Method for preparing functional yoghourt capable of reducing blood fat through fermentation of lactobacillus paracasei

A technology of Lactobacillus and para-cheese, applied in Lactobacillus, bacteria used in food preparation, dairy products, etc., can solve problems such as low production efficiency, unreachable equipment and environment, and reduction of beneficial ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for preparing hypolipidemic functional yoghurt by fermentation of Lactobacillus paracasei, which is prepared from the following raw materials, and the parts are parts by weight:

[0065] 1 part Lactobacillus paracasei;

[0066] 1 part yogurt lactic acid bacteria;

[0067] 100 parts of milk;

[0068] 8 parts white sugar;

[0069] In the fermentation premixing device, heat the milk to 60 degrees Celsius by means of water-proof heating, add white granulated sugar, dissolve it fully and then raise it to 95 degrees Celsius, stay at this temperature for five minutes, and then drop it to 43 degrees Celsius; Put the mixture in the device into the fermentation device, add Lactobacillus paracasei and yoghurt lactic acid bacteria into the fermentation device through a quantitative feeder, ferment statically for 8 to 10 hours, and then pack it.

[0070] The yogurt lactic acid bacteria include the following components in parts by weight: Lactobacillus bulgaricus and Stre...

Embodiment 2

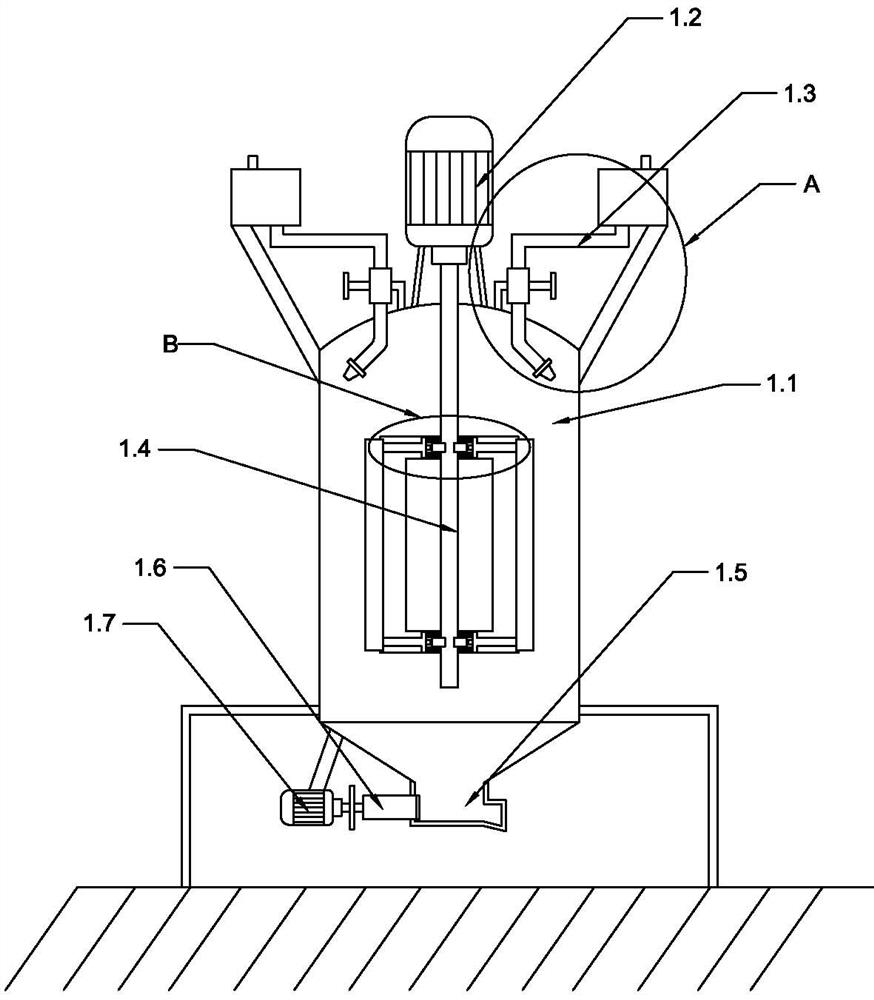

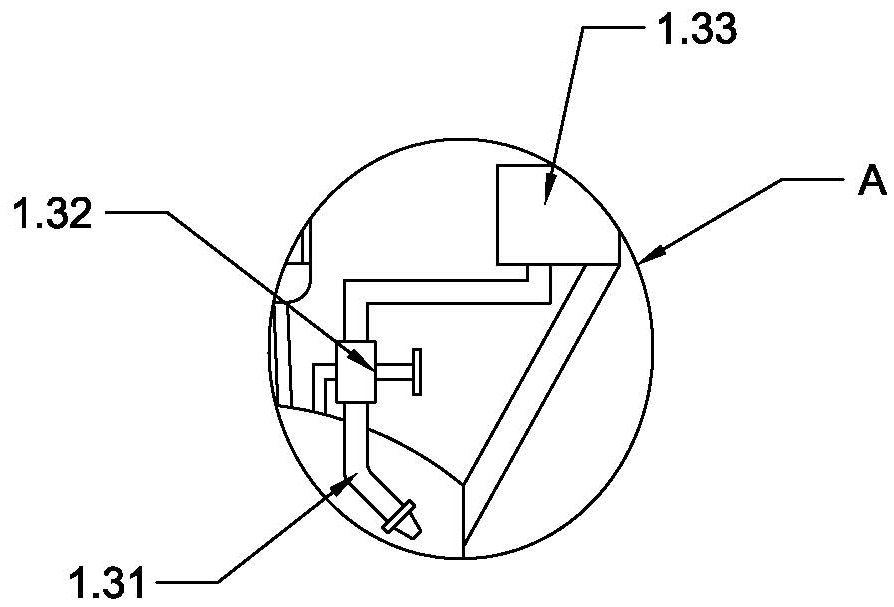

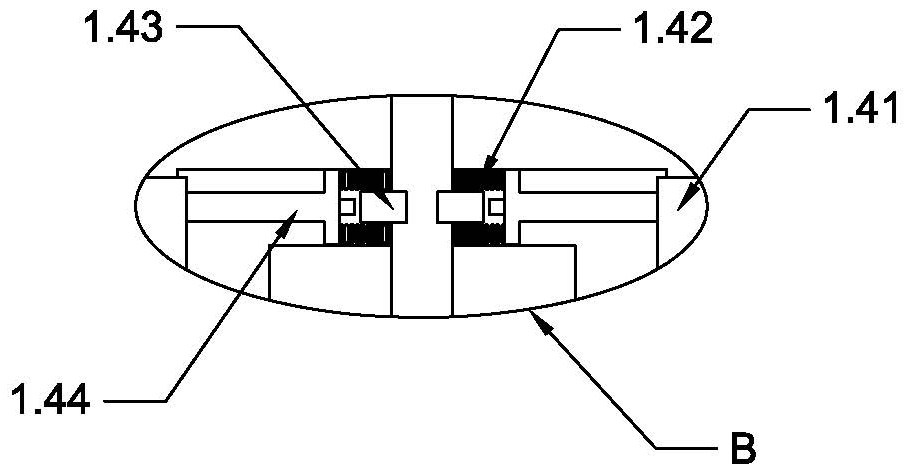

[0074] Such as Figure 1-4 As shown, the fermentation premixing device includes a fermentation premixing tank shell and a feeding device. A hollow water heating interlayer is arranged in the fermentation premixing tank shell, and a water bath heating coil is spirally coiled in the water heating interlayer. Flowing heating circulating water is passed into the heating coil; a through hole is provided at the center of the upper surface of the fermentation premix tank, and a stirring paddle motor is provided directly above the through hole, and the stirring paddle motor is fixed on the fermentation premixing tank through a bracket. On the upper surface of the tank shell, there are feeding devices on both sides of the stirring paddle motor. The feeding device and the stirring paddle motor are on the same straight line. The through hole at the center of the upper surface of the shell is connected to the through hole through a sealed bearing, the lower end is located in the shell of ...

Embodiment 3

[0081] Such as Figure 5-6 As shown, the fermentation device includes a fermenter shell, and several hollow constant temperature heating rods are arranged in the fermenter shell, and a heating interlayer is arranged in the fermenter shell, and heating water or heating is passed into the heating interlayer and the hollow constant temperature heating rods. Steam; a temperature sensor is set on the inner wall of the fermenter shell; the fermenter shell is in the shape of a cylinder with an open upper end, and a sealed tank cover is arranged at the upper end of the fermenter shell, and the sealed tank cover includes an upper cover plate, a middle cover plate and the lower cover, several sets of one-to-one corresponding upper ventilation holes and lower ventilation holes are vertically set on the upper cover and the lower cover; the middle ventilation holes are set on the middle cover, and the rotating shaft is installed in the middle of the middle cover. The threaded shaft passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com