Coke oven intelligent masonry machine and coke oven continuous masonry process

A coke oven and intelligent technology, which is applied in the field of coke oven intelligent masonry machine and coke oven continuous masonry technology, can solve the problems of manpower consumption and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

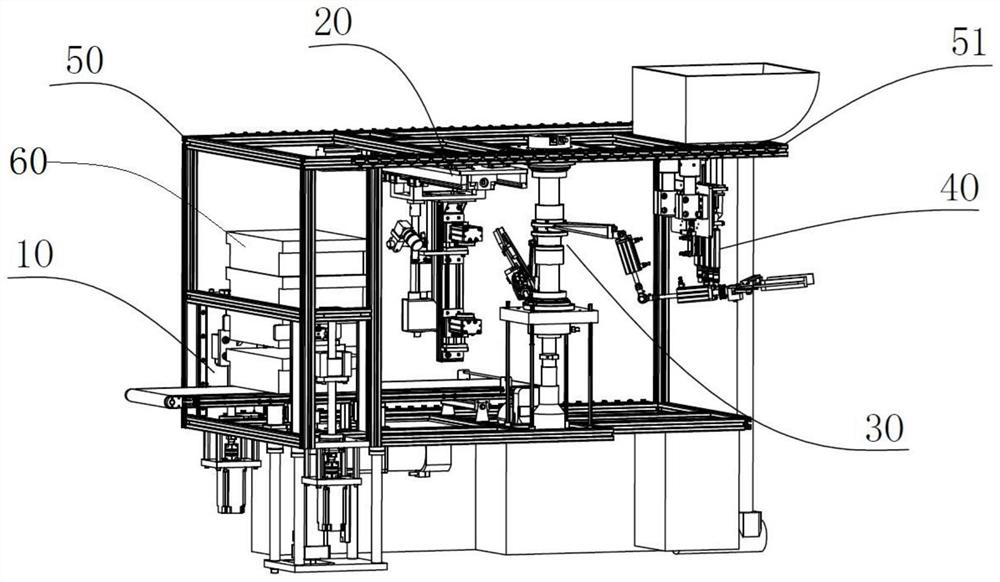

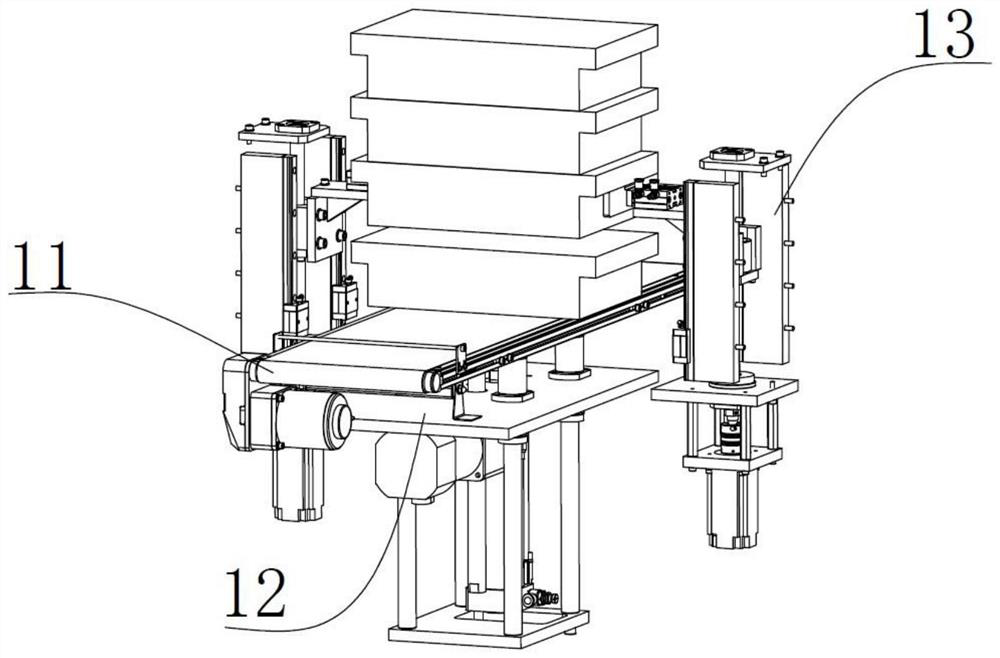

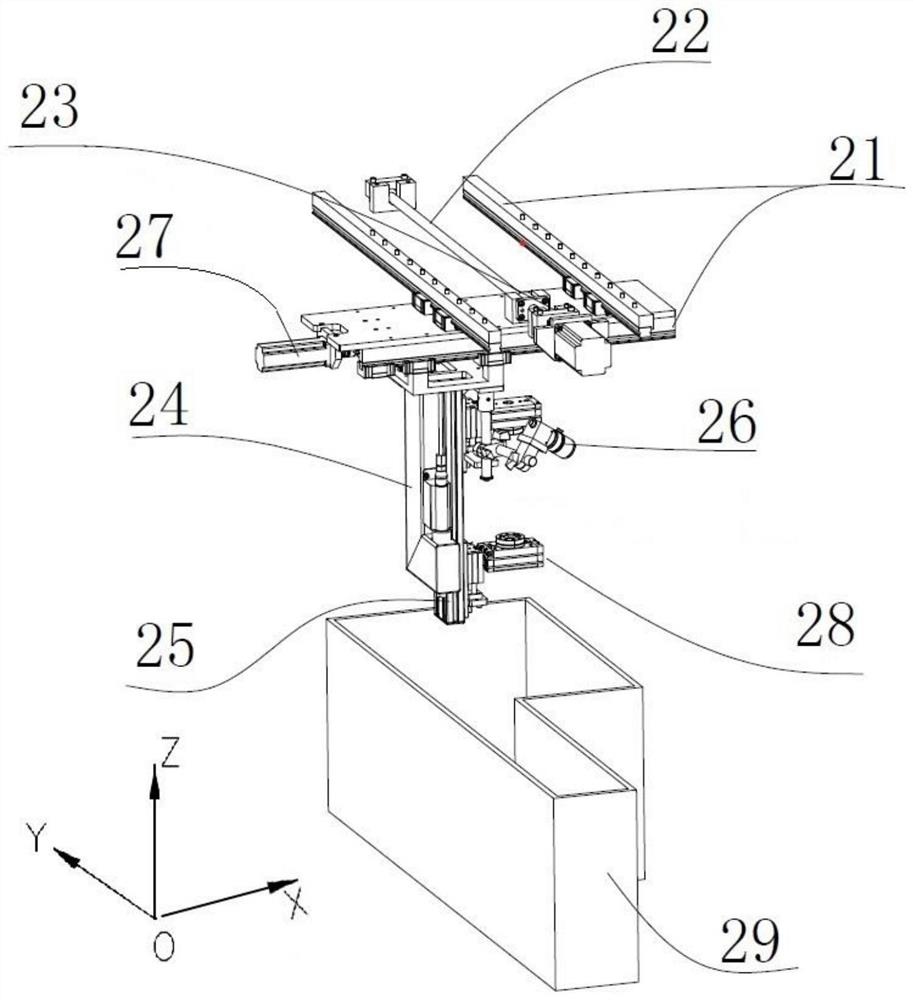

[0048] like Figure 1-Figure 5 As shown in the figure, a coke oven intelligent masonry machine according to the present invention includes a block conveying unit 10, a cutting unit 20, a manipulator 30 and a mortar spraying unit 40 that are integrated into one through a fixed bracket 50; the block conveying unit 10 A belt conveyor 11 and a clamping mechanism 13 are provided. One end of the belt conveyor 11 is the block receiving end, and the other end extends to the cutting unit 20. The two sides of the belt conveyor 11 at the block receiving end are respectively provided with clamping mechanisms 13; the cutting unit 20 A vertical and horizontal sliding mechanism, a vertical sliding rail, a cooling medium generator 24, an infrared transmitter 26 and a cutting mechanism 28 are provided. The vertical sliding rail 25, the cooling medium generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com