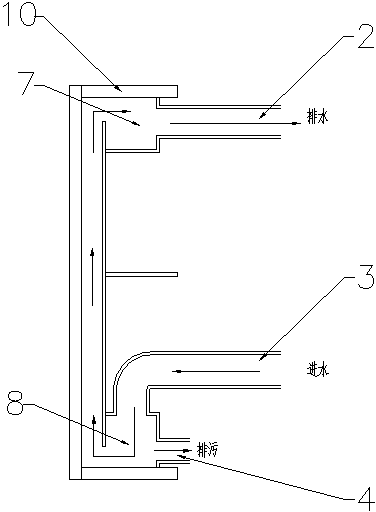

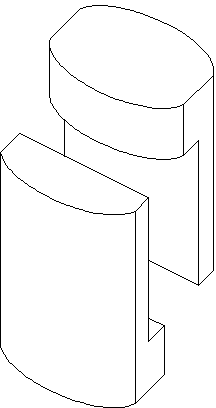

Electroslag smelting and casting sector-plate special-shaped crystallizer

The invention discloses an electroslag smelting and casting sector-plate special-shaped crystallizer, and belongs to the technical field of crystallizers. The electroslag smelting and casting sector-plate special-shaped crystallizer is composed of a front portion and a rear portion which are symmetrical. Taking the front portion as an example , the front portion is composed of an inner cavity shaping plate, an outer cavity shaping plate, a water discharging pipeline and a water feeding pipeline. When the electroslag smelting and casting sector-plate special-shaped crystallizer is used, the front portion and the rear portion are connected together through nuts in the mode that bolts penetrating through bolt holes A, and a plurality of electroslag smelting and casting sector-plate special-shaped crystallizers can be stacked for use in the vertical direction. After the front portion and the rear portion are combined, a cavity is formed by the inner cavity shaping plate, wherein the left side and the right side of the cavity are parallel, and the upper side and the lower side of the cavity are respectively in an arc shape; the outer cavity shaping plate has the same shape as the inner cavity shaping plate, a water trough is located between the inner cavity shaping plate and the outer cavity shaping plate, and the thickness of the water trough ranges from 15 mm to 25 mm. The lower portion of the outer cavity shaping plate is provided with a water feeding pipe, the upper portion of the outer cavity shaping plate is provided with a water discharging pipe, the water feeding pipe is connected with the water feeding pipeline, the water discharging pipe is connected with the water discharging pipeline, and the water feeding pipeline is further provided with a sewage discharging hole. The electroslag smelting and casting sector-plate special-shaped crystallizer has the advantages that the number of forging procedures is reduced, production procedures are simplified, and production cost is reduced.

Owner:HEILONGJIANG XINYUAN SPECIAL STEEL

Manufacturing method of molybdenum tube target

ActiveCN104646929BHigh purityGuaranteed purityVacuum evaporation coatingSputtering coatingIngotOxygen content

The invention discloses a manufacturing method of a molybdenum target tube material. The method is that molybdenum powder is used as the raw material. The method comprises the steps of preparing a molybdenum ingot; mechanically processing for the first time; extruding; thermally processing; mechanically processing for the second time to obtain the final product. The method has the advantages of being simple in process, low in production cost, high in purity of target material, high in density, low in oxygen content, large in length, uniform in structure, and small in crystal grains.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Wind-powered main shaft forging method

ActiveCN102806291BEnsure forging quality requirementsReduce fire consumptionMetal-working apparatusFurnace typesElectricityThermal treatment

The invention relates to a wind-powered main shaft forging method. The wind-powered main shaft forging method comprises the following steps of inspecting a material; heating the material; taking out a blank which is formed by annealing the material for the first time, pre-forging, upsetting, drawing and printing the blank, performing pre-forging to form the blank, and blanking; finally forging the blank to form a main shaft by annealing for the second time, forging a flange end on a hollow rotary worktable, and drawing the main shaft until a shaft body has forging size; performing re-crystallization normalized tempering thermal treatment by using a one-time thermal loading furnace after forging the wind-powered main shaft; roughly turning the wind-powered main shaft and detecting flaws through ultrasonic wave; hardening and tempering the wind-powered main shaft, and performing nondestructive inspection and physical and chemical inspection on the wind-powered main shaft; finely turning the wind-powered main shaft; and packaging the wind-powered main shaft. The wind-powered main shaft forging method provided by the invention has the characteristics that the efficiency is high, the energy is saved, the cost is reduced, and the forging quality is improved.

Owner:JIANGSU LINGFEI FORGING

Free forging forming process and die for large bent knife plate forgings

ActiveCN112008025AEasy to shapeIncrease profitForging/hammering/pressing machinesWire cuttingDumbbell shaped

The invention relates to the technical field of forging, and discloses a free forging forming process and die for large bent knife plate forgings. The method comprises the following steps of firstly performing high-temperature free forging forming by using a convex anvil by taking a rectangular billet as an initial blank to obtain a strip-shaped blank with a dumbbell-shaped section; secondly, cutting the long-strip-shaped blank along the center line, and obtaining two prefabricated blanks which are different in thickness on the two sides and are in smooth transition; and thirdly, using a freeforging and finish forging drawing-out die with a flow guide groove and asymmetric baffles on the two sides for conducting high-temperature forging drawing-out on the cut prefabricated blank, the material thickness of the outer side area of the prefabricated blank is reduced, the prefabricated blank extends in the feeding direction, the prefabricated blank is forced to be bent inwards, and therefore the large bent knife plate forgings are obtained through forming. By means of the free forging forming process and die, forging forming of the large bent knife plate forgings is achieved, the forging performance and the material utilization rate can be improved, the equipment load is reduced, the forging forming effect is improved, and the production efficiency is improved.

Owner:JILIN UNIV

Pouring method for large-section consumable electrode

The invention relates to a pouring method for a large-section consumable electrode. The pouring method has the requirement that an electrode blank is frustum-shaped, the diameter of the lower end is smaller than that of the upper end, and the height is 2000-6000mm; the length of an ingot mould is 38-42mm larger than that of the electrode blank, the inner diameter of an upper opening of the ingot mould is 815-835mm, and the inner diameter of a lower opening is 805-825mm; and the steel type of a steel ingot is any one of S44SY, H13 and TSM166. The pouring method includes the following steps sequentially that I. the pouring temperature is 60-80 DEG C higher than that of a liquid phase wire, argon sealing protection is adopted in pouring, and the temperature of the ingot mould is 50-100 DEG C; II. composite slag is poured in a protection mode in the protection slag pouring process with the adding quantity being 15.6-16.4 kg / piece; III. a heat generating agent is gently added when the portion of a rise with 0.64-0.70 of the weight of the riser is poured in the riser pouring process, and the adding quantity is 11.8-12.2 kg / piece; and IV. the pouring time of the an ingot body is 16-19min, and the pouring time of the riser is 7-10min. The pouring method for the large-section consumable electrode reduces the working procedure of rolling or forging and reduces production cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Ordinary press machine blocking forging tool set

InactiveCN103170567AIncrease profitSimple transmission structureForging/hammering/pressing machinesEngineeringEnergy conservation

The invention discloses an ordinary press machine blocking forging tool set which comprises a tool set support and a die forging punch penetrating the upper end of the tool set support and being capable of vertically reciprocating. A die assembly mechanism and a lateral pressing mechanism are further arranged on the tool set support, wherein the die assembly mechanism and the lateral pressing mechanism are driven by the die forging punch. Due to the fact that a purely mechanical structure is adopted, and a cone-shaped surface machined on the punch is used for controlling separation and closing of a die, the ordinary press machine blocking forging tool set has the advantages of being capable of simplifying a transmission structure, effectively reducing development cost, solving the technical problems of complex structure and high development cost of a common blocking forging tool set and influences of leakage and temperature on product quality, enlarging application range of blocking forging, effectively reducing forging processes, saving energy, obviously improving utilization of materials, and reducing product cost.

Owner:SOUTH CHINA UNIV OF TECH

Gear forging die and forging process thereof

InactiveCN112108602AReduce forging processGuaranteed matching accuracyForging/hammering/pressing machinesWheelsHydraulic cylinderGear wheel

The invention discloses a gear forging die, and relates to a die. The gear forging die particularly comprises a base, a workbench, a lower die and an upper die; the workbench is installed on the basethrough support legs, the lower die for gear forging is installed on the workbench, and four corners of the top surface of the workbench are correspondingly and fixedly connected with the bottom surface of a top plate through support rods; a punch hammer used for forging work is installed in the middle of the bottom face of the top plate through a hydraulic cylinder, vertical connecting rods are slidably installed at the four corners of the top plate correspondingly, the top ends of the connecting rods are fixedly connected with the four corners of the bottom face of a lifting plate correspondingly, and the bottom ends of the connecting rods are fixedly connected with the four corners of the top face of a mounting plate correspondingly; the mounting plate is located below the punch hammer;and the upper die for gear forging is installed on the bottom surface of the mounting plate. According to the gear forging die and the forging process thereof, in the implementation process, the gearcan be formed at a time through the matching effect of the upper die, the lower die and a sliding block, and the gear forging forming process is effectively reduced.

Owner:王建国

Ordinary press machine blocking forging tool set

InactiveCN103170567BIncrease profitSimple transmission structureForging/hammering/pressing machinesEngineeringEnergy conservation

The invention discloses an ordinary press machine blocking forging tool set which comprises a tool set support and a die forging punch penetrating the upper end of the tool set support and being capable of vertically reciprocating. A die assembly mechanism and a lateral pressing mechanism are further arranged on the tool set support, wherein the die assembly mechanism and the lateral pressing mechanism are driven by the die forging punch. Due to the fact that a purely mechanical structure is adopted, and a cone-shaped surface machined on the punch is used for controlling separation and closing of a die, the ordinary press machine blocking forging tool set has the advantages of being capable of simplifying a transmission structure, effectively reducing development cost, solving the technical problems of complex structure and high development cost of a common blocking forging tool set and influences of leakage and temperature on product quality, enlarging application range of blocking forging, effectively reducing forging processes, saving energy, obviously improving utilization of materials, and reducing product cost.

Owner:SOUTH CHINA UNIV OF TECH

A processing method to effectively improve the quality of large forgings

The invention discloses a machining method for effectively improving quality of a large forging, belongs to the technical field of smelting and forging, and belongs to an improvement on the smelting and forging of the large forging. The method comprises the steps of firstly, in the smelting process, prefabricating a water gap jaw in the water gap end of an ingot, so the distribution state of water gap deposition cones is changed and the metallurgical quality of the ingot is improved; secondly, adopting riser-free forging in the forging loop and changing the fiber direction of the forging, so the forging quality of the ingot water gap is effectively improved. Through the improvement on the smelting and forging, the hot-working quality of the large forging is effectively improved.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

Thick-wall super 13cr seamless steel pipe with yield strength 125 steel grade and production method

ActiveCN113481434BHigh strengthHigh yieldOther gas emission reduction technologiesTemperingSurface oxidation

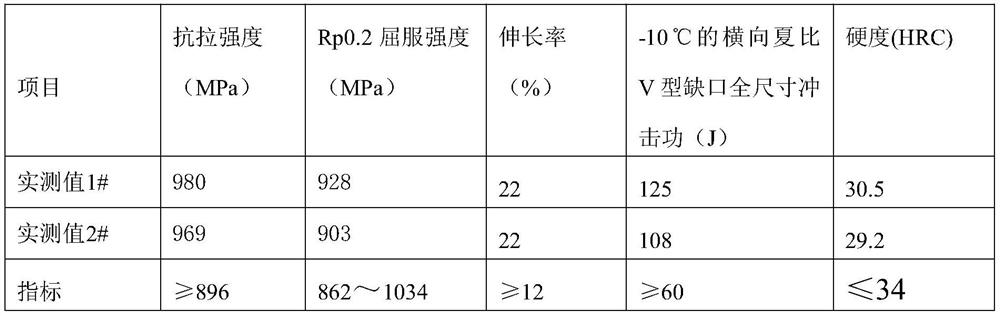

The invention relates to a thick-walled super 13Cr seamless steel pipe with a yield strength of 125 steel grade and a production method. The properties of the seamless steel pipe are: tensile strength ≥ 896 MPa, Rp0.2 yield strength 862-1034 MPa, elongation ≥ 12% . The production method of seamless steel pipe is: ⑴ electric furnace smelting + continuous casting to produce super 13Cr billet; ⑵ billet annealing to reduce hardness; ⑶ billet processing to remove surface scale, center looseness and cracks; ℃, hot extrusion molding; ⑸ preheating treatment, steel pipe heating 960 ℃ ~ 1010 ℃, blowing to cool to room temperature; ⑹ heating 960 ℃ ~ 1010 ℃, quenching oil rapid cooling, reheating 560 ℃ ~ 610 ℃, tempering treatment, Get super 13Cr steel pipe with 125 steel grade properties. The invention improves the finished product rate and quality of the seamless steel pipe and reduces the production cost. The seamless steel pipe has good surface quality, high mechanical properties after oil quenching heat treatment, high strength and good toughness.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Thick-wall super 13Cr seamless steel pipe with yield strength of 125 steel grade and production method

ActiveCN113481434AOvercome the long processReduce forging processOther gas emission reduction technologiesSteel tubeElectric furnaces

The invention relates to a thick-wall super 13Cr seamless steel pipe with a yield strength of 125 steel grade and a production method. The performance of the seamless steel pipe is characterized in that a tensile strength is larger than or equal to 896 MPa, an Rp0.2 yield strength is 862 MPa to 1034 MPa, and an elongation is larger than or equal to 12%. The production method of the seamless steel pipe comprises the following steps of (1) producing a super 13Cr casting blank through electric furnace smelting and continuous casting; (2) annealing the casting blank to reduce hardness; (3) processing the blank to remove surface oxide skin, central porosity and cracks; (4) conducting electromagnetic induction heating to 1150 DEG C to 1220 DEG C, and conducting hot extrusion forming; (5) conducting preheating treatment, specifically, heating the steel pipe to 960 DEG C to 1010 DEG C and cooling the steel pipe to a room temperature through air blowing; and (6) heating to 960 DEG C to 1010 DEG C, quickly cooling quenching oil, heating to 560 DEG C to 610 DEG C, and tempering to obtain the super 13Cr steel pipe with the 125 steel grade performance. According to the steel pipe and the method, a yield and quality of the seamless steel pipe are improved, the production cost is reduced, and the seamless steel pipe is good in surface quality, high in oil quenching heat treatment mechanical performance, high in strength and good in toughness.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

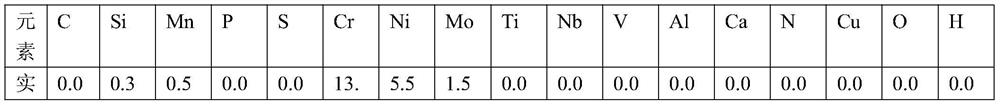

Cast steel matrix for process for preparing forging mould through double-layer build-up welding and preparation method thereof

ActiveCN102242318BExtend your lifeShorten the manufacturing cycleForging/hammering/pressing machinesThermal insulationManganese

The invention discloses a cast steel matrix for a process for preparing a forging mould through double-layer build-up welding and a preparation method thereof. The cast steel matrix is prepared from the following materials in percentage by element content: 0.2-0.35% of carbon, 0.1-0.5% of silicon, 1.0-1.8% of manganese, not more than 0.01% of phosphorus, not more than 0.01% of sulfur, 0.3-0.8% of chromium, 0.1-0.8% of nickel, 0.1-0.5% of molybdenum, not more than 0.5% of copper and the balance of iron; and the cast steel matrix is obtained by a tempering after normalizing process, wherein the normalizing temperature is within 980-1020 DEG C, the tempering temperature is within 550-600 DEG C, and the thermal insulation time is determined according to the size of a mould. The cast steel matrix prepared by the method disclosed by the invention can simultaneously greatly meet performance requirements of the forging mould on hardness, strength and two aspects, such as ductility and toughness, and also has excellent welding property.

Owner:CHONGQING UNIV +1

A kind of pouring method of electrode billet

The invention relates to a pouring method of an electrode blank. Its requirements are: the electrode blank is in the shape of a truncated cone, the diameter of the lower end is greater than the diameter of the upper end, and the height is 3640-4240mm; the length of the ingot mold is 38-42mm longer than the electrode blank, The inner diameter of the mouth is 546-566mm; the inner diameter of the lower mouth is 580-600mm; the pouring method includes the following sequential steps: Ⅰ Pouring temperature: 60-80°C higher than the liquidus temperature, protected by argon seal during pouring, and the temperature of the ingot mold is 50-100°C. Ⅱ The pouring mold slag is poured with composite slag, and the addition amount is 7.8-8.2kg / piece; Ⅲ When the cap mouth is poured to 0.64-0.70 of the weight of the cap mouth, gently add heating agent, the amount added is 5.8-6.2? kg / piece. Ⅳ The pouring times are as follows: Pouring time for the ingot body? 9'-11': The pouring time of the cap mouth? 5'-7'. The pouring method of the electrode blank reduces the rolling or forging process, shortens the preparation time of the electrode blank, and saves the cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Production method of continuous casting of titanium-containing austenitic stainless steel round tube blanks for seamless steel tubes

The invention discloses a continuous casting production method of a titanium-containing austenitic stainless steel round tube blank for a seamless steel tube. The continuous casting production method comprises the specific steps as follows: before AOD steel blending, 5-20kg carburetant per ton of steel is added according to steel tapping components of an electric furnace, and the carbon content is not less than 2.0% at AOD initial stage; AOD is carried out; reduction desulfurization is carried out, silicoferrite is added for reduction, lime and fluorite are added for slag making desulfurization, and after the reduction desulfurization is finished, slag removal is carried out in an AOD furnace; deep deoxidization is carried out; steel tapping and titanium alloying are carried out, after the deep deoxidization is finished, the steel tapping is carried out, and ferrotitanium is added along with a steel flow in a steel tapping process; LF heating is carried out; calcium treatment is carried out, silicon-calcium wires are fed to molten steel by a wire feeding machine, and the feeding quantity of pure calcium is 0.2-0.8kg per ton of steel; soft blowing is carried out; and round blank continuous casting is carried out, after the soft blowing is finished, a steel ladle is moved to a continuous casting station for pouring, and the continuous casting round tube blank is produced by using a round blank crystallizer. With the adoption of the continuous casting production method, sequence casting is realized; the yield is increased; a forging procedure is saved; the production cost is low; and the economic benefits are high.

Owner:浙江青山钢铁有限公司

A Method of Improving Microstructure Uniformity of gh4169 Disc Forging

ActiveCN111761014BReduce manufacturing costFast manufacturing cycleForging/hammering/pressing machinesWheelsTemperature controlCrazing

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Production method of corrosion resistant alloy plates and split type pouring die used by same

ActiveCN102941322BImprove mechanical propertiesMechanical properties unchangedCorrosion resistant alloyEnergy consumption

The invention aims at the defects of complex manufacturing process and large energy consumption for producing plates by using the pouring die and the production method in the prior art and provides a production method of corrosion resistant alloy plates and a split type pouring die used by the same. A die body is composed of a half square cylinder-shaped female die and a half square cylinder-shaped male die, the female die and the male die are combined to form a square cylinder-shaped die cavity by a female die matching surface and a male die matching surface, and the female die and the male die are fastened into a whole by a fastening device. The production method comprises the following steps of: carrying out vacuum pouring to obtain a rough plate blank by adopting the split type pouring die, removing oxide skins and feed heads for the rough plate blank to obtain a plate blank, and rolling the plate blank to obtain the plate. According to the split type pouring die and the production method, because the shape of an inner cavity of the die body is in consistent with the plate blank shape required by the plate, the rough plate blank formed by pouring can become the required plate blank so long as the oxide skins and the feed head are removed, the forging process is saved, and the processing cost is reduced by 20%.

Owner:秦皇岛核诚镍业有限公司

A short process manufacturing process for the retaining ring

ActiveCN105903869BIncrease profitReduce forging processMetal-working apparatusManufacturing technologySlag

The invention relates to a retaining ring short-flow manufacture technology, and belongs to the electroslag technology field. <{EN2}>The method comprises the steps of A) electroslag hollow steel pipe, namely employing electroslag continuous casting mobile core rod production principle, i.e. consumable electrode for continuously uniform fusing, so that a slag surface rises continuously to start an ingot device after reaching a predetermined height, so as to tract the hollow steel ingot move downwards slowly; the tract speed is in direct proportion with the consumable electrode fusing speed, and the two speeds are balanced; after melting, the steel ingot and the core rod are lifted; the core rod is taken out and the hollow steel pipe retaining ring is completed; B) pulling; C) solid melting; D) mechanical processing, namely processing the internal and external surface of a blank and two transverse planes until ho black dots appear; E) cold expansion, namely deforming the retaining ring by means of hydraulic pressure by using a water press over 8000ton through a special die to obtain a retaining ring that has a high strength that is larger than or equal to 1000 Mpa; F) tempering, namely employing insulating the retaining ring between 35- DEG C and 400 DEG C for a long time after cold expansion to eliminate the deformation pressure.

Owner:海南岛隆环保科技有限公司

Method for molding large ring piece by casting blank ring rolling

The invention relates to a method for molding a large ring piece by casting blank ring rolling, belonging to a method for processing and molding a large metal ring piece. The invention mainly solves the technical difficulty of more material waste and serious energy waste of the existing ring rolling method. The method has the technical scheme that the method for molding the large ring piece by casting blank ring rolling comprises the steps of alloy melting, refining, casting ring blank, casting blank ring rolling, rough processing, heat treatment and finishing; the refining means that an LF furnace is used for external refining, molten steel content and temperature are rapidly homogenized by argon blowing stirring, so that molten steel with high purity can be obtained; the casting ring blank means that when the temperature of the refined molten steel is reduced to 1580-1600 DEG C, self-hardening sand molding pouring is adopted to obtain a ring-shaped casting blank; and the casting blank ring rolling means that the ring-shaped casting blank is heated to 1100-1200 DEG C and is treated by ring rolling on a ring rolling machine, the feeding amount is controlled, and the ring rolling ratio is 2-3.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Non-flash groove, non ingot tail smithing method for large-scale wind power principal axle

InactiveCN101293269BEffective Weight Heated ForgingStands vertically for convenienceForging/hammering/pressing machinesEngine componentsElectricityIngot

Owner:JIANGYIN LEGAO ENERGY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com