Piezoelectric-gas mixture control type fluid jet device

A gas mixing and fluid jetting technology, applied in liquid jetting devices, jetting devices, etc., can solve the problems of weak bearing capacity, easy to be affected by load, small output force, etc., and achieve the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

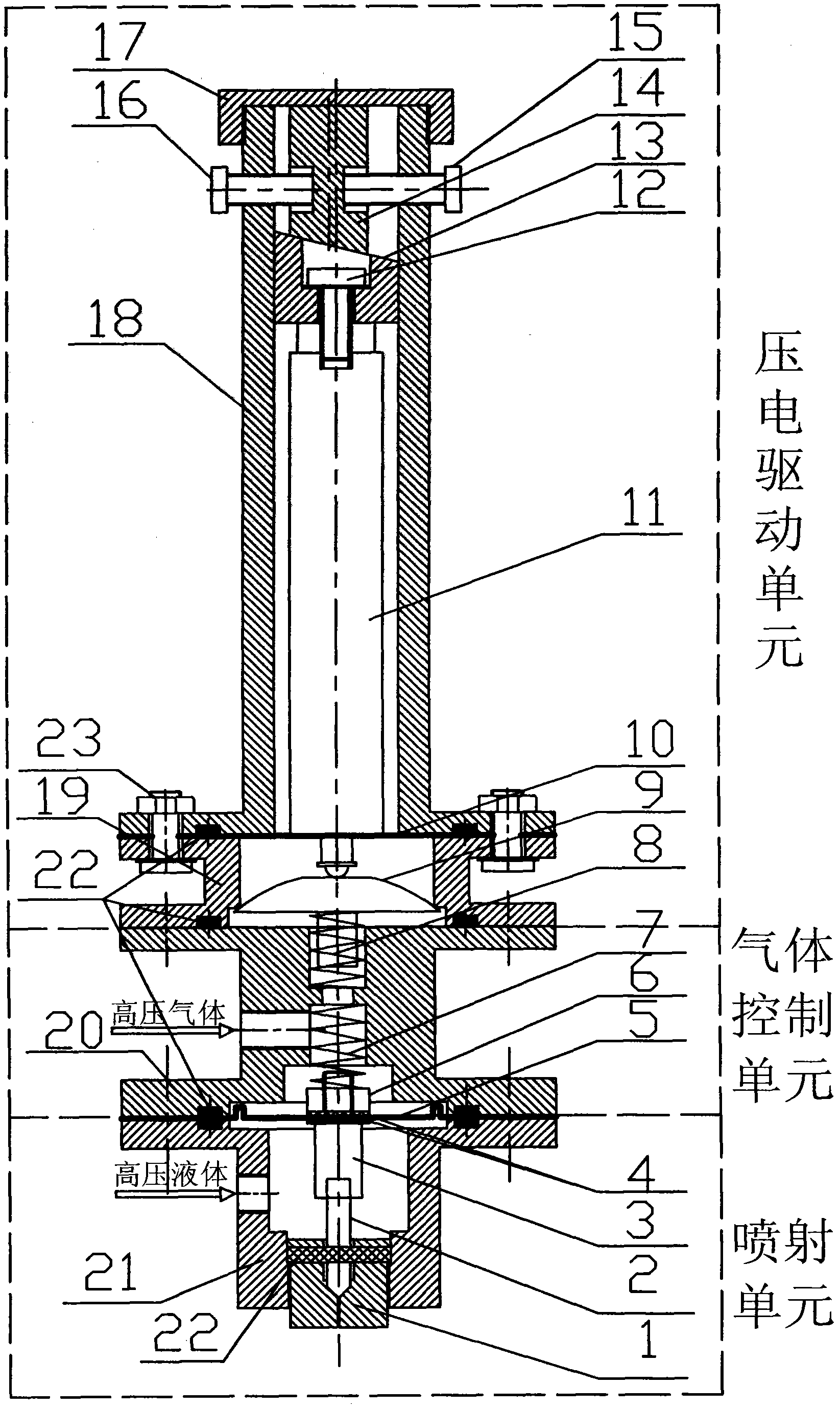

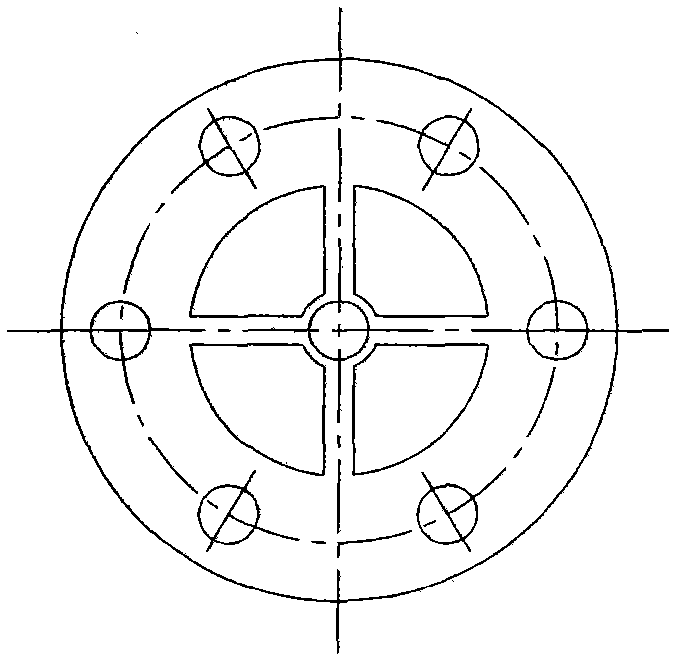

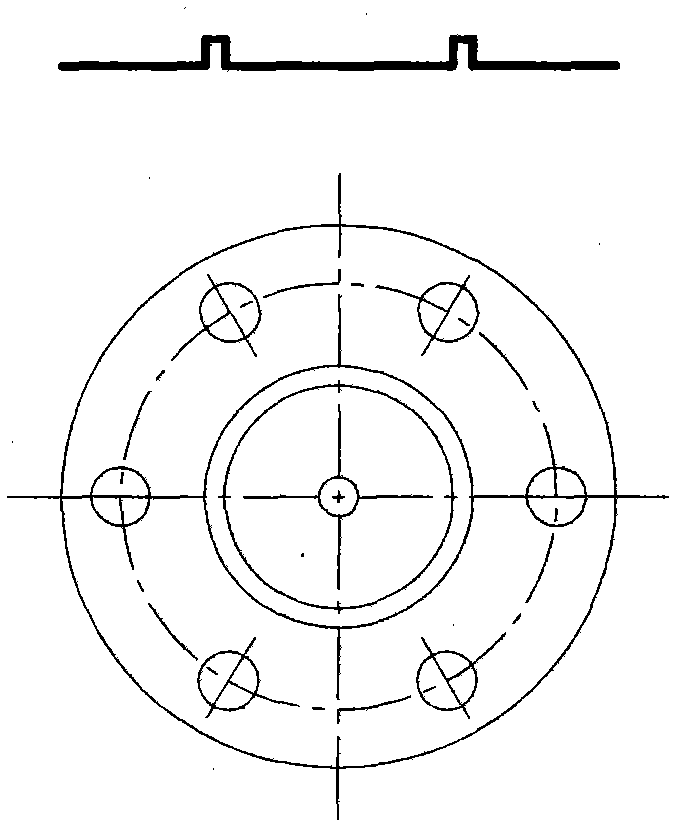

[0020] See figure 1 As shown, a piezoelectric-gas hybrid control type fluid injection device of the present invention includes three unit injection units, a gas control unit and a piezoelectric drive control unit. The injection unit includes a nozzle (1), a needle valve (2), a connecting column (3), a rubber gasket (4), a diaphragm spring (5), a liquid cavity (21), and the gas control unit includes a pneumatic cavity (20) ), a return spring (8), an air valve (9), an air valve seat (19), and the piezoelectric drive control unit includes a piezoelectric stack (11), an adjusting spring sheet (10), and a pretensioning device. The nozzle (1) is in interference fit with the liquid cavity (21) and is equipped with a sealing ring (22), the needle valve (2) is threadedly connected with the connecting column (3), and the connecting column (3) is used with the diaphragm spring (5) The nut (6) is connected with the rubber gasket (4), the piezoelectric stack (11) is connected with the pre-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com