Dispersive dye microcapsule and preparation method thereof

A disperse dye and microcapsule technology, applied in the field of textile printing and dyeing, can solve the problems of low core-encapsulation rate, no mechanical strength and hardness, and increased cost of disperse dye microcapsules, and achieve low pollution, low manufacturing cost, and high core-encapsulation rate. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

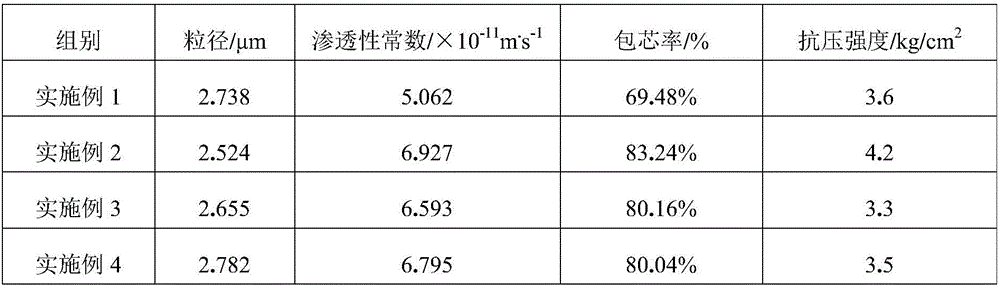

Embodiment 1

[0029] Embodiment 1, a kind of disperse dye microcapsule

[0030] The disperse dye microcapsule described in Example 1 of the present invention is made up of the following components by weight: the weight ratio of described disperse dye, wall material and dispersant is 1:5:1, and described wall material is made of polyurethane and bacterial fiber The element is composed at a weight ratio of 1:0.3, wherein the dispersant is composed of citric acid and calcium hydrogen phosphate at a weight ratio of 1:0.2.

[0031] Preparation:

[0032] A) Mix the disperse dye with an appropriate amount of distilled water, emulsify, stir for 10 minutes, add 1 / 3 of the wall material dropwise, raise the temperature to 50°C, keep warm for 1 hour, add the dispersant, stir for 5 minutes, cool down to room temperature, and perform single-layer wall building;

[0033] B) Continue to add the remaining wall material dropwise, raise the temperature to 60°C, keep it warm for 1 hour, then lower it to room ...

Embodiment 2

[0034] Embodiment 2, a kind of disperse dye microcapsule

[0035] The disperse dye microcapsules described in Example 2 of the present invention consist of the following components in parts by weight: the weight ratio of the disperse dye, wall material and dispersant is 1:6.5:1.3, and the wall material is made of polyurethane and bacterial fiber The element is composed at a weight ratio of 1:0.6, wherein the dispersant is composed of citric acid and calcium hydrogen phosphate at a weight ratio of 1:0.4.

[0036] Preparation:

[0037] A) Mix the disperse dye with an appropriate amount of distilled water, emulsify, stir for 15 minutes, add 1 / 3 of the wall material dropwise, raise the temperature to 60°C, keep warm for 2 hours, add the dispersant, and at the same time continue to pass the normal voltage current, stir for 8 minutes, and drop to At room temperature, perform single-layer wall construction and turn off the power;

[0038] B) Continue to add the remaining wall mater...

Embodiment 3

[0039] Embodiment 3, a kind of disperse dye microcapsule

[0040]The disperse dye microcapsules described in Example 3 of the present invention are made up of the following components in parts by weight: the weight ratio of the disperse dye, wall material and dispersant is 1:8:3, and the wall material is made of polyurethane and bacterial fiber The element is composed by a weight ratio of 1:0.9, wherein the dispersant is composed of citric acid and calcium hydrogen phosphate by a weight ratio of 1:0.6.

[0041] Preparation:

[0042] A) Mix the disperse dye with an appropriate amount of distilled water, emulsify, stir for 20 minutes, add 1 / 3 of the wall material dropwise, raise the temperature to 70°C, keep warm for 2 hours, add the dispersant, and at the same time continue to pass through the normal voltage current, stir for 12 minutes, and drop to At room temperature, perform single-layer wall construction and turn off the power;

[0043] B) Continue to add the remaining wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com