Quantitative liquid transfer device

A technology for transferring devices and liquids, which can be used in fluid controllers, measuring tubes/pipettes, laboratory utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

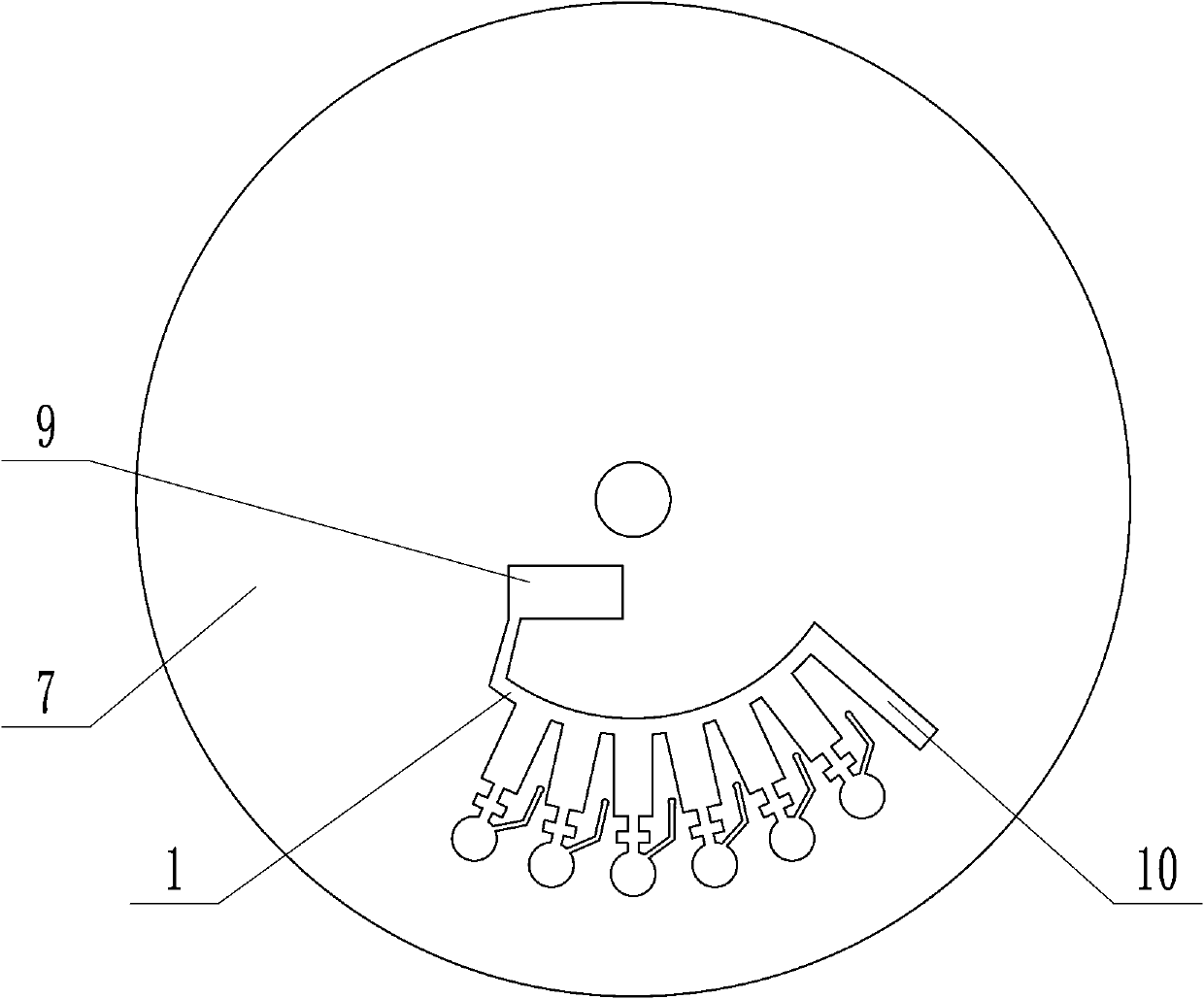

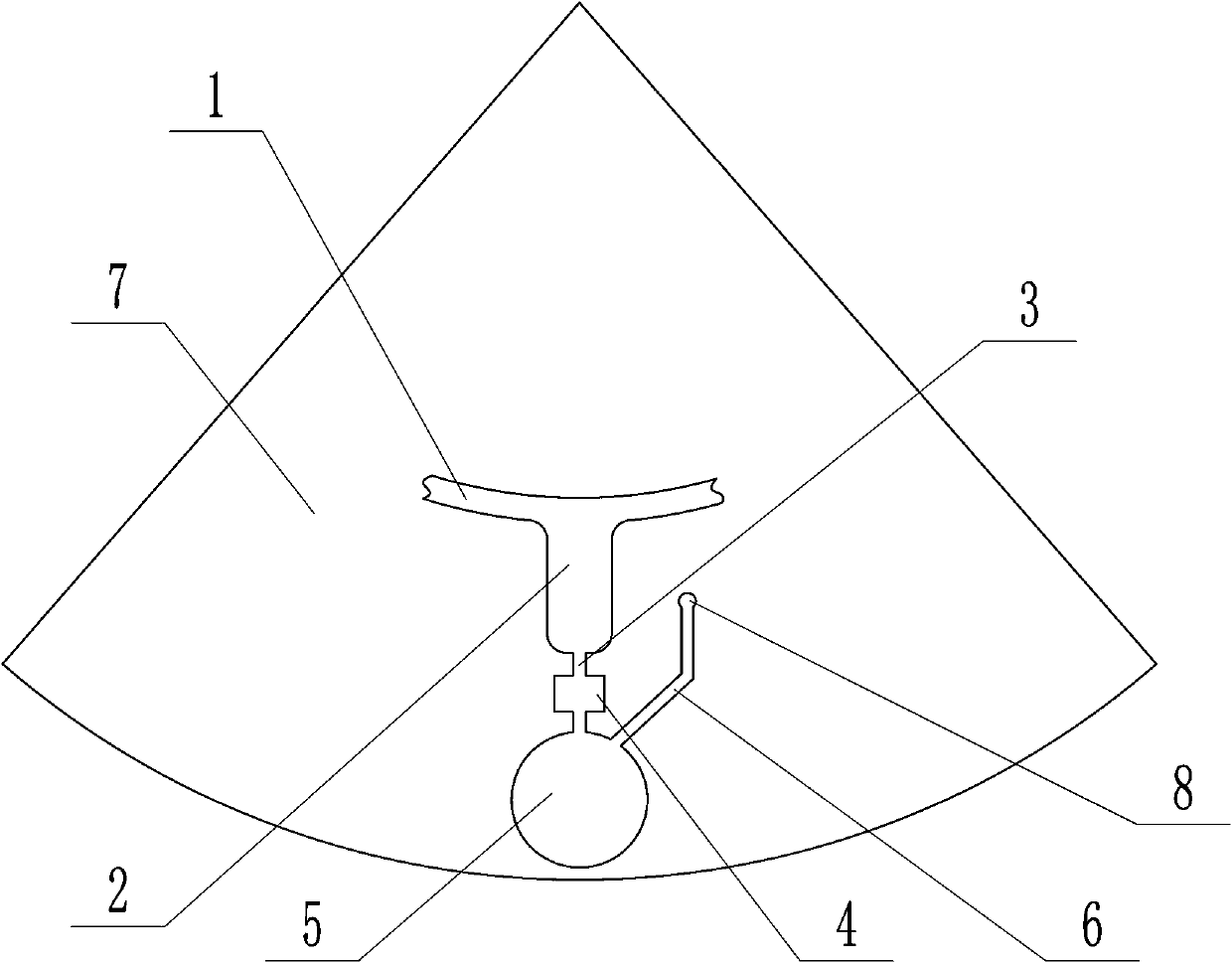

[0016] Embodiment 1: as attached figure 1 , 2 As shown, the present invention includes a rotating reagent disk 7, a third chamber 9 arranged on the rotating reagent disk 7, a third flow channel 1 communicated with the third chamber 9, and several liquid delivery channels communicated with the third flow channel 1 structure and the fourth chamber 10 arranged at the end of the third channel 1 . The first chambers 2 of the plurality of liquid delivery structures are at the same distance from the rotation axis of the rotating reagent disk 7 . The third chamber 9, the third flow channel 1, and the liquid delivery structure are set outwards in sequence relative to the rotation axis of the reagent disk. When the rotating reagent disk 7 rotates, the liquid in the third chamber 9 enters the liquid through the third flow channel 1. The delivery structure, when all the first chambers 2 of the liquid delivery structure are filled, the remaining liquid enters the fourth chamber 10 .

[...

Embodiment 2

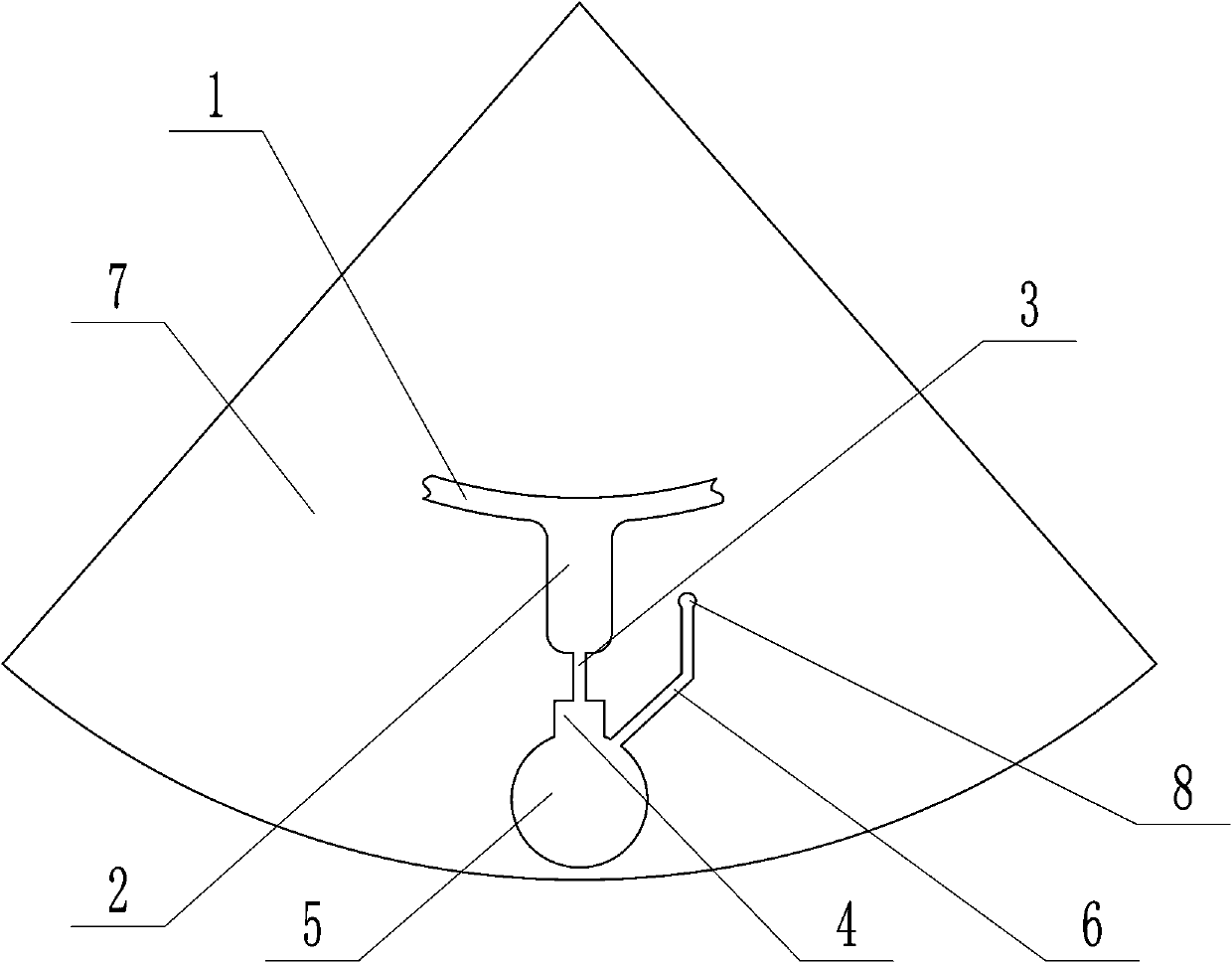

[0020] Embodiment 2: as attached image 3 As shown, on the basis of Embodiment 1, keep other structures unchanged, only change the position of the variable diameter chamber 4, and make the variable diameter chamber 4 connect with the second chamber 5 to form a chamber, and the embodiment can also be realized 1 effect.

[0021] When the present invention is in use, an appropriate amount of liquid is first added to the third chamber, and the rotating reagent disk rotates at a speed lower than a certain speed threshold. In this case, the liquid entering the first chamber 2 will not open the capillary passive valve, When the rotational speed is higher than the threshold, the liquid in the first chamber 2 will open the capillary passive valve, and the liquid will enter the second chamber 5 . In the case of low speed, the liquid in the third chamber 9 is thrown out into the third flow channel 1, and then transported forward along the third flow channel 1, and then enters into multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com