Energy-containing powder material automatic press-fitting device and method based on servo pressurization

A powder material, automatic technology, used in weapon accessories, ammunition, offensive equipment, etc., to achieve the effect of realizing man-machine isolation, improving quality and safety control level, and solving pressure transmission problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

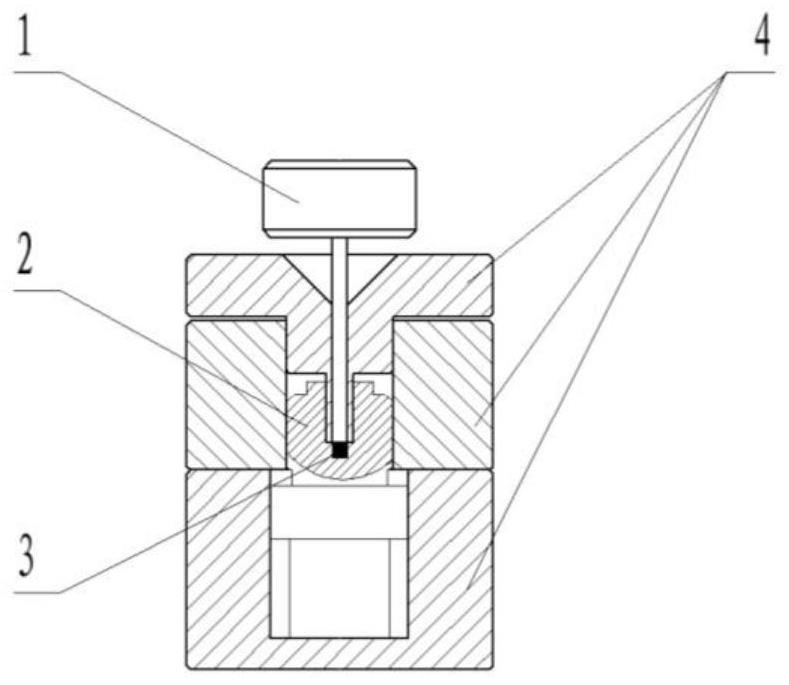

[0031] An automatic press-packing device and method for energetic powder materials based on servo pressurization. The automatic press-packing device is used to replace manual operations for press-packing energetic powder materials, which can realize human-machine isolation and solve the problem of energy contained in aerospace explosives. For the problem of automatic pressing of powder materials, the specific structure of the automatic pressing device is as follows:

[0032] Including indenter, igniter housing, energetic powder material, positioning mold, indenter disassembly station, pressurization station, indenter assembly station, manipulator, conveyor belt, positioning carrier, servo press, jacking cylinder , the intercepting cylinder, the second manipulator, the igniter housing and the positioning mold are assembled on the positioning carrier, the energetic powder material is placed in the igniter housing, the positioning carrier is provided with a pressure head, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com