Automatic slitting equipment for electronic digital detonator chip

An electronic digital detonator and chip technology, which is applied in metal processing and other directions, can solve the problems of no forming and reliable digital detonator chip automatic slitting equipment, inability to meet safety production and safety quota, and failure to achieve man-machine isolation, etc., to improve safety in production. The effect of management level and production efficiency, elimination of potential safety hazards, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

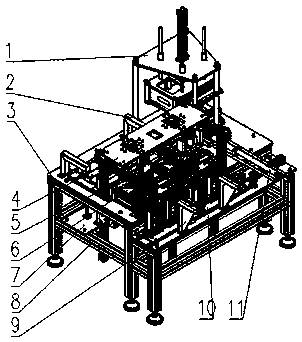

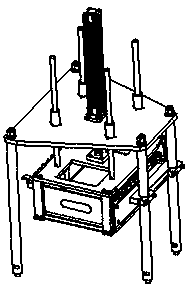

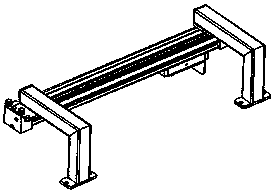

[0028] figure 1 As shown, the digital detonator chip automatic slitting equipment of the present invention includes making the upper mold and the lower mold enter the equipment to install the cut and separated chips and assemble them into a combined mold push-out equipment to enter the transmission equipment 1, and make the bottom mold enter the equipment. Bottom mold translation mechanism 2. Cut and separate the chips in the hopper and enter the corresponding bottom mold. Chip separation and switching mechanism 3. Separate the cut chips and enter the chip separation mechanism at the designated position 4. Make the upper and lower molds form a combined mold The mold clamping lifting mechanism 5, the push mold mechanism 6 that pushes the combined mold to the transmission equipment, the waste slideway mechanism that guides waste into the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com