Automatic box retreating system of detonator

An automatic and detonator technology, used in detonators, offensive equipment, etc., can solve the problems of hidden safety hazards and high labor intensity of staff, and achieve the effects of convenient operation, complete man-machine isolation, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

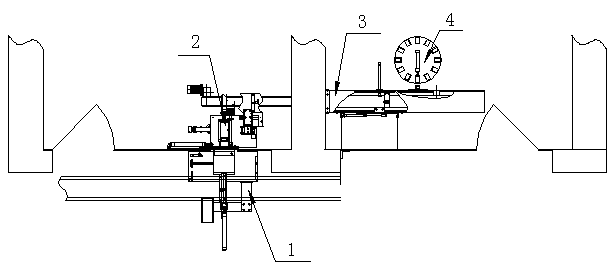

[0034] see figure 1As shown, the detonator automatic box receiving system of the present invention includes: a mold transfer device 1 for making the mold automatically enter and exit the process room and return the empty mold to the transmission belt, for completing the exit of the shell from the mold, the automatic drop of the shell, collection and The formed box receiving device 2 is used to make the finished product box reach the delivery device 3 of the finished product collection place and the empty box feeding device 4 for making the empty box reach the box receiving device through the belt conveyor. The mold transmission device 1 and the receiving box The device 2 is connected, and the box receiving device 2 is connected with the empty box feeding device through the conveying device 3 .

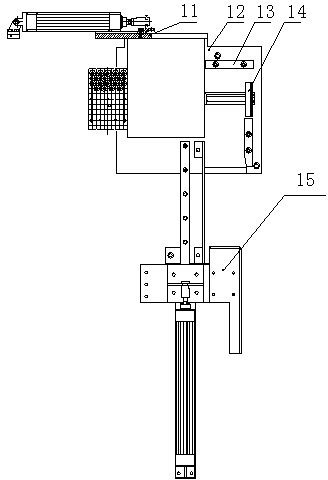

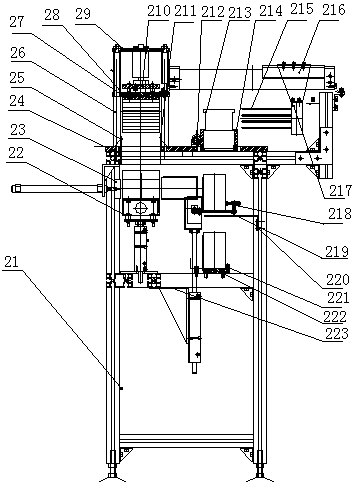

[0035] see figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com