Power-driven wall body beaming machine

A skin scraping machine and wall technology, which is applied in the direction of construction and building construction, can solve the problems of uneven force on the blade, uneven wall surface, poor wear resistance, etc., achieve good flatness of the substrate, save time and effort Good efficiency and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

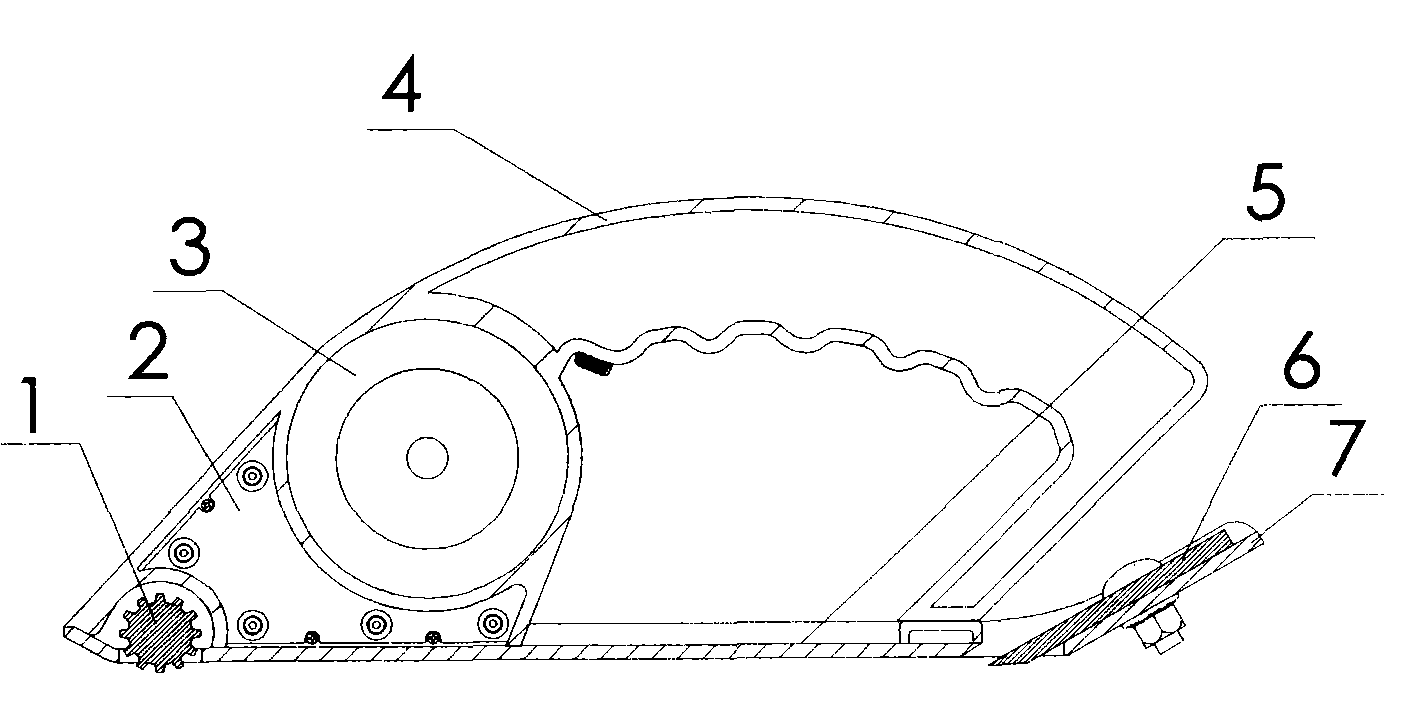

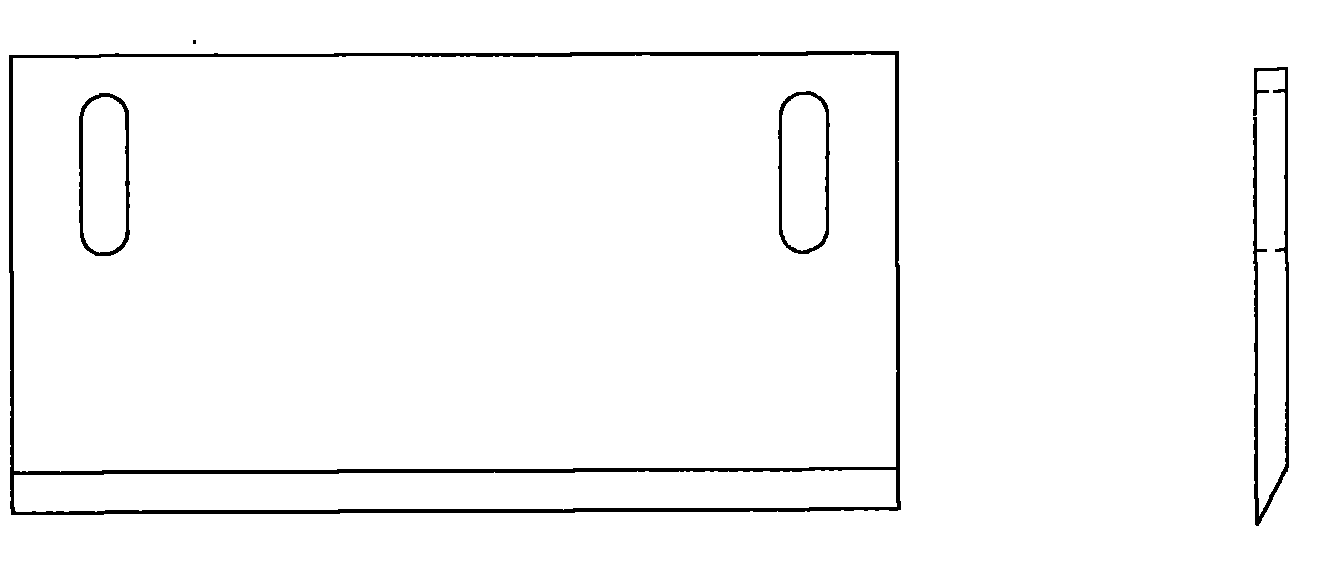

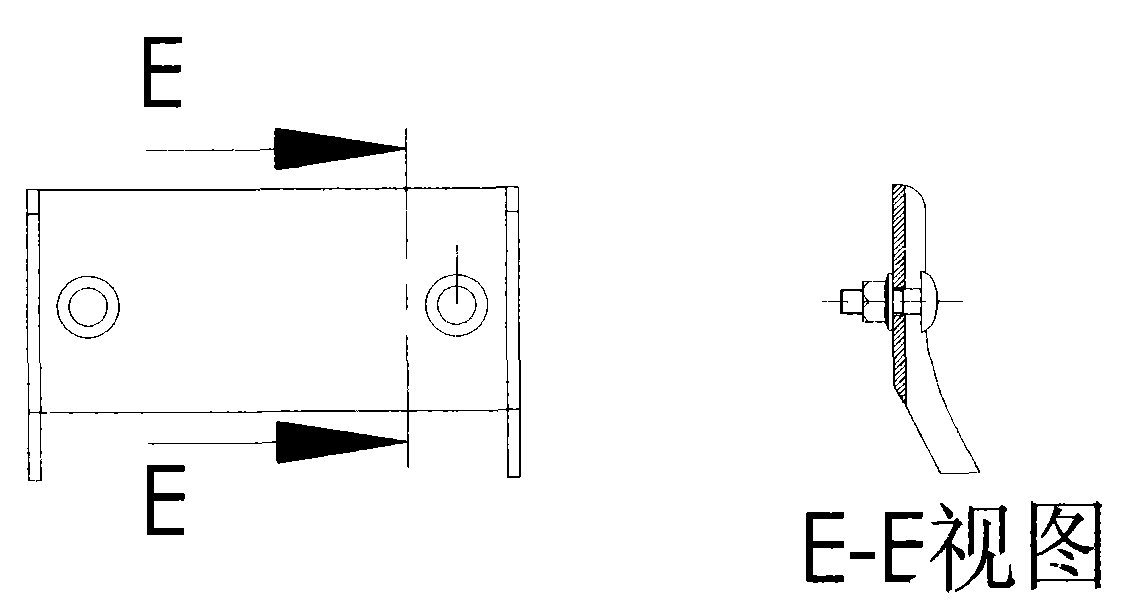

[0017] When in use, the operator connects the plug to the external power supply, holds the control handle and places the chassis of the equipment flat on the wall to be scraped, so that the driving wheel and the edge of the scraper are in full contact with the paint layer, and apply a certain pressure. Turn the equipment control switch, the equipment is started, the motor drives the driving wheel to rotate through the reduction box, the driving wheel uses the strong friction between the coating layer to drive the equipment forward, and the forward movement of the equipment drives the scraper forward, because the scraper edge and the coating are moving forward There is a certain angle downward in the direction, so the scraper scrapes the paint layer under the action of forward and downward force. The scraper fixed adjustment seat can adjust the scraper, and then adjust the scraping depth.

[0018] The above embodiments are intended to illustrate that the present invention can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com