Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Realize human-machine isolation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

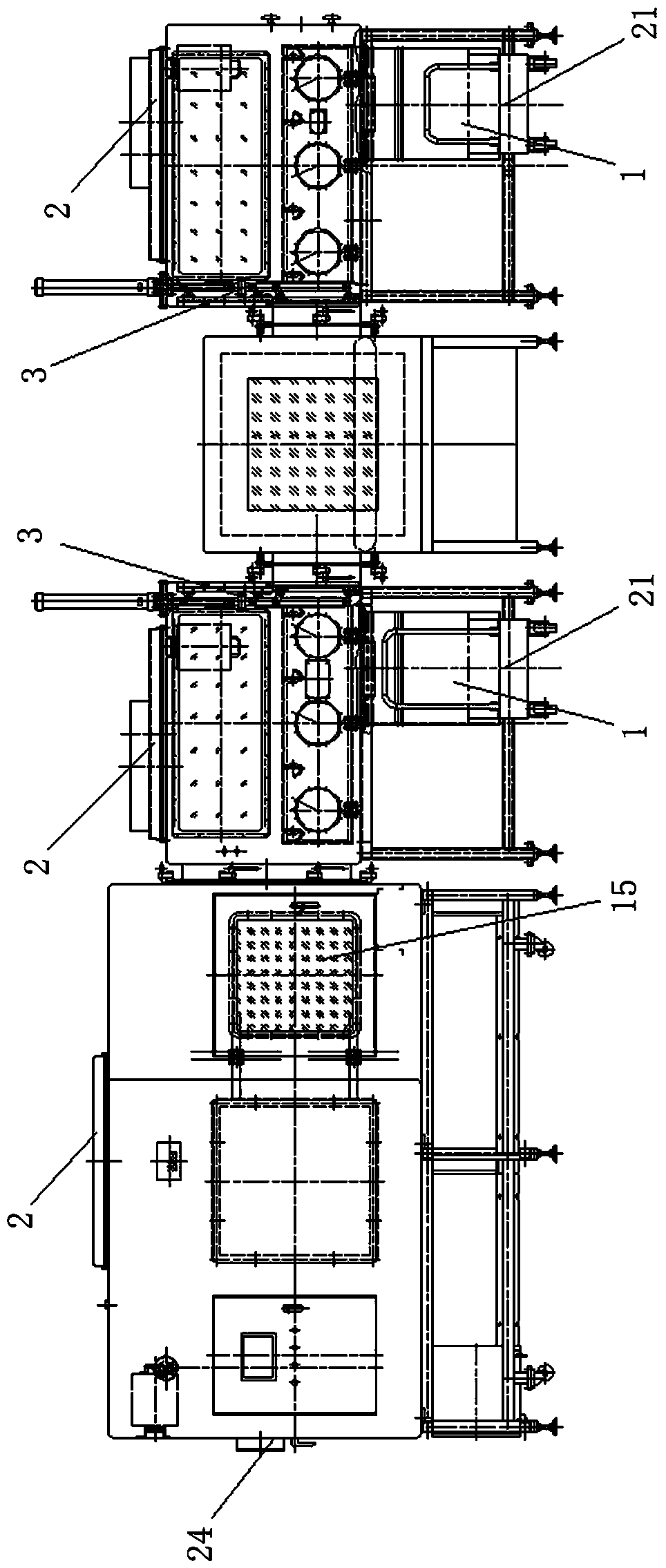

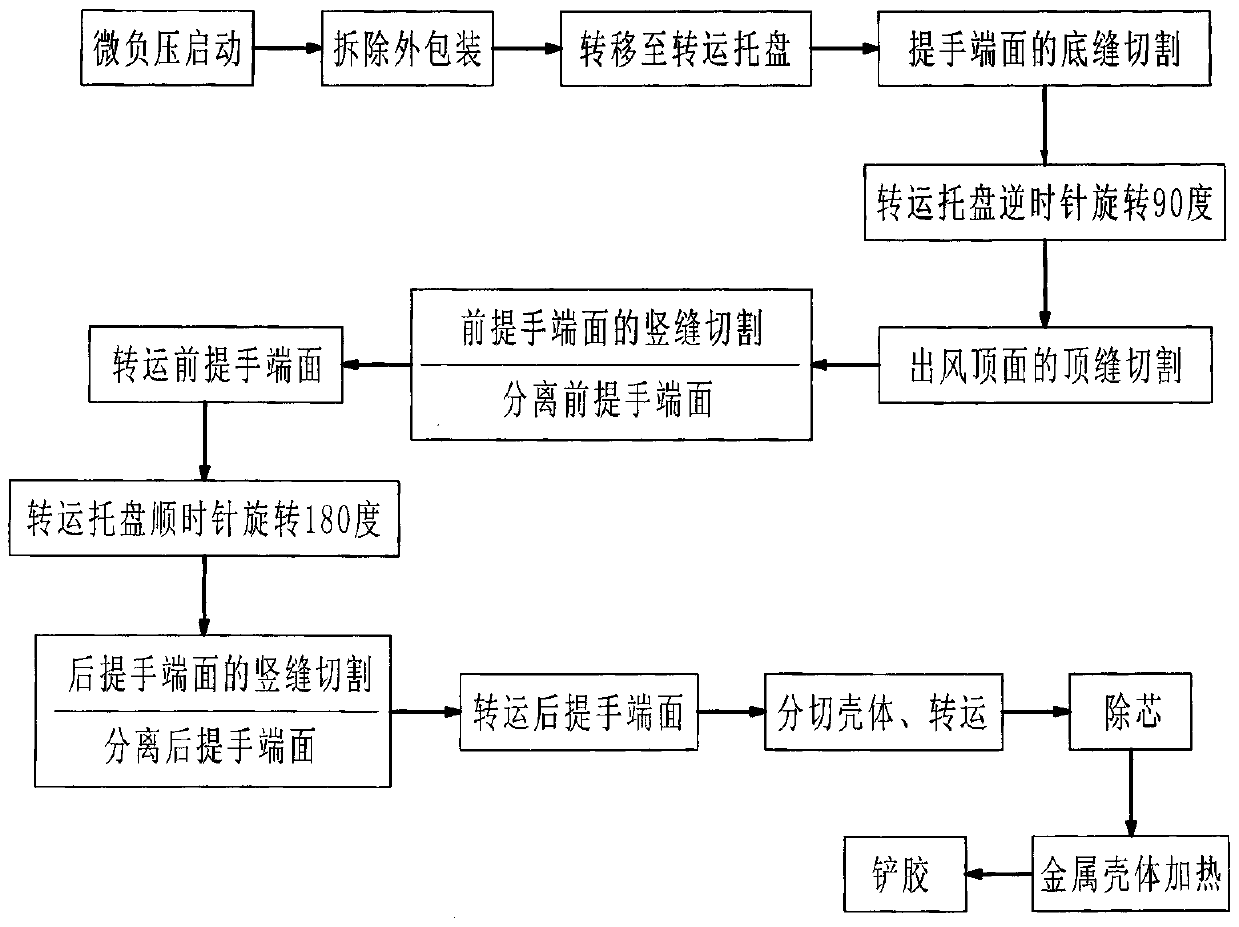

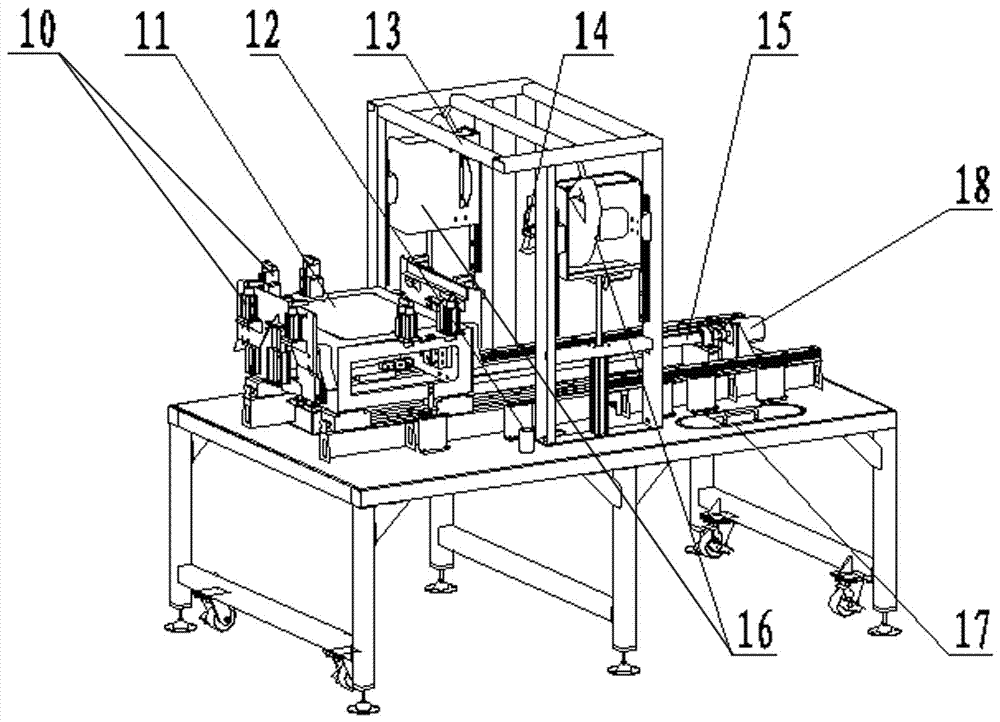

Device and method for disassembling low-radioactivity gather type waste filter

PendingCN107812781AGuaranteed safe collectionCause secondary pollutionSolid waste disposalPlastic recyclingAgricultural engineeringWaste treatment

The invention discloses a device and method for disassembling a low-radioactivity gather type waste filter. The low-radioactivity gather type waste filter to be disassembled is placed into a disassembling system, after an outer package is removed, a bottom seam cutting machine, a top seam cutting machine, a vertical seam cutting machine and a transfer tray are cooperated for carrying out bottom seam cutting on the front handle end face, top seam cutting on the air exhaust top face, vertical seam cutting on the front handle face and vertical seam cutting on the rear handle face of a metal shellof the low-radioactivity gather type waste filter, the front handle face and the rear handle face are separated in first batch, a core is recycled after cut, and the metal shell and glue attached tothe metal shell are heated in a tunnel type drying oven and subjected to glue shoveling treatment through a glue shoveling negative pressure ventilation cabinet to be classified and recycled. The gather type waste filter can be disassembled before waste treatment, meal materials and nonmetal materials are classified, and the device and method have the advantages of being high in automation degree,high in efficiency, safe and environmentally friendly, saving energy and the like.

Owner:HENAN HEJING CLEANING TECH

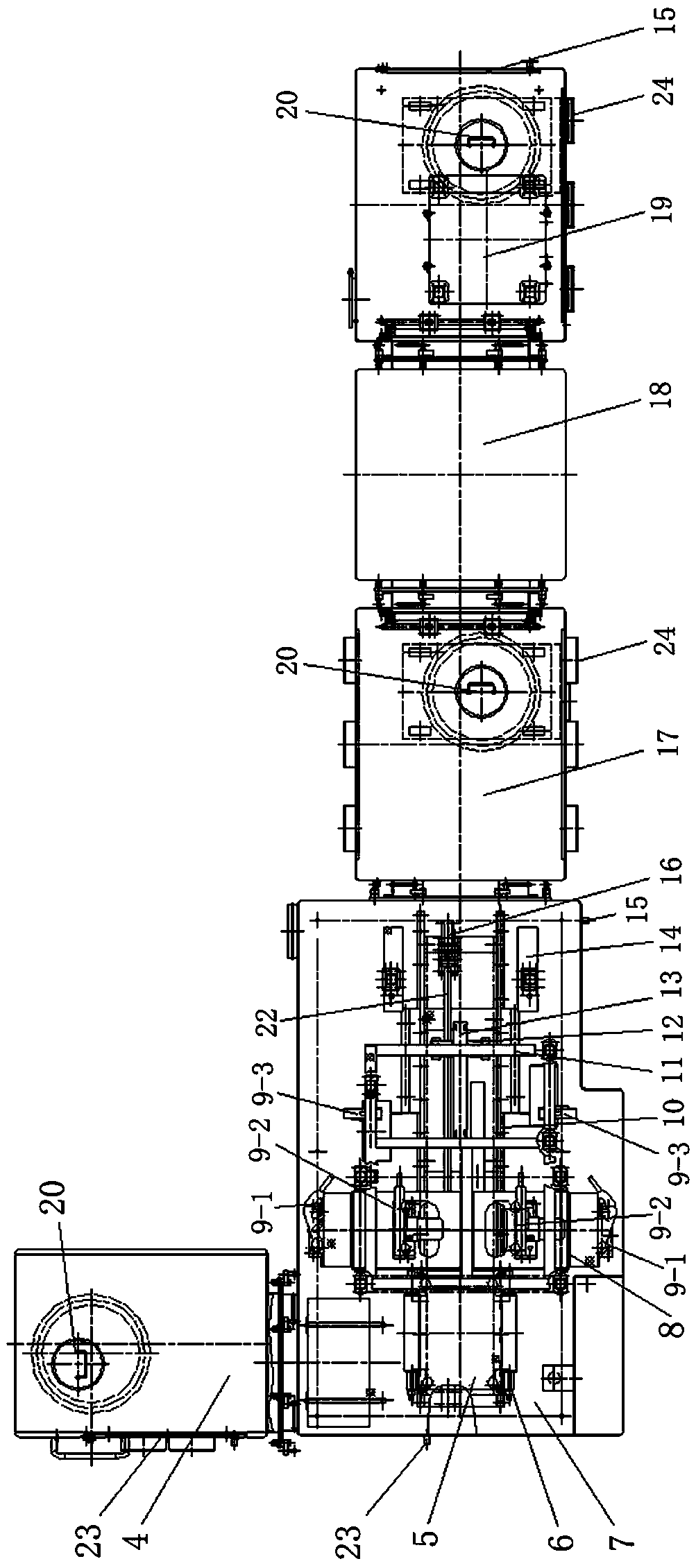

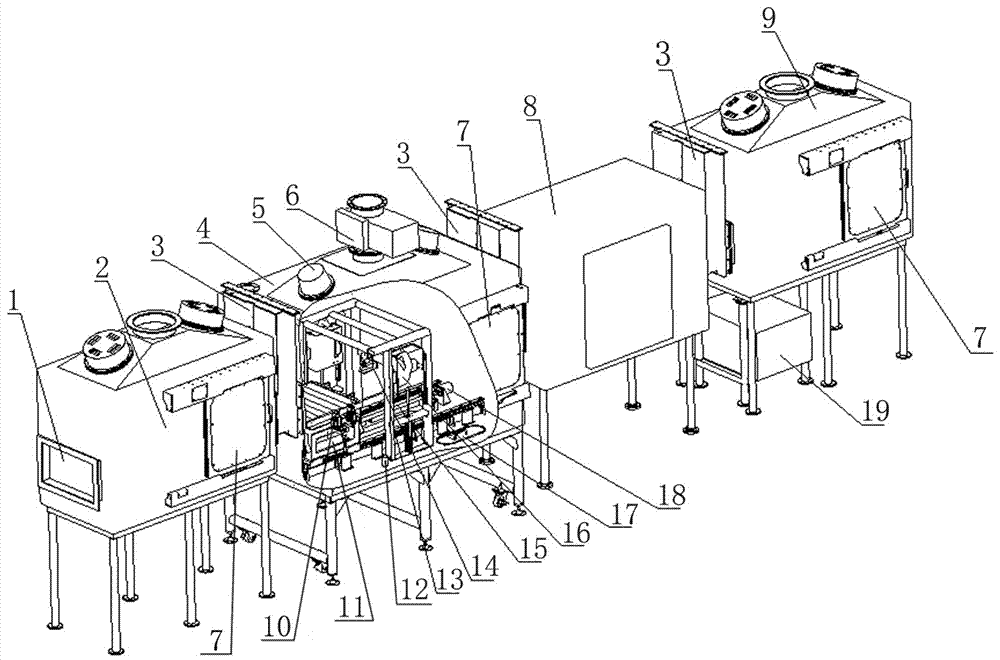

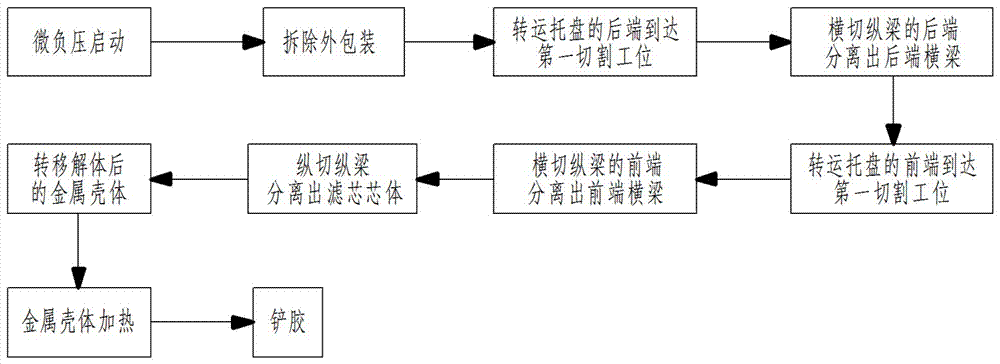

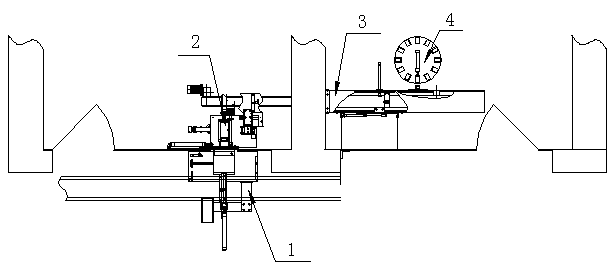

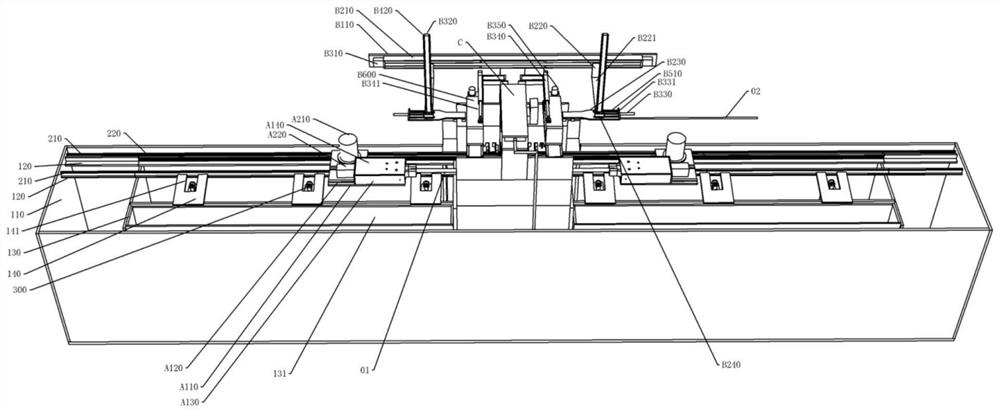

Equipment and method for disassembling low-radioactivity folding type waster filter

ActiveCN107009135AAvoid secondary pollutionImprove operational safetyMetal working apparatusStringerWire cutting

The invention discloses equipment and method for disassembling a low-radioactivity folding type waster filter. According to the equipment and method, the folding type waster filter to be disassembled is installed into a disassembling system, after an external package is disassembled, a shell cutting machine is used for transversely cutting the two ends of each of two longitudinal beams in a rectangular frame type metal shell of the folding type waster filter to separate out transverse beams at the front and back end, a core cutting machine is used for conducting linear cutting on combining seams of the inner sides of the two longitudinal beams in the rectangular frame type metal shell of the folding type waster filter and a core of a filter element to separate out the core of the filter element, finally the disassembled metal shell is heated by a tunnel type oven to change the caking property of attached glue, and separation of the glue and the metal shell is achieved through electric shovel glue in a shovel glue negative pressure ventilation cabinet. According to the equipment and method, the folding type waster filter can be disassembled before waste is treated, classification of metal materials and nonmetal materials is achieved, and the beneficial effects of being high in automatic degree, high in efficiency, safe, energy-saving, environment-friendly and the like are achieved.

Owner:HENAN HEJING CLEANING TECH

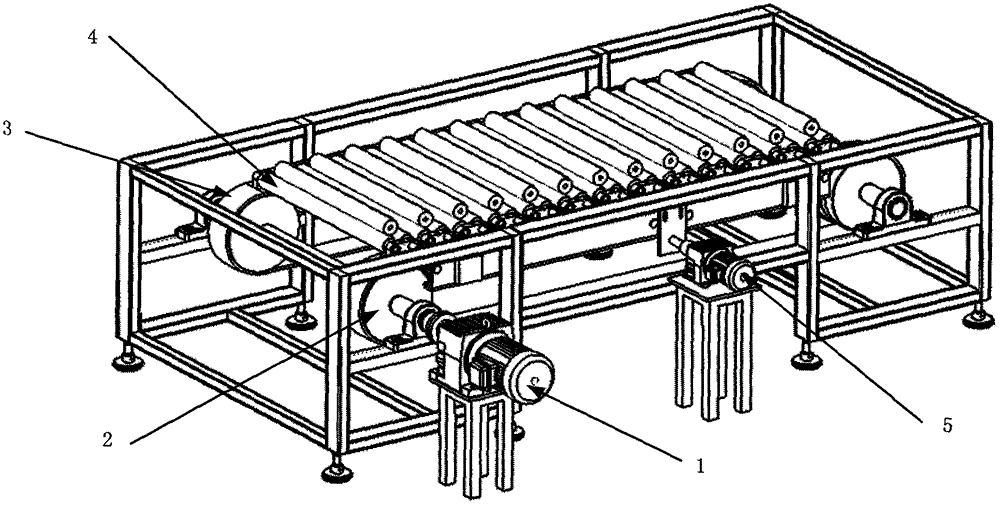

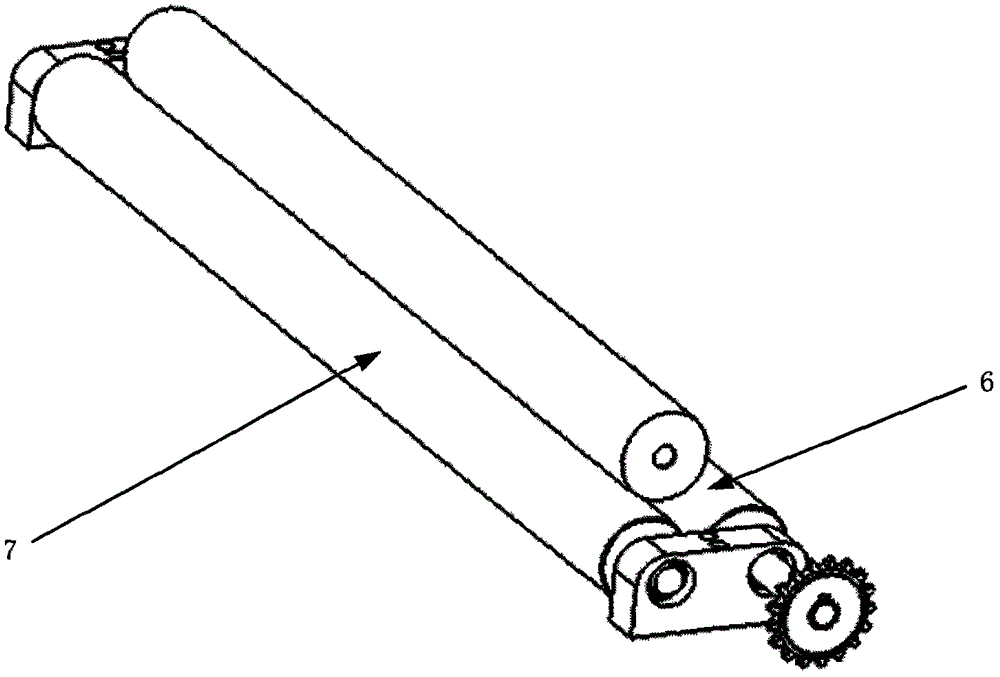

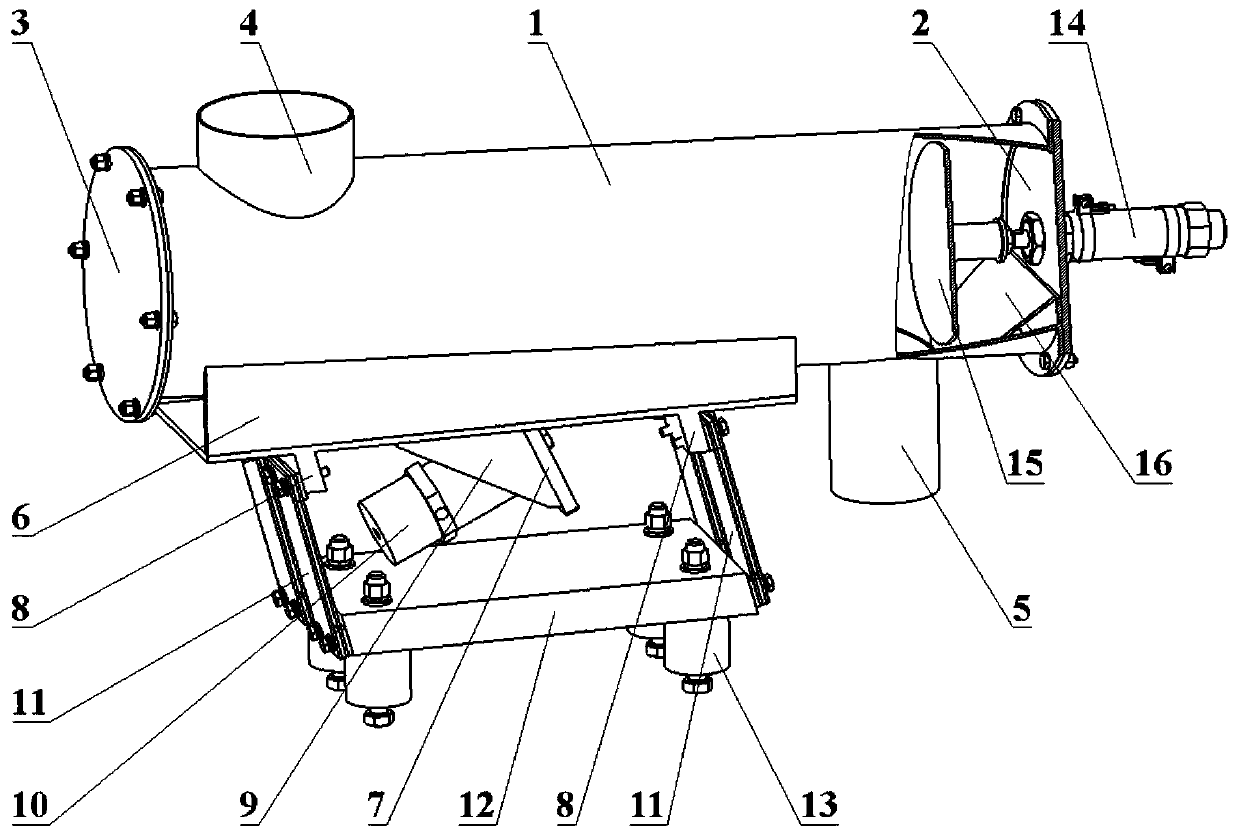

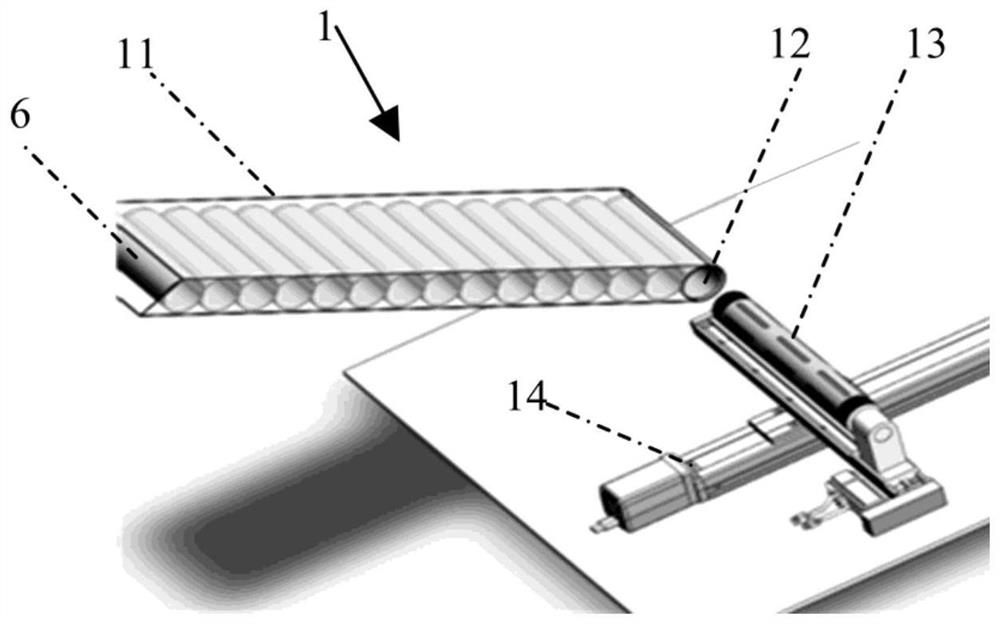

Automated grain-airing aging device for propellant high in slenderness ratio

ActiveCN106322956AFully automatedAchieve serializationDrying machines with progressive movementsDrying solid materialsMan machineRise rate

The invention relates to an automated grain-airing aging device for propellant high in slenderness ratio and belongs to the field of mechano-electronic automation. The device comprises a first motor, rolling wheels, conveying belts, roll shafts, a second motor, gears and chains. The two rolling wheels are fixedly connected through a connection rod. The two parallel rolling wheels are movably connected with the conveying belts. The connection rod of the rolling wheels is connected with the first motor. Connection blocks are fixedly connected to the conveying belts. Each connection block is provided with two through holes which are used for placing corresponding shaft rods therein. Each shaft rod penetrates one end of the corresponding through hole and is fixedly connected with the corresponding driving roll shaft, and the other end of each shaft rod is fixedly connected with the corresponding gear. Each driving roll shaft is movably connected with the corresponding driven roll shaft. After each driven roll shaft is fixedly connected with the other corresponding shaft rod, the shaft rod is placed in the other corresponding through hole. Each gear occludes with the corresponding chain. Each chain is engaged with the corresponding gears fixed to a support. By means of the automated grain-airing aging device, under the circumstance that safety is guaranteed, continuity, automation and man-machine isolation of the grain-airing aging production process are achieved; and the continuous aging device is provided with a breeze circulating system and a system through which the temperature and the temperature rising rate can be controlled in a remote distance.

Owner:CHINA WUZHOU ENG GRP +1

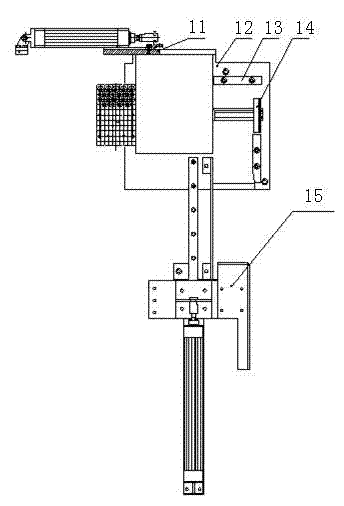

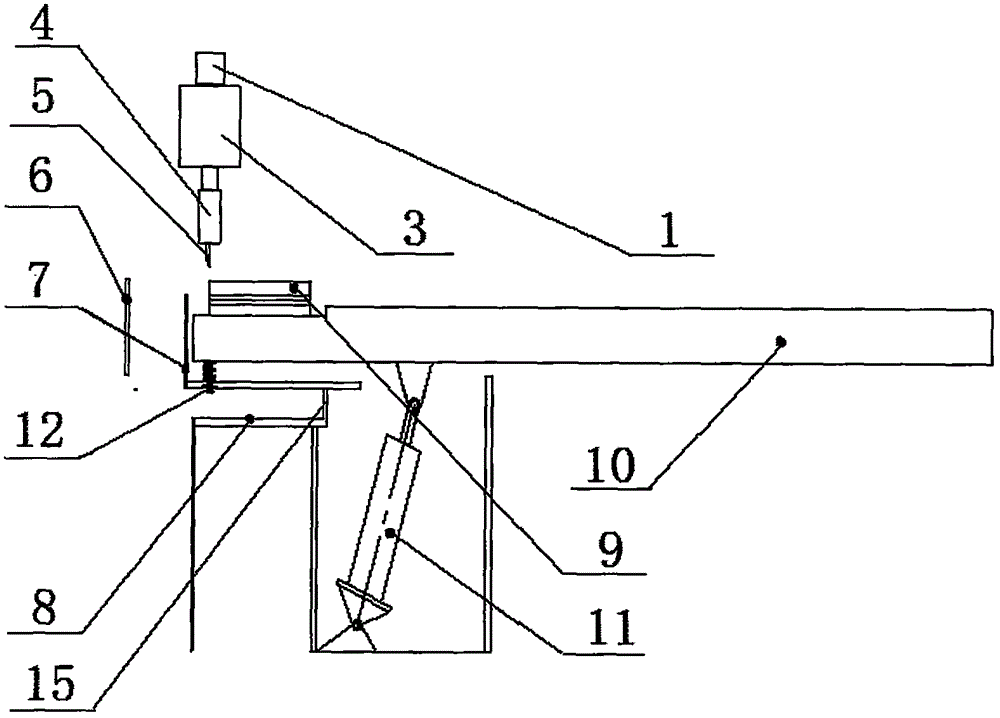

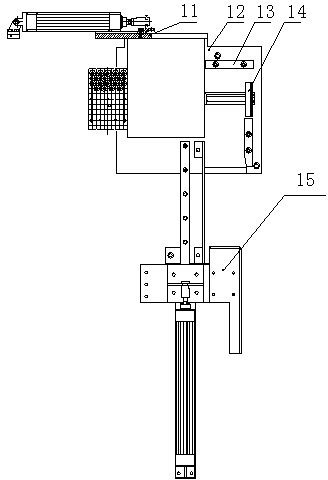

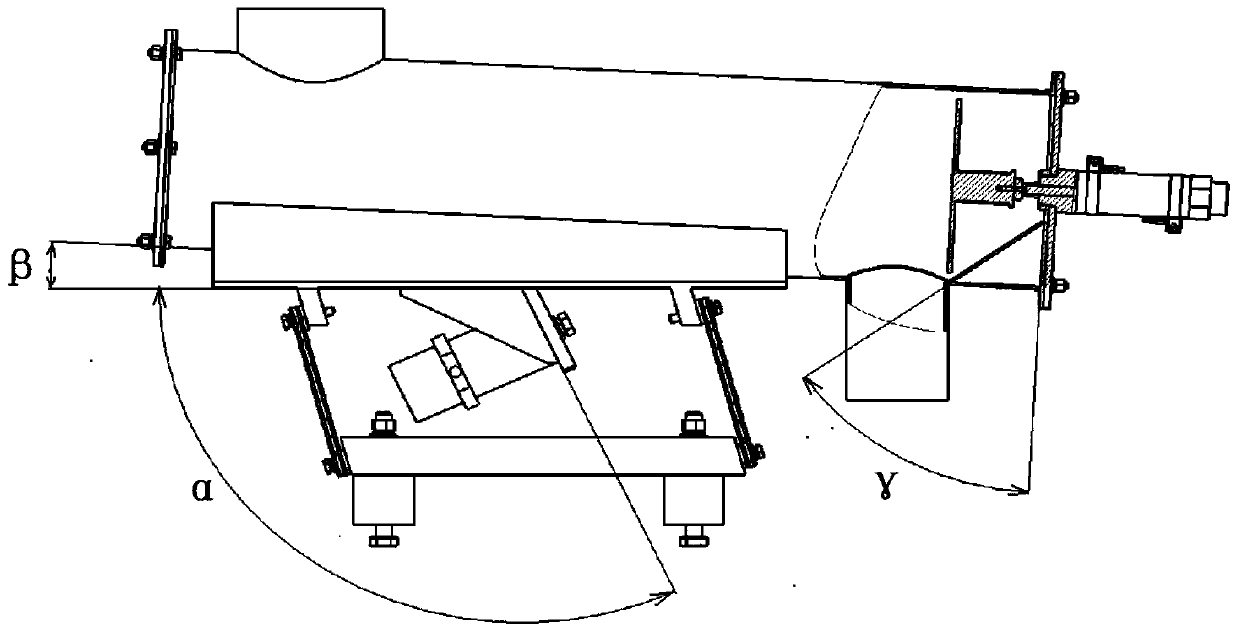

Pneumatic pressing medicine cutting device and cutting method

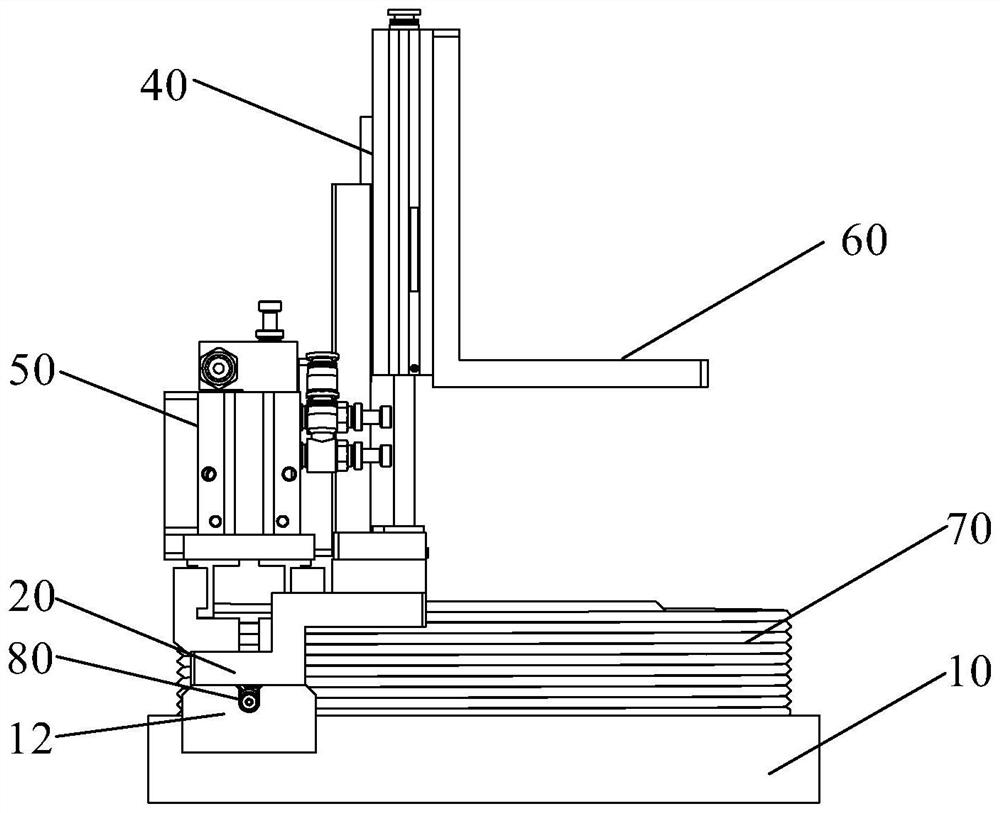

PendingCN110877353ARealize flexible productionRealize human-machine isolationMetal working apparatusEngineeringMechanical engineering

The invention belongs to a gunpowder processing device and a processing method. In order to solve technical problems that gunpowder cutting is mostly performed manually in the prior art, consequentlythe risk is high, and labor intensity is high, the pneumatic pressing medicine cutting device and a cutting method are provided. Three air cylinders are fixed to a bracket of the medicine cutting device, the output end is connected with pressing blocks and a cutting knife respectively, the cutting knife and the two pressing blocks are coaxially arranged in the axial direction of a material guide seat, the two pressing blocks are located on both sides of the cutting knife, and the material guide seat is located directly below the cutting knife and the two pressing blocks; a positioning mechanism includes a positioning seat and a positioning rod, the positioning seat is mounted on a base, the positioning rod is perpendicular to the axial direction of the material guide seat, and one end of the positioning rod is hinged to the positioning seat. According to the cutting method, a material to be cut is placed on the material guide seat, the axial direction of the material to be cut is positioned through the positioning mechanism, the direction perpendicular to the axial direction of the material to be cut is positioned through the pressing blocks to complete cutting.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

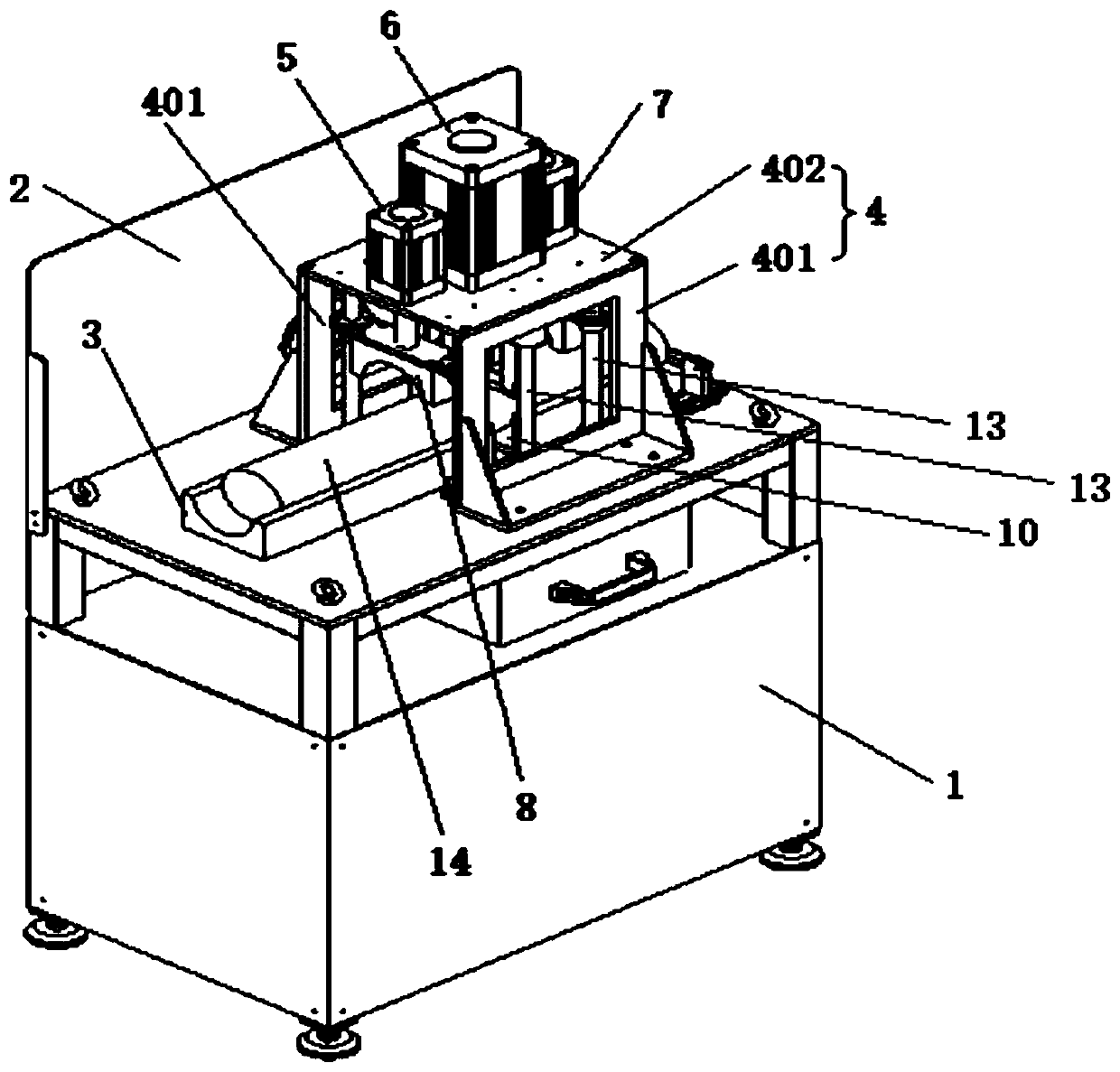

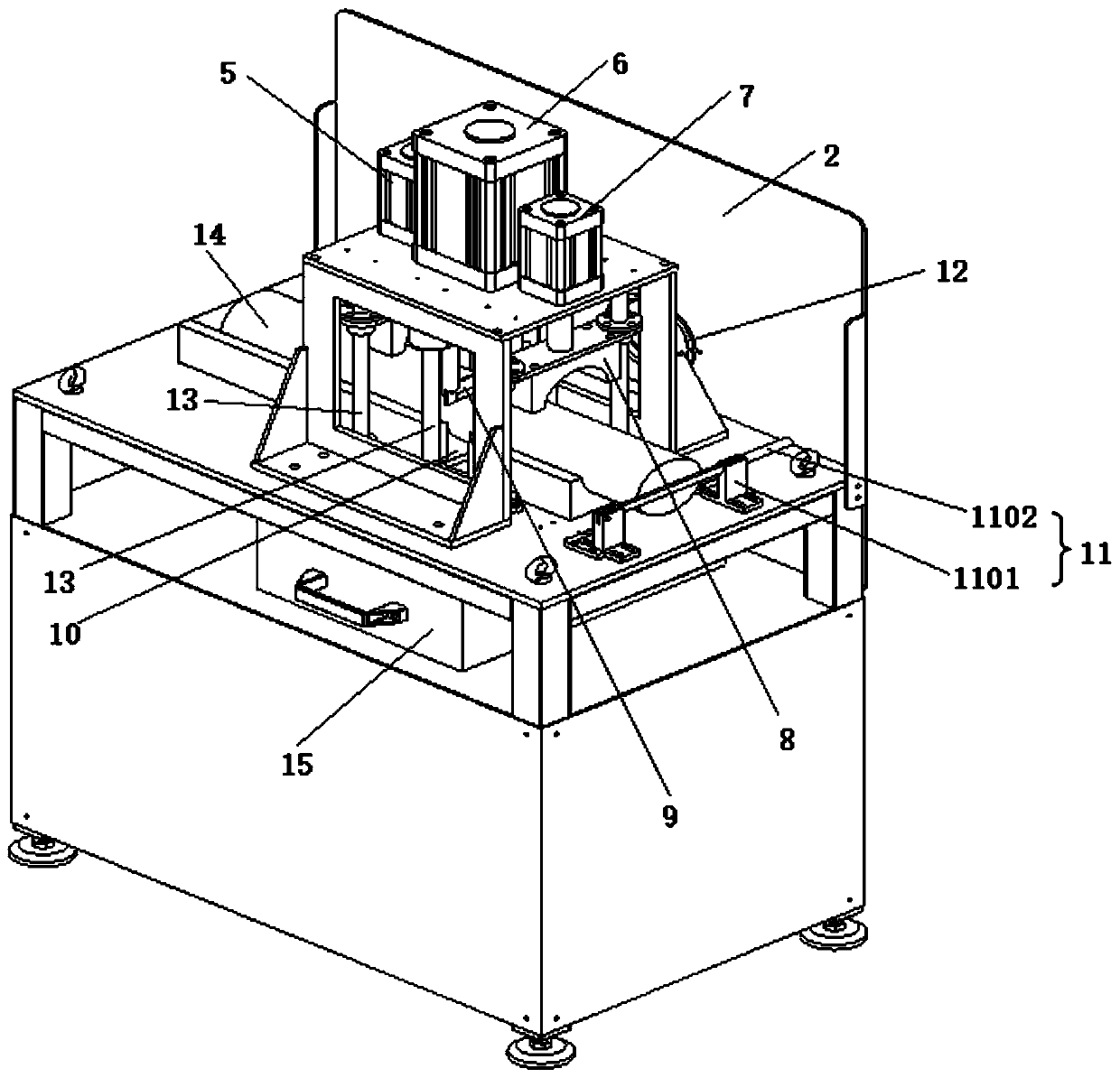

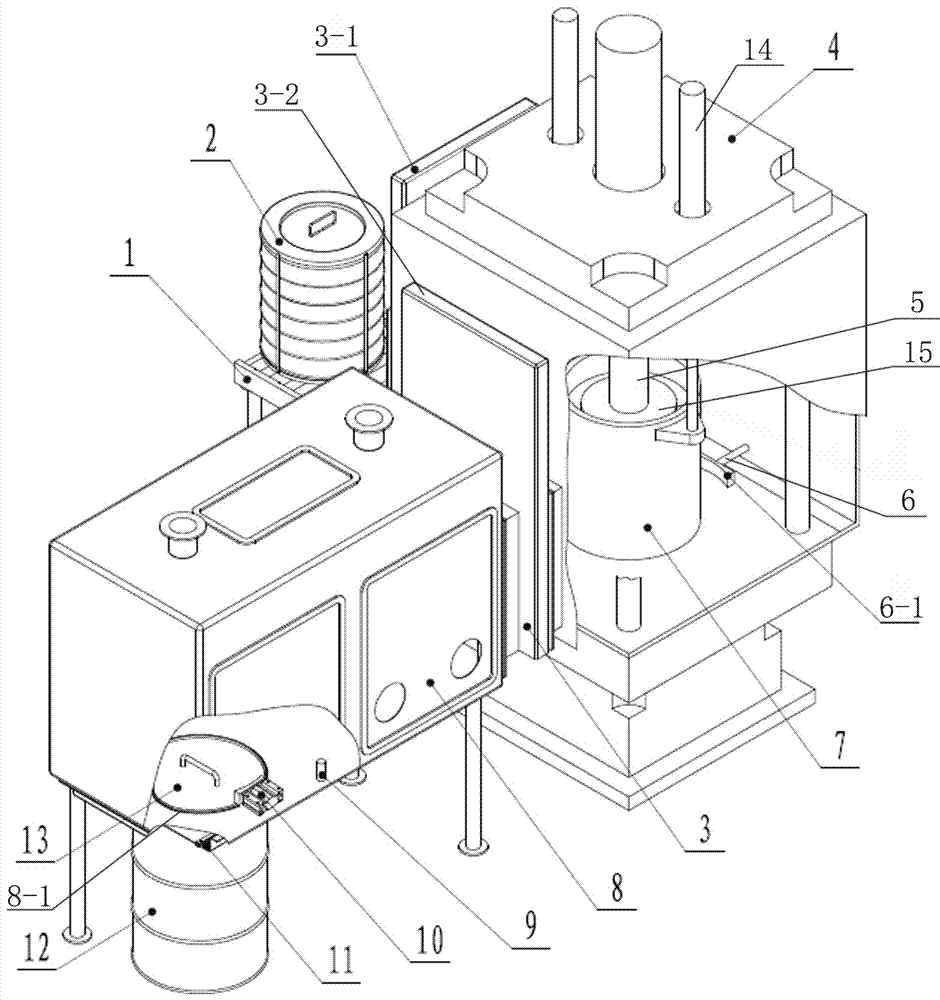

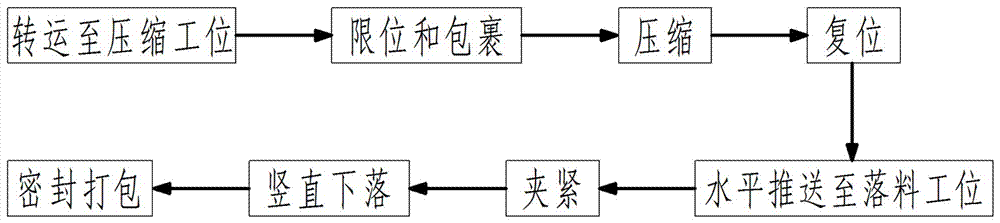

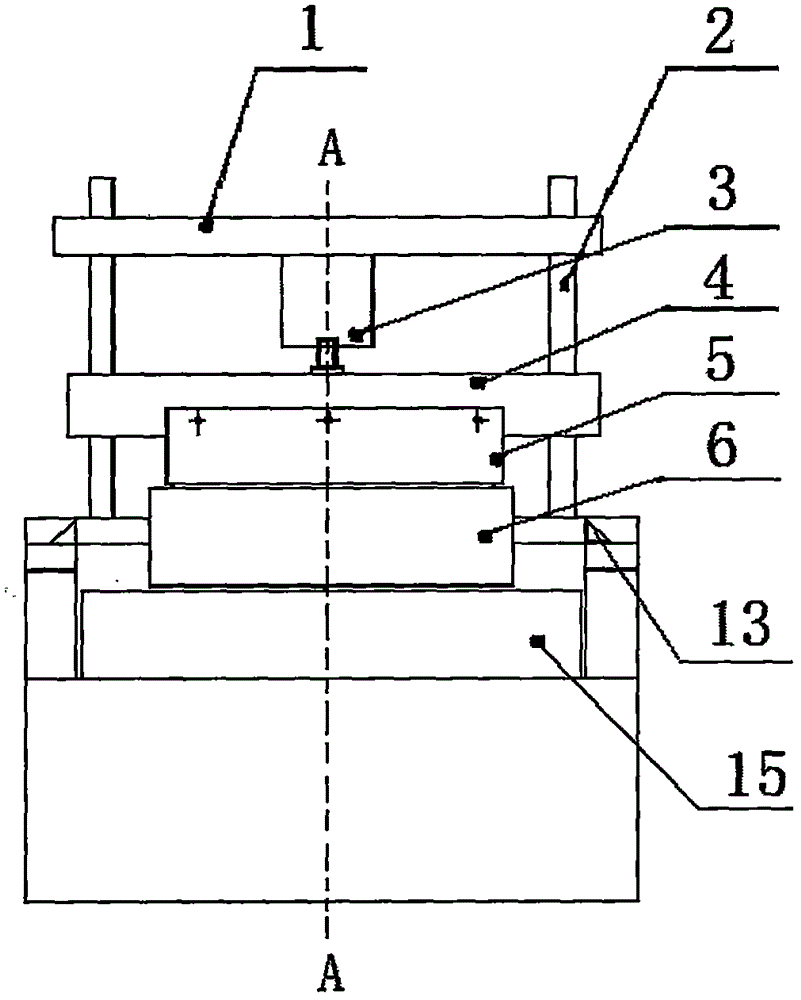

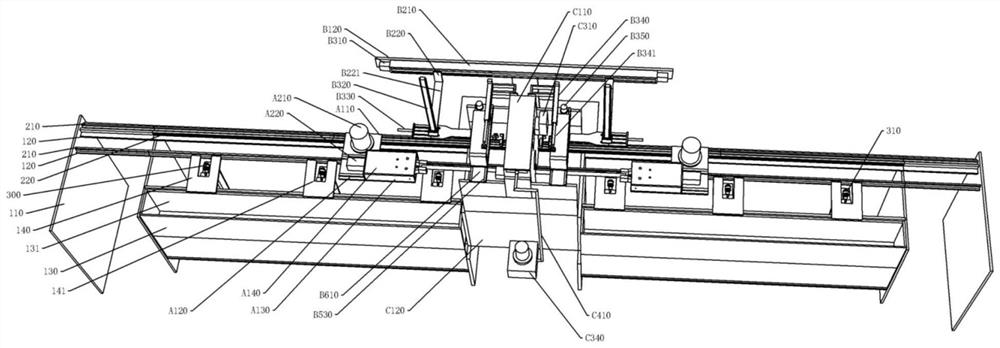

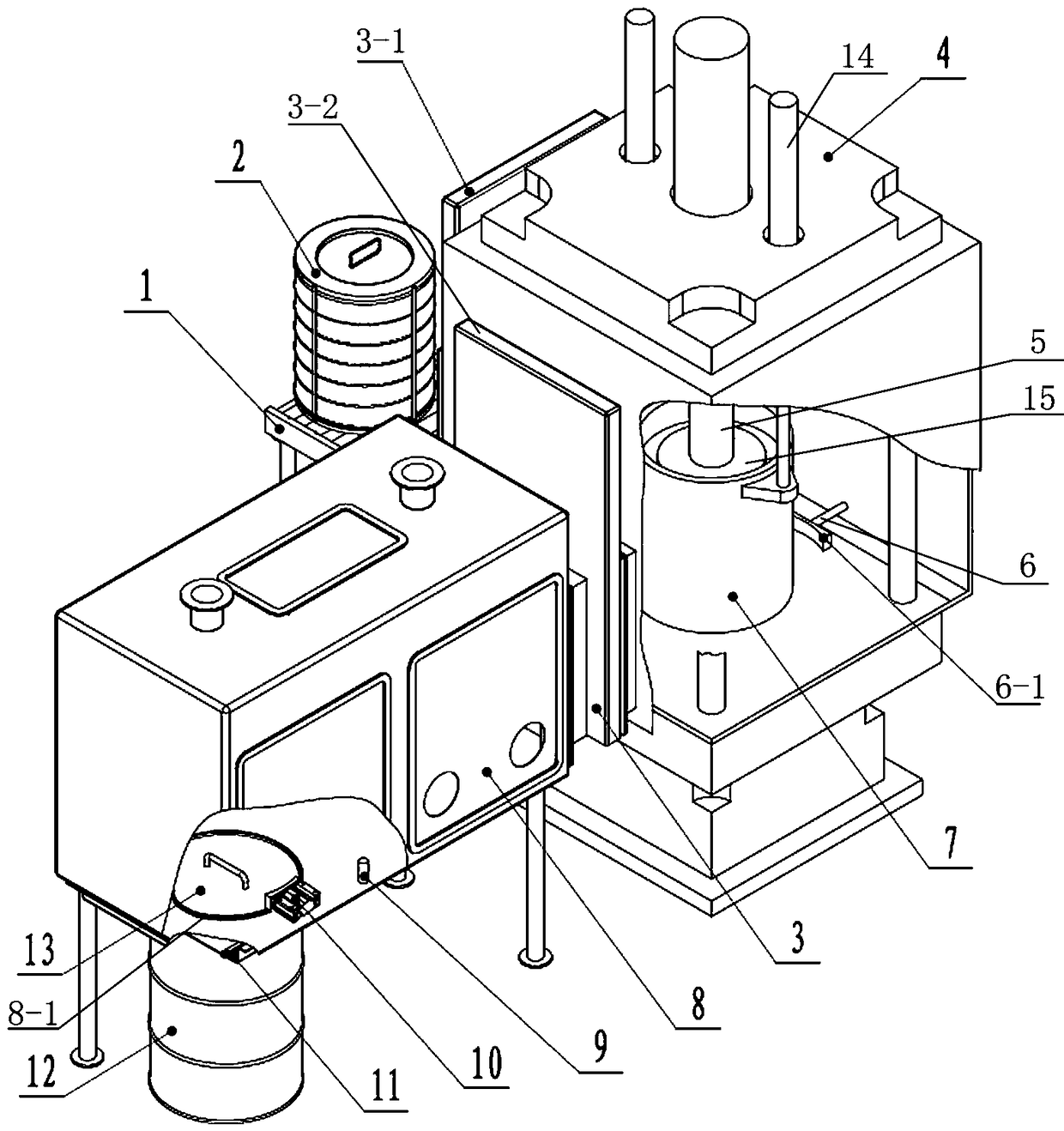

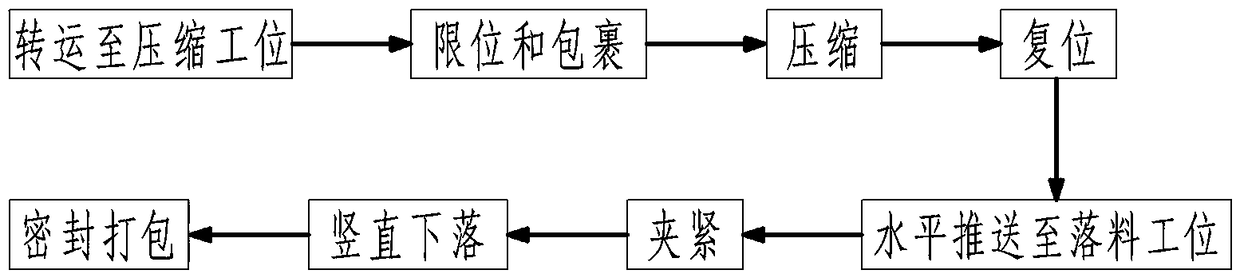

Method and equipment for volume reduction treatment of low-radioactivity waste circular filters

ActiveCN106898405APrevent proliferationGuaranteed cleanlinessRadioactive decontaminationAutomationWaste management

The invention discloses a method and equipment for volume reduction treatment of low-radioactivity waste circular filters. The method includes: transferring a to-be-compressed waste circular filter to a compression station, and adopting a limiting oil cylinder for driving a limiting barrel to vertically move downwards so as to limit and wrap the to-be-compressed waste circular filter in an inner cavity of the limiting barrel; adopting a main cylinder of a hydraulic press for driving a compression plate to press downwards vertically to downwardly compress the waste circular filter into a cake shape; pushing to a discharging station at the bottom surface of a cavity of a receiving glove box by a pushing device; after a clamping device clamps, allowing an isolation device to horizontally move away from a circular discharging hole, so that the waste circular filter is vertically discharged into a lining seal bag in a cavity of a waste bucket; after the cavity of the waste bucket is full, performing sealing, packaging, transferring and storing. The compression volume reduction ratio is high, storage volumes of the waste circular filters are greatly reduced, and aftertreatment cost is reduced. In addition, the method and the equipment have advantages of high automation degree, high efficiency, safety, energy saving, environmental friendliness and the like.

Owner:HENAN HEJING CLEANING TECH

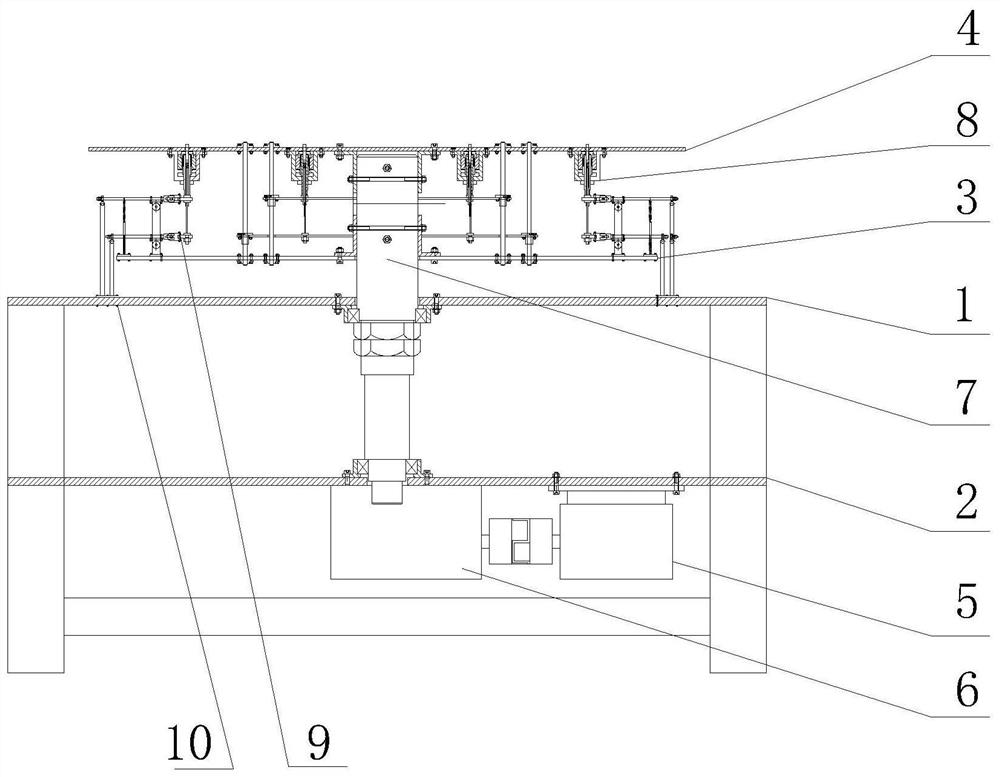

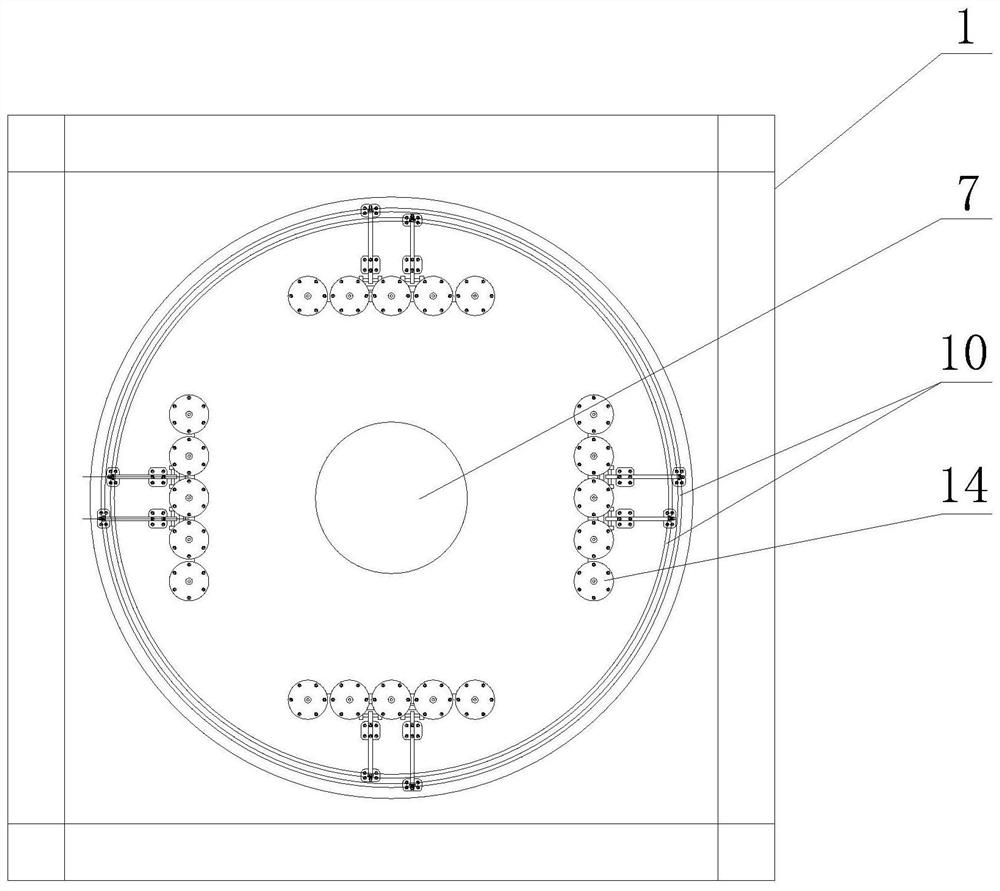

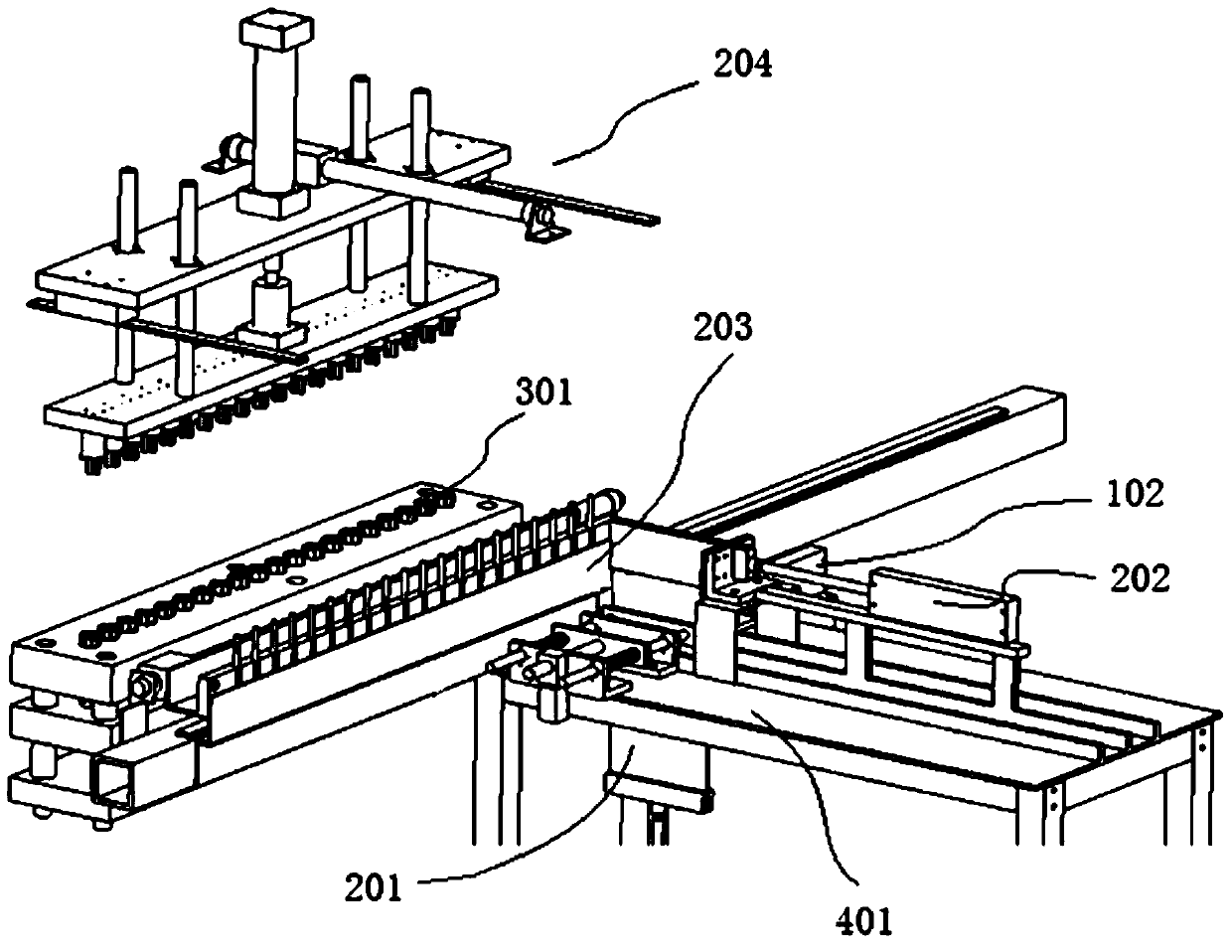

Automatic box retreating system of detonator

ActiveCN102515993AComplete human-computer isolationCompletely realize human-machine isolationDetonatorsDetonatorDetonation

The invention relates to an automatic box retreating system of a detonator, which belongs to the field of detonator propellant equipment of civil detonation devices and comprises a mould conveying device used for enabling a mould to automatically entering and leaving a process room and returning an empty mould to a conveying belt, a box retreating device used for achieving the effect that a pipe casing retreats from the mould and the pipe casing is automatically dropped, collected and molded, a conveying device used for enabling a finished box to reach the conveying device at the finished product collection position and an empty box feeding device used for enabling the empty box to reach the box retreating device through a belt conveyor. The mould conveying device is connected with the box retreating device which is connected with the empty box feeding device through the conveying the device. The automatic box retreating system of the detonator has the advantages of being capable of replacing manual workers to completely achieve the whole process of detonator box retreating procedures in basic detonator production, achieving complete man-machine separation, resolving safety hazards existing in the production process and having the advantages of being safe and reliable, reducing labor intensity and the like.

Owner:长春汇维科技股份有限公司 +1

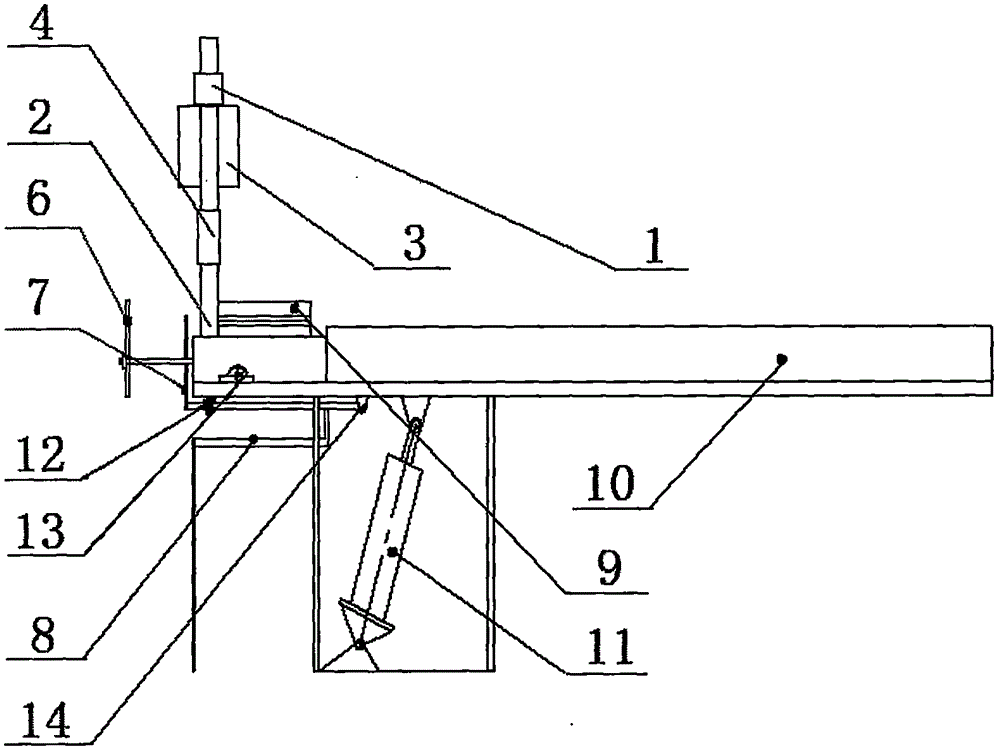

Continuous slicing machine for tubular propellant

InactiveCN106113113AReduce labor intensityImprove work efficiencyMetal working apparatusMan machinePropellant

The invention relates to a continuous slicing machine for a tubular propellant, and belongs to the processing field of propellants. The continuous slicing machine comprises a machine base, a workbench, a propellant guide frame, a positioning baffle plate and a propellant cutter; the workbench is connected to the machine base through a rotary shaft of the workbench; the propellant guide frame is fixedly arranged on the upper surface of the workbench; the front end of the workbench is fixed to the positioning baffle plate; the upper end of the workbench is connected to the propellant cutter through a propellant cutting air cylinder; during cutting, long propellant strips are separately inserted into each propellant guide hole of the propellant guide frame; the workbench is controlled by a workbench lifting air cylinder to turn over upwards around the rotary shaft of the workbench relative to the machine base; the long propellant strips downwards slide to the front end under action of self-gravity to abut against the positioning baffle plate; and the propellant cutter is controlled by the propellant cutting air cylinder to cut downwards, so that a propellant finished product with length consistent with required length is obtained. The continuous propellant slicing machine realizes automatic operation of a cutting process, so that working efficiency is improved, product consistency is good, man-machine isolation of a cutting process can be realized, and safety of the whole process is guaranteed.

Owner:SHANXI BEIFANG XINGAN CHEM IND

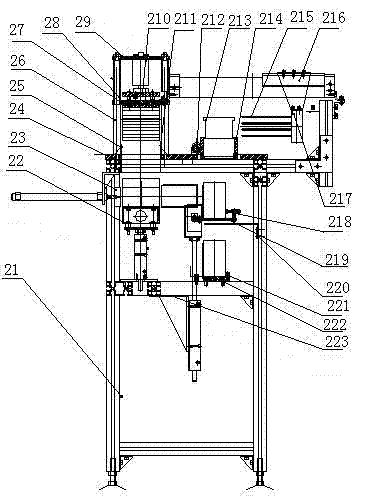

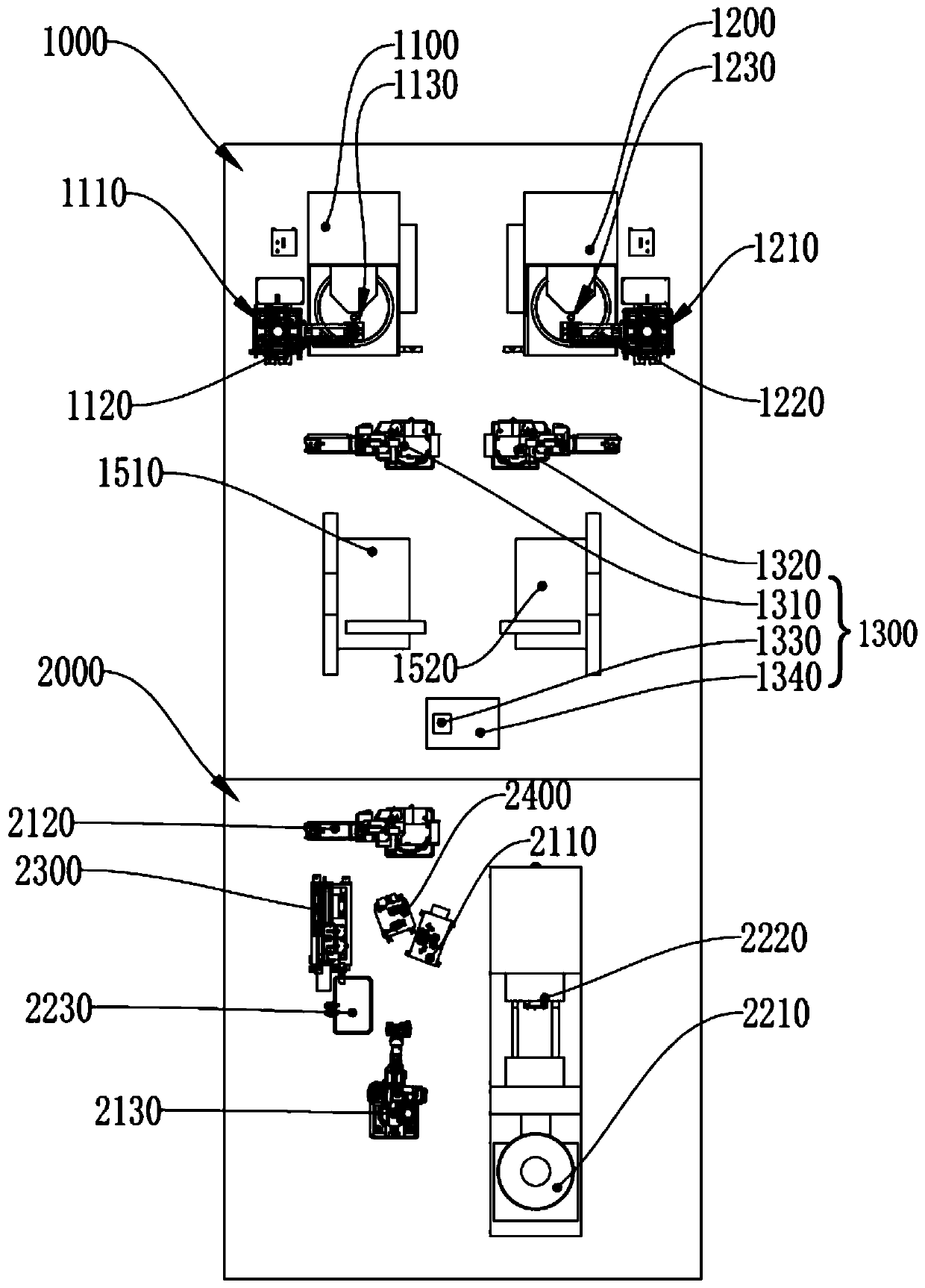

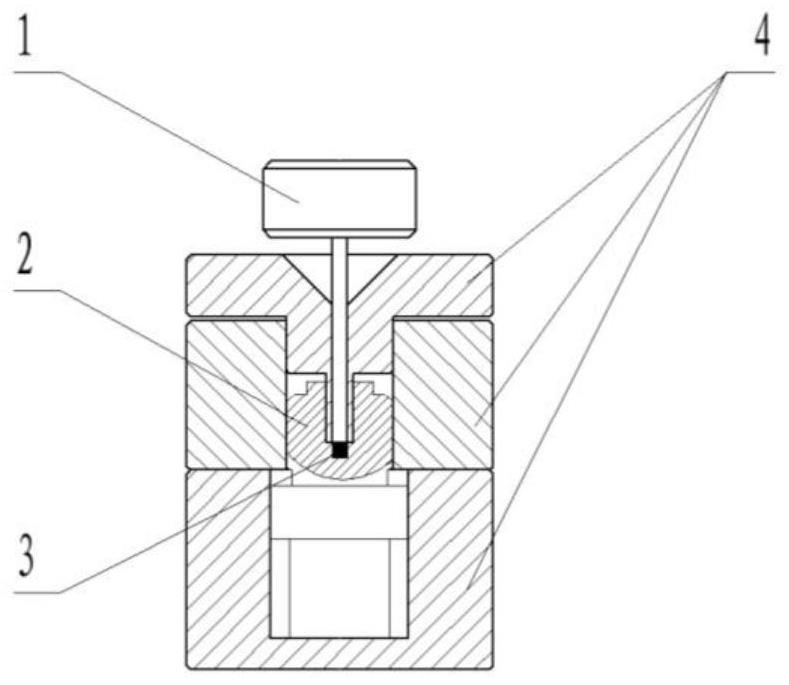

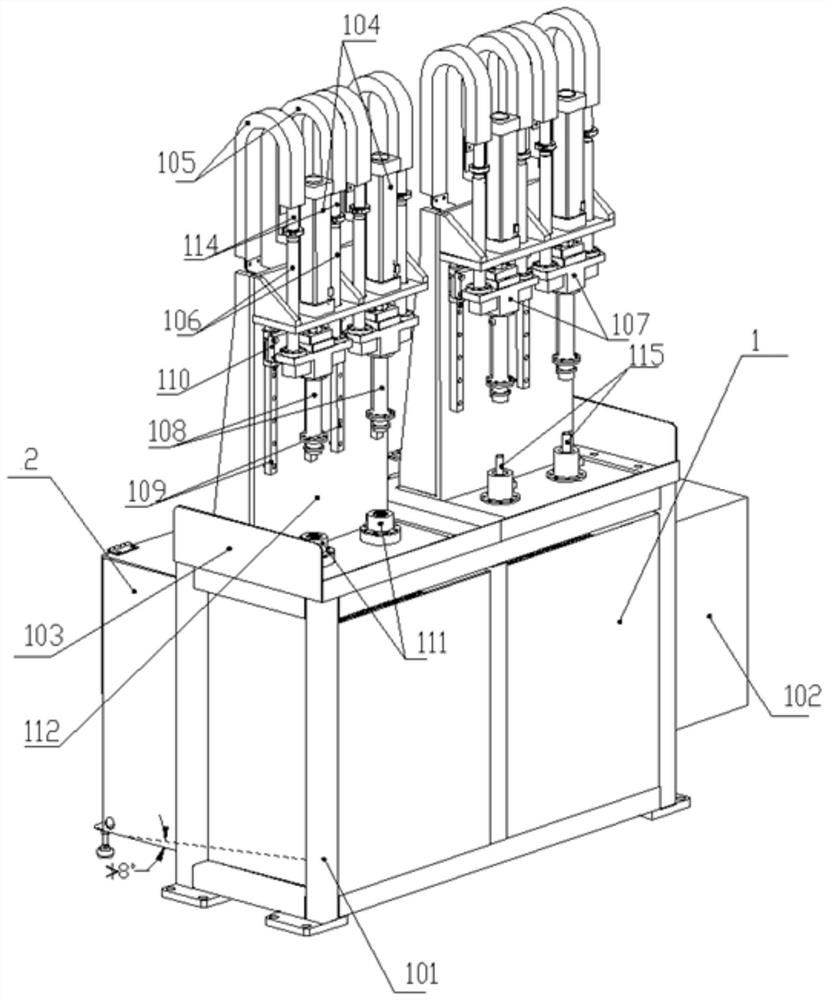

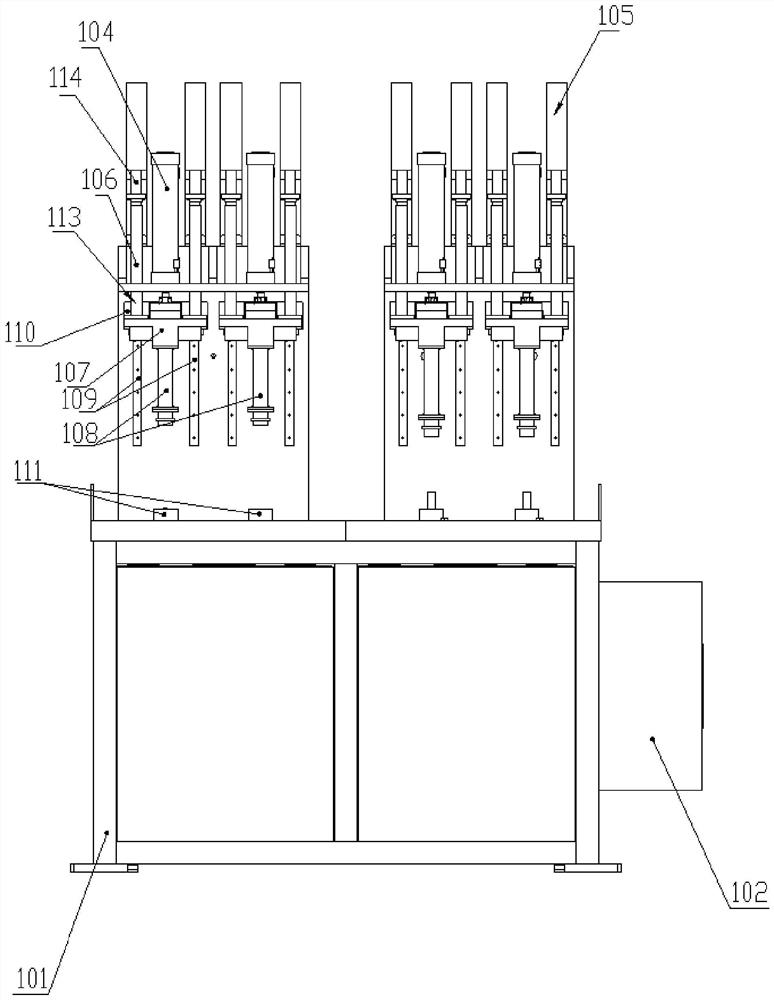

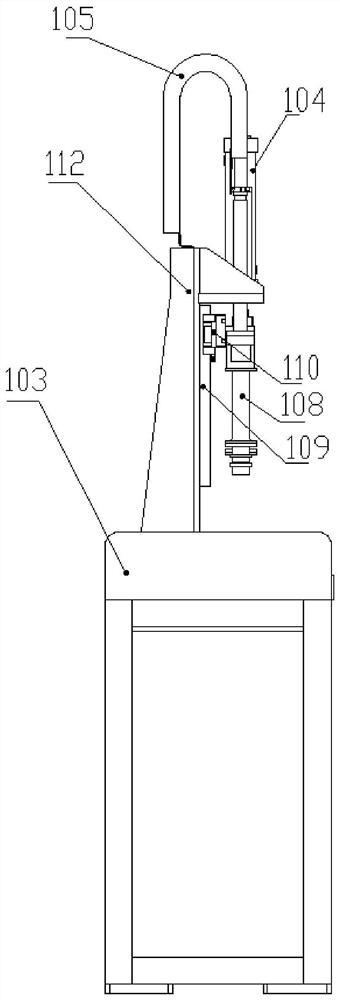

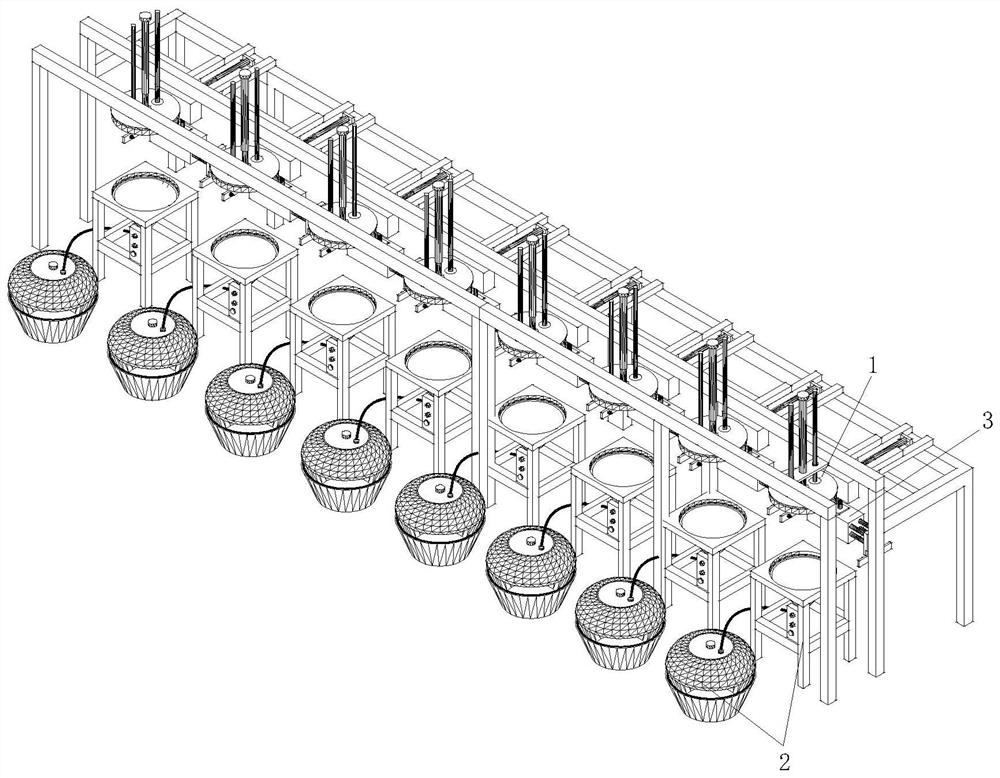

Automatic injection molding assembling line for grenade shells

ActiveCN111546569ARealize human-machine isolationEliminate potential safety hazardsDomestic articlesManufacturing engineeringInjection moulding

The invention discloses an automatic injection molding assembling line for grenade shells. The assembling line involves a bushing assembling system and a shell injection molding system; the bushing assembling system involves an upper bushing injection molding station, a lower bushing injection molding station and a pressing station; and the shell injection molding system involves a core rod pressing-in station, a shell injection molding station and a core removing station. According to the assembling line, the bushing assembling system and the shell injection molding system are arranged, so that automatic production and machining of grenade upper bushing and lower bushing injection molding, inner bushing pressing assembling and grenade shell injection molding are achieved; personnel is notneeded in the production process, so that the man-machine isolation in dangerous procedures is achieved, potential safety hazards are eliminated, and the production safety is improved; the labor intensity is reduced, and an automatic conveying mode is adopted in the production process, so that field workers are reduced, and the safety production management level and the production efficiency areimproved; and upper bushings and lower bushings are subjected to injection molding and pressing at the same time, so that the production efficiency is effectively improved.

Owner:GUANGDONG MINGHUA MACHINERY

Automatic box retreating system of detonator

ActiveCN102515993BComplete human-computer isolationCompletely realize human-machine isolationDetonatorsDetonatorDetonation

The invention relates to an automatic box retreating system of a detonator, which belongs to the field of detonator propellant equipment of civil detonation devices and comprises a mould conveying device used for enabling a mould to automatically entering and leaving a process room and returning an empty mould to a conveying belt, a box retreating device used for achieving the effect that a pipe casing retreats from the mould and the pipe casing is automatically dropped, collected and molded, a conveying device used for enabling a finished box to reach the conveying device at the finished product collection position and an empty box feeding device used for enabling the empty box to reach the box retreating device through a belt conveyor. The mould conveying device is connected with the box retreating device which is connected with the empty box feeding device through the conveying the device. The automatic box retreating system of the detonator has the advantages of being capable of replacing manual workers to completely achieve the whole process of detonator box retreating procedures in basic detonator production, achieving complete man-machine separation, resolving safety hazards existing in the production process and having the advantages of being safe and reliable, reducing labor intensity and the like.

Owner:长春汇维科技股份有限公司 +1

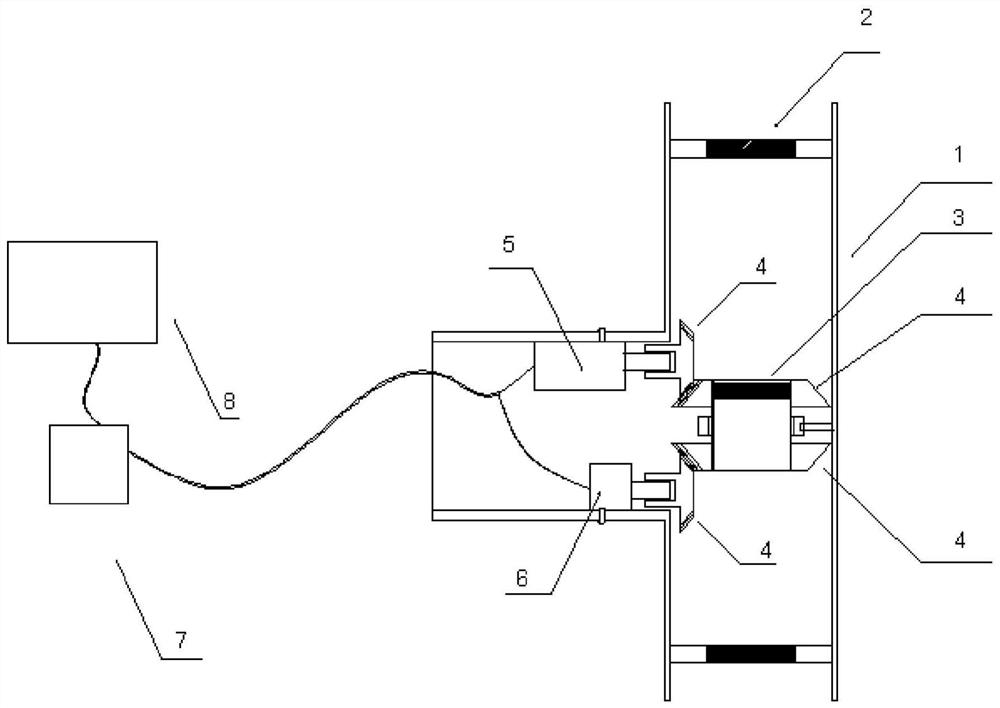

Online detection system for main speed reducer assembly test

PendingCN112461536AFully automatedAvoid the influence of human factorsVehicle testingMachine gearing/transmission testingIntrinsic safetySignal conditioning

The invention discloses an on-line detection system for a main speed reducer assembly test. The on-line detection system comprises a measurement and control cabinet, a plurality of PLC switching cabinets and a detection device; the measurement and control cabinet comprises an industrial personal computer and a display; the PLC transfer cabinet comprises a PLC module and a signal conditioning module; the detection device comprises a noise sensor, an infrared temperature measurement sensor and a pressure sensor which are respectively installed at corresponding positions on a test bed for testinga main speed reducer assembly and connected with the input end of a signal conditioning module, the output end of the signal conditioning module is connected with a PLC module, and the PLC module anda display are both connected with an industrial personal computer. The system realizes the functions of online acquisition, storage, printing and the like of test data, the test data is real, and theinfluence of human factors is avoided; abnormal phenomena in the test process can be timely alarmed, so that the expansion of accidents is avoided; meanwhile, an operator does not need to monitor ina test room, man-machine isolation is achieved, potential safety hazards are eradicated, and the intrinsic safety of the process is improved.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

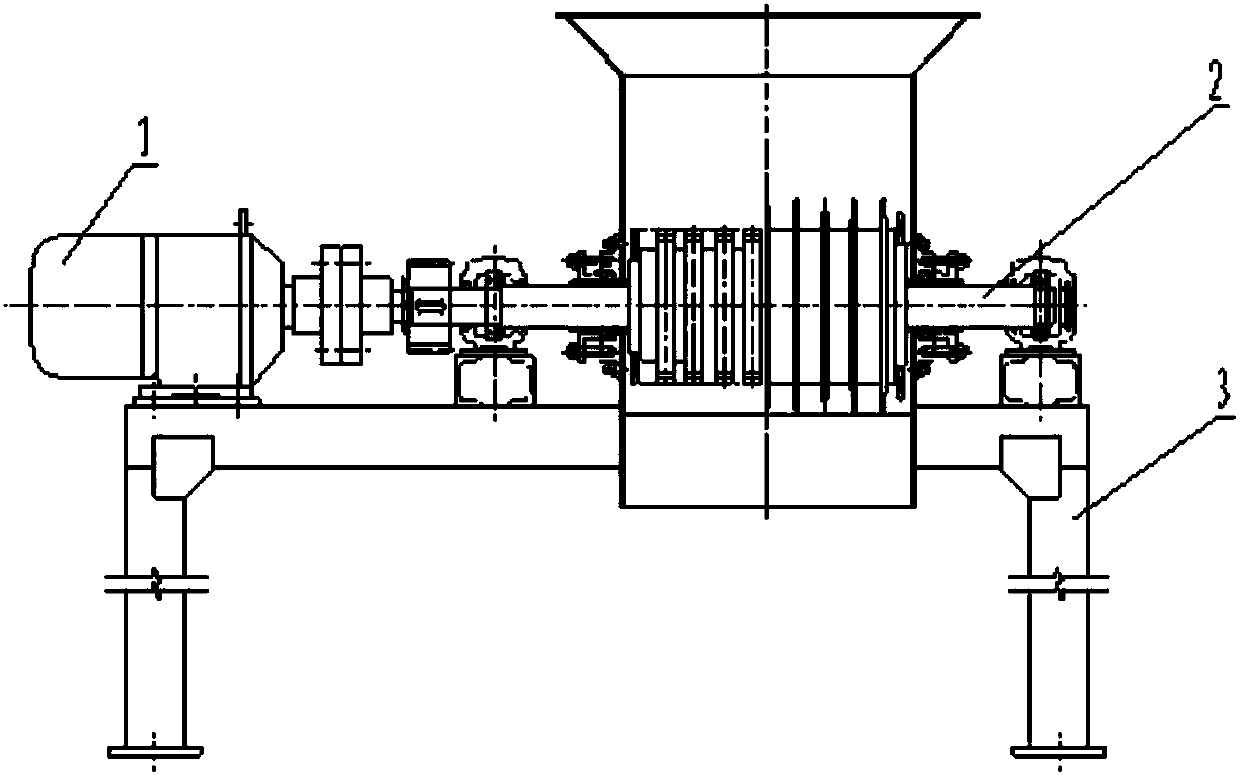

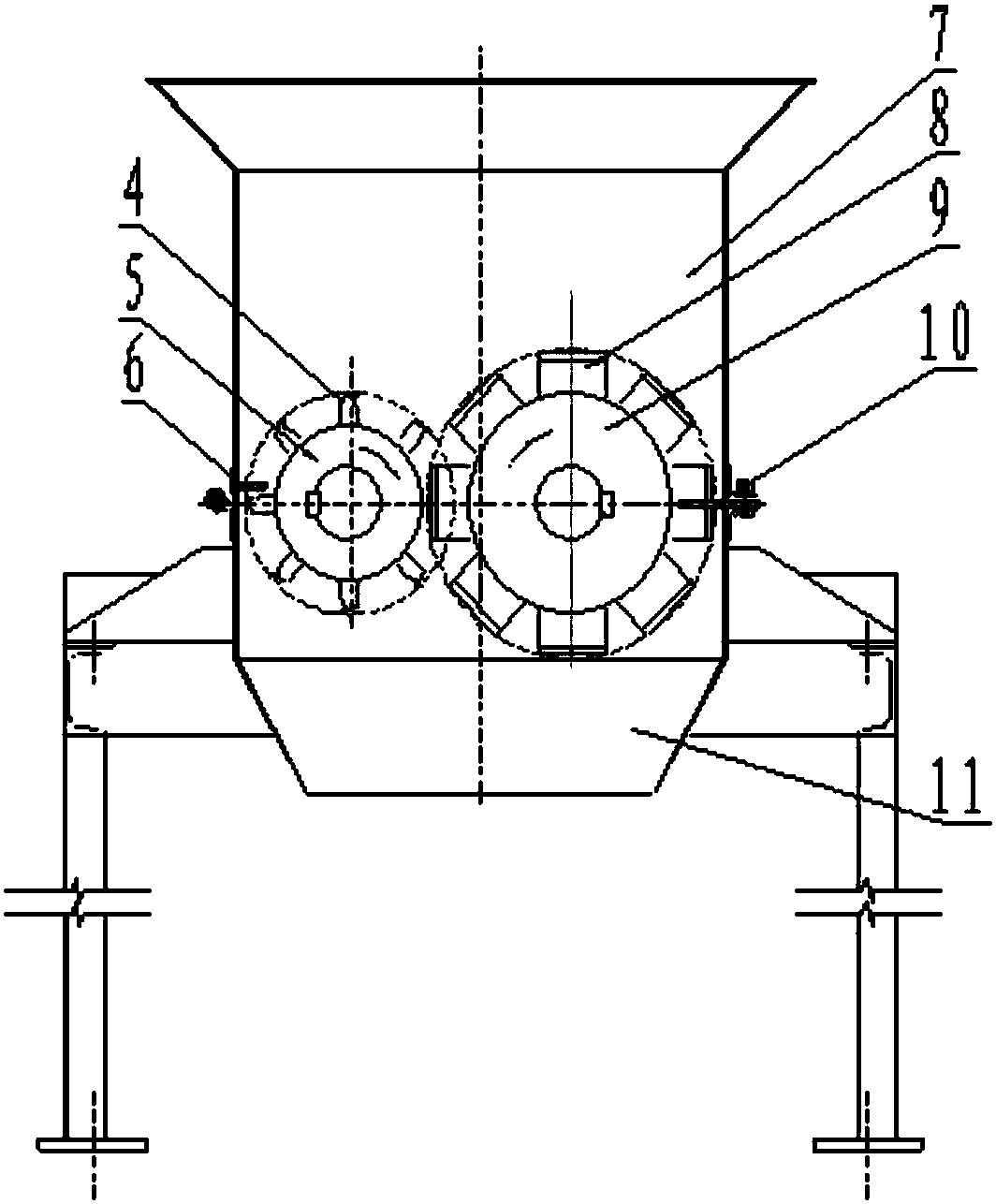

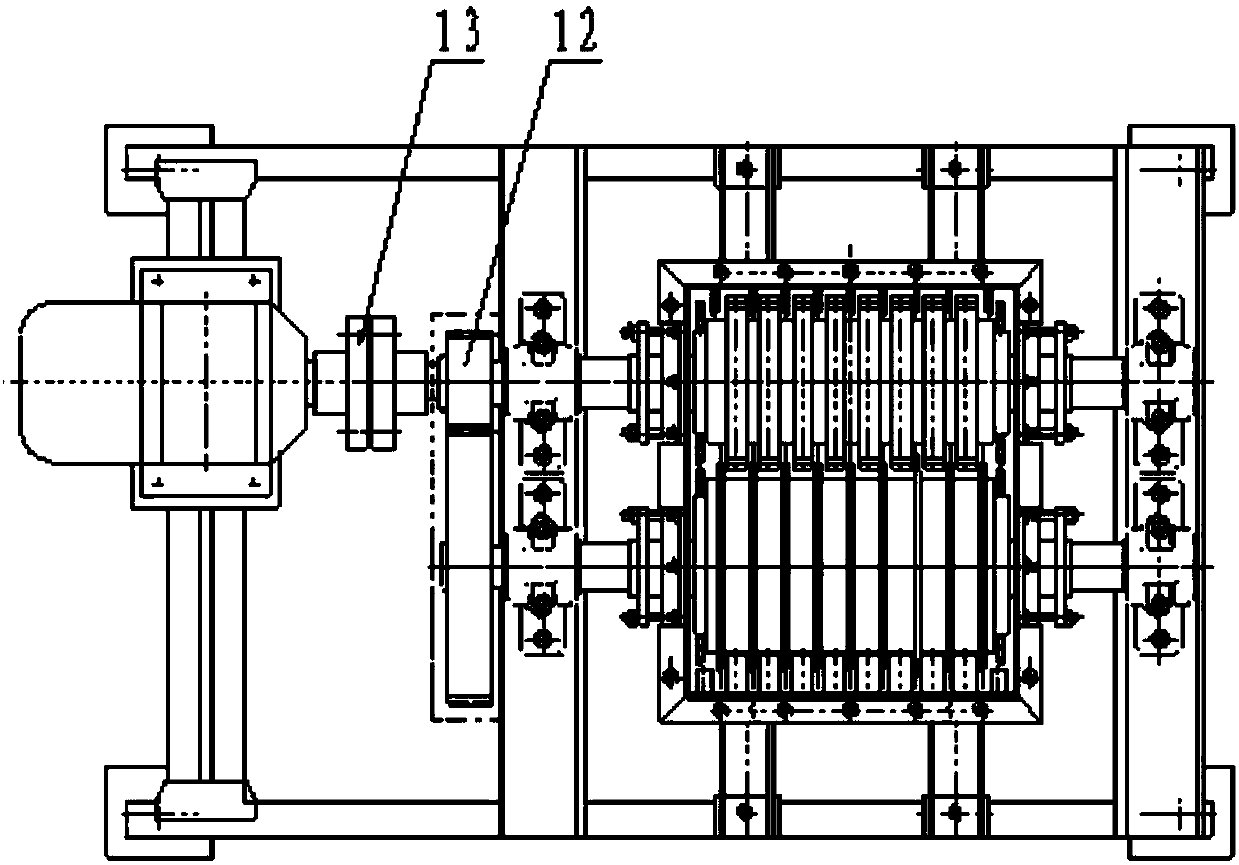

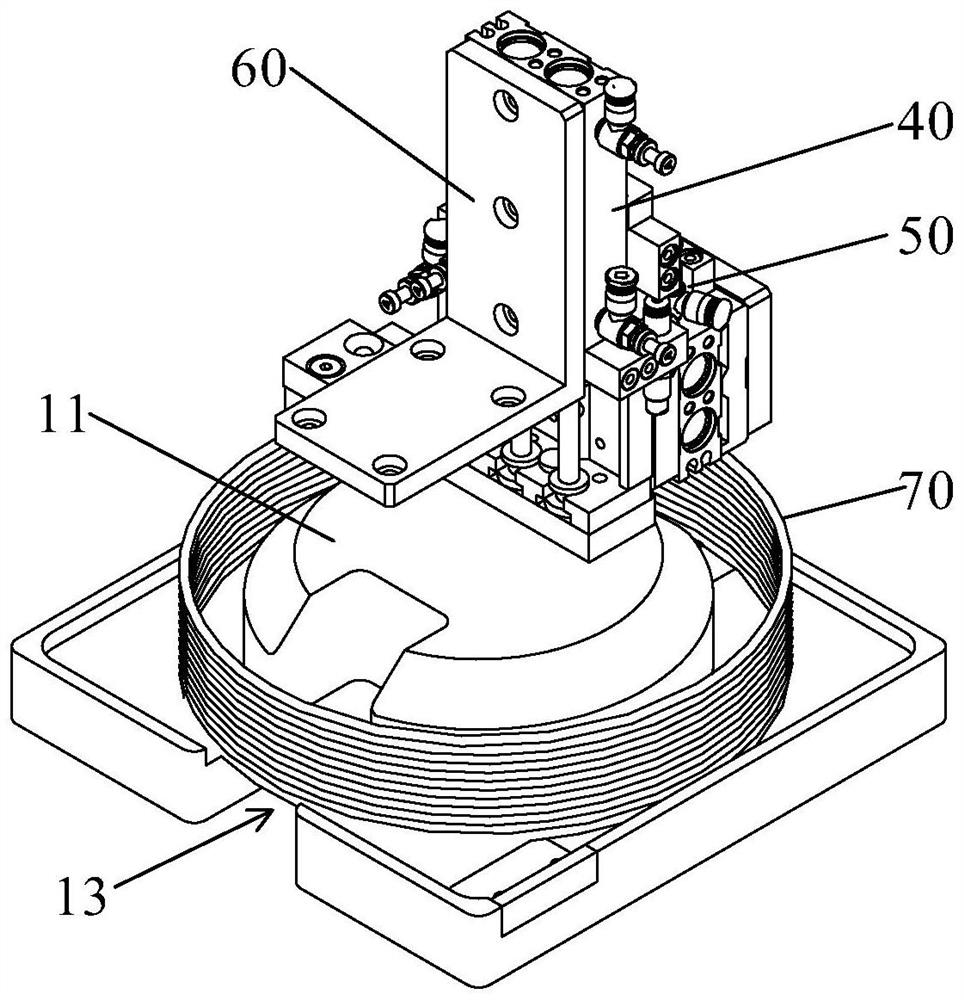

A dough crusher

ActiveCN105833963BRealize human-machine isolationReduce security risksGrain treatmentsCouplingEngineering

The invention discloses a material mass crushing machine which comprises an explosion-proof motor, a rotating shaft, a bracket, a cutting roller, a feed bin, a strip roller, a discharge bin, a transmission gear and a coupling, wherein the cutting roller meshes with the strip roller; a strip tooth longitudinal section of the strip roller is triangular or tapered; and a cutting tooth longitudinal section of the cutting roller is square. According to the material mass crushing machine, inflammable, explosive, high-plasticity and irregular lumps of which the side lengths are from 100 mm to 400 mm can be made into small-mass materials of which the side lengths are smaller than or equal to 50 mm through rolling cutting and rolling pulling, a motor accelerator and a motor reducer are adopted for power transmission, on-site electrical equipment adopts explosion prevention of the same grade, and the material mass crushing machine is a full-mechanical rolling type crushing machine of which the production capacity is 40 kg / min.

Owner:LUZHOU NORTH CHEM IND

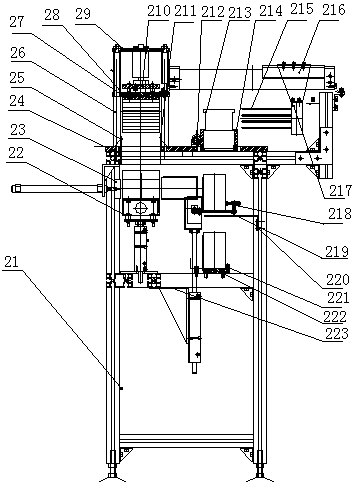

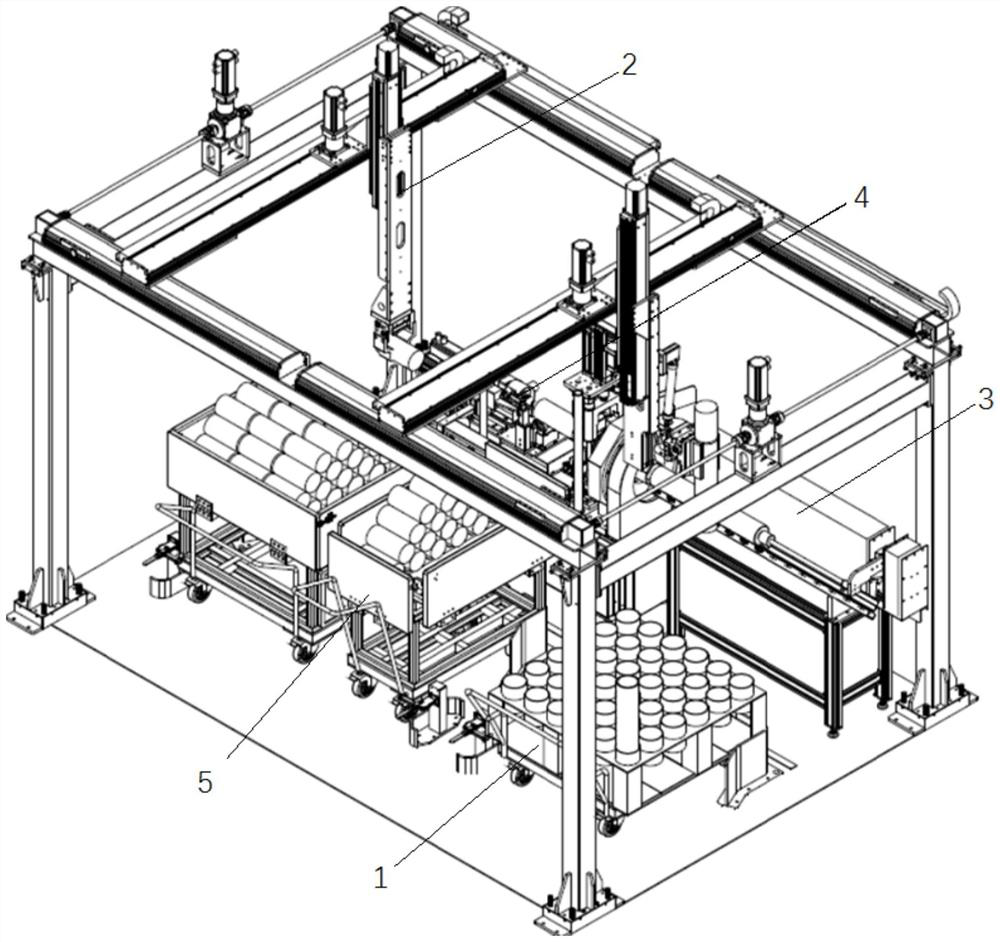

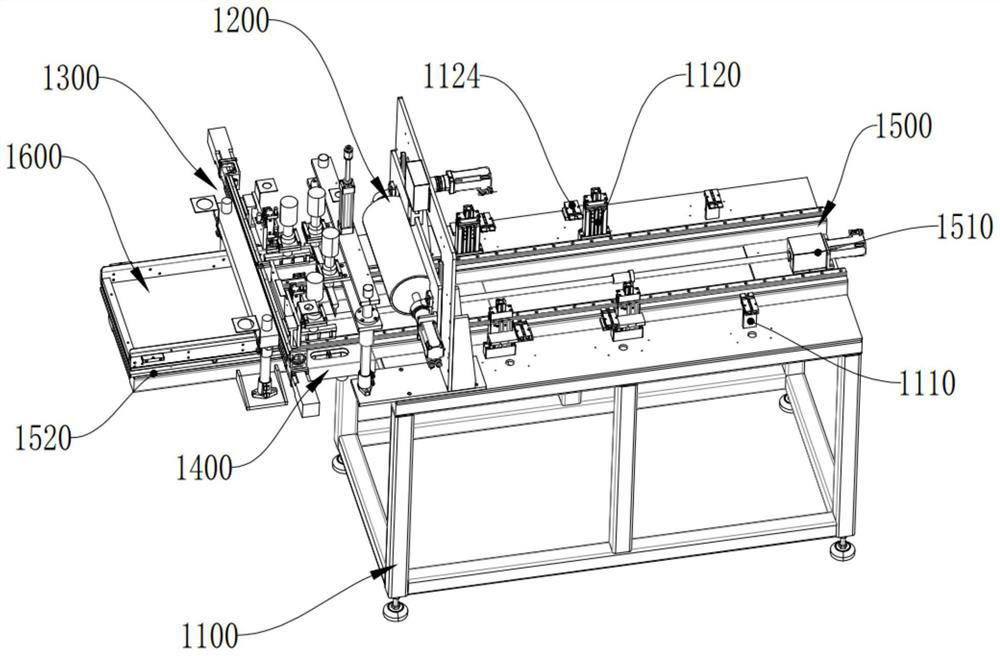

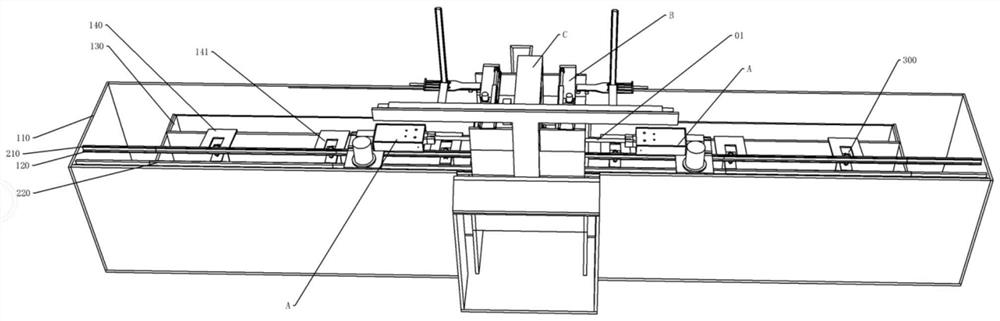

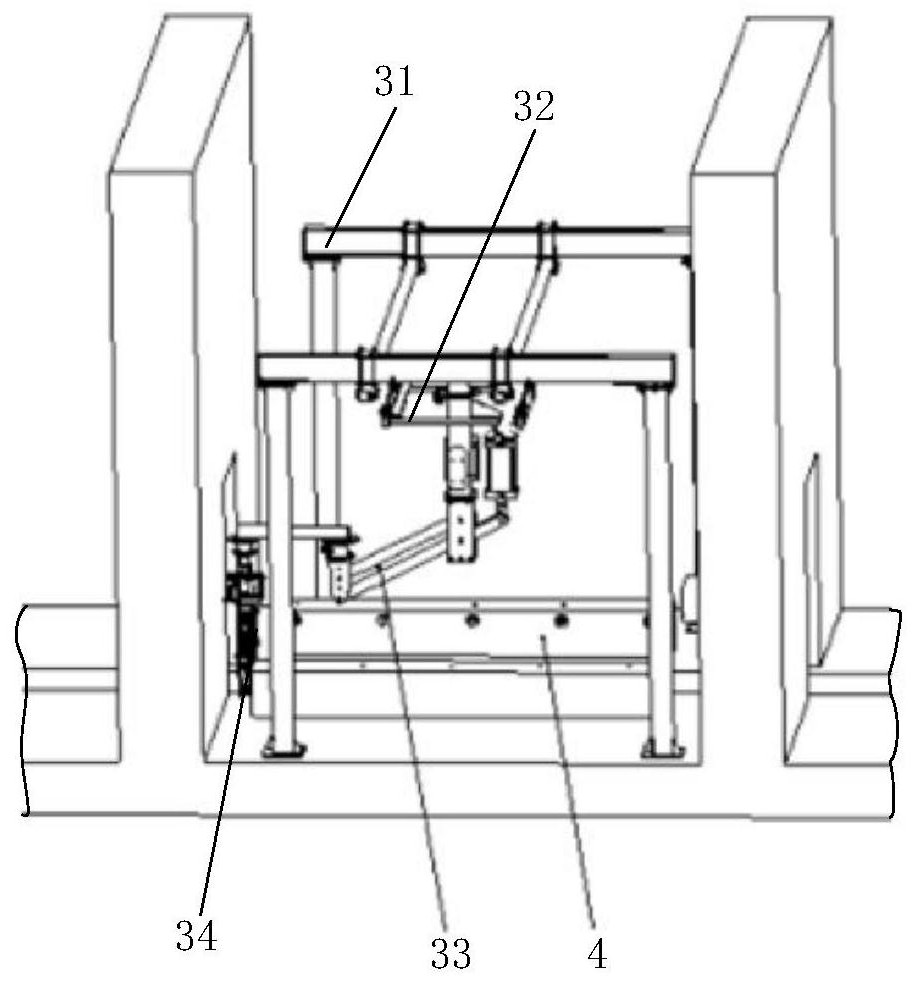

Cutting-off and shaping system for solid propellant filling grain

PendingCN113442201ARealize flexible cut-to-lengthRealize end face automatic shaping operationMetal working apparatusIndustrial engineeringSupport plane

The invention provides a cutting-off and shaping system for a solid propellant filling grain. The problems that in the cutting-off and end face shaping operation process of an existing solid propellant filling grain, the production efficiency is low, harm is caused to a human body, and accidents are likely to happen are solved. In the system, a feeding trolley is used for completing storage of the original grain; a truss mechanical arm comprises a supporting frame, a feeding clamping jaw and a discharging clamping jaw and is used for completing feeding of original grains and discharging of finished grains; a feeding device is located below the feeding clamping jaw and used for axially conveying the original grain to a fixed-length cutting-off and end face shaping device; the fixed-length cutting-off and end face shaping device is arranged on one side of the feeding device and used for achieving flexible fixed-length cutting-off and end face shaping operation of the original grain; a discharging trolley is arranged below the discharging clamping jaw and used for completing storage of the finished grain; and a control device is used for controlling the feeding trolley, the truss mechanical arm, the feeding device, the fixed-length cutting-off and end face shaping device and the discharging trolley, and cutting-off and shaping operation of the grain is completed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

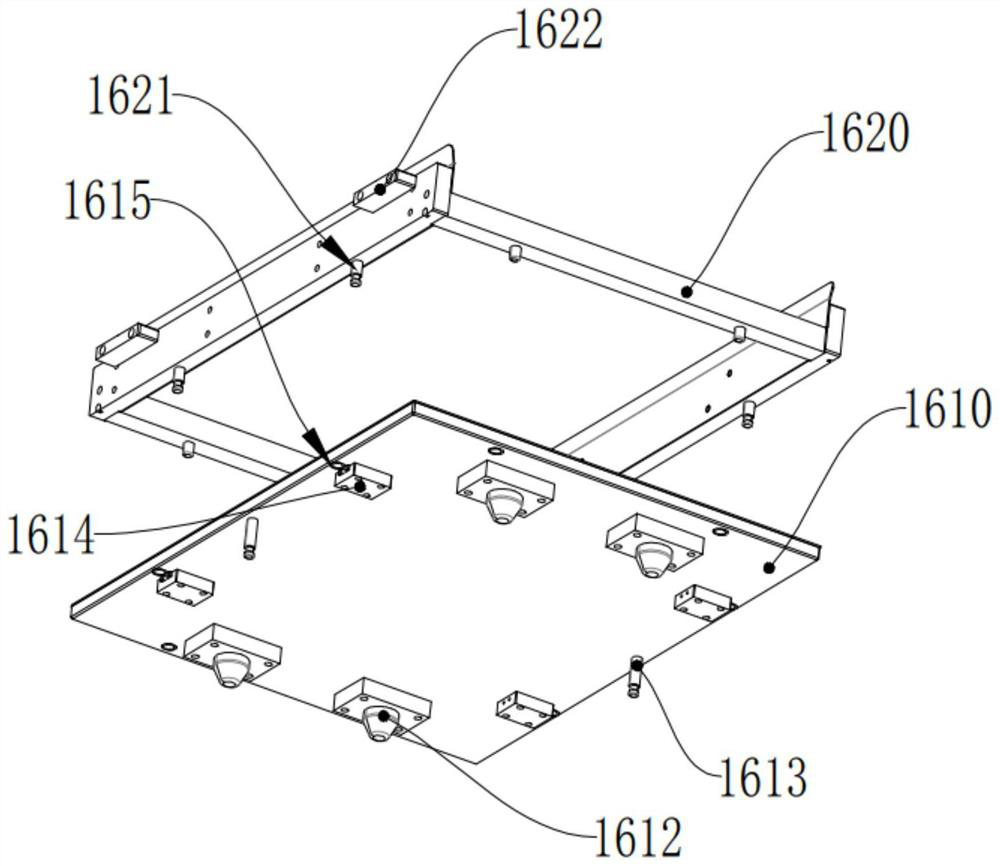

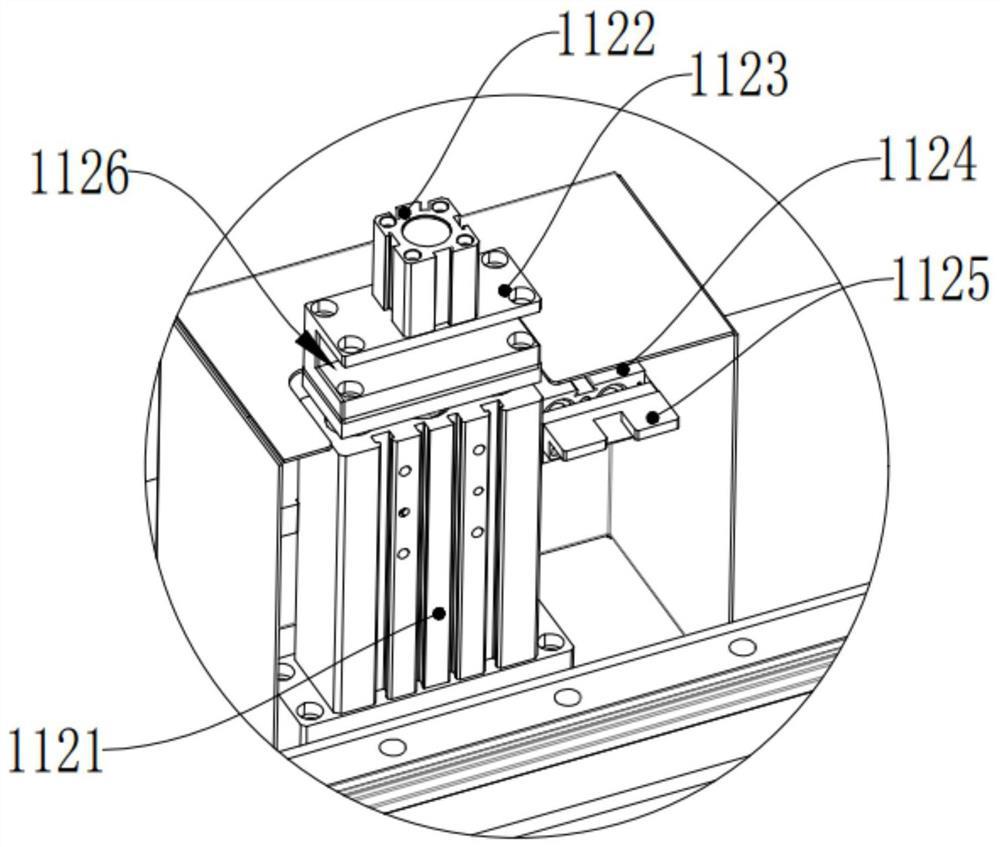

Plastic explosive slitting and weighing device, double-station slitting system and control method of double-station slitting system

ActiveCN113432492AFully automatedAvoid stickingAmmunitionWeighing apparatus for materials with special property/formExplosive AgentsStructural engineering

The invention discloses a plastic explosive slitting and weighing device, a double-station slitting system and a control method of the double-station slitting system. The plastic explosive slitting and weighing device comprises a workbench, an explosive pressing mechanism, an explosive slitting mechanism, weighing units, a linear moving mechanism and an explosive carrying tray, wherein the explosive carrying tray is used for carrying plastic explosives; the linear moving mechanism is used for driving the explosive carrying tray to move, so that the explosive carrying tray sequentially passes through the explosive pressing mechanism and the explosive slitting mechanism; the explosive pressing mechanism is used for rolling and flattening the plastic explosives in the explosive carrying tray; the explosive slitting mechanism is used for slitting the plastic explosives in the explosive carrying tray into explosive blocks and shifting the slit explosive blocks into the weighing units; and the weighing units are used for weighing the explosive blocks split by the explosive splitting mechanism. Automatic blocking in the plastic explosive slitting process is realized, no operator is required, so that man-machine isolation of dangerous procedures is realized, then potential safety hazards are eliminated, and production safety is improved.

Owner:GUANGDONG MINGHUA MACHINERY

Pneumatic vibration material feeding device

InactiveCN111532685AMovement precisionPrecise automatic feedingControl devices for conveyorsJigging conveyorsControl systemMan machine

The invention relates to a pneumatic vibration material feeding device. The pneumatic vibration material feeding device comprises material feeding equipment, weighing equipment and a self control system, wherein the material feeding equipment, the weighing equipment and the self control system are connected through a control loop. According to preset self control program, set weight parameters, and signals transmitted and fed back by the weighing equipment in real time, a pneumatic vibrator and a precise material feeding assembly of the material feeding equipment are automatically started andstopped; the precise, continuous and quantitative automatic material feeding of powder materials in energetic material production is realized; the man-machine isolation is realized; the work intensityof employees is reduced; and the essential safety degree is improved.

Owner:GANSU YINGUANG CHEM IND GRP CO LTD

Energy-containing powder material automatic press-fitting device and method based on servo pressurization

The invention discloses an energetic powder material automatic press fitting device and method based on servo pressurization, and the device part comprises a pressure head, an igniter shell, an energetic powder material, a positioning mold, a pressure head dismounting station, a pressurization station, a pressure head assembling station, a manipulator, a conveying belt, a positioning carrier, a servo press, a jacking air cylinder, an intercepting air cylinder and a second manipulator. The automatic press-fitting device is used for replacing manual operation for press-fitting of the energetic powder material, man-machine isolation can be achieved, and the problem of automatic press-fitting of the energetic powder material of the aerospace initiating explosive device is solved.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

Secondary docking device and method applied to detonating tube and rubber plug

PendingCN114407379ASolve the technical problems of insufficient dockingFirmly connectedButt jointMan machine

The invention relates to the technical field of civil explosive equipment production, in particular to a secondary butt joint device and method applied to a detonating tube and a rubber plug. The secondary butt joint device comprises a mold platform, wherein a rubber plug fixing seat is further arranged on the mold platform; the mold pressing mechanism and the clamping and grabbing mechanism are located above the mold platform and can move, the mold pressing mechanism is used for pressing the rubber plug fixing base, the clamping and grabbing mechanism is provided with a clamping jaw, and the clamping jaw is used for clamping the detonating tube and driving the detonating tube to be pushed in the tube diameter extending direction of the rubber plug till the detonating tube and the rubber plug are in butt joint in place. According to the secondary butt joint device and method, the technical problem that butt joint of the detonating tube and the rubber plug is not in place is solved, production automation is further achieved, man-machine isolation is effectively achieved, and the production and installation efficiency is improved.

Owner:YAHUA GROUP MIANYANG INDAL

Automatic liquid flow test device for nozzle

PendingCN114414228AImprove work efficiencyHigh accuracy of resultsMachine part testingEngine testingTest stationWater pipe

The invention discloses an automatic liquid flow test device for a nozzle. The automatic liquid flow test device comprises a liquid flow test bed and a water return system mounted on one side of the liquid flow test bed, the liquid flow test bench comprises a frame, a measurement and control cabinet, a C-shaped support panel and a plurality of test stations. Each test station comprises a lifting cylinder, a water guide tool, an upper tool, a lower tool, two sliding blocks, two guide rails, two water pipes and two hoses; the lifting air cylinder is installed on the top of the C-shaped supporting panel, the guide rails are installed on the vertical face of the C-shaped supporting panel, the water guiding tool is installed on the two guide rails through two symmetrical sliding blocks respectively, and the water guiding tool can be driven by a piston rod of the lifting air cylinder to move up and down in the vertical direction. The lower end of a water outlet of the water guide tool is connected with an upper tool, and a lower tool is installed on the bottom face of the C-shaped supporting panel. A plurality of nozzle products are tested at the same time through the plurality of parallel test stations, so that the working efficiency is effectively improved, and the result accuracy is improved at the same time.

Owner:XIAN AEROSPACE PROPULSION INST

An automatic calibration device for a smoke transmission rate testing system

ActiveCN108801943BHigh degree of automationFast calibrationTransmissivity measurementsColor/spectral properties measurementsControl engineeringProcess engineering

The invention discloses an automatic calibration system for a smoke transmittance testing system. The automatic calibration system consists of a sleeve, a benchmark mirror, a rotating mirror, a driving device, a servo motor, an angle transducer, a control box and a calibration procedure, wherein the sleeve is in an integral T shape; an operator can set calibration parameters and automatically finish the whole calibration process through the calibration procedure installed on a computer and obtains a calibration curve and calibration parameters. The device has the advantages of high degree of automation, high calibration speed, high accuracy and the like, and can be used for quickly calibrating the smoke transmittance testing system for propellant and gun propellant combustion.

Owner:XIAN MODERN CHEM RES INST

A self-adaptive grinding device for the inner wall of a polyurethane-coated cylinder

ActiveCN109483342BImprove consistencyReduce labor intensityRevolution surface grinding machinesGrinding/polishing safety devicesEngineeringProcess safety

Owner:XIAN MODERN CHEM RES INST

Primer inner explosive filling device

PendingCN109253665ASimple designRealize human-machine isolationBlasting cartridgesAmmunitionPistonEngineering

The invention aims to provide a primer inner explosive filling device which comprises a frame, an explosive filling device, an explosive receiving connection device and an explosive feeding device. Anexplosive receiving connection device connecting plate of the explosive filling device is integrally connected with a cylinder connecting plate, a driving cylinder is fixedly connected in the upper middle of the cylinder connecting plate, a piston of the driving cylinder is fixedly connected with a bottle mold fixing device, a vibrator is mounted on the lower side of the cylinder connecting plate, supporting rods are fixedly connected on the lower side of a horizontal panel of the frame in a matrix distribution manner, the lower ends of the supporting rods are in gap connection with the cylinder connecting plate, so that the cylinder connecting plate is vertically vibrated by the vibrator, the explosive receiving connection device is fixed onto a fixing groove of the explosive receiving connection device connecting plate, and the explosive feeding device and is connected with the explosive receiving connection device. According to the device, explosive filling efficiency is high, floating explosive is avoided in the explosive filling process, man-made safety hazards are removed, and intrinsic safety of primer assembly is improved.

Owner:SHANXI HUHUA GRP

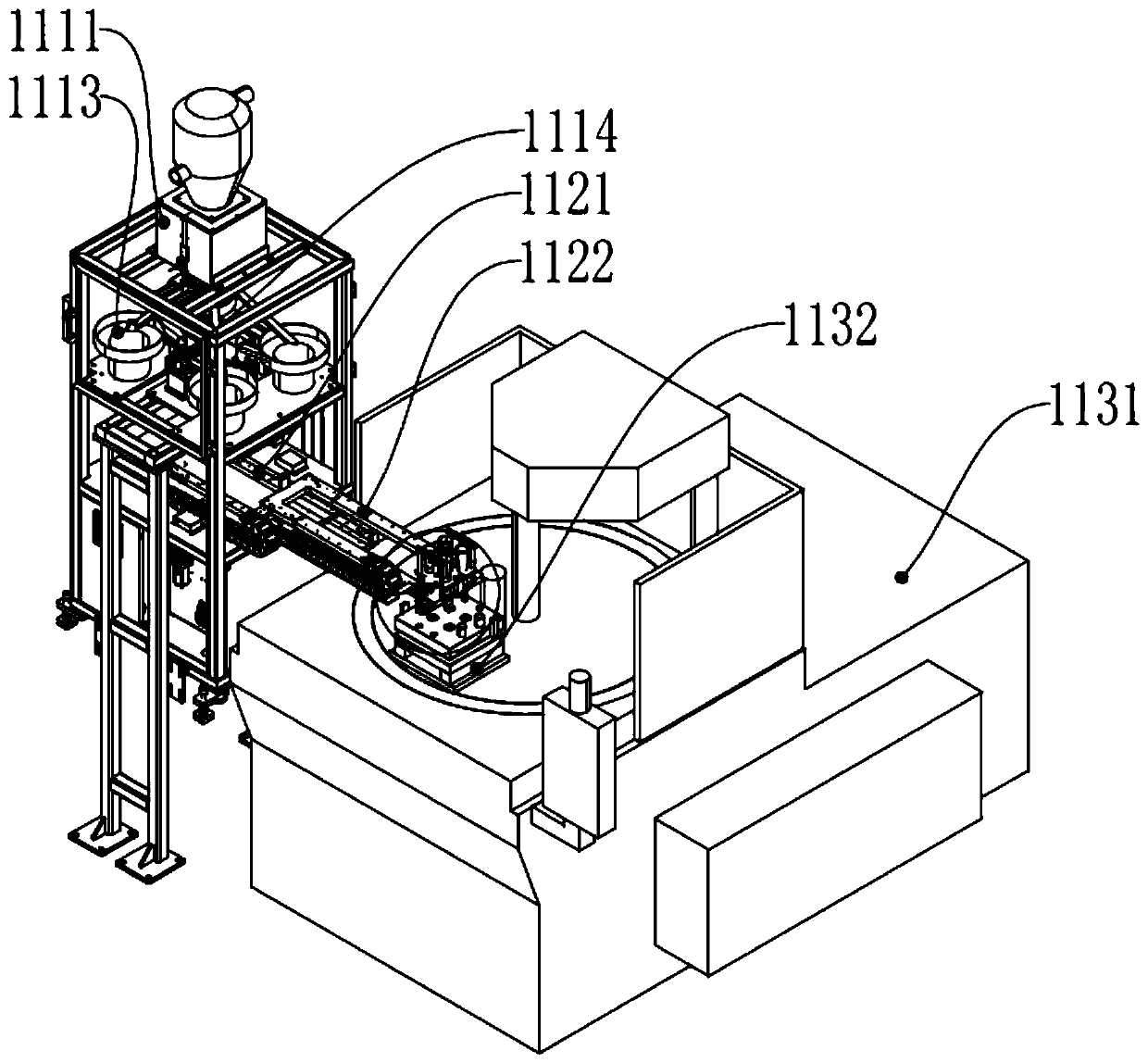

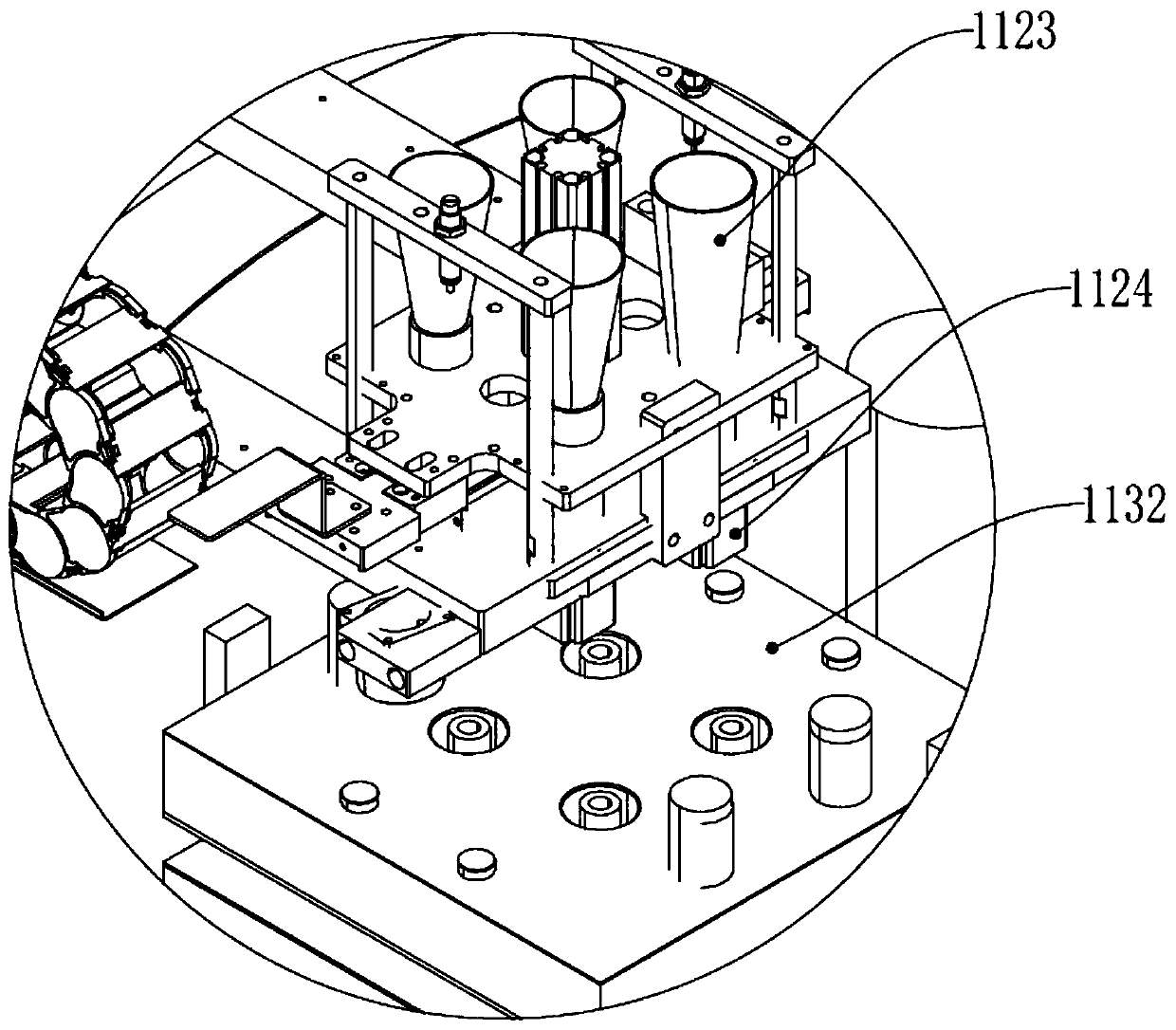

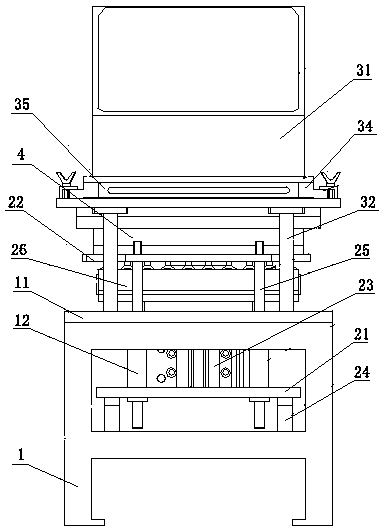

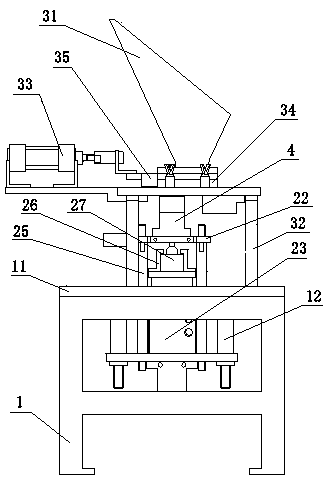

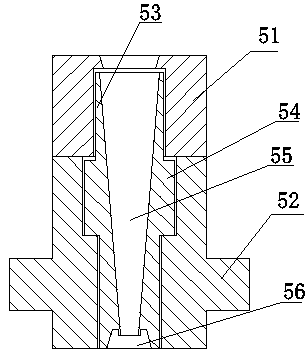

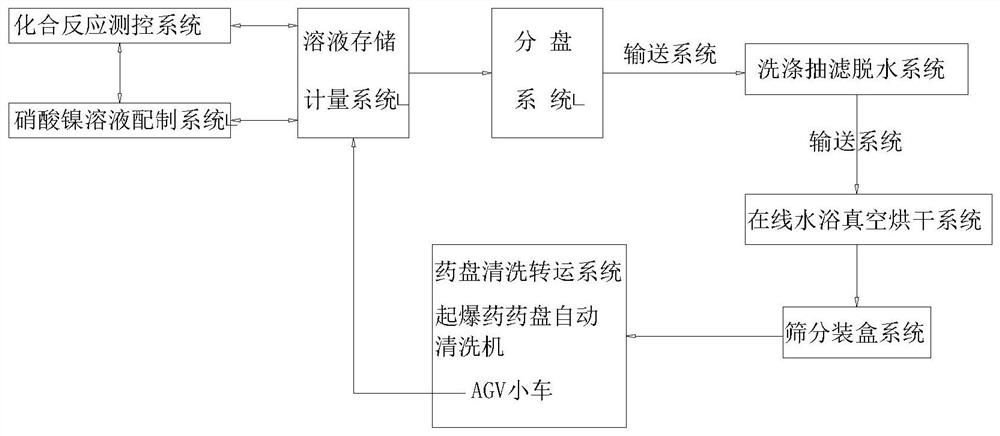

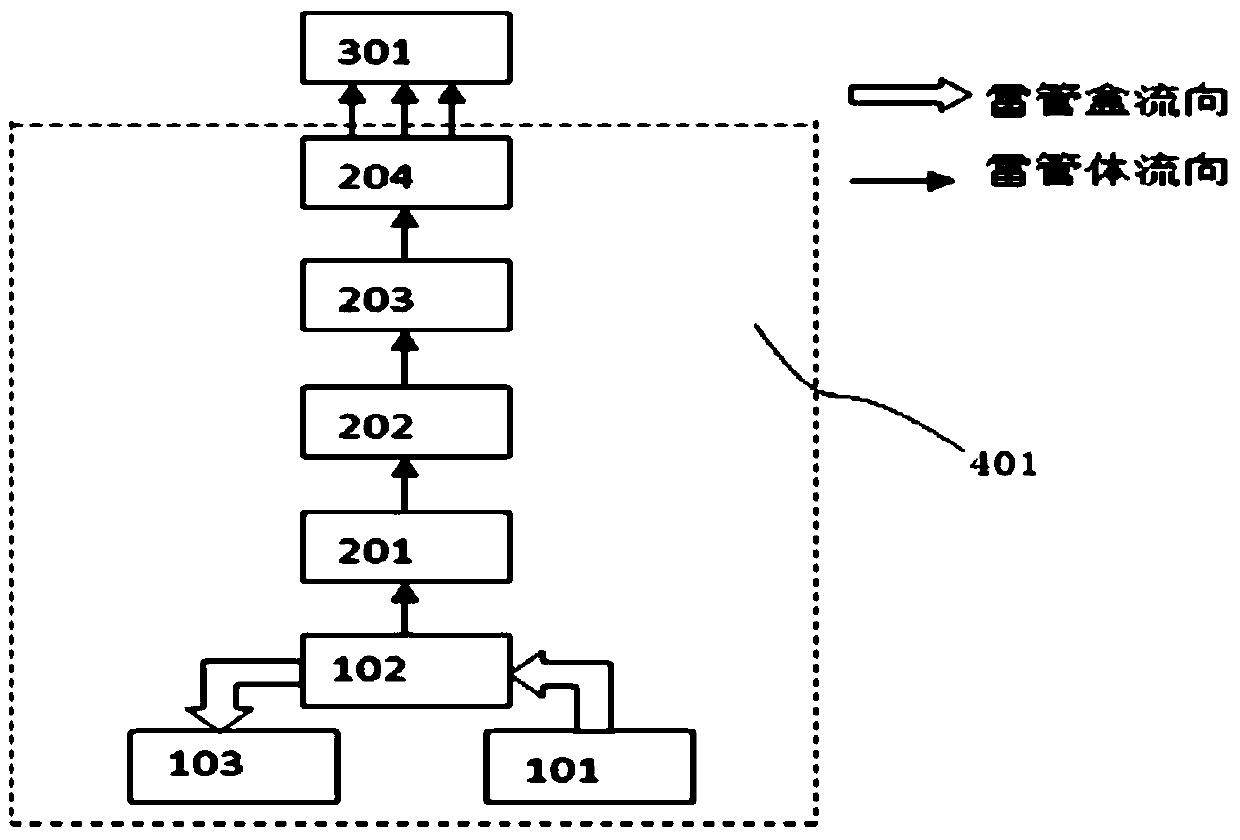

Automatic production line for nickel hydrazine nitrate primary explosive

ActiveCN111908986AReduce labor costsReduce security costsExplosive working-up apparatusDetonatorsVacuum dryingIndustrial engineering

The invention provides an automatic production line for nickel hydrazine nitrate primary explosive. The production line comprises a nickel nitrate solution preparation system, a solution storage and metering system, a combination reaction measurement and control system, a tray separation system, a washing, suction filtration and dehydration system, a conveying system, an online water bath vacuum drying system, a screening and boxing system for quantitatively distributing primary explosive, an explosive tray cleaning and transferring system and a control system for controlling all the systems in the production line to work and operate. The nickel nitrate solution preparation system is used for preparing a nickel nitrate solution and conveying the nickel nitrate solution to the solution storage and metering system, and the chemical combination reaction measurement and control system is used for heating in a water bath and measuring and controlling the temperature of a chemical combination reaction. According to the invention, the automatic tray washing system of the initiating explosive trays is added to the production line, a low-temperature low-vacuum water bath drying process is adopted for the initiating explosive trays, empty trays are transferred through an AGV, mechanization on the whole line is achieved, the number of workers is reduced to the minimum, and continuous andautomatic production of the nickel hydrazine nitrate initiating explosive is achieved.

Owner:NANJING POLYTECHNICAL CHEM CO LTD

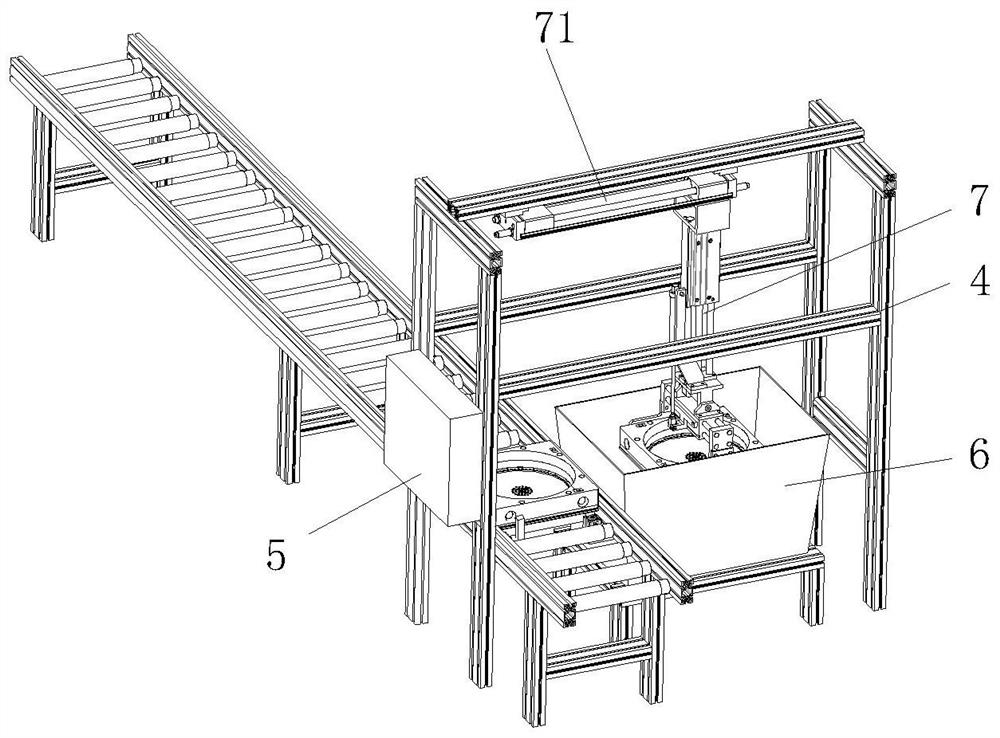

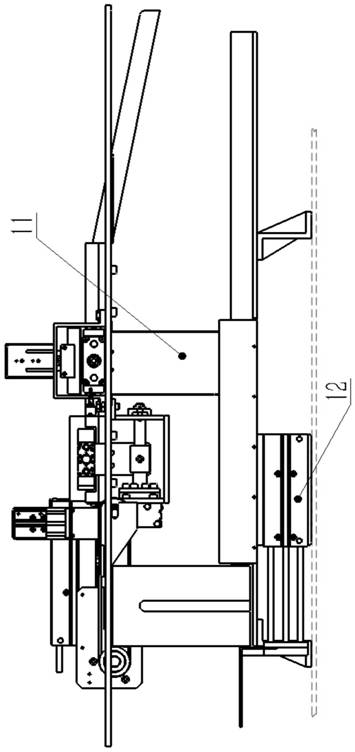

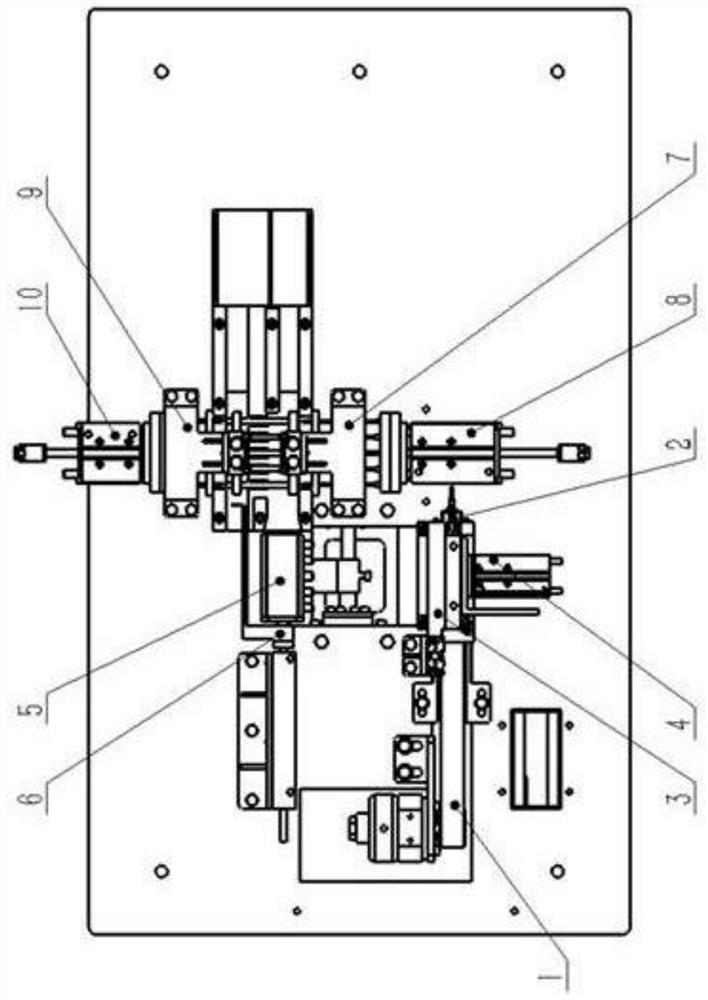

Detonator demoulding device

PendingCN111646873AImprove work efficiencyReduce labor intensityDetonatorsAutomatic controlProcess engineering

The invention discloses a detonator demoulding device. The main technical characteristics are as follows: the device comprises a conveying assembly 1, an inductive switch 2, a mold blocking assembly 3, a mold pushing assembly 4, a rotating assembly 5, a transverse pushing assembly 6, a lower mold clamping assembly 7, a separating assembly 8, an upper mold clamping assembly 9, a retreating assembly10, an automatic collecting assembly 11 and an industrial control box 12. Time and safe working pressure are set in mold splitting and detonator quitting steps; man-machine isolation, automatic demolding, automatic fault detection, automatic alarm and forced reset shutdown are realized; and a PLC is adopted to automatically control mechanical actions, automatically count and collect detonators, upper dies and lower dies and quantitatively box the withdrawn detonators, so that the working efficiency can be effectively improved, the labor intensity can be reduced, and the detonator demoulding device has the advantages of reasonable structural design, safety and reliability in use, suitability for batch production and the like.

Owner:HUNAN SHENFU GRP XIANGHONG MACHINERY CHEM

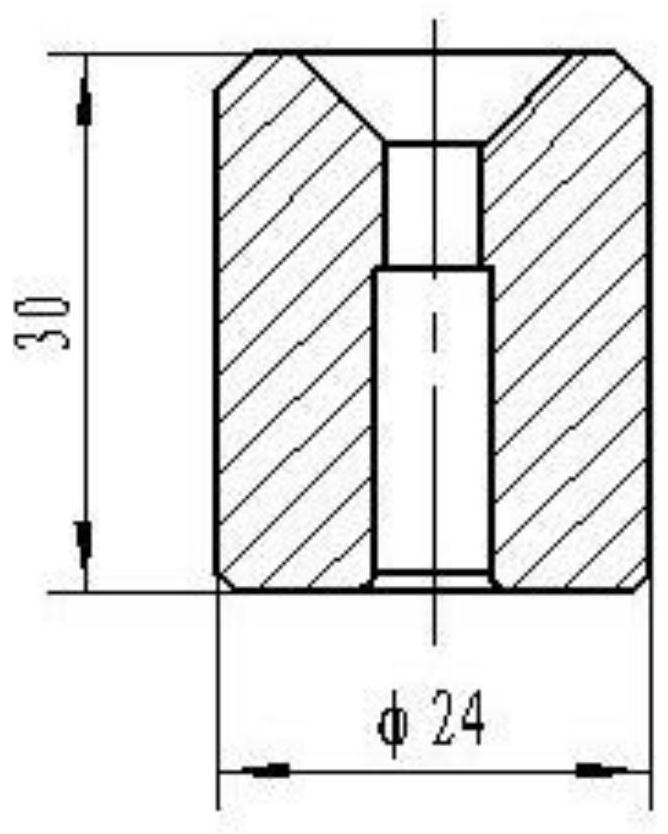

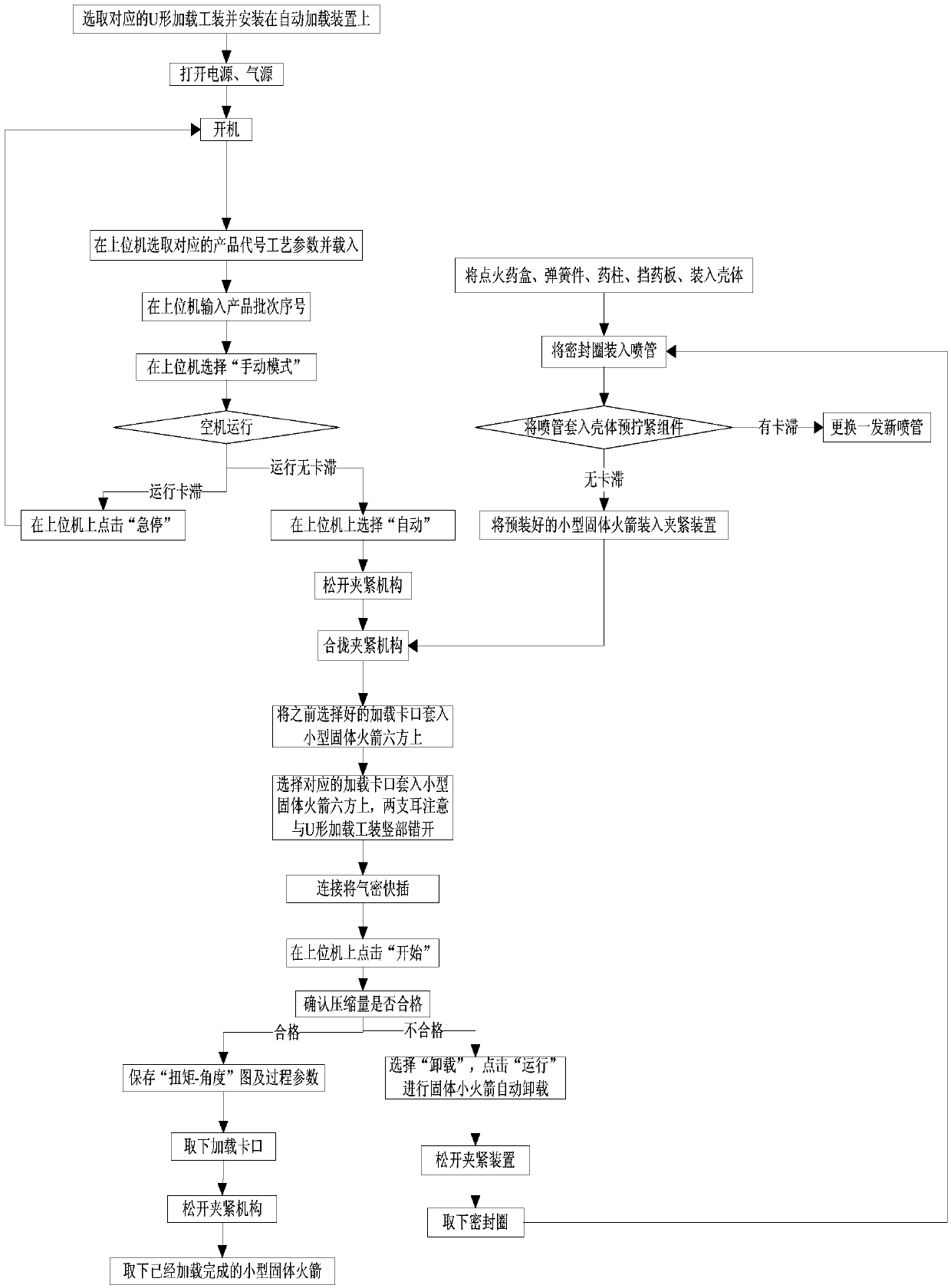

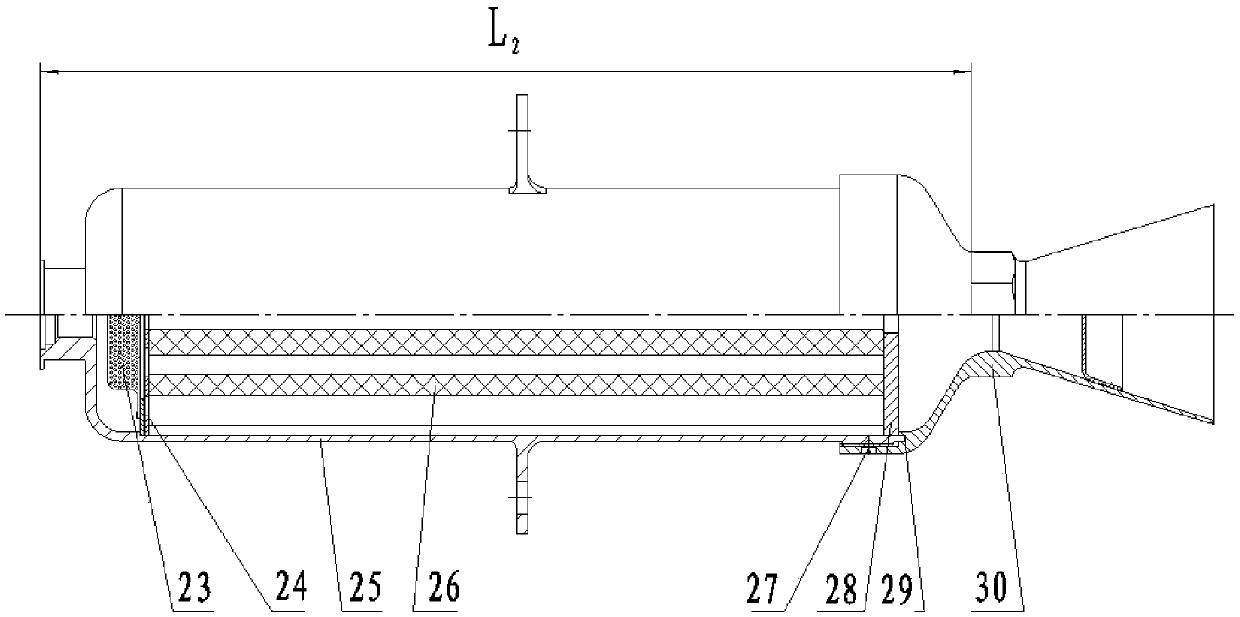

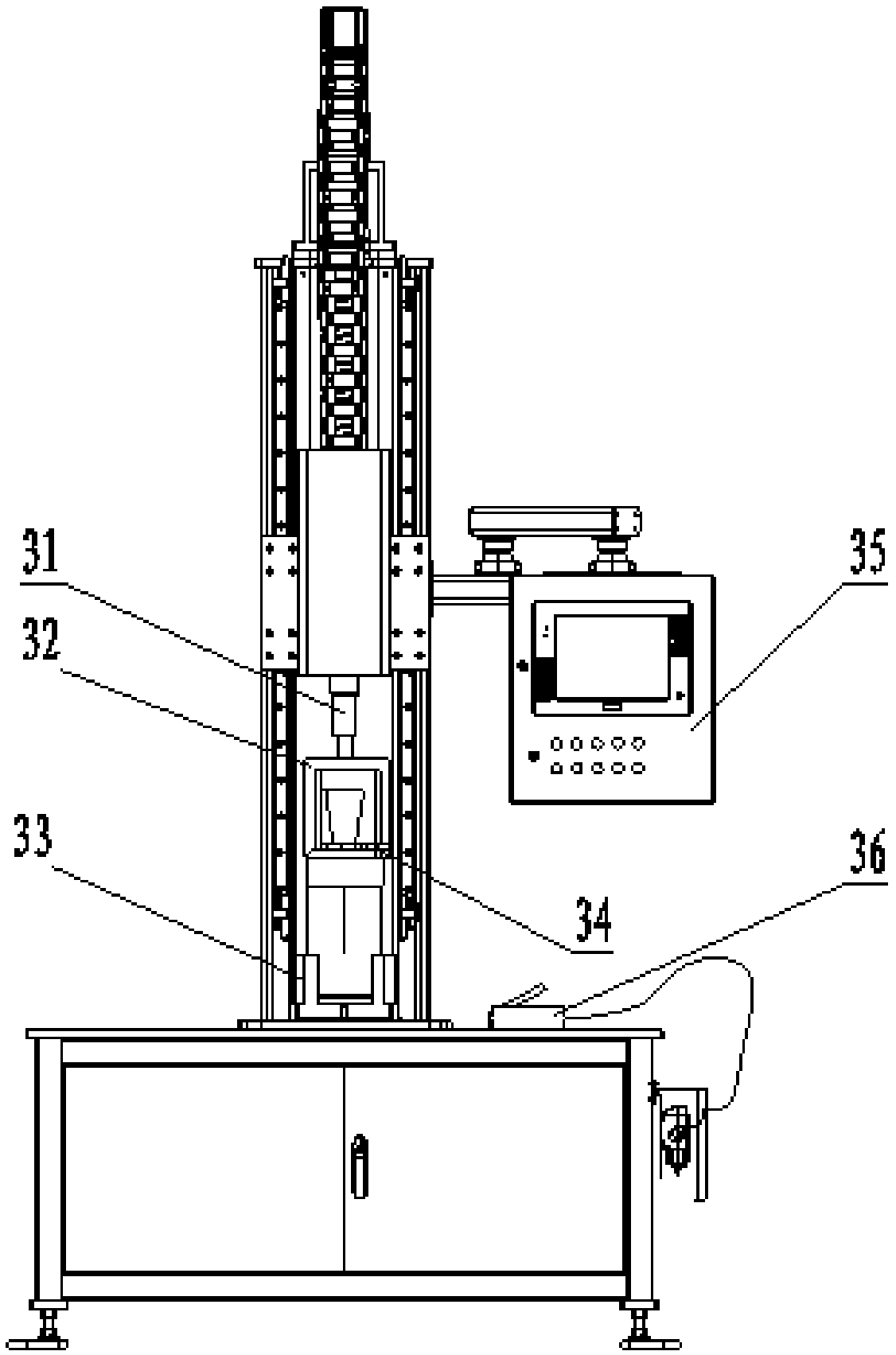

A method and device for automatic loading of small solid rockets based on compression amount control

ActiveCN107617852BTorque protectionImprove Assembly Loading ConsistencyMetal working apparatusRocketSpaceflight

The invention provides a small solid rocket automatic loading method and device based on compression amount control, and belongs to the field of spaceflight initiating explosive devices. According tothe method, automatic loading of a small solid rocket is realized by setting small solid rocket process parameters on the small solid rocket automatic loading device in the whole small solid rocket loading process. The small solid rocket loading process is controlled by setting target compression amount of the small solid rocket, so that product loading consistency is guaranteed. Meanwhile, human-machine isolated operation is achieved, and potential safety operation hazards are eliminated. The process parameters are automatically recorded by the loading device, troubles caused by manual recording of compression amount on a paper recording book after loading and manual photographing recording of the loading process are avoided, and efficiency is improved about twice. Meanwhile, the small solid rocket loading process is controlled based on a compression amount method, and the situation that by utilizing unreasonable moment of force for loading, seal cannot be achieved, and consequently the performance of the small solid rocket is affected is avoided.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

Multi-station electric detonator card waist bayonet machine

ActiveCN111780627BImprove work efficiencyImprove securityAmmunitionDetonatorsCircular discControl engineering

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

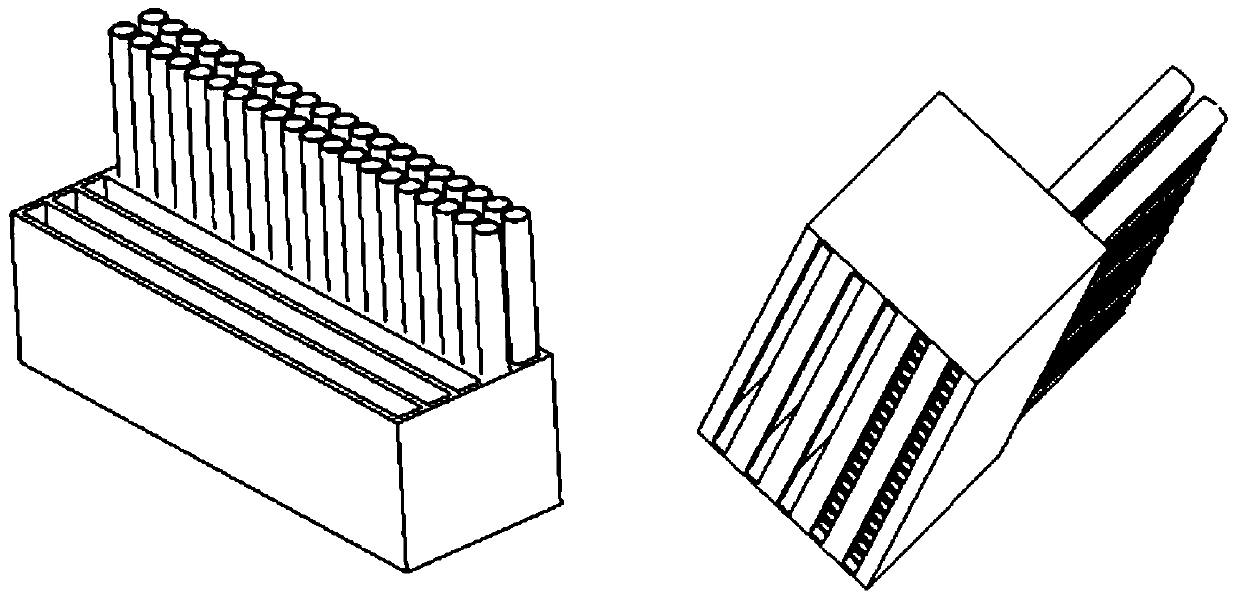

A method and device for automatically sending a detonator tube body into a bayonet

ActiveCN104672038BRealize unmanned operationRealize human-machine isolationDetonatorsDetonatorAutomatic control

The invention discloses a method and a device for automatically sending detonator bodies into a bayonet device. The method comprises the following steps: arranging the detonator bodies in a special temporary storage box, locating by a mechanical clamping device, inserting a jacking push plate into the box bottom, jacking up one row of the detonator bodies into a gap formed by two flat plates, pushing the row of the detonator bodies towards the horizontal direction by virtue of another flat push plate, sending the row of the detonator bodies into sliding plate preset grooves which carry out linear motion, after a sliding plate is in place and stops, drawing out the row of the detonator bodies from the sliding plate by virtue of a manipulator, and translating the row of the detonator bodies into a group sending bayonet device. The device comprises a box entering mechanism, a box translation locating device, a box exiting mechanism, a whole row pipe body jacking mechanism, an elastic flat pushing mechanism, a sliding pipe arranging mechanism, a translation manipulator, a mounting workbench and an automatic control device. According to the method and the device disclosed by the invention, unmanned operation of hazard stations and man-machine separation is realized, multiple detonator bodies can line up and be put into the bayonet device at one time, and the efficiency is very high; meanwhile, the method and the device have the characteristics of simple structure and high performance-price ratio and is worthy of vigorous popularization.

Owner:贵州全安密灵科技股份公司

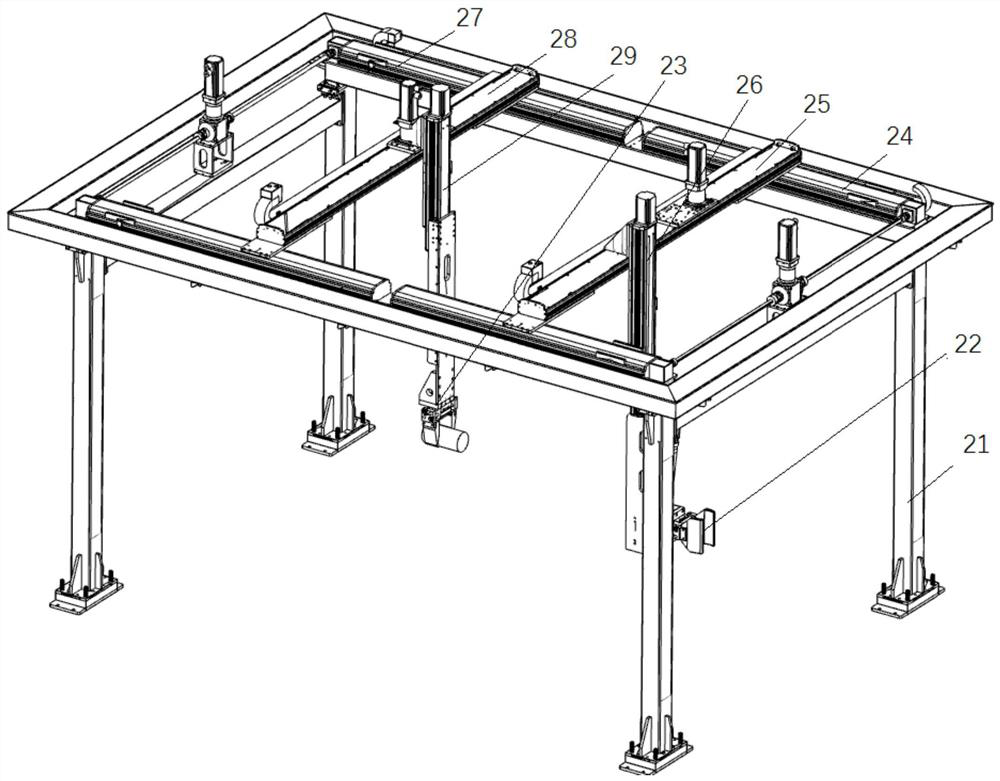

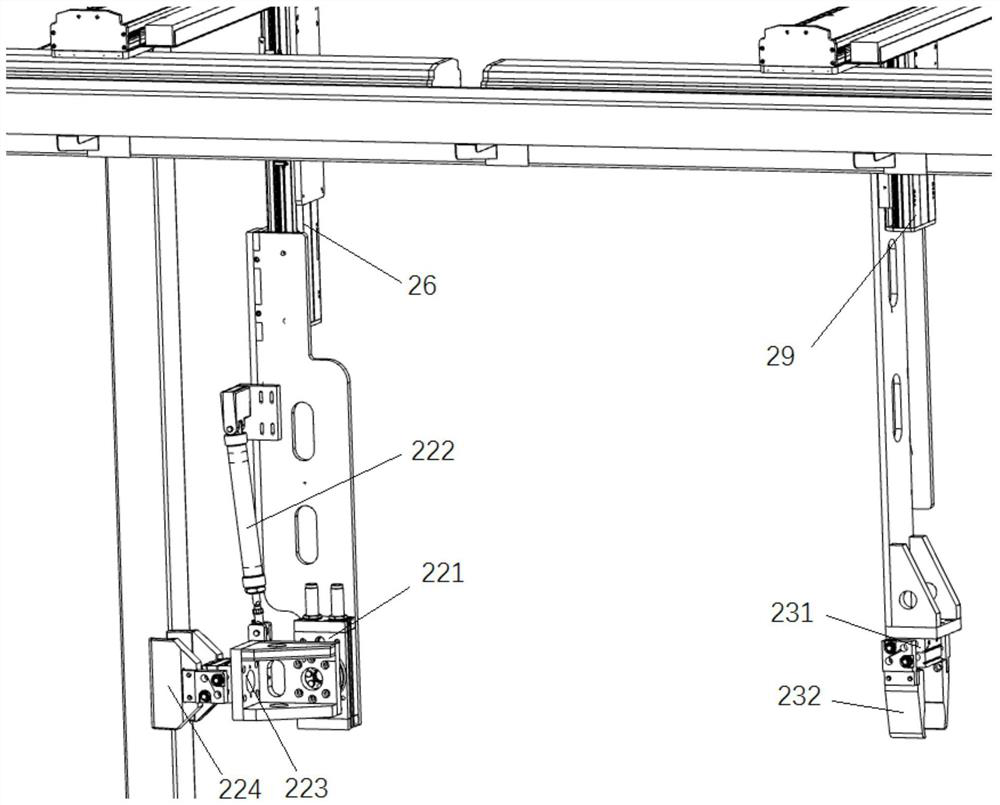

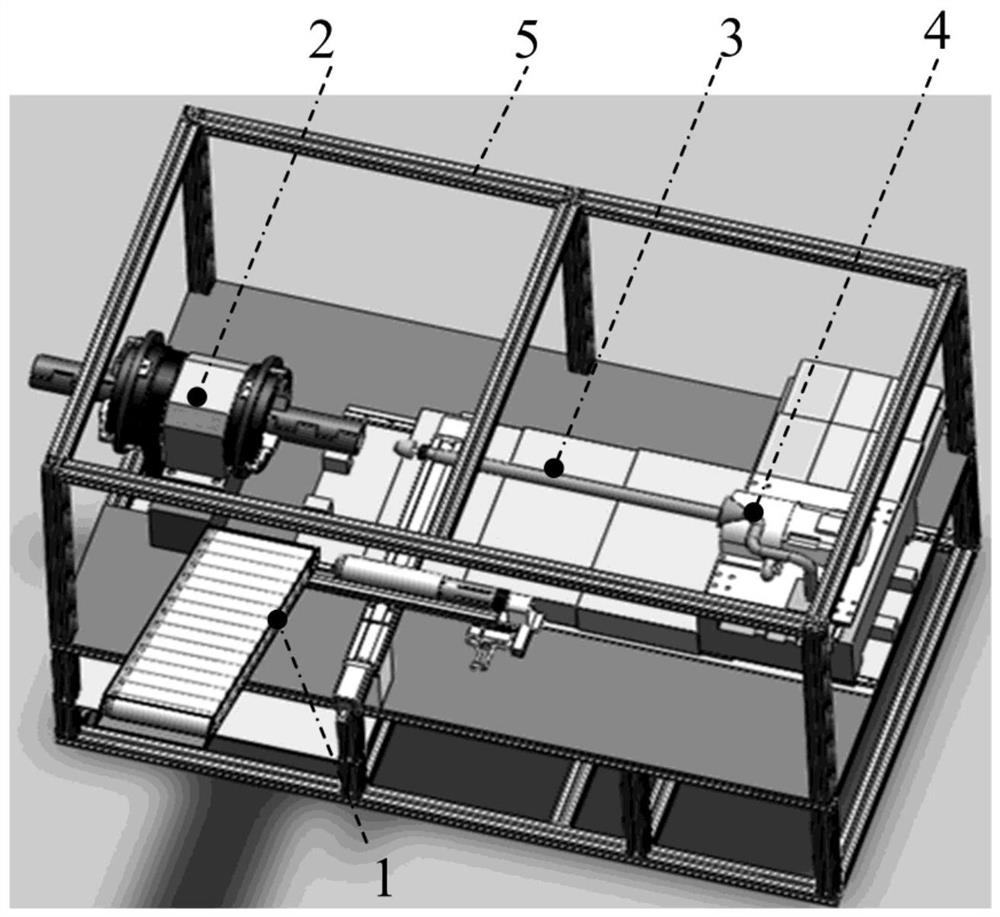

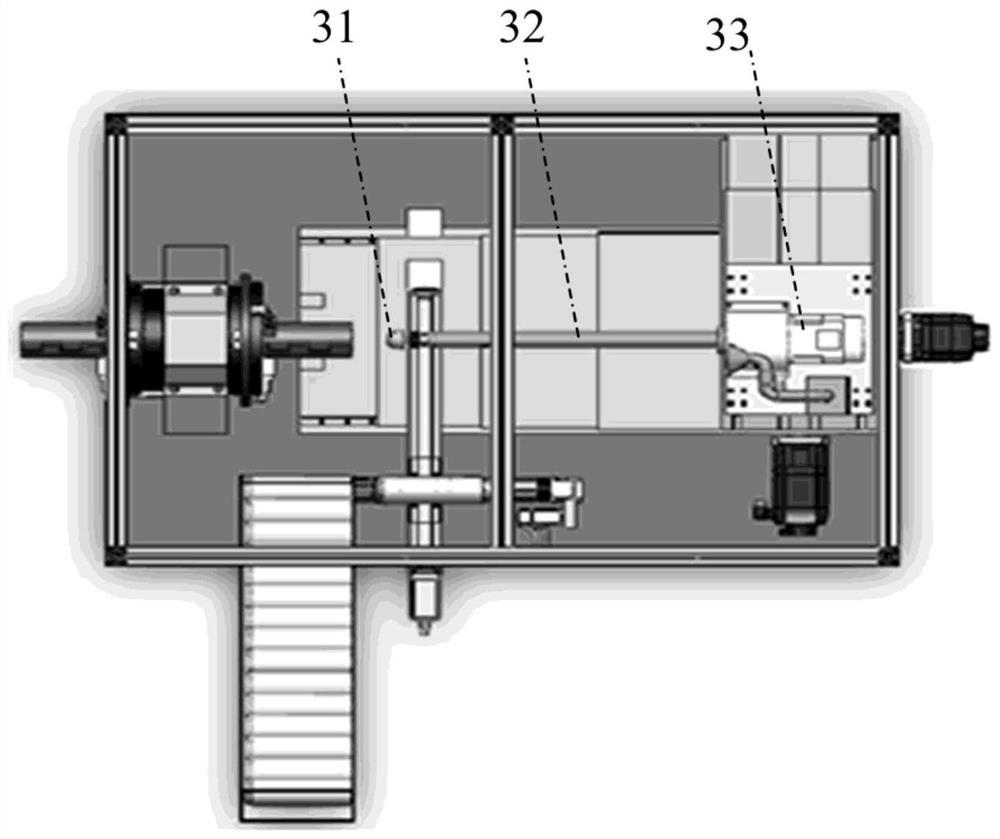

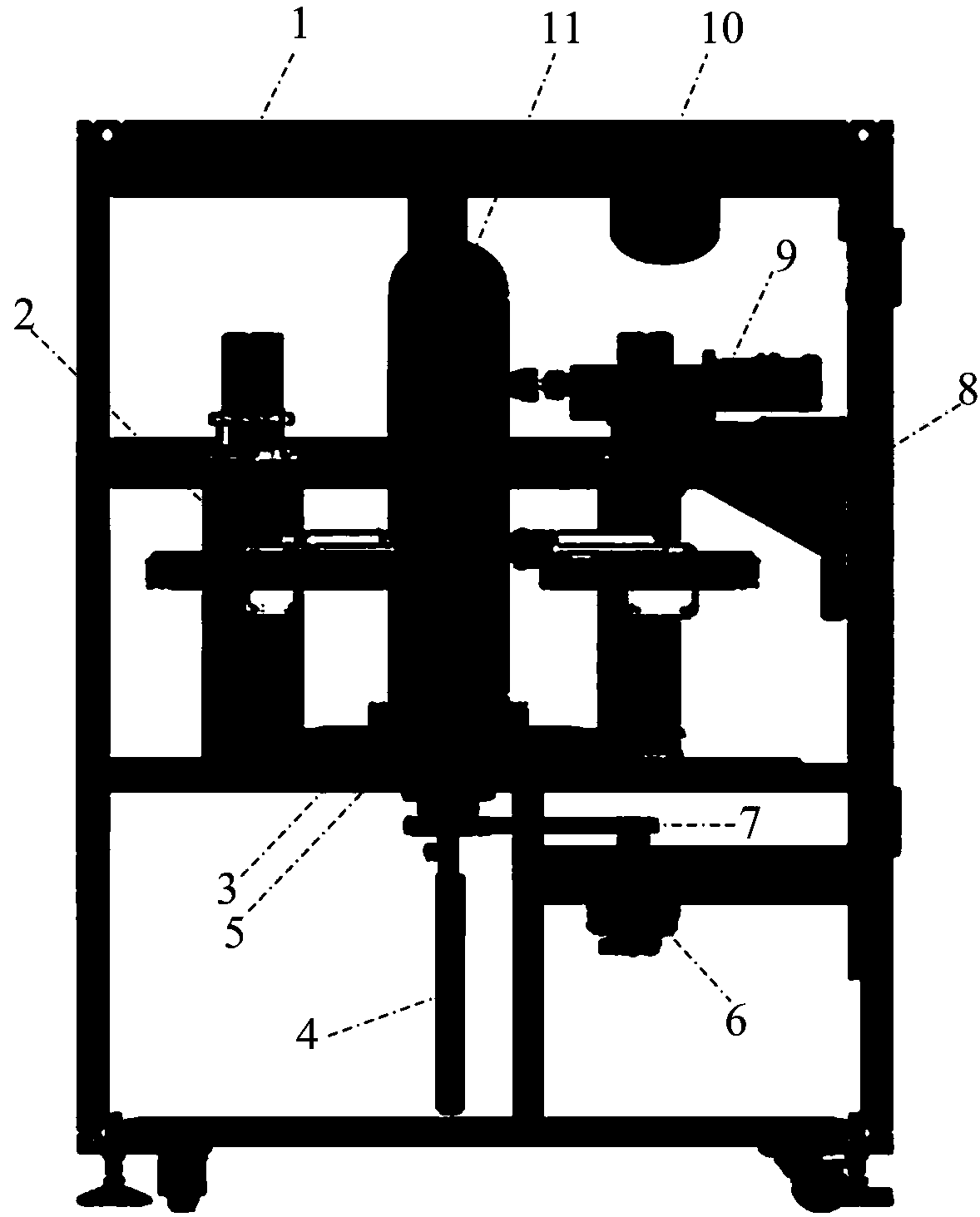

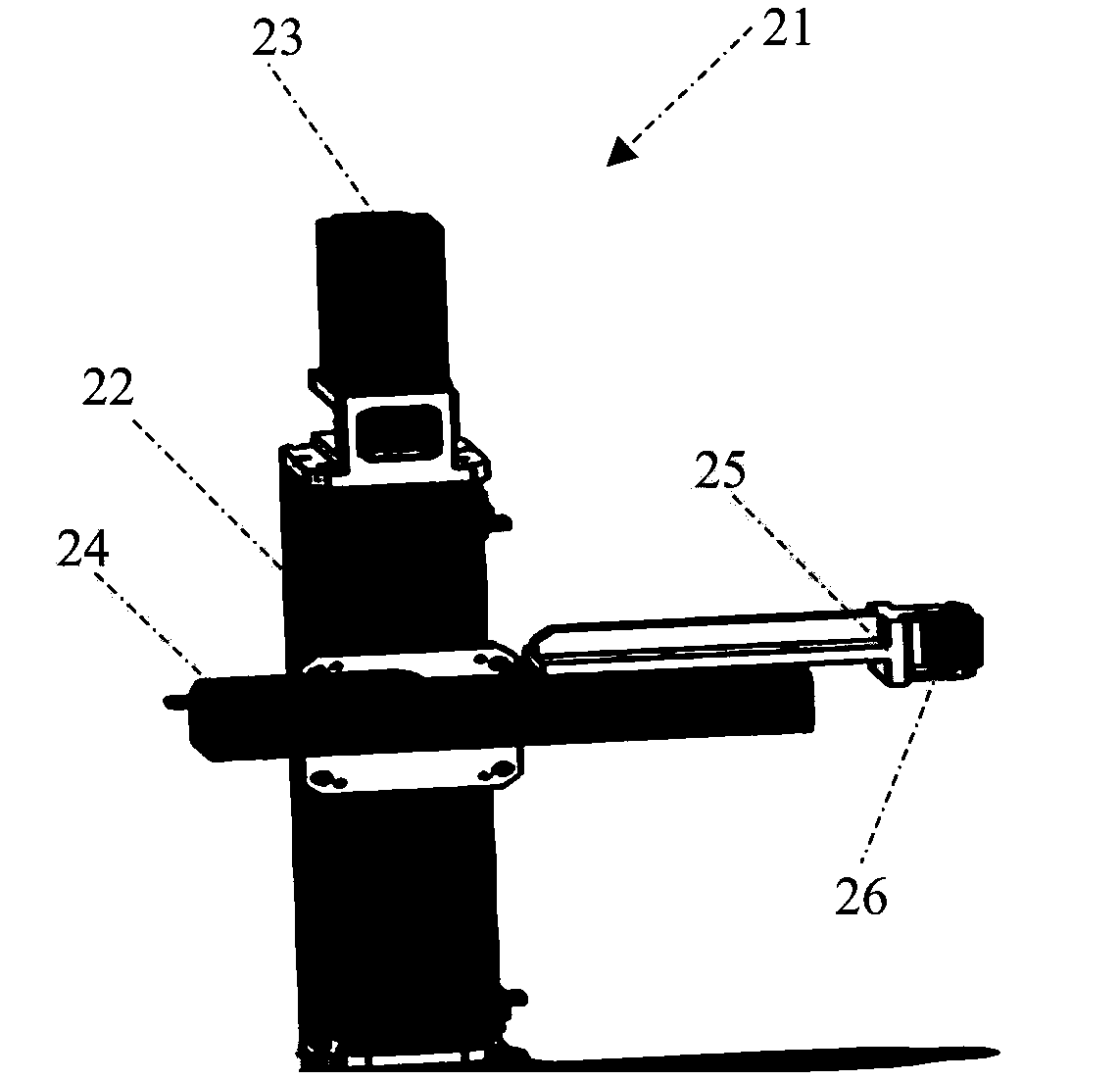

Self-adaptation grain outer wall face grinding device

InactiveCN109483385AImprove consistencyReduce labor intensityPolishing machinesGrinding machine componentsMan machineProcess safety

The invention discloses a self-adaptation grain outer wall face grinding device. The problems that a traditional grinding device is high in personnel labor intensity, low in grinding efficiency, poorin process safety and the like are solved. The self-adaptation grain outer wall face grinding device comprises a rack (1), a centering mechanism (2), a die core base (3), a vacuum pipe (4), a materialreceiving disc (5), a rotation motor (6), a belt wheel (7), a lifting guide rail (8), a grinding mechanism (9) and an anti-explosion camera (10). The centering mechanism (2) is composed of three centering arms (21). Each centering arm (21) comprises a vertical sliding rail (22), a lead screw motor (23), a horizontal sliding rail (24), a horizontal arm (25) and a centering roller (26). The grinding mechanism (9) comprises a grinding head (91), a servo motor (92) and a linear guide rail (93). The self-adaptation grain outer wall face grinding device can achieve man-machine isolation for grain outer wall face grinding, the grinding efficiency is improved, and process danger is reduced.

Owner:XIAN MODERN CHEM RES INST

Automatic stretching device for energetic powder material copper pipe for spaceflight pyrotechnic device

PendingCN114226478AImprove pass rateUnified specificationsMetal working apparatusSpaceflightMachining

The invention relates to an automatic stretching device for an energetic powder material copper pipe for a spaceflight pyrotechnic device, which comprises a stretching die used for enabling a spaceflight cutting cable to be stretched to pass through a die hole of the stretching die so as to realize cold-drawing stretching of the spaceflight cutting cable; the pointing mechanism is used for pointing the end part of the spaceflight cutting rope to be pointed, so that the end part of the spaceflight cutting rope can penetrate through the die hole, and the spaceflight cutting rope can be conveniently stretched; the first stretching trolley and the second stretching trolley are located on the two sides of the stretching die correspondingly and can move on the rack along the rack, the spaceflight cutting cable penetrates through the die hole, and the first stretching trolley is used for carrying the spaceflight cutting cable in the stretching machining state to move towards one side of the stretching die; the second stretching trolley is used for carrying the spaceflight cutting rope in the stretching machining state to move towards the other side of the stretching die in turn, so that the spaceflight cutting rope is stretched under extrusion of a die hole; and the rack is used for mounting the stretching die, the pointing mechanism and the stretching trolley, and is also used for supporting the spaceflight cutting rope during stretching and pointing.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

A device and method for reducing the volume of low-radioactive waste circular filters

ActiveCN106898405BPrevent proliferationGuaranteed cleanlinessRadioactive decontaminationRadioactive wasteAutomation

The invention discloses a method and equipment for volume reduction treatment of low-radioactivity waste circular filters. The method includes: transferring a to-be-compressed waste circular filter to a compression station, and adopting a limiting oil cylinder for driving a limiting barrel to vertically move downwards so as to limit and wrap the to-be-compressed waste circular filter in an inner cavity of the limiting barrel; adopting a main cylinder of a hydraulic press for driving a compression plate to press downwards vertically to downwardly compress the waste circular filter into a cake shape; pushing to a discharging station at the bottom surface of a cavity of a receiving glove box by a pushing device; after a clamping device clamps, allowing an isolation device to horizontally move away from a circular discharging hole, so that the waste circular filter is vertically discharged into a lining seal bag in a cavity of a waste bucket; after the cavity of the waste bucket is full, performing sealing, packaging, transferring and storing. The compression volume reduction ratio is high, storage volumes of the waste circular filters are greatly reduced, and aftertreatment cost is reduced. In addition, the method and the equipment have advantages of high automation degree, high efficiency, safety, energy saving, environmental friendliness and the like.

Owner:HENAN HEJING CLEANING TECH

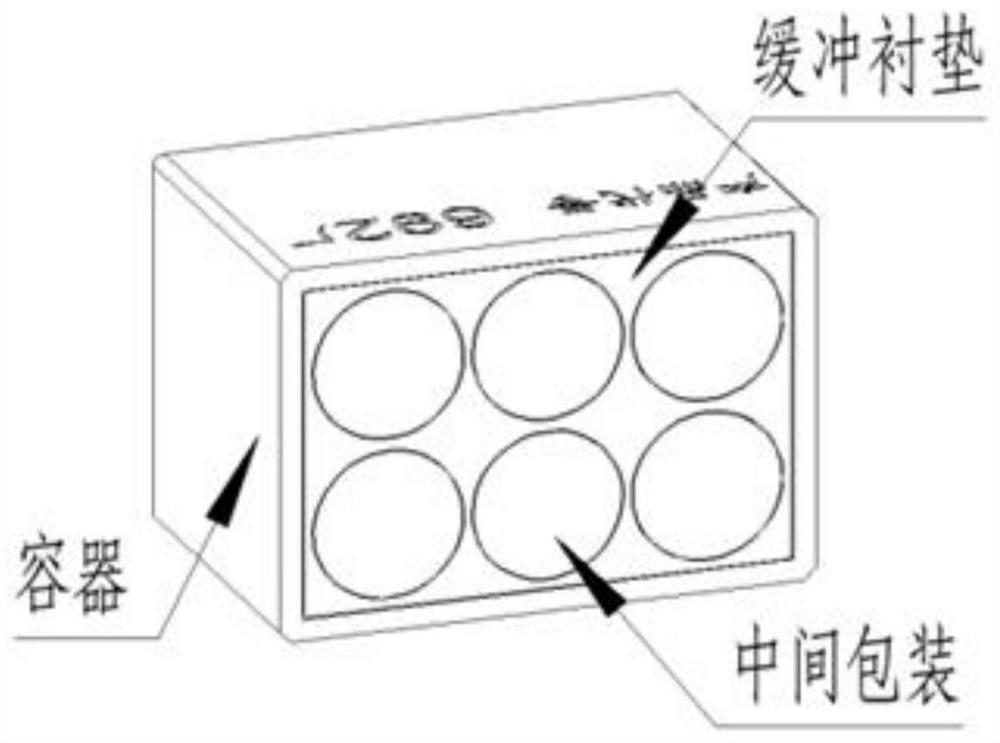

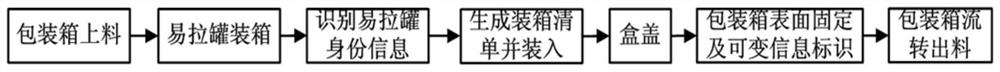

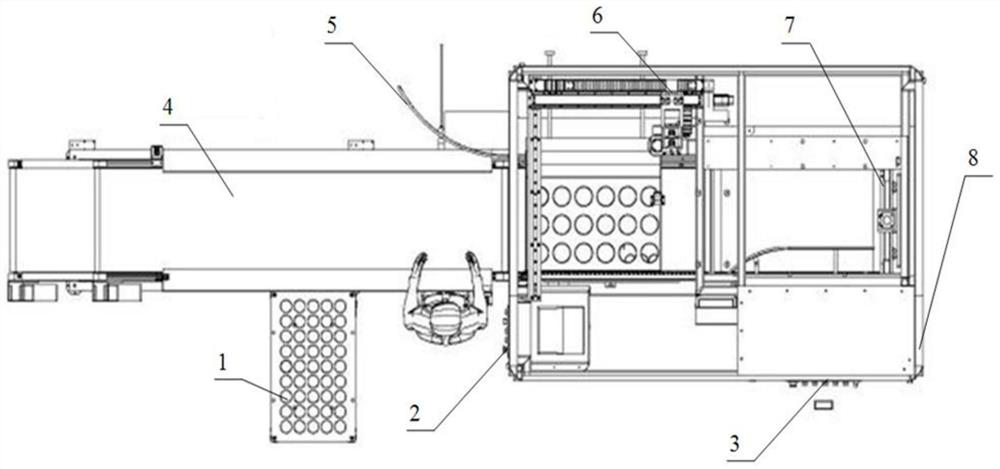

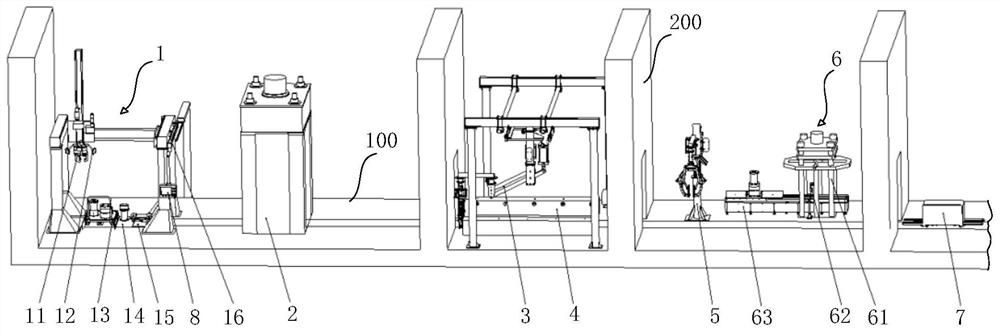

Automatic packaging device and process method for outer package of initiating explosive device

ActiveCN114104363AIncrease productivityAvoid quality hazardsPackaging automatic controlTotal factory controlMachine controlControl system

The invention relates to an automatic packaging device and process method for an outer package of an initiating explosive device. The process method comprises the following steps: 1) designing information reliable identification, identification and transmission methods for the outer package of the initiating explosive device; the method comprises the following steps: designing a surface identification code identification mode of a canned initiating explosive device, determining an online combination method of outer package (variable + fixed) information, realizing group closed-loop transmission of package information, identifying product information by using hardware, analyzing and integrating the product information by using software, and pushing the product information to terminal code spraying equipment, thereby realizing efficient and reliable product information transfer in a package process; and 2) combining the characteristics of military initiating explosive device packaging boxes, designing a packaging box identification module, and adopting a multi-axis moving part to drive a code spraying module to realize rapid and firm identification on the surfaces of the packaging boxes with different sizes. And 3) on the basis of determining the process method, adopting a ring-pull can code scanning module, a boxing list output and loading module, a packaging box identification module and a packaging box circulation module which are controlled by a complete machine control system to cooperate with one another, and constructing an automatic packaging device for outer packages.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

Powder forming production line and control method

PendingCN114872365ARealize human-machine isolationIncrease productivityTotal factory controlPressesControl systemManufacturing line

The invention discloses a powder forming production line and a control method, the powder forming production line comprises an assembling device, a pressing device, a cooling device and a mold splitting device which are sequentially arranged along an assembling process, further comprises a conveying device used for conveying objects to the assembling device, the pressing device, the cooling device and the mold splitting device, and further comprises a control system; the assembling device is used for loading powder in a powder medicine box into a mold; the pressing device is used for pressing the powder in the mold into a grain; the cooling device is used for cooling the formed powder; the mold splitting device is used for taking the grain out of the mold; the control system is used for achieving automatic operation of the powder forming production line. According to the powder forming production line, automatic production of forming the powder into the grain can be achieved, the production efficiency is improved, and the safety risk and the labor intensity are reduced.

Owner:中国兵器装备集团自动化研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com