Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Realize quantitative delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

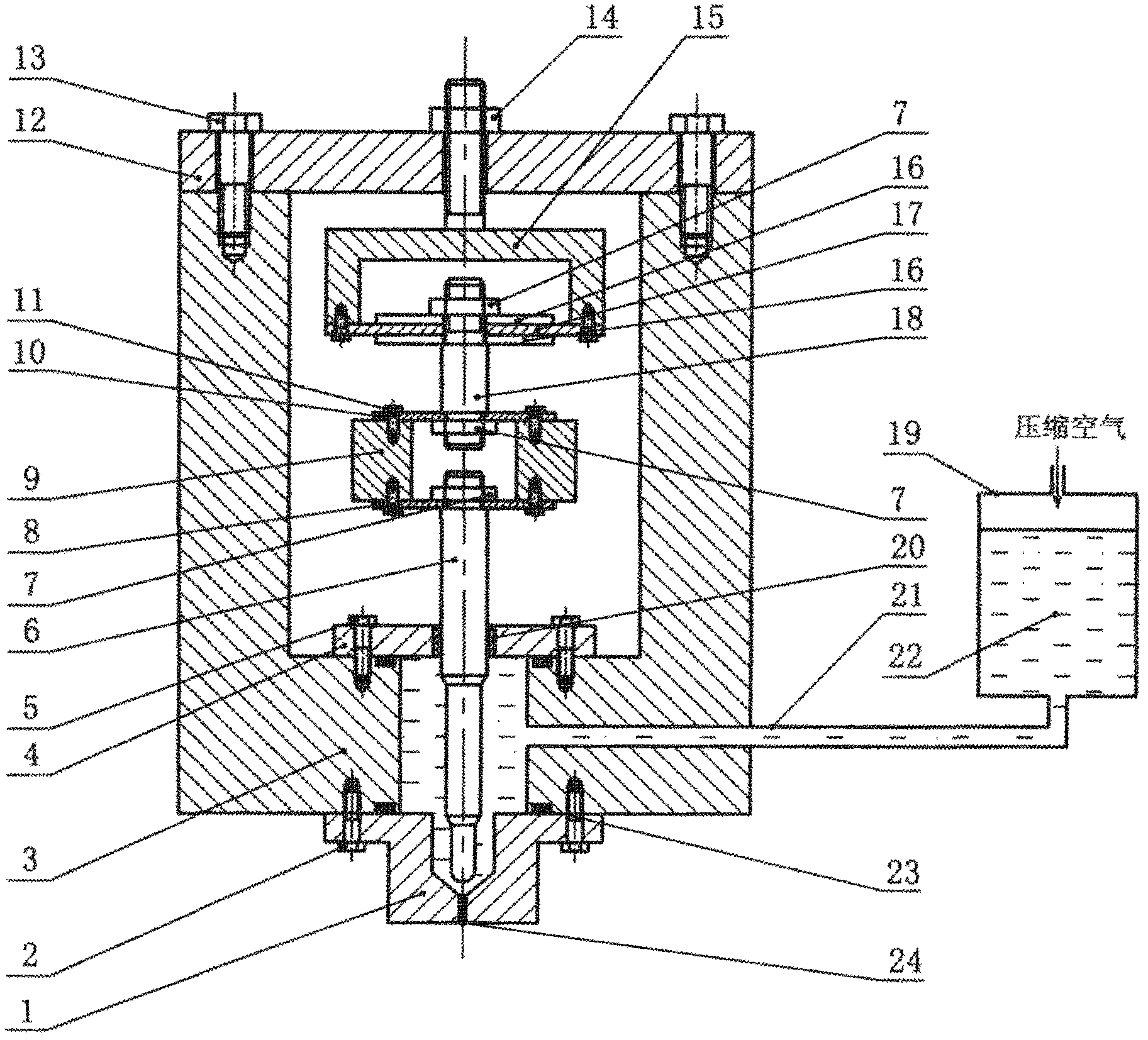

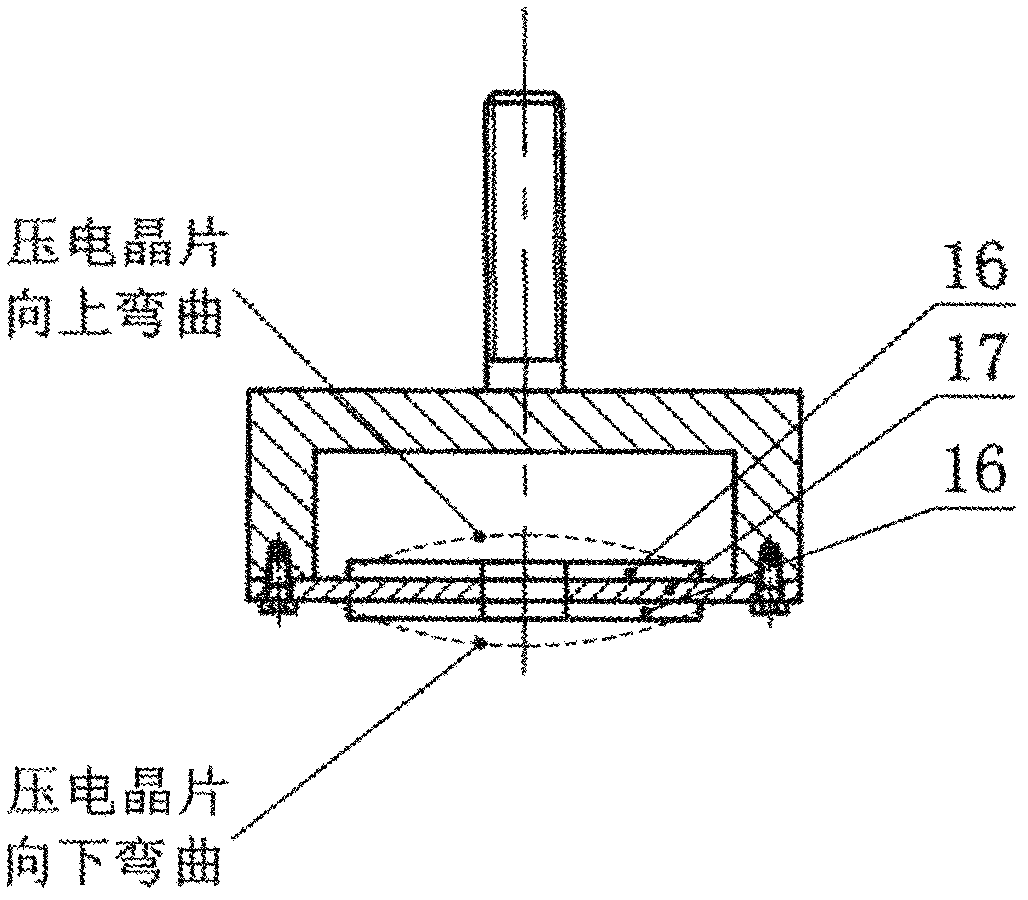

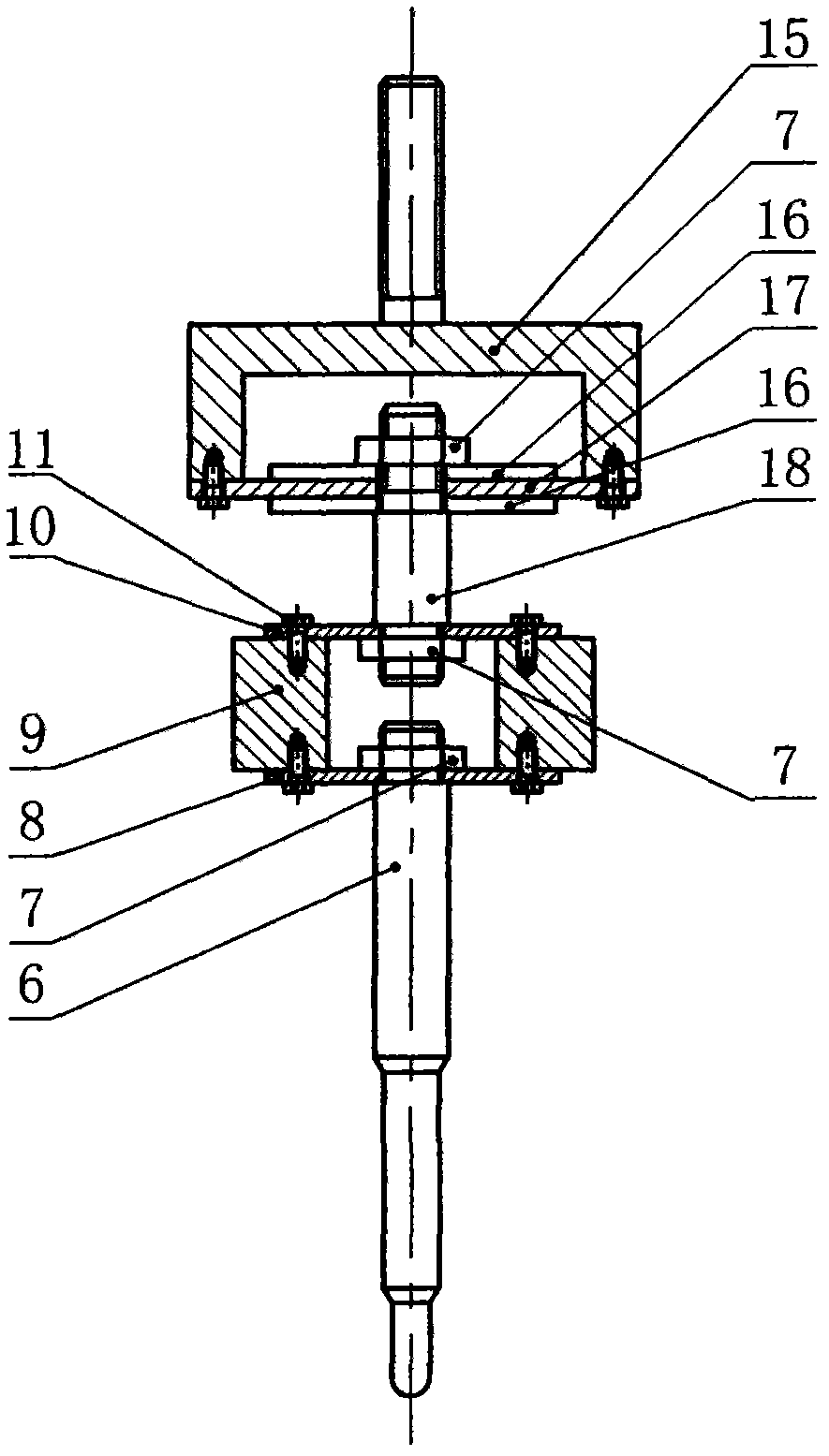

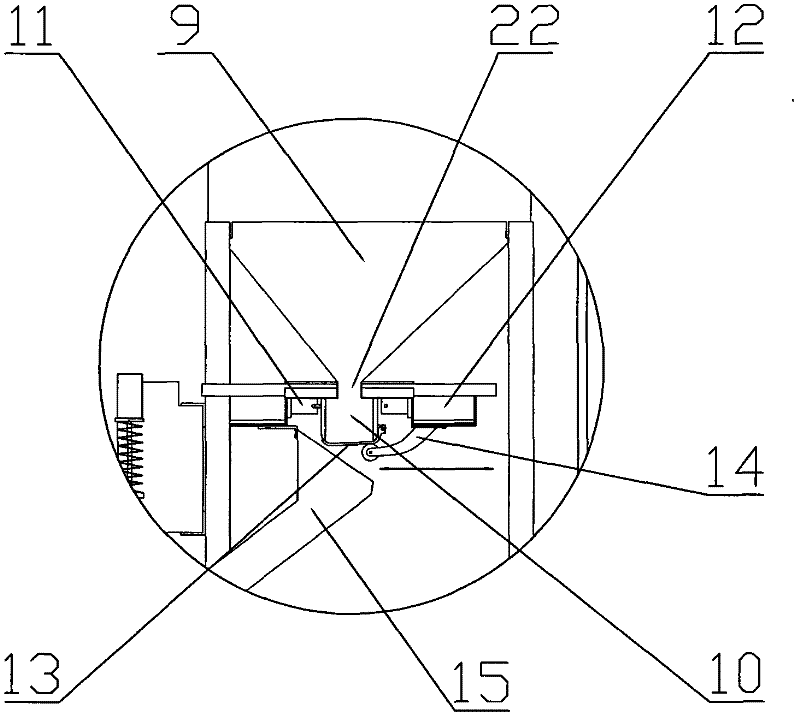

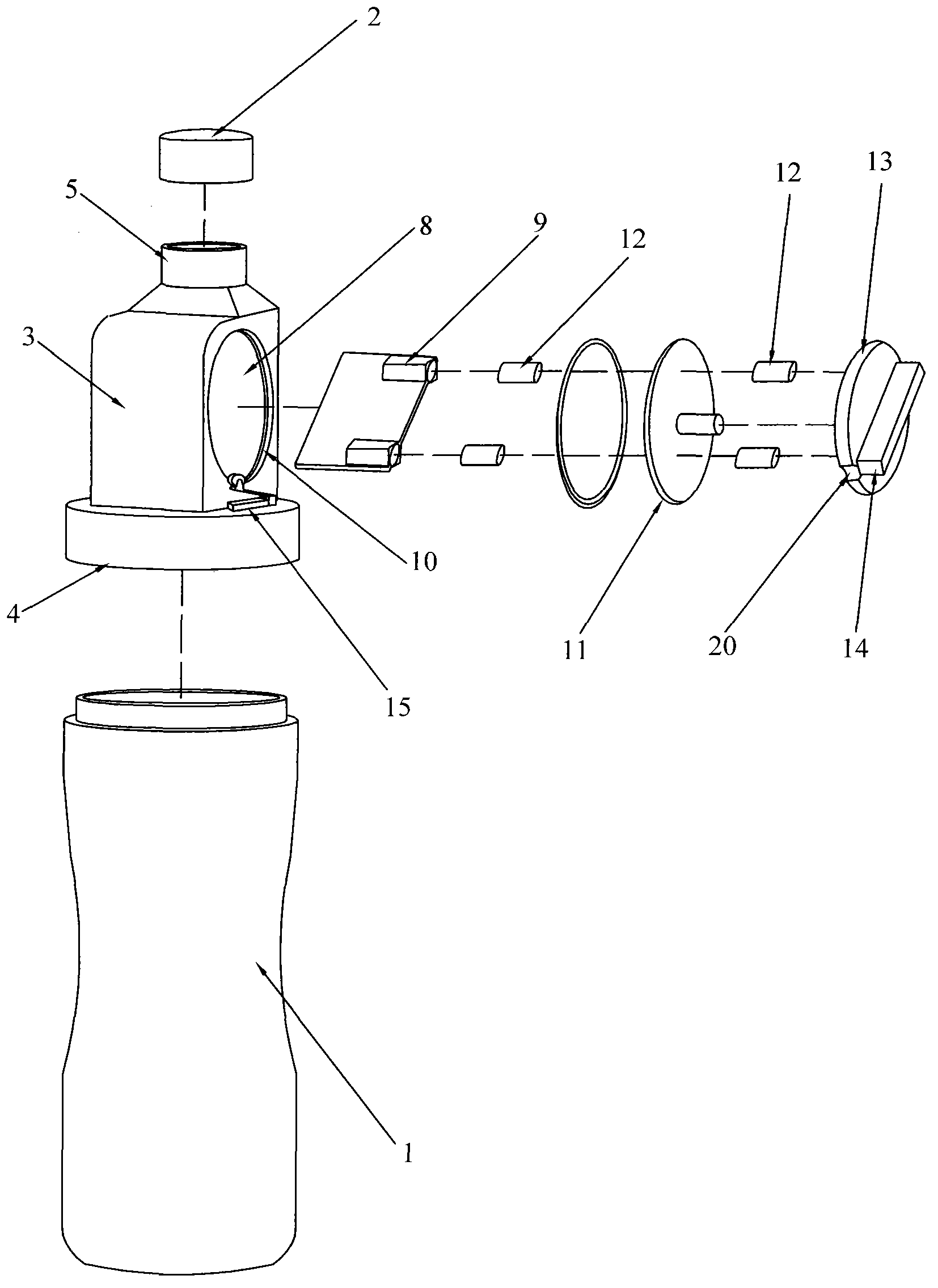

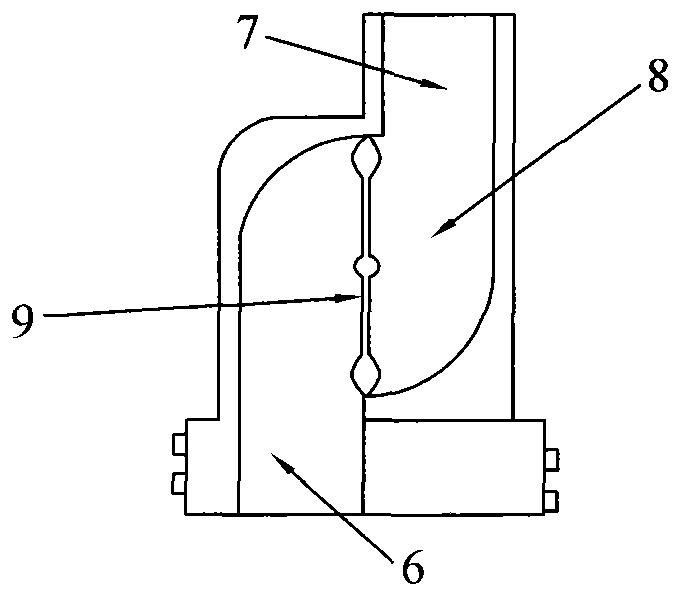

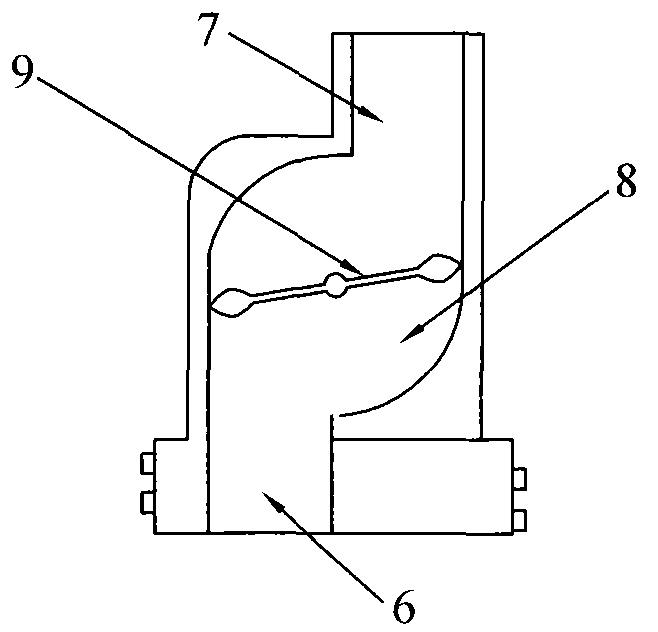

Piezoelectric wafer control type non-contact glue dispensing device

InactiveCN102615018AGuaranteed not to leakTimely supplementLiquid surface applicatorsCoatingsElectricityLiquid-crystal display

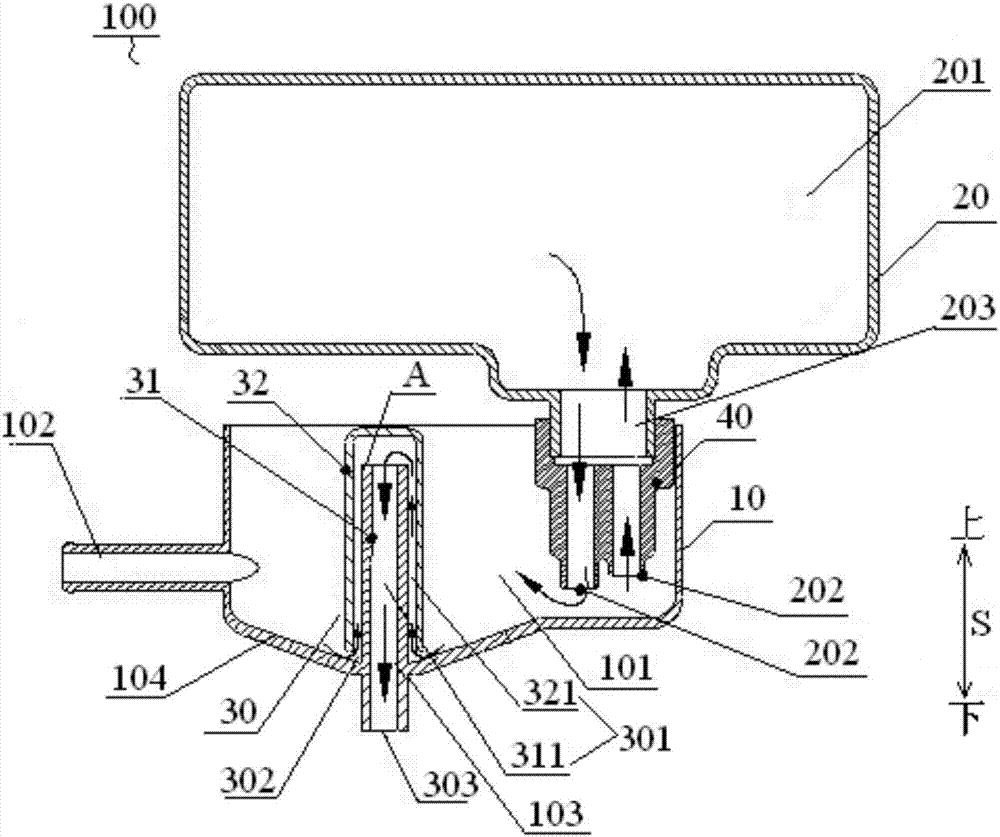

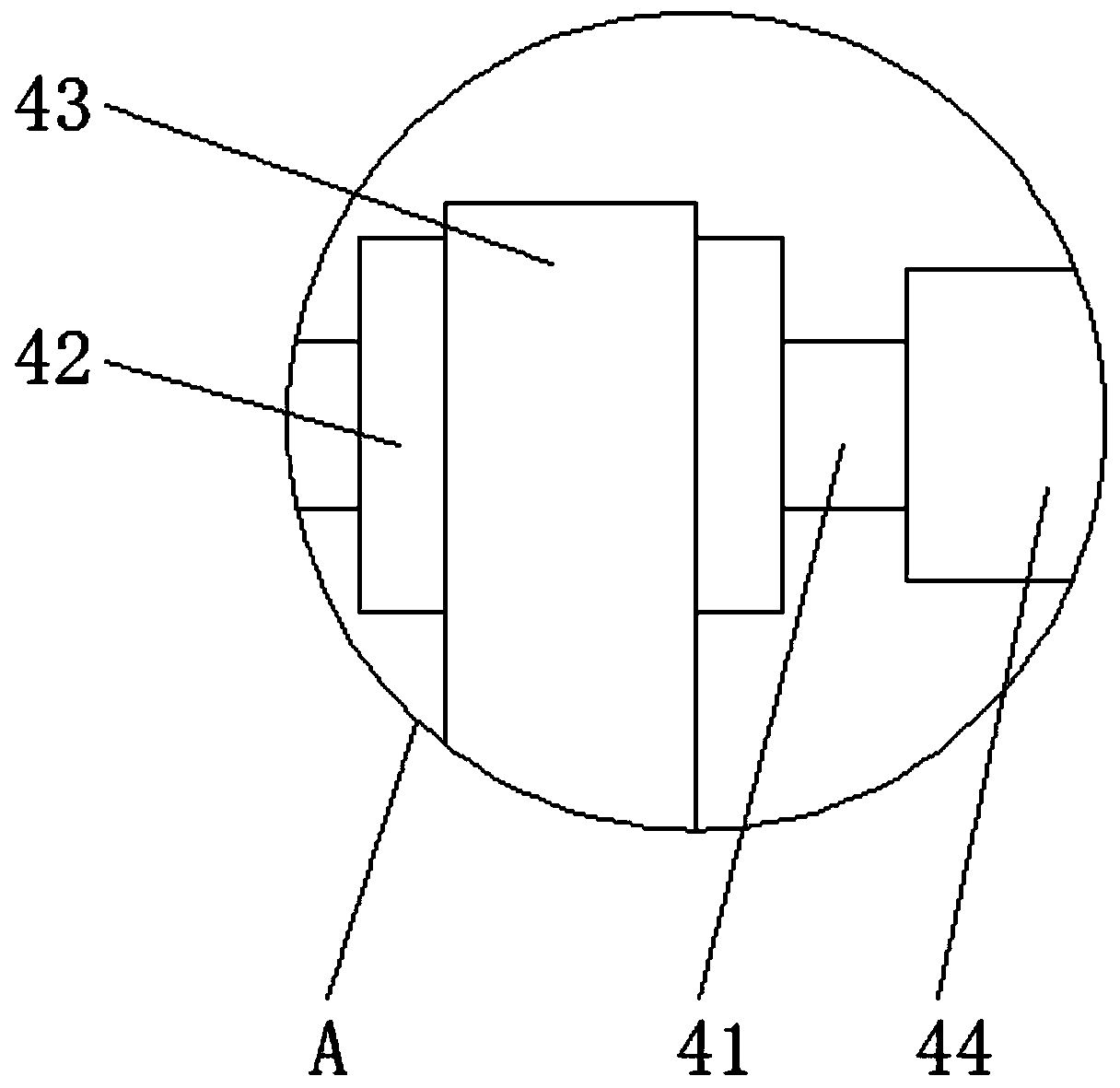

The invention provides a novel piezoelectric wafer control type non-contact glue dispensing device with the advantages that the structure is simple, the maintenance is convenient, and the cost is low. The micro vibration displacement of a piezoelectric wafer is amplified through a displacement amplification mechanism, a firing pin is driven to vertically move, and the glue liquid spraying is realized. The novel piezoelectric wafer control type non-contact glue dispensing device adopts the following technical scheme that the displacement amplification mechanism consists of the piezoelectric wafer, a diaphragm spring, a mass block, a vibration rod and the firing pin, when the voltage frequency exerted on the piezoelectric wafer approaches to or is identical to the inherent frequency of the displacement amplification mechanism, the displacement amplification mechanism reaches the resonance state, the output displacement and the speed of the firing pin reach the maximum values, the glue liquid is driven to be sprayed out from a spray nozzle, and the automatic distribution of the glue liquid is realized. The novel piezoelectric wafer control type non-contact glue dispensing device can be used for the fields of precise chemicals, medicine quantitative distribution, biomedicine and the like, is particularly applied to the technical field of high-viscosity glue dispensing in semiconductor encapsulation and is used for the chip fixation, the surface mounting and the bottom filling in the electronic encapsulation, the fluorescent powder coating in a liquid crystal display flat plate and the like.

Owner:JILIN UNIV

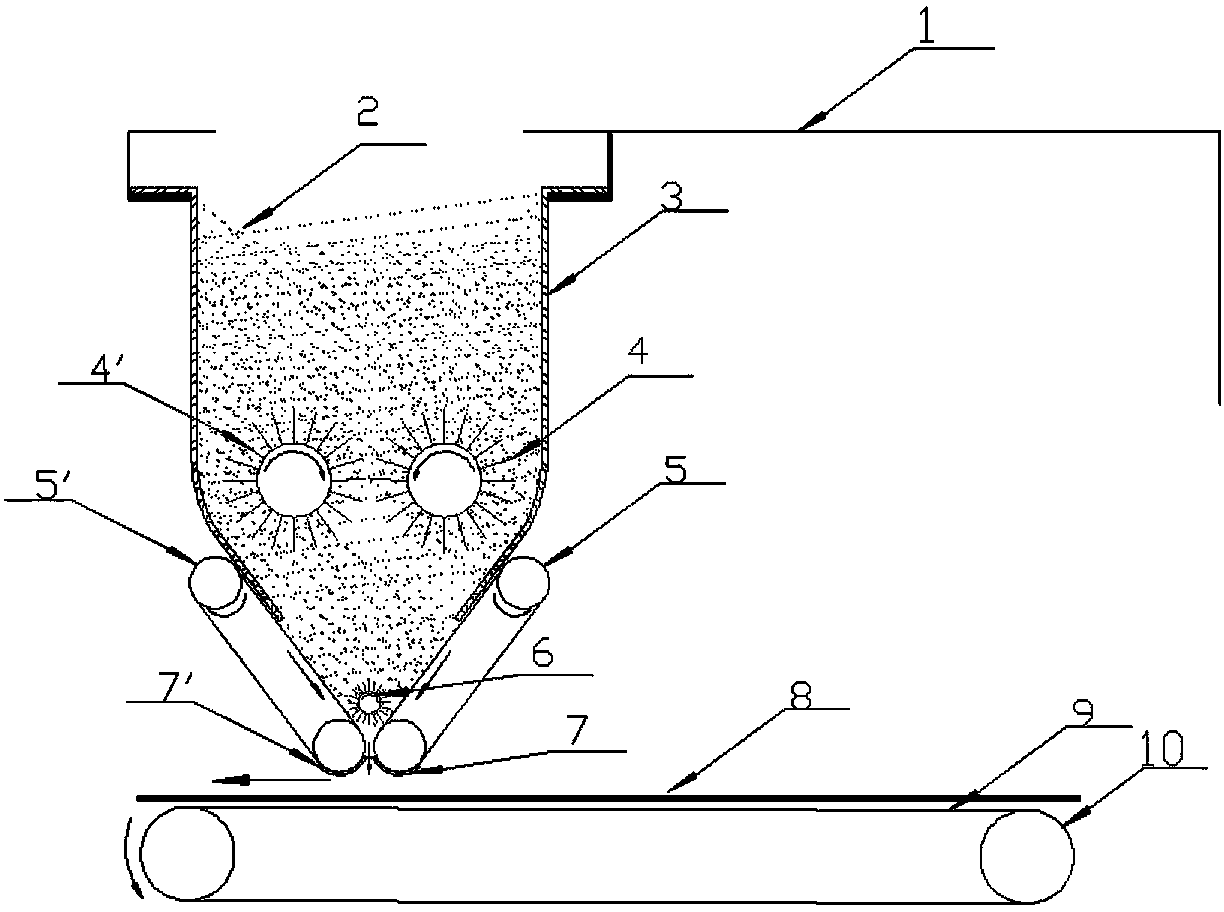

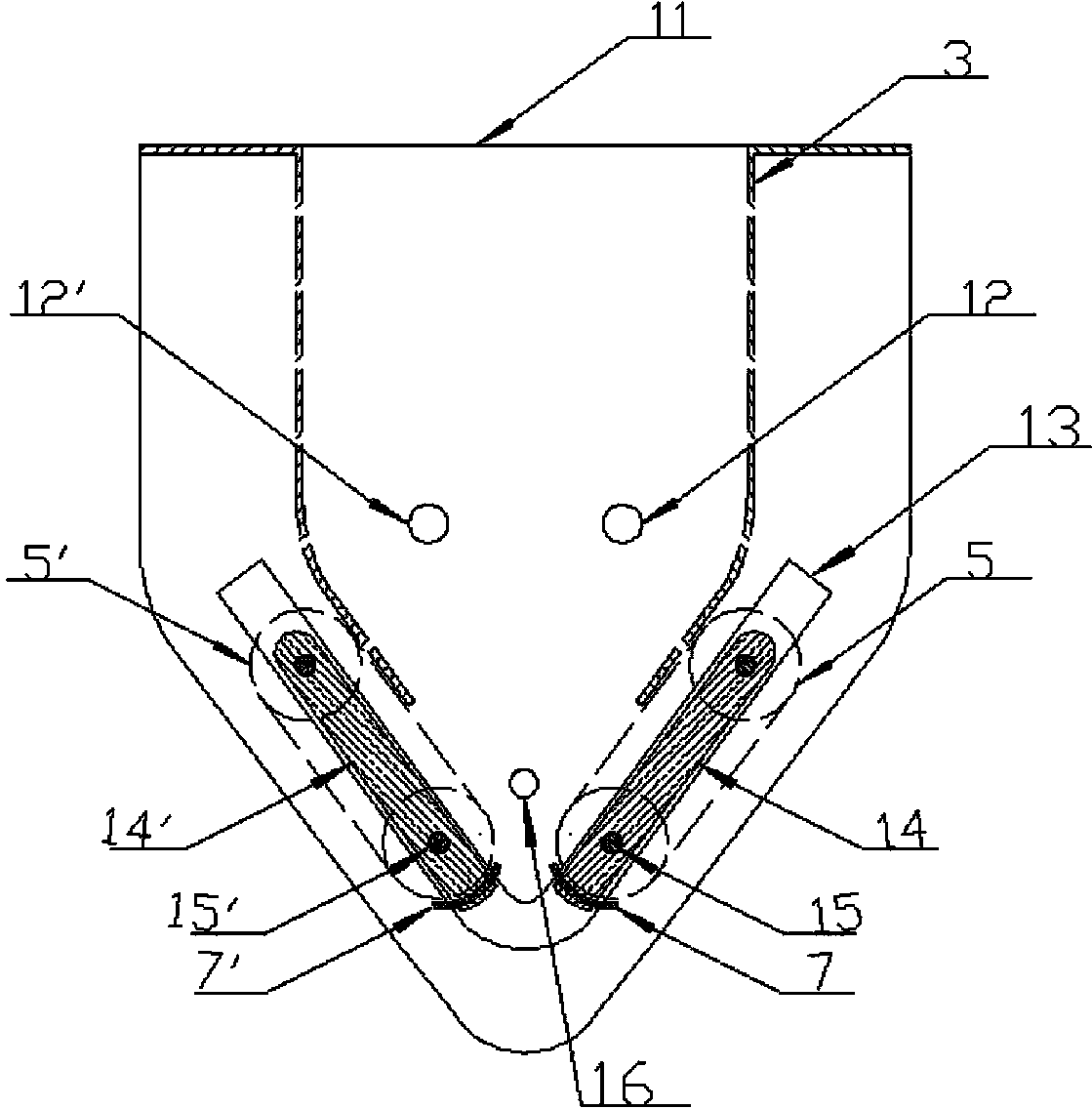

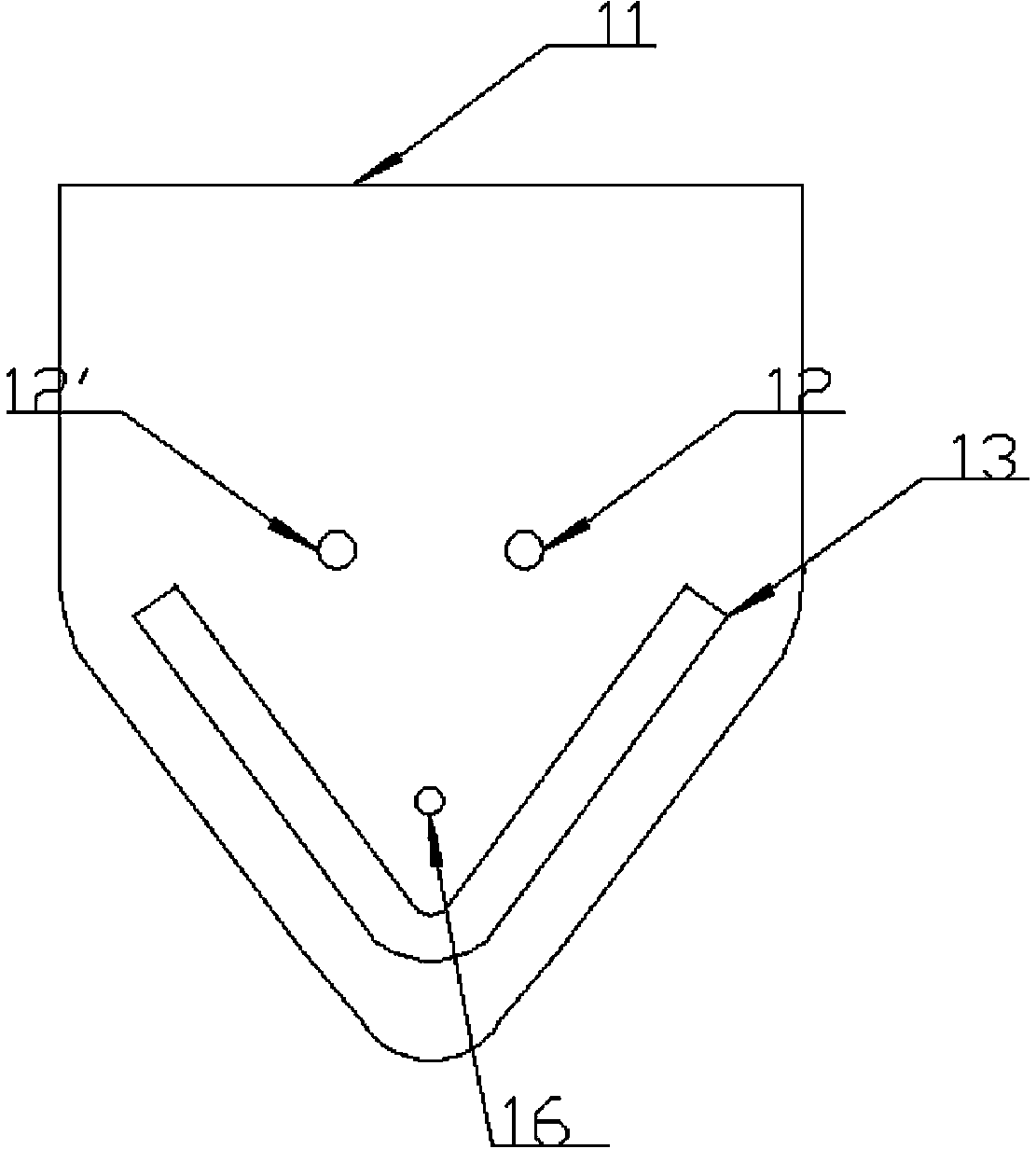

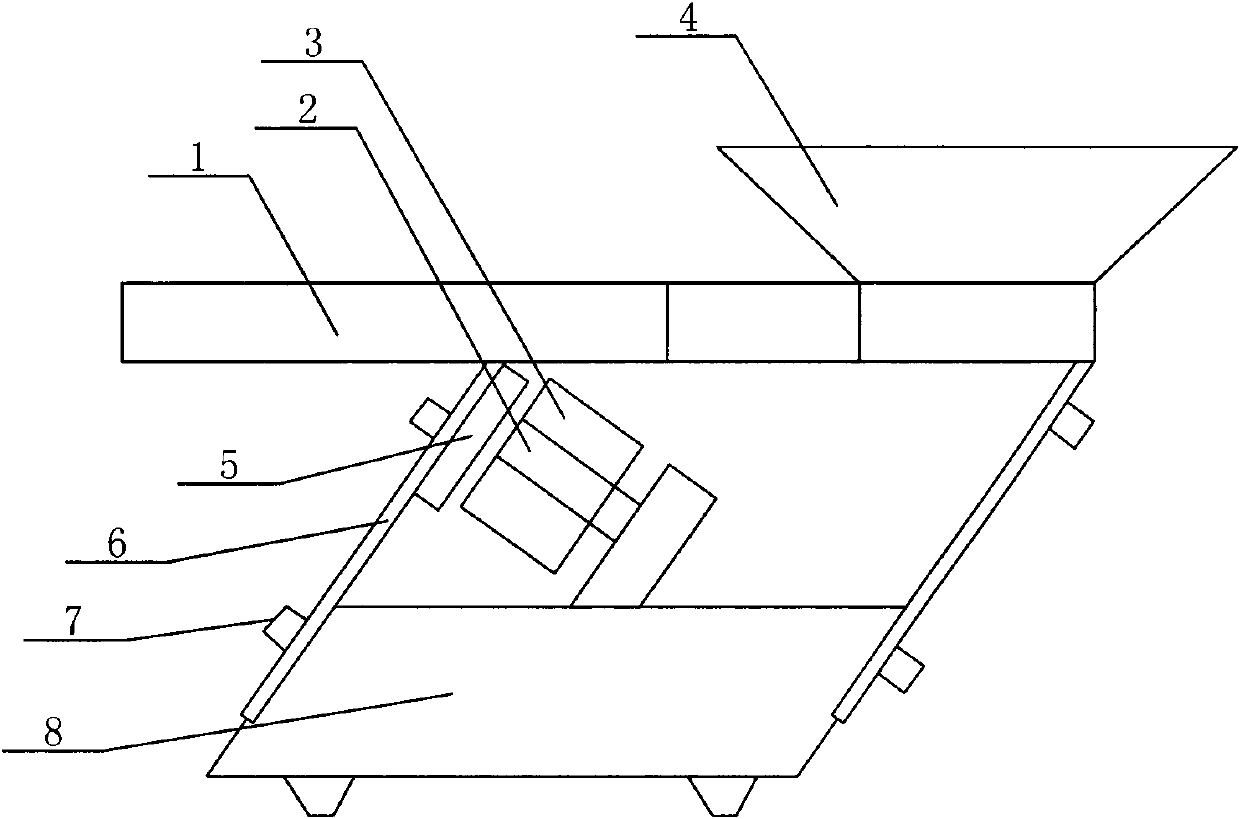

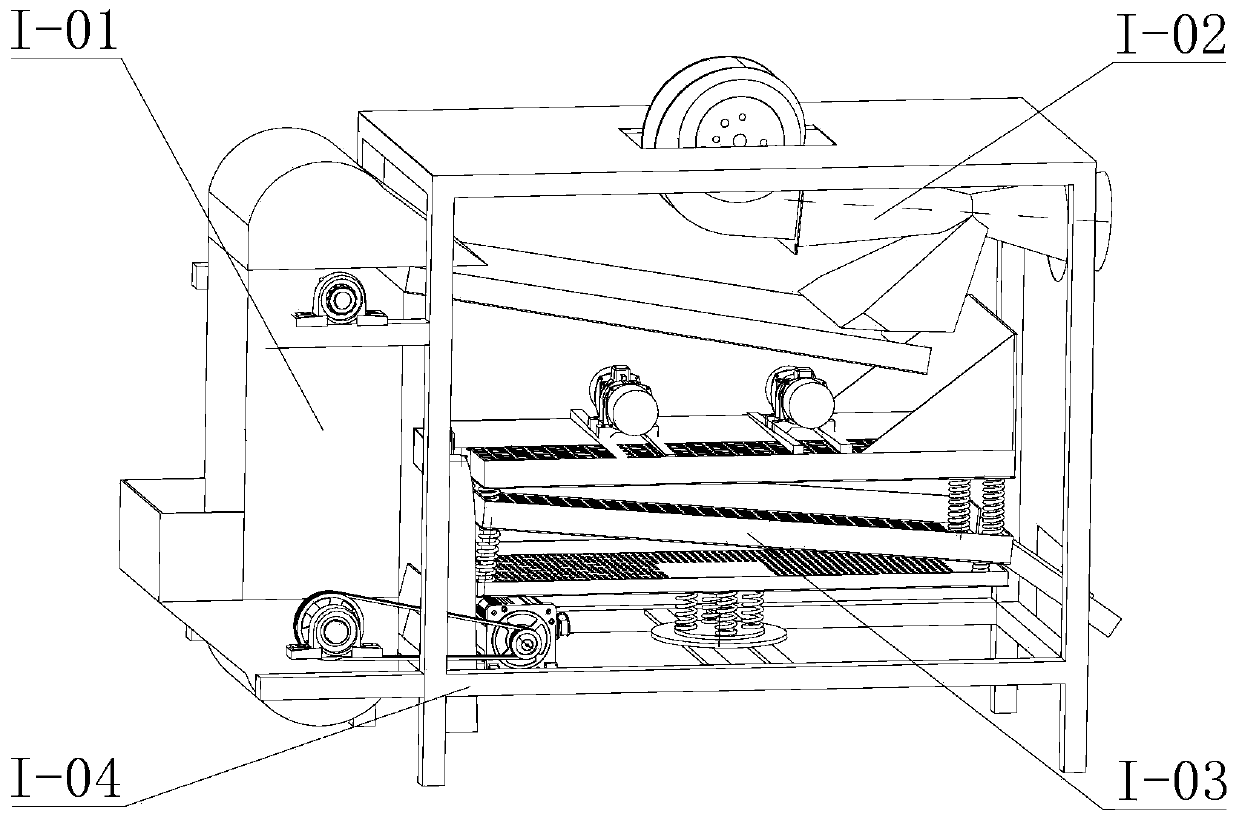

Mixed powder quantitative conveying and paving device

A mixed powder quantitative conveying and paving device comprises a silo, a powder conveying device, a powder paving device, a powder scattering device and an anti-blocking device. The powder scattering device is two large pin shafts fixed to the middle of the silo and rotating in the opposite directions, and scattering and carding are conducted on mixed powder through the powder scattering device. The anti-blocking device is a small rotatable pin shaft fixed to the upper portion of a silo outlet, and the mixed powder is prevented from being blocked through rotation, the powder conveying device comprises a symmetrically arranged and synchronously operated belt pulley pair, the two belt pulley pair is fixed in belt pulley pair bearing holes through sliding groove rails, bearing sliding blocks are fixedly arranged between spindles of the belt pulley pairs, the bearing sliding blocks can slide in the sliding groove rails, and the belt pulley pair can slide along with sliding of the bearing sliding block to adjust the size of a gap of the outlet. The mixed powder quantitative conveying and paving device is suitable for quantitative and even paving conveying of various mixed powders of different particle sizes.

Owner:CHINA THREE GORGES UNIV +1

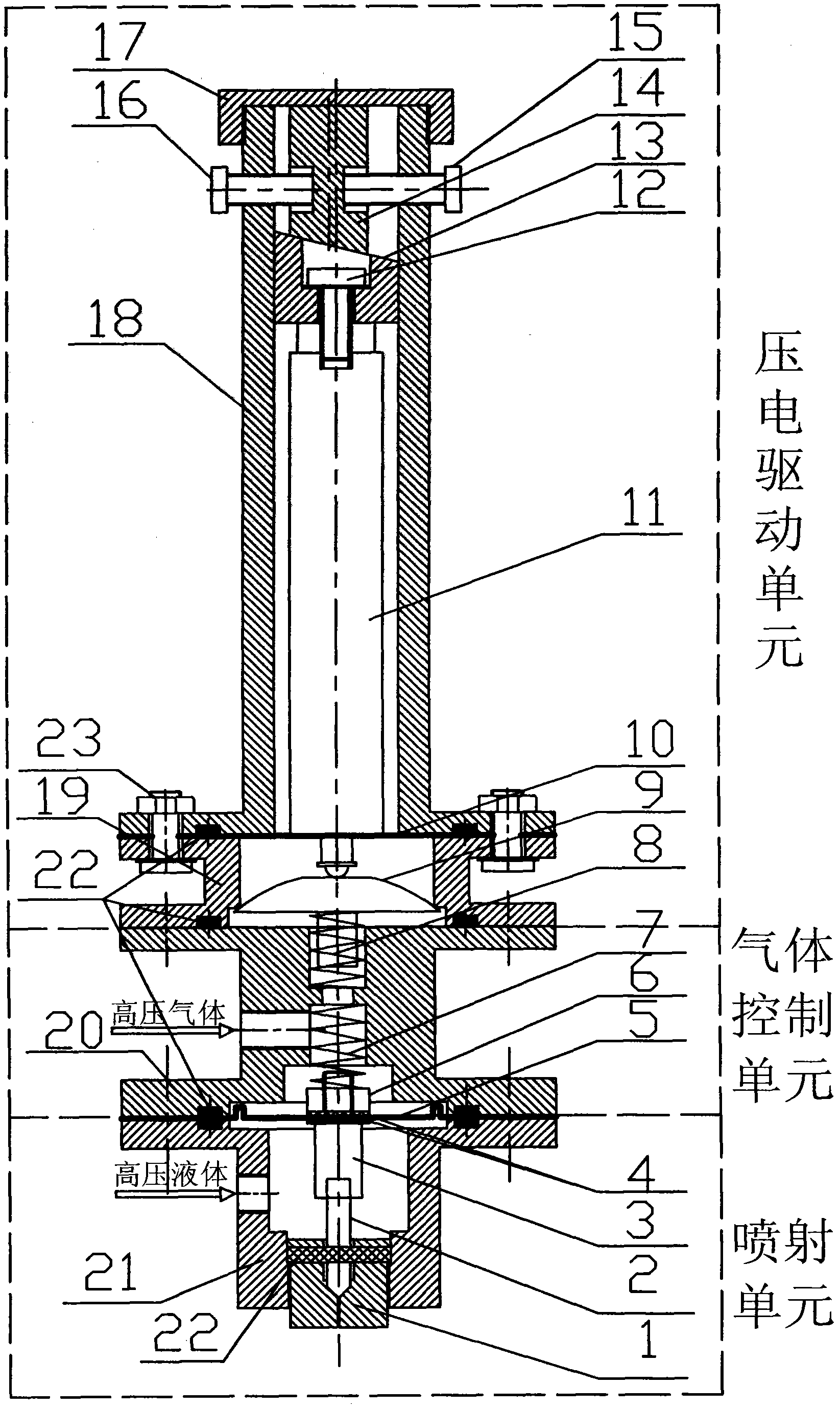

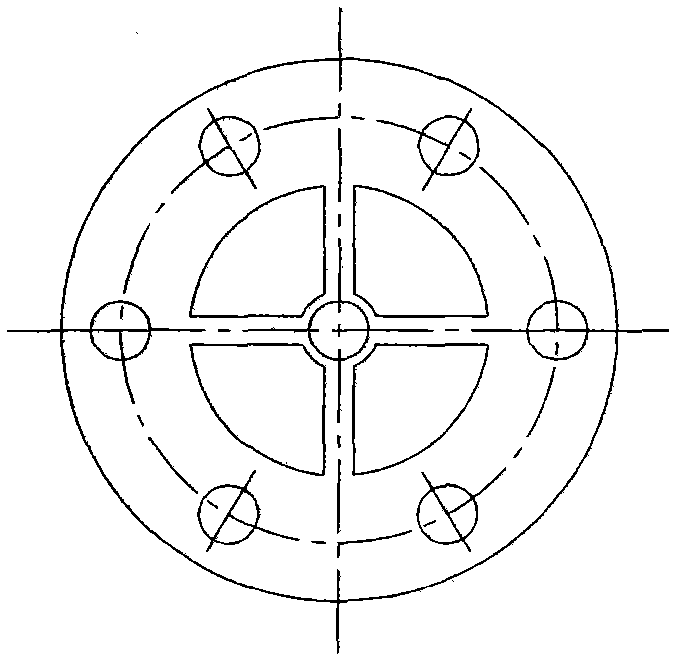

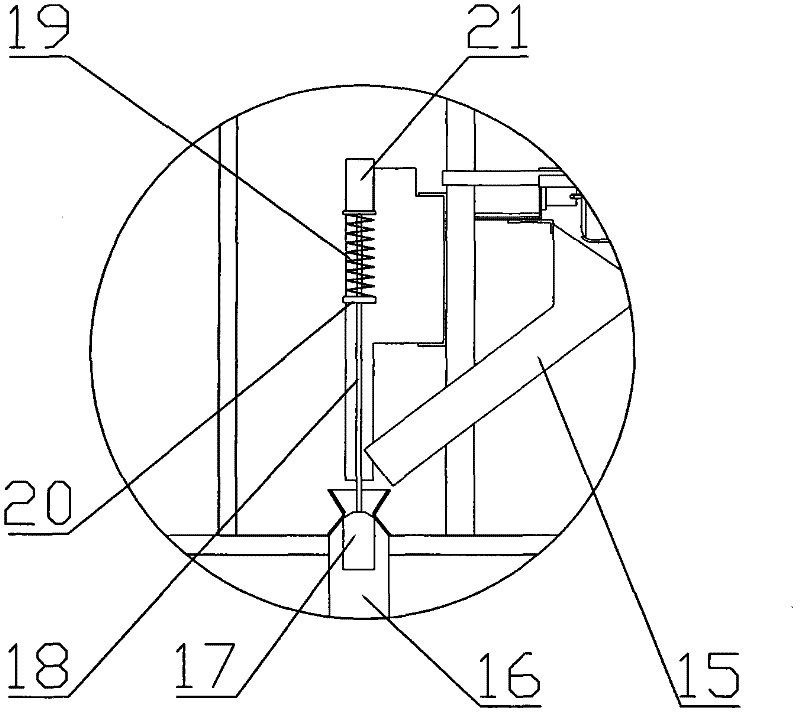

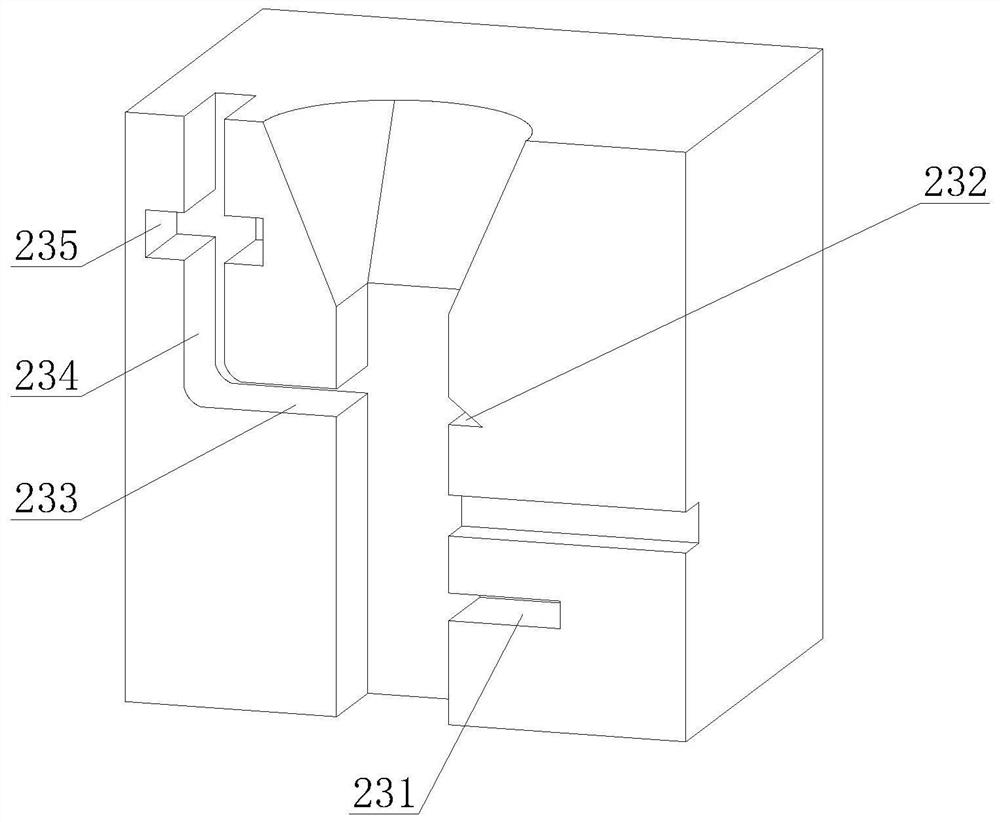

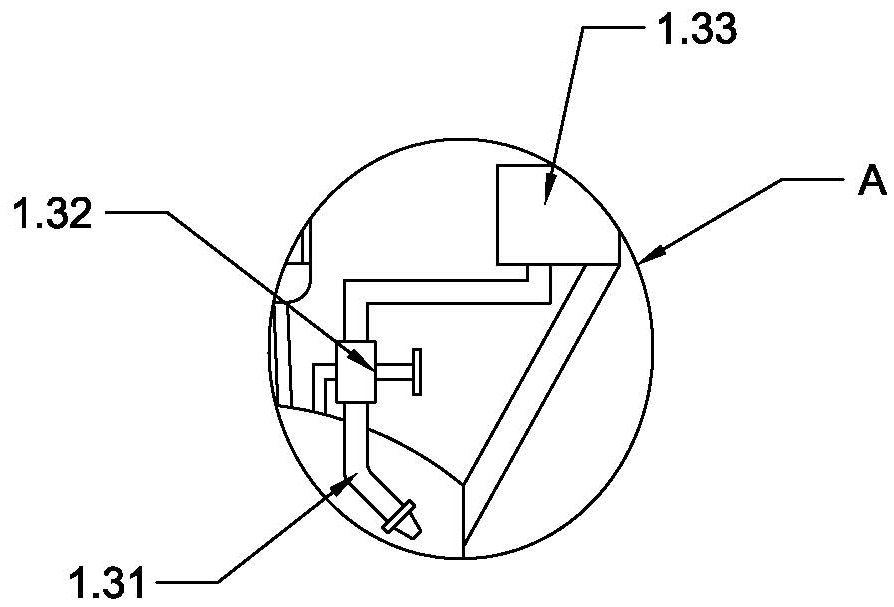

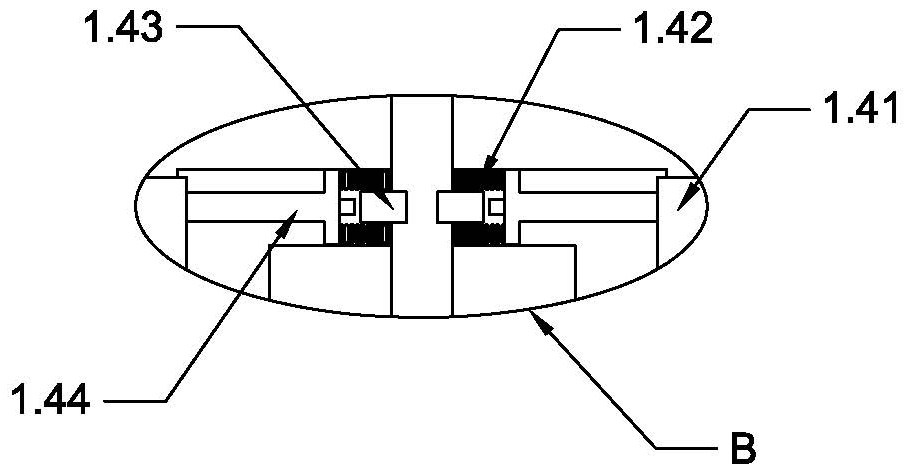

Piezoelectric-gas mixture control type fluid jet device

InactiveCN102553754ARealize quantitative deliveryRealize quantitative distributionLiquid spraying apparatusElectronValve seat

The invention provides a novel piezoelectric-gas mixture control type fluid jet device, which is simple in structure and convenient in maintenance. The technical scheme includes that the piezoelectric-gas mixture control type fluid jet device comprises a jet unit, a gas control unit and a piezoelectric driving control unit, the jet unit comprises a nozzle, a needle valve, a connecting column, a rubber gasket, a diaphragm spring and a liquid cavity, the gas control unit comprises a gas pressure cavity, a return spring, a gas valve and a gas valve seat, and the piezoelectric driving control unit comprises a piezoelectric stack, an adjusting spring sheet and a pre-tightening device. The novel piezoelectric-gas mixture control type fluid jet device can be applied to the fields of precision chemistry, quantitative drug distribution, biomedicine and the like, is particularly applicable to the technical field of high-viscosity fluid dispensing in semiconductor package, and is used for chip fixation in electronic package, surface mount, underfilling, fluorescent powder coating in liquid crystal display panel and the like.

Owner:JILIN UNIV

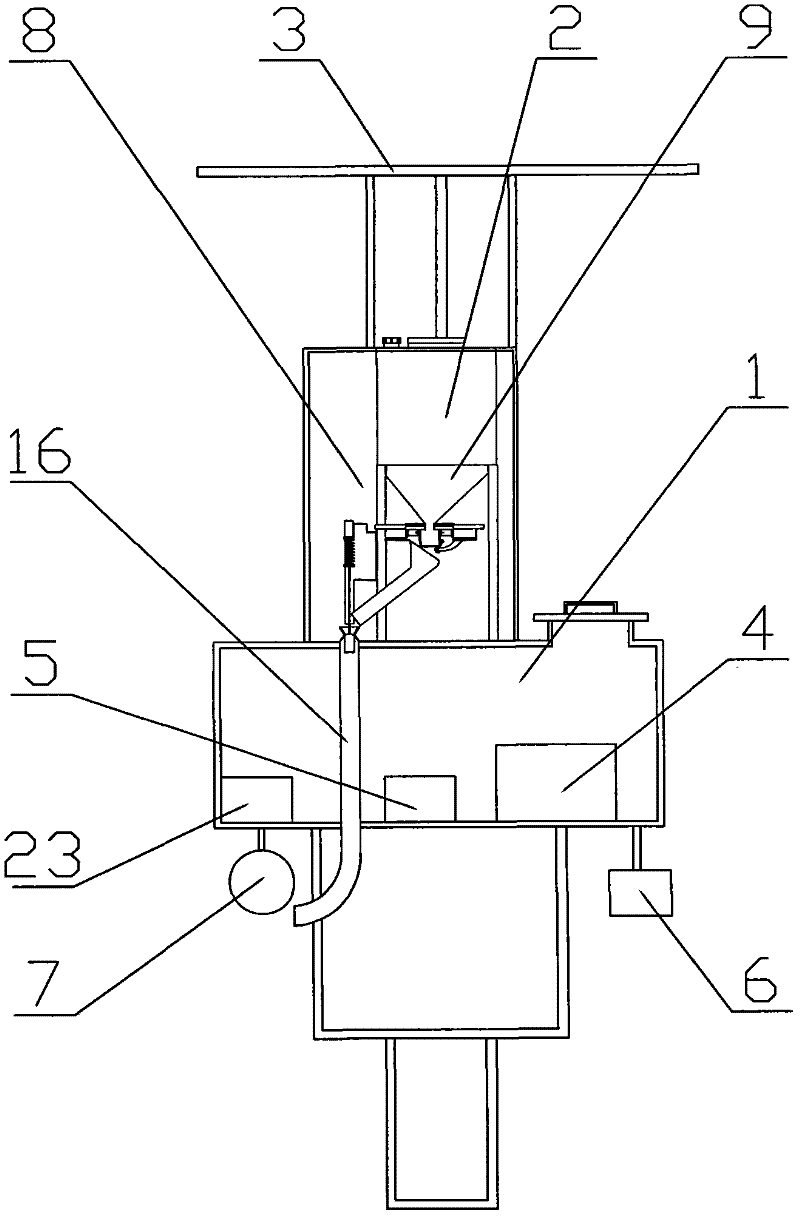

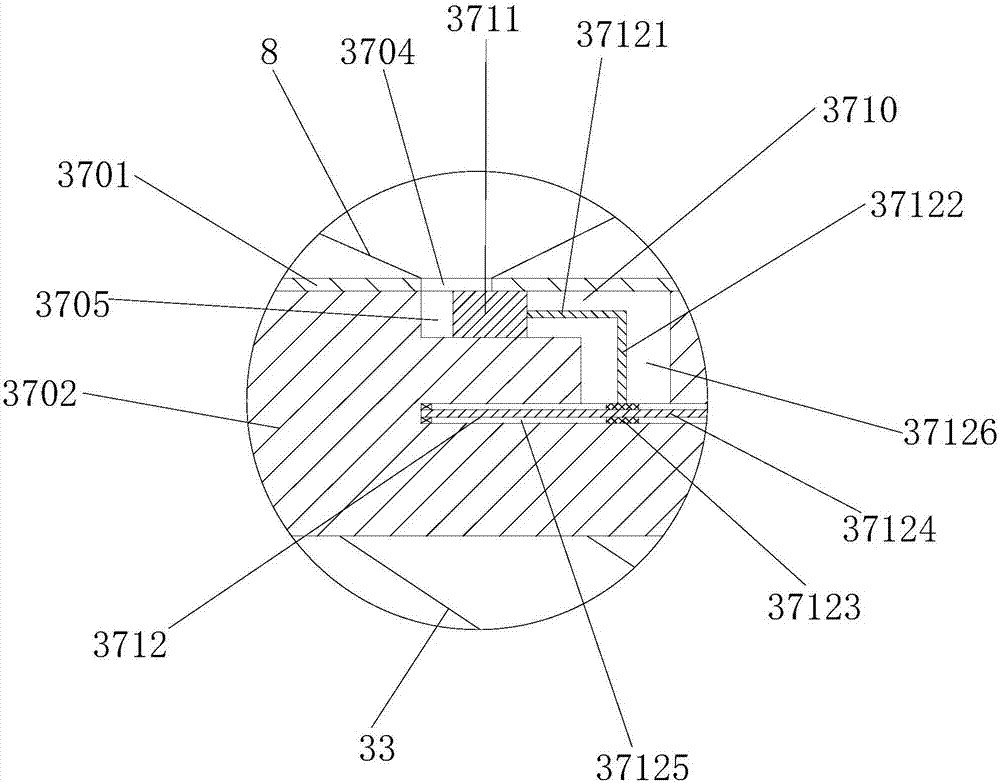

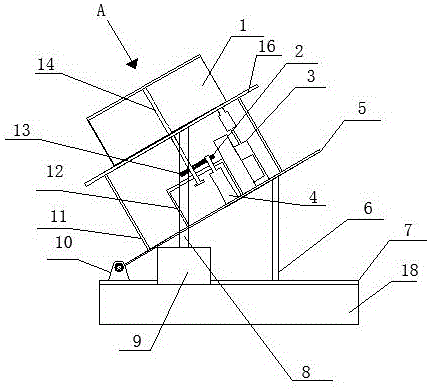

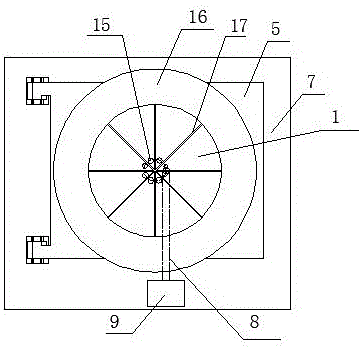

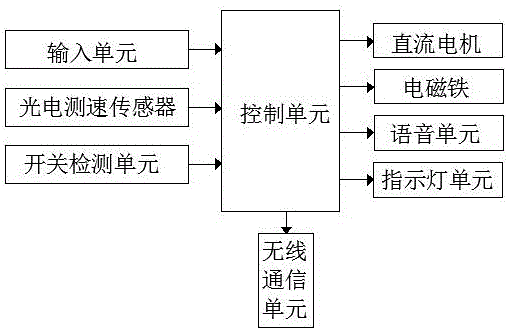

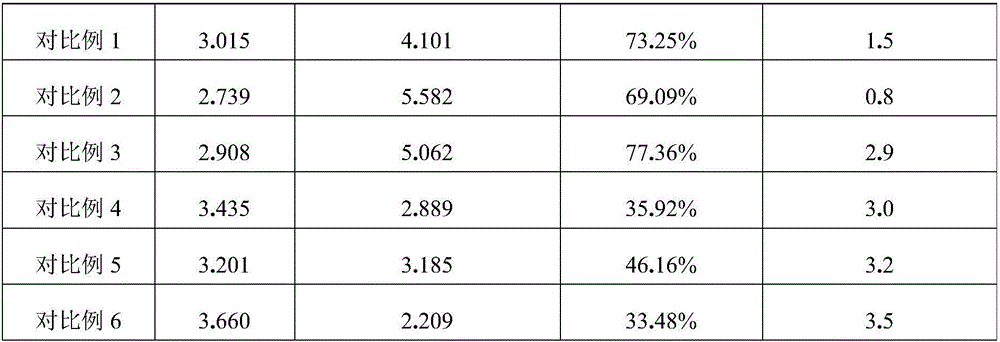

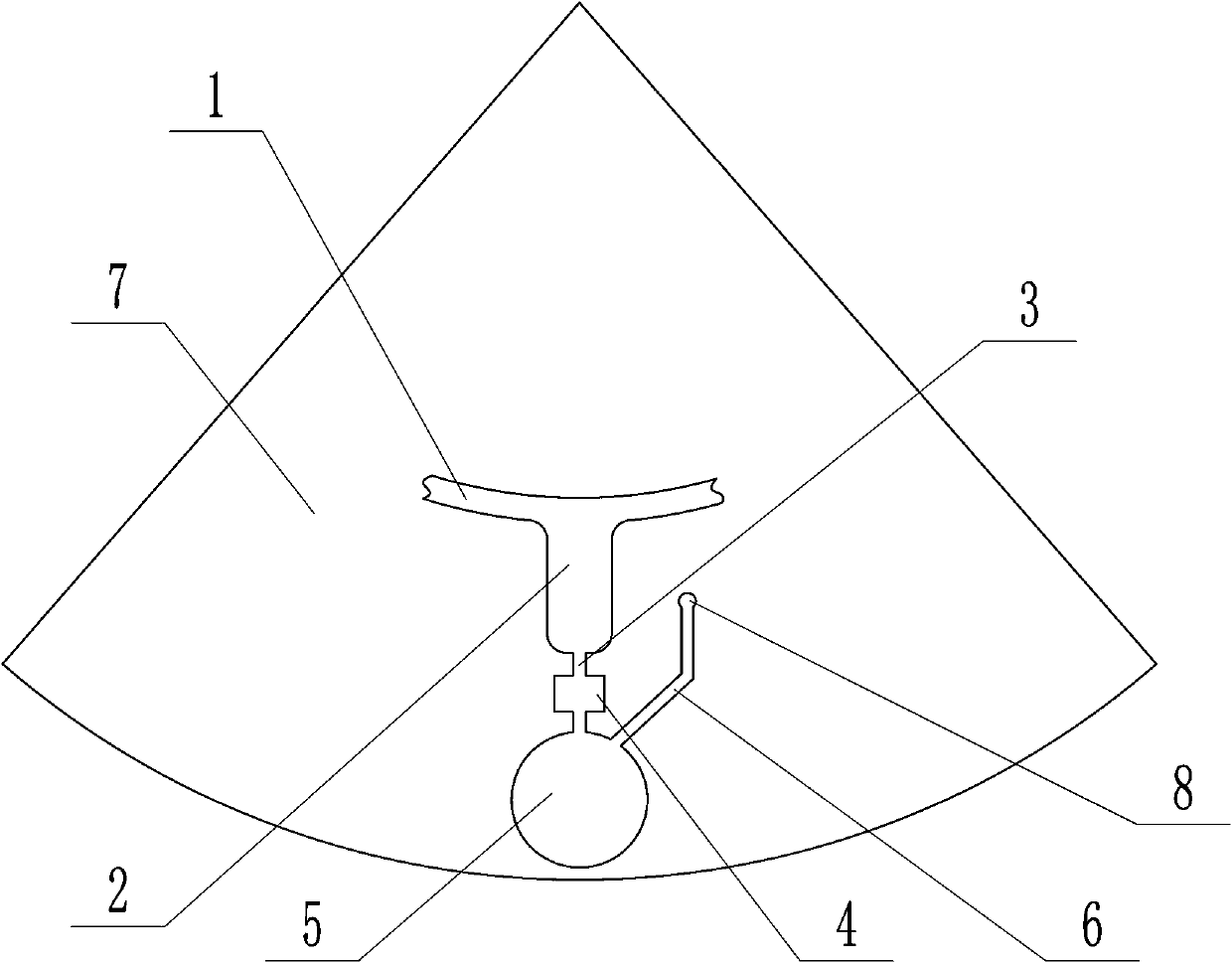

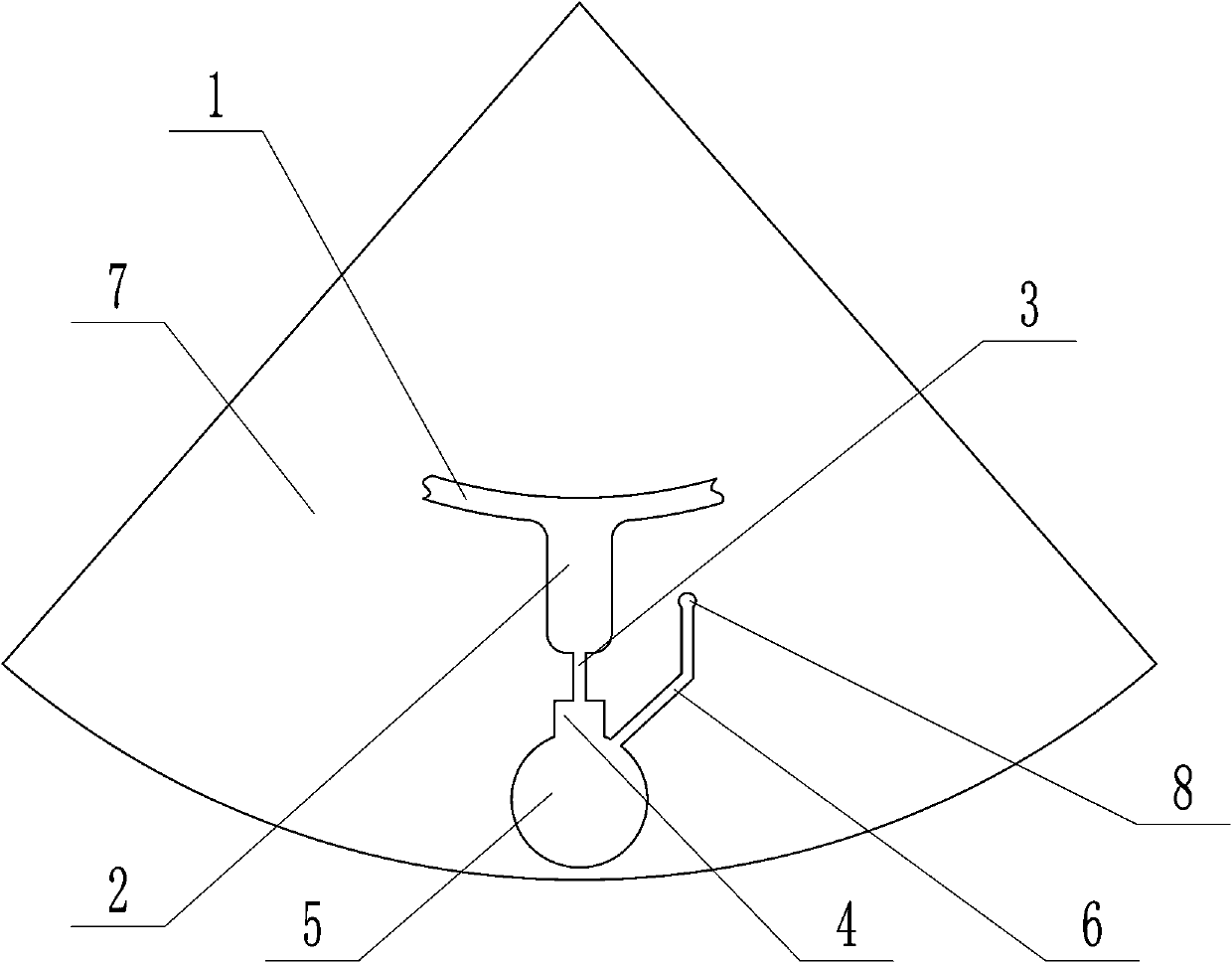

Automatic bait feeding machine for culturing marine products

InactiveCN102124980ARealize quantitative deliveryPrevent moistureAgricultural fishingPisciculture and aquariaProgrammable logic controllerControl system

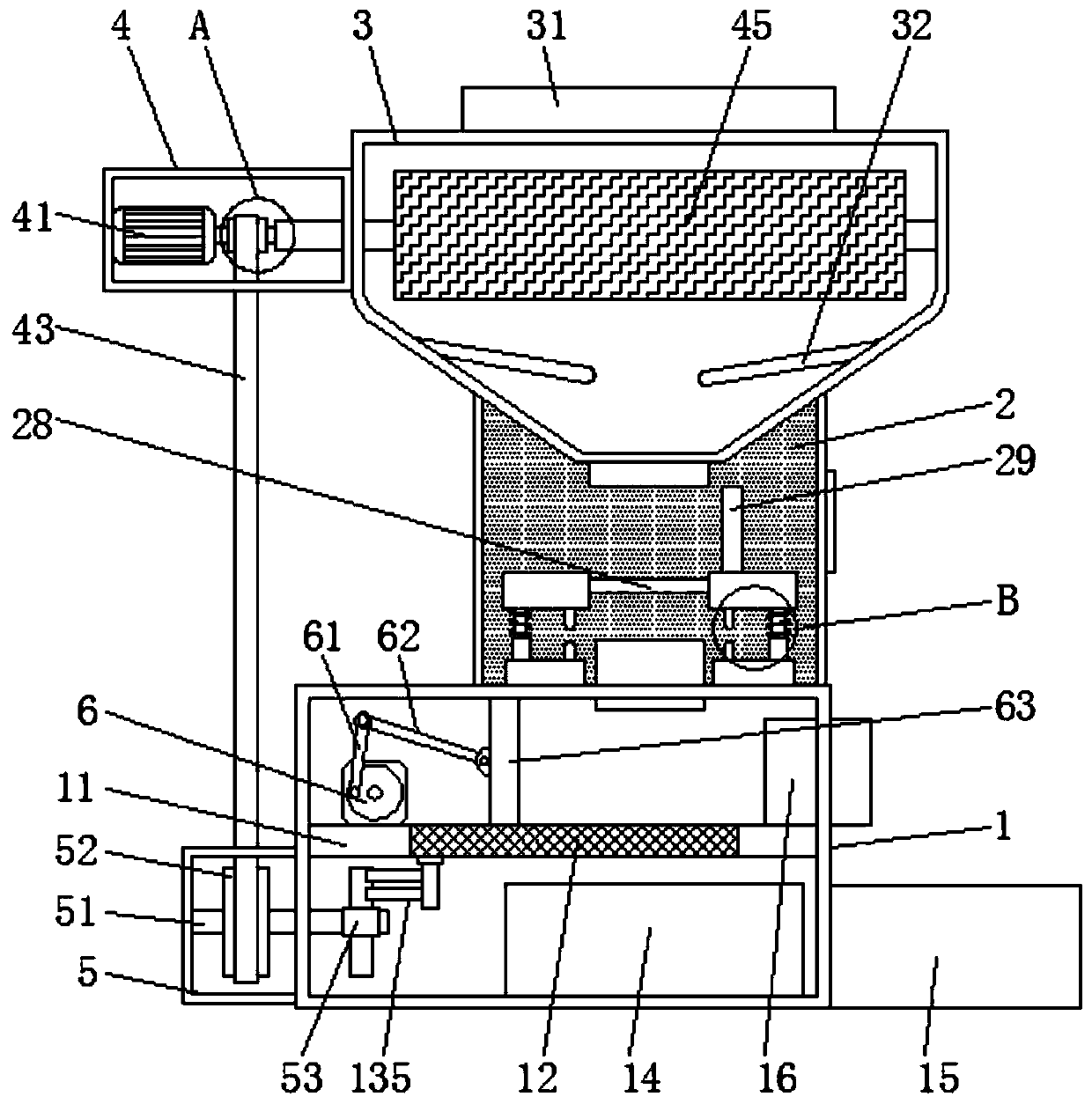

The invention discloses an automatic bait feeding machine for culturing marine products, comprising a floater body (1) provided with a bait bin (2). The automatic bait feeding machine is characterized in that the upper end of the bait bin (2) is provided with a solar cell plate (3); a storage cell (4) arranged in the floater body (1) is connected with the solar cell plate (3); a PLC (programmable logic controller) control system (5) is arranged in the bait body (1); an audio transmitter (6) and a camera (7) connected with the PLC control system (5) are both arranged on the bottom of the floater body (1); a wireless data module (22) is arranged in the floater body (1); and a quantitative bait feeding device (8) is also arranged below the bait bin (2). The automatic bait feeding machine for culturing marine products provided by the invention has an artful structure, power is provided by solar energy, quantitative bait feeding is realized, and underwater conditions are monitored.

Owner:DALIAN OCEAN UNIV

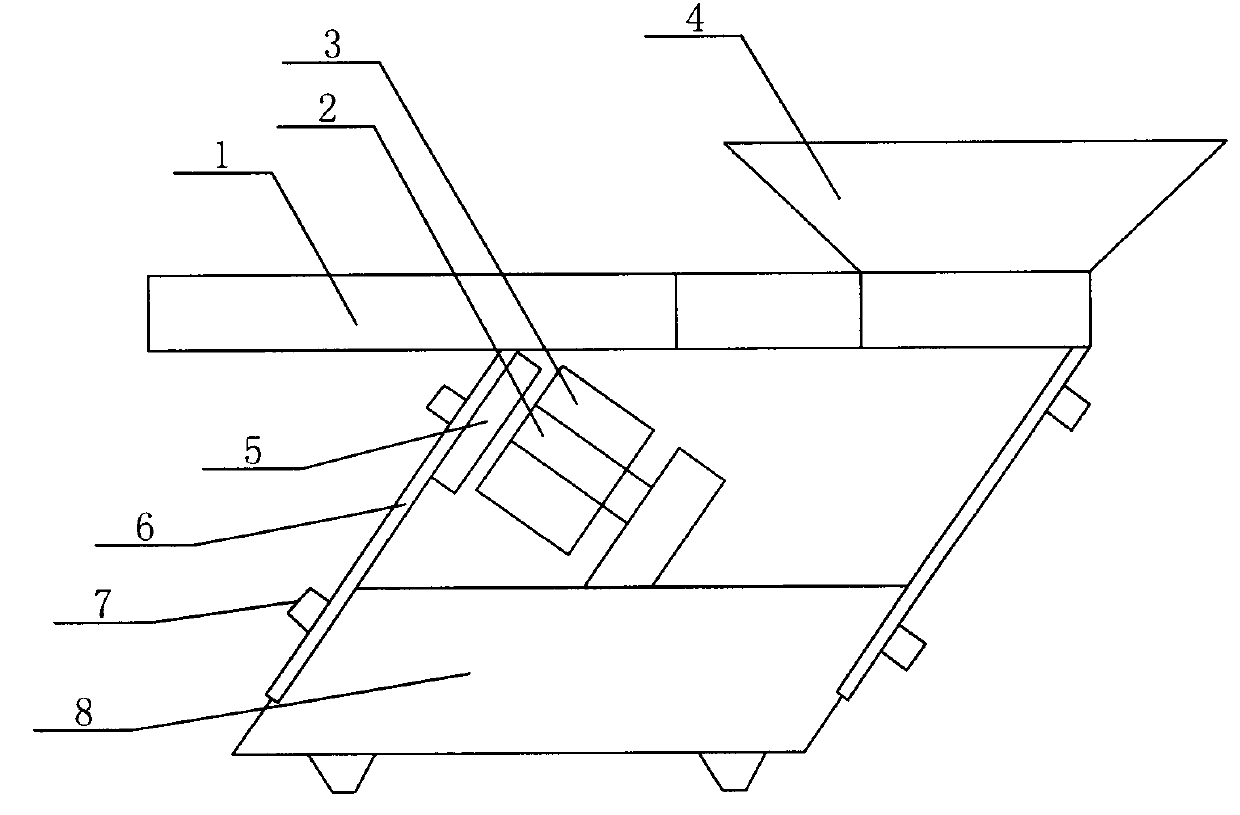

Electromagnetic vibrator

InactiveCN102020098AReal-timeRealize quantitative deliveryControl devices for conveyorsPackaging automatic controlEngineeringElectromagnet

The invention relates to an electromagnetic vibrator, in particular to a feeding device for packaging sites of various vibrating machines or granular products. In the feeding device, a feeding groove (1) is formed at the upper end of a machine base (8); a hopper (4) is arranged at the upper end of the right side of the feeding groove (1); nuts (7) are arranged on the outer side of plate springs (6) uniformly; the plate springs (6) are arranged on both sides of the machine base (8); an armature (5) is arranged on the inner side of the plate spring (6) on the left side; and an electromagnet (2) and a coil (3) are fixed in the machine base (8). The electromagnetic vibrator is accurate, is simple, convenient, quick and reliable in operation, overcomes the defects of low accuracy, complex operation, artificial feeding and the like of the conventional mechanical weighing equipment, and has the critical effect on the improvement of the integral packaging efficiency of the products.

Owner:张春霞

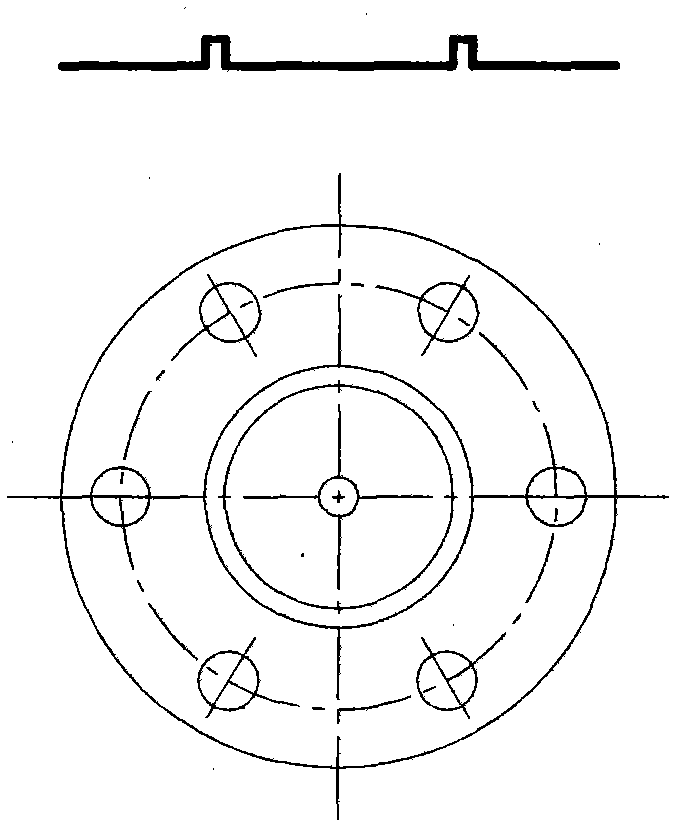

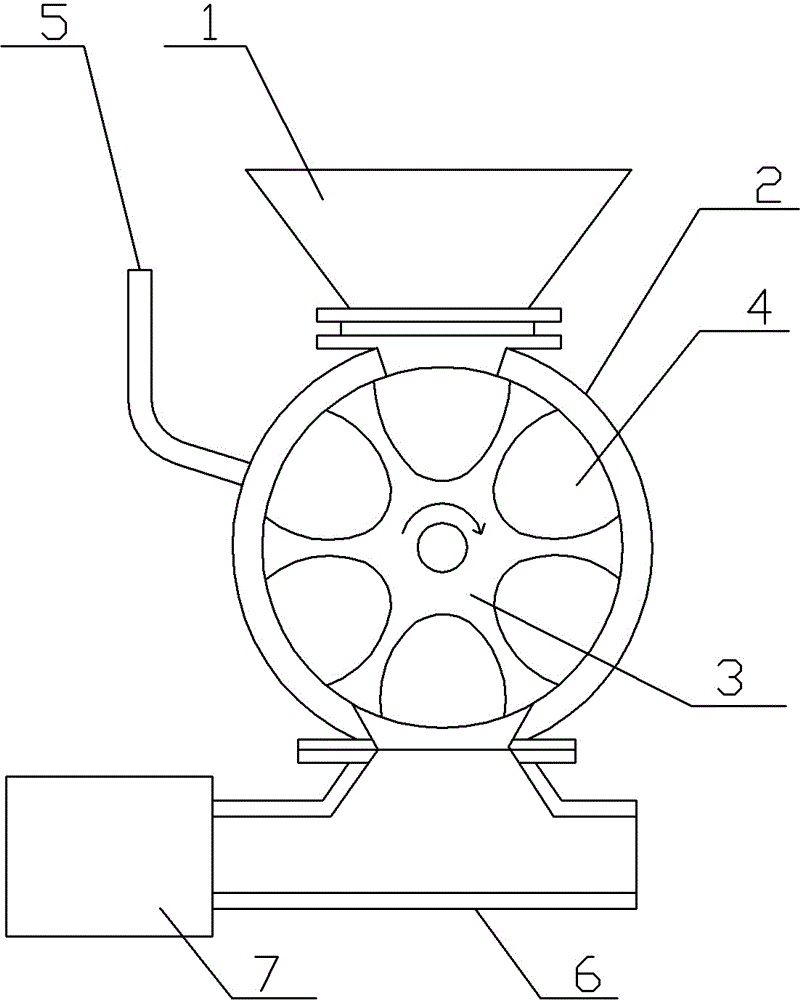

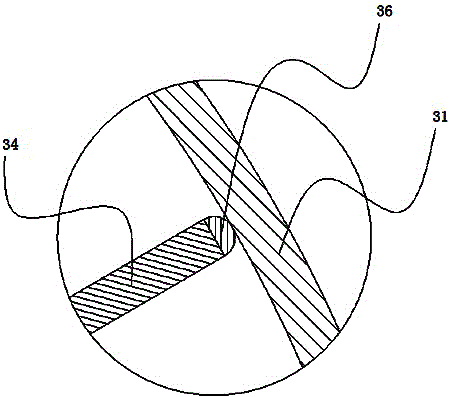

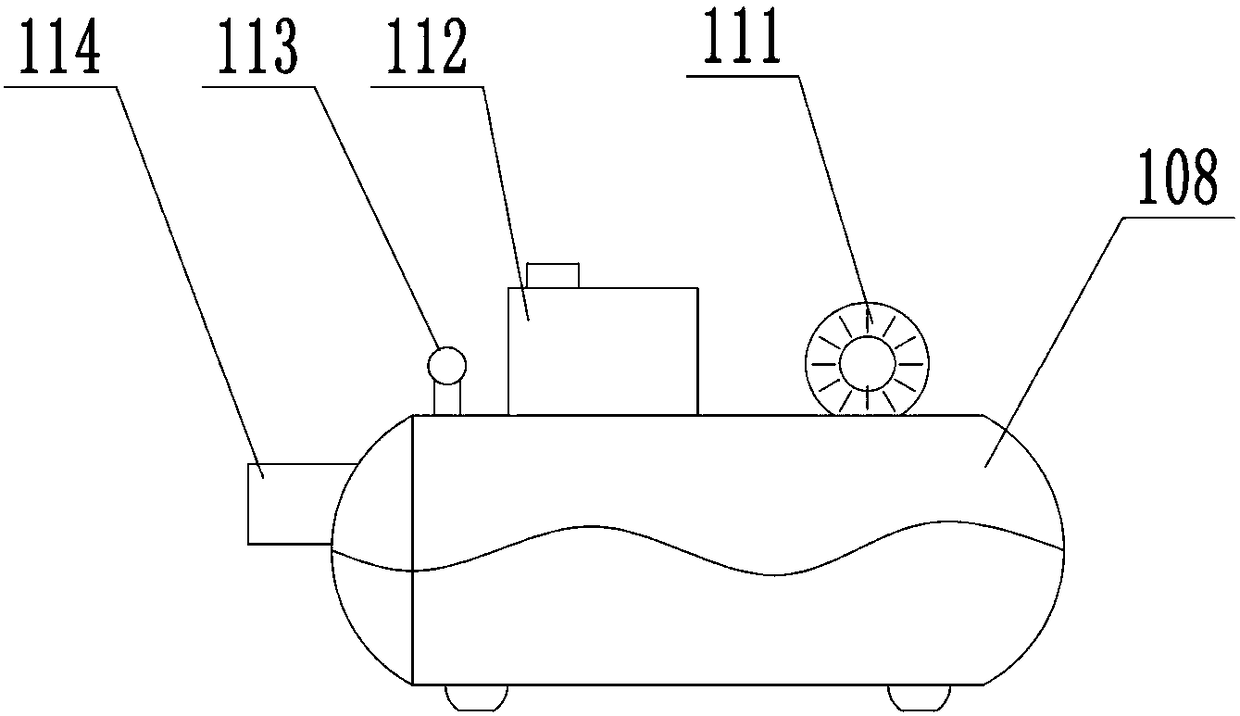

Maize pulp amount-adjusting conveyor

InactiveCN104528408ASimple structureRealize quantitative deliverySolid materialLoading/unloadingAgricultural engineeringFood processing

The invention belongs to the technical field of food processing machines, and relates to a maize pulp amount-adjusting conveyor. The maize pulp amount-adjusting conveyor comprises a rack and a hopper, the hopper is installed at the upper end of the rack, an outlet of the hopper is vertically downward, a cylinder with the upper end communicated with the hopper is installed on the rack, and the lower end of the cylinder is communicated with a conveying pipe. A groove wheel driven by an intermittent motion mechanism to rotate is arranged in the center of the cylinder, and feeding grooves are evenly distributed in the circumference of the groove wheel. One end of the conveying pipe is connected with an air compressor, and the other end of the conveying pipe is connected with a packaging machine. By means of the maize pulp amount-adjusting conveyor, when being conveyed, maize pulps cannot be extruded, and materials are not damaged.

Owner:CHONGQING QINFA FOOD

Intermittent feeding device for powder packing

ActiveCN106275599AGuaranteed production environmentGuaranteed stable packagingConveyorsLarge containersImpellerIron removal

The invention discloses an intermittent feeding device for powder packing. The intermittent feeding device for powder packing comprises a feeding bin (1), a packing machine (2), an impeller feeding device (3), a rotation stopping type level gage A (6), a rotation stopping type level gage B (7) and a pipe type iron remover (4), wherein the rotation stopping type level gage A (6) and the rotation stopping type level gage B (7) are mounted on a receiving hopper of the packing machine (2); the feeding bin (1) is connected with the packing machine (2); the impeller feeding device (3) and the pipe type iron remover (4) are successively arranged on a connecting channel for the feeding bin (1) and the packing machine (2) from top to bottom; and a plug valve (5) is further mounted on a discharging opening of the feeding bin (1) and comprises a plug board (106), a guide plate (102), a driving mechanism (103) and an elastic sealing device (105). The intermittent feeding device for powder packing has the beneficial effects of intermittent quantitative discharging, high iron removal efficiency, high packing efficiency, zero powder leakage, low powder waste rate and low production cost.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

Sewage intelligent stage treatment device

InactiveCN107188337AAvoid wet and dry separationRealize wet and dry separationWater treatment parameter controlTreatment involving filtrationActivated carbonWastewater

The invention discloses an intelligent classification treatment equipment for sewage, which comprises a stirring motor, a stirring motor controller, a reaction pool and a water inlet tank. Two support seats are arranged on the top of the reaction pool, and the water inlet tank is set between the two support seats. During this period, the device crushes the bulky waste existing in domestic sewage through the setting of crushing rollers and squeezing rollers, and a metal screen is set in the connecting pipe to collect the crushed waste in a centralized manner, avoiding the occurrence of clogging , and through the treatment filter and the secondary filter, the mixed small particles of waste in the sewage are blocked in the debris partition box to realize the separation of dry and wet sewage, which is convenient for subsequent treatment. The single treatment volume can be controlled through the water level sensor. In order to realize the quantitative feeding of activated carbon particles and avoid waste, the agitator used in this design is a two-way agitator, which is more efficient and more fully agitated than the one-way agitator, and the power supply of the agitating motor has an anti-interference function. Stability control is achieved.

Owner:冷冰

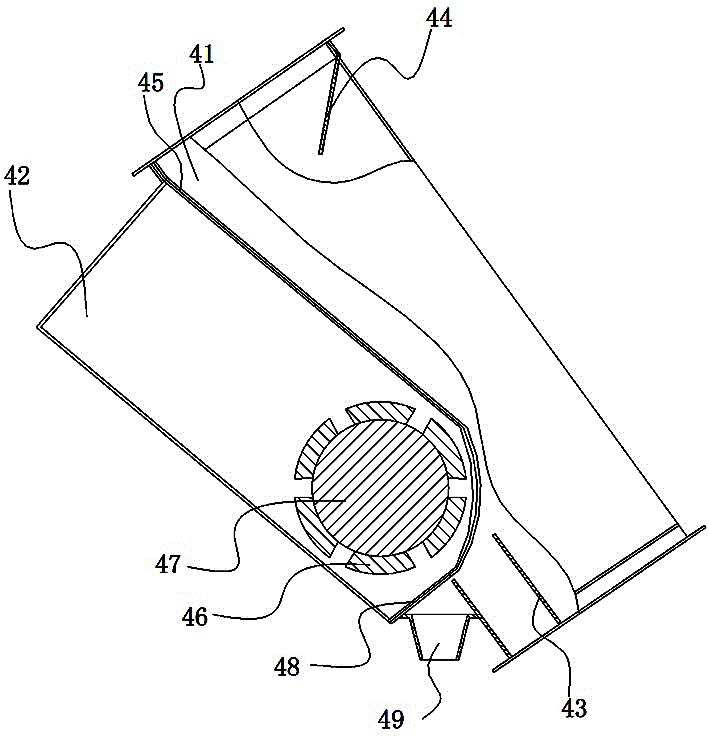

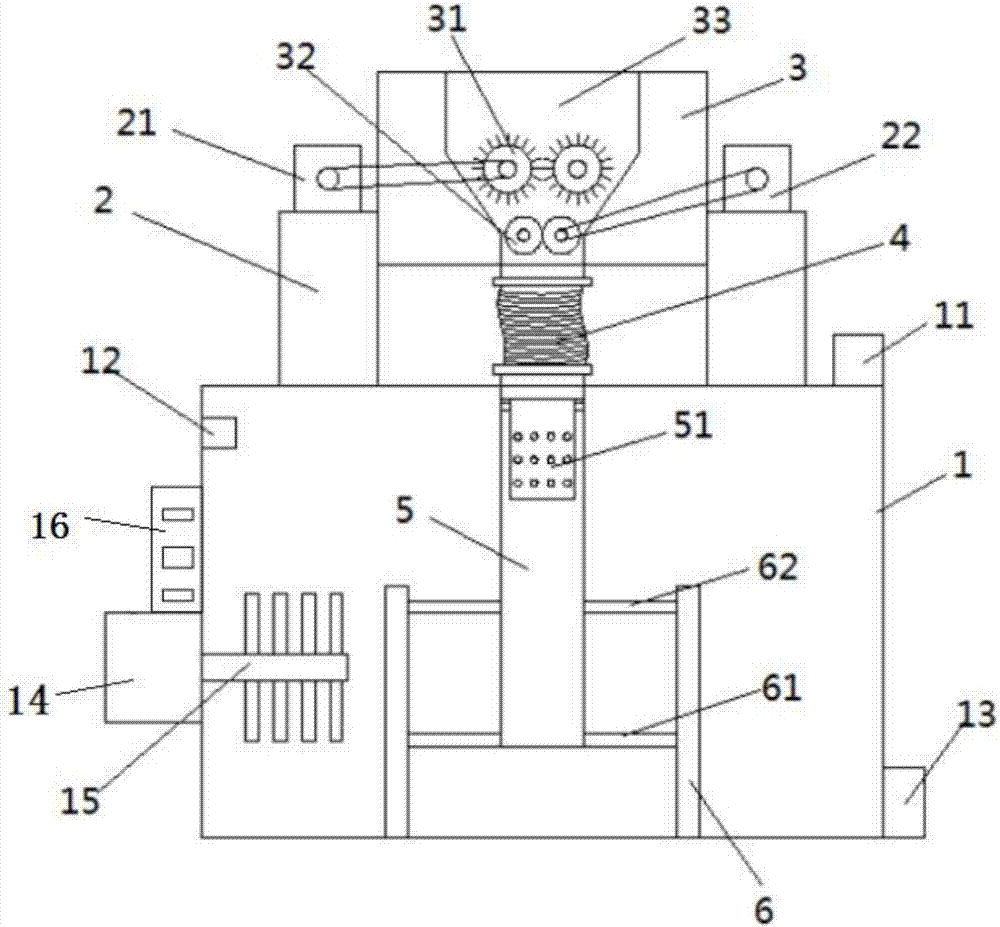

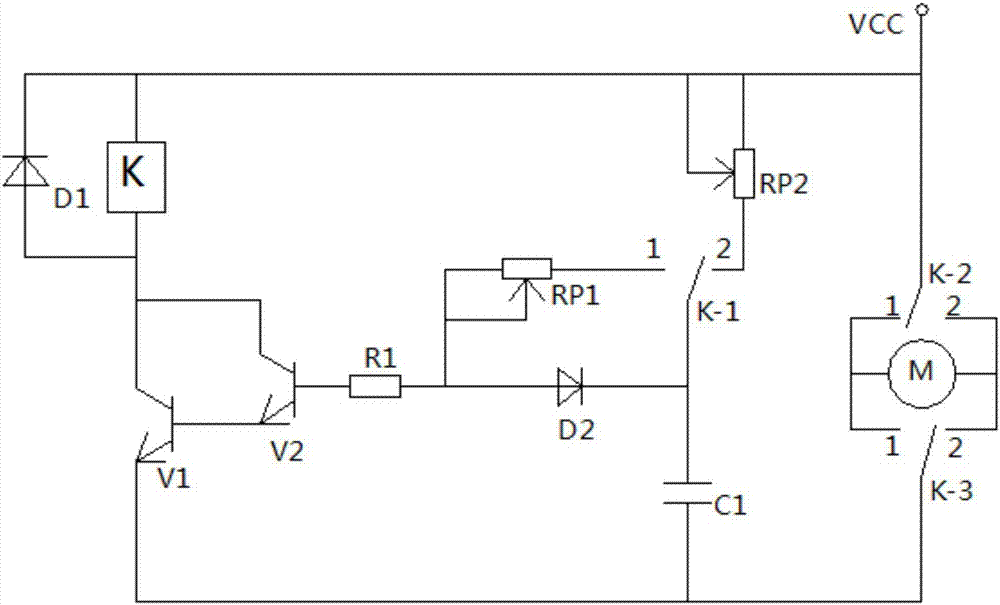

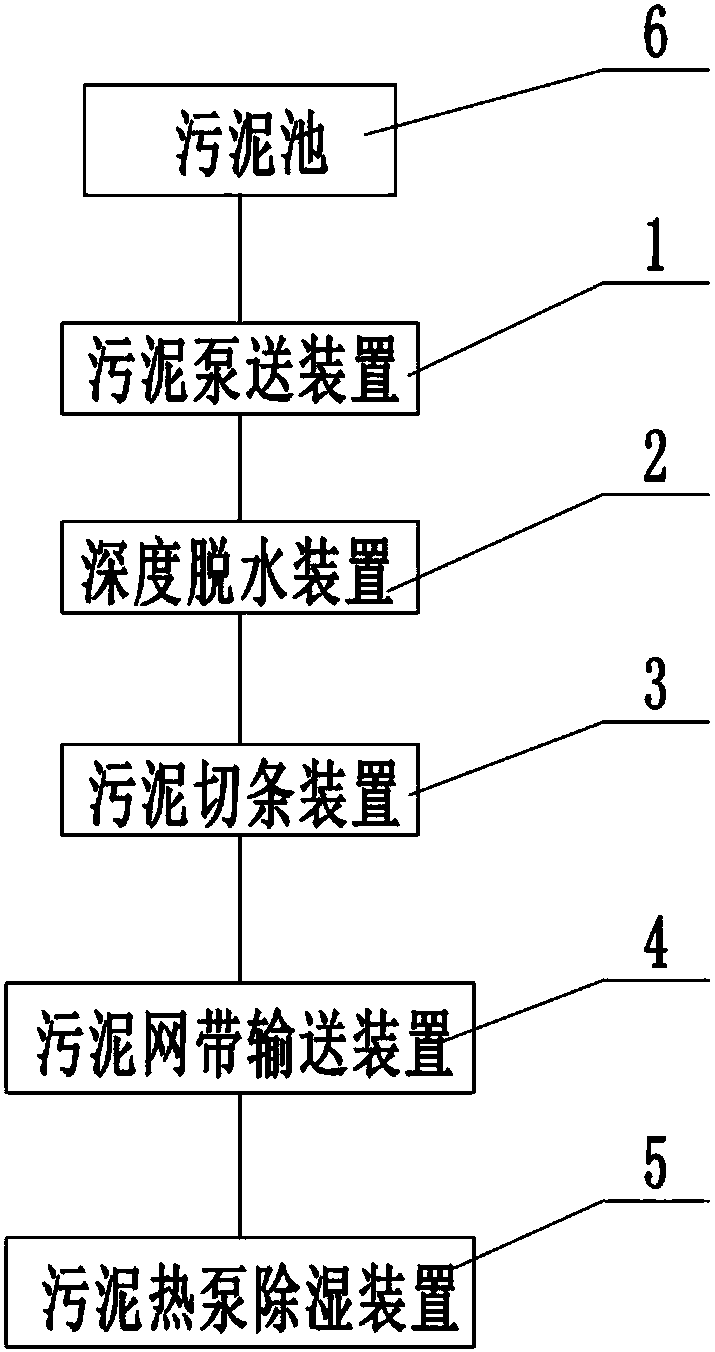

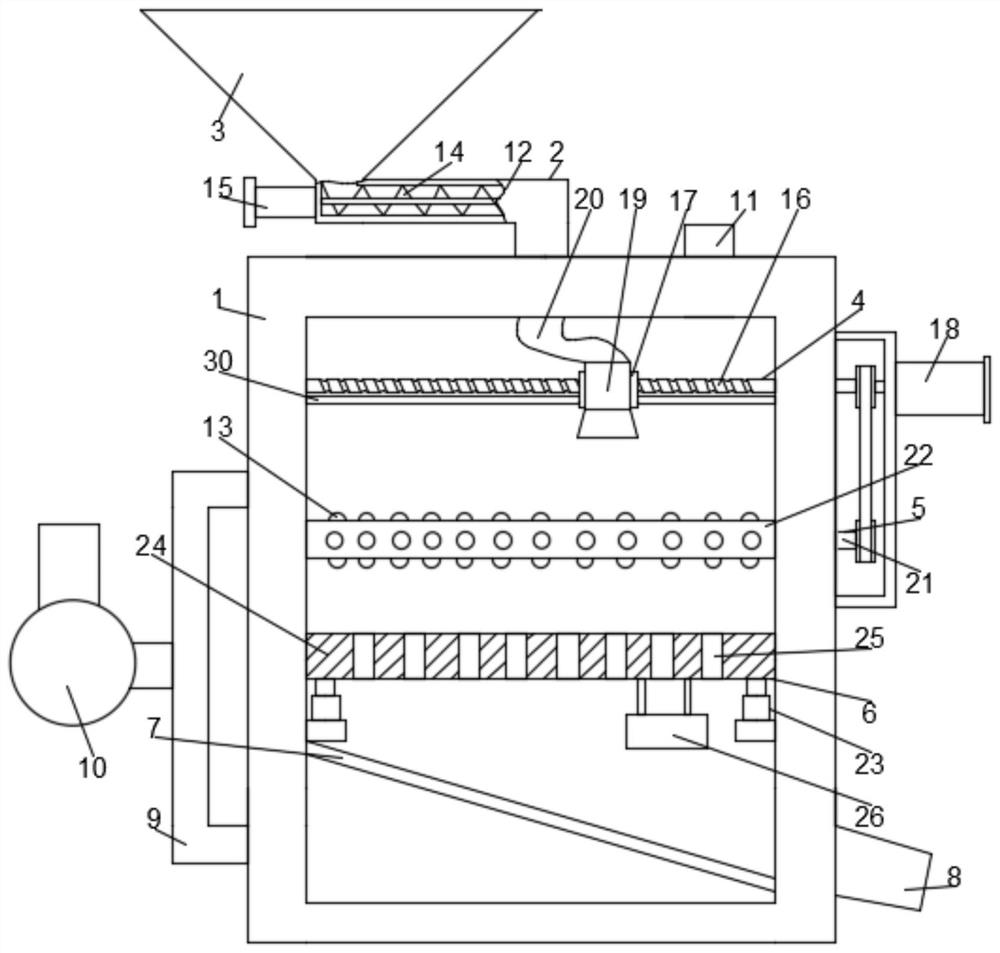

Low-temperature belt-type drying system

PendingCN108314293ARealize quantitative deliverySolve the problem that cannot be delivered quantitativelySludge treatment by de-watering/drying/thickeningHeat pumpsSludgePulp and paper industry

The invention relates to a low-temperature belt-type drying system. The low-temperature belt-type drying system comprises a sludge pumping device, a deep dehydrating device, a sludge slicing device, asludge screen belt conveying device and a thermal pump dehumidifying device. By adopting the low-temperature belt-type drying system, the sludge pumping device, the deep dehydrating device, the sludge slicing device, the sludge screen belt conveying device and the thermal pump dehumidifying device are improved respectively, so that the working efficiency is improved integrally, the working reliability and drying effect of the drying system are improved.

Owner:YIXING IDEAL TECH CO LTD

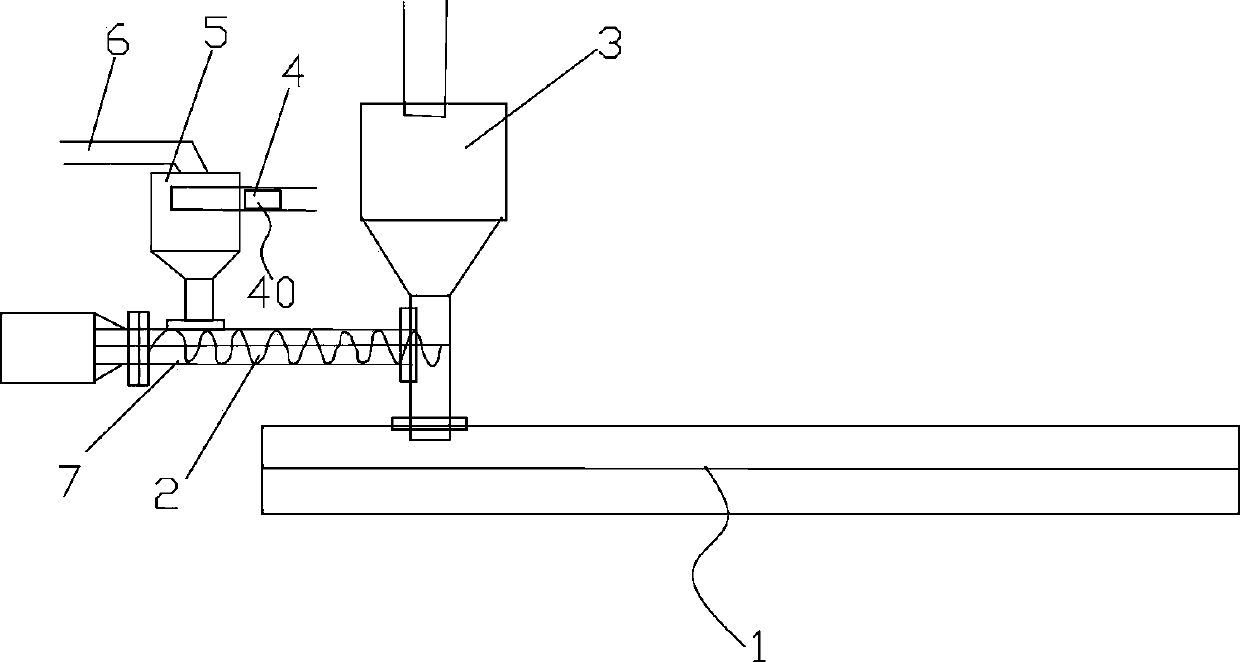

Online recycling device for leftovers of cast film

InactiveCN103737741ARealize quantitative deliveryReduce the chance of bridging blockagePlastic recyclingEngineeringMechanical engineering

The invention discloses an online recycling device for leftovers of a cast film. The online recycling device comprises a new material hopper communicated with an extruder, wherein an old material conveying pipeline is horizontally arranged on one side of the new material hopper; a conveying screw rod for conveying a powder material is arranged in the old material conveying pipeline; an old material conveying hopper is communicated with the upper part of the old material conveying pipe; one side of the old material conveying hopper is communicated with the old material conveying pipeline. Due to the adoption of the online recycling device disclosed by the invention, the powder material is quantitatively conveyed, so that the extrusion amount is stable. Therefore, the thickness stability of the product can be ensured; meanwhile, the device is uniform to stir in a blanking process and the bridging and blocking probabilities of the powder material can be reduced.

Owner:NINGBO RUICHENG PACKING MATERIAL

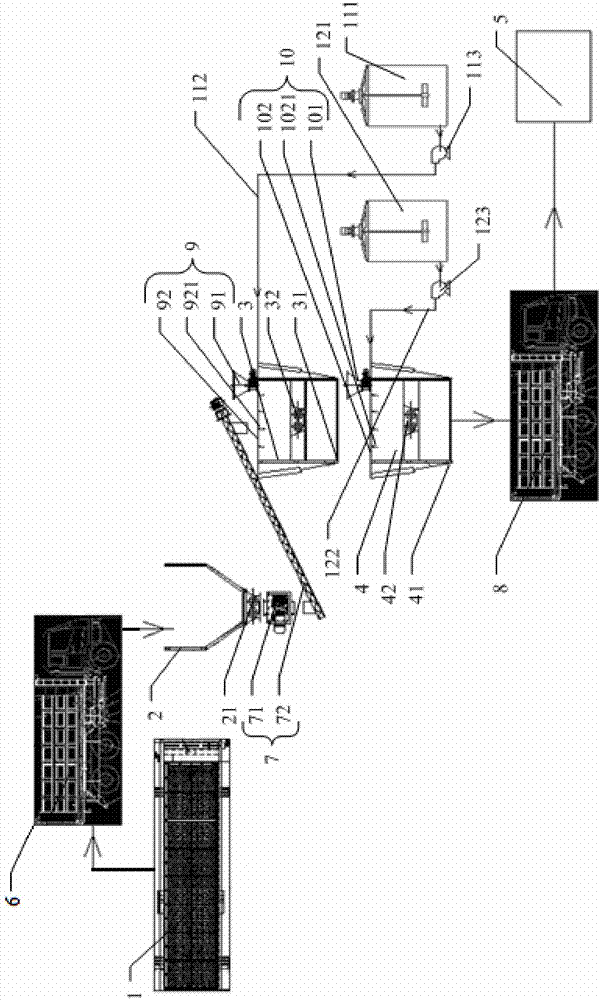

Peanut whole-process production line and method

ActiveCN111317148AEfficient separationReduce the impactGas current separationSolid materialEngineeringProcess engineering

The invention provides a peanut whole-process production line and method. The peanut whole-process production line comprises a peanut cleaning system, a shell breaking system, a red skin removing system, a peanut kernel grading system, a superfine grinding system and a grading packaging system. The first process is peanut cleaning and impurity removing, peanut shell breaking is arranged behind peanut cleaning and impurity removing, peanut kernel red skin removing and peanut shell superfine grinding are respectively arranged behind the peanut shell breaking, peanut kernel grading is arranged behind the peanut kernel red skin removing, and peanut shell superfine powder grading packaging is arranged behind the peanut shell superfine grinding. By the peanut whole-process production line, peanut whole-process processing is completed, and peanut resources are fully utilized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

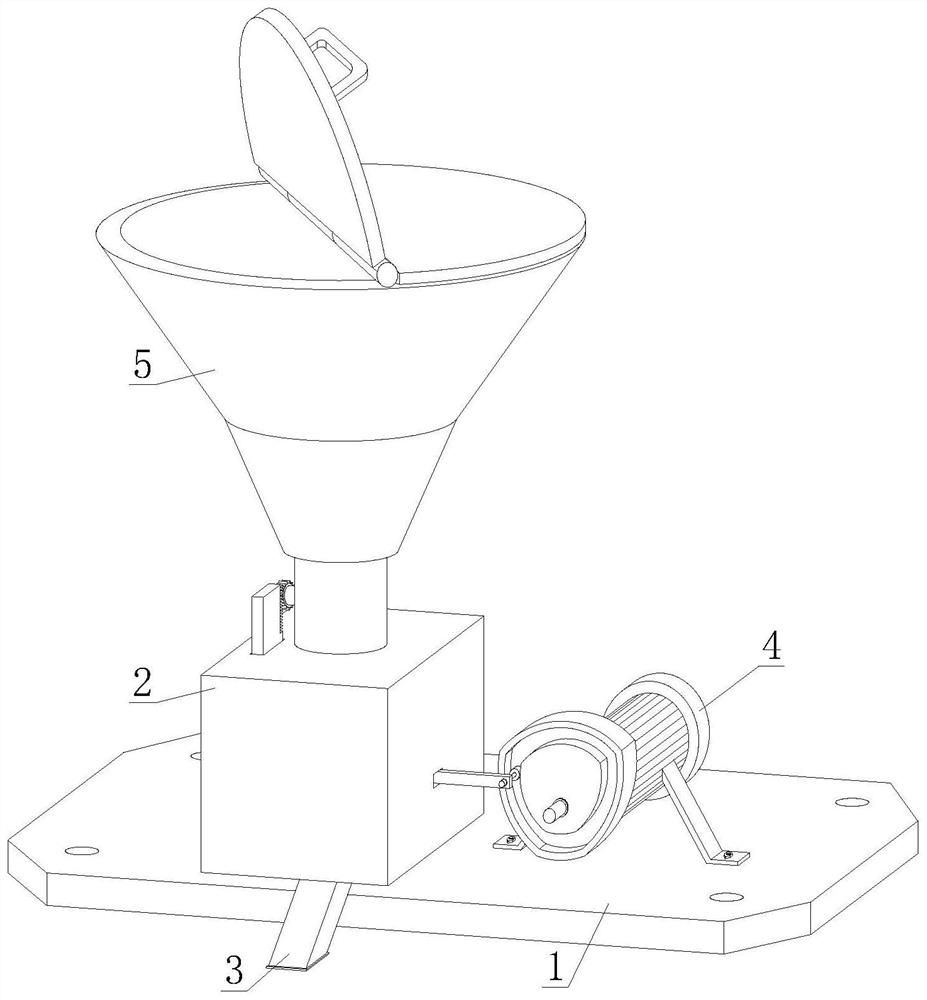

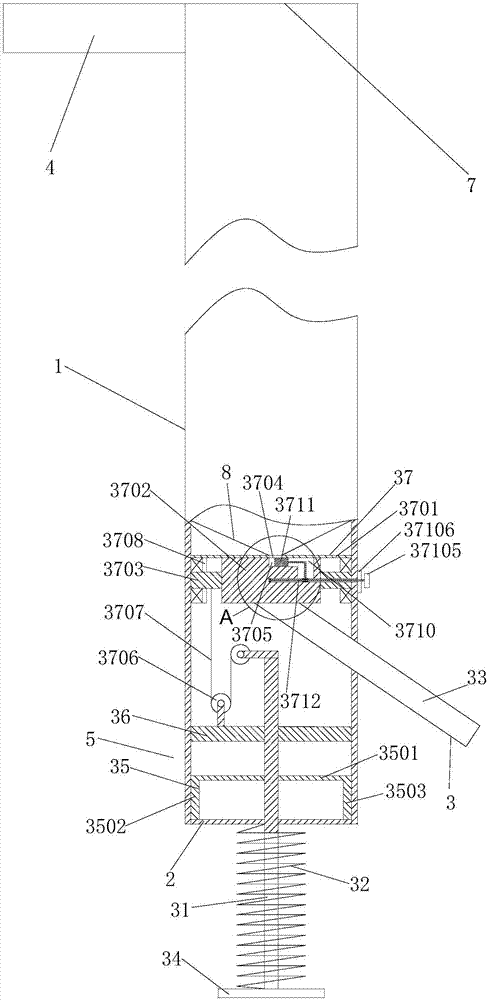

Sustainable discharging device for preparing rare earth electrolysis waste fused salt and implementation method thereof

ActiveCN113073359ARealize quantitative deliveryPrevent affecting experimental efficiencyCellsElectrolysisReciprocating motion

The invention discloses a sustainable discharging device for preparing rare earth electrolysis waste fused salt. The sustainable discharging device comprises a bottom plate, a quantitative control mechanism, a discharging port, a transmission motor and a hopper, a reciprocating transmission part rotates to enable a quantitative spacing plate to do reciprocating motion in a discharging channel, when an upper baffle moves into a second storage groove, the discharging channel is sealed by a lower baffle, when molten salt in the hopper falls to the position above the lower baffle and the transmission rod drives the lower baffle to move into a first storage groove, the upper baffle seals an upper end of the discharging channel, and the molten salt at an upper end of the lower baffle falls and is discharged, so that quantitative feeding is realized, and timely adjustment is facilitated. The invention further discloses an implementation method of the sustainable discharging device for preparing the rare earth electrolysis waste molten salt, when a transmission plate moves up and down, convex teeth and gears are engaged to drive a shaft body to rotate in a reciprocating mode, a plurality of dredging rods rotate in a matched mode, the molten salt can be well loosened, the dredging rods are relatively dense, and massive fused salt can be blocked or ground and crushed with the inner wall of a loose pipe.

Owner:カン州晨光希土新材料有限公司

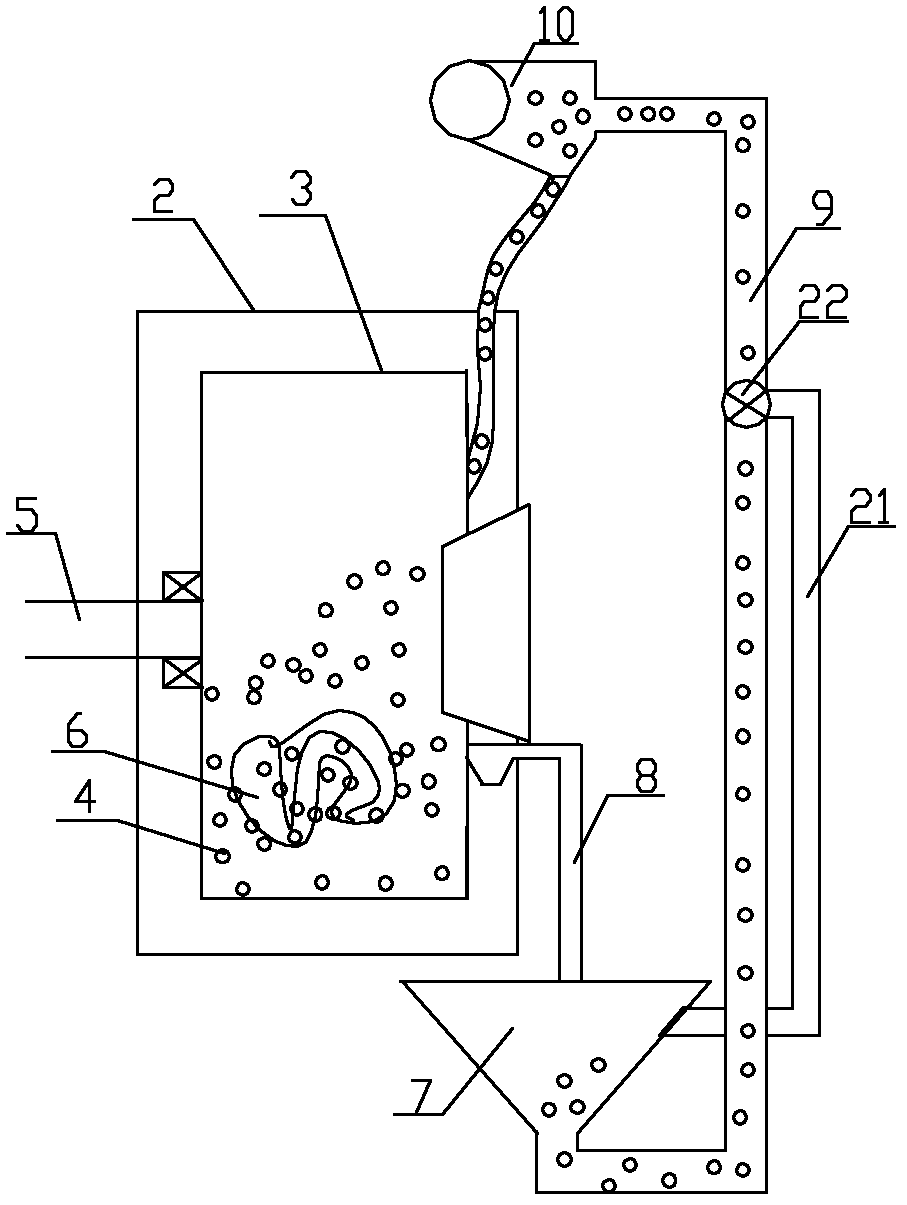

Ex-situ chemical restoration system of polluted soil

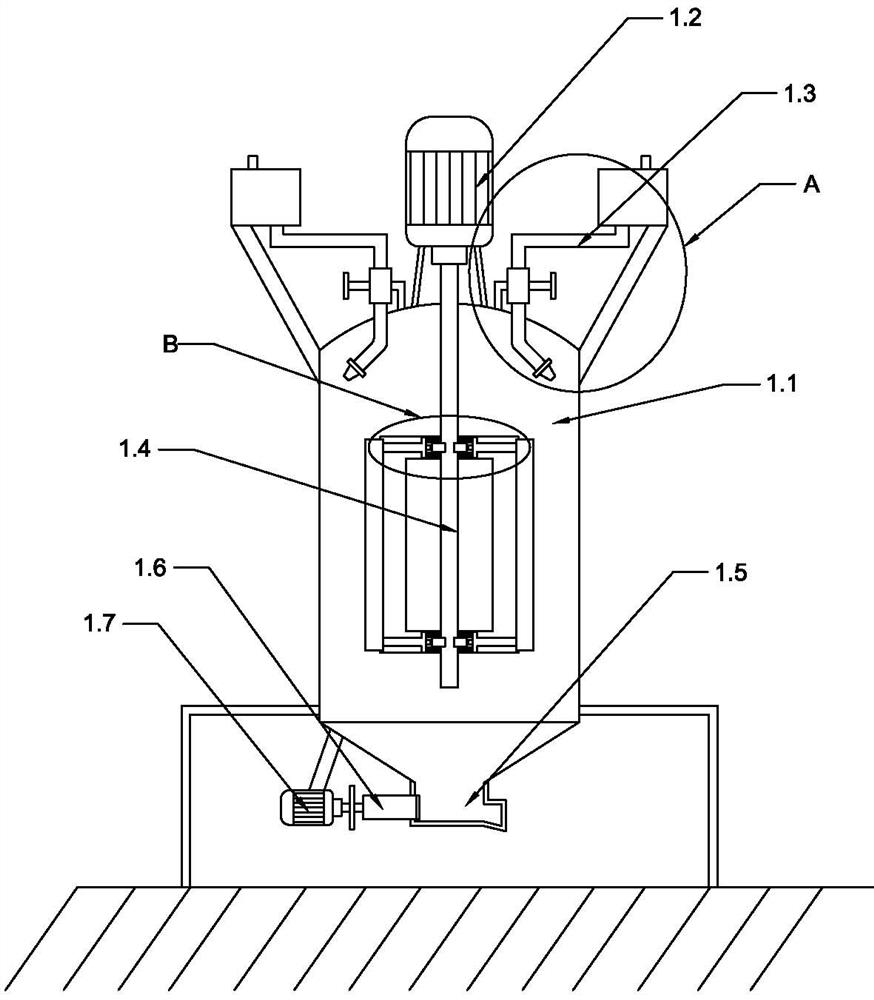

PendingCN106914485ARealize quantitative deliveryAvoid wastingContaminated soil reclamationRestoration methodEnvironmental engineering

The invention provides an ex-situ chemical restoration system of polluted soil. The system is sequentially provided with a pretreatment device, a storage bin, a primary reactor, a secondary reactor and a maintenance device, a first conveying device used for conveying is arranged between the pretreatment device and the material inlet of the storage bin, a second conveying device used for conveying is arranged between the material outlet of the storage bin and the material inlet of the primary reactor, the material outlet of the primary reactor corresponds to the material inlet of the secondary reactor, and a third conveying device used for conveying is arranged between the material outlet of the secondary reactor and the maintenance device. The invention provides an ex-situ chemical restoration method of polluted soil. The ex-situ chemical restoration system of polluted soil allows a liquid or solid reagent to be quantitatively added, can continuously automatically run or intermediately run, can control the reaction time to guarantee the ex-situ chemical restoration effect of the polluted soil, realizes uniform mixing and stirring, is simple to operate, and can be widely applied to the ex-situ chemical restoration of the polluted soil.

Owner:上海中耀环保实业有限公司

Rat poison bait casting device

The invention discloses a rat poison bait casting device which can effectively reduce the labor intensity of operators, is high in safety and can achieve quantitative casting. The rat poison bait casting device comprises a poison storage barrel used for storing a rat poison. The cross section of the poison storage barrel is rectangular, the lower end of the poison storage barrel is sealed through a bottom plate, and the lower end of the poison storage barrel is connected with a feeding device. The feeding device comprises a supporting rod, a spring, a guiding pipe and the like. In the whole bait casting process of rat poison bait casting device, the operators do not need to stoop and can complete operation only by standing, the labor intensity of the operators is greatly reduced, the operators do not make contact with bait in the bait casting process, the situation of poisoning of the operators is also avoided, and the safety is greatly improved; in addition, bait of different quantities can be cast according to the degrees of rat damage, the quantity of the bait cast every time is fixed only by adjusting a sliding block to be fixed, and quantitative casting can be achieved. The rat poison bait casting device is suitable for being applied and popularized in the field of grassland treatment.

Owner:SICHUAN ACAD OF GRASSLAND SCI

Intelligent medicine box

InactiveCN105816328AHigh precision of dispensingPracticalOral administration deviceOther accessoriesBiomedical engineeringTimer

The invention provides an intelligent medicine box, which comprises a medicine storage device, a transmission device and a control device, wherein a medicine outlet is formed in the medicine storage device; the medicine storage device rotates under the effect of the transmission device so that medicine falls down through the medicine outlet; the control device adopts a control unit with a timer; the control unit controls and connects the transmission device. The intelligent medicine box has the advantages that the timed and quantitative medicine discharging can be realized; the intelligent medicine box can remind a patient to take medicine in time; the taking quantity of various tablets is adjustable; the medicine taking time is adjustable; the intelligent medicine box is applicable to most medicine on the market; the practicability is high; the application range is wide; intelligence and convenience are realized.

Owner:HENAN POLYTECHNIC UNIV

Cold storage cavern device for grain dust removal and freshness preservation

InactiveCN110553453AAvoid undriedEasy to operateLighting and heating apparatusStationary refrigeration devicesGrain storageEngineering

The invention discloses a cold storage cavern device for grain dust removal and freshness preservation, and belongs to the field of grain storage devices. The device comprises a storage cabinet, a quantitative feeding mechanism, a grain drying mechanism and a dust removal mechanism, wherein the grain drying mechanism and the dust removal mechanism are arranged inside the storage cabinet, a refrigerating chamber is arranged at the lower section inside the storage cabinet, a feeding box is arranged at the top of the storage cabinet, the grain drying mechanism comprises a drying assembly, a material turning assembly and a pouring assembly, the material turning assembly comprises a supporting table, a material turning component and a material turning box, the material turning box is provided with a vent hole, and the material turning box is provided with a material discharging nozzle. According to the device, by means of the dust removal mechanism, the dust removal operation can be carriedout on grains on a vibration plate and a material guide slide way, by means of the grain drying mechanism, the material turning operation can be carried out on the grains, and the situation that thegrains are not dried locally is avoided, and by means of the pouring assembly, the grains can be poured so as to enable the grains to fall onto the material guide slide way.

Owner:惠州市安谷农业开发有限公司

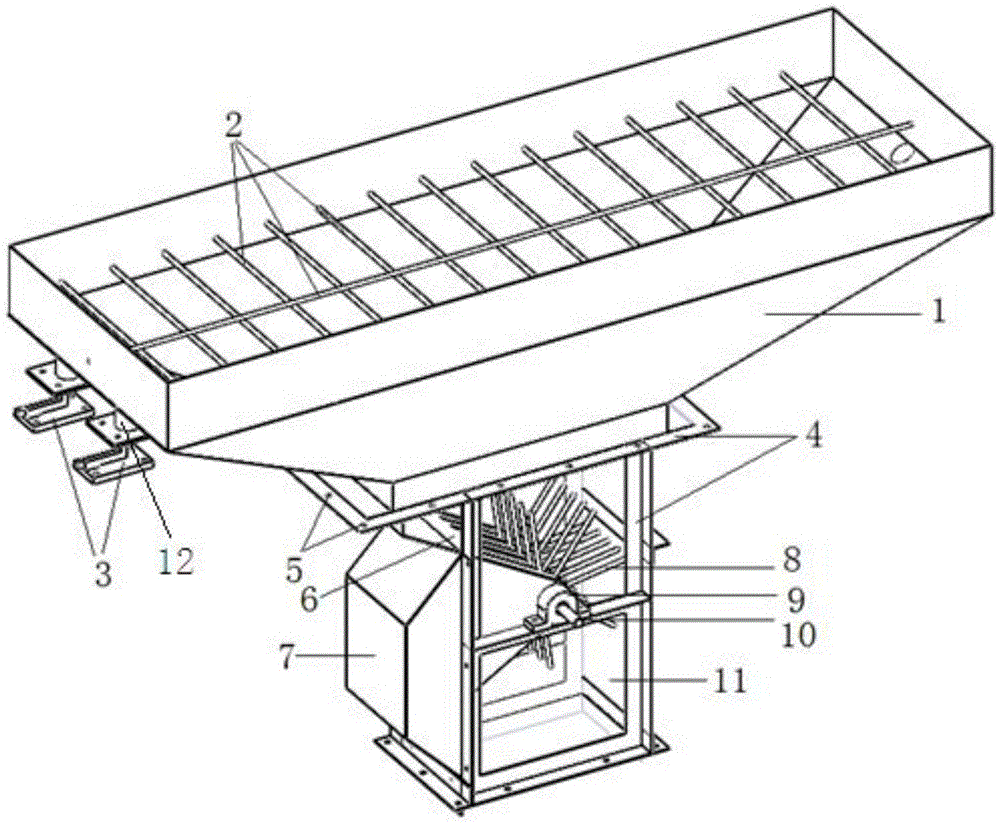

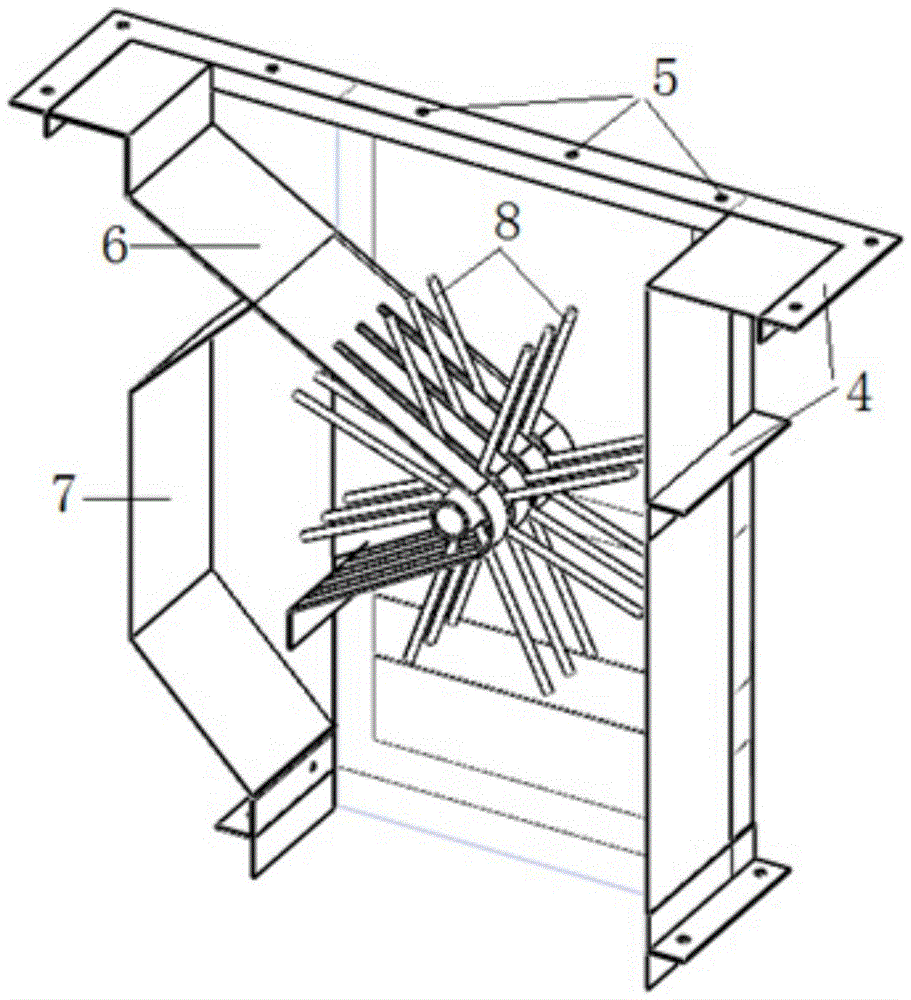

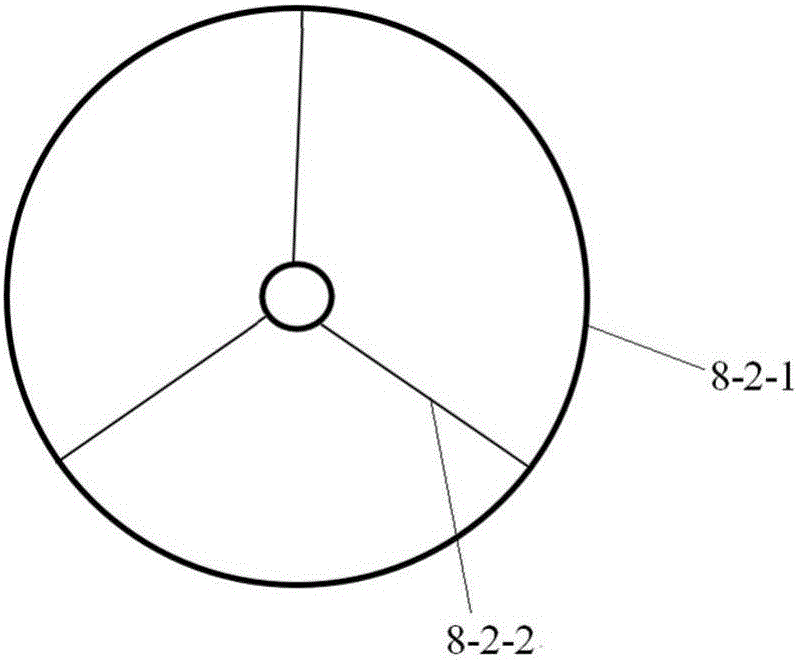

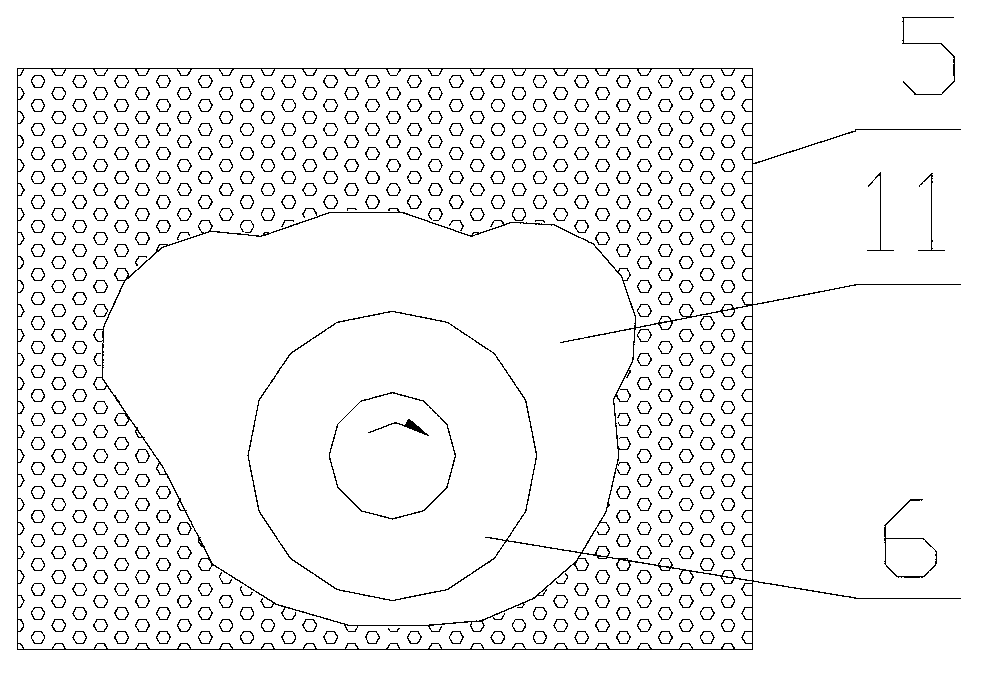

Glass fiber quantitative conveyer

InactiveCN105648583APrevent quantitative delivery is not easyNovel structureFibre feedersGlass fiberEngineering

The invention relates to a glass fiber quantitative conveyer. The glass fiber quantitative conveyer comprises a hopper (1), a steel angle framework (4), an inner attaching plate (6), a material stirring roller (8) and a material stirring shaft (10); a fence (2) is installed on an inlet of the hopper (1); the steel angle framework (4) is in an outlet of the bottom end of the hopper (1); the inner attaching plate (6) and the material stirring roller (8) are installed in the steel angle framework (4); the inner attaching plate (6) is of a horizontal V-type structure and fixed to the steel angle framework (4); the material stirring roller (8) is installed on the material stirring shaft (10) which is connected with the output end of a servo motor; the material shifting shaft (10) is arranged at the bottom end of the inner attaching plate (6); the material stirring roller (8) is provided with material stirring teeth which are evenly distributed in the circumferential direction; the inner attaching plate (6) is provided with a rack gap for the material stirring teeth to pass. By means of the glass fiber quantitative conveyer, it can be prevented that glass fibers are clustered and cannot be easily conveyed, quantitative conveying can be achieved, automation of a production procedure is achieved, manpower is reduced, and production efficiency is improved.

Owner:SHANGHAI INST OF TECH +1

Novel rice plant potting system

InactiveCN105724097AOvercoming the problem of not being easy to be strongAchieve drainageLiquid fertiliser regulation systemsPressurised distribution of liquid fertiliserWater sourcePotassium

The invention relates to a novel rice plant potting system. A culturing bucket comprises an inner cylinder and an outer cylinder, wherein the inner cylinder is sleeved by the outer cylinder; a detection device is placed in the inner cylinder; a root fixing bracket is further mounted in the inner cylinder; a water inlet and a water outlet are respectively formed in the upper end of the outer cylinder; a water source bucket is communicated with the water inlet through a pipe; a connection port is further formed in the bottom of the outer cylinder; the detection device comprises a gas collection device, a soil temperature monitor, a soil moisture monitor and a water level monitor; the water level monitor is mounted between the inner cylinder and the outer cylinder. According to the invention, the water level monitoring device is introduced, to strictly control the depth of water in each processed rice plant field and to achieve the free water supply and drainage during rice plant cultivation; the quantitative application of fertilizers is achieved to solve the problem of leaching loss of nitrogen-potassium fertilizer and other instant fertilizers during potting; an accurate quantitative research can be performed on the water and fertilizer management for the rice plant field; and the continuous monitoring for soil moisture and temperature is achieved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

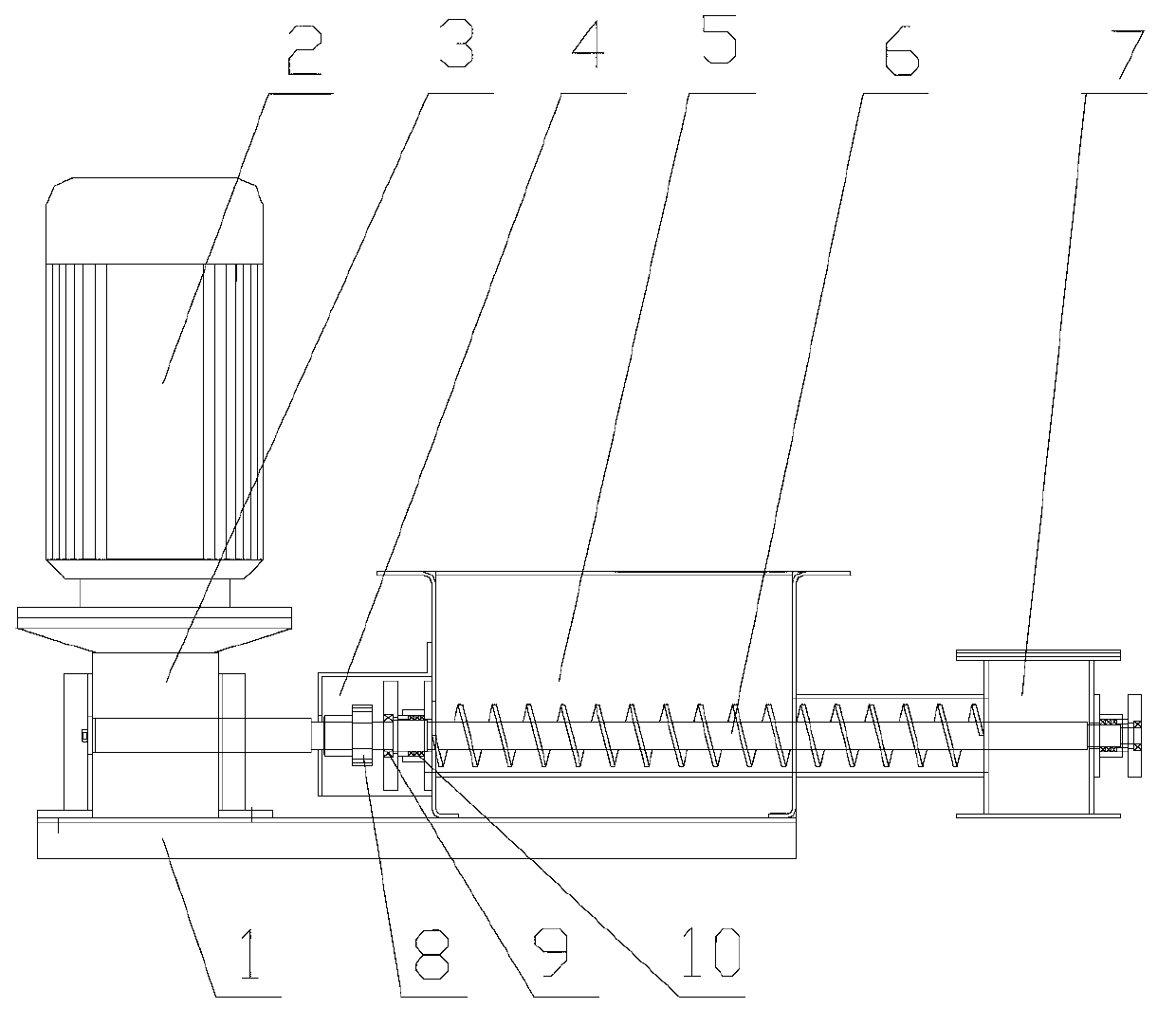

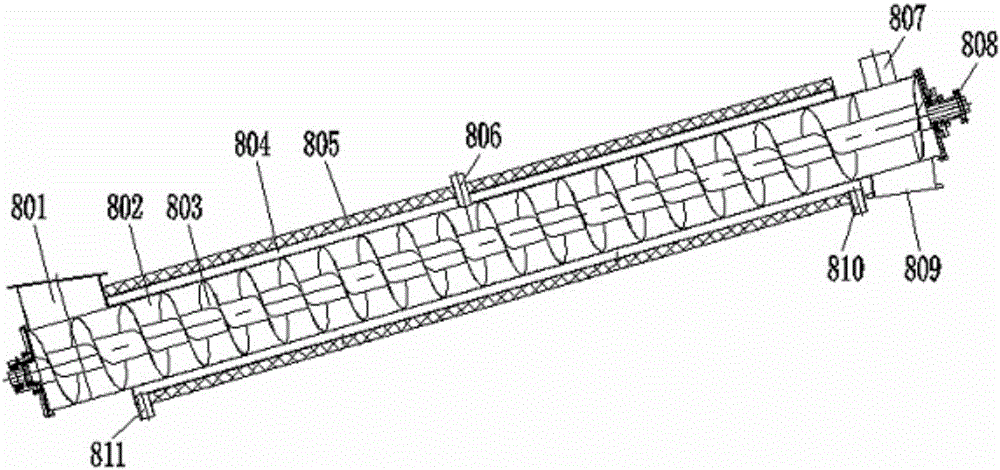

Multi-spiral high-precision quantitative feeding device

InactiveCN102992046ARealize quantitative deliveryPrevent bridgingSustainable packaging industryPackagingDrive shaftSpiral blade

The invention relates to a multi-spiral high-precision quantitative feeding device, which comprises a base, wherein a motor is sequentially connected with a gearcase on the base through a speed reducer; and one end of a spiral feeding mechanism arranged at the lower part of a feeding case is connected with a driving shaft in the gearcase, and the other end of the spiral feeding mechanism extends into a discharging mechanism. The multi-spiral high-precision quantitative feeding device is characterized in that at least three spiral rods are arranged in the spiral feeding mechanism in parallel, spiral blades of the spiral rods are consistent in spiral angle and diameter, and every two adjacent spiral rods are different in rotating direction and are embedded to each other. According to the invention, five spiral rods are arranged in the spiral feeding mechanism in parallel. The multi-spiral high-precision quantitative feeding device has the beneficial effects that a dry powder agent with unchanged dosage is conveyed after being distributed to a plurality of spiral rods, so that the powder agent in a storage bin can be prevented from being crosslinked and the problems of uneven feeding, even no feeding and the like are solved, and therefore high-precision quantitative feeding of the dry powder agent is achieved.

Owner:奥卡威科技(大连)有限公司

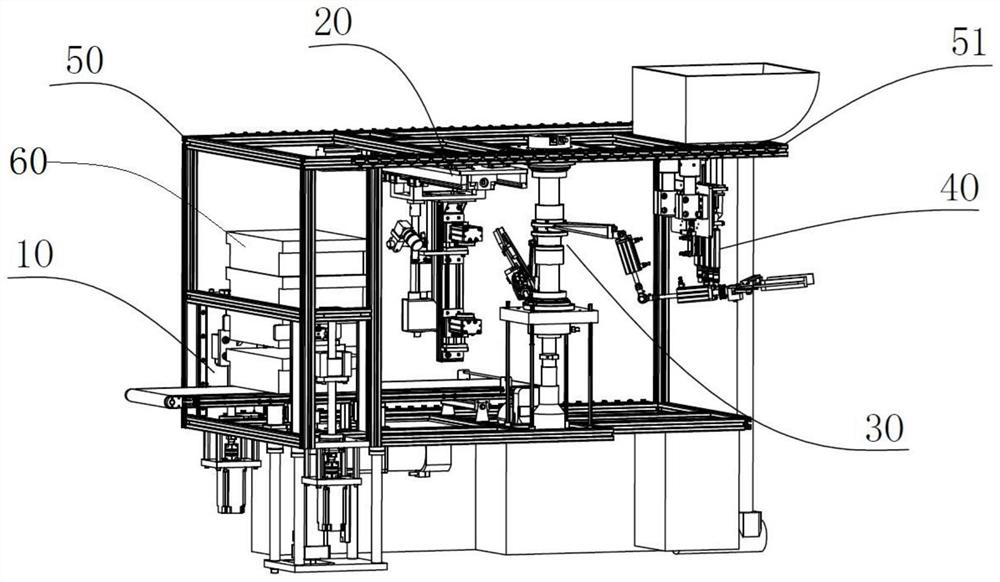

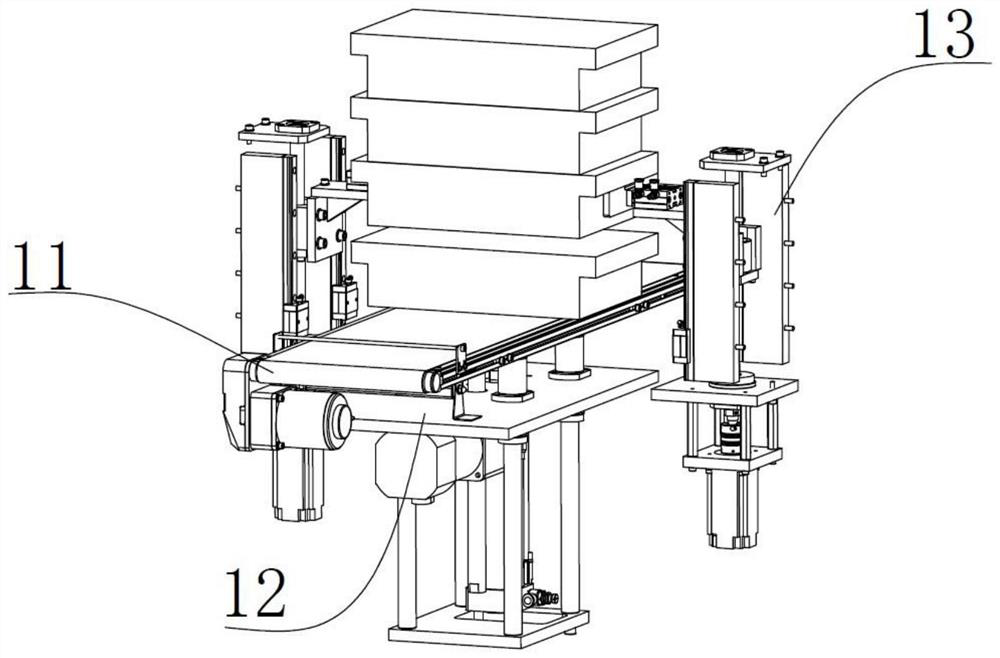

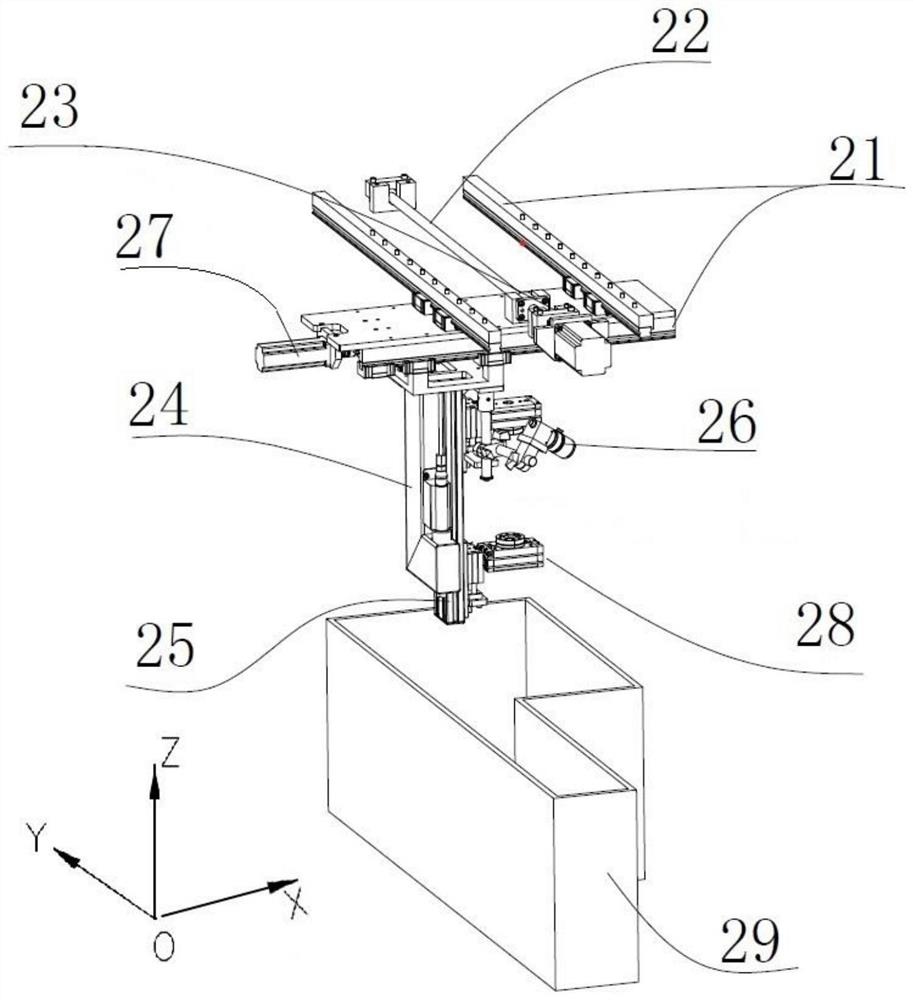

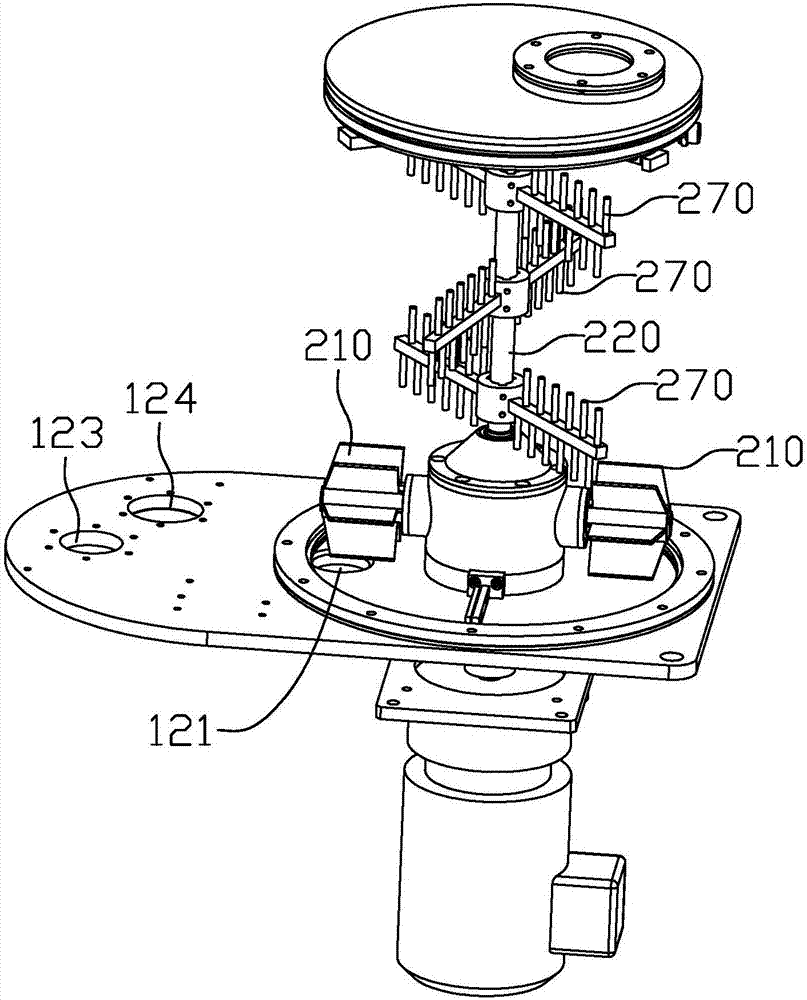

Coke oven intelligent masonry machine and coke oven continuous masonry process

PendingCN112812788ARealize quantitative deliveryAvoiding the Risk of Brickmaking ErrorsCoke oven brickworkBrickCoke burner

The invention relates to a coke oven intelligent masonry machine and a coke oven continuous masonry process. The coke oven intelligent masonry machine comprises a building block conveying unit, a cutting unit, a manipulator and a mortar spraying unit which are integrated into a whole through a fixed support; the building block conveying unit is provided with a belt conveyor and a clamping mechanism; the cutting unit is provided with a longitudinal and transverse sliding mechanism, a vertical sliding rail, a cooling medium generator, an infrared emitter and a cutting mechanism; the manipulator is provided with at least two clamping arms; and the mortar spraying unit is provided with a mortar stirring tank and parallel nozzles. Mechanical equipment is adopted to replace manpower, continuous masonry operation is achieved, the coke oven intelligent masonry machine integrates the functions of building block conveying, brick type cutting, mortar spraying, masonry placing and the like, a series of masonry processes are integrated, and the problems that in the traditional manual coke oven masonry process, manpower is consumed, and efficiency is not high are solved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

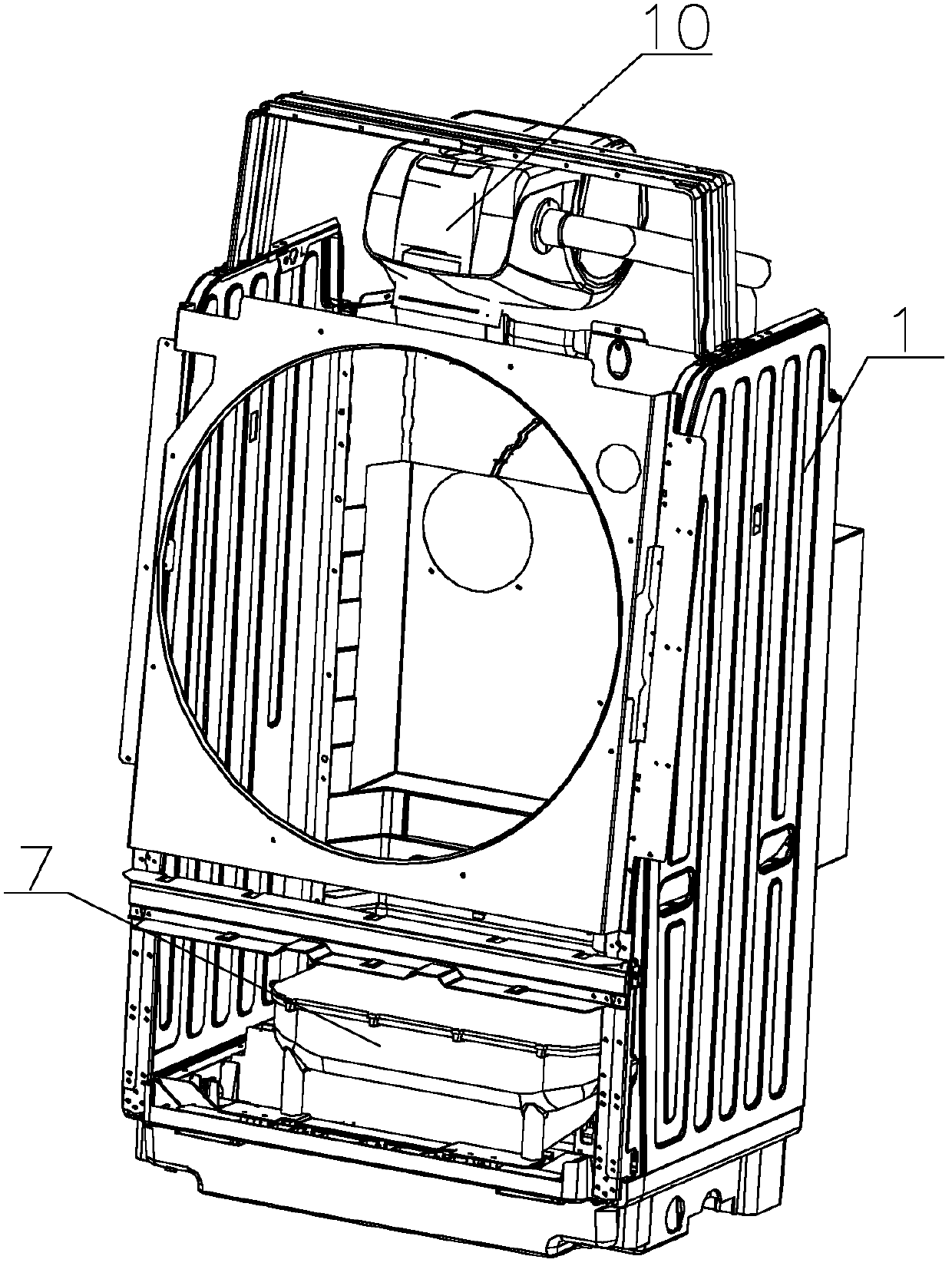

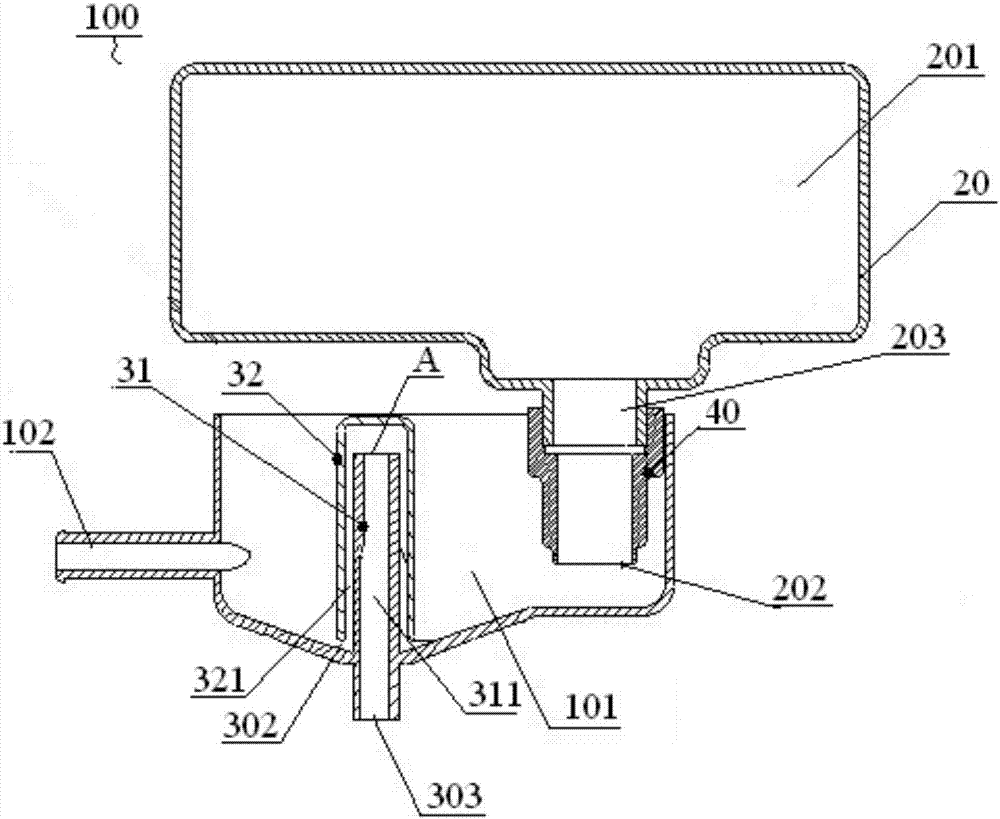

Suction device of washing machine and washing machine

ActiveCN103290653AStable deliveryEasy to deliver quantitativelyOther washing machinesTextiles and paperPulp and paper industryControl valves

The invention relates to a suction device of a washing machine and the washing machine. The washing machine comprises an inner barrel, an outer barrel, washing particles serving as the washing media, and a storage tank used for storing the particles. The suction device is further arranged in the washing machine and comprises a casing and a fan, wherein a feed inlet, a discharge outlet and an exhaust port are formed in the casing; the exhaust port is formed in the air inlet end or air outlet end of the fan; a discharge funnel is arranged at the bottom of the casing; the discharge outlet is formed in the bottom of the discharge funnel; and a baffle or a control valve used for opening or closing the discharge outlet is arranged at the discharge outlet. According to the suction device and the washing machine, the particles in the storage tank are sucked out by the fan automatically, stored temporarily in the suction device, and thrown into the outer barrel or the inner barrel, so that the particles are delivered more smoothly; meanwhile, during particle separation and recovery, suction out of the particles and delivery into the storage tank are also facilitated; the baffle structure is used to achieve quantitative particle throwing, not only can the washing efficiency be improved, but also waste can be avoided.

Owner:QINGDAO HAIER MOLDS

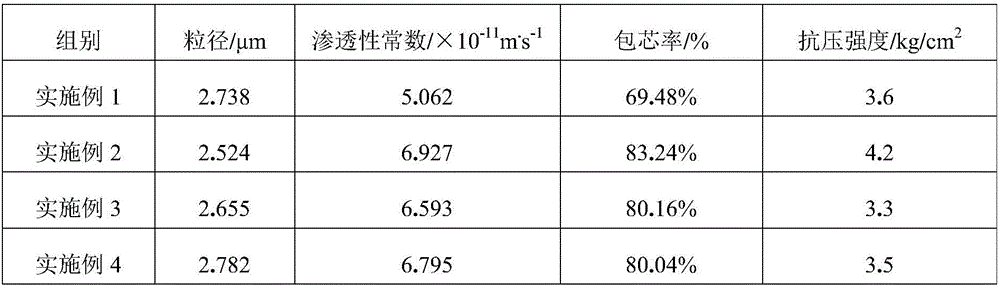

Dispersive dye microcapsule and preparation method thereof

ActiveCN107523094ADecentralized advantageRealize quantitative deliveryOrganic dyesHardnessTextile dyeing

The invention belongs to the field of textile dyeing and printing, and particularly relates to a dispersive dye microcapsule. The dispersive dye microcapsule is prepared from the following components in parts by weight: dispersive dye, wall material and dispersant according to a weight ratio of 1:(2 to 8):(0.6 to 2); the wall material is prepared from polyurethane and bacterial cellulose according to a weight ratio of 1:(0.3 to 0.9). The dispersive dye microcapsule has the advantages that the dispersive dye microcapsule can be quantitatively fed, the labor intensity is decreased, the enough hardness and mechanical strength are realized, the core coating rate is high, the preparation cost is low, the operation is simple and convenient, the pollution is little, and the dispersive dye microcapsule is suitable for being widely popularized and applied.

Owner:JIANGSU NEW REBA TECH CO LTD

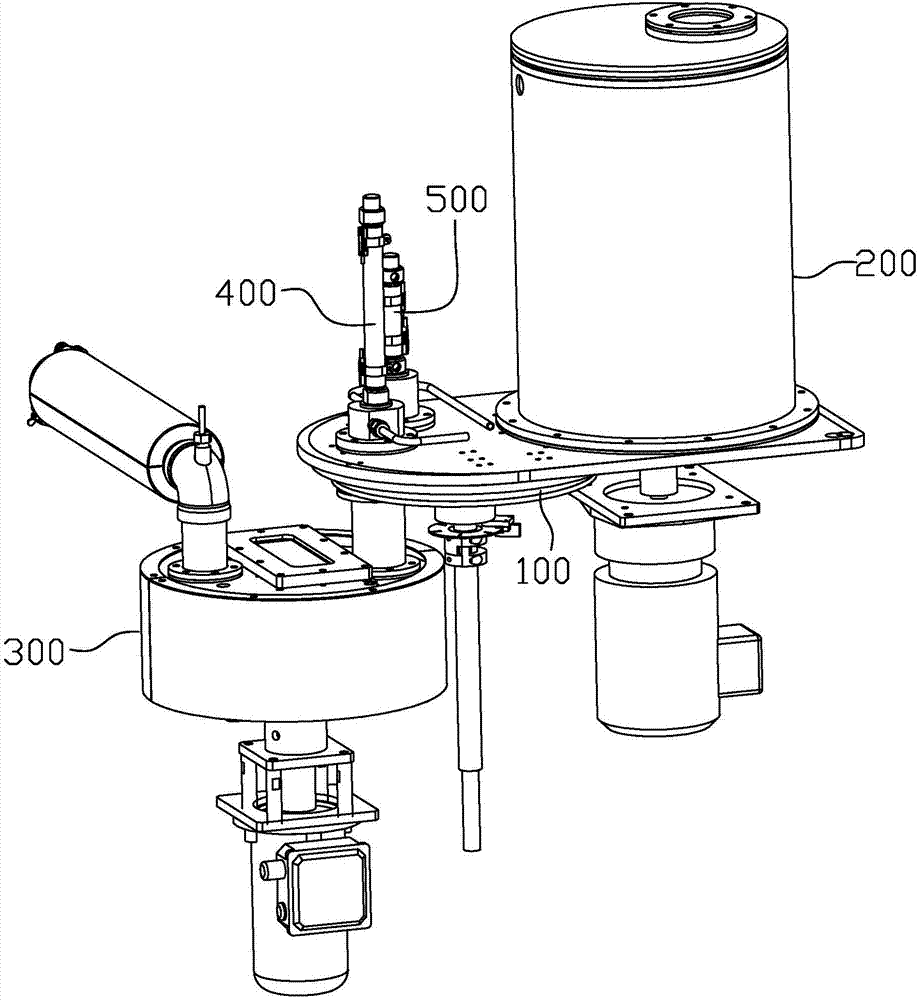

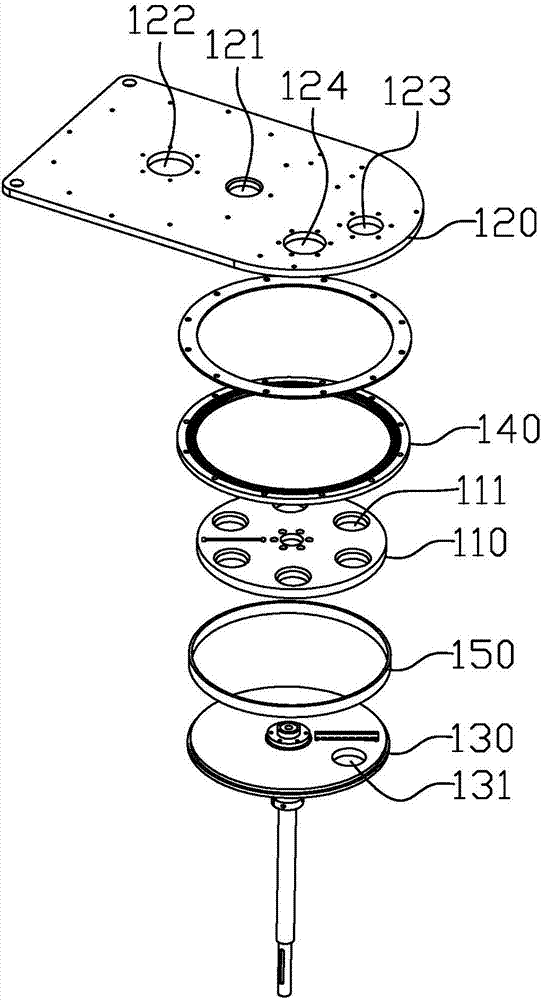

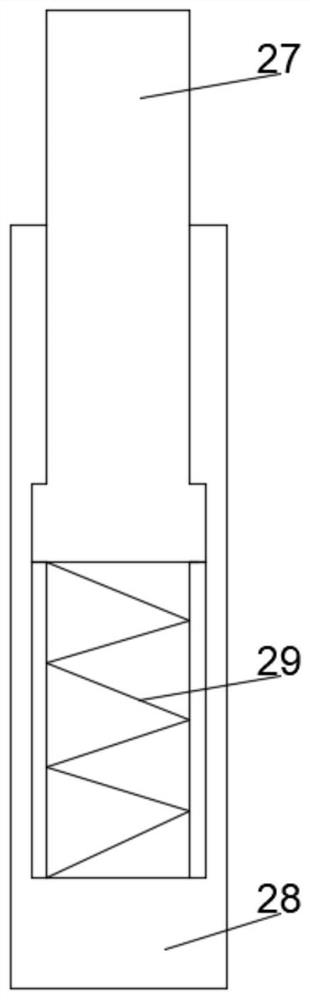

Quantitative liquid transfer device

PendingCN109967151AQuantitative extractionRealize quantitative deliveryBurettes/pipettesFluid controllersEngineeringLiquid transfer

The invention relates to a quantitative liquid transfer device. The quantitative liquid transfer device comprises a rotating reagent tray, a third chamber, a third flow channel, a plurality of liquidconveying structures and a fourth chamber, wherein the liquid conveying structures comprise first chambers, second chambers and diameter varying chambers, and the inner diameters of the diameter varying chambers are greater than that of a first flow channel to form capillary tube passive valves; when the rotating reagent tray rotates, liquid located in the third chamber flows out through the thirdflow channel under the action of the centrifugal force, then the first chambers of the liquid conveying structures are filled with the liquid in sequence, the excess liquid enters the fourth chamber;when the rotation speed of the rotating reagent tray is controlled to be lower, due to the action of the capillary tube passive valve, the liquid stays in the first chambers and cannot enter the second chambers, when the rotation speed is increased, the centrifugal force in the first chambers is increased, the liquid breaks through the limitation of the capillary tube passive valves and enters the second chambers; by adjusting the sizes of the first chambers, it can be achieved that the liquid is taken out quantitatively and conveyed into the second chambers, and quantitative conveying of theliquid is achieved.

Owner:DEMODE SUZHOU MACHINERY TECH CO LTD

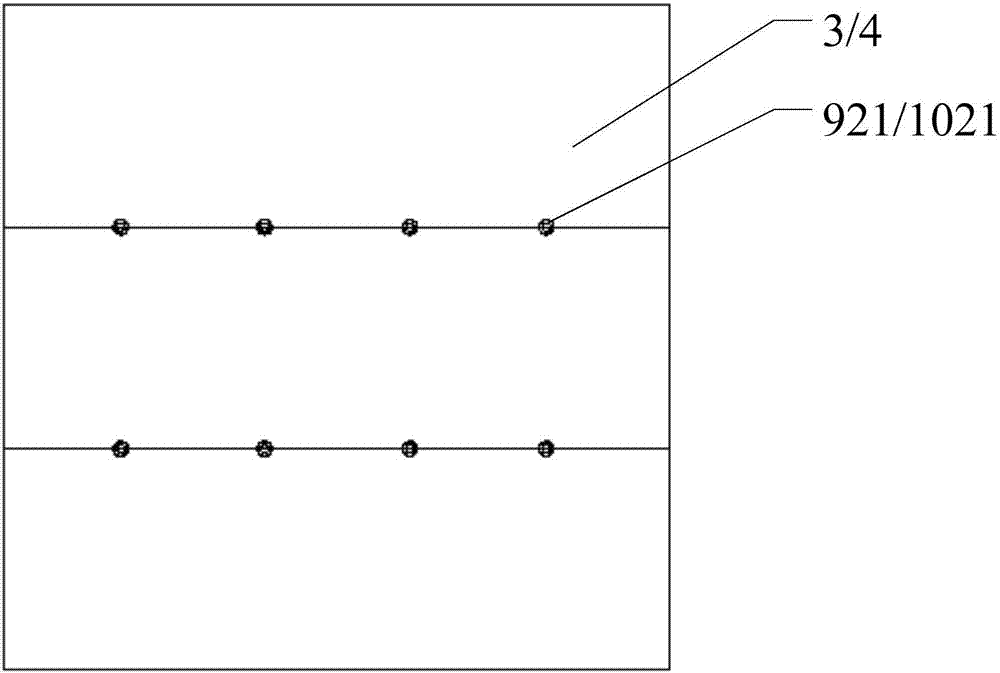

Quantitative conveying mechanism and catalysis degreasing furnace

PendingCN106986197ARealize quantitative deliveryReduce production and maintenance costsConveyorsRotary stirring mixersReciprocating motionEngineering

The invention relates to the field of automatic devices, and discloses a quantitative conveying mechanism and a catalysis degreasing furnace. The quantitative conveying mechanism comprises a feed plate, a top plate and a bottom plate, wherein the top plate and the bottom plate are arranged on the upper side and the lower side of the feed plate correspondingly. Feed grooves are formed in the feed plate. A feed port is formed in the top plate. A discharge port is formed in the bottom plate. The feed plate can move relative to the top plate and the bottom plate. When each feed groove passes by the feed port, materials enter the feed groove from the feed port and make the feed groove full filled with the materials, and when each feed groove passes by the discharge port, the materials in the feed groove are discharged through the discharge port. According to the quantitative conveying mechanism and the catalysis degreasing furnace, by means of reciprocating of the feed plate, provided with the fixed-volume feed grooves, between the feed port and the discharge port, quantitative conveying of the materials can be achieved, no complex control systems or automatic mechanisms need to be used, and therefore the production and maintenance cost of the device is greatly reduced; and meanwhile, conveying of oxalic acid is achieved through the mechanical structure, compressed air does not need to be used as power, and therefore safety accidents can be effectively avoided.

Owner:SHENZHEN SINTERZONE TECH CO LTD

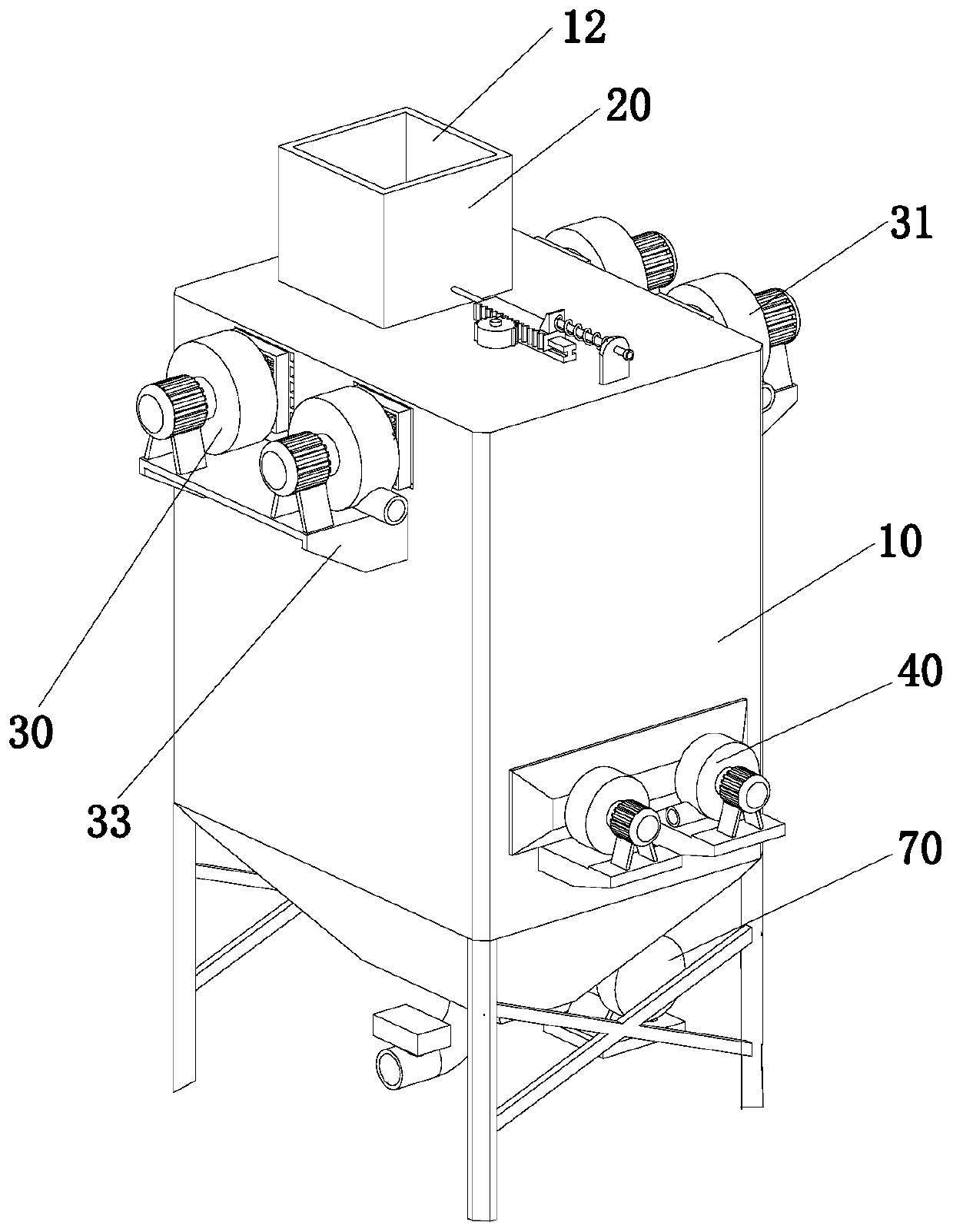

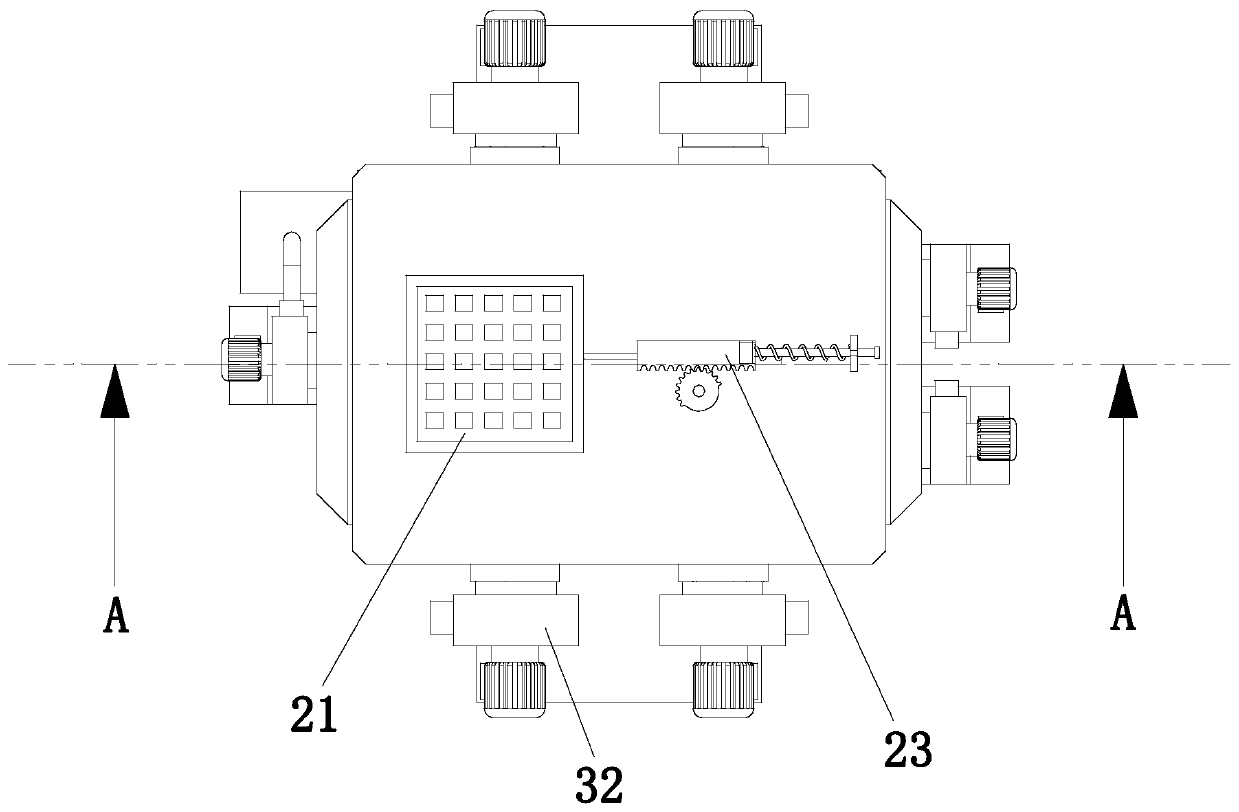

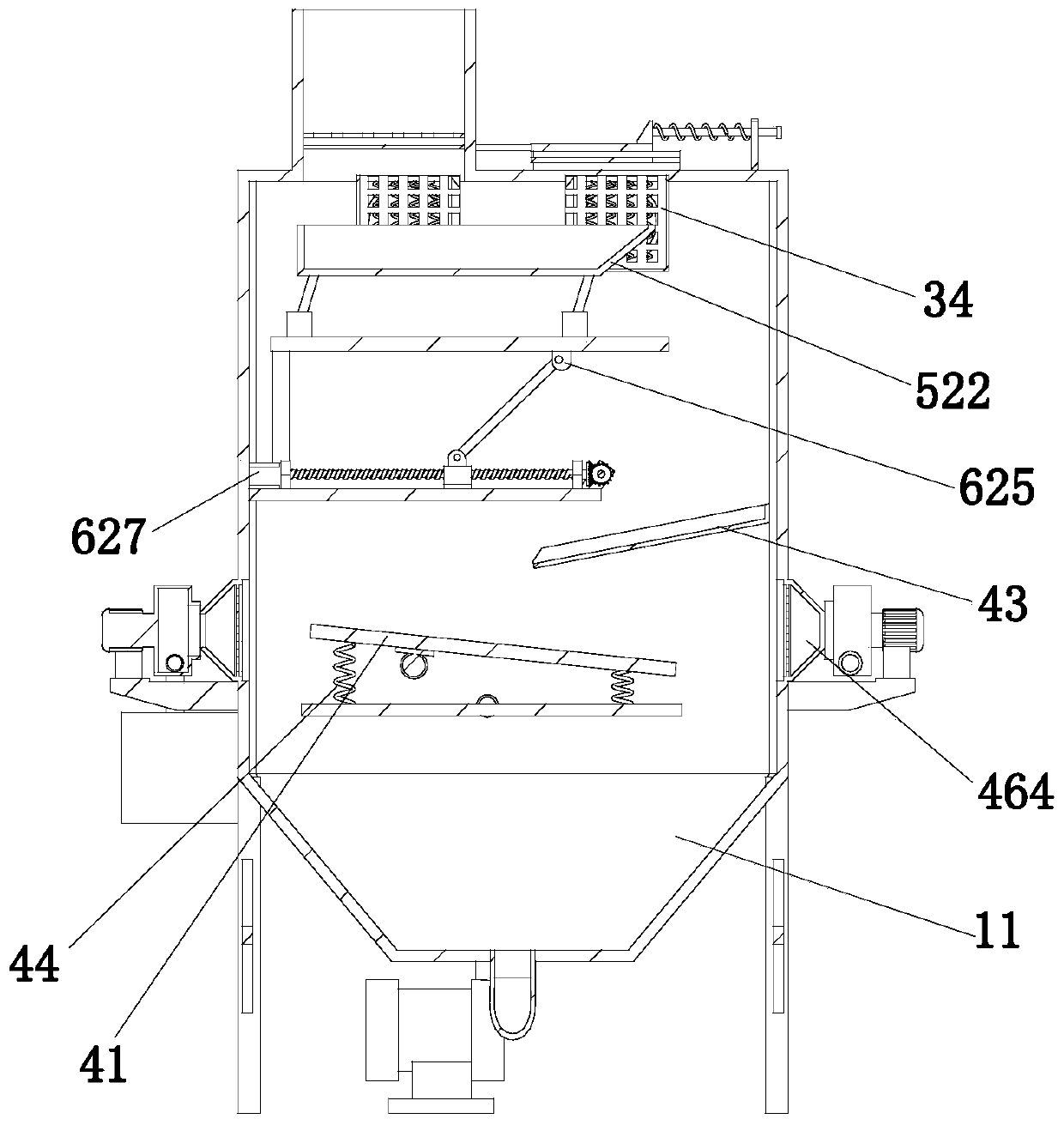

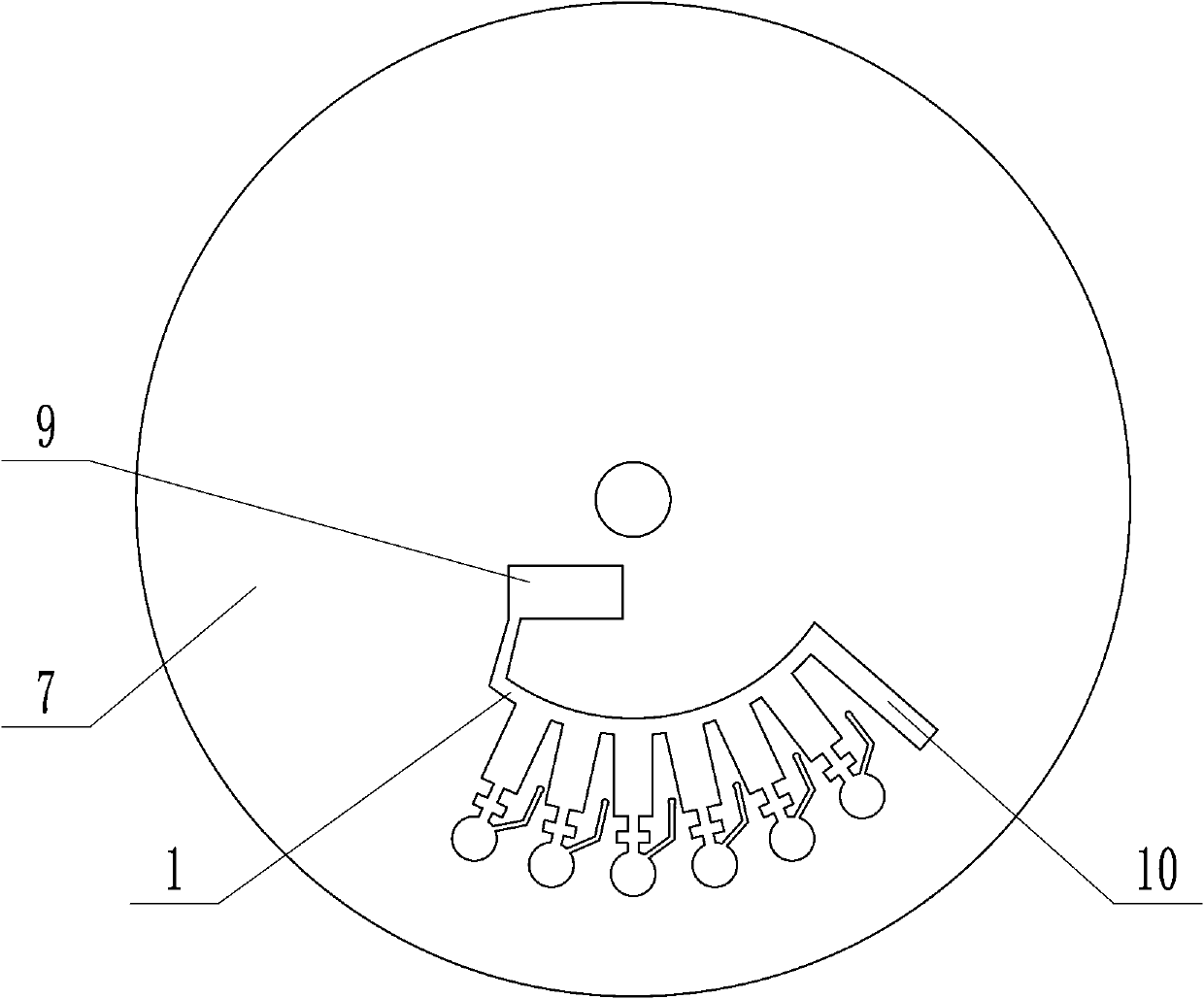

Hulling and polishing machine with quantitative conveying capacity function for rice processing

InactiveCN111729712AEffective shellingEfficient polishingGrain huskingGrain polishingProcess engineeringMechanical engineering

The invention discloses a hulling and polishing machine with quantitative conveying capacity function for rice processing. The hulling and polishing machine comprises a treatment box, wherein a quantitative conveying assembly is arranged in the center of the top of the treatment box; an air inlet is formed in one side of the top of the treatment box, and a hulling assembly is arranged in the center of the interior of the treatment box; a uniform material applying assembly is arranged at the position, located over the hulling assembly, in the treatment box; a polishing assembly is arranged at the position, located under the hulling assembly, in the treatment box; and a filter screen is obliquely arranged at the position, located under the polishing assembly, in the treatment box, and the side wall of the filter screen is attached to the side wall in the treatment box. Through the arrangement of the quantitative conveying assembly, quantitative conveying in the rice hulling and polishingprocess is achieved, and the quantitative conveying assembly is matched with the uniform material applying assembly, so that quantitatively conveyed rice is evenly scattered in an extrusion area of an extrusion roller, and the probability of breakage in the rice hulling process is greatly reduced.

Owner:梧州青弧农业有限公司

Liquid delivery device and clothes handling equipment with same

PendingCN106868798ARealize quantitative deliveryImprove the delivery effectOther washing machinesTextiles and paperBiomedical engineeringElectrical and Electronics engineering

The invention discloses a liquid delivery device and clothes handling equipment with the same. The liquid delivery device comprises a delivery box. A delivery cavity is defined in the delivery box. The delivery cavity comprises an liquid inlet and a liquid outlet. A liquid storage cavity is defined in a liquid storage box. A communicating hole communicated with the delivery cavity is formed in the liquid storage box. A siphoning device is arranged in the delivery cavity and provided with a siphoning channel. A siphoning inlet of the siphoning channel is communicated with the delivery cavity. The siphoning outlet of the siphoning channel is communicated with a liquid outlet. The siphoning inlet is located at the lowermost position of the liquid storage cavity. The through-flow area of the communicating hole is smaller than the through-flow area of the siphoning channel. In the vertical direction, the communicating hole is higher than the siphoning inlet and lower than a bending high point of the siphoning channel. The liquid delivery device can achieve quantitative delivery with good delivery effect, and can attain the effect of taking cost and delivery precision into consideration simultaneously.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Crushing and recycling equipment for solid garbage

ActiveCN109847835AAvoid the problem of difficult burning affecting the subsequent burning rateRealize quantitative deliveryMagnetic separationGrain treatmentsEngineeringConstruction waste

The invention relates to the technical field of garbage treatment equipment, and discloses crushing and recycling equipment for solid garbage. The crushing and recycling equipment comprises a dust separation box. A supporting plate is fixedly mounted in the middle of an inner cavity of the dust separation box. A filter screen is fixedly mounted in the middle of the supporting plate. A vibration plate is fixedly mounted at the bottom of the bottom face of the filter screen. Mounting grooves are formed in the left side face of the vibration plate. Fixed blocks are fixedly mounted at the left endand the right end in each mounting groove. According to the crushing and recycling equipment for the solid garbage, due to the fact that concrete is in powder shapes after being crushed, the filter screen is arranged for screening, building garbage is screened out from the solid garbage; meanwhile, a rotating block is arranged to intermittently stirring the vibration plate to vibrate, so that thefilter screen vibrates, therefore, the problem that hole parts of the filter screen are blocked due to powder is avoided, the whole screening efficiency is increased, and the problem that subsequentwaste residue treatment difficulty is increased due to the fact that the building waste cannot be combusted is avoided.

Owner:山东国晟环境科技有限公司

Method for preparing functional yoghourt capable of reducing blood fat through fermentation of lactobacillus paracasei

ActiveCN112616919AAutomate implementation operationsIncrease productivityMilk preparationBiotechnologyLactic acid bacterium

The invention relates to a method for preparing functional yoghourt capable of reducing blood fat through fermentation of lactobacillus paracasei, and belongs to the technical field of yoghourt preparation. The functional yoghourt is characterized by being prepared from the following raw materials in parts by weight: 1 part of lactobacillus paracasei, 1 part of yoghourt lactic acid bacteria, 100 parts of milk and 8 parts of white granulated sugar. The method comprises the following steps of: heating milk to 60 DEG C in a fermentation premixing device in a waterproof heating manner, adding the white granulated sugar, heating to 95 DEG C after the white granulated sugar is fully dissolved, staying for 5 minutes under the temperature condition, and cooling to 43 DEG C; and putting the mixture in the fermentation premixing device into a fermentation device, adding the lactobacillus paracasei and the yoghourt lactic acid bacteria into the fermentation device through a quantitative feeder, performing static fermentation for 8-10 hours, and performing packaging. According to the invention, due to scientific proportioning and process, lactobacillus casei is used for fermentation to prepare the functional yoghourt capable of reducing blood fat; in addition, by improving equipment for fermentation preparation, automatic implementation operation of fermentation operation can be achieved; and the production efficiency and the yield are improved.

Owner:山东悠乐滋生物科技有限公司

Quantitative putting-in bottle

InactiveCN103625785AEasy to use quantitativelyRealize quantitative deliveryPowdered material dispensingEngineeringControl room

The invention discloses a quantitative putting-in bottle. The quantitative putting-in bottle comprises a bottle body (1) and a bottle cap (2) and further comprises a communication base (3), wherein the bottom surface of the communication base is provided with an opening connection port (4), the top surface of the communication base is provided with a bottle cap connection port (5), a material channel communicated with the opening connection port and the bottle cap connection port is formed in the communication base and comprises a bottle side material channel (6), the bottom end of the bottle side material channel (6) is communicated with the opening connection port, and the top end of the bottle side material channel (6) stretches to the middle portion of the communication base. The quantitative putting-in bottle further comprises a cap side material channel (7) and a material flowing control chamber (8), wherein the top end of the cap side material channel (7) is communicated with the bottle cap connection port, the bottom end of the cap side material channel (7) stretches above the middle portion of the communication base, the material flowing control chamber (8) is arranged on the middle portion of the communication base, the material flowing control chamber (8) is communicated with the top end of the bottle side material channel downwards and is communicated with the bottom end of the cap side material channel upwards, a material flowing control valve (9) is arranged in the material flowing control chamber (8), and the communication base is provided with a valve control device used for controlling the material flowing control valve. According to the quantitative putting-in bottle, contained material can be taken quantitatively and conveniently, the contained material can be effectively prevented from being polluted by bacteria and moisture, and the quantitative putting-in bottle is economical and practical.

Owner:龚振杰

Aroma enhancement tobacco stem microwave expansion system and method

ActiveCN106820247AEfficient removalRealize quantitative deliveryTobacco treatmentMicrowaveEngineering

The invention relates to an aroma enhancement tobacco stem microwave expansion system and method and belongs to the technical field of tobacco processing. The system comprises, sequentially from a feeding end to a discharging end, a screening machine, a first conveyer, a measuring and conveying scale, a second conveyer, a pneumatic conveying pipe, a gas and solid separating blanking device, a heating and humidifying conveyer, a feeding cross-port blanking device, a microwave expansion device, a discharging cross-port blanking device and a third conveyer. The aroma enhancement tobacco stem microwave expansion system can effectively eliminate impurities from tobacco stems, achieves quantitative tobacco stem conveying; after being heated and humidified, the tobacco stems are conveyed into the microwave expansion device and kept at 140-220 DEG C for 2-10 min to enhance aroma, meanwhile, a ceramic tube is ventilated at a volume of 1000-2200 m3 / h to eliminate green stems, wood gas and moisture from the tobacco stems and further to obtain microwave-expanded tobacco stems high in quality and rich in aroma. The aroma enhancement tobacco stem microwave expansion system is reasonable and effective, and the aroma enhancement tobacco stem microwave expansion method is thorough and can increase the mixing quantity of the tobacco stem in cigarettes, save tobacco resources and reduce the production cost.

Owner:KUNMING XUBANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com