Silicon rubber compound added with modified nano calcium carbonate and preparing method thereof

A technology of nano-calcium carbonate and compound rubber, which is applied in the field of organic silicon materials, can solve the problems of increasing processing costs and increasing production processes, and achieve the effects of reducing raw material costs, improving demoulding pass rate, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

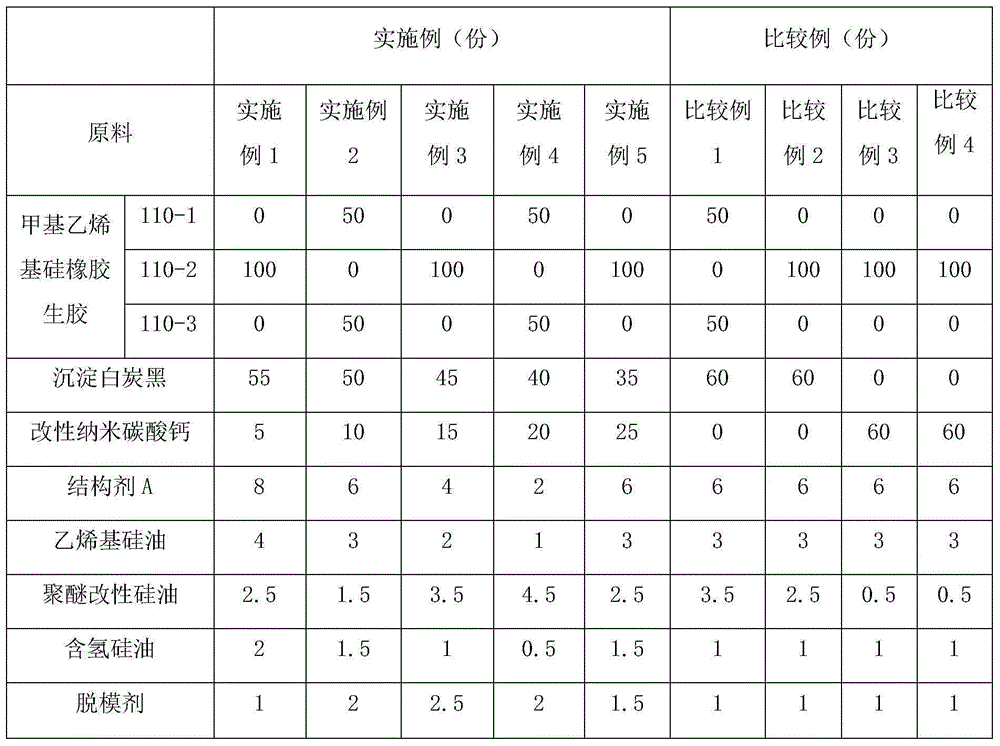

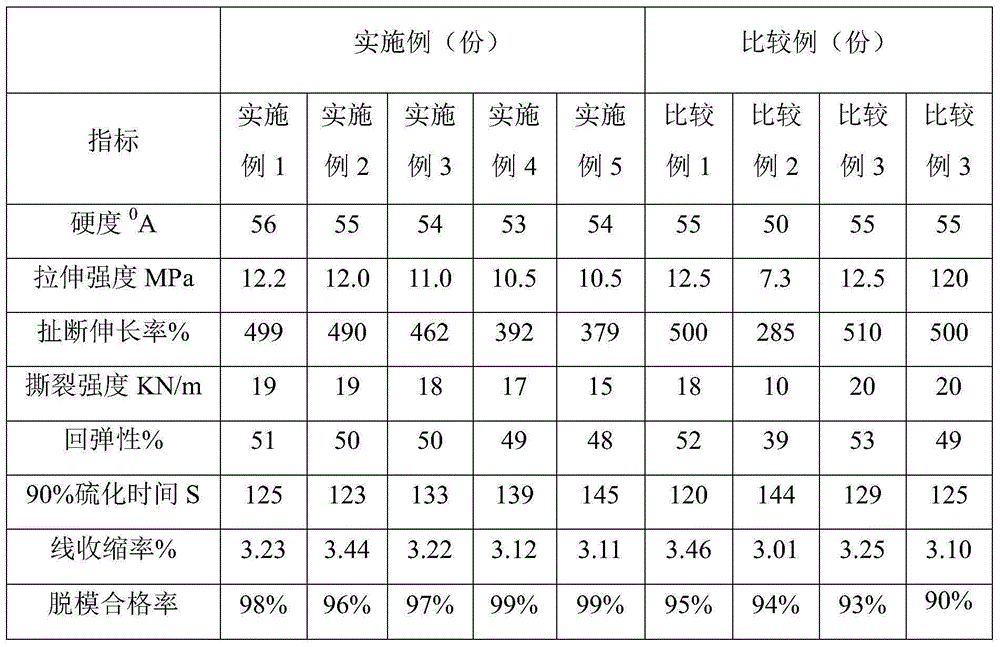

Embodiment 1

[0034] According to the composition ratio in Table 1, 100 parts of methyl vinyl silicone rubber raw rubber 110-2, 55 parts of precipitated silica, 5 parts of modified nano-calcium carbonate, 8 parts of hydroxyl silicone oil, 4 parts of vinyl Add silicone oil, 2.5 parts of polyether modified silicone oil, 0.5 parts of zinc stearate, and 0.5 parts of methyl silicone oil into the kneader. After kneading for 6 minutes, add 2 parts of hydrogen-containing silicone oil, and initially knead (50°C, speed 30r / min , 2h) After uniformity, high-temperature mixing for 1h (120°C, vacuum degree of -0.05MPa, 30r / min), and then opening the late stage of mixing for 0.5h (rotational speed 45r / min) and then discharging, cooling, re-milling, The rubber compound product can be obtained by filtering the rubber. Then vulcanize the sheet, test various properties, the product test results are shown in Table 3.

Embodiment 2

[0036] According to the composition ratio in Table 1, 50 parts of methyl vinyl silicone rubber raw rubber 110-1, 50 parts of methyl vinyl silicone rubber raw rubber 110-3, 50 parts of precipitated silica, 10 parts of modified Add nano-calcium carbonate, 6 parts of diphenylsilanediol, 3 parts of vinyl silicone oil, 1.5 parts of polyether modified silicone oil, and 1 part of methylphenyl silicone oil into the kneader. After mixing for 10 minutes, add 1.5 parts of hydrogen-containing Silicone oil, after preliminary mixing (50°C, speed 30r / min, 2h), after uniformity, high temperature mixing for 1h (120°C, vacuum degree -0.05MPa, 30r / min), and then open the cover and later mixing for 0.5h (speed 45r / min) after discharge, cooling, re-milling, and filtering the rubber to obtain the mixed rubber product. Then vulcanize the sheet, test various properties, the product test results are shown in Table 3.

Embodiment 3

[0038] According to the component ratio in Table 1, 100 parts of methyl vinyl silicone rubber raw rubber 110-2, 45 parts of precipitated white carbon black, 15 parts of modified nano calcium carbonate, 4 parts of hexamethyldisilazane , 2 parts of vinyl silicone oil, 3.5 parts of polyether modified silicone oil, 1.5 parts of liquid silicone rubber, and 0.5 parts of zinc stearate were added to the kneader, and after kneading for 8 minutes, 1 part of hydrogen-containing silicone oil was added for preliminary mixing (50°C, Rotational speed 30r / min, 2h) after uniformity, high temperature mixing 1h (120 ℃, vacuum degree -0.05MPa, 30r / min), and then open the cover later mixing 0.5h (rotational speed 45r / min) after discharge, after cooling , re-milling, and filtering the rubber to obtain the mixed rubber product. Then vulcanize the sheet, test various properties, the product test results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com