Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Realize the cutting action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

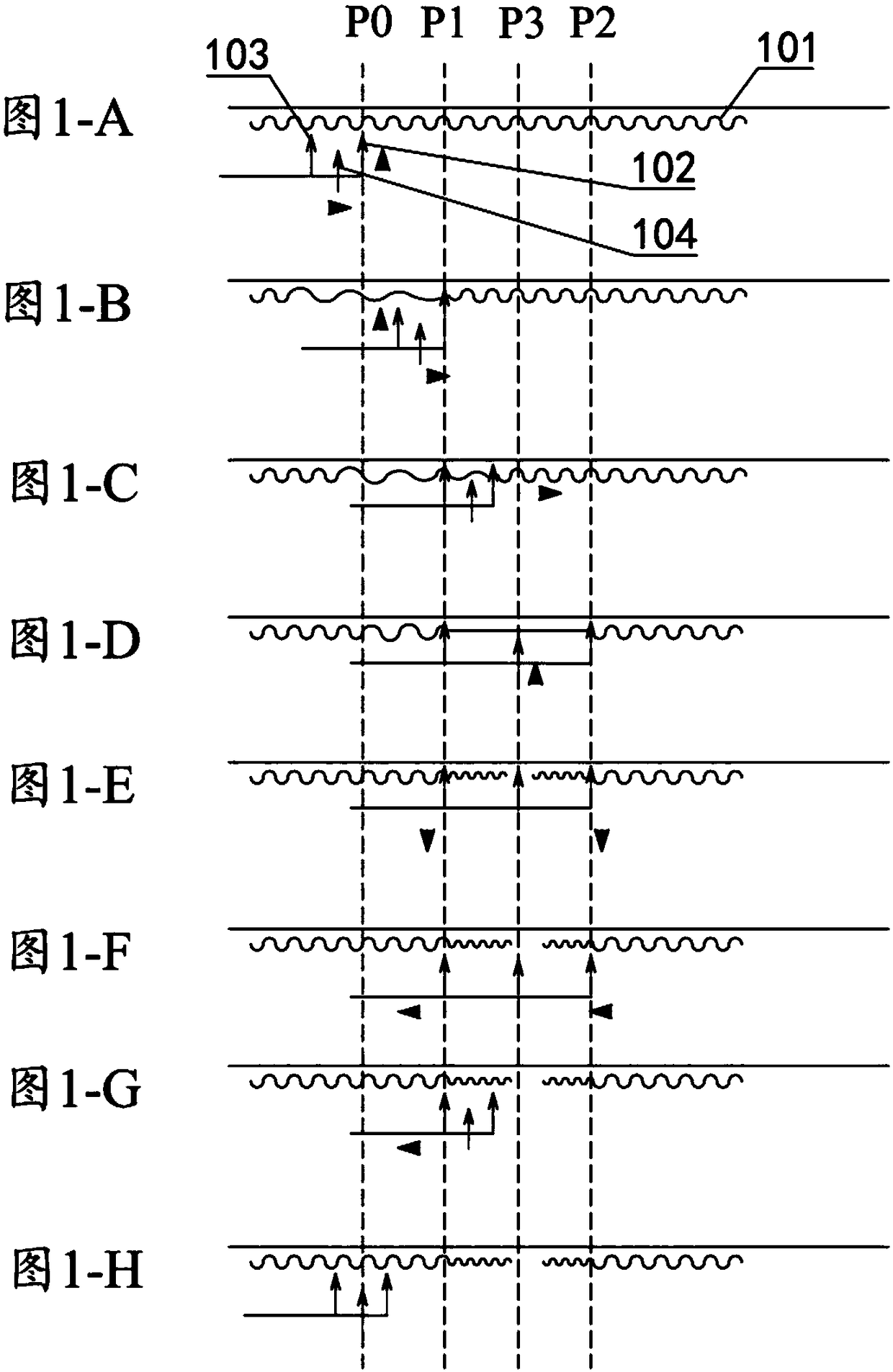

Method and system for multimode touch three-dimensional modeling

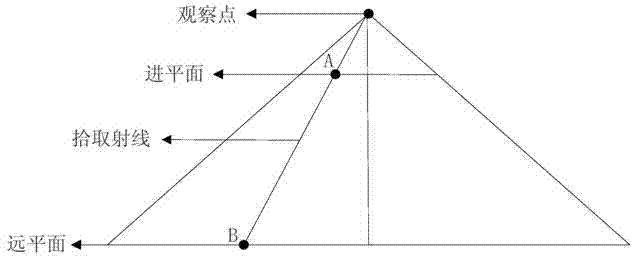

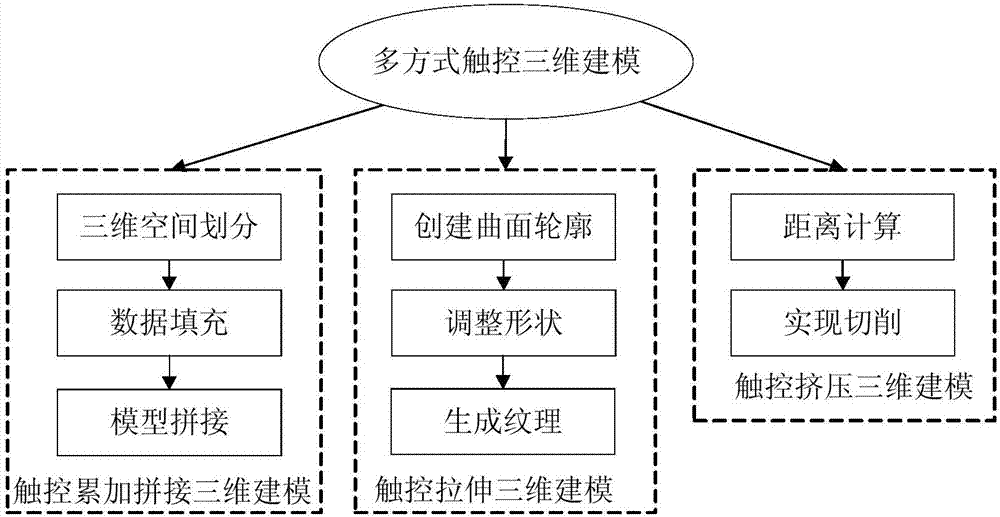

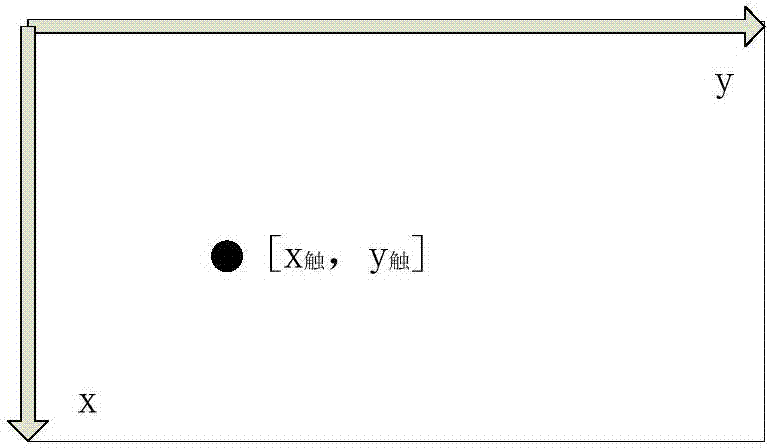

The invention relates to a method and system for multimode touch three-dimensional modeling. The method comprises the steps of touch accumulation splicing three-dimensional modeling and comprises a three-dimensional space division step, a data filling step and a model splicing step. Touch stretch three-dimensional modeling comprises a step of creating a curved surface contour and a step of adjusting the shape; and touch extrusion three-dimensional modeling comprises a distance calculation step and a cutting step. According to the method, a terminal screen can be touched by adopting multiple different modes, touch three-dimensional modeling is achieved by recognizing touch point coordinates and performing three-dimensional world coordinate conversion and by utilizing modes of accumulated splicing, stretching and extrusion, a three-dimensional model construction mode is simplified, the high freedom of modeling is guaranteed, and random man-machine interaction three-dimensional modeling can be achieved only by means of the matching of fingers and the touch terminal screen.

Owner:北京毛豆科技有限公司

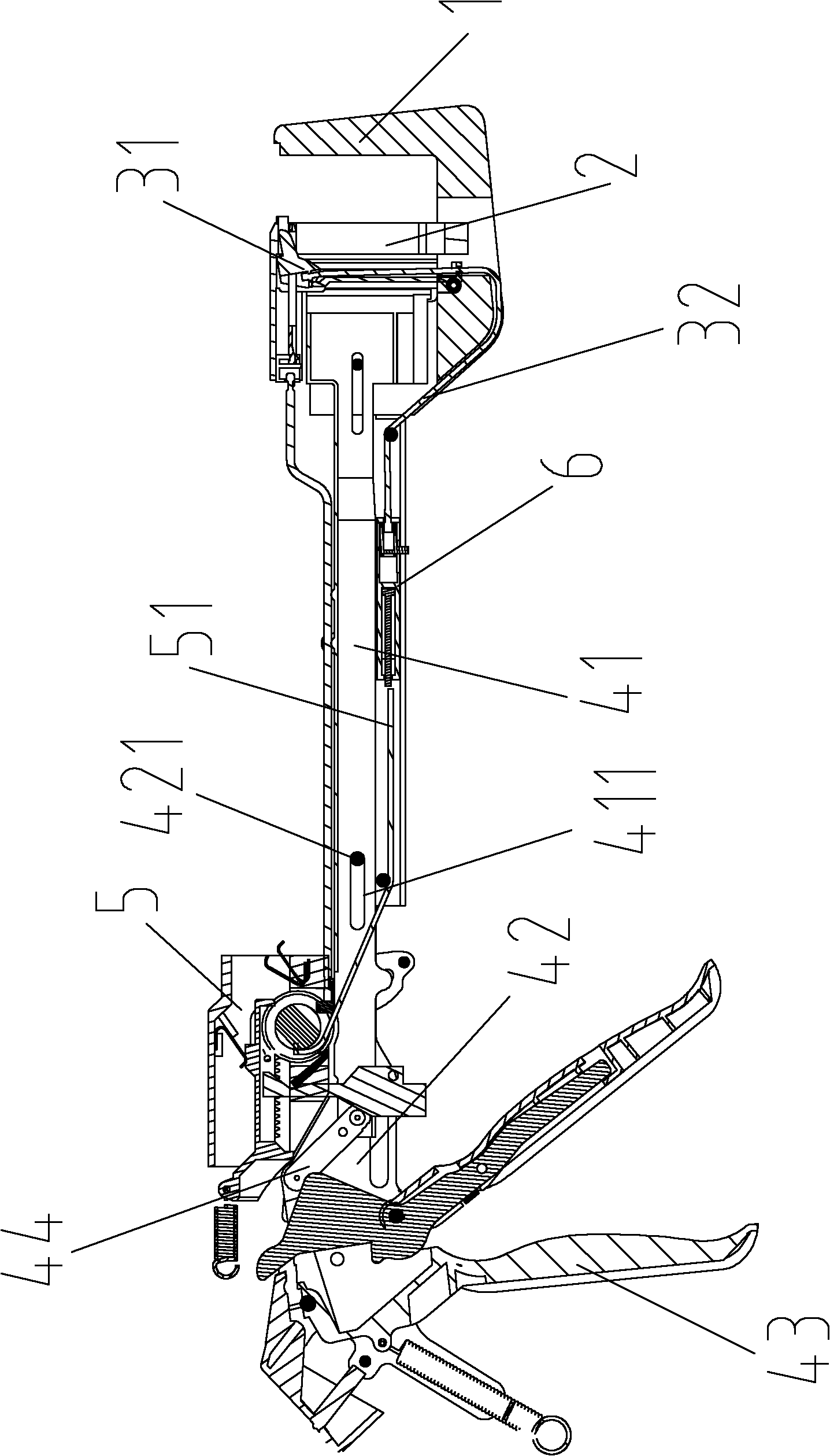

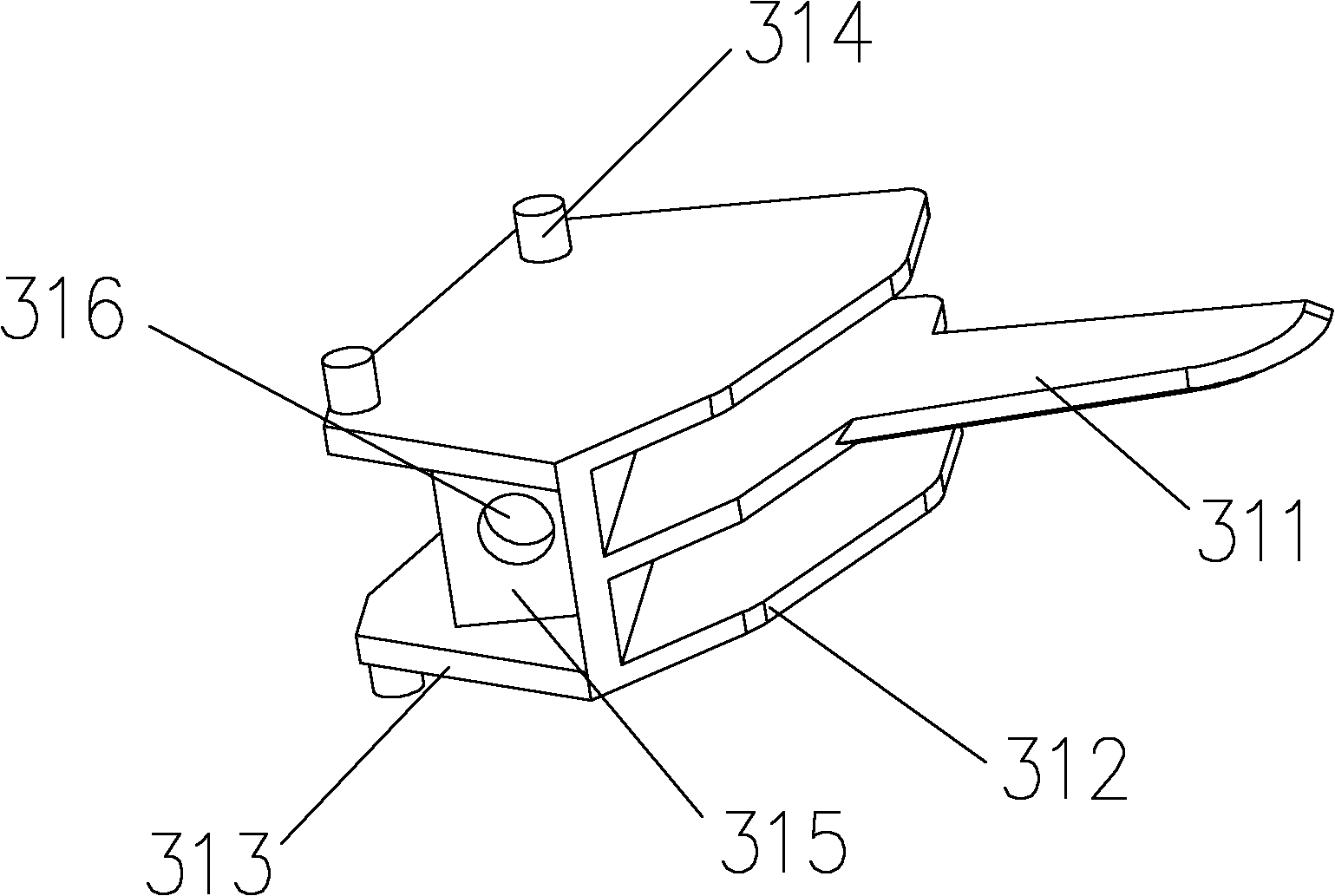

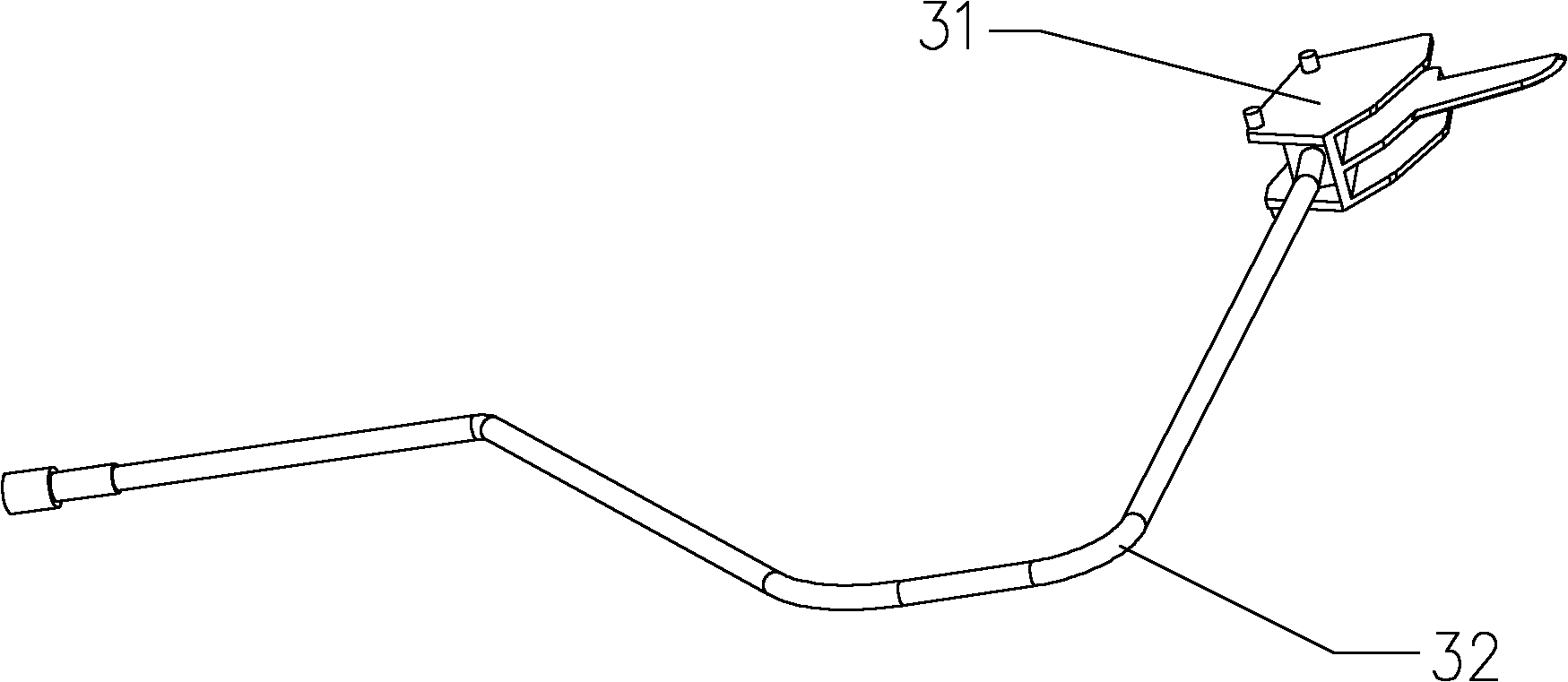

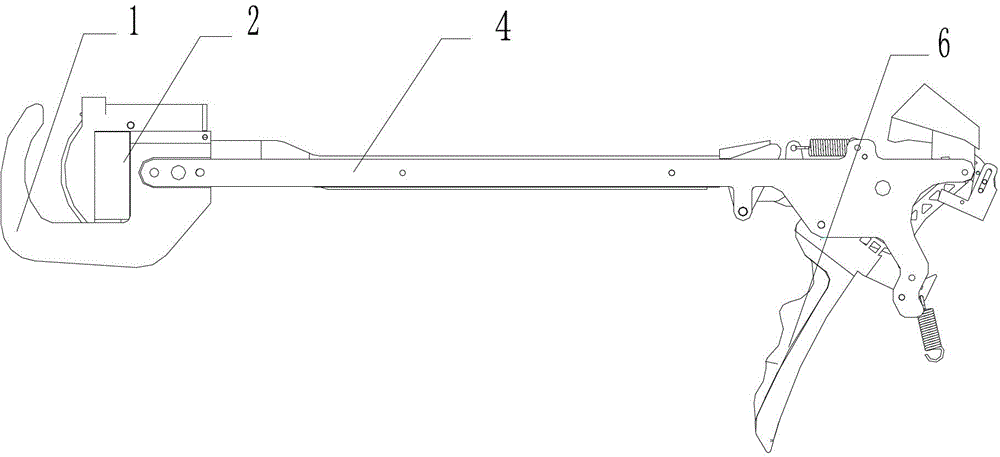

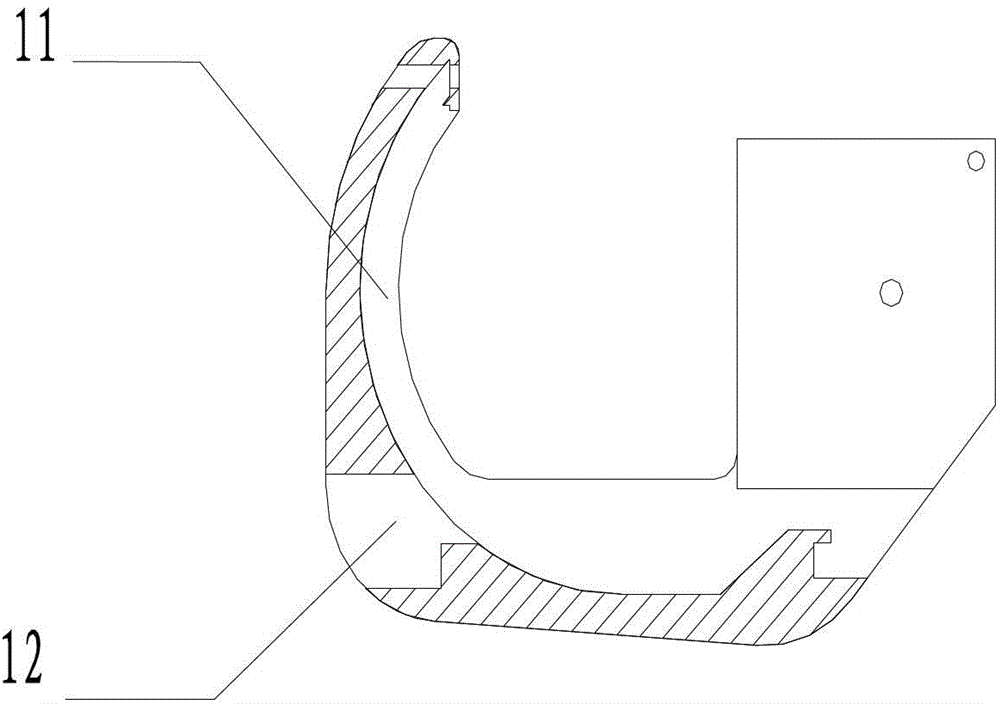

Arc-shaped cutting stitching instrument

ActiveCN102895010BReduce firing forceWell formed staplesSurgical staplesMechanical engineeringEngineering

Owner:B J ZH F PANTHER MEDICAL EQUIP

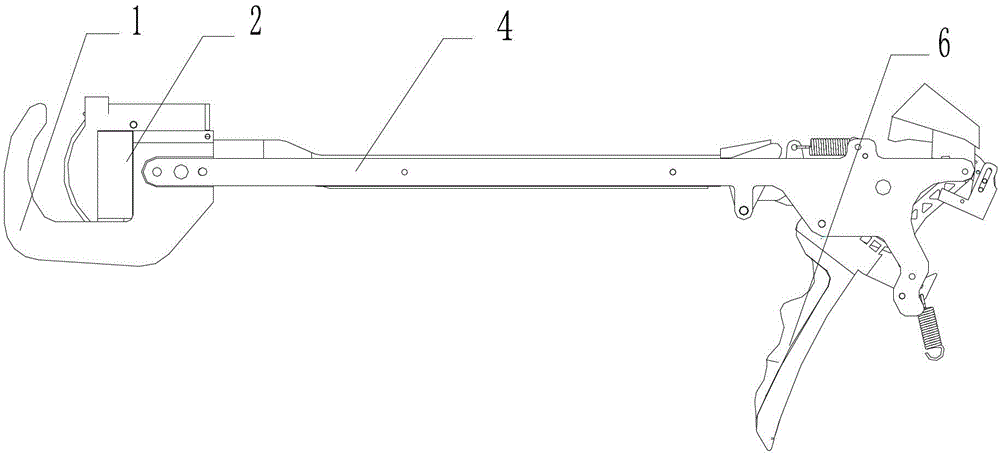

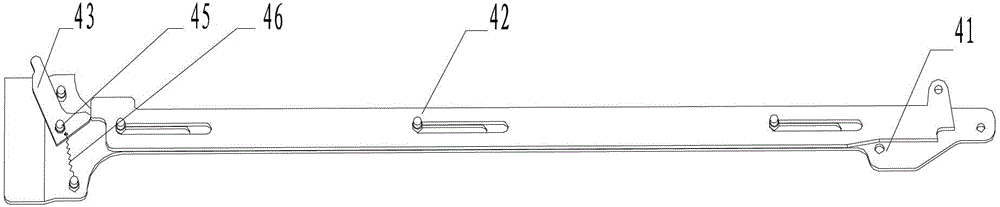

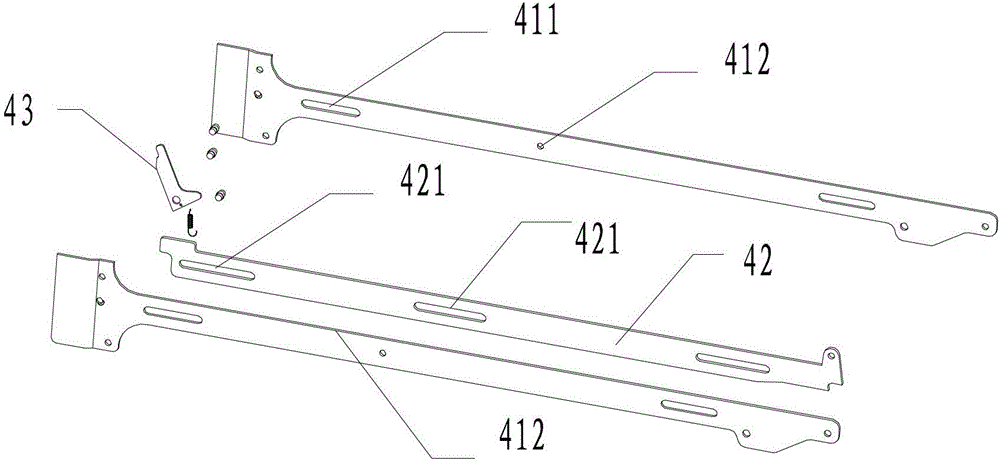

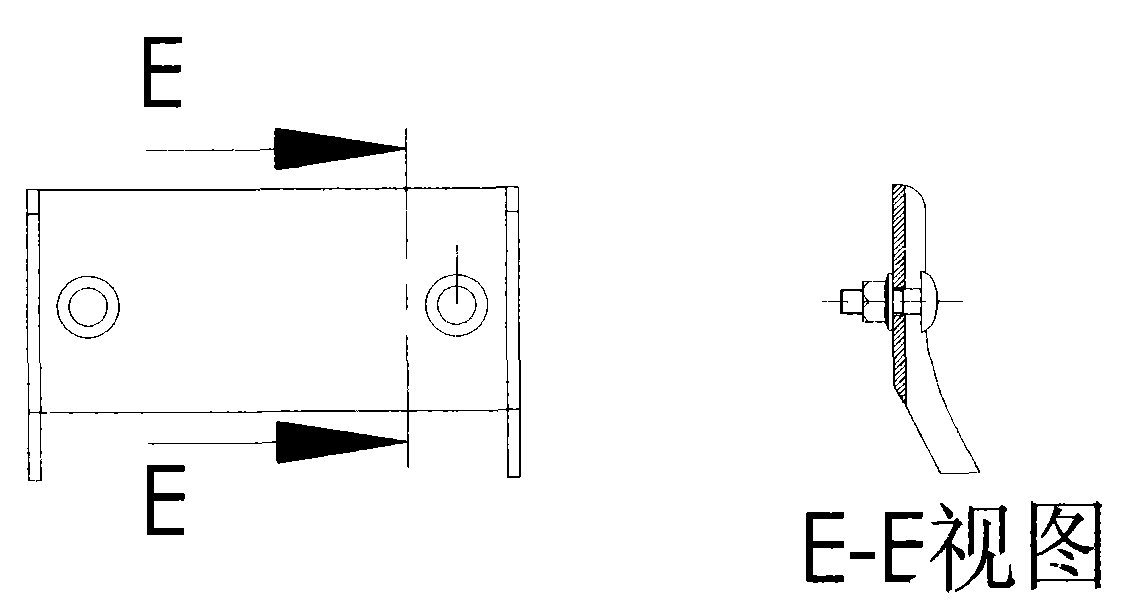

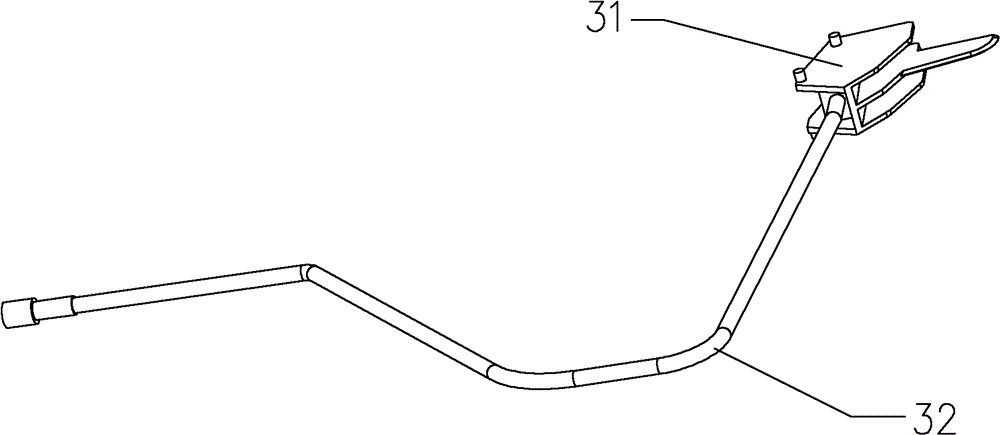

Stitching instrument with cutter

ActiveCN102551827AReduce firing forceSimple structureSurgical staplesEngineeringMechanical engineering

The invention relates to a stitching instrument with a cutter, which comprises a support plate, a nail abutting seat, a nail bin, a cutter component, a propelling mechanism and a traction mechanism. The propelling mechanism and the traction mechanism are mounted on the support plate; the propelling mechanism is connected with the nail bin; the cutter component is mounted in an inner cavity of the nail bin and comprises a cutter slider and a cutter connecting steel wire rope; and the traction mechanism comprises a traction steel wire rope which is connected with a free end of the cutter connecting steel wire rope. The stitching instrument with the cutter is a linear type cutting stitching instrument with a sliding cutter, is applicable to the nail bin with the small longitudinal space, and is simple in structure, convenient in assembly and safe in use, triggering force of the stitching instrument is low, stitching nails are formed well, stitching and cutting actions are simultaneously realized by the effect of tension of the traction mechanism, the cutting direction of the stitching instrument is parallel to the direction of a stitching thread, and accordingly the stitching instrument is more applicable to popularization and application.

Owner:B J ZH F PANTHER MEDICAL EQUIP

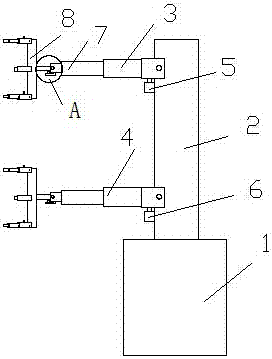

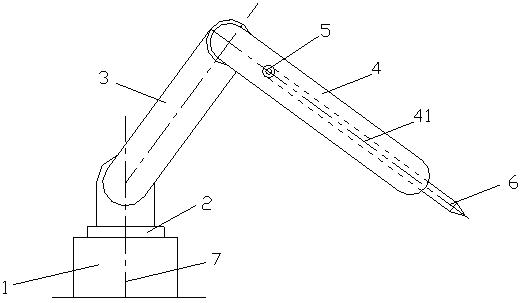

Multi-functional six-axis robot

PendingCN107053238AReduce use costVersatilityProgramme-controlled manipulatorGripping headsEngineeringPressure pipe

The invention discloses a multi-functional six-axis robot. The multi-functional six-axis robot comprises a base and a supporting seat, wherein the supporting seat is mounted on the base through a bearing, and can rotate on the base; an upper arm and a lower arm are hinged to the supporting seat; telescopic rods are separately connected to the upper arm and the lower arm; each gripper is hinged to the corresponding telescopic rod, and comprises a T-shaped supporting part; three fingers, a spray head and a welding head are mounted on each T-shaped supporting part; the central angle of center lines of the three fingers is 120 degrees; a knife head is mounted on each of the three fingers; a plurality of negative pressure holes are formed in the central position of each T-shaped supporting part; and a negative pressure pump is connected to the corresponding negative pressure hole through a negative pressure pipe. The multi-functional six-axis robot disclosed by the invention can bear working types, and can realize multiple functions, so that the using cost of an enterprise is reduced.

Owner:浙江长兴平适尔机器人科技有限公司

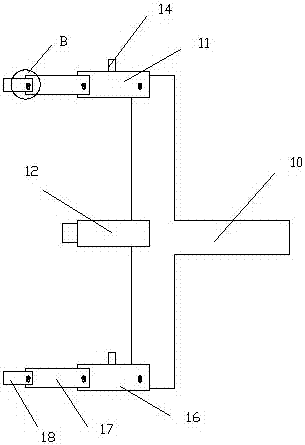

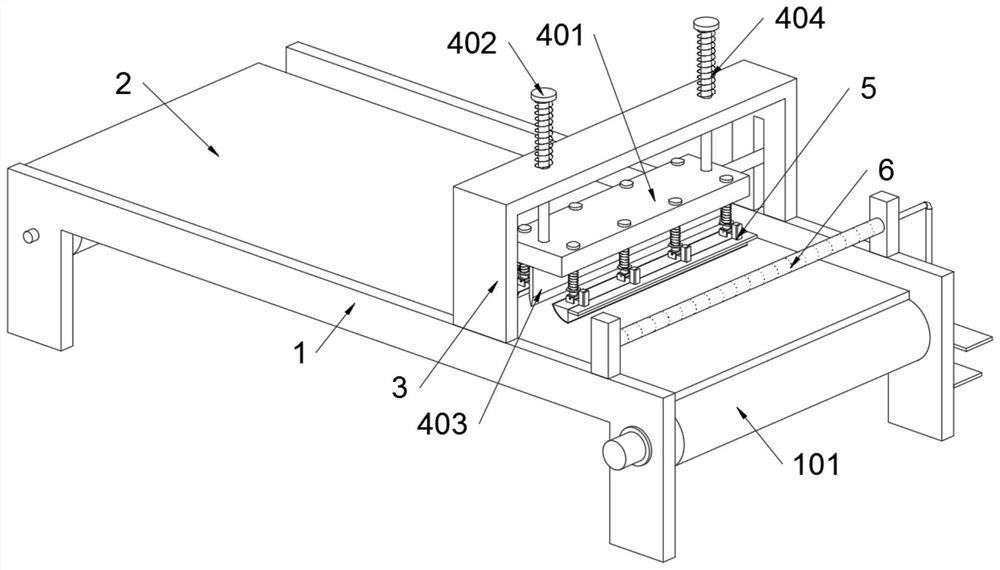

Workpiece automatic forming machine tool cutting mechanism

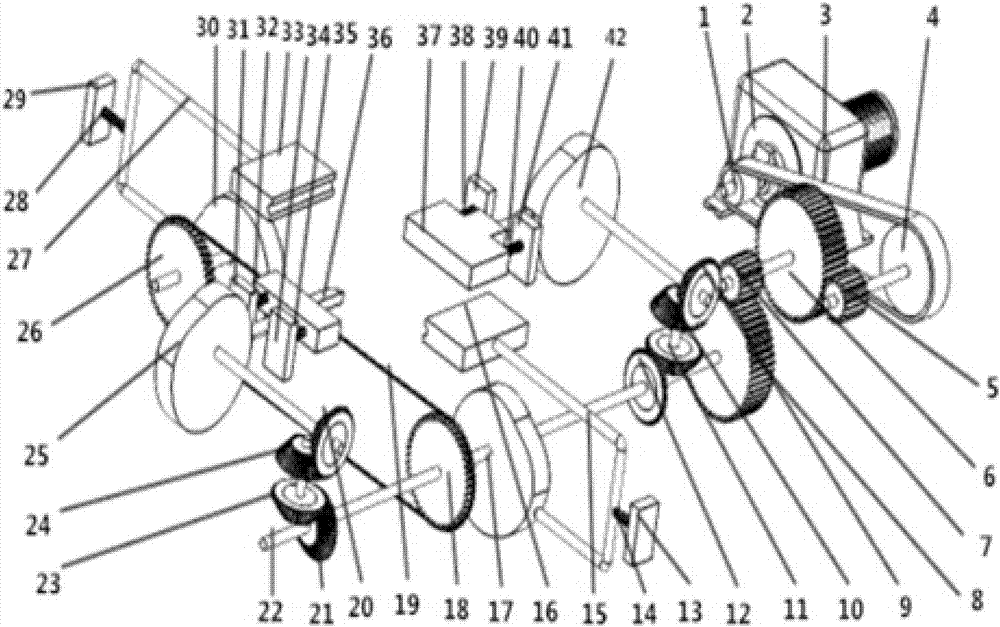

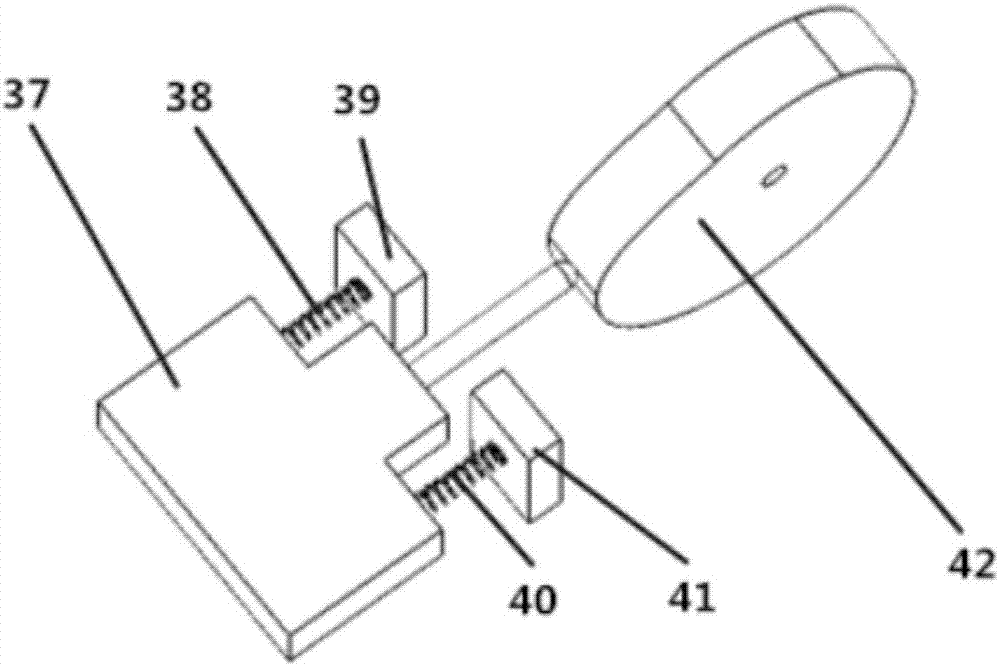

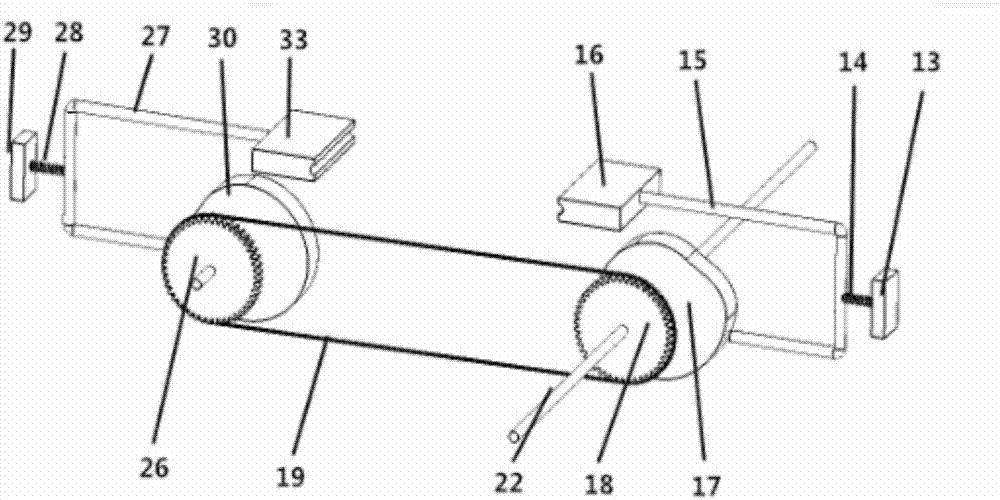

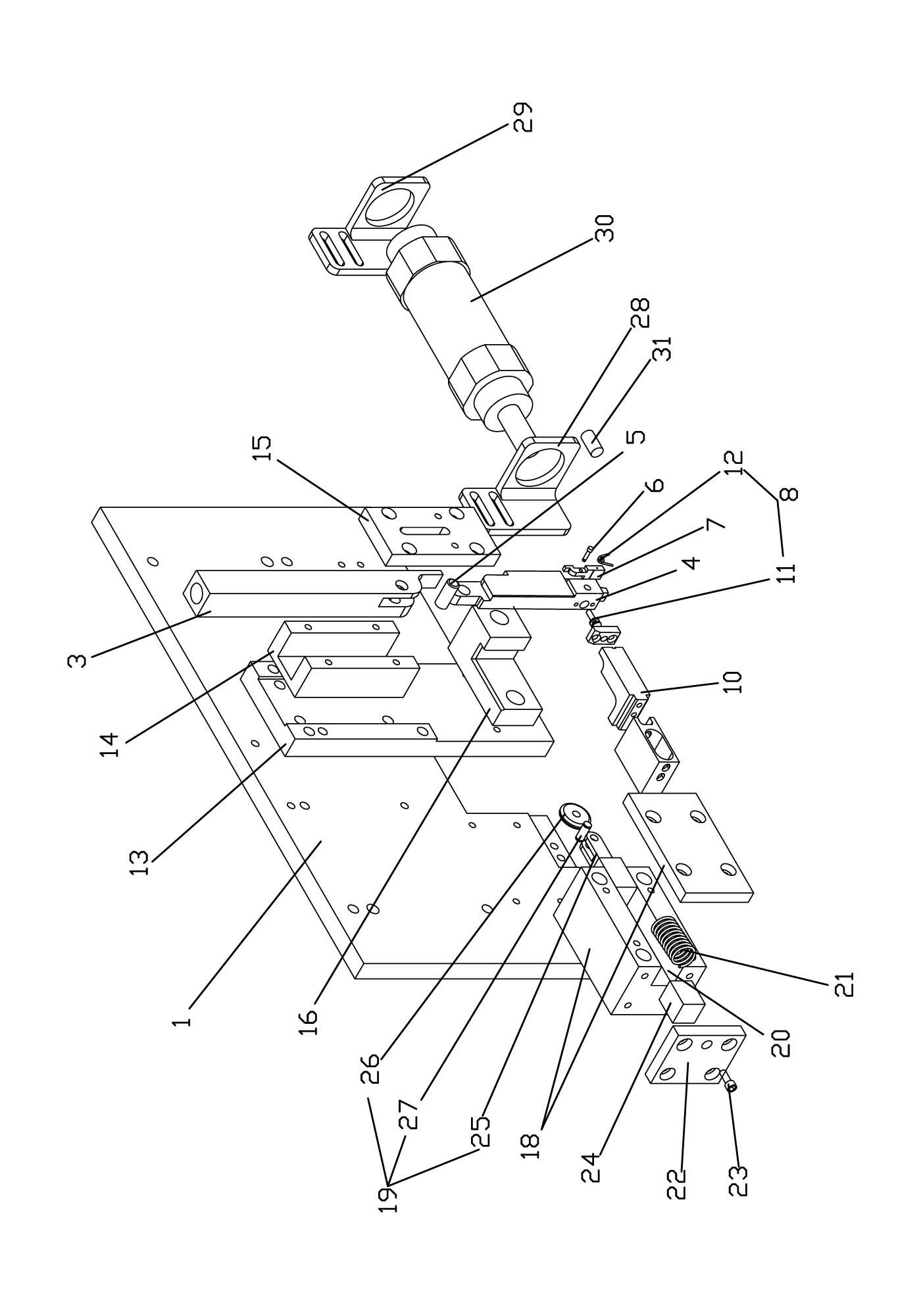

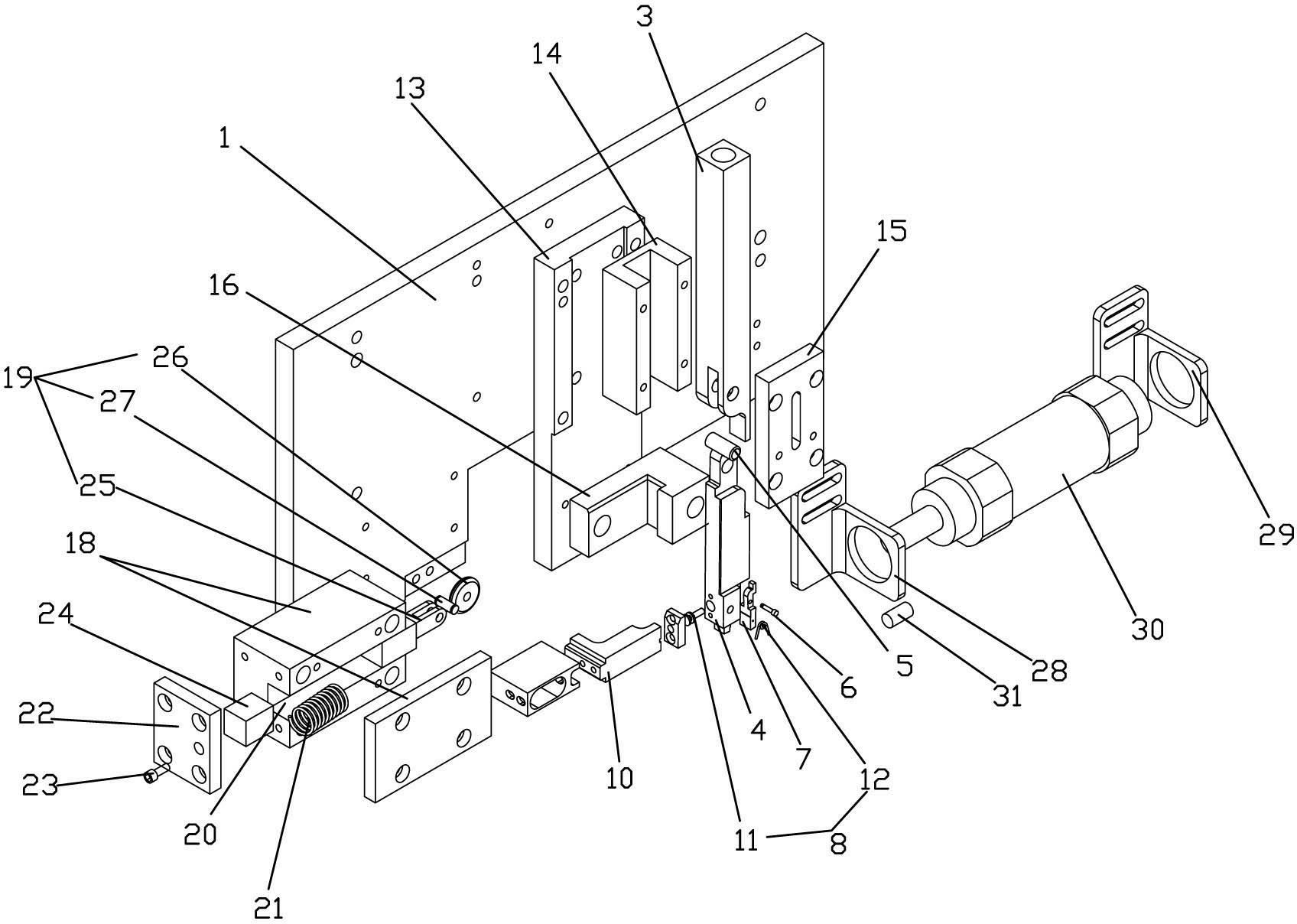

InactiveCN107052849ARealize the cutting actionRealize the function of cuttingFeeding apparatusDriving apparatusEngineeringMachine tool

The invention discloses a workpiece automatic forming machine tool cutting mechanism, which includes a power system, a feeding mechanism, a clamping mechanism and a feed cutting mechanism; the feeding mechanism includes a feeding slider and a feeding slider driving mechanism, and the power system passes through The feeding slider driving mechanism is connected with the feeding slider; the clamping mechanism includes a first clamping block, a first clamping block driving mechanism, a second clamping block and a second clamping block driving mechanism, and the power system passes through The first clamping block driving mechanism is connected with the first clamping block, and the power system is connected with the second clamping block through the second clamping block driving mechanism; the feed cutting mechanism includes a cutting tool holder and The cutting tool holder driving mechanism, the power system is connected with the cutting tool holder through the cutting tool holder driving mechanism. The present invention can not only realize the functions of continuously conveying workpieces and positioning and clamping, but also realize the function of automatic cutting after positioning and clamping, integrating multiple functions into one.

Owner:HOHAI UNIV CHANGZHOU

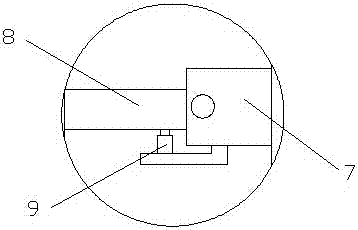

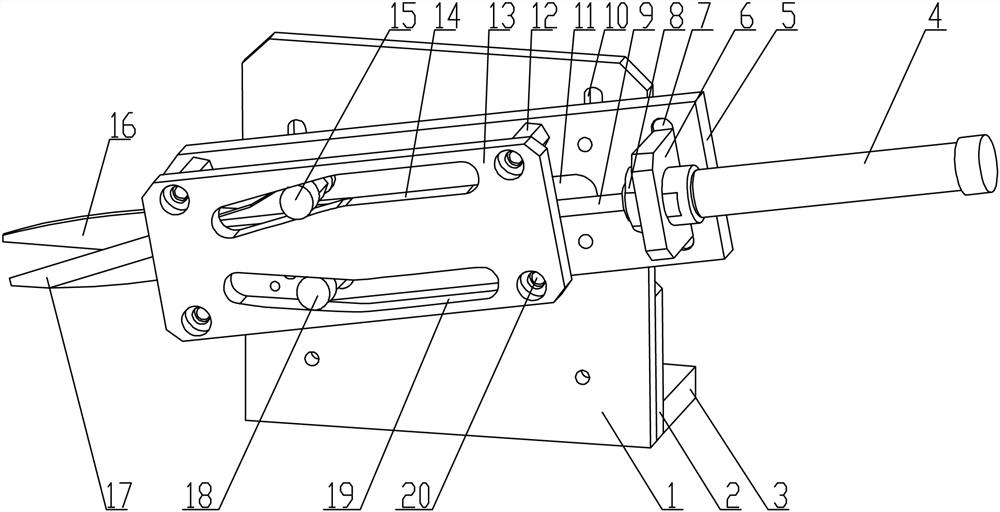

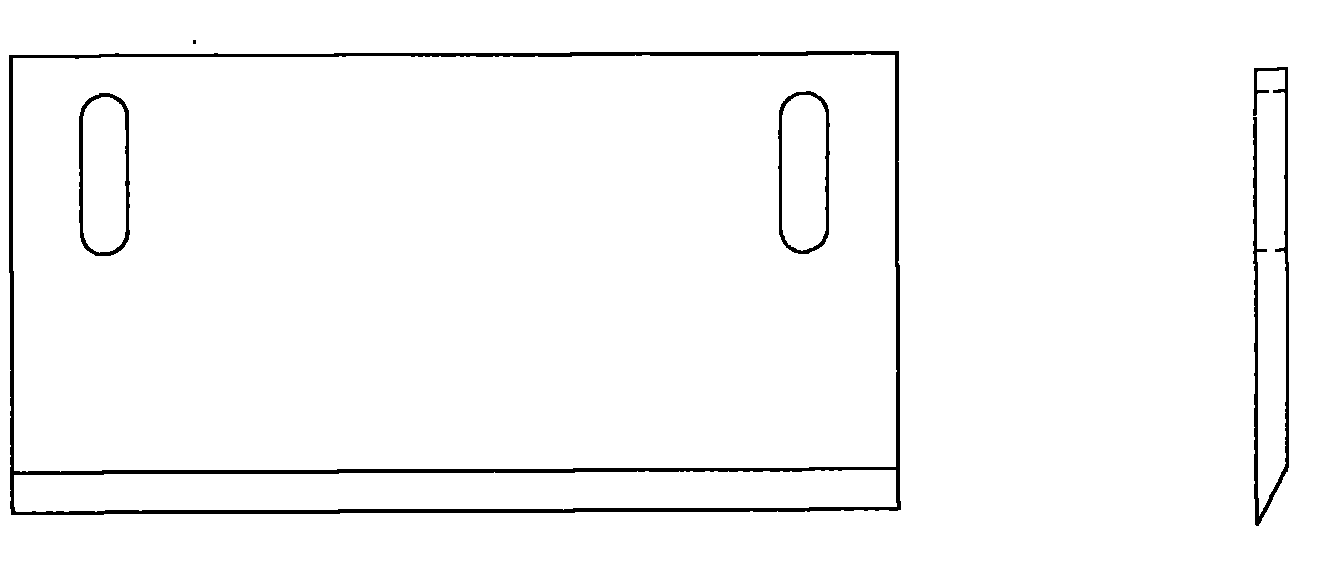

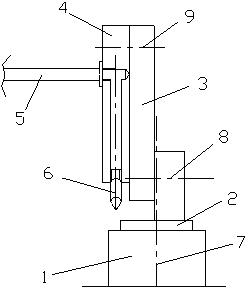

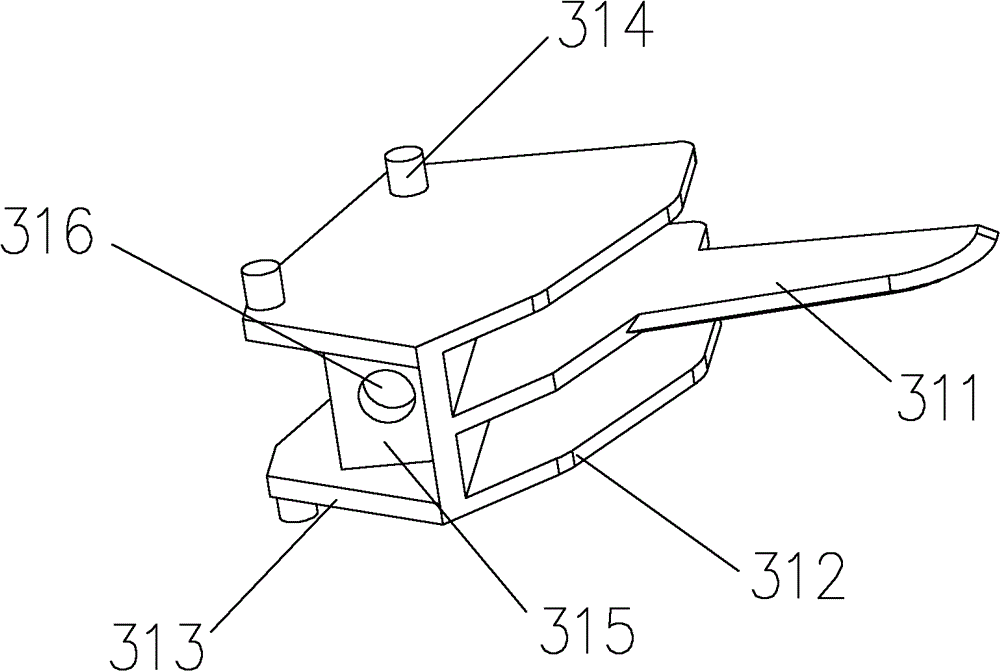

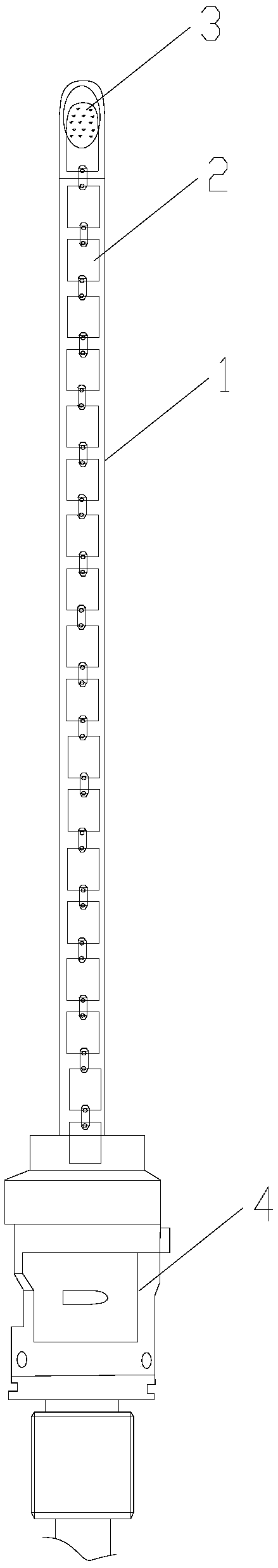

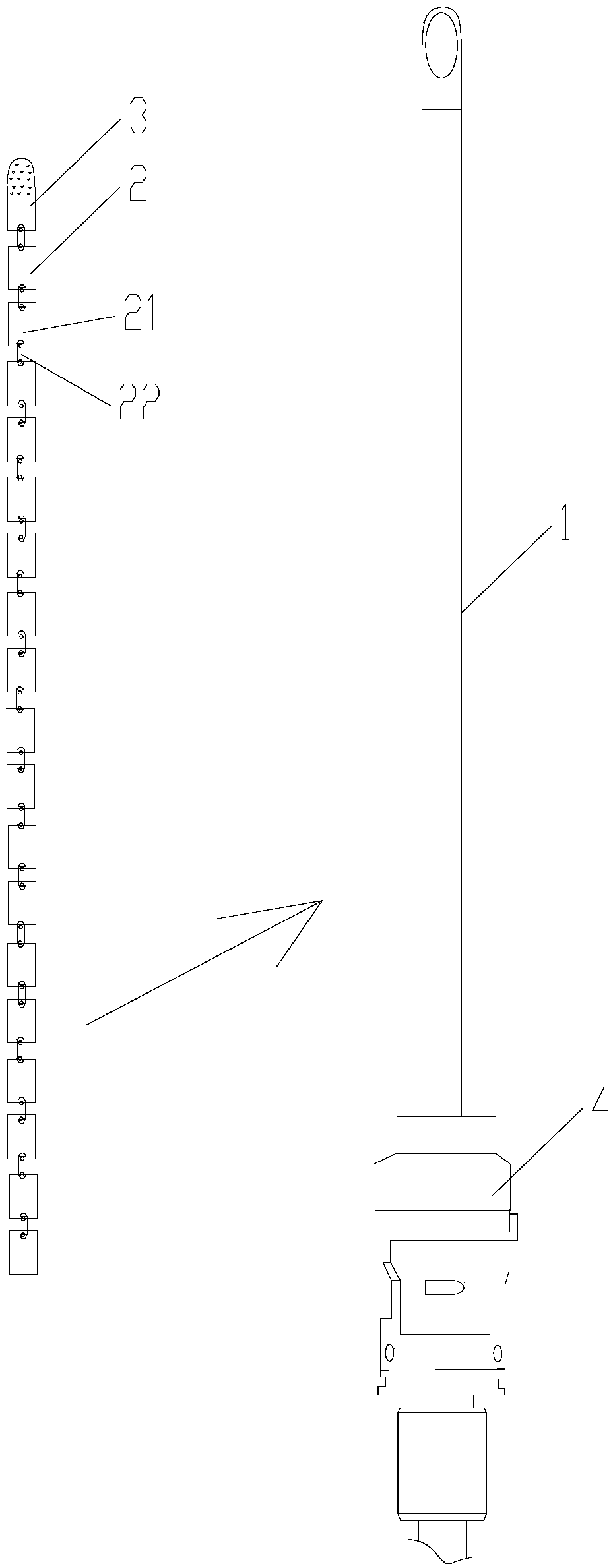

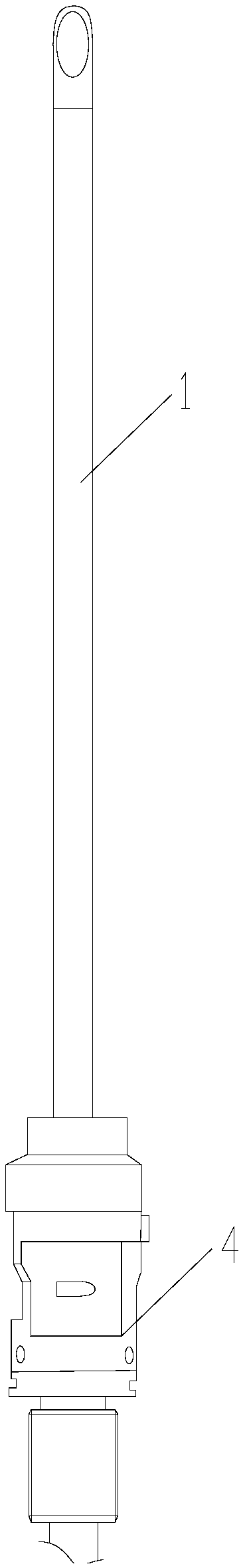

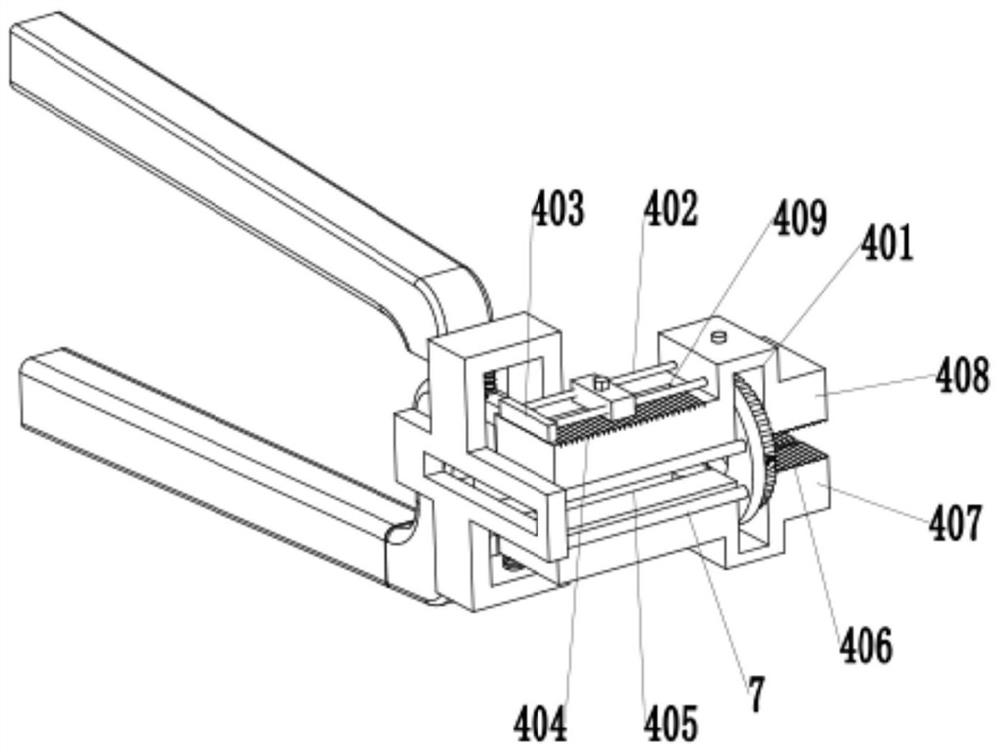

Plug-in board head of fully-automatic terminal plug-in board machine

ActiveCN102159038ARealize automatic reset actionRealize the cutting actionPrinted circuit assemblingElectrical componentsEngineeringFully automatic

The invention discloses a plug-in board head of a fully-automatic terminal plug-in board machine, which comprises a bottom plate, wherein a guide rail assembly is fixed on the bottom plate, a plug-in shaft is arranged on the guide rail assembly and is movably connected with a pressing rod through a shaft pin, a movable cutter is connected to the pressing rod, a movable cutter driving assembly is arranged on the pressing rod, one side of the pressing rod is provided with a cutting driving assembly, and the other side of the pressing rod is provided with a fixed cutter member which is arranged on a path of the movable cutter rotating along the pressing rod. The invention has the advantages of simple structure, high production efficiency and less manual operation; and labor force can be greatly reduced, processing cost of the plug-in board head is saved, reject ratio and scrap rate of plug-in board processing can be greatly reduced, and quality of the plug-in board is ensured.

Owner:珠海市宇腾自动化设备制造有限公司

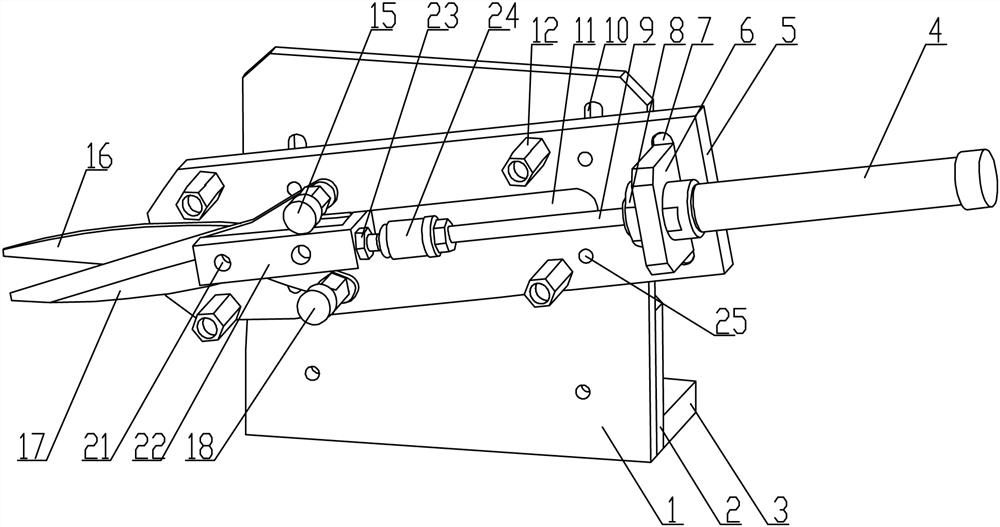

Mask ear band shearing device based on sliding groove mechanism and using method

InactiveCN113084897AGuaranteed stabilityGuaranteed reliabilityMetal working apparatusClassical mechanicsStructural engineering

The invention provides a mask ear band shearing device based on a sliding groove mechanism and a using method. The mask ear band shearing device comprises a vertical plate, the vertical plate is fixedly installed on a rack of a mask machine through a vertical plate base, and an inclined knife rest plate is installed on the outer side wall of the vertical plate. A sliding groove is machined in the knife rest plate, a sliding base is in sliding fit with the sliding groove, and a first scissor body and a second scissor body which are arranged in a crossed mode are hinged to the sliding base through a pin shaft. The tail parts of the first scissor body and the second scissor body are matched with a roller guide mechanism and are used for realizing the closing and separating actions of the scissor heads. The sliding base is connected with a sliding device used for driving the sliding base to slide along a sliding groove.

Owner:CHINA THREE GORGES UNIV

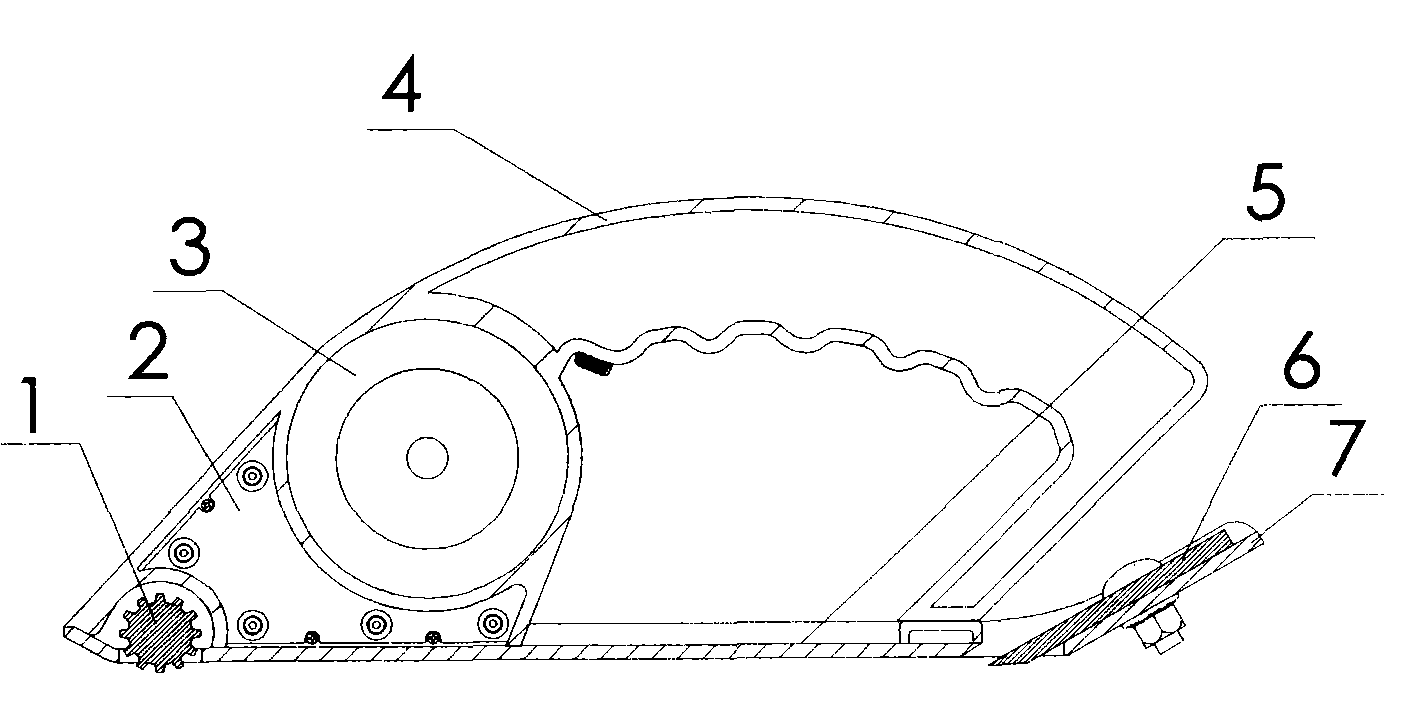

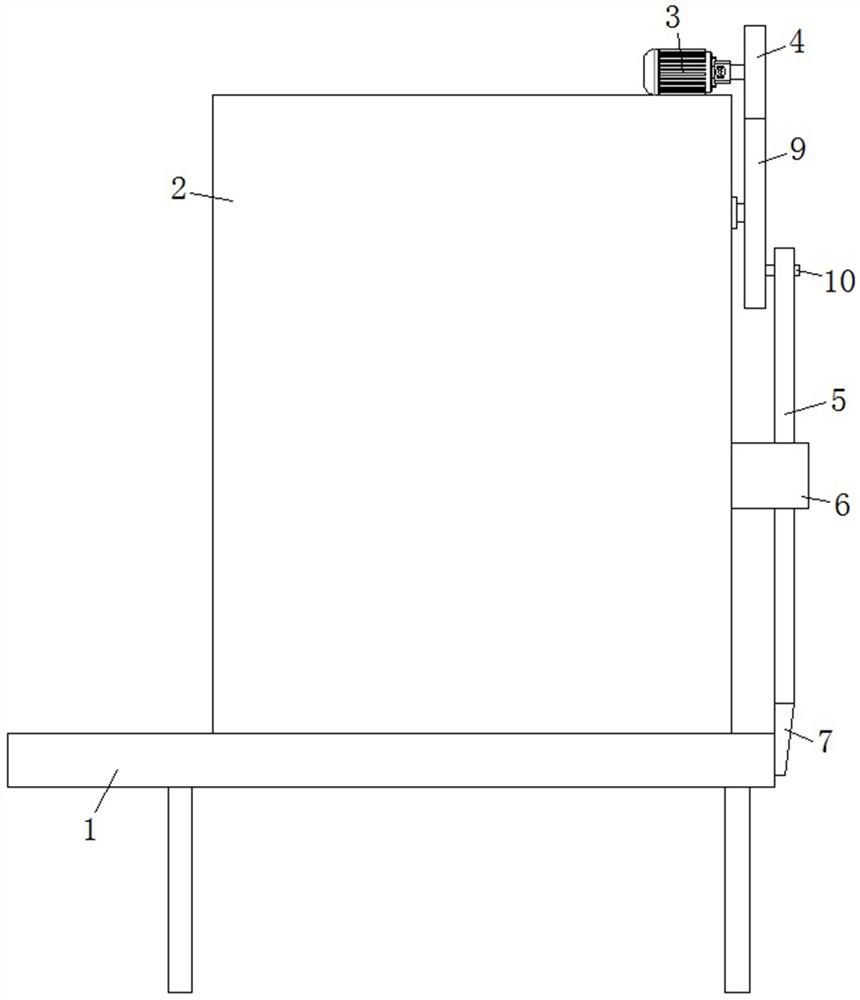

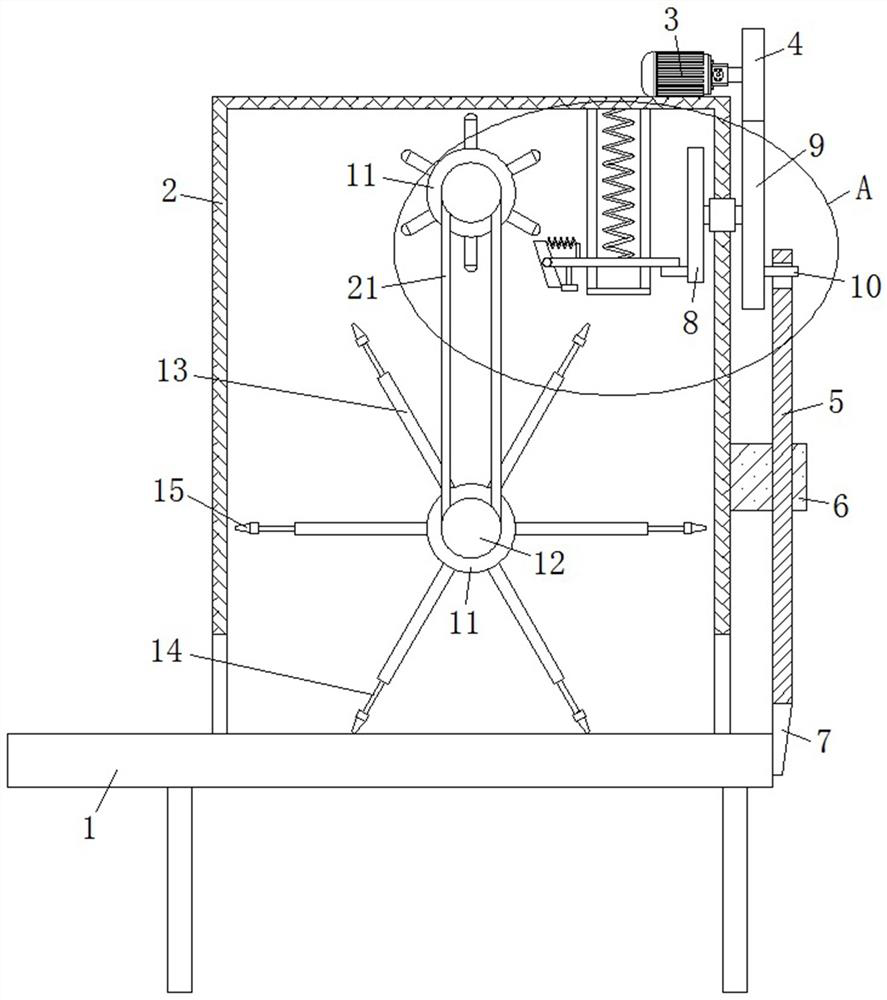

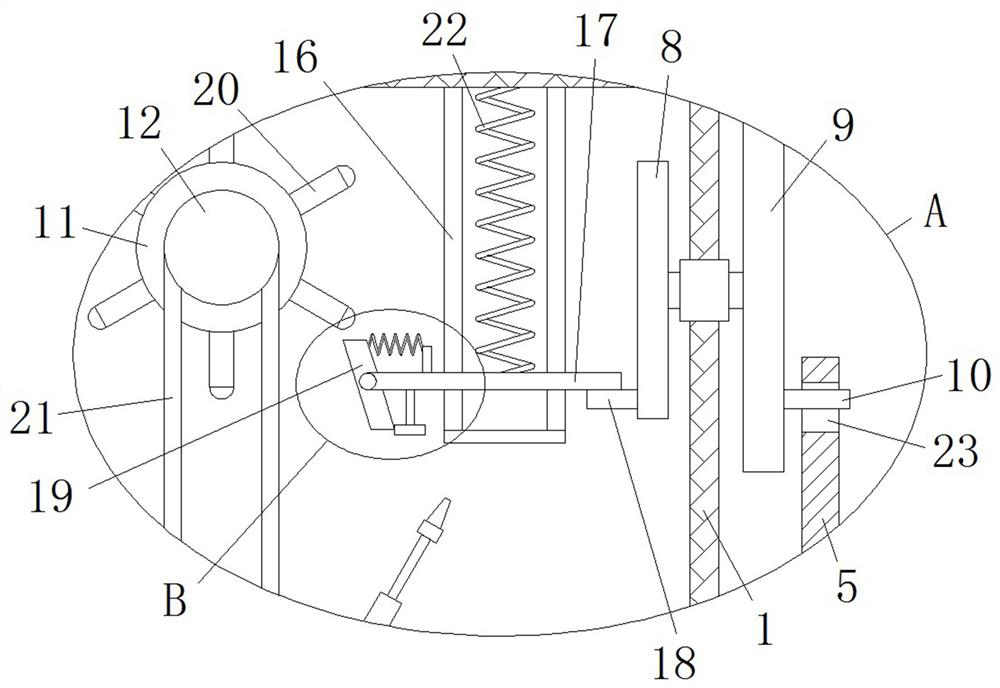

Power-driven wall body beaming machine

The invention mainly discloses a power-driven wall body beaming machine which mainly comprises a driving wheel 1, a reduction gearbox 2, a driving motor 3, a control handle and a casing 4, a chassis 5, a scraper 6 and a scraper fixing adjusting seat 7, wherein bearings are mounted on the two sides of the driving wheel; the bearings are in transition fit connection with bearing seats; the bearing seats are fixed on the chassis; the reduction gearbox is connected with one side of the driving wheel through a reduction gearbox output shaft; the reduction gearbox is connected with the driving motor through a driving motor output shaft, and is connected the control handle and the casing through screw bolts; the control handle and the casing are connected with the chassis and the driving motor in a bolting manner; the scraper fixing adjusting seat is connected with the chassis in a welding manner; the scraper is connected with the scraper fixing adjusting seat in a bolting manner.

Owner:刘永鹏

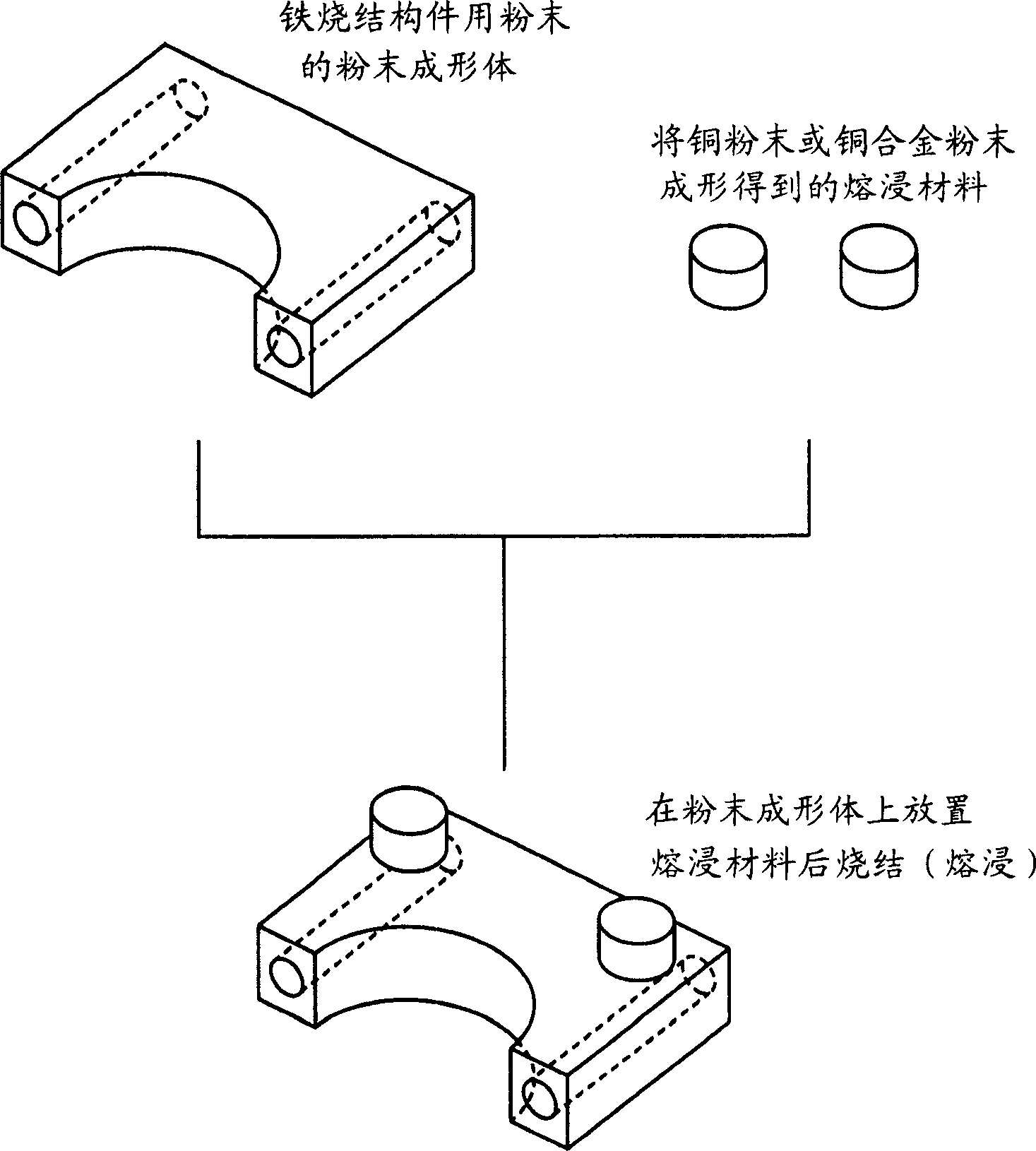

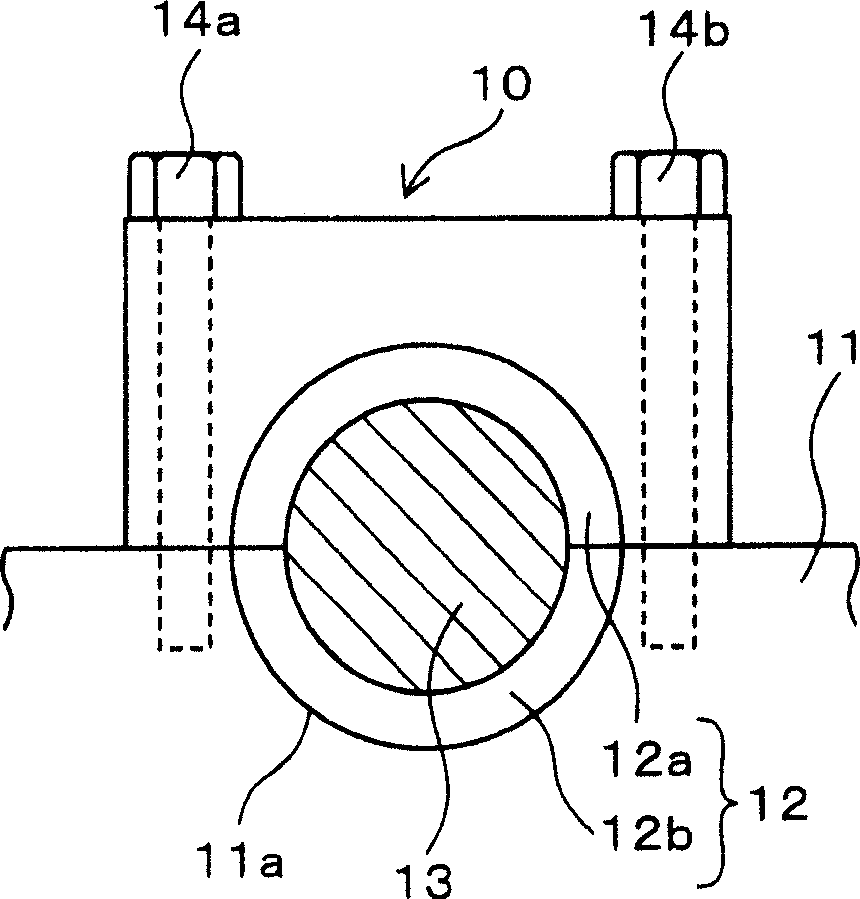

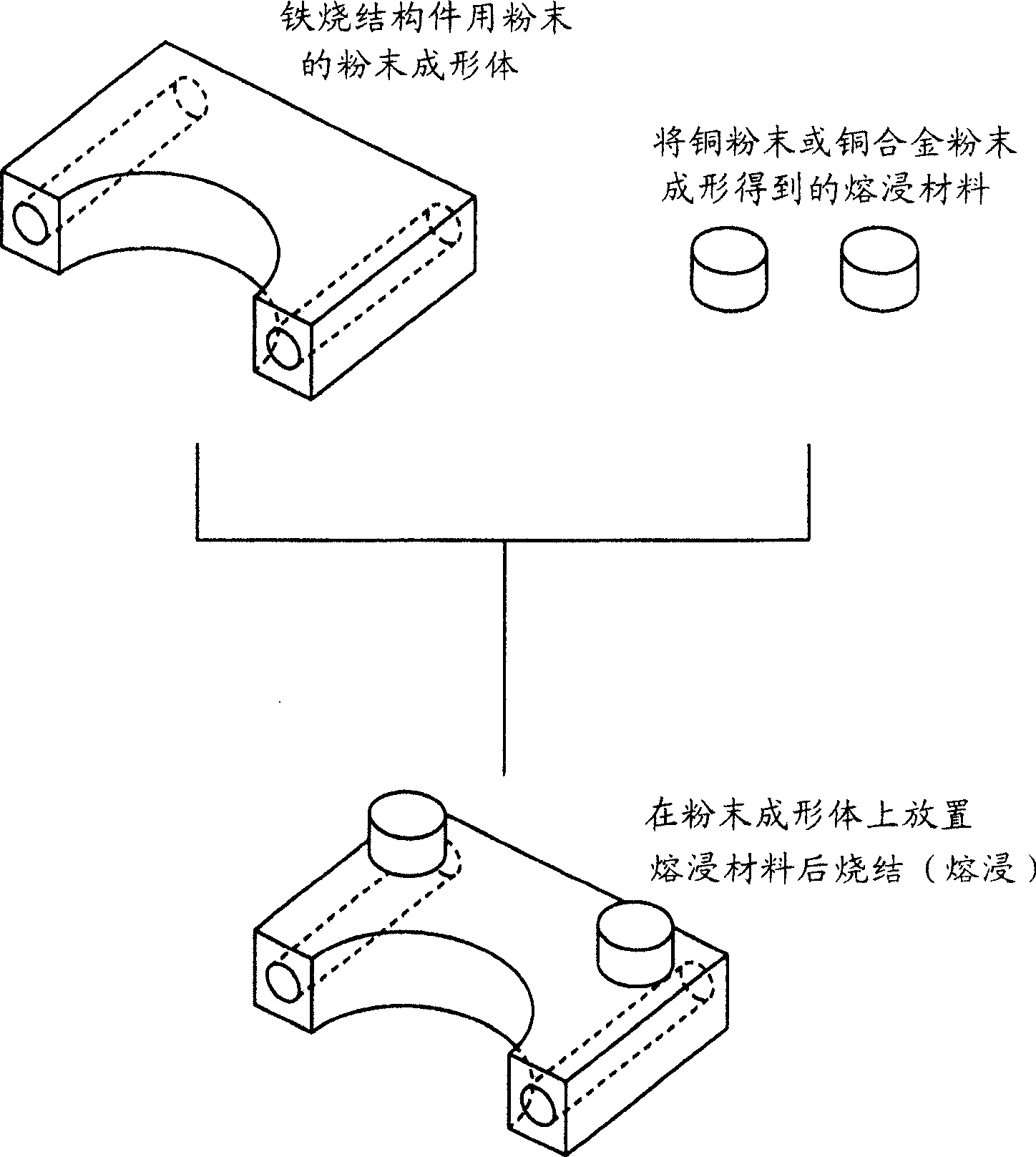

Iron sintered component and producing method and sintered mechanical parts

The invention relates to an iron sinter element and relative production, which can improve high strength and cutting property. Wherein, arranging the fuse dip material formed by molding metallic powder on at least one part of the surface of sinter element that obtained by heating the powder former on the iron sinter element; sintering the powder former with said fuse dip material, at the temperature above the carbon disperse temperature and under the fuse point of fuse dip material; and said powder is the iron powder mixture that removed graphite powder from the power mixture of iron sinter element that in pearlite organism; adding 0.01-1.0 mass% boric oxide and 0.1-2.0 mass% graphite powder, then said metallic powder is the copper or copper alloy powder.

Owner:昭和电工MATERIALS株式会社

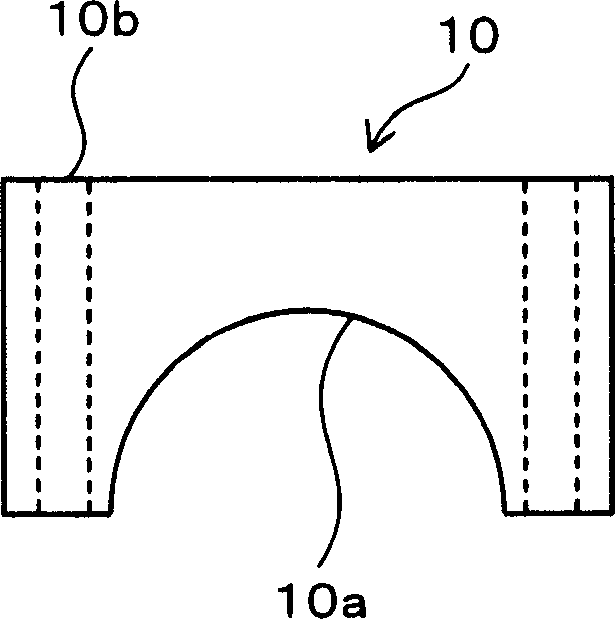

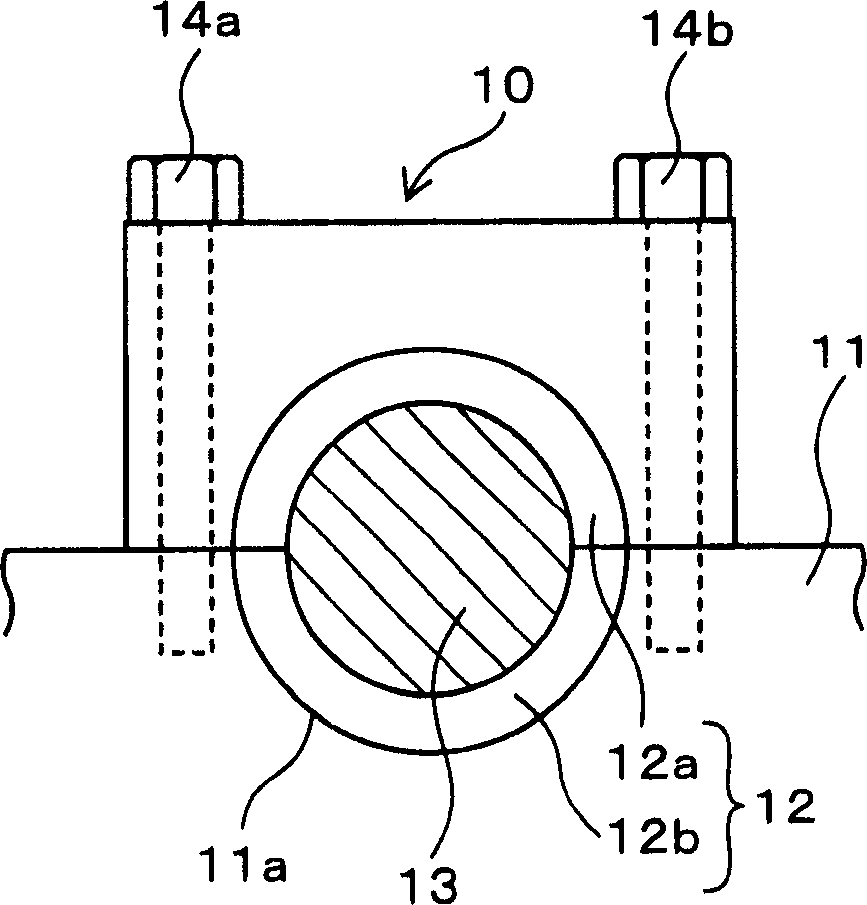

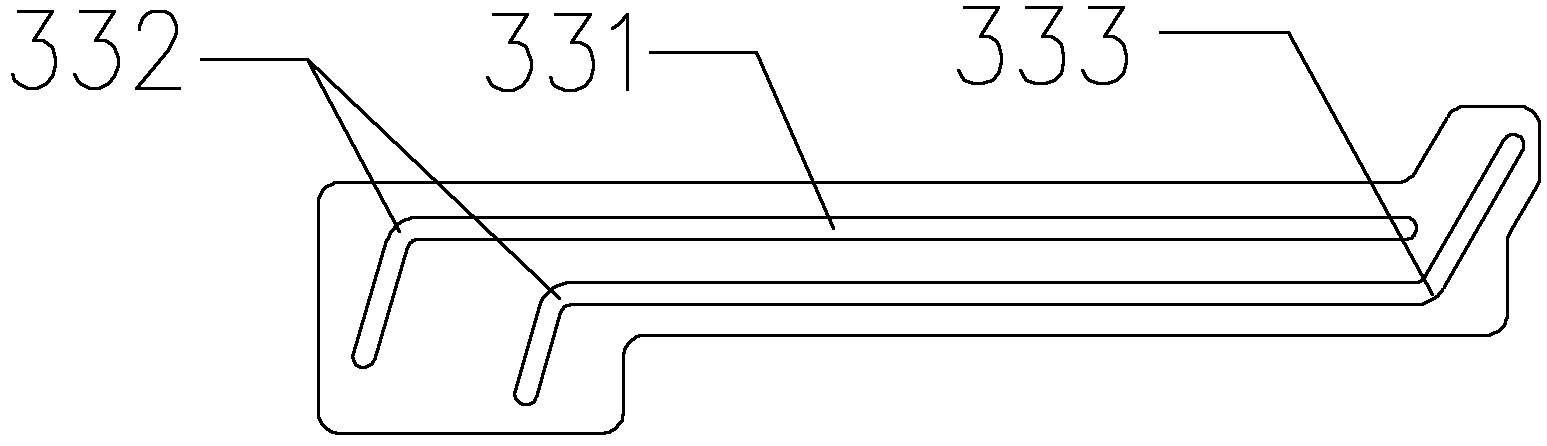

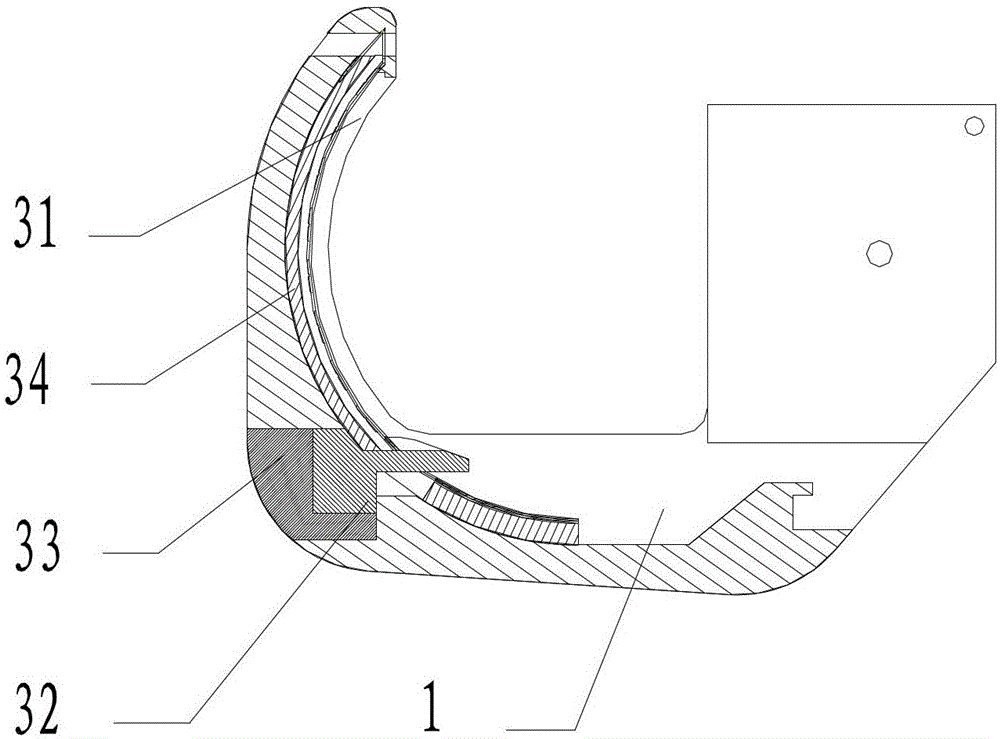

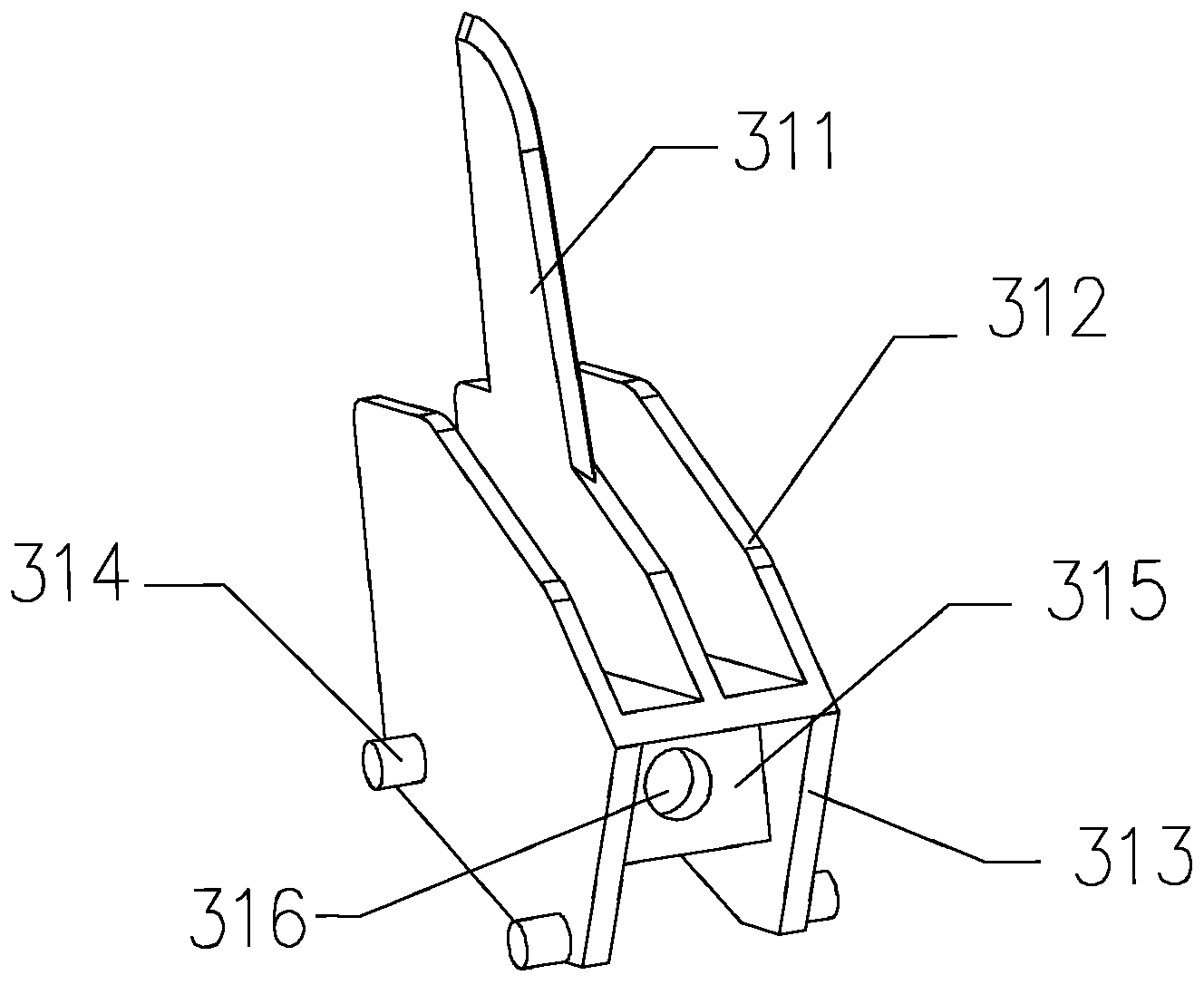

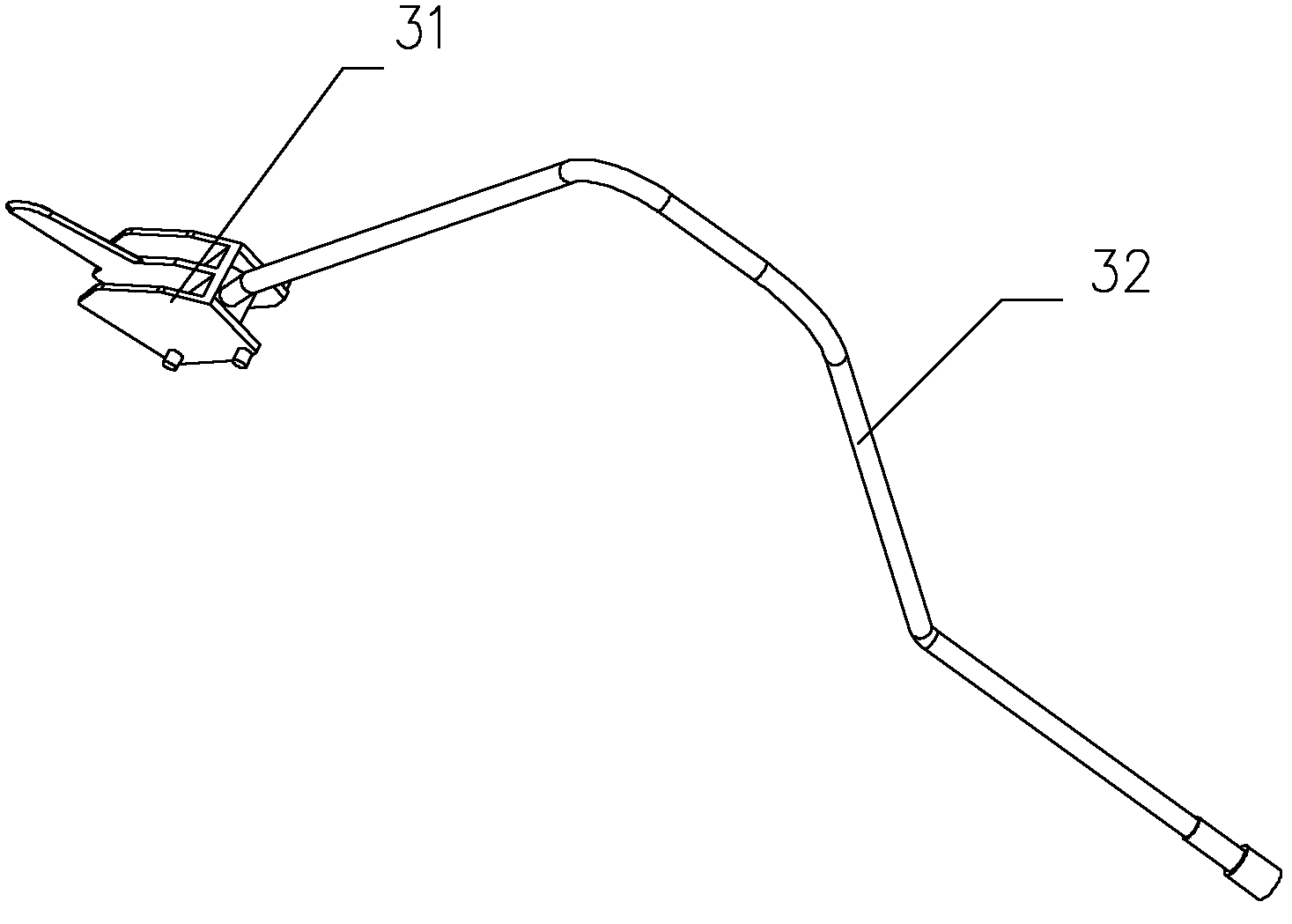

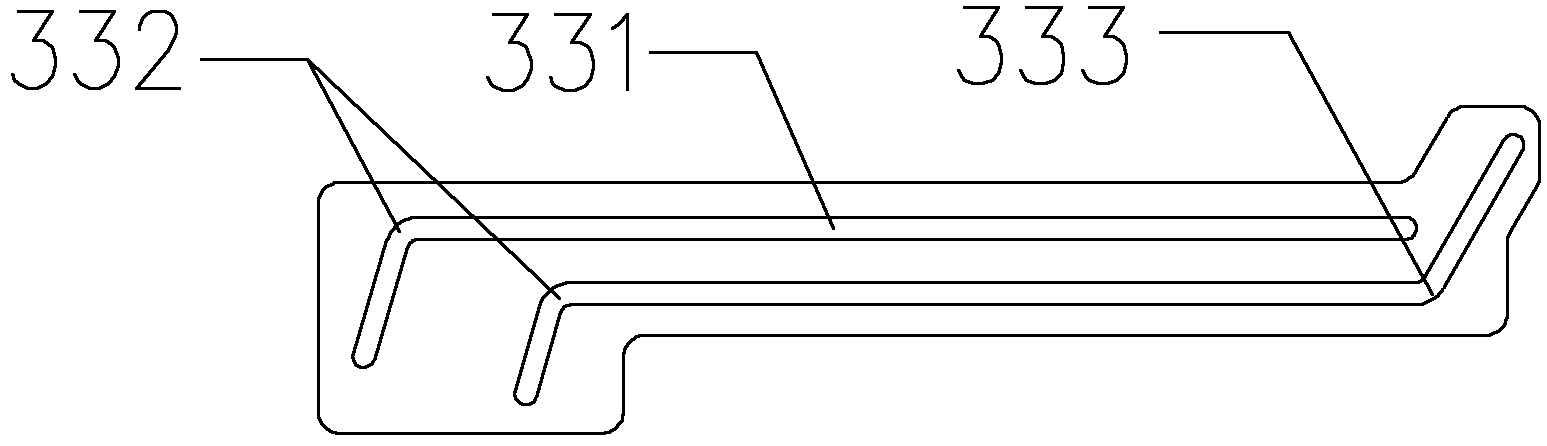

Stitching instrument with cutter and cutter component of stitching instrument with cutter

ActiveCN102551828AReduce firing forceSimple structureIncision instrumentsSurgical staplesPull forceSuture cutter

The invention relates to a stitching instrument with a cutter and a cutter component of the stitching instrument with the cutter. The cutter component comprises a cutter slider, a cutter connecting steel wire rope, guiding plates and a fixing block; the cutter slider is provided with the cutter, a triggering plate, a positioning plate, positioning pins, a steel wire rope mounting block and a mounting hole; one end of the cutter connecting steel wire rope penetrates through the mounting hole and is fixed; each guiding plate is provided with a guiding groove, the guiding grooves correspond to the positioning pins, and the cutter slider is slidably mounted between the two guiding plates via the positioning pins; and the fixing block is mounted below the guiding plates and the cutter slider. The cutter component of the stitching instrument with the cutter is mounted in an inner cavity of a nail bin, and the cutter connecting steel wire rope of the cutter component is connected with a traction mechanism. The stitching instrument with the cutter is applicable to the nail bin with the small longitudinal space, and is simple in structure, convenient in assembly and safe in use. The triggering force of the stitching instrument is low, stitching nails are formed well, stitching and cutting actions are simultaneously realized by the effect of tension of the traction mechanism, the cutting direction of the stitching instrument is parallel to the direction of a stitching thread, and accordingly the stitching instrument is more applicable to popularization and application.

Owner:B J ZH F PANTHER MEDICAL EQUIP

Arc-shaped cutting stitching instrument

The invention relates to an arc-shaped cutting stitching instrument, which comprises a supporting plate, a jaw bracket, a nail cabin assembly, a nail pressing holder, a connecting assembly, a pushing mechanism and a striking mechanism, wherein corresponding faces of the nail pressing nail holder, the nail cabin assembly and nail pressing holder are arc-shaped. The arc-shaped cutting stitching instrument has the advantages of reduction in instrument size at the same stitching length, smaller striking force of the instrument, and better stitch forming; and the arc-shaped cutting stitching instrument has the advantages of simple structure, convenience in assembling, safety in using, and simultaneous realization of stitching and cutting actions under the action of the striking mechanism.

Owner:B J ZH F PANTHER MEDICAL EQUIP

Cantilever water gun

The invention discloses a cantilever water gun. The cantilever water gun comprises a bed body, a turntable rotationally arranged on the bed body through a first rotating shaft, a big arm rotationally arranged on the turntable through a second rotating shaft, and a small arm rotationally arranged on the big arm through a third rotating shaft; the first rotating shaft extends along the vertical direction; the second rotating shaft and the third rotating shaft are parallel to each other and extend along the horizontal direction respectively; and a section of cavity is formed in the small arm, the cavity is provided with an inlet and an outlet, a high-pressure copper pipe communicated with a water source is arranged on the inlet, and a gun head is arranged on the outlet. The invention overcomes the defects of the prior art, and provides the cantilever water gun capable of realizing arc line cutting.

Owner:ZHANGJIAGANG YUCHENG MASCH C0 LTD

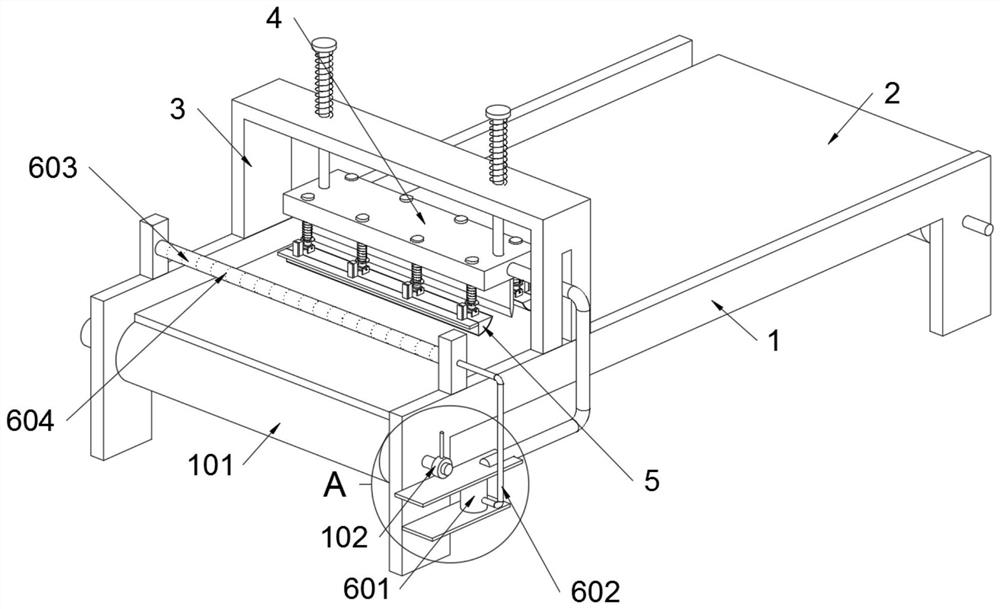

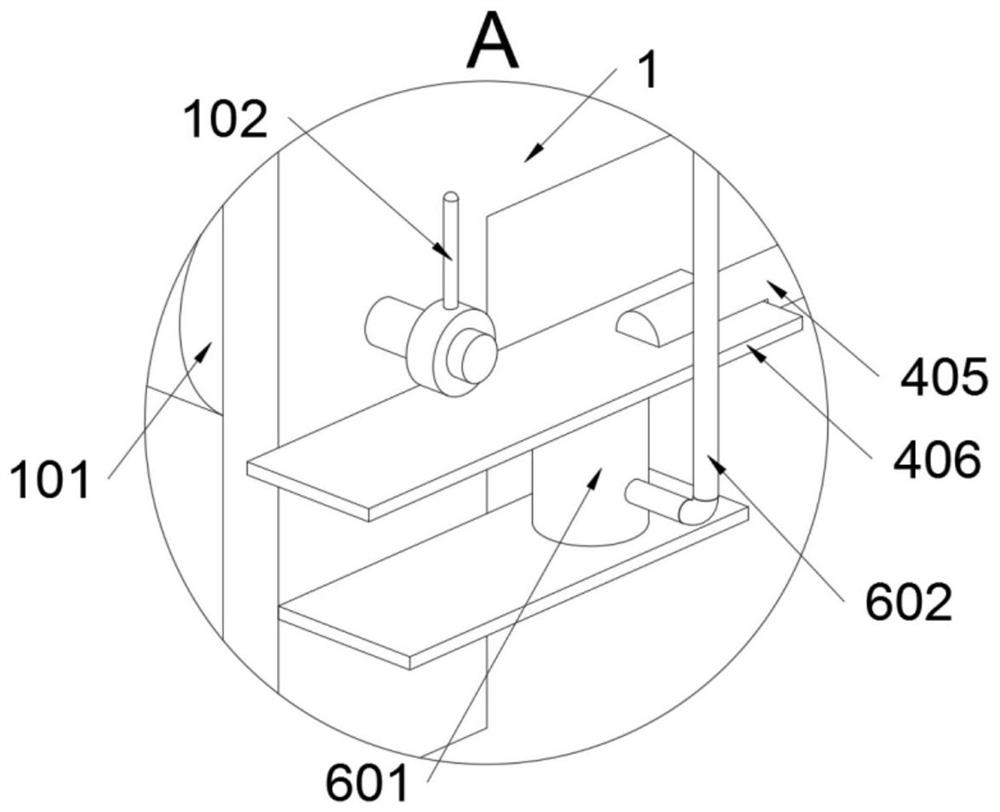

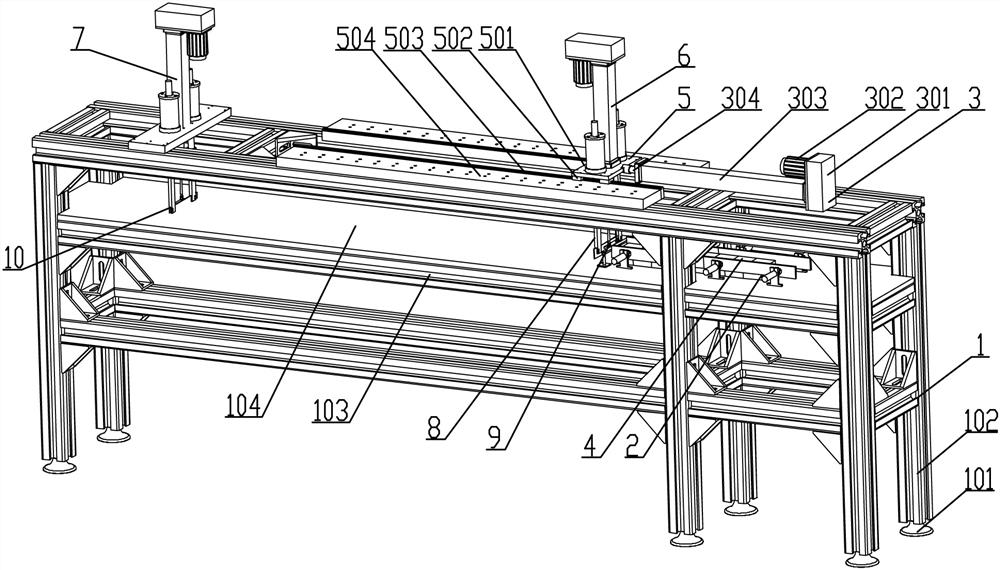

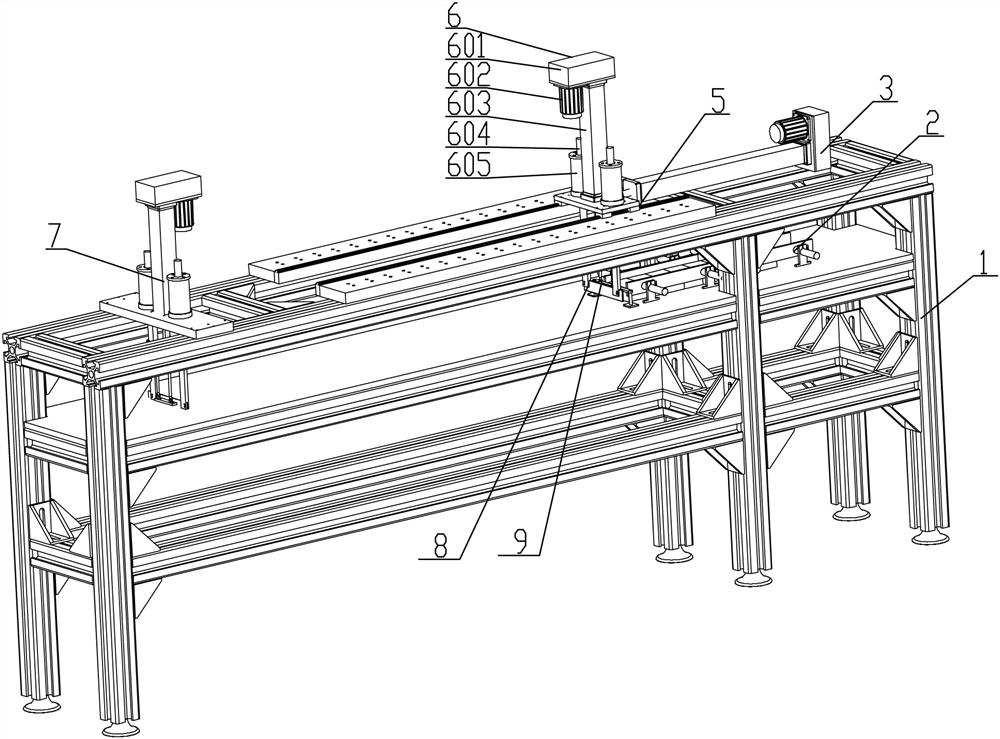

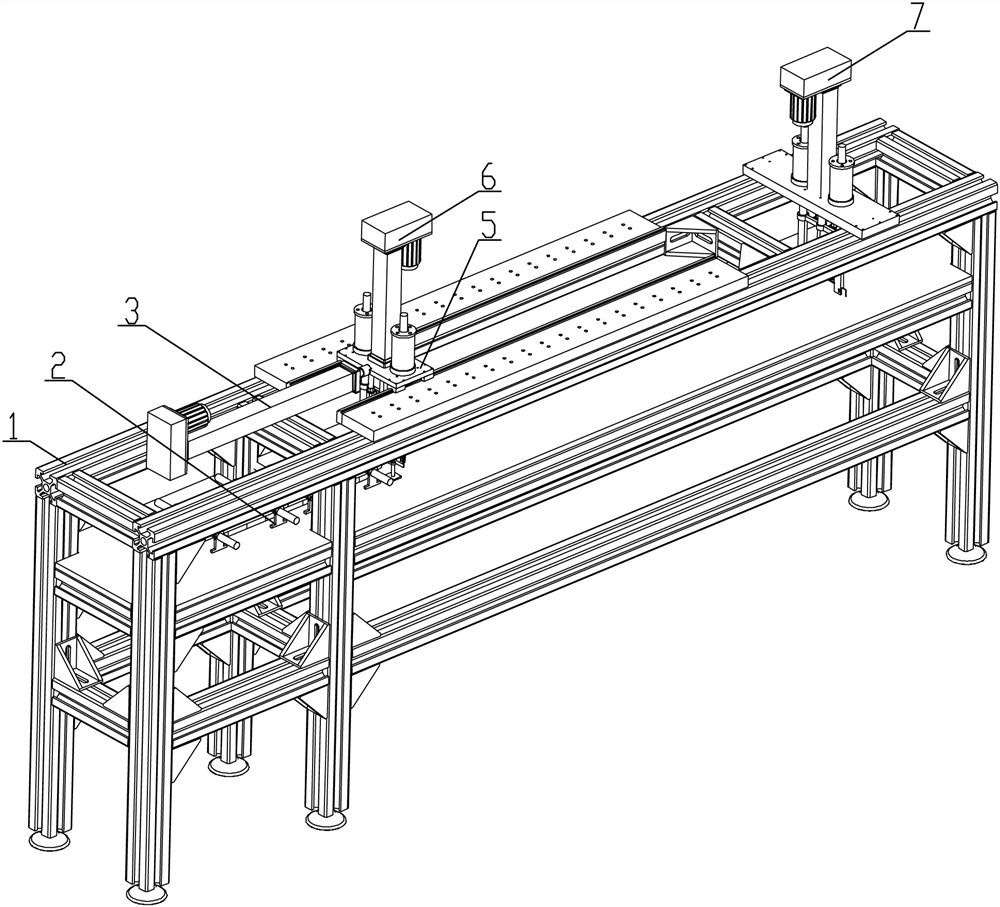

Automatic cutting and conveying device based on melt-blown cloth processing

PendingCN113005754AAchieve tensionRealize the cutting actionSevering textilesLiquid/gas/vapor removal by gas jetsProcess engineeringManufacturing engineering

The invention provides an automatic cutting and conveying device based on melt-blown cloth processing, relates to the technical field of cloth processing, and solves the problems that continuous cutting of cloth cannot be synchronously realized in the cloth conveying process through structural improvement, diffusion type jet drying of the cloth cannot be achieved in a linkage mode in the cloth conveying process, and the cloth cannot be tensioned in advance through structural improvement. The automatic cutting and conveying device based on melt-blown cloth processing comprises a frame body; the cloth is conveyed on the frame body; and a cutter frame is welded to the frame body. A stress arm is welded on a cutter seat, and a stress plate is welded on the stress arm; and the stress plate is located below a poke rod, and the poke rod makes elastic contact with the stress plate, so that the cutting action of a cutter can be achieved through extrusion and poking of the poke rod.

Owner:余青婷

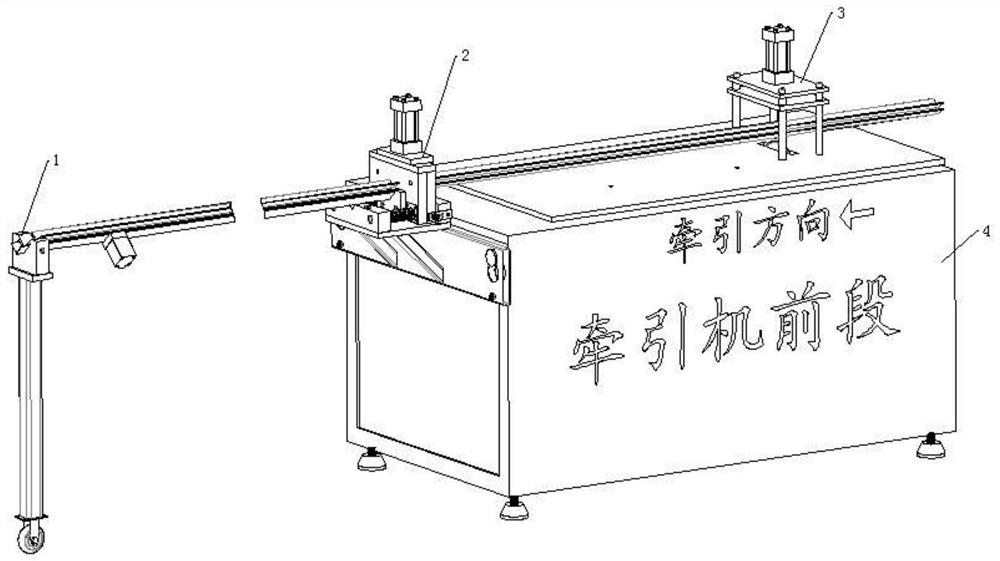

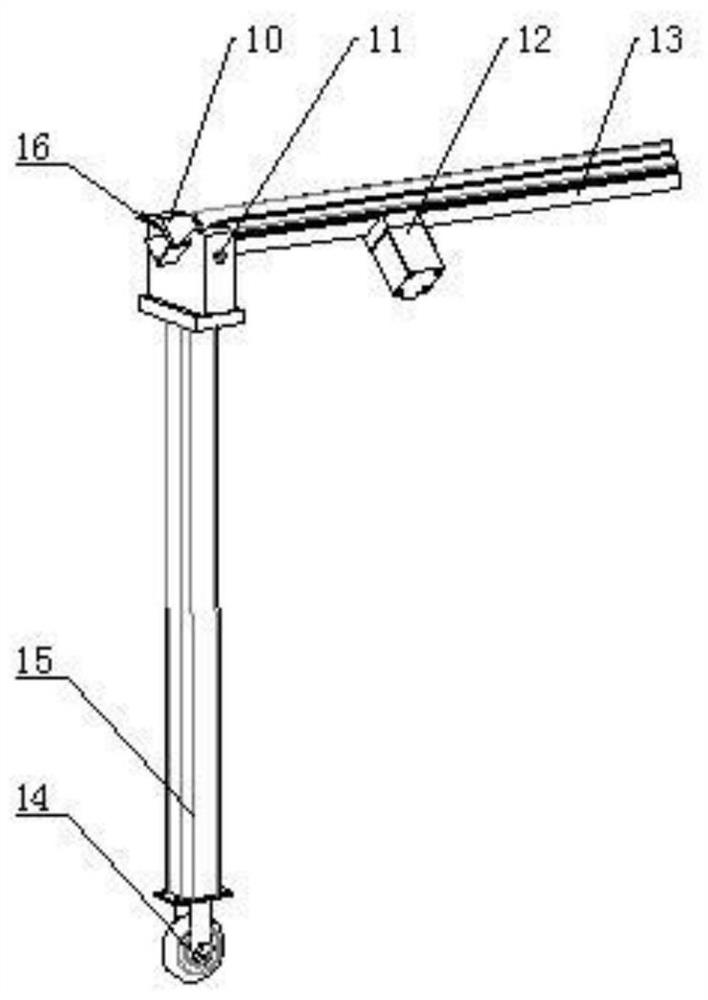

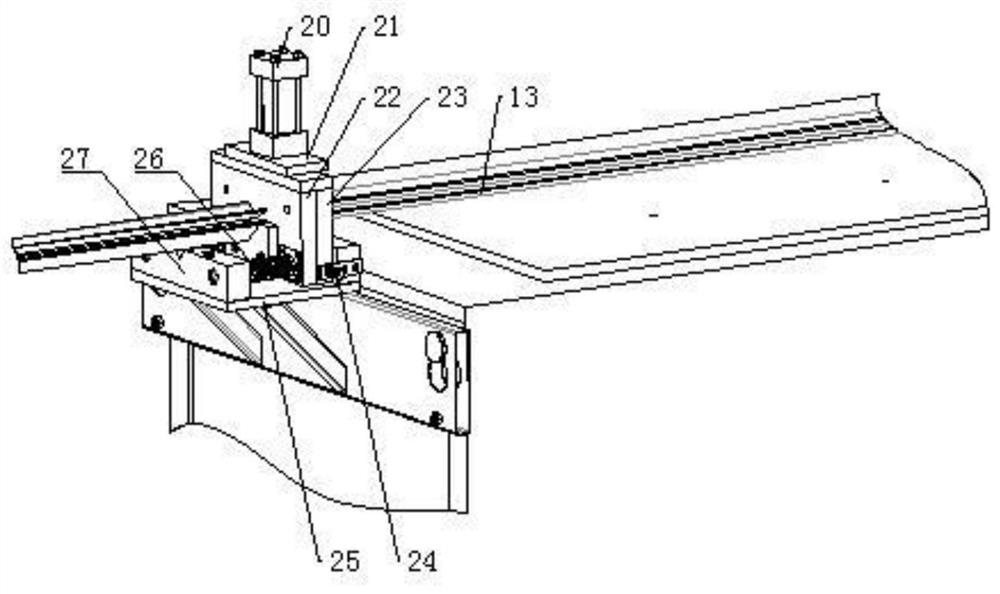

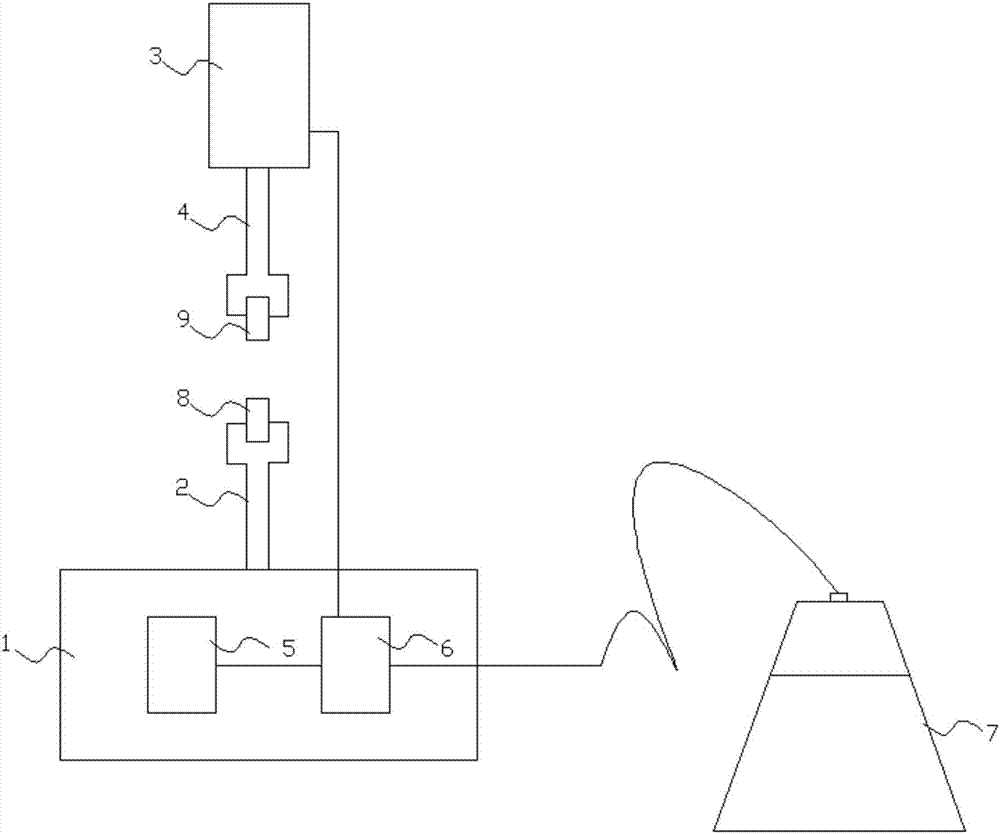

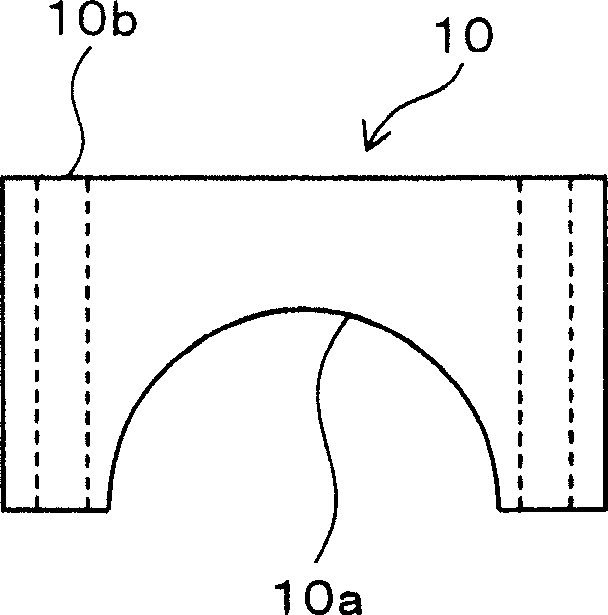

Fixed-length cutting device for angular panel

PendingCN112847493AEffective guidanceRealize synchronous linkageMetal working apparatusStructural engineeringWorkbench

The invention belongs to the technical field of cutting equipment, and relates to cutting equipment for plastic products, in particular to a fixed-length cutting device for an angular panel. The device comprises a worktable, wherein the worktable is installed at the downstream position of an extrusion process, an extruded panel is guided in from one side of the worktable and guided out from the other side of the worktable, a head cutting assembly is installed in the table top of the worktable, and a cutting assembly and a length fixing assembly are sequentially installed at the downstream position of the head cutting assembly. The cutting assembly and the length fixing assembly are arranged at an interval, the gap between the cutting assembly and the length fixing assembly is the fixed length of a panel to be cut, and the cutting assembly is used for cutting the panel with the fixed length. The length fixing assembly and the cutting assembly are connected through a positioning plate, and the two ends of the positioning plate are fixed to the end surfaces, on the same side, of the length fixing assembly and the cutting assembly respectively.

Owner:TIANJIN LIGHT IND VOCATION TECHN COLLEGE +1

Molybdenum rod shearing machine for tungsten halogen lamp tubes

The invention discloses a molybdenum rod shearing machine for tungsten halogen lamp tubes. The shearing machine comprises a pressing base, a lower cutter mold mounting column is perpendicularly arranged on the pressing base, and an air cylinder with the downward output end is arranged on the pressing base. An upper cutter mold mounting column is coaxially arranged at the output end of the air cylinder, the lower cutter mold mounting column and the upper cutter mold mounting column are located on the same base line, and the upper end face of the lower cutter mold mounting column is provided with a mounting groove for detachably mounting a lower cutter mold. An upper cutter mold and the lower cutter mold of the molybdenum rod shearing machine for the tungsten halogen lamp tubes are both made of a high-hardness alloy material. A foot switch controls the upper cutter mounting column of the air cylinder to move vertically to achieve the cutting-off action of tungsten halogen lamp bulb lamp feet; and meanwhile a driving motor is arranged on the pressing base to conduct telescopic control over the lower cutter mounting column according to the actual cutting-off gap distance, so that the defects that due to manual molybdenum rod shearing, efficiency is low, and consistency is poor are overcome.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

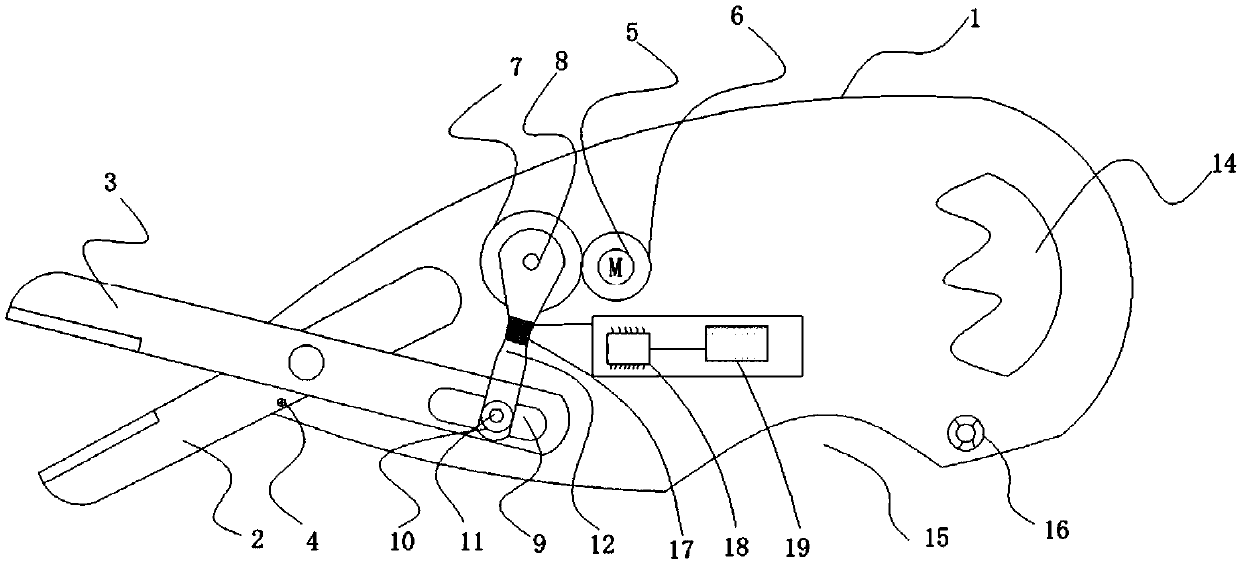

General Surgery Trauma Nursing Instrument

InactiveCN108814707BRelieve painAnesthesia Precise IntelligenceSurgical instruments for coolingNurse agencyGeneral surgery specialty

The invention discloses an operation wound nursing instrument for the general surgery department, and relates to the technical field of medical apparatuses. The instrument comprises a liquid supply box, a handheld shell and a low-temperature anesthesia nursing mechanism at the right end of the handheld shell; the low-temperature anesthesia nursing mechanism comprises an installing box and a fixingplate, and the installing box and the fixing plate are fixedly connected with the upper and lower sides of the right end of the handheld shell respectively; an air inflation bag is fixedly installedat the inner top of the installing box; a low-temperature anesthesia device at the lower end comprises heat conduction boxes; a semiconductor refrigerating sheet is installed in an installing groove;a heat conduction clamping sheet is fixedly connected to the upper end of the semiconductor refrigerating sheet; the cutting device comprises a driving motor fixed to the right part inside the installing box; an upper cutter is inserted to the lower end of a control block. The operation wound nursing instrument has the advantages that lower-temperature anesthesia effect or ultralow-temperature cell death is utilized, wounded redundant tissue is subjected to precise and intelligent anesthesia excision, the operation is convenient, and the pain of a patient is relieved; meanwhile, flushing nursing can be conducted, and the instrument is more convenient to use.

Owner:JILIN UNIV

Optical fiber shearing tool and operating method

ActiveCN110531464AImprove work efficiencyReduce labor intensityCoupling light guidesHigh pressureHigh pressure gas

The invention provides an optical fiber shearing tool and operating method. A tailstock is fixedly installed at the tail part of a handheld barrel, and an end cap is locked and fixed at the head partof the handheld barrel via a round nut; a piston cavity is arranged in the handheld barrel, a piston body is matched and installed in the piston cavity in a sliding manner; the piston body is fixedlyconnected with a piston rod arranged in the piston cavity; a push rod is connected with the other end of the piston rod; the push rod penetrates through the end cap; the push rod is hinged and connected with the bottom end of a movable blade via a link mechanism; the movable blade is hinged to a fixed blade via a rotation shaft; the fixed blade is fixedly installed on a blade mounting base via a blade fixing bolt; the blade mounting base is fixed on the top of the end cap; and a control valve rod used for controlling high-pressure air to enter is installed in the tailstock. The shearing tool adopts a high-pressure air source as a power source, adopts the link mechanism to drive the blades to act, and thus finally achieves shearing operation.

Owner:YICHANG POWER SUPPLY CO OF STATE GRID HUBEI ELECTRIC POWER CO LTD

Stitching instrument with cutter

ActiveCN102551827BReduce firing forceSimple structureSurgical staplesEngineeringMechanical engineering

The invention relates to a stitching instrument with a cutter, which comprises a support plate, a nail abutting seat, a nail bin, a cutter component, a propelling mechanism and a traction mechanism. The propelling mechanism and the traction mechanism are mounted on the support plate; the propelling mechanism is connected with the nail bin; the cutter component is mounted in an inner cavity of the nail bin and comprises a cutter slider and a cutter connecting steel wire rope; and the traction mechanism comprises a traction steel wire rope which is connected with a free end of the cutter connecting steel wire rope. The stitching instrument with the cutter is a linear type cutting stitching instrument with a sliding cutter, is applicable to the nail bin with the small longitudinal space, and is simple in structure, convenient in assembly and safe in use, triggering force of the stitching instrument is low, stitching nails are formed well, stitching and cutting actions are simultaneously realized by the effect of tension of the traction mechanism, the cutting direction of the stitching instrument is parallel to the direction of a stitching thread, and accordingly the stitching instrument is more applicable to popularization and application.

Owner:B J ZH F PANTHER MEDICAL EQUIP

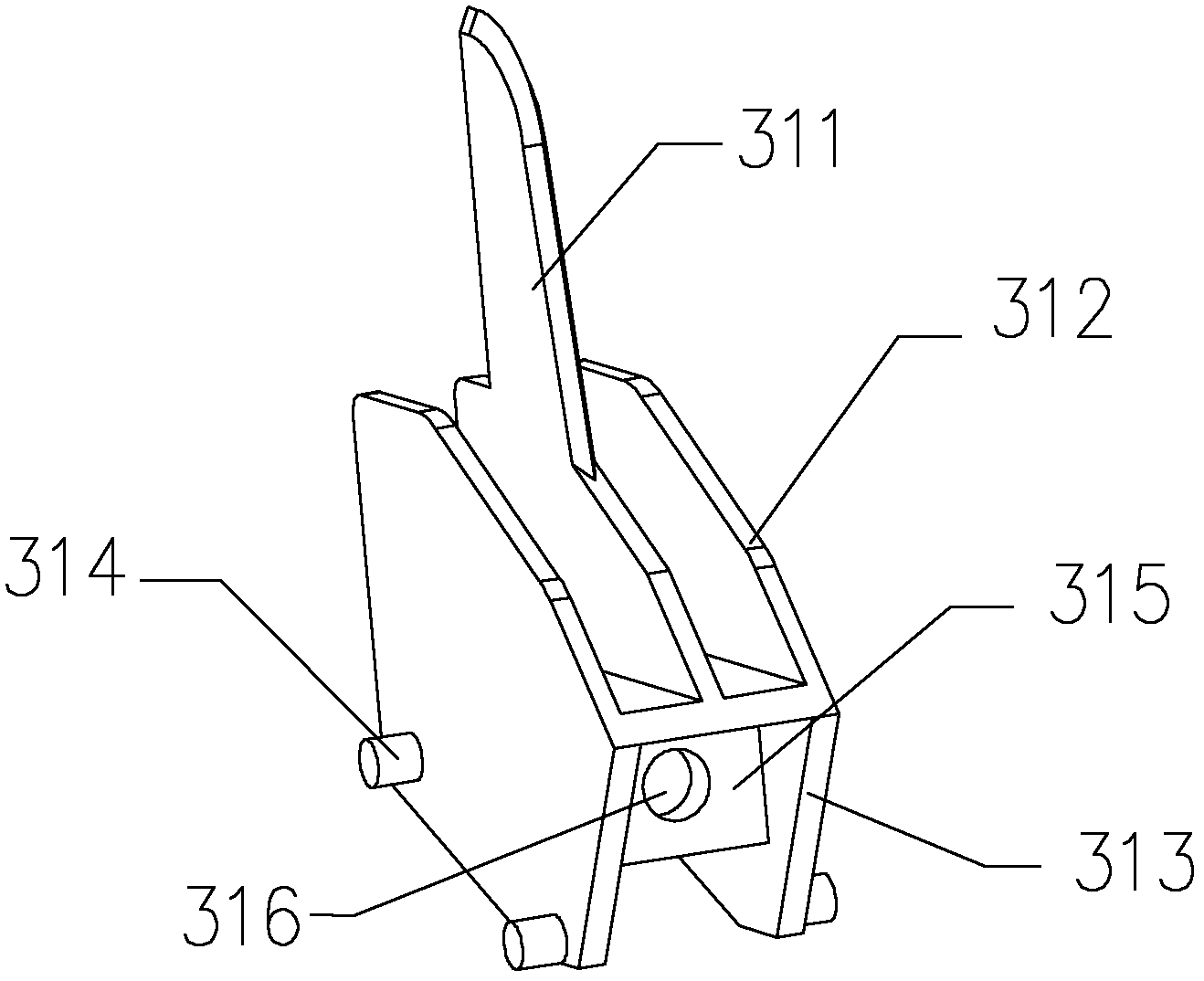

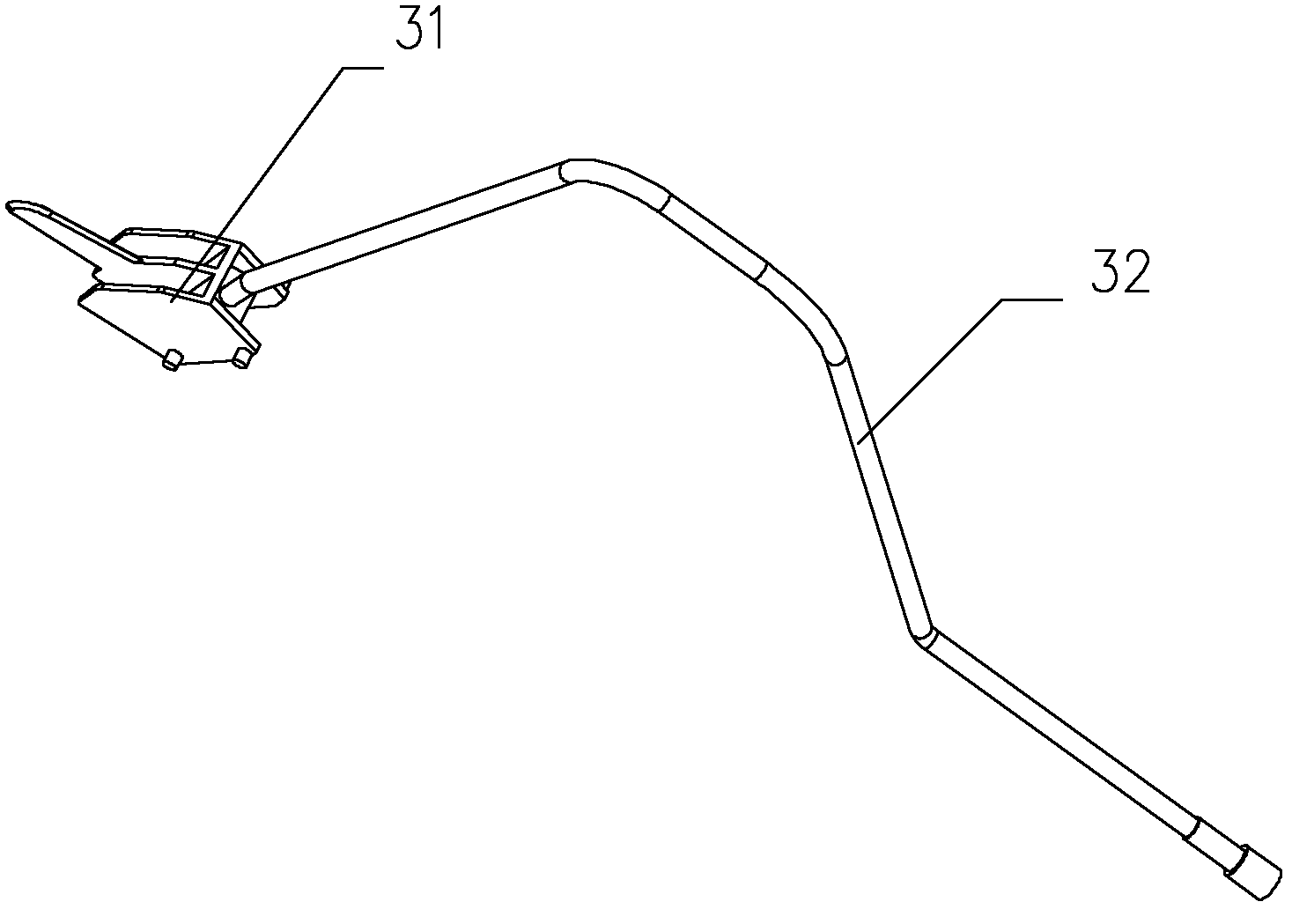

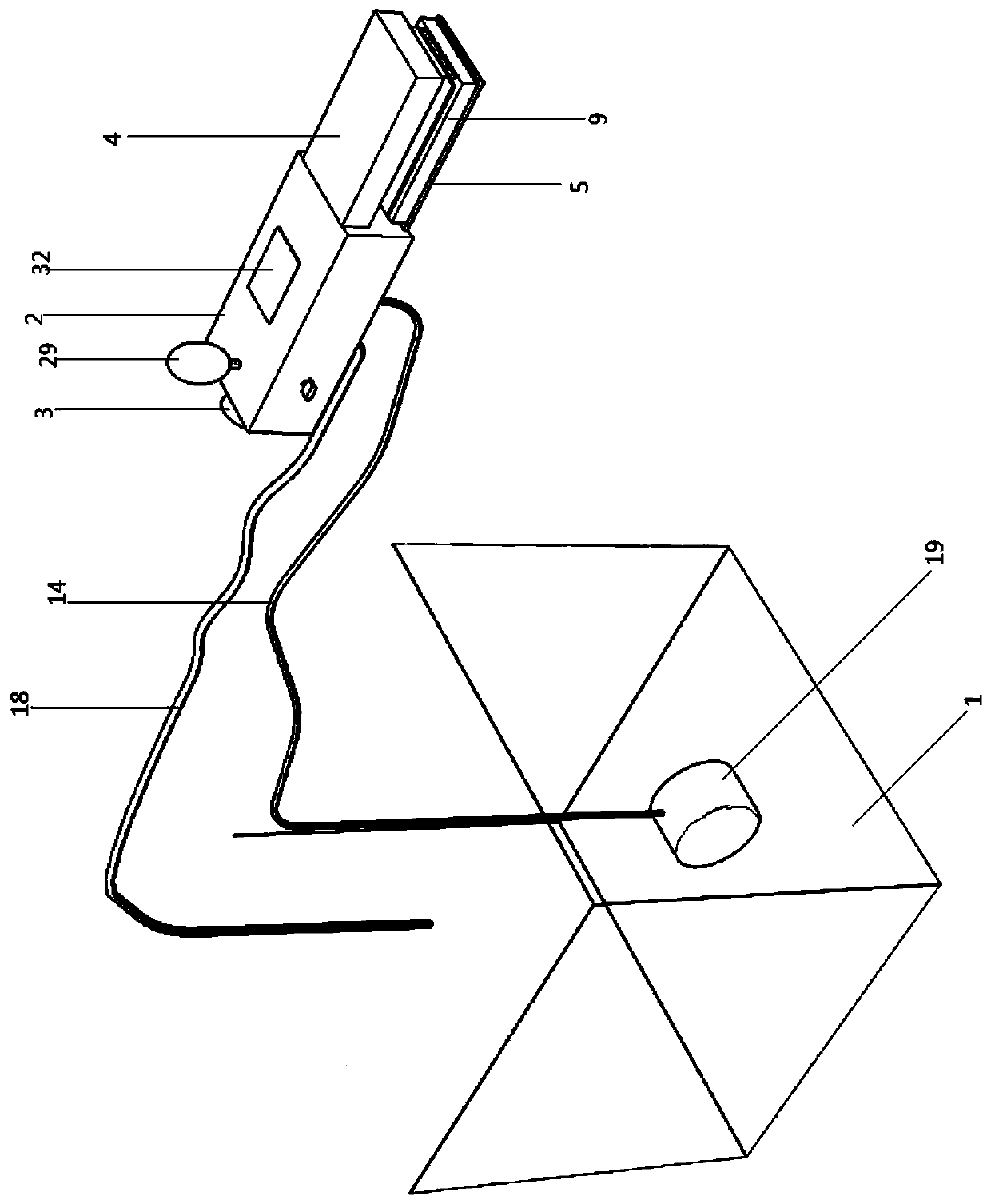

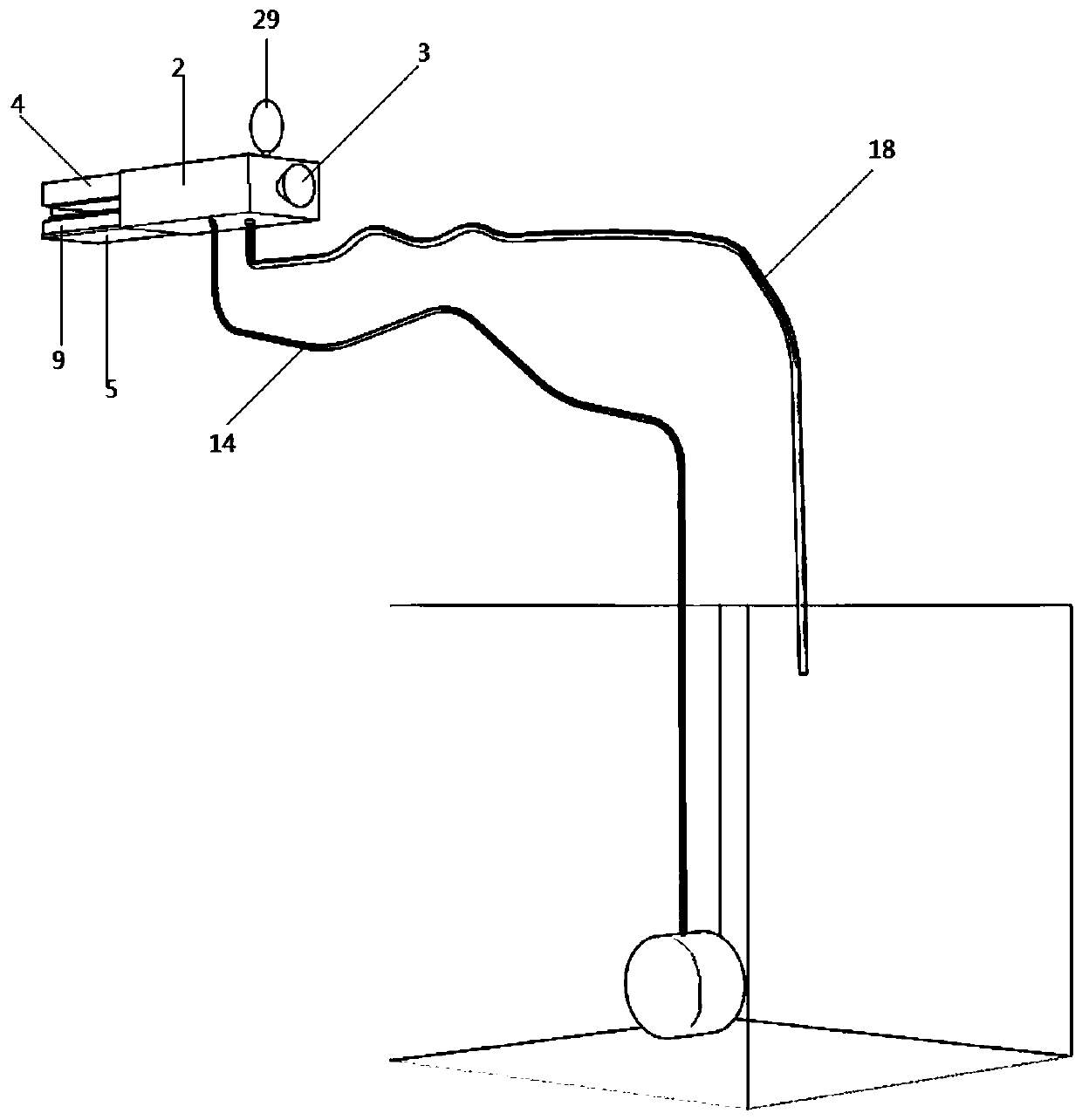

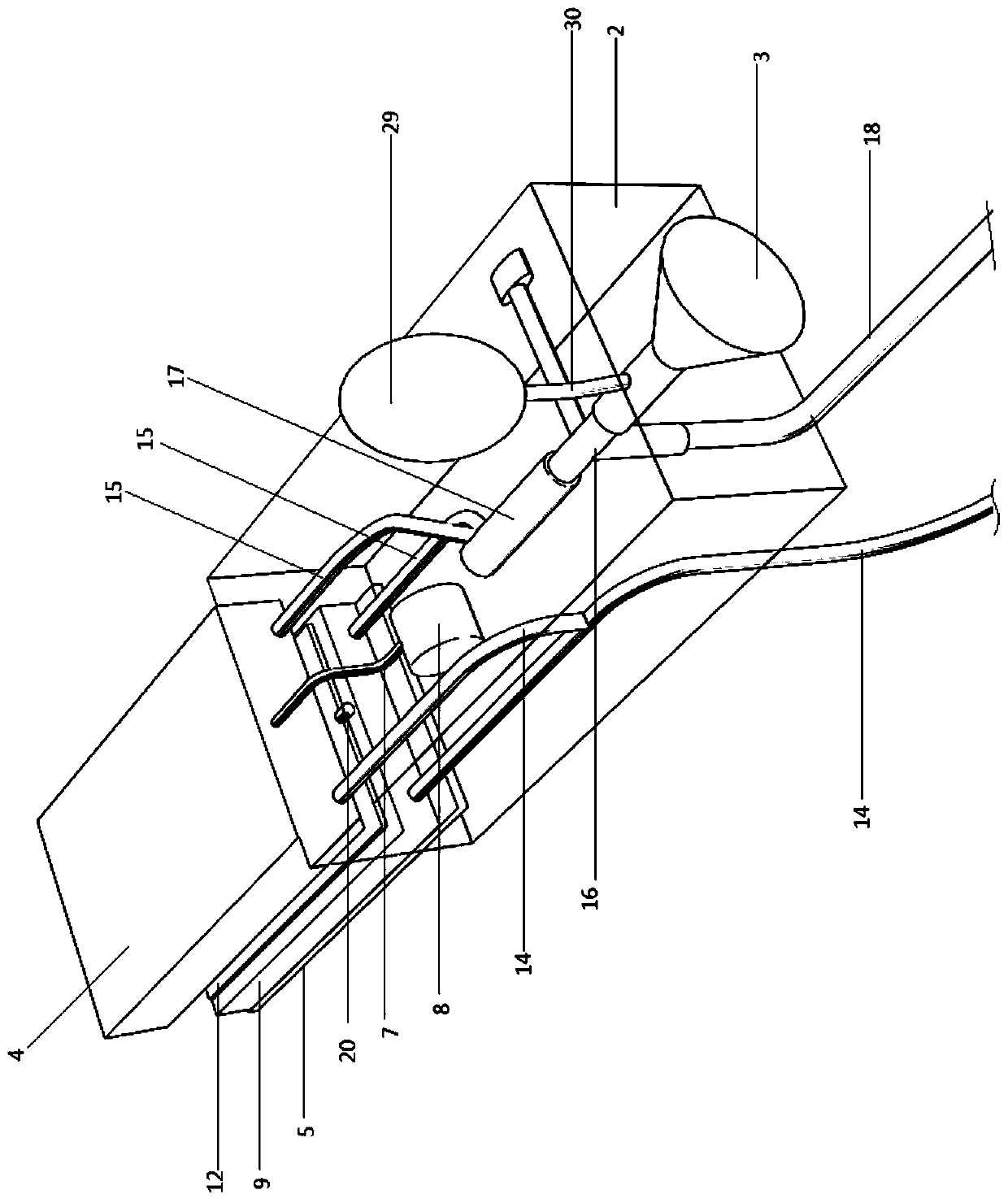

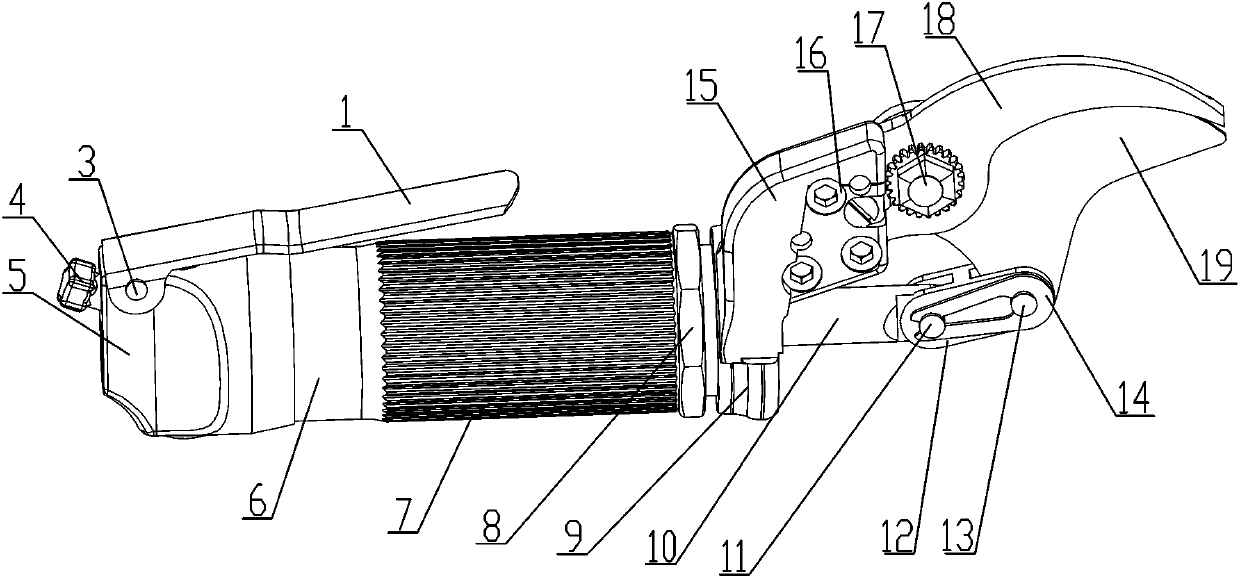

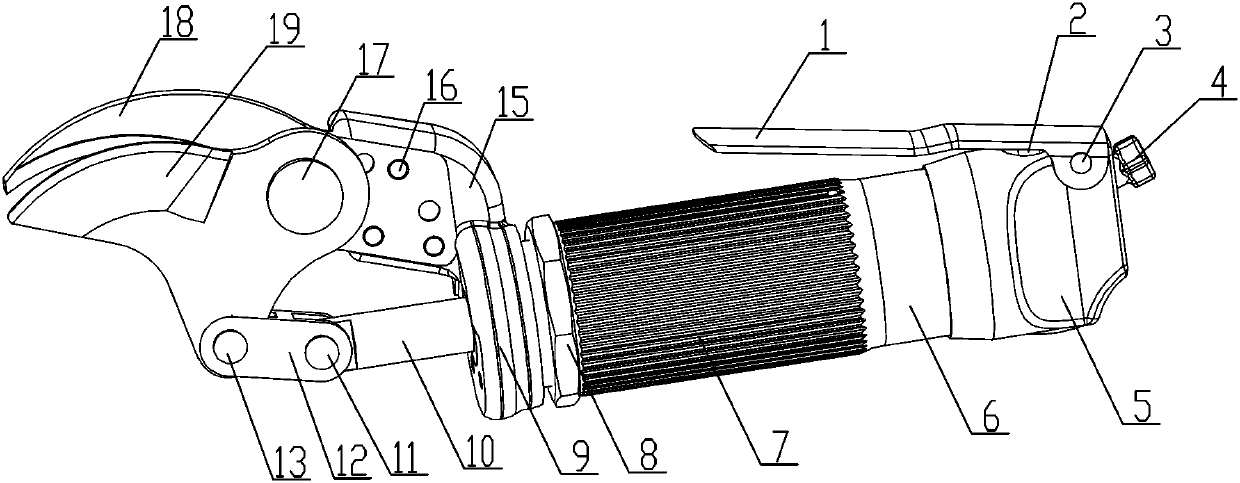

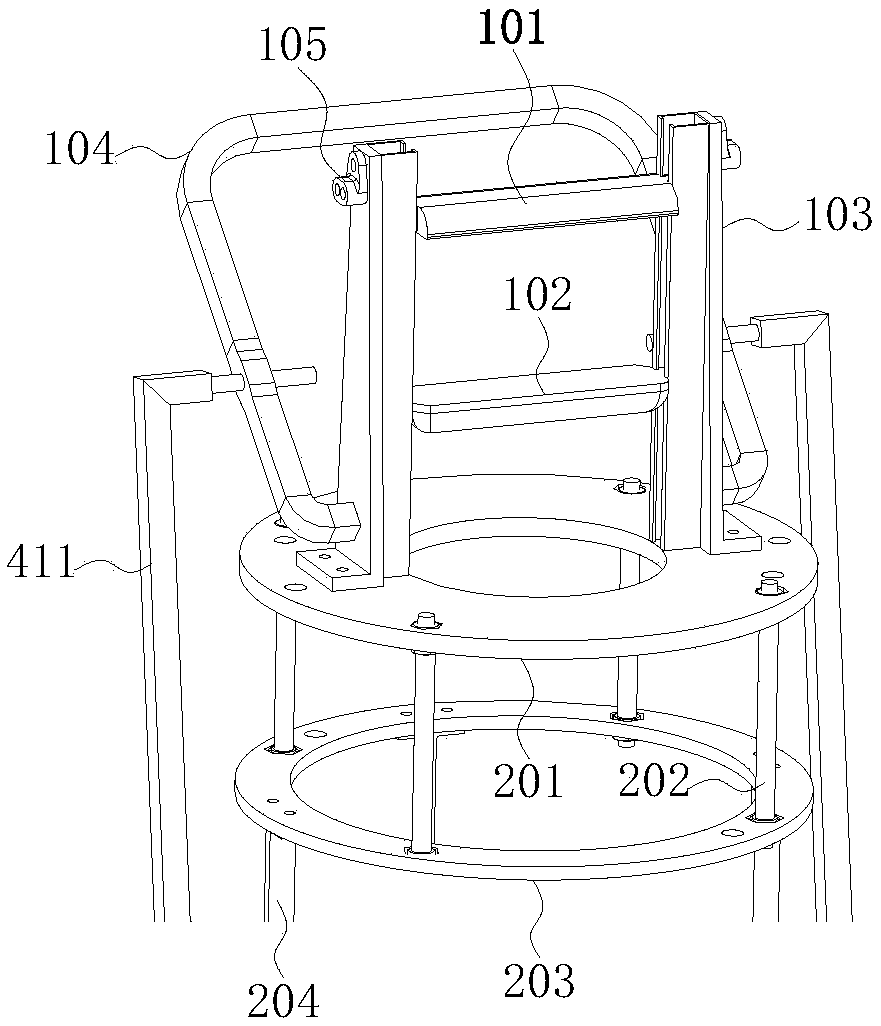

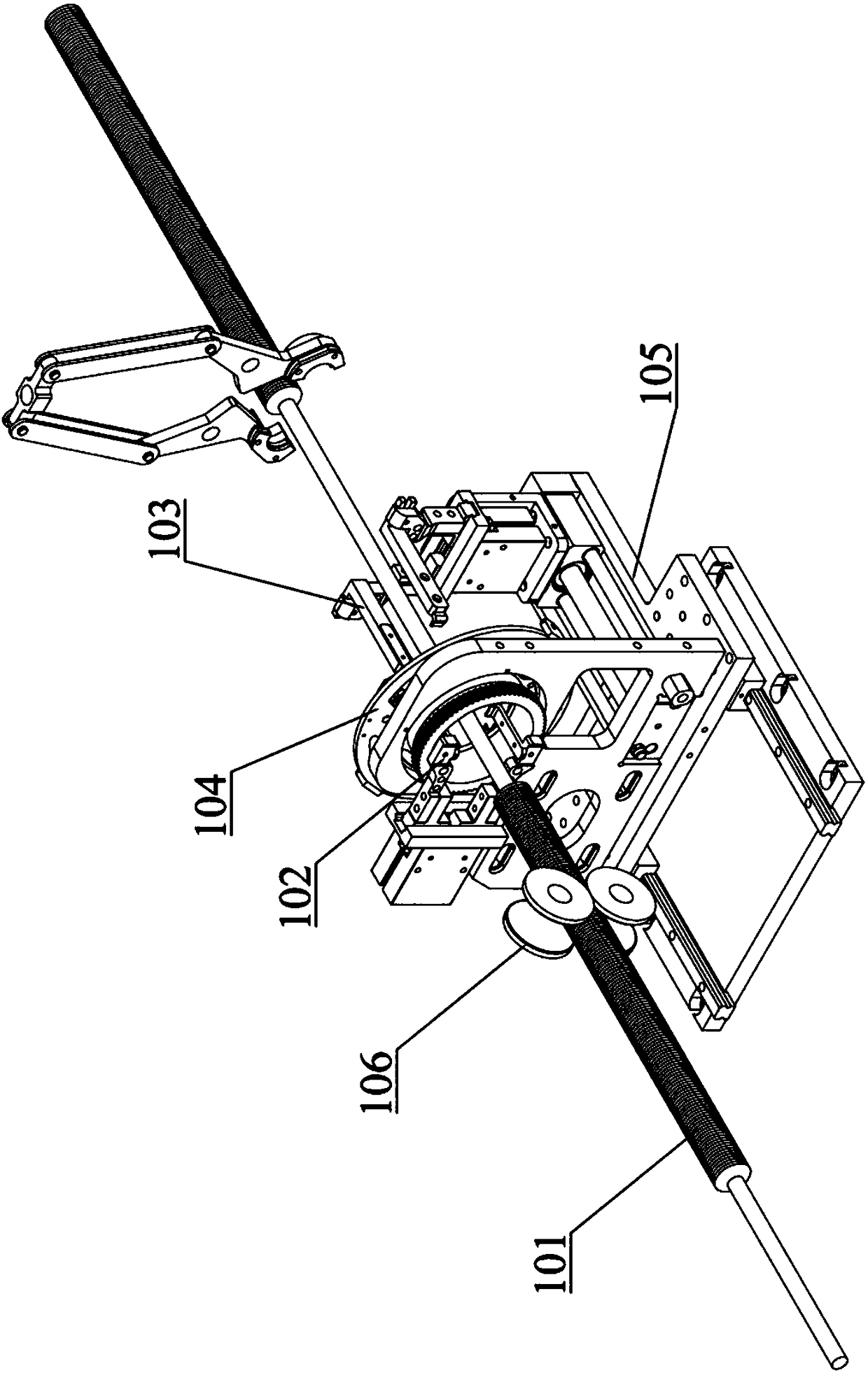

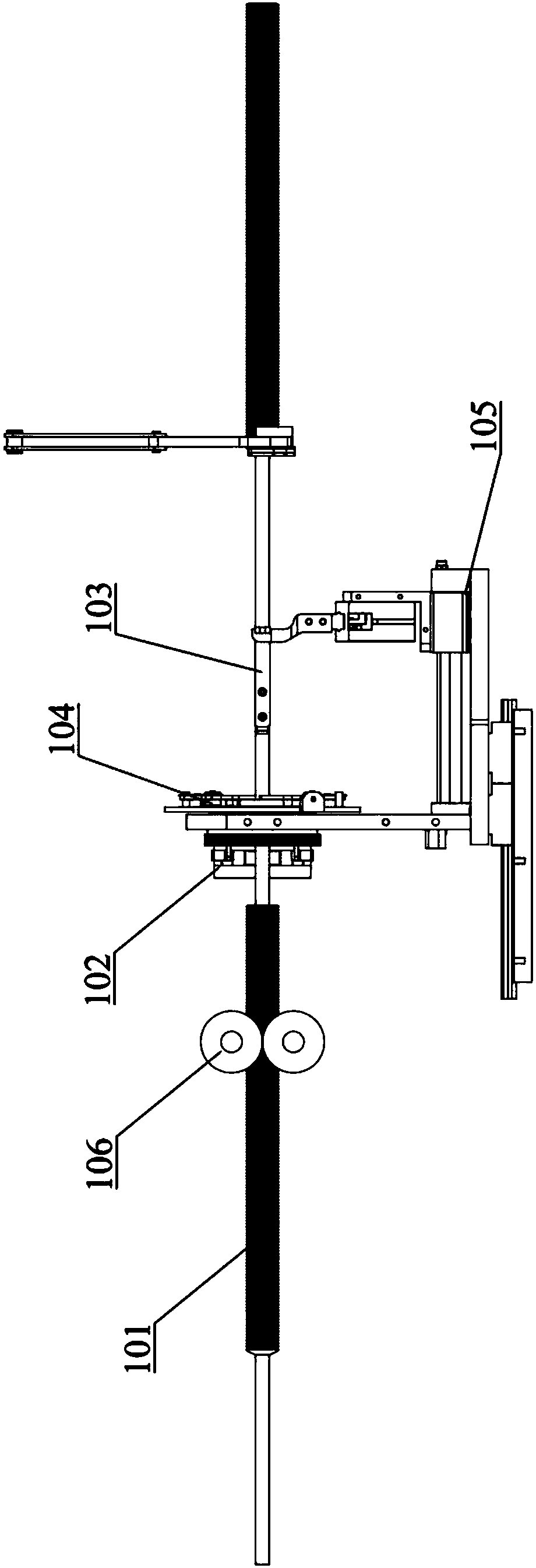

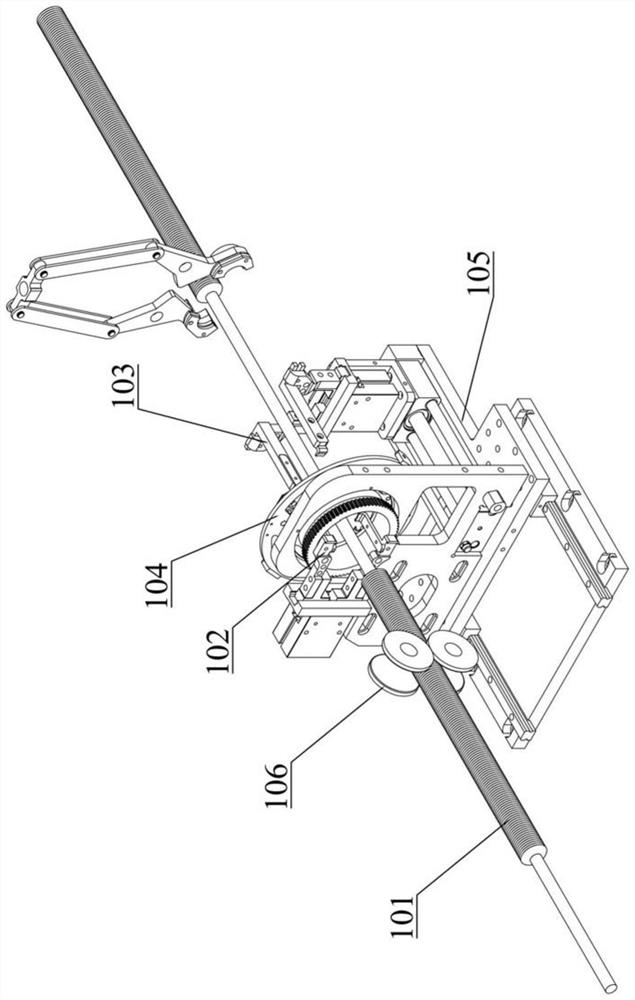

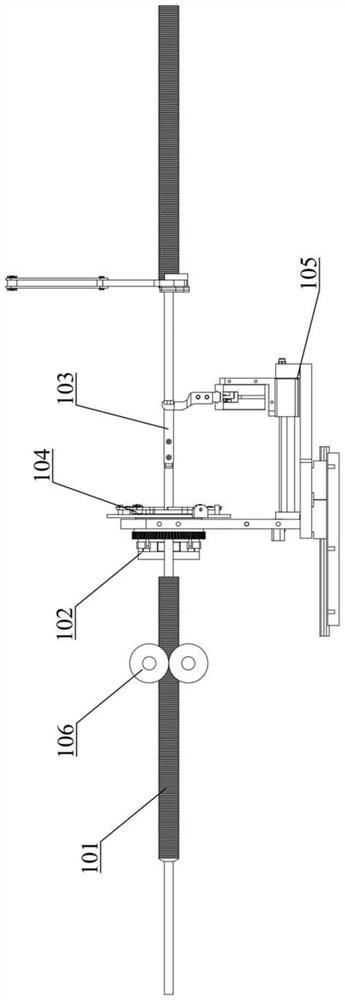

Handheld pineapple picking device

ActiveCN109005889ARealize the cutting actionReduce usageHarvestersAgriculture gas emission reductionEngineering

A handheld pineapple picking device belongs to the technical field of pineapple picking, and aims to solve the high labor intensity, the low picking efficiency, and the injury proneness of manual picking, and the inconvenient power supply, inaccurate positioning, and the decreased pineapple picking quality of mechanized picking. The handheld pineapple picking device comprises a support transmission unit; an operation unit disposed on the support transmission unit and including two fixed rails fixed vertically on the support transmission unit, a fixed handle having two ends fixedly connected with the middles of the two fixed rails, a clamping handle having two ends in sliding fit with two fixed rails, and a cutting operating lever in running fit with the sides of the two fixed rails; a clamping unit disposed on the lower end of the support transmission unit, and realizes the clamping movement by the clamping handle; and a cutting unit disposed on the lower end of the clamping unit, andrealizing a cutting operation by the clamping handle and the cutting operating lever.

Owner:BEIHUA UNIV

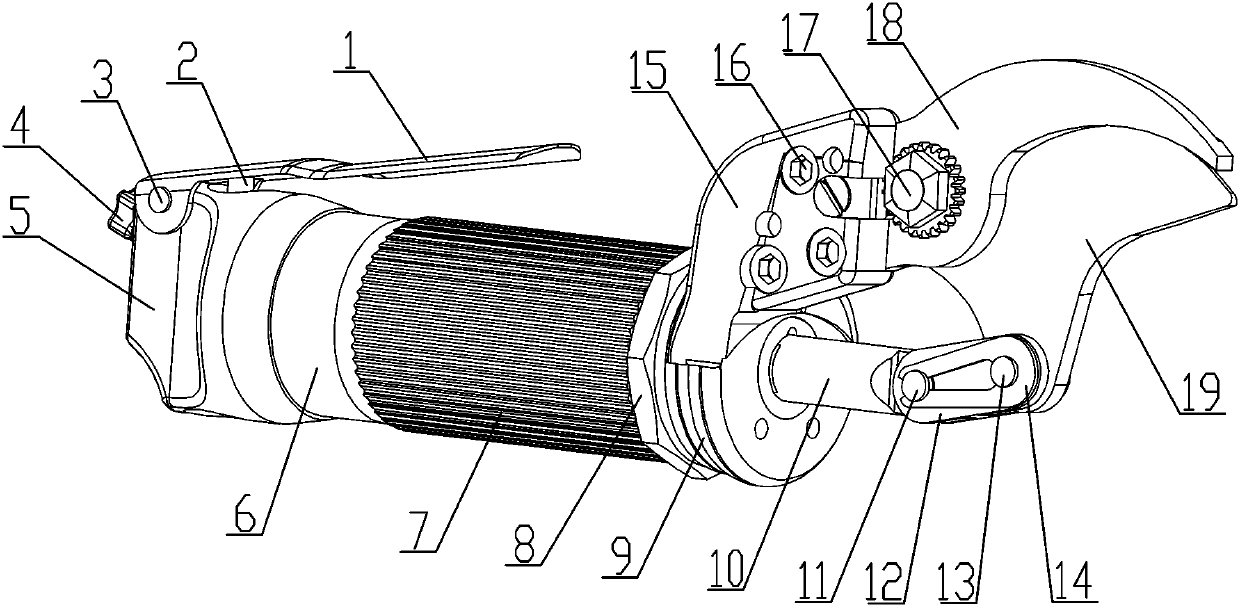

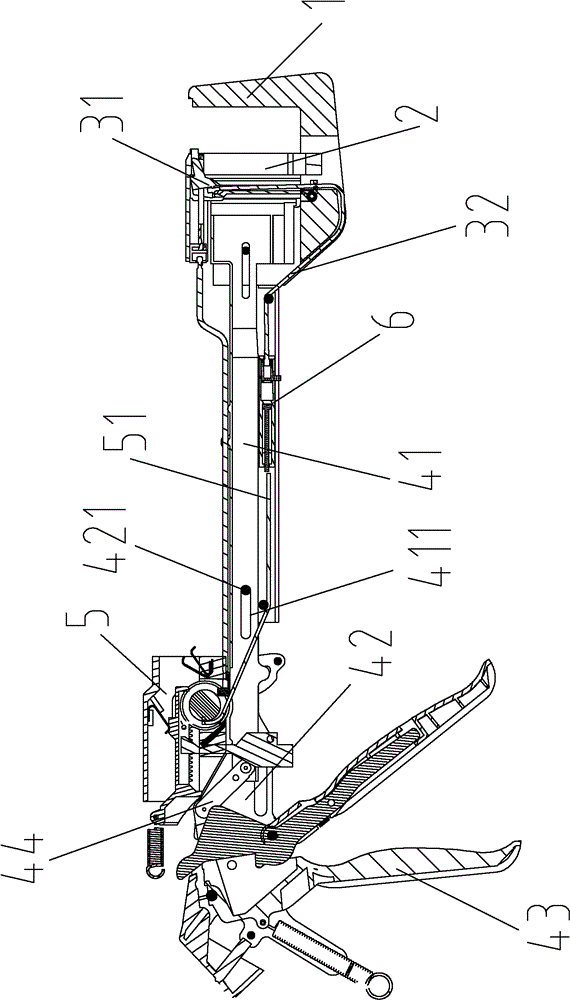

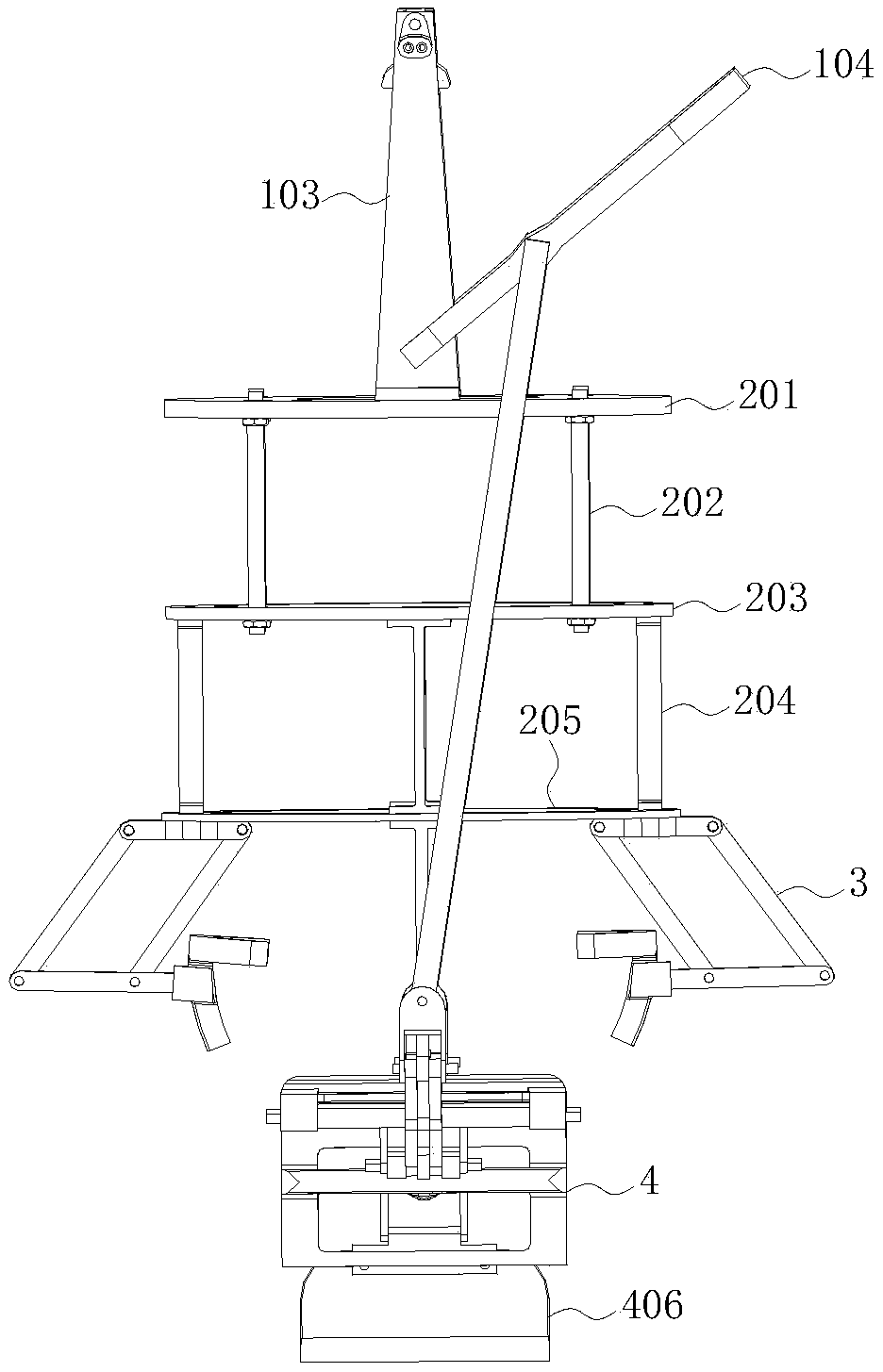

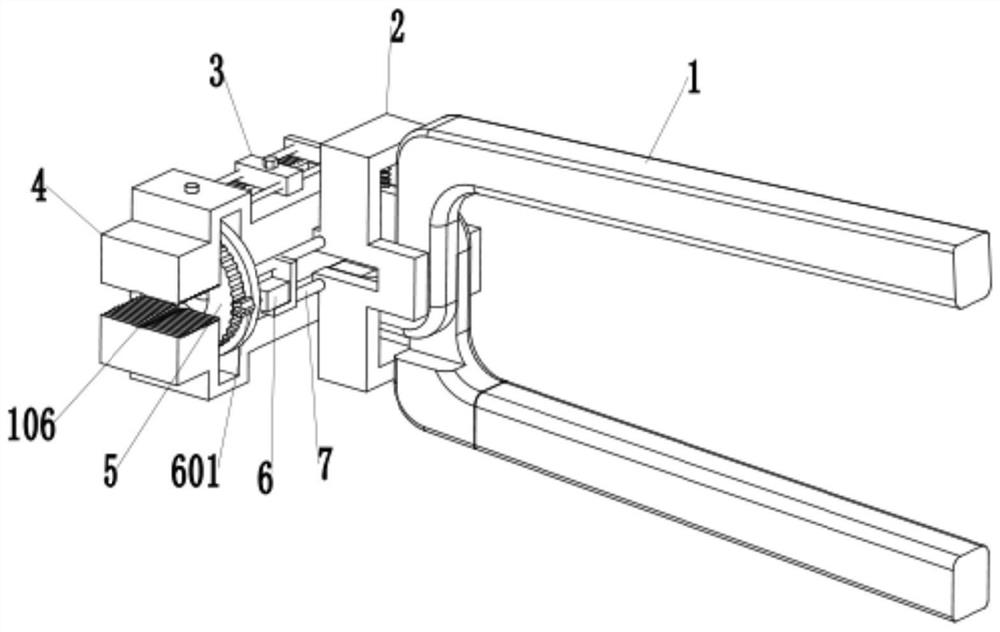

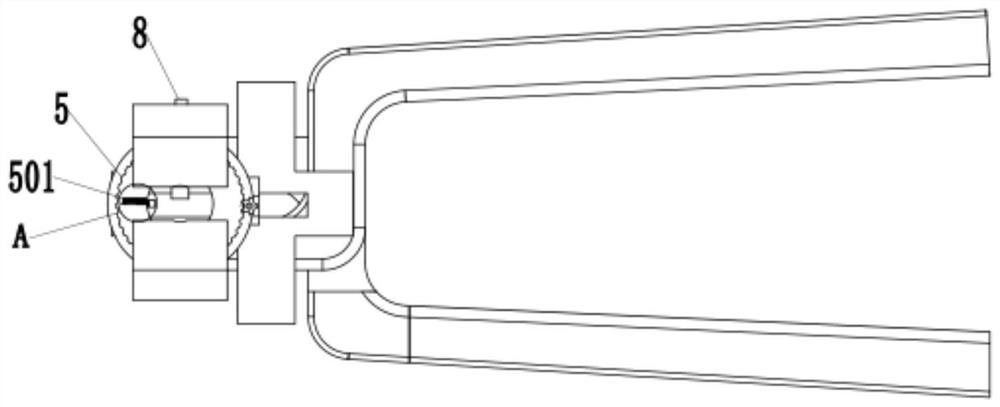

Electric scissor with monitorable shear force in real time

InactiveCN109719766AReal-time monitoring of shearing forceRealize the cutting actionMetal working apparatusEngineeringShear force

The invention provides an electric scissor with monitorable shear force in real time. The electric scissor comprises a scissor body and a fixed scissor blade and a movable scissor blade, wherein the fixed scissor blade and the movable scissor blade are arranged at the scissor port of the scissor body, the fixed scissor blade and the movable scissor blade are hinged and fixed through a hinge shaft,the fixed scissor blade is fixed at the scissor port of the scissor body through a screw, a motor is arranged in the scissor body, the output shaft of the motor is connected with a first gear, the first gear is meshed with a second gear, the second gear is provided with an eccentric shaft, a movable long hole is formed in the tail end of the movable shear blade, a bearing is clamped in the movable long hole in a clamped mode, the bearing is connected with a movable rod through a pin body, the upper end of the movable rod is connected with the eccentric shaft; the electric scissor further comprises a processing chip, a mechanical sensor and a display screen, wherein the mechanical sensor and the display screen are connected with the processing chip, the mechanical sensor is arranged on theeccentric shaft, the display screen is arranged on the scissors body. According to the electric scissor with monitorable shear force in real time, the shearing strength is monitored in real time, sothat the working efficiency is improved.

Owner:新昌县永益包装有限公司

Full-automatic unattended propellant sampling machine and preparation method

ActiveCN112847504AImprove securitySimple frame structureMetal working apparatusTotal factory controlStructural engineeringManufacturing engineering

The invention provides a full-automatic unattended propellant sampling machine and a preparation method. The middle of the top of a rack structure is provided with a sliding rail mechanism, the sliding rail mechanism is fixedly provided with a first cutting-off power mechanism used for slicing propellants, and the bottom end of the first cutting-off power mechanism is fixedly provided with a first cutter assembly; the sliding rail mechanism is connected with a pushing mechanism used for pushing the sliding rail mechanism to move, and the pushing mechanism is fixed to the top of the rack structure; a feeding guide structure used for conveying propellant powder blanks is in butt joint under the first cutter assembly; a second cutting-off power mechanism used for cutting cut medicine strips into dumbbell shapes is mounted on the tail section of the rack structure in a supporting mode; and a second cutter assembly is fixed to the bottom end of the second cutting-off power mechanism. According to the sampling machine, full-automatic equipment is adopted for completing the whole sampling technological process, and parameterized cutting, slicing and slitting of the propellant powder blanks and machining of dumbbell-shaped test pieces are achieved in an unattended mode.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

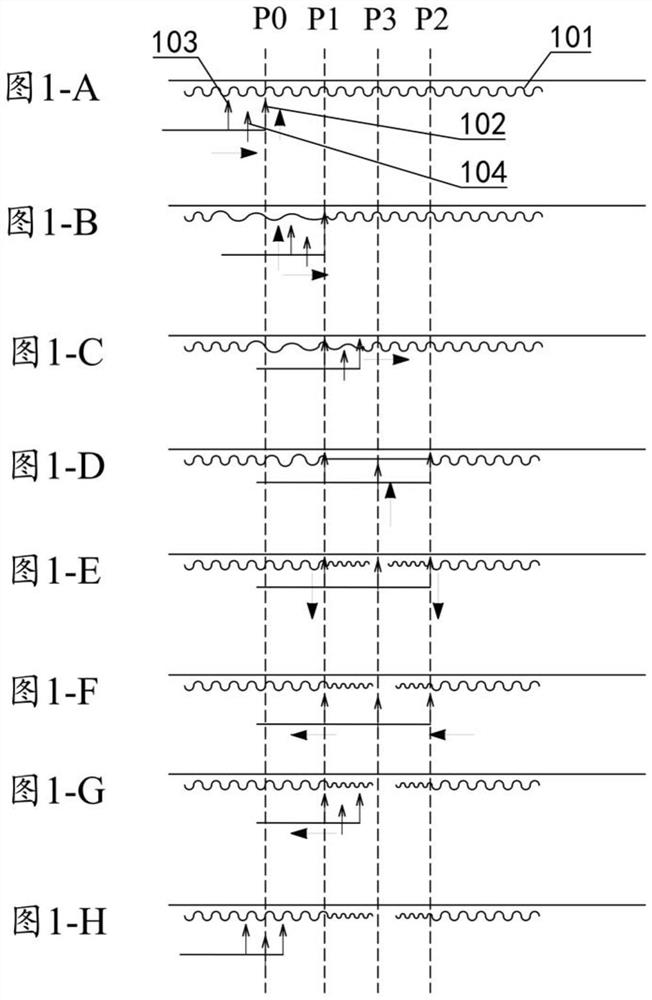

Method for improving shearing precision of head-cutting flying shear

PendingCN114871495AImprove accuracyHigh precisionMeasurement/indication equipmentsStock shearing machinesEconomic benefitsEngineering

The invention provides a method for improving the shearing precision of a head cutting flying shear. The method comprises the steps that a rolled piece passes through a length calculation formula: L = N * LPP; the method comprises the following steps: 1) calculating the pulse equivalent from the working roll diameter: LPP1 = pi * Dw / (PRR * i); (2) measuring the pulse equivalent through two HMDs: LPP2 = L2 / N2; finally, when the rolled piece passes through the length L, LPP = (LPP1 + LPP2average) / 2; according to the method, the pulse equivalent LPP1 is calculated from the working roll diameter, the pulse equivalent LPP2 is measured through the two HMDs, the two methods are combined to obtain the average value, and therefore the accuracy and precision of the algorithm are improved, the detection precision of a detection mechanism is improved, the shearing precision of the head-cutting flying shear is improved, the cutting loss rate is reduced, and the working efficiency is improved. And the yield and the economic benefit are improved.

Owner:SHANDONG LAIGANG YONGFENG STEEL & IRON

Iron sintered component and producing method and sintered mechanical parts

The invention relates to an iron sinter element and relative production, which can improve high strength and cutting property. Wherein, arranging the fuse dip material formed by molding metallic powder on at least one part of the surface of sinter element that obtained by heating the powder former on the iron sinter element; sintering the powder former with said fuse dip material, at the temperature above the carbon disperse temperature and under the fuse point of fuse dip material; and said powder is the iron powder mixture that removed graphite powder from the power mixture of iron sinter element that in pearlite organism; adding 0.01-1.0 mass% boric oxide and 0.1-2.0 mass% graphite powder, then said metallic powder is the copper or copper alloy powder.

Owner:RESONAC CORP

Bendable planer tool device

The invention discloses a bendable planer tool device. The bendable planer tool device comprises an outer-layer protection sleeve, a rotatable inner pipe arranged inside the outer-layer protection sleeve and a planer tool bit, wherein one end of the rotatable inner pipe is used for being connected with a rotating driving device, and the other end of the rotatable inner pipe is connected with the planer tool bit; a metal pipe is arranged at the tail end of the outer-layer protection sleeve, and a memory alloy pipe is arranged at the front end of the outer-layer protection sleeve; the rotatableinner pipe comprises multiple single-section inner pipe units and multiple hinging connecting pieces, the multiple single-section inner pipe units are sequentially connected, the single-section innerpipe unit located at the tail end is specifically connected with the planer tool bit, and any two adjacent single-section inner pipe units are connected through the corresponding hinging connecting pieces. The bendable planer tool device can be bent in the certain angle range, and better adapts to different to-be-cut positions inside the human tissue and cutting angle adjustment accordingly, and thus operative efficiency is remarkably improved.

Owner:STAR SPORTS MEDICINE CO LTD

Stitching instrument with cutter and cutter component of stitching instrument with cutter

ActiveCN102551828BReduce firing forceSimple structureIncision instrumentsSurgical staplesPull forceSuture cutter

The invention relates to a stitching instrument with a cutter and a cutter component of the stitching instrument with the cutter. The cutter component comprises a cutter slider, a cutter connecting steel wire rope, guiding plates and a fixing block; the cutter slider is provided with the cutter, a triggering plate, a positioning plate, positioning pins, a steel wire rope mounting block and a mounting hole; one end of the cutter connecting steel wire rope penetrates through the mounting hole and is fixed; each guiding plate is provided with a guiding groove, the guiding grooves correspond to the positioning pins, and the cutter slider is slidably mounted between the two guiding plates via the positioning pins; and the fixing block is mounted below the guiding plates and the cutter slider. The cutter component of the stitching instrument with the cutter is mounted in an inner cavity of a nail bin, and the cutter connecting steel wire rope of the cutter component is connected with a traction mechanism. The stitching instrument with the cutter is applicable to the nail bin with the small longitudinal space, and is simple in structure, convenient in assembly and safe in use. The triggering force of the stitching instrument is low, stitching nails are formed well, stitching and cutting actions are simultaneously realized by the effect of tension of the traction mechanism, the cutting direction of the stitching instrument is parallel to the direction of a stitching thread, and accordingly the stitching instrument is more applicable to popularization and application.

Owner:B J ZH F PANTHER MEDICAL EQUIP

Stepping feed crushing device

InactiveCN111919607AImprove crushing efficiencyReasonable designFeeding-stuffCuttersGear wheelElectric machinery

The invention relates to the technical field of feed processing equipment, and discloses a stepping feed crushing device. The device comprises a workbench, the top of the workbench is fixedly connected to a box body, one side of the top of the box body is fixedly connected to a motor, a guide plate is arranged on the outer side of the box body, a cutter is fixedly connected to the bottom of the guide plate, the cutter movably abuts against the outer side of the workbench, the outer side of the guide plate is slidably sleeved with a limiting plate, the limiting plate is fixedly connected to theouter side of the box body, the box body is rotationally connected to a rotary disc and a driven gear which are in coaxial transmission, the rotary disc is located on the inner side of the box body,the driven gear is located on the outer side of the box body, the front side of the driven gear is fixedly connected to a sliding shaft, the sliding shaft is sleeved with the guide plate, and a driving gear is fixedly connected to an output shaft of the motor. The device is reasonable in design, under the driving effect of the motor, automatic feeding and straw sectioning actions can be achieved,the straw feeding and sectioning actions are conducted in a staggered mode and matched with each other, the automation degree is high, and the straw crushing efficiency is effectively improved.

Owner:宁夏海原国华农机制造有限责任公司

Sausage casing cutting device, sausage casing sleeve shrinkage machine and sausage casing cutting method

The present invention relates to a sausage casing cutting device. The sausage casing cutting device is used for cutting continuously fed sleeve shrinkage sausage casings on a sleeve shrinkage rod. Thesausage casing cutting device comprises a cutting mechanism and a first sausage casing limiting member; the cutting mechanism is used for cutting the sleeve shrinkage sausage casings around the circumference of the sleeve shrinkage sausage casings; the first sausage casing limiting member is designed to be inserted into the radial ranges of the sleeve shrinkage sausage casings to block the feeding movement of the upstream sleeve shrinkage sausage casings; wherein the first sausage casing limiting member and the cutting mechanism are designed to enable the first sausage casing limiting memberto be inserted into the radial ranges of the sleeve shrinkage sausage casings at an initial position; then the first sausage casing limiting member moves downstream along the feeding direction of thesleeve shrinkage sausage casings to a first position; and thus the cutting mechanism can conduct cutting of the sleeve shrinkage sausage casings between the primary position and the first position. The present invention also relates to a sausage casing sleeve shrinkage machine with the sausage casing cutting device and a sausage casing cutting method.

Owner:佛山磐砻智能科技有限公司

A device for removing insulation layer of a power cable

ActiveCN112490951BAvoid damageGuaranteed cutting accuracyApparatus for removing/armouring cablesPower cableCross connection

The invention discloses a device for removing insulation layer of a power cable, which comprises a handle, a support frame, a chuck, a wire cutting ring and a motor, the handle includes a first handle and a second handle, and the end of the first handle There is a first lever at the end, and a second lever is arranged at the end of the second lever, and the first lever and the second lever are cross-connected by a rotating shaft, and the first lever and the second lever are connected The outer side is covered with a support frame connected to the rotating shaft. The chuck includes an upper clamping block and a lower clamping block. The upper clamping block is connected with the second driving rod, the lower clamping block is connected with the first driving rod, and the upper clamping block A tangent ring is provided between the clamping block and the lower clamping block, and the tangent ring is connected to the support frame through a support rod, and a motor for driving the tangent ring to rotate is fixed on the support rod. The cable is fixed by the upper and lower clamping blocks, and the insulation layer of the cable can be automatically cut circularly by using the tangent ring, which solves the problems of cumbersome manual cutting and peeling operations, easy damage to the cable, and time-consuming and labor-intensive problems.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO TAOXIAN POWER SUPPLY CO

Casing cutting device, casing shrinking machine and casing cutting method

ActiveCN108522616BRealize the cutting actionQuality improvementSausage casing shirringStructural engineeringMechanical engineering

Owner:佛山磐砻智能科技有限公司

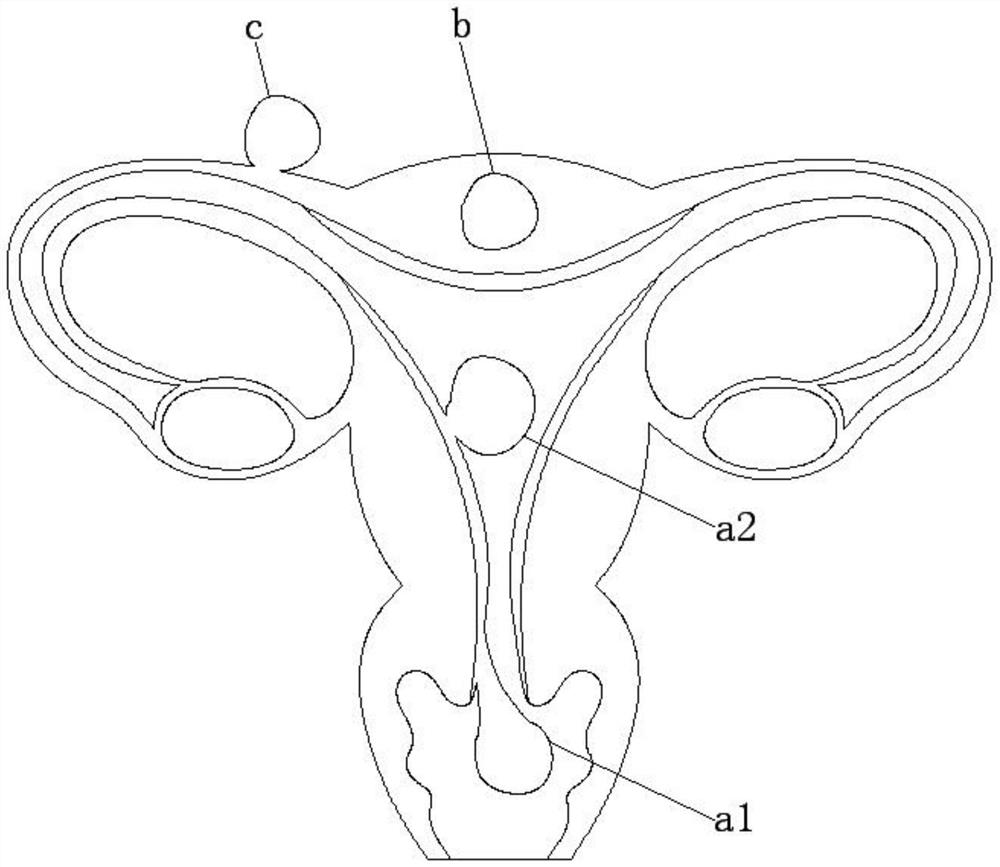

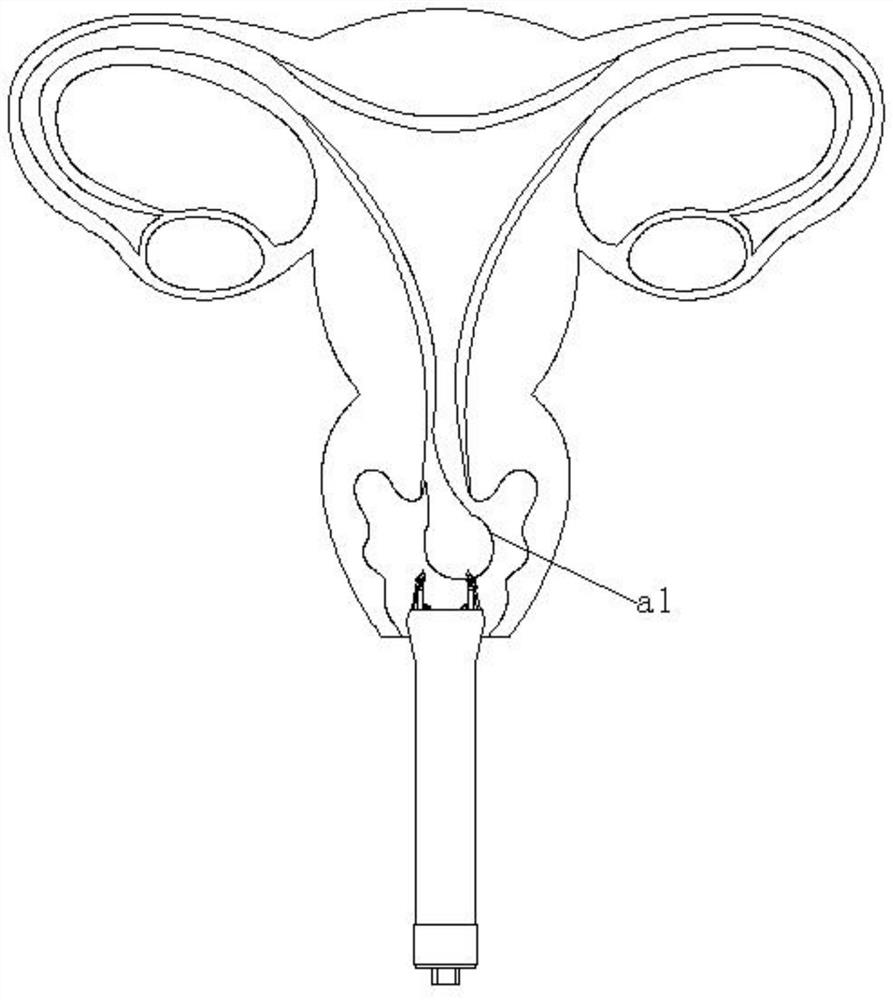

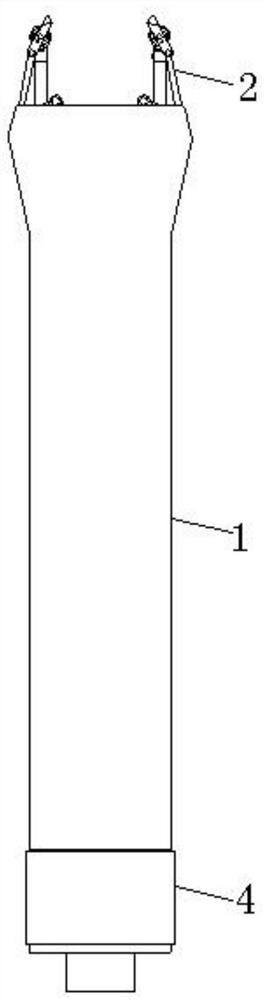

Hysteromyoma sampling device for gynecology department

ActiveCN113367741AEasy to insertEasy to sampleSurgical needlesVaccination/ovulation diagnosticsEngineeringGynecology department

A hysteromyoma sampling device for the gynecology department comprises a probing rod body and clamping assemblies. The probing rod body comprises a hollow outer cylinder, a sliding core cylinder, placement side holes and side insertion strips; the number of the clamping assemblies is two, and one clamping assembly is arranged in each placement side hole. Each clamping assembly comprises a hinged mandrel, a right swing rod, a left transmission rod, a left driving rod and a left driven rod. Each right swing rod comprises a follow-up rod body and further comprises a follow-up lantern ring, a rotation stopping plug and a rotation stopping stop rod.

Owner:张建玲 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com