Automatic cutting and conveying device based on melt-blown cloth processing

A technology of conveying device and melt-blown cloth, which is applied in the field of cloth processing, can solve the problems of single device structure, inability to realize continuous cutting of cloth synchronously, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

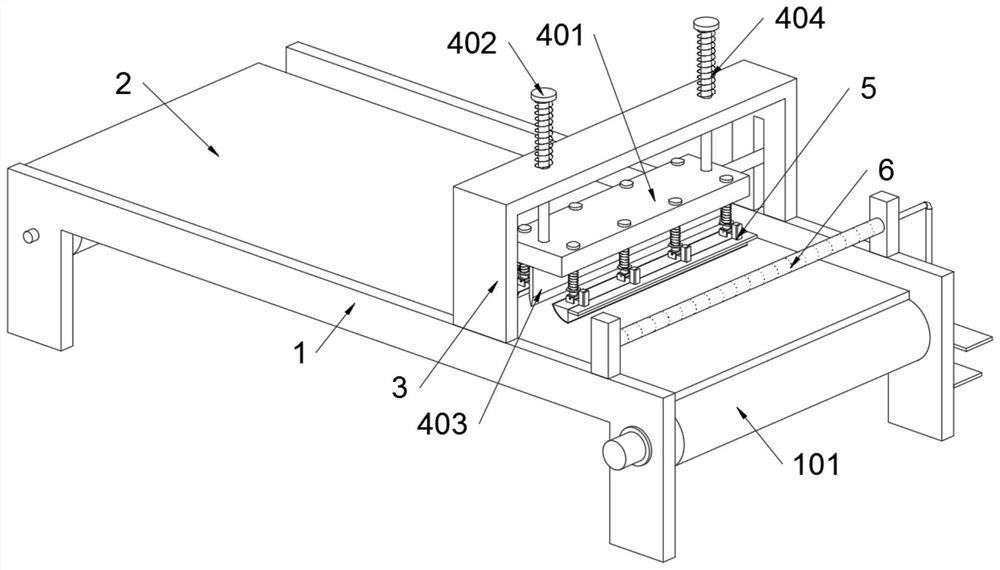

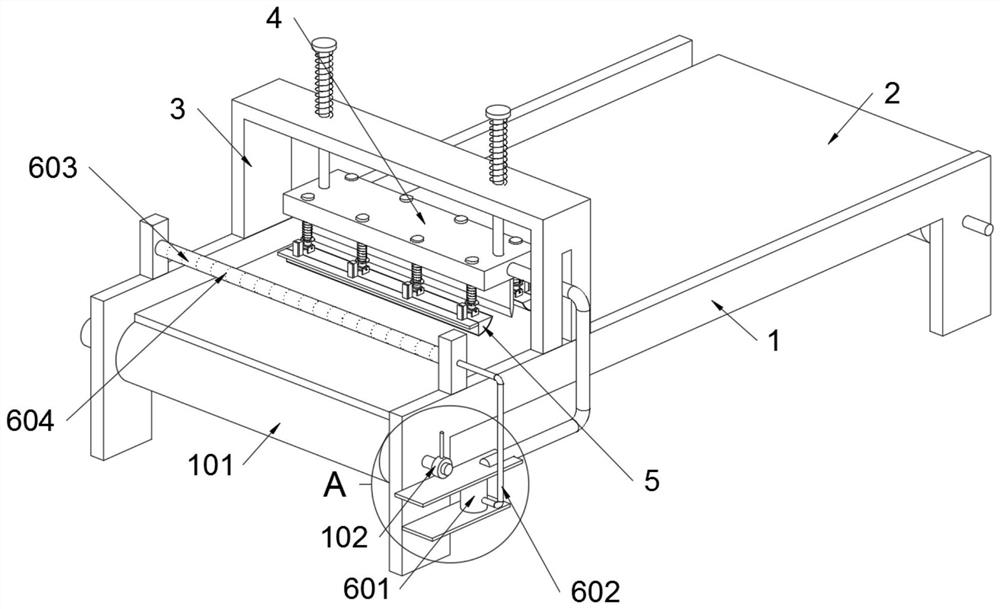

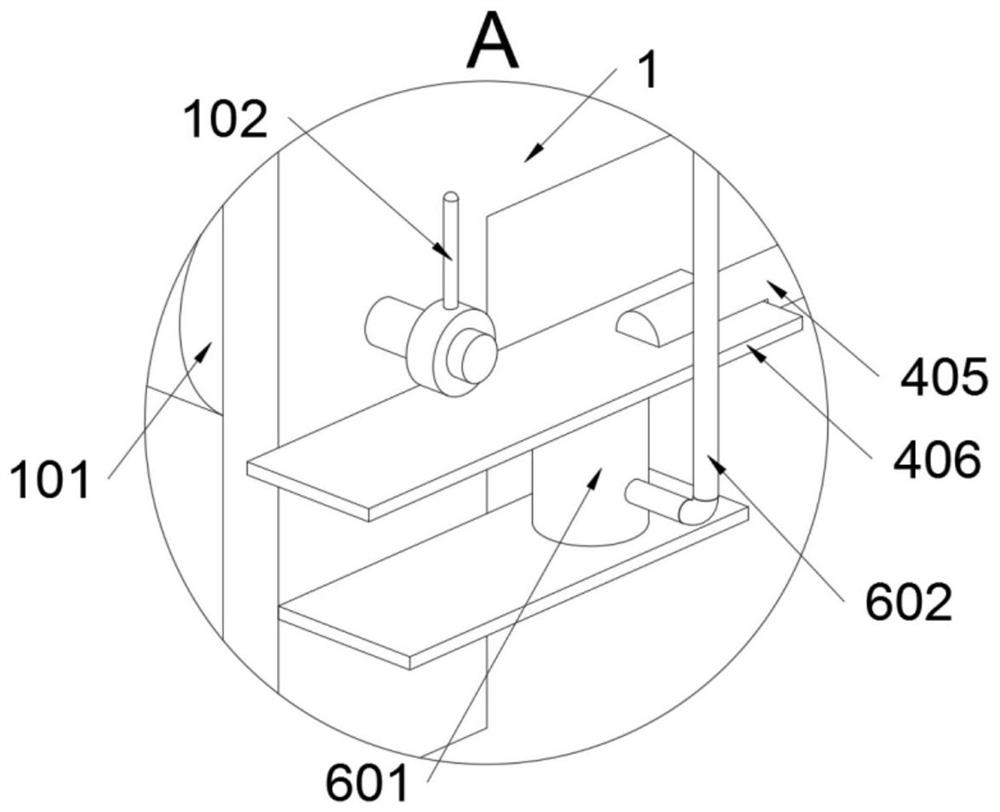

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The present invention provides an automatic cutting and conveying device based on melt-blown cloth processing, including a frame body 1; cloth 2 is conveyed on the frame body 1, and a cutter frame 3 is welded on the frame body 1; There is a cutting structure 4, and two auxiliary structures 5 are installed in a mirror image on the cutting structure 4; a drying structure 6 is installed on the frame body 1; refer to for example figure 2, the frame body 1 includes a toggle lever 102, and the toggle lever 102 is welded on the rotating shaft of the conveying roller 101; the cutting structure 4 includes a force arm 405 and a force plate 406, and the force arm 405 is welded on the cutter seat 401 , and a force plate 406 is welded on the force arm 405; the force plate 406 is located at the lower position of the toggle lever 102, and the toggle lever 102 is in elastic contact with the force plate 406, thereby pressing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com