Glass fiber quantitative conveyer

A glass fiber and conveyor technology, used in fiber processing, fiber feeding, textiles and papermaking, etc., can solve the problems of difficult automatic quantitative conveying, glass fiber lack of fluidity, difficult automatic quantitative conveying, etc., and achieves novel structure, The effect of reducing manpower and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

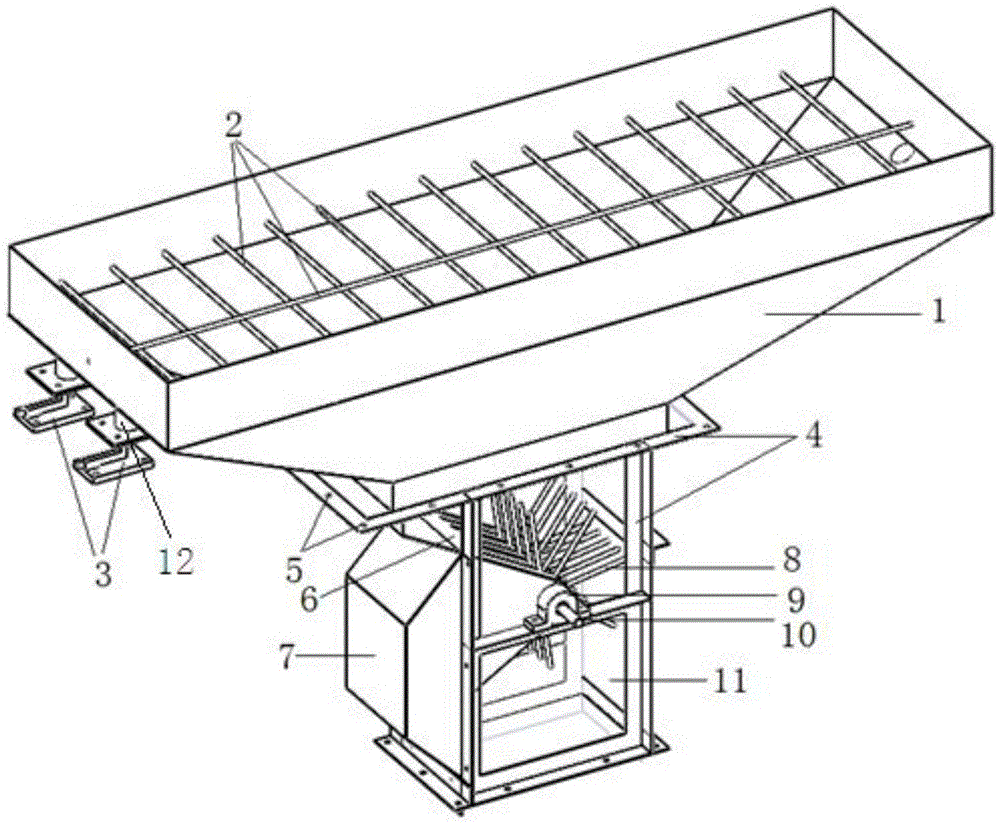

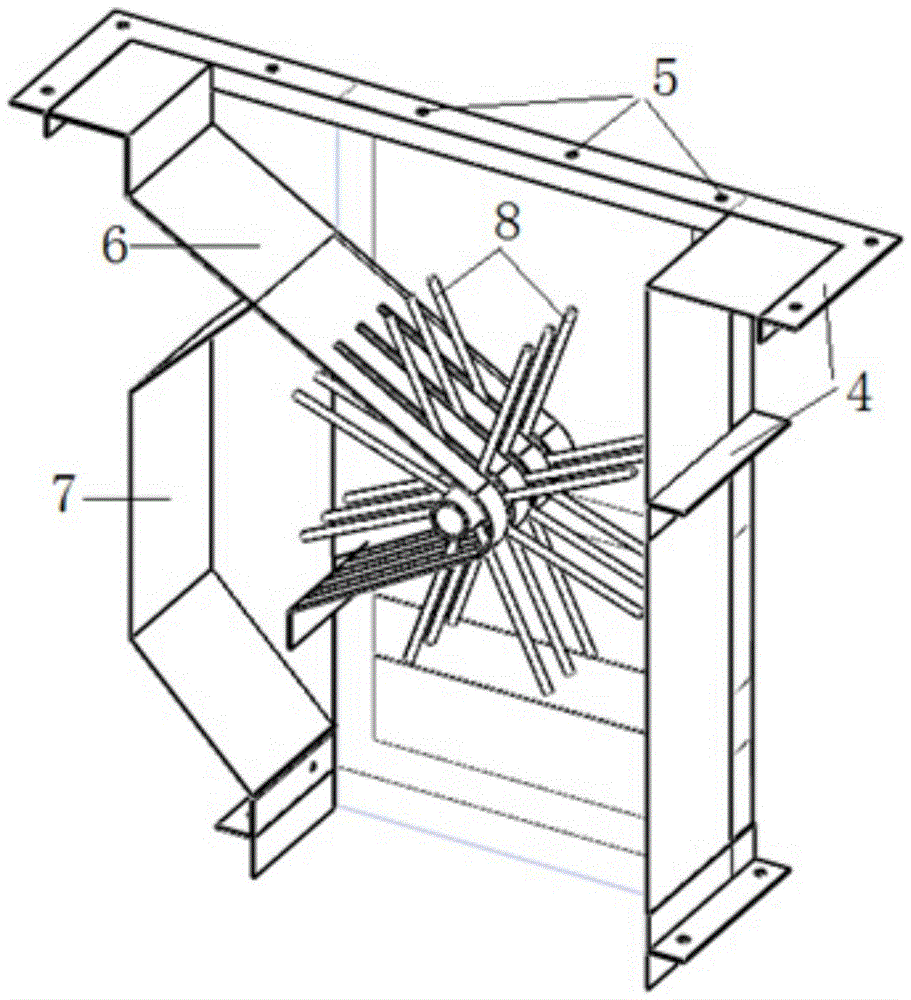

[0018] As shown in the accompanying drawings, the present invention includes: a hopper 1, an angle steel frame 4, an attached plate 6, a shifting roller 8 and a shifting shaft 10, the entrance of the hopper 1 is equipped with a fence 2 for preliminary combing of glass fiber feeding, The outlet at the bottom of the hopper 1 is equipped with an angle steel frame 4, the hopper 1 is fixedly connected with the angle steel frame 4 through bolts 5, and the angle steel frame 4 is sealed with a left attachment plate 7 and a panel 11 around the angle steel frame 4, and an inner attachment plate 6 is installed inside the angle steel frame 4 And the shifting roller 8, the inner attachment plate 6 is a horizontal V-shaped structure, the inner attachment plate 6 is fixed on the angle steel frame 4, the shifting roller 8 is installed on the shifting shaft 10, and the shifting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com