Automatic liquid flow test device for nozzle

A test device and liquid flow technology, applied in the direction of measurement device, engine test, mechanical component test, etc., can solve the problems of relying on labor efficiency, low, cumbersome test process, etc., to reduce noise, symmetrical and stable structure, and protect personnel. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

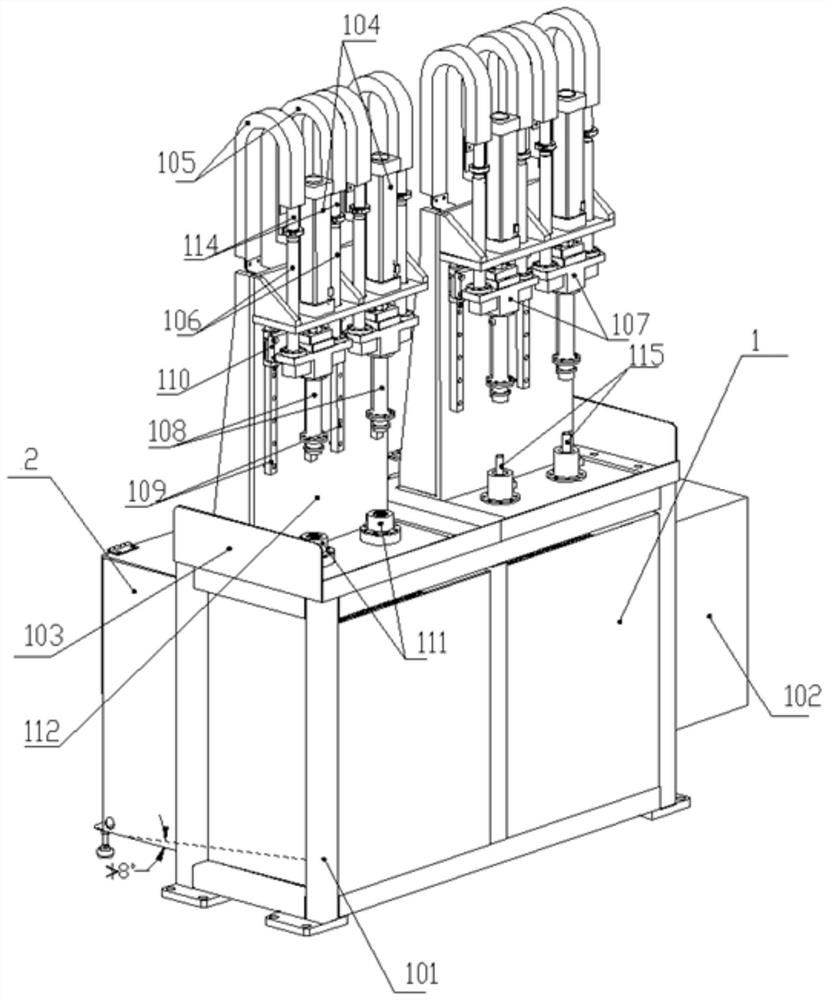

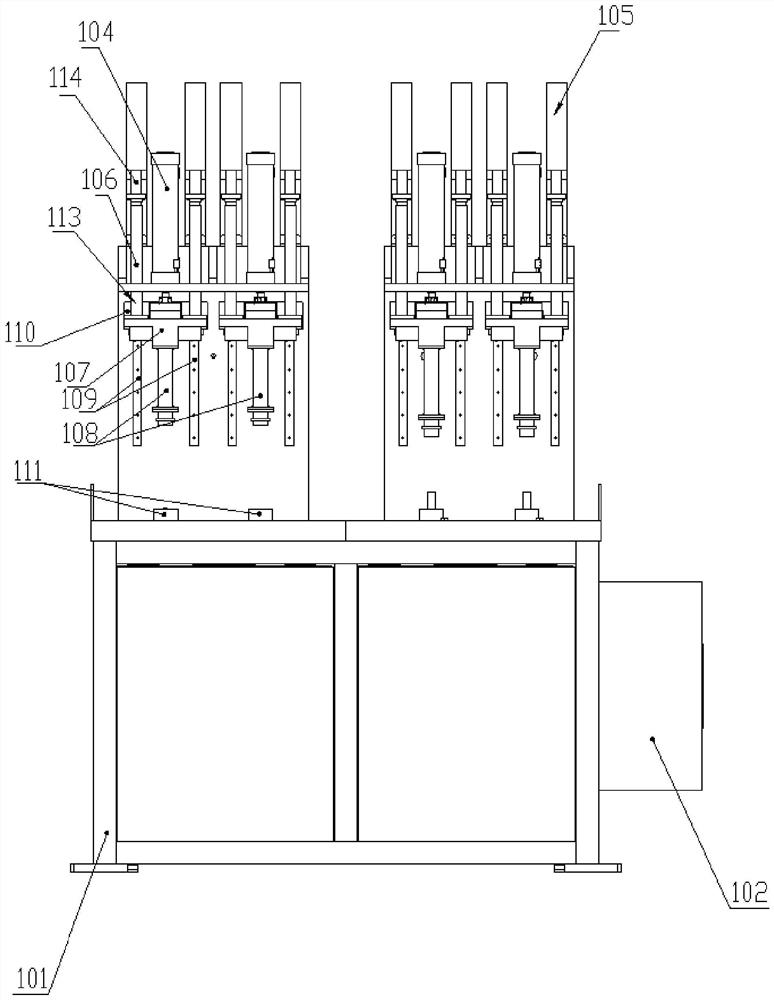

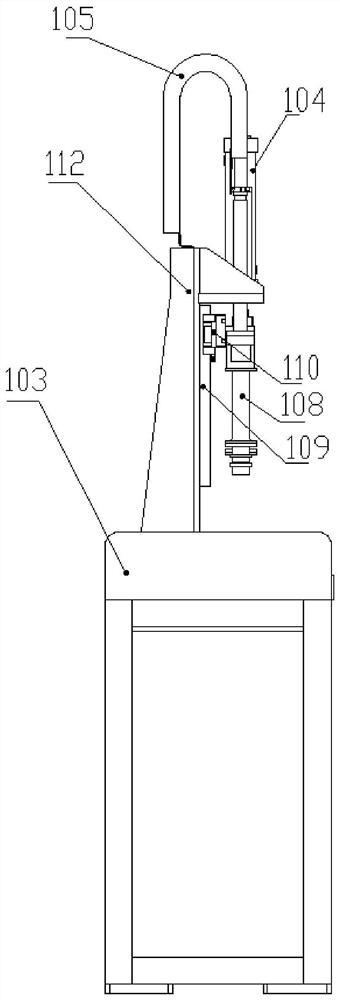

[0035] The nozzle automatic liquid flow test device provided by the present invention includes a liquid flow test bench 1 and a return water system 2; wherein:

[0036] Such as Figure 1-Figure 4 As shown, the liquid flow test bench 1 includes a frame 101, a measurement and control cabinet 102, a C-shaped support panel 112, and a plurality of test stations (preferably 4); wherein, the measurement and control cabinet 102 is installed on the side of the frame 101 for installing the system. This integrated installation structure is convenient for equipment maintenance; the C-shaped support panel 112 is installed on the frame 101, and the C-shaped structure is welded by stainless steel plates. After welding, the stress is released to make it waterproof and rust-proof And the advantages of high strength; each test station includes lifting cylinder 104, water guide tool 107, upper tool 108, lower tool 111, two sliders 110, two guide rails 109, two water pipes 106 and two hoses 114 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com