Sustainable discharging device for preparing rare earth electrolysis waste fused salt and implementation method thereof

A cutting and molten salt technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of affecting efficiency, molten salt agglomeration, reduction of solution contact area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

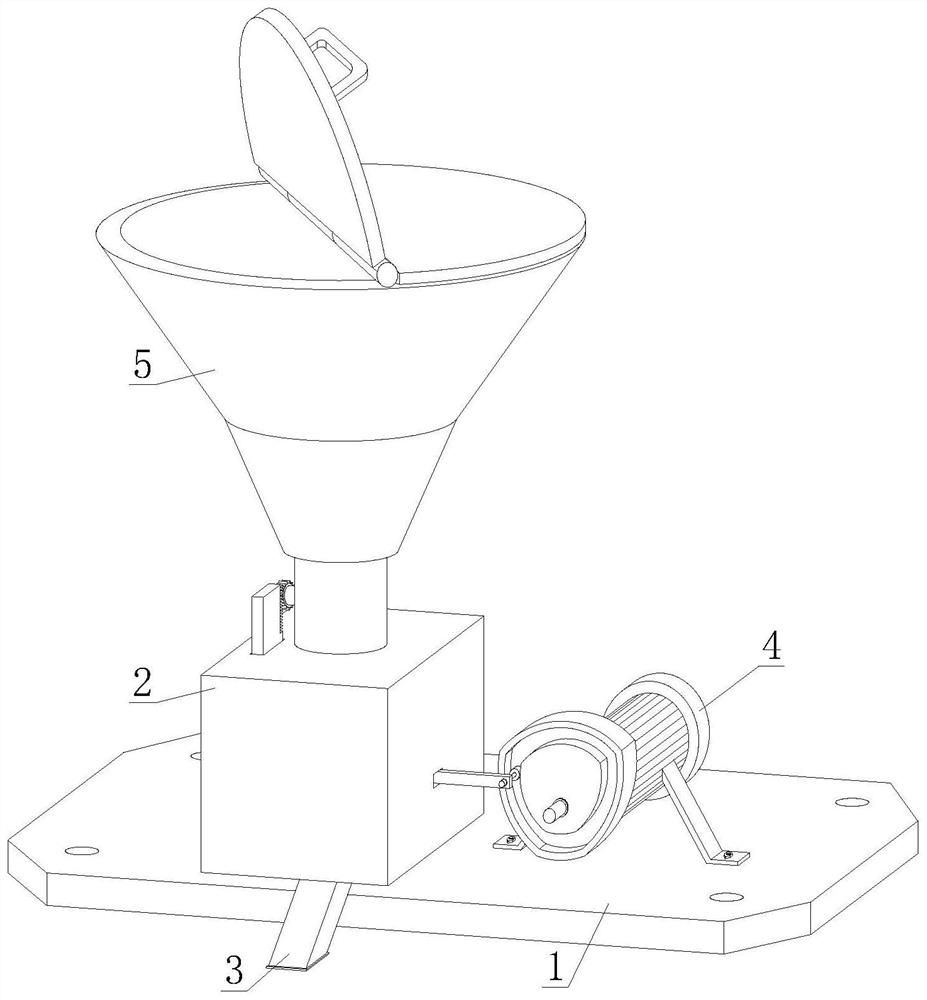

[0038] In order to demonstrate better, this embodiment now proposes an implementation method of a sustainable feeding device for the preparation of rare earth electrolytic waste molten salt, including the following steps:

[0039] Step 1: Add molten salt into the hopper 5, start the transmission motor 4 to drive the reciprocating transmission part 27 to rotate, and at the same time, the reciprocating transmission part 27 rotates through the transmission rod 245 to make the quantitative partition plate 24 reciprocate inside the feeding channel 23;

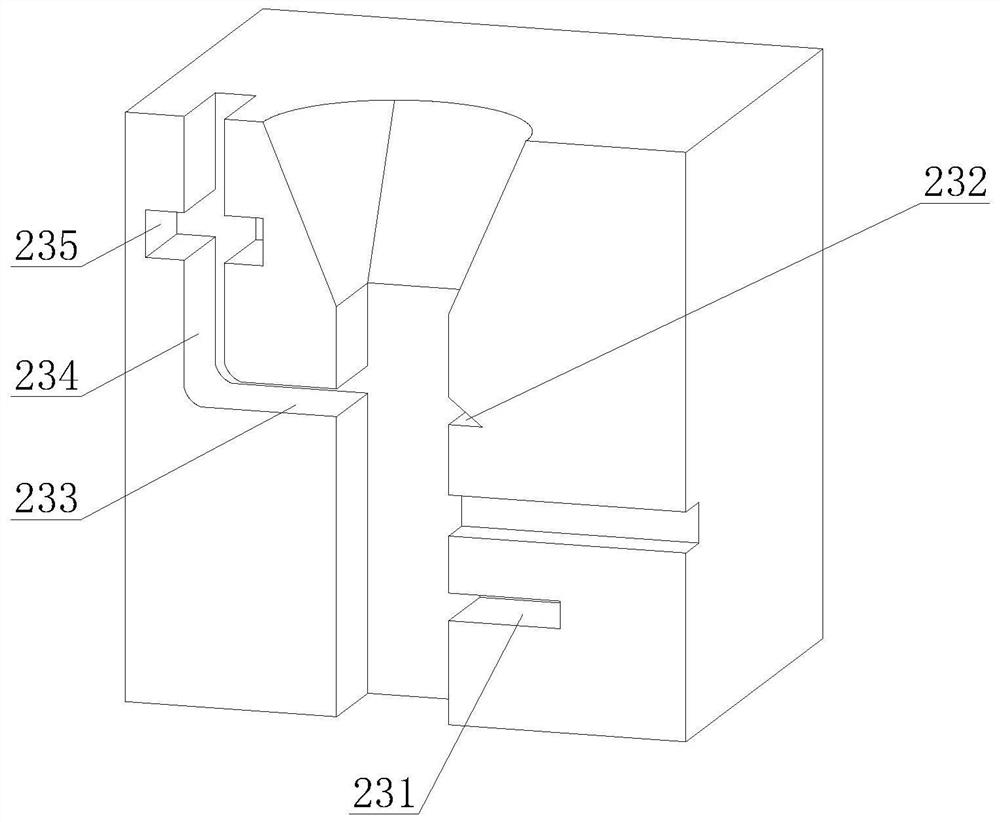

[0040] Step 2: When the upper baffle 243 moves to the inside of the second storage tank 233 , the lower baffle 241 seals the discharge channel 23 , and the molten salt in the hopper 5 falls to the top of the lower baffle 241 ;

[0041] Step 3: When the transmission rod 245 drives the lower baffle 241 to move to the inside of the first storage tank 231, the upper baffle 243 moves while sealing the upper end of the feeding channel 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com