Detonator demoulding device

A detonator and demoulding technology, which is applied in the direction of detonators and offensive equipment, can solve problems such as high safety risks, jamming, and easy explosion, and achieve the effects of reducing safety risks, reasonable structural design, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

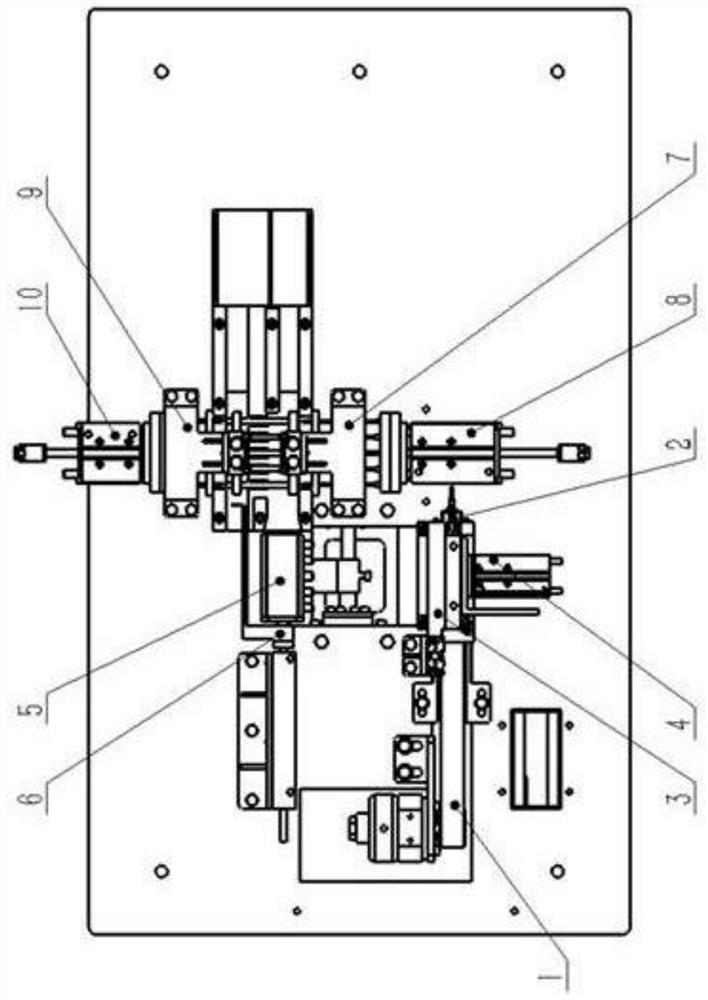

[0032] Specific embodiments of the present invention will be further described below in conjunction with accompanying drawings;

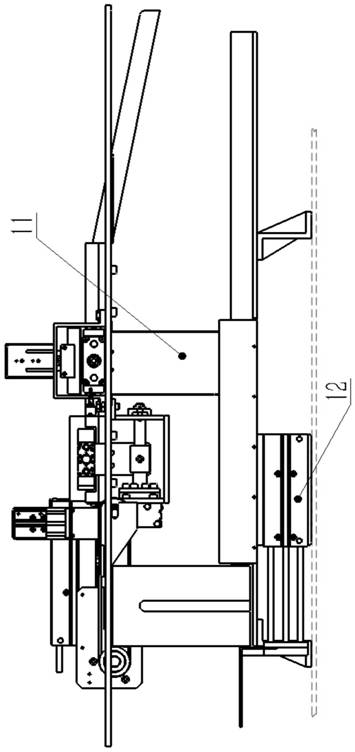

[0033] see figure 1 , figure 2 , a device for ejecting a detonator, which includes a conveying assembly (1), an induction switch (2), a blocking assembly (3), a pushing assembly (4), a rotating assembly (5), and a horizontal pushing assembly (6) , a lower die clamping component (7), a separation component (8), an upper die clamping component (9), an exit component (10), an automatic collection component (11), and an industrial control box (12).

[0034] see figure 1 , The conveying assembly (1) includes an orbital turntable and an air motor.

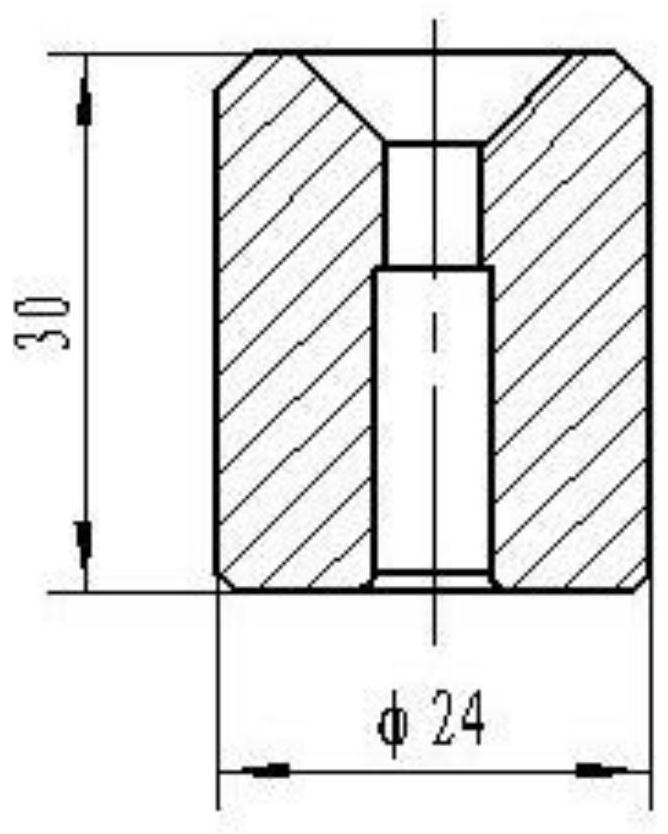

[0035] see image 3 , Figure 4 , Figure 5 , before the detonator is transported to the detonator ejection device, each detonator should be buckled with a reinforcing cap in the upper mold and the lower mold. The detonator, upper mold and lower mold form a single mold, and the height of each single mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com