Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Realize crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

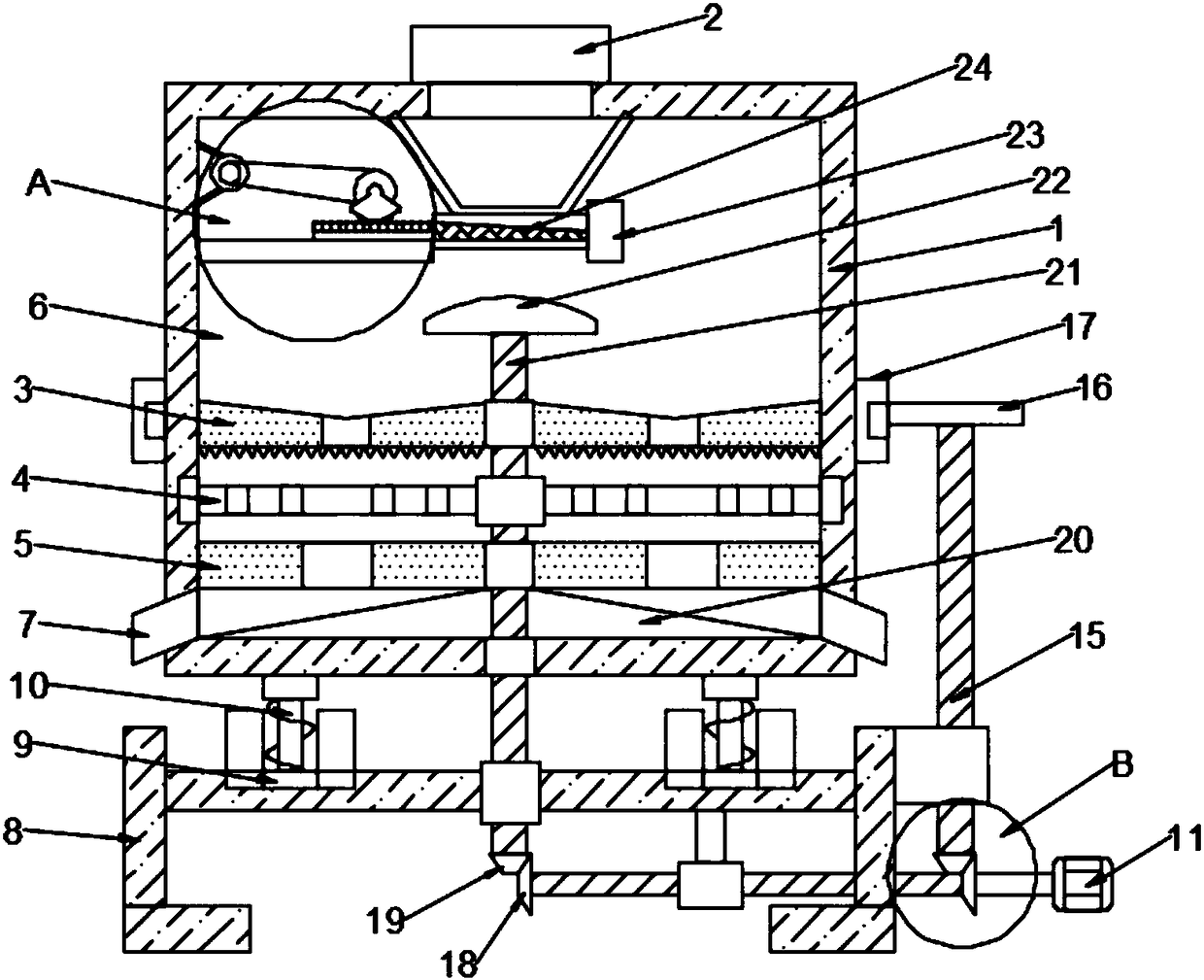

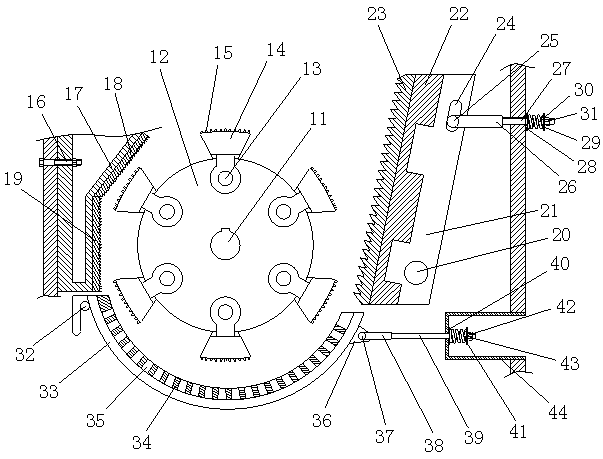

Solid waste crushing treatment device for machining

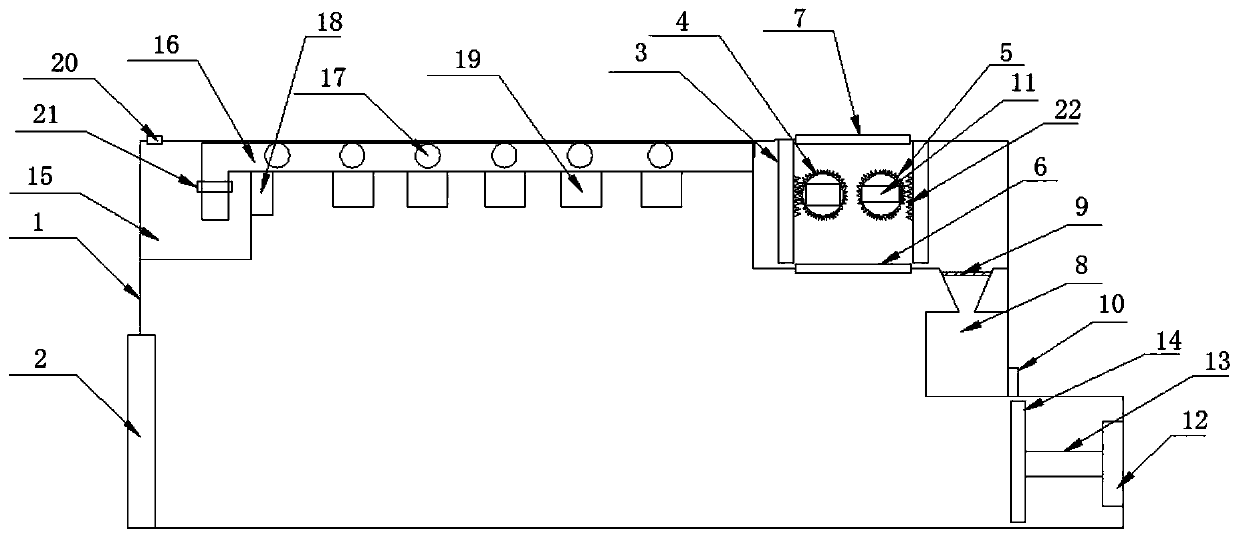

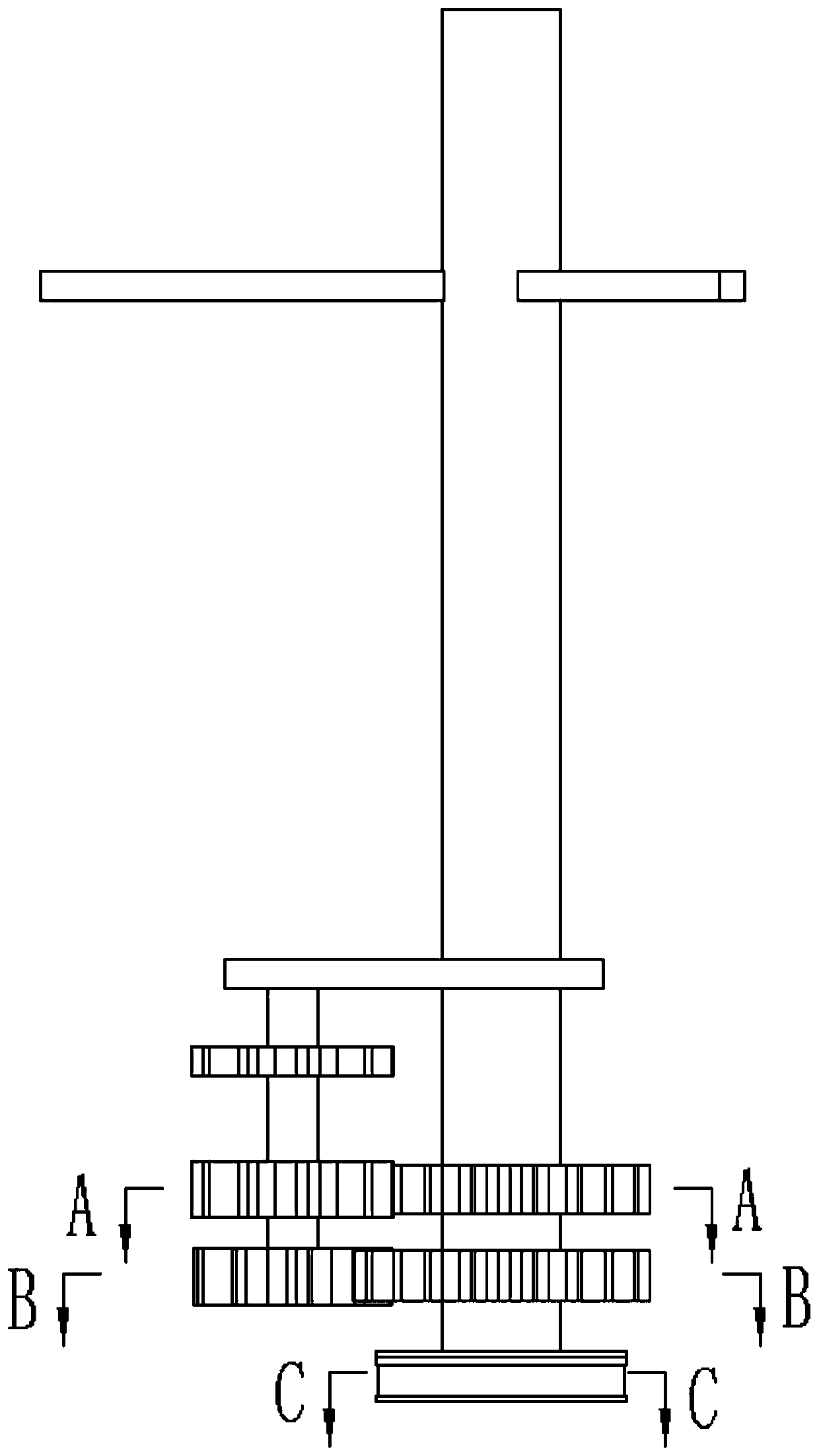

The invention discloses a solid waste crushing treatment device for machining. The solid waste crushing treatment device for machining disclosed by the invention is reasonable and simple in structure,low in production cost and convenient to mount. The solid waste crushing treatment device for machining disclosed by the invention is convenient to operate, quick to treat and time- and labor-saving.Solid wastes are placed in a concave chamber, a rolling motor drives a crushing hammer to crush the solid wastes, then the solid wastes are placed in a grinding chamber, a first motor drives a grinding roller to grind the solid wastes, the solid wastes enter a crushing chamber, a crushing shaft crushes the solid wastes which then enter a grinding chamber and are ground by means of the grinding roller, then the solid wastes enter an upper refining particle chamber, a grinding rotating rod grinds and refines the solid wastes, and the solid wastes are filtered by means of a filter screen, the solid wastes which are big in particle are continuously ground and refined by the grinding rotating rod, and finally, a pinch roller further refines the solid wastes. By means of the technical points, the solid wastes are crushed, and the solid waste crushing treatment device for machining is automatic in full course and high in efficiency.

Owner:NANTONG INST OF TECH

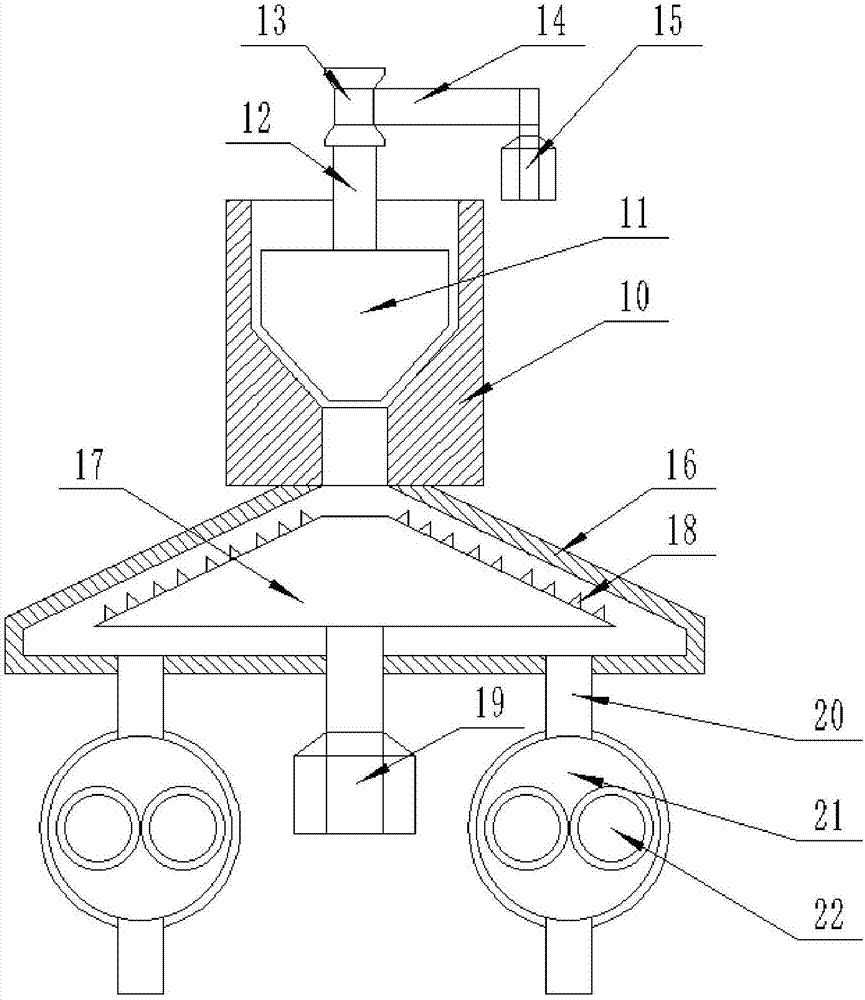

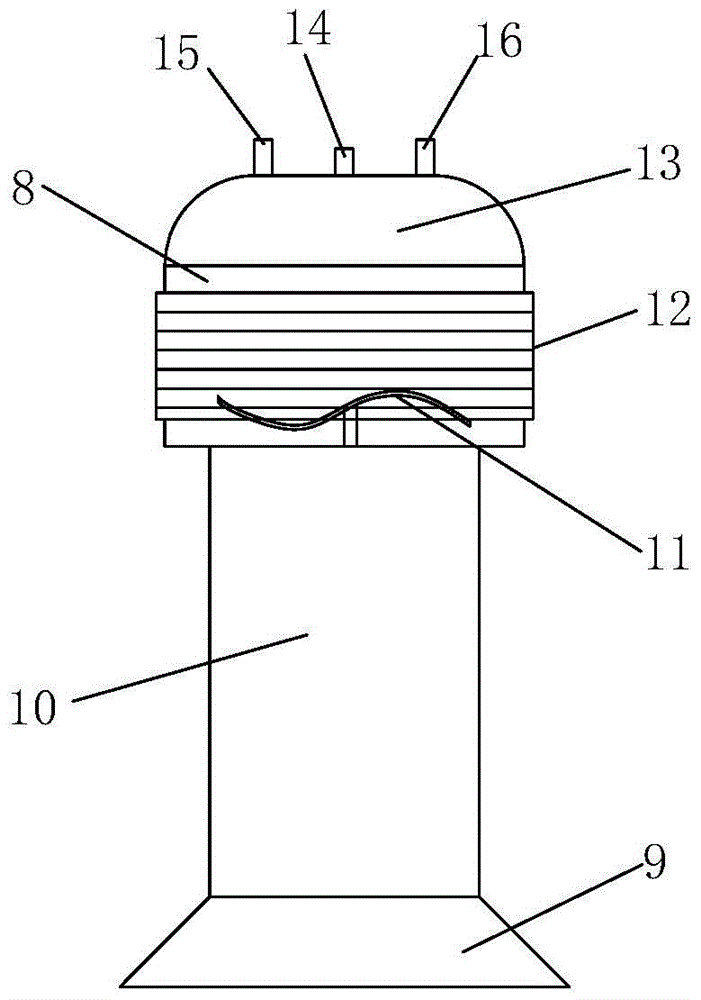

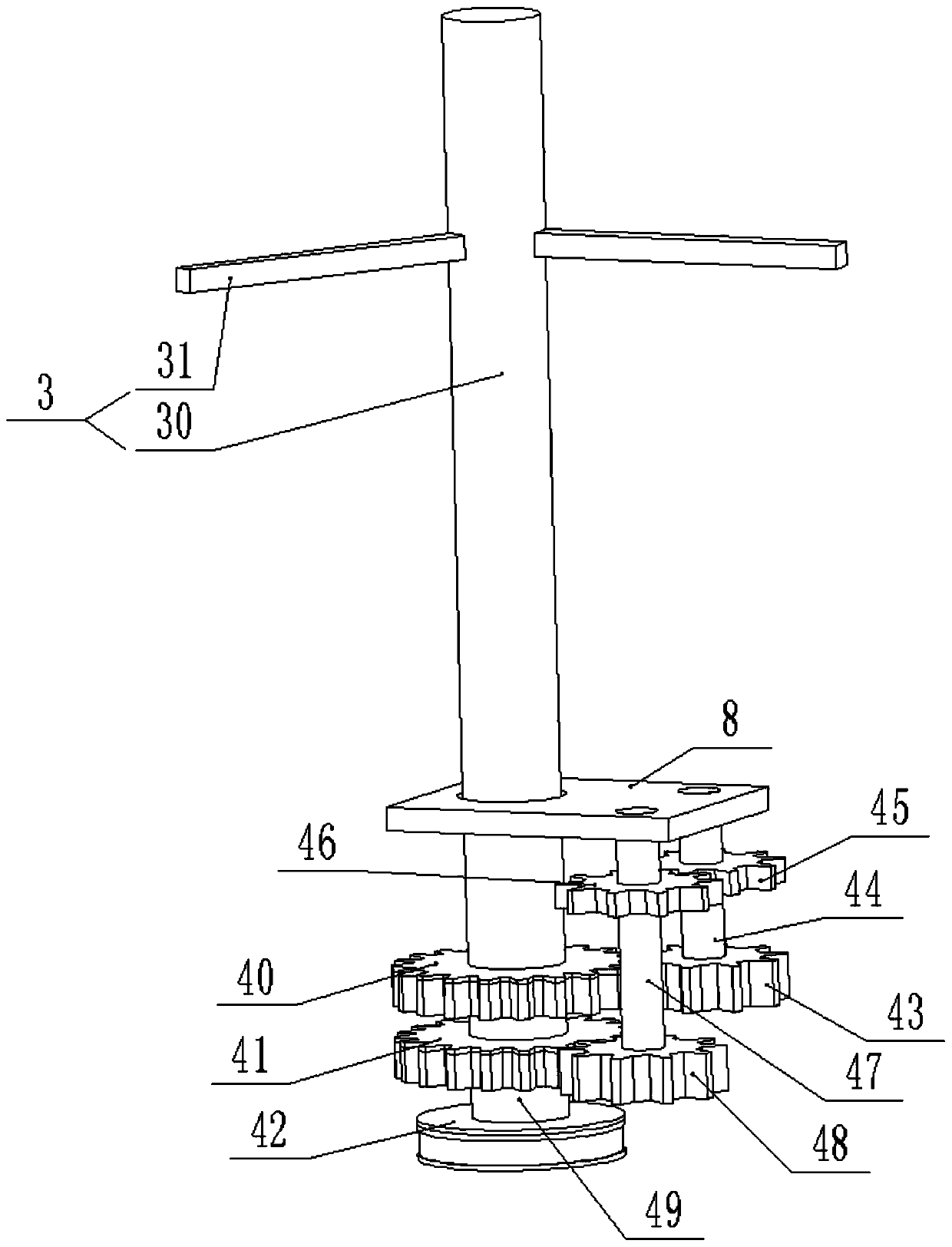

Health food material grinding device achieving complete grinding

The invention discloses a health food material grinding device achieving complete grinding. The health food material grinding device achieving complete grinding comprises a shell, a feeding hopper, agrinding cavity, discharging openings and a supporting base. The grinding cavity is arranged in the shell. The feeding hopper is arranged in the middle of the upper surface of the shell. The feeding hopper communicates with the grinding cavity. The discharging cavities are symmetrically formed in the bottom of the side wall of the shell. The grinding cavity communicates with the discharging openings. The supporting base is arranged at the bottom of the shell. The supporting base is rotationally connected with the shell. The health food material grinding device is characterized in that a servomotor is installed on the right side of the supporting base, a first rotating shaft is welded to the left side of an output shaft of the servo motor, a first bevel gear is fixedly installed on the left side of the first rotating shaft, and a second rotating shaft is vertically arranged above the first bevel gear. The health food material grinding device achieving complete grinding has the advantages of quantitative feeding, rapid grinding and time and effort saving. Meanwhile, raw material blockage of raw materials in the grinding process can be avoided, operation is easy, and the health foodmaterial grinding device achieving complete grinding is suitable for application and popularization.

Owner:山西华欣久泰科技有限公司

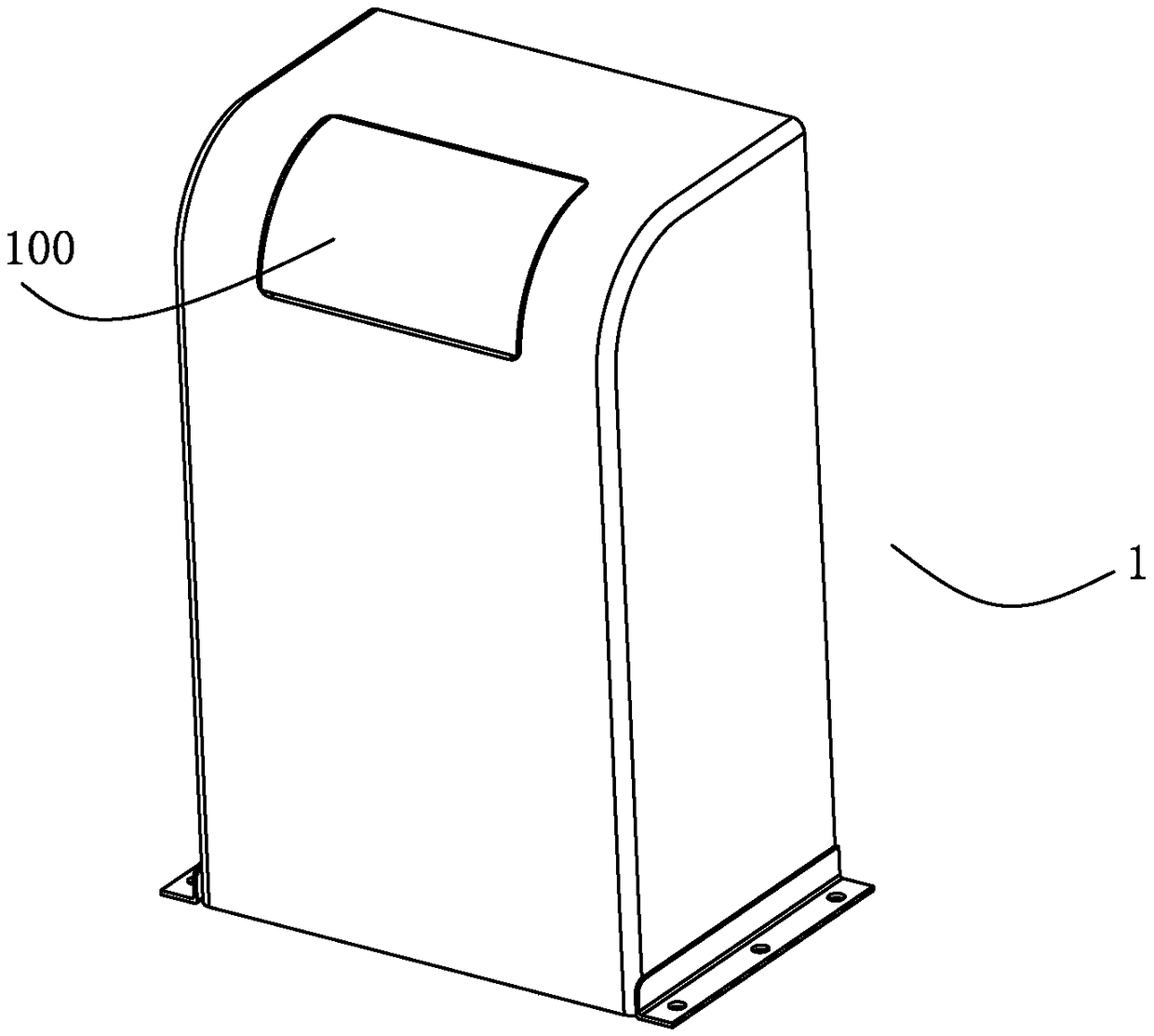

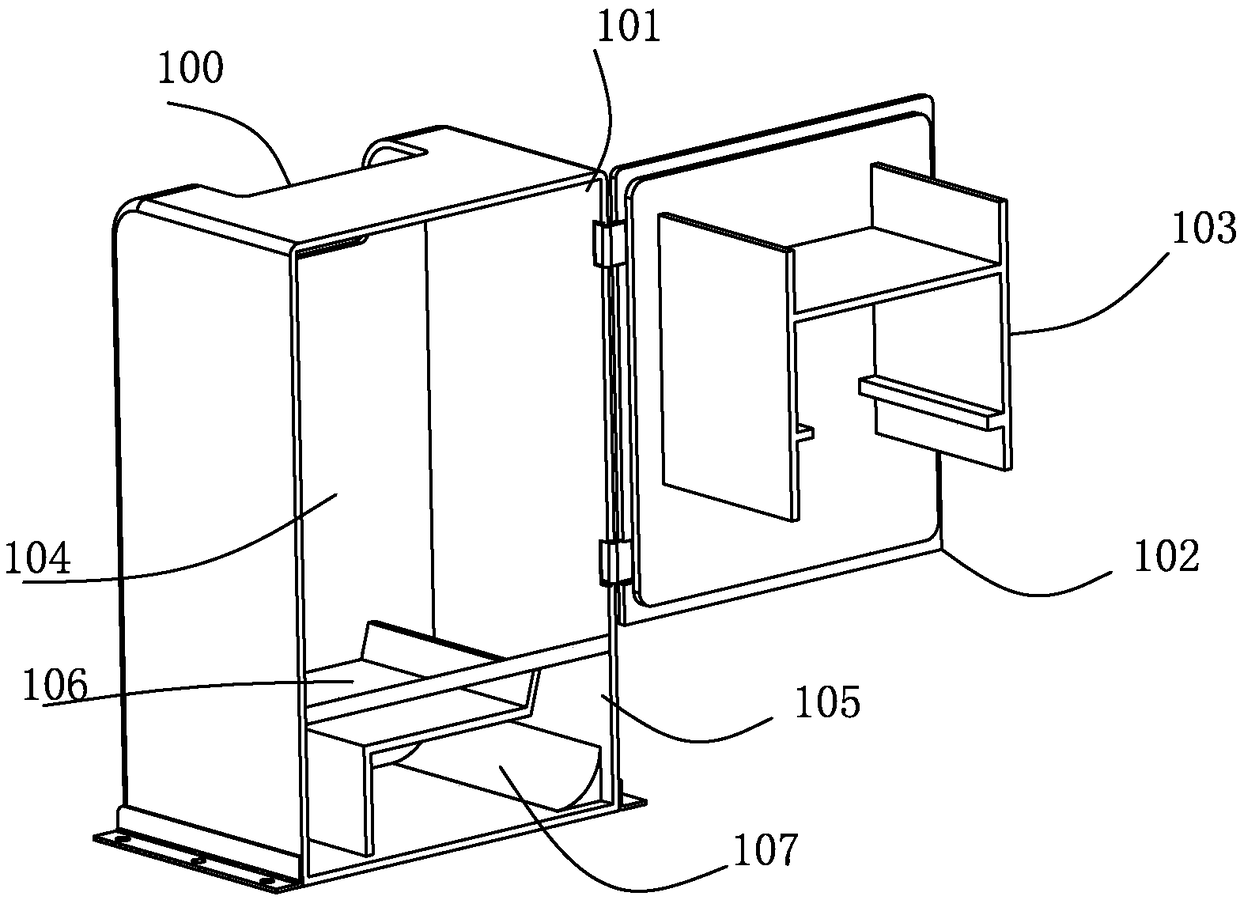

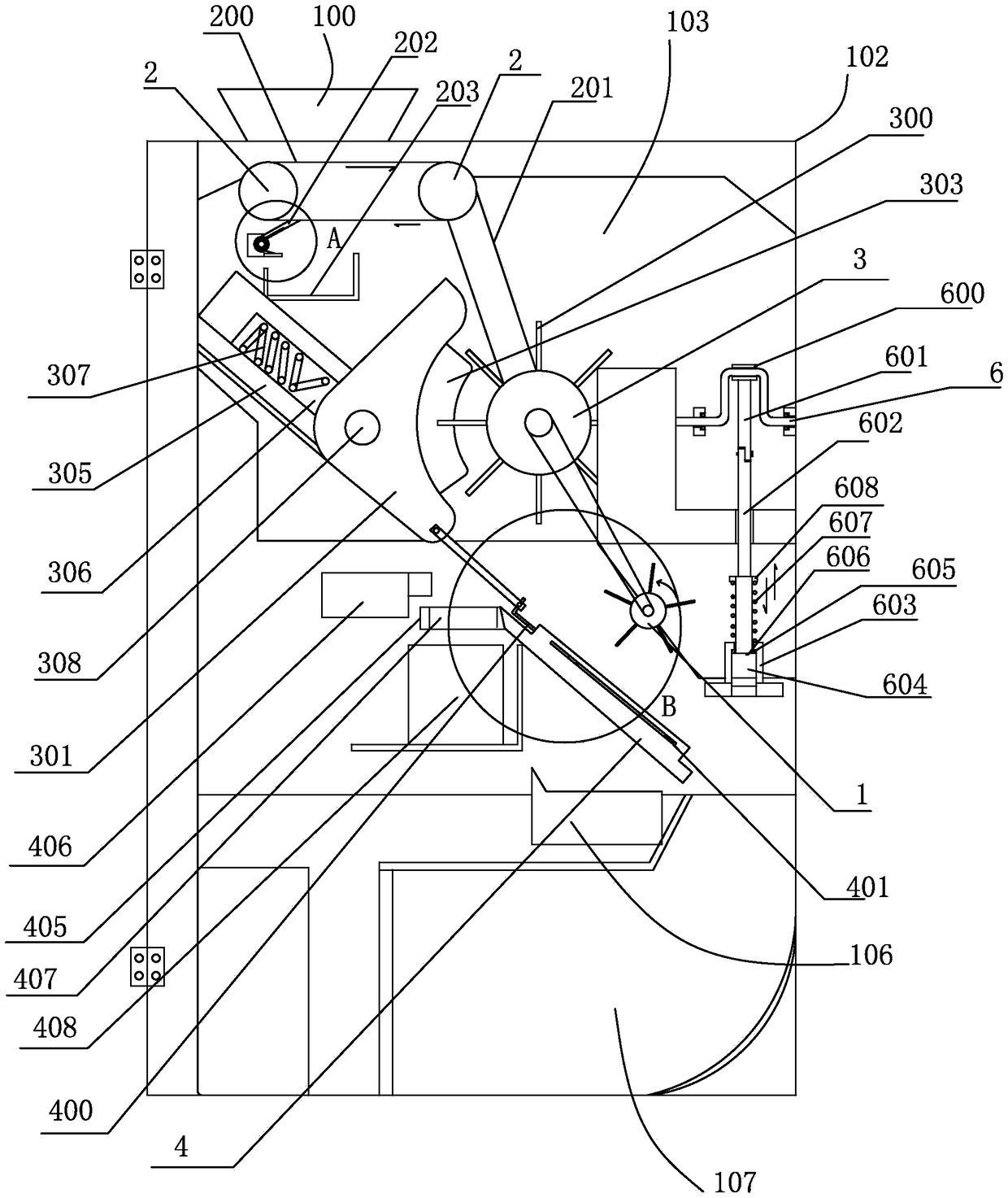

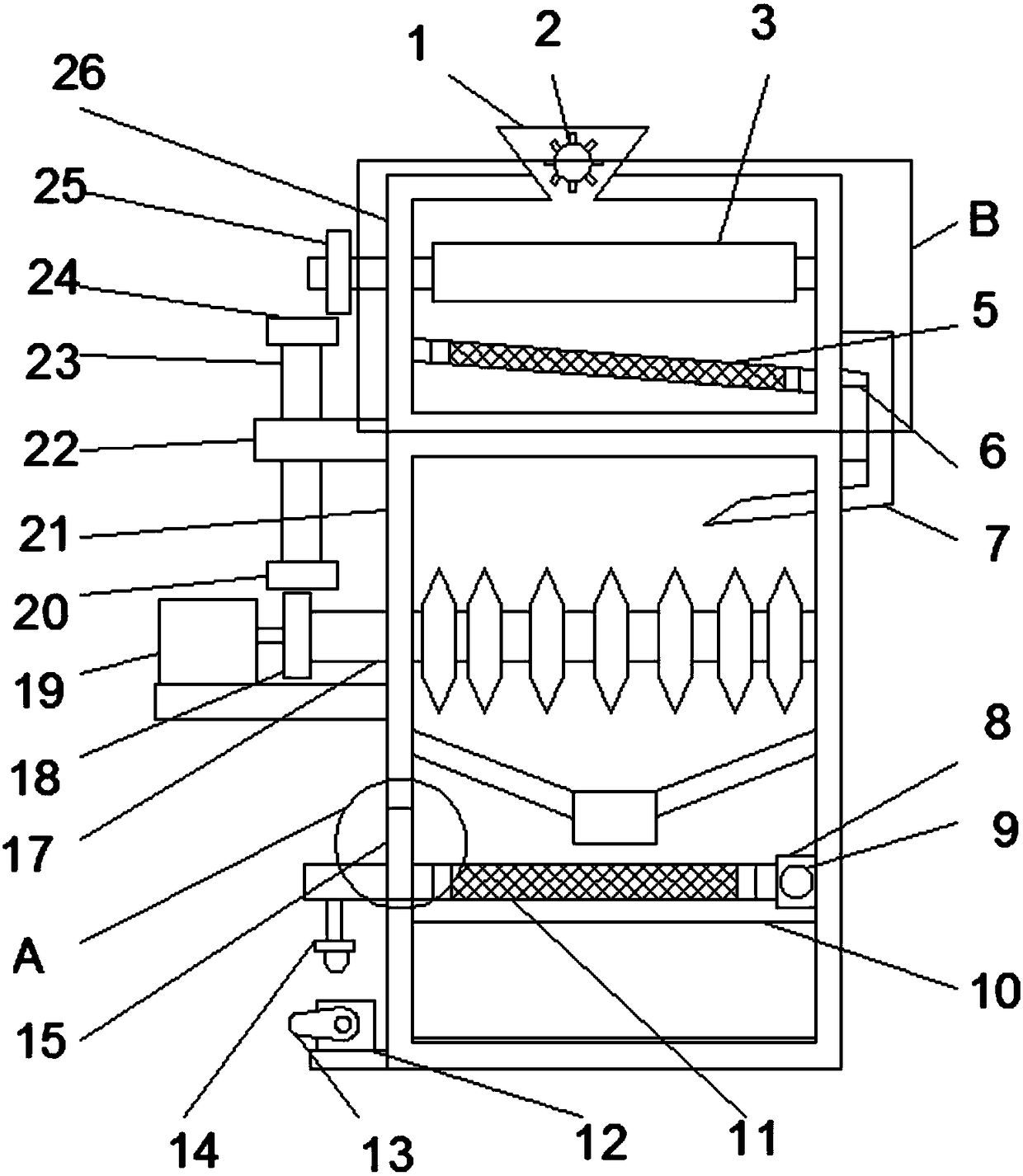

Environment-friendly garbage can

InactiveCN108773613ASmall footprintAvoid safety hazardsRefuse receptaclesWaste collectionDrive motor

The invention discloses an environment-friendly garbage can. The environment-friendly garbage can comprises a garbage can body; an inner cavity, a garbage feeding opening and a garbage discharging opening are formed in the garbage can body, and a garbage conveying device, a crushing mechanism, a screening mechanism, a compressing mechanism, a driving motor and at least two garbage collecting siloscommunicating with the garbage discharging opening are arranged in the inner cavity of the garbage can body; the garbage conveying device is arranged below the garbage feeding opening, the crushing mechanism is arranged below the output end of the garbage conveying device; the screening mechanism is arranged below the crushing mechanism, and a plurality of leaking holes are formed in the screening mechanism to sort the garbage into two types; and the compressing mechanism is used for compressing the lightweight garbage falling from the lower end of the screening mechanism. The environment-friendly garbage can is compact and simple in structure, the burden of the follow-up garbage disposal can be reduced, the garbage can be compressed, the garbage occupying space is saved, the amount of the garbage storage is improved, and the garbage sorting collection and cleaning are facilitated.

Owner:叶于诚

Crushing equipment for attapulgite

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

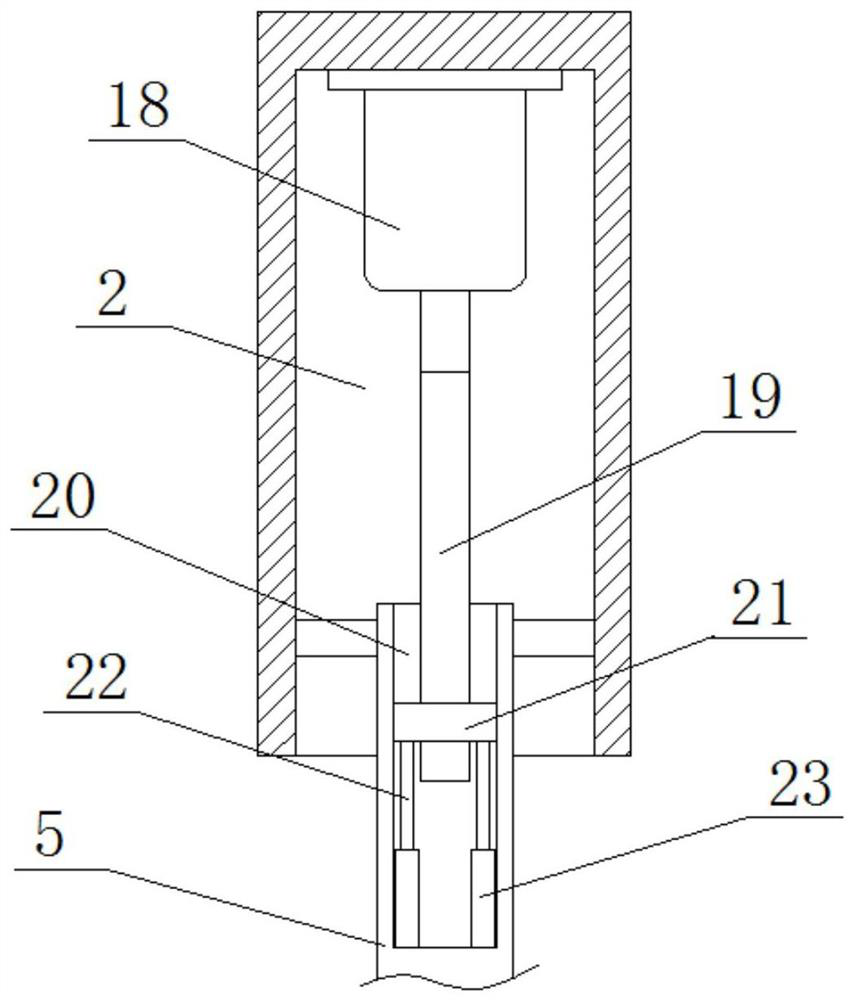

Waste material recycling device for high-carbon soldering iron production

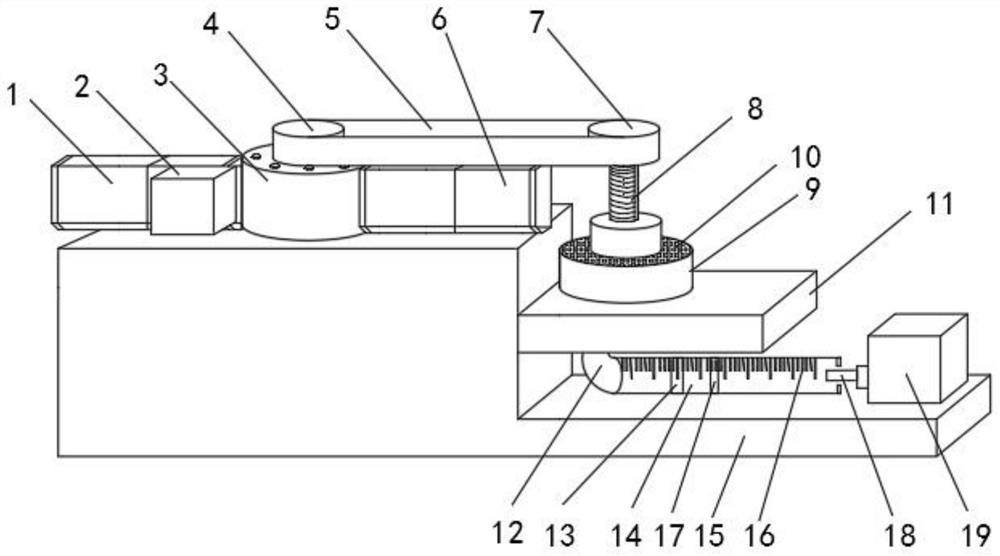

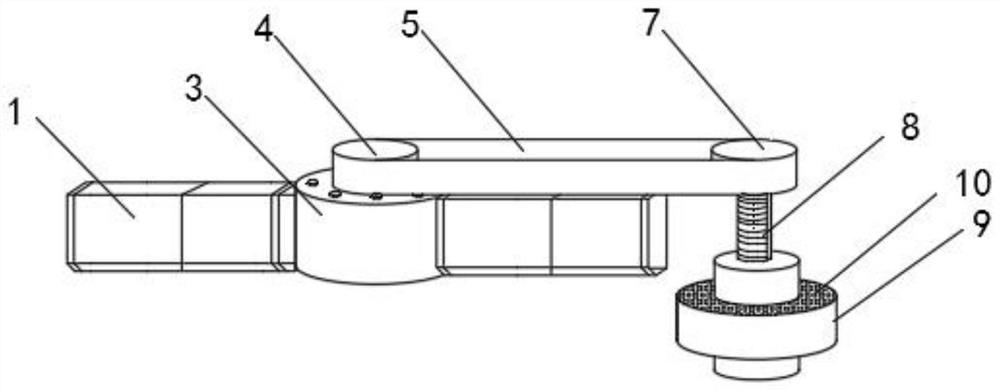

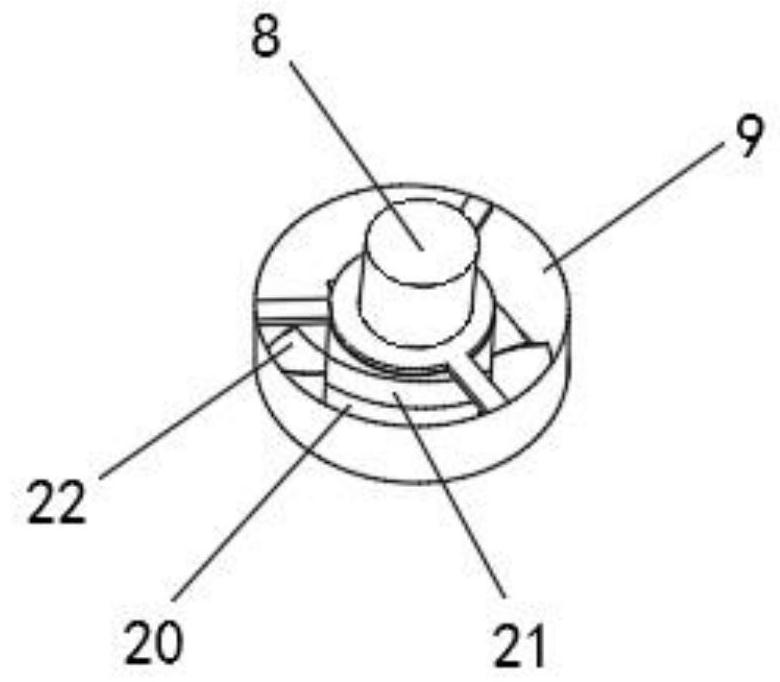

InactiveCN109290010ARealize crushingIncrease storage spaceCleaning using liquidsGrain treatmentsGraduated cylinderWaste material

The invention belongs to the field of high-carbon soldering iron production, and particularly relates to a waste material recycling device for high-carbon soldering iron production. For the problems that an existing recycling device is simple in structure, and waste materials can not be pretreated, the following scheme is proposed, the waste material recycling device for high-carbon soldering ironproduction comprises a device shell, a water tank and a feeding measuring cylinder are installed at the upper end of the device shell, a partition plate is fixedly arranged in the device shell, and the water tank and the feeding measuring cylinder are located on the two sides of the partition plate; a first motor is fixed to the front end of the feeding measuring cylinder, an output shaft of thefirst motor penetrates through the feeding measuring cylinder to be fixedly connected with a first tooth roller, and the first tooth roller meshes with a second tooth roller; and a second motor is fixed to the bottom end of the interior of the device shell and located on the side, close to the feeding measuring cylinder, of the partition plate. According to the waste material recycling device forhigh-carbon soldering iron production, the waste material storing space can be reduced, cleaning treatment can be conducted on waste materials, operation is convenient and fast, and the automation degree is high.

Owner:阜宁凯盛不锈钢材料有限公司

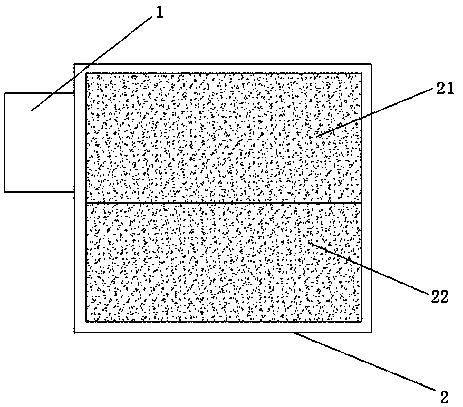

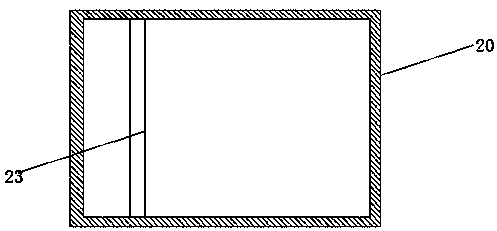

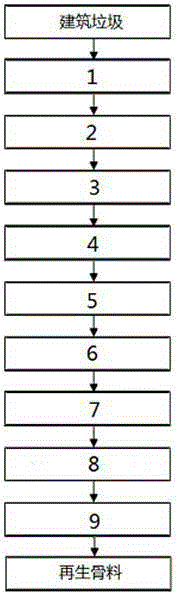

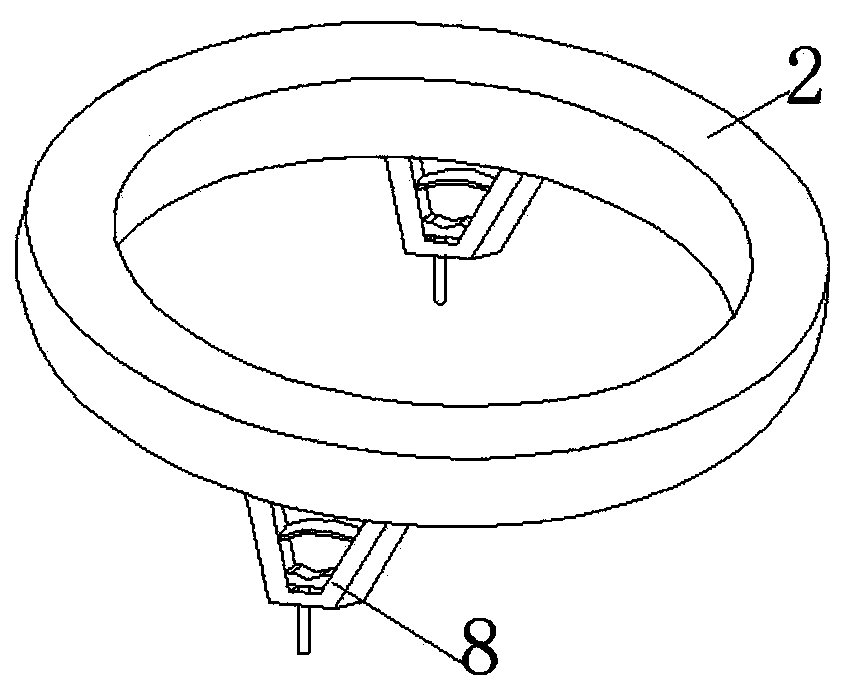

Construction waste recycling treatment system

The invention provides a construction waste recycling treatment system which comprises the following parts connected in sequence through a conveyer belt: a material storage cabin (1), a pre-treatment device (2), an unloading device (3), a primary screening device (4), a primary crushing device (5), an electromagnetic separation device (6), a secondary screening device (7), a second crushing device (8) and a third screening device (9). The construction waste recycling treatment system provided by the invention has the following technical effects: the crushing devices, the screening devices, a conveying device and an impurity removal device which are different in function are reasonably combined together to efficiently crush the construction waste; the screened construction waste crushed by coarse crushing, medium crushing or even fine crushing devices is processed to regenerated gravel aggregate with a certain grain, and the gravel aggregate can be widely applied to the field of roadbed building stones, baking-free bricks, cement admixtures and the like.

Owner:HAIAN TIANPENG MACHINERY MFG

Experiment device and method for underground coal mine CO source mechanism and disappearing mechanism research

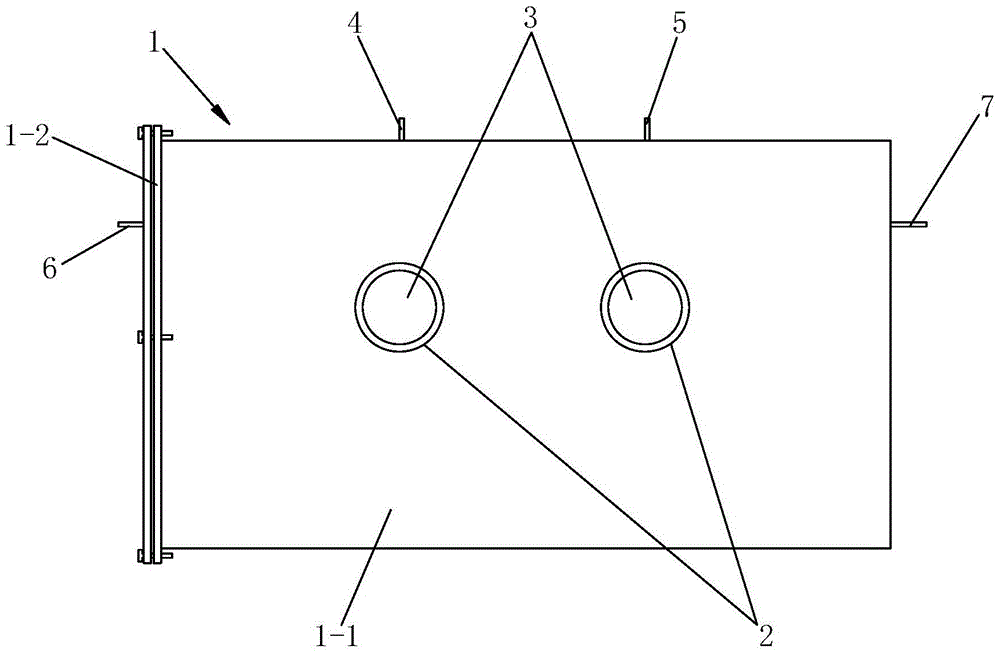

The invention discloses an experiment device for underground coal mine CO source mechanism and disappearing mechanism research. The experiment device comprises a sealed box, wherein a cutting tool is arranged in the sealed box, a crusher is arranged in the sealed box, a crushing chamber is arranged on the crusher, a heating device is arranged on the crushing chamber, and an exhaust pipe, a gas taking pipe and two gas inlet pipes are arranged on the sealed box. The experiment device is used for providing a necessary and sufficient experiment environment for underground coal mine CO source mechanism and disappearing mechanism research. The invention further discloses an experiment method for underground coal mine CO source mechanism and disappearing mechanism research. Crushing treatment is conducted on a coal sample in an anaerobic environment under certain temperature condition, the CO gas concentration of the gas released out of the crushing chamber is detected, and the experiment method is simple and convenient. According to the experiment method for underground coal mine CO source mechanism and disappearing mechanism research, the coal sample is subjected to crushing treatment in the anaerobic environment, the crushing chamber is filled with nitrogen, then the coal sample is heated, then the concentration of the gas released out of the crushing chamber is detected, and the experiment method is simple and convenient.

Owner:XIAN UNIV OF SCI & TECH

Land leveler

InactiveCN111492732AAchieve brokenSatisfy Cleanup OperationsSpadesPloughsTraction frameStructural engineering

The invention relates to the technical field of mechanical equipment, in particular to a land leveler. The land leveler comprises a mounting frame and a fixing seat, wherein the fixing seat is fixed to the edge of the lower side face of the mounting frame through bolts; a traction frame is fixed on the upper side of the mounting frame through bolts; a rotating shaft is fixed on the lower side of the mounting frame; compacting pieces are pivoted on the rotating shaft; a plurality of compacting pieces are distributed along the axial direction of the rotating shaft; an adjusting frame is fixed onthe lower side of the mounting frame; a scraper blade is fixed on the adjusting frame; a scraper blade frame is fixed on the lower side of the adjusting frame; and in the radial direction of the mounting frame, the compacting pieces, the scraper blade and the scraper blade frame are sequentially arranged.

Owner:李云鹏

Dry type environment-friendly mineral separation system

PendingCN114749250AEasy to achieve dehydrationRealize dehydrationDrying solid materials without heatDrying gas arrangementsMining engineeringMechanical engineering

The invention relates to the technical field of mineral separation systems, in particular to a dry type environment-friendly mineral separation system which comprises a treatment box. The upper part of the treatment box is movably connected with a box cover; a treatment barrel is rotationally connected into the treatment box, an opening is formed in the side wall of the treatment barrel, a baffle plate is movably connected to the opening, a through hole is formed in the side wall of the treatment barrel, a treatment block is movably connected to the outer side of the treatment box, and one end of the treatment block penetrates through the side wall of the treatment barrel and is located in the treatment barrel; a containing groove is formed in the portion, located in the treatment cylinder, of the treatment block, a movable plate is movably connected into the containing groove, and crushing teeth are fixedly connected to the opposite side walls of the movable plate and the treatment cylinder. And a loading plate is movably connected to the bottom of the treatment box, a loading groove is formed in the upper surface of the loading plate downwards, ore washing, drying and crushing treatment is achieved, and convenience is brought to ore processing.

Owner:黄露瑶

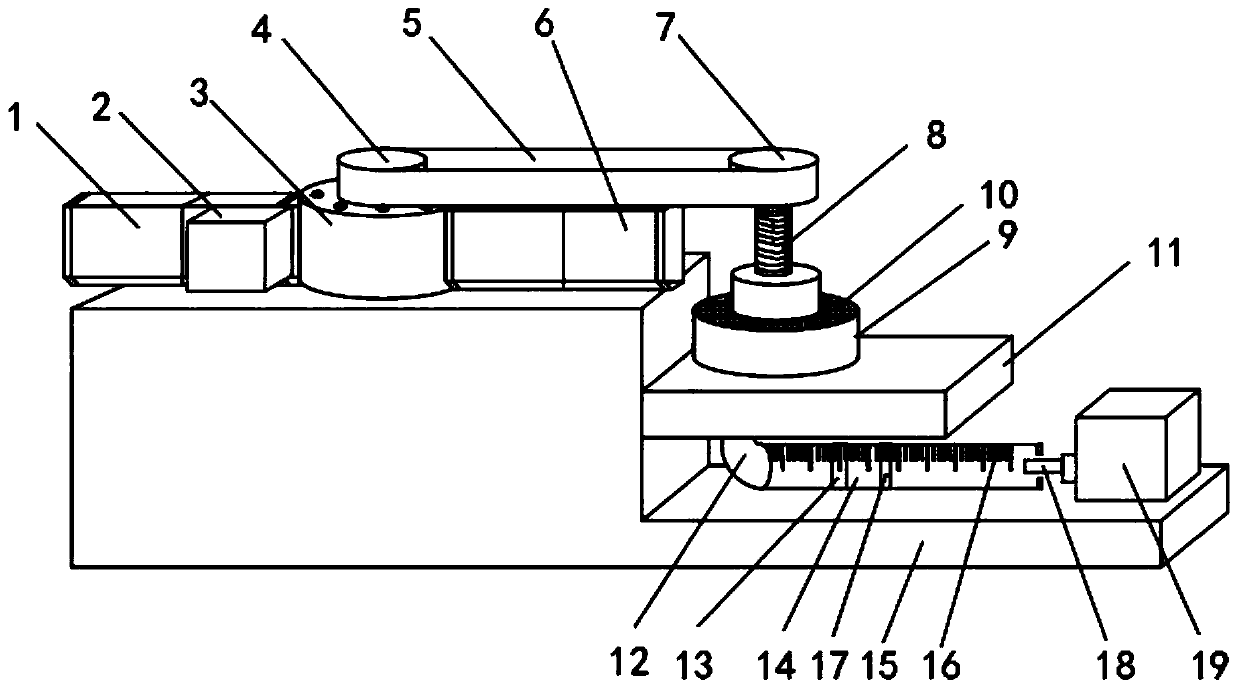

Smashing structure of biopharmaceutical equipment

The invention discloses a smashing structure of biopharmaceutical equipment. The smashing structure comprises a bottom plate, a grinding assembly and a crushing assembly; a frame plate is fixedly connected to one side of the surface of the bottom plate, a rotating shaft penetrates through the top of the side face of the frame plate, an auxiliary gear fixedly sleeves one end of the rotating shaft, a first motor is fixedly connected to the bottom of the side face of the frame plate, a main gear fixedly sleeves an output shaft of the first motor, and the main gear meshes with the auxiliary gear, wherein an auxiliary assembly and a collecting assembly are arranged on the rotating shaft, wherein an adjusting assembly, a limiting assembly and a control assembly are arranged on the collecting assembly; and the grinding assembly comprises arc-shaped plates, a fixing sleeve, a fixing rod, a support, a fixing shaft, rolling wheels, supporting legs and an arc-shaped groove, wherein the supporting legs are symmetrically and fixedly connected to the two sides of the surface of the bottom plate. According to the smashing structure of the biopharmaceutical equipment, medicine can be thoroughly smashed, smashing is relatively uniform, a good smashing effect is achieved, and the smashed medicine can be conveniently collected, so that the practicality is relatively strong.

Owner:温州乔断信息科技有限公司

Sand and stone sorting equipment

The invention relates to the related field of civil engineering, in particular to sand and stone sorting equipment. The sand and stone sorting equipment comprises a box body and a first cavity fixedlyformed in the box body, a driving shaft is rotatably mounted on the end wall of the upper side of the first cavity, the driving shaft is in power connection with a main shaft of a motor, the motor isfixedly mounted on the end wall of the upper side of the driving shaft, a first bevel gear is fixedly mounted on the outer surface of the driving shaft, the first bevel gear and a second bevel gear are in engaging transmission, and the second bevel gear is fixedly mounted on the outer surface of the tail end of the front side of a rotating shaft. According to the sand and stone sorting equipment,large stones in sand and stone can be screened through a screening plate, the screened large stones can be crushed, the crushed stones are placed at corresponding positions through a conveying mechanism, the sand and the stones can be separated through vibration and shaking of a sorting box, and the sand and the stones are placed in corresponding areas through the conveying mechanism.

Owner:HANGZHOU PUDUAN TECH CO LTD

Sewage discharge capacity detection device for environmental monitoring and detection method of detection device

ActiveCN110657844AAchieve cleanupAvoid cloggingVolume/mass flow by mechanical effectsVolume meteringWater dischargeAir blower

The invention discloses a sewage discharge capacity detection device which comprises a water inlet pipe, a water discharging tank, a water discharging pipe, an air blower and a transparent long pipe,one end of the water inlet pipe is connected with the water discharging tank, the sidewall of the water discharging tank is connected with the water discharging pipe, and a power source is installed in one side of the water inlet pipe. The problems that a traditional detection device is difficult in detection when the sewage discharge amount is large in the sewage discharge amount detection process, a detection result is inaccurate, the detection difficulty is high, too many tasks are included, a series of complex detection instruments are needed, and the production and using, event maintenance, cost of the whole detection device is high are solved; and further, the problem that sewage water with large amount and high flowing speed main damage internal assemblies of the detection device isalso solved.

Owner:安徽世纪科技咨询服务有限公司

Constructional engineering sewage treatment device

PendingCN112093967ARealize crushingRealize disinfection and sterilization treatmentSpecific water treatment objectivesTreatment involving filtrationClassical mechanicsElectric machinery

The invention belongs to the field of constructional engineering, particularly relates to a constructional engineering sewage treatment device, which aims to solve the problems that an existing sewagetreatment device cannot perform multiple treatment, is poor in treatment effect, low in automation degree and complex to operate and control. The device in the following scheme comprises a device shell; a buffer funnel is fixedly installed at the upper end of the device shell through two supporting rods, the buffer funnel communicates with the device shell through a connecting pipe, a second motor is fixedly installed at the rear end of the device shell, an output shaft of the second motor is connected with a first rotating shaft, the front end of the first rotating shaft penetrates through the device shell and is in rotary connection with the inner wall of the device shell through a bearing, and a third rotating shaft is rotarily arranged on theinner wall of the device shell through a bearing. Thus, the multiple treatment on the sewage is achieved, the sewage treatment effect is substantially improved, the operation is simple and convenient, and the practicality is high.

Owner:湖南傲创科技有限公司

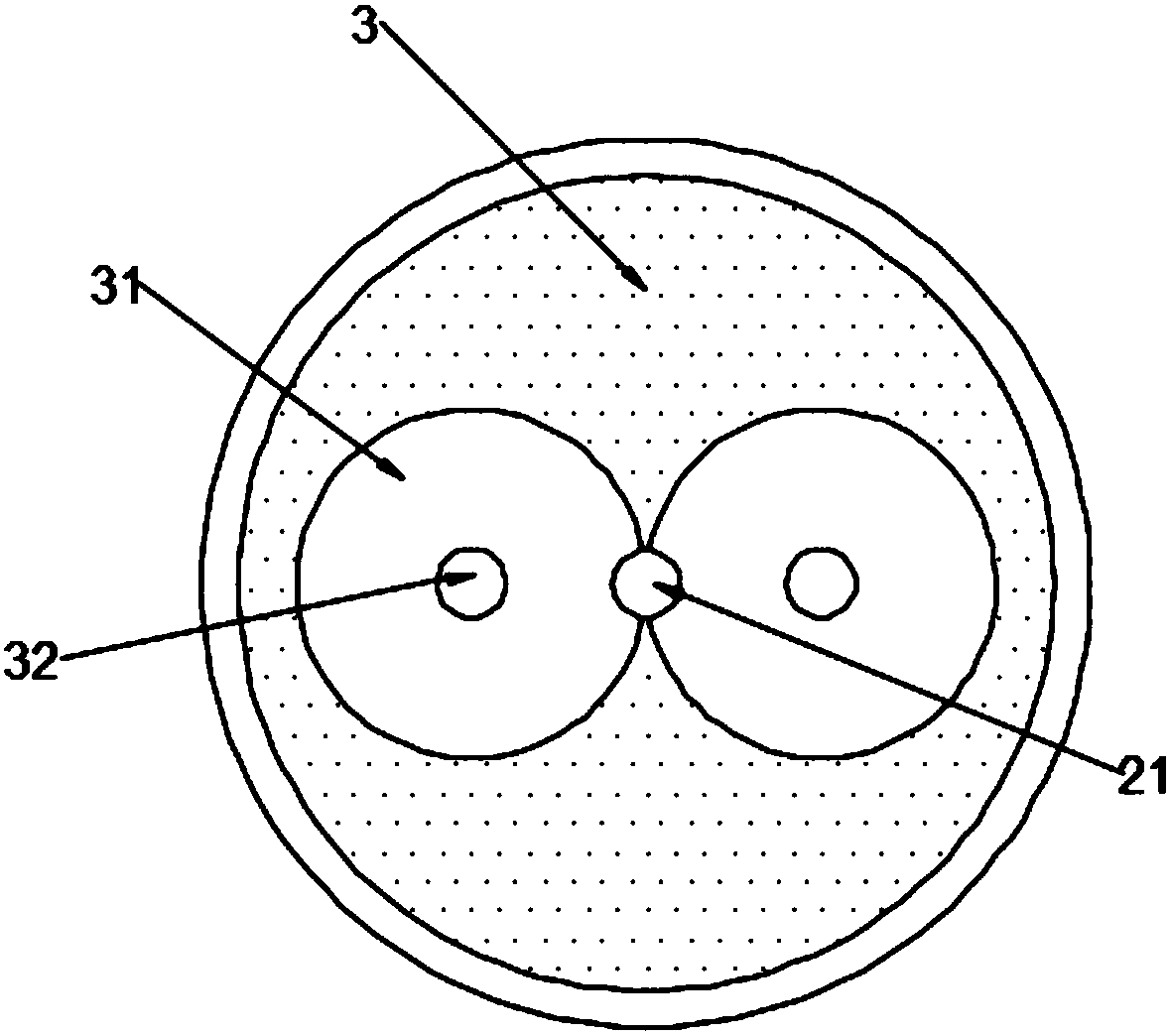

Industrial sewage filtering treatment equipment

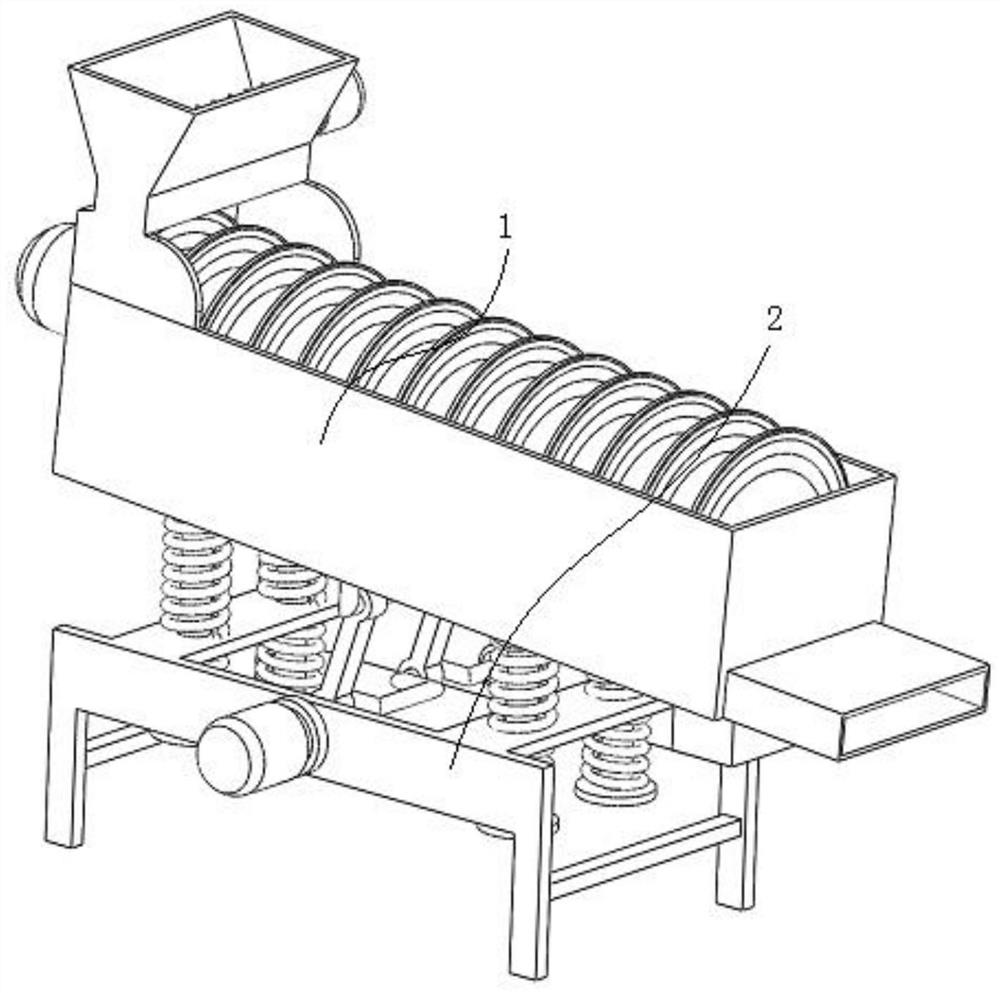

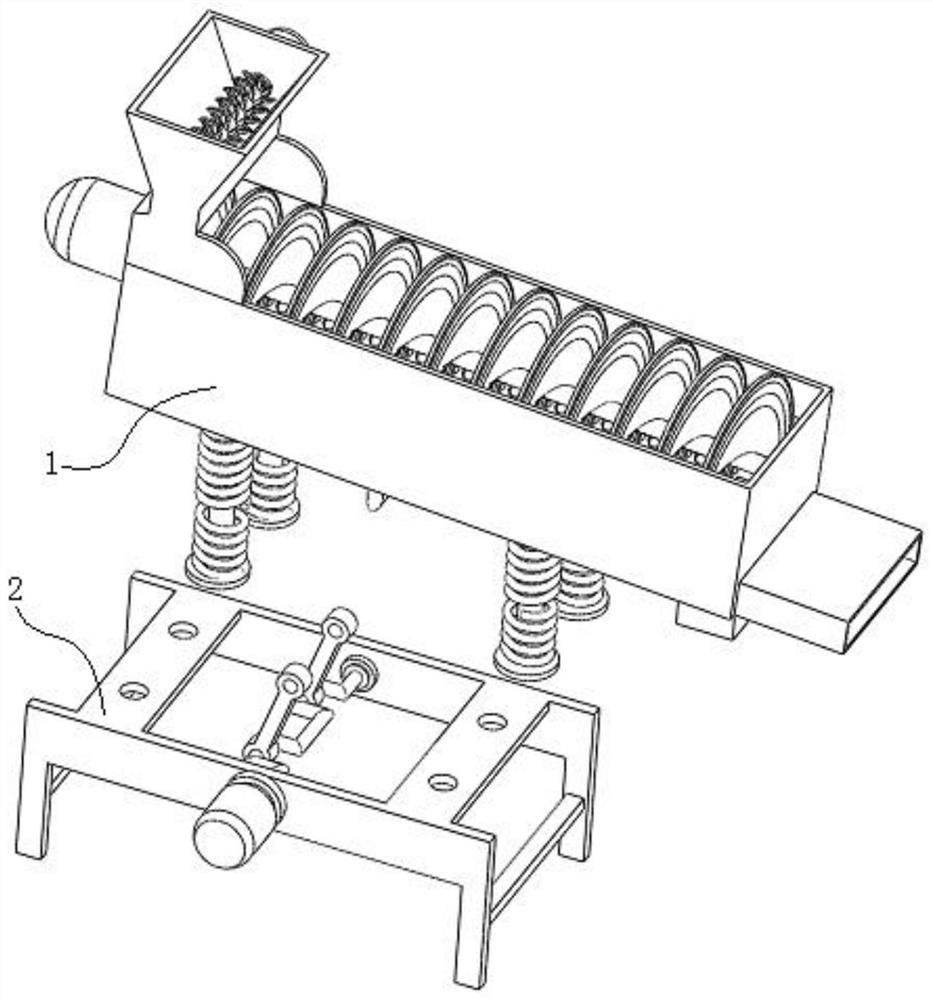

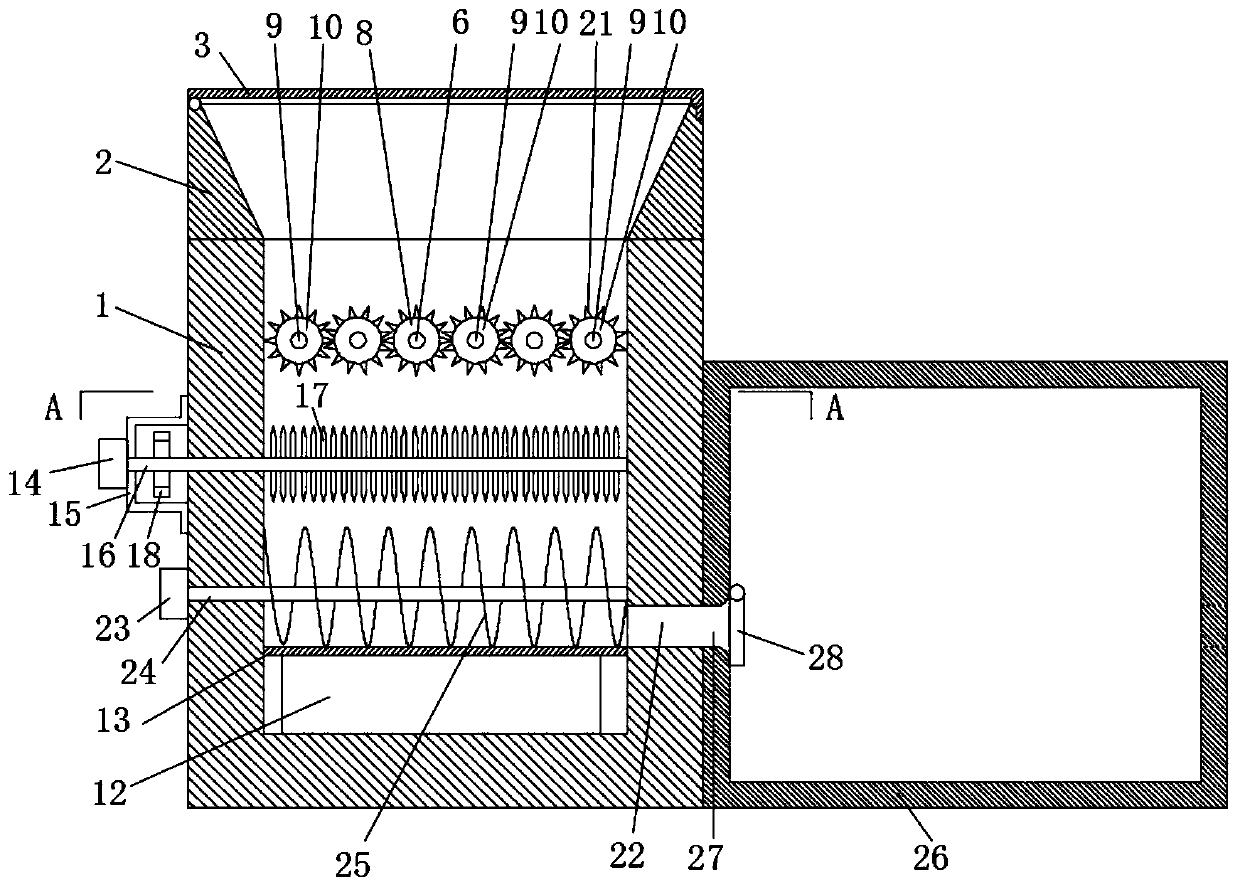

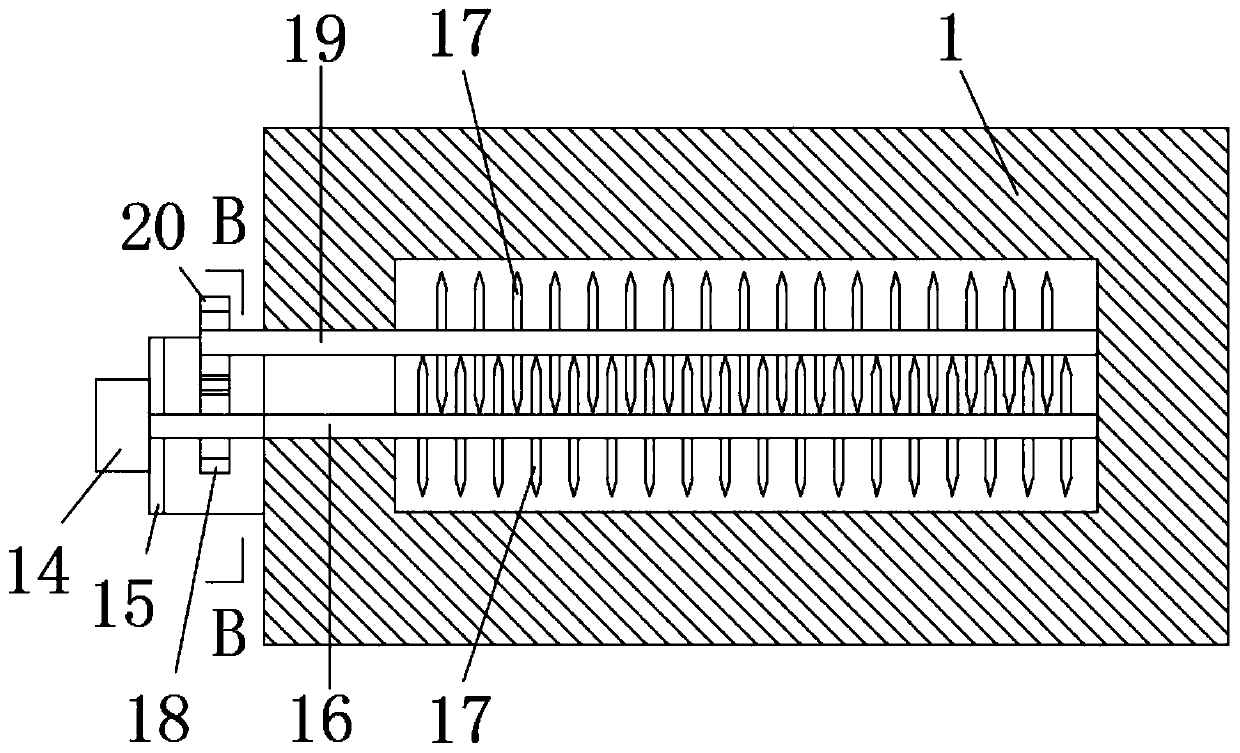

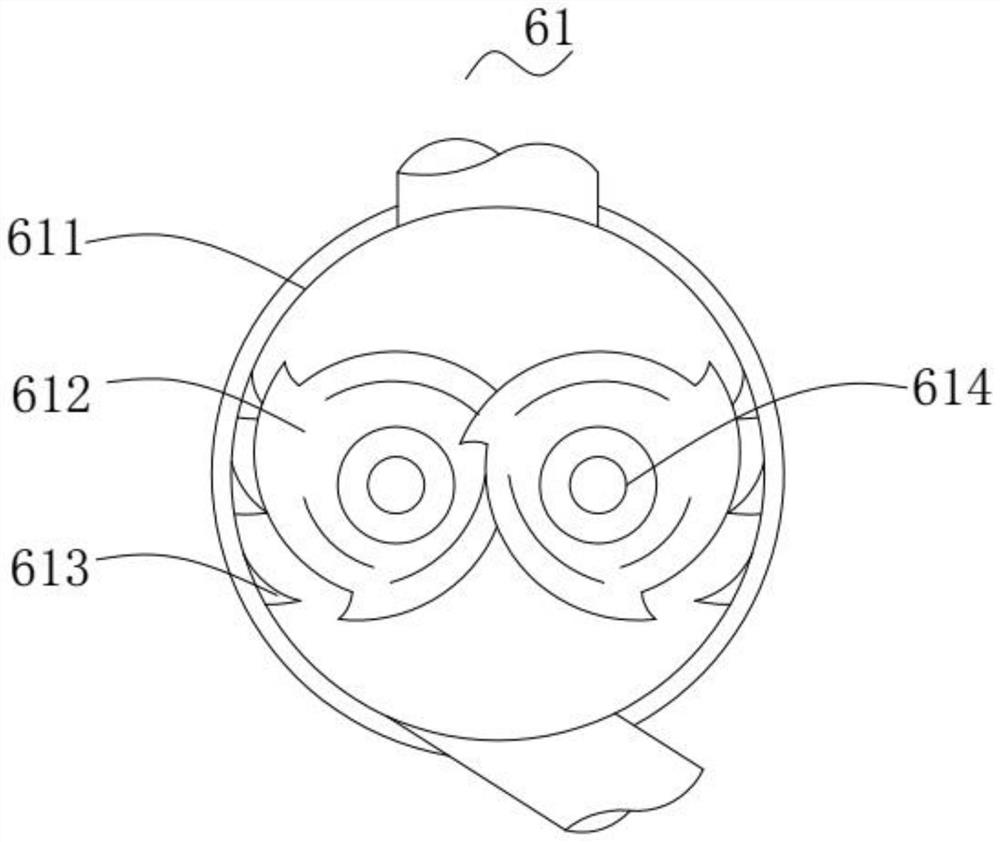

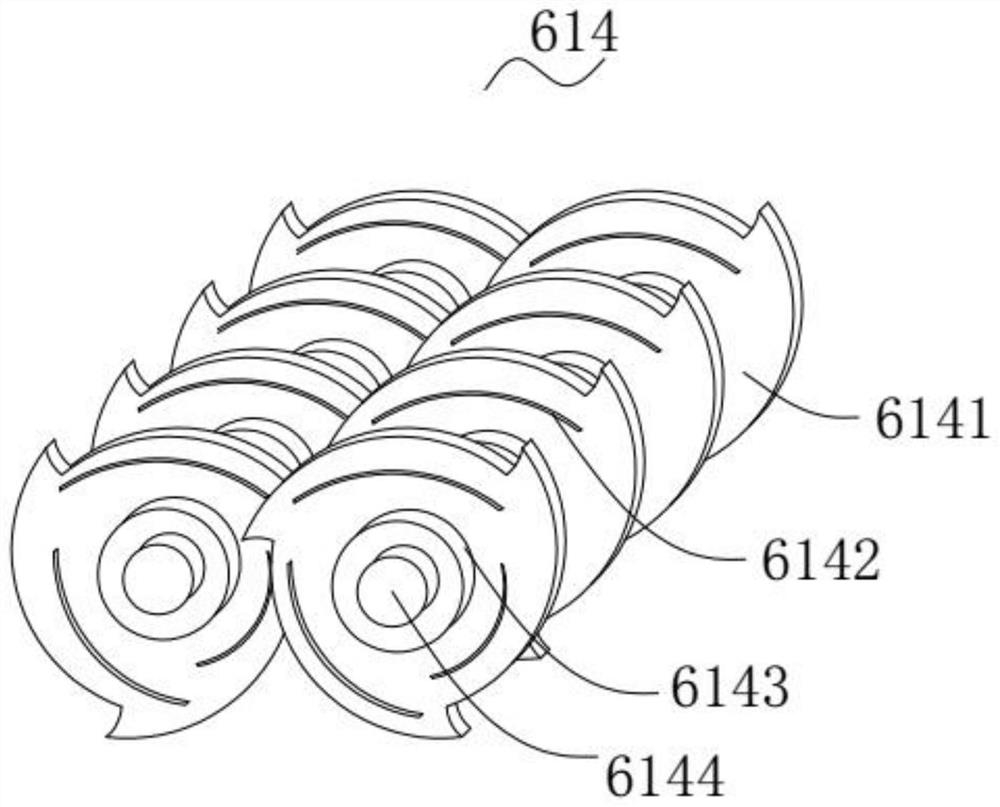

PendingCN112619253ASpeed up filteringAvoid buildup and cloggingTreatment involving filtrationGrain treatmentsElectric machinerySewage

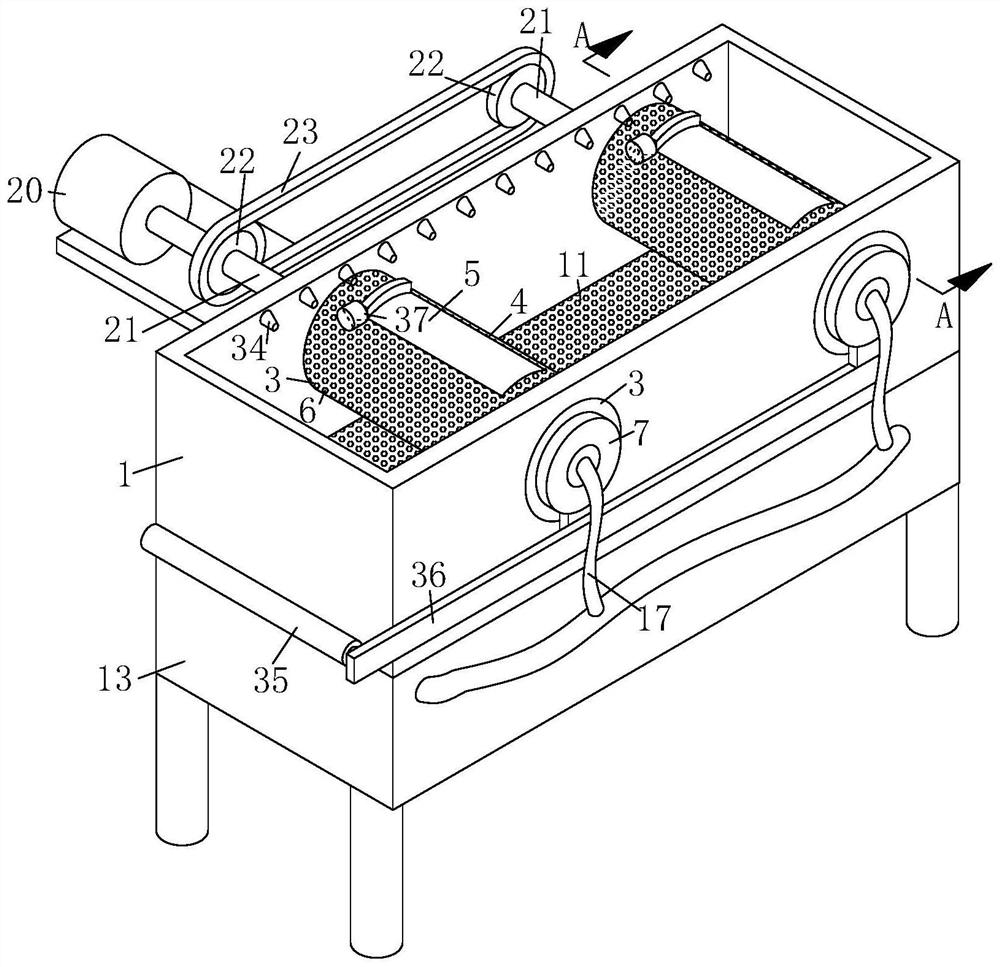

The invention discloses industrial sewage filtering treatment equipment. The industrial sewage filtering treatment equipment comprises an industrial sewage filtering tank assembly, wherein a supporting bottom rack assembly is arranged below the industrial sewage filtering tank assembly. According to the invention, a water inlet hopper driving motor drives a crushing rotating shaft rod and crushing blades to rotate, so crushing treatment of large particles in industrial sewage is achieved; the industrial sewage is filtered through inclined elastic up-and-down vibration of an industrial sewage filter box assembly and screening of a semicircular filter screen; filtered small particles are conveyed into a filtered material outlet pipe through inclined vibration of the industrial sewage filter box assembly and rotation of a filtered material conveying spiral shaft rod; the filtered industrial sewage is discharged through a water outlet pipe; and the filtering of the industrial sewage is accelerated in the semicircular filter screen through inclined elastic up-down vibration of the industrial sewage filter box assembly, so filtered substances are prevented from being accumulated and blocked in the semicircular filter screen, and meanwhile, downward output of the filtered substances is accelerated.

Owner:彩虹(合肥)液晶玻璃有限公司

Medical waste crushing device

The invention discloses a medical waste crushing device. The medical waste crushing device comprises a crushing box body and a sterilization and disinfection device, wherein the crushing box body is provided with a crushing unit, the crushing unit comprises a crushing motor, a first driving shaft is fixedly installed on the crushing motor, a driving crushing roller is fixedly installed on the first driving shaft, a first driving gear is fixedly installed on the first driving shaft, the crushing box body is provided with first driven shafts, and a driven crushing roller is fixedly installed oneach first driven shaft. By arranging the crushing unit, the crushing motor rotates to drive the first driving gear and the driving crushing roller to rotate, through the gear pair transmission principle, crushing teeth on the driving crushing roller and the driven crushing rollers crush medical waste, the crushing treatment of the medical waste is realized, then the crushed medical waste is sterilized and disinfected by the sterilization and disinfection device, and thus the treatment of the medical waste is completed and meanwhile the environment can be protected.

Owner:BEIHUA UNIV

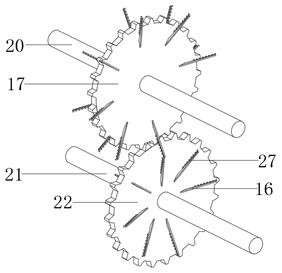

Soil loosening device for garden construction

PendingCN112889371AImprove soil loosening effectRealize crushingSpadesSoil-working equipmentsAgricultural engineeringSprocket

The invention provides a soil loosening device for garden construction, relates to the technical field of garden construction. The problems that in an existing soil loosening device for garden construction, when soil is loosened through a soil turning shovel, the soil loosening effect is not ideal due to the fact that turned soil blocks are large and the soil is not loose enough, meanwhile, grass roots are adhered between the turned soil, vegetation planting in the later period is inconvenient, and the garden construction efficiency is greatly impacted are solved. The soil loosening device comprises a bottom frame, the middle position of the bottom of the bottom frame is rotationally connected with front wheels through a bearing, a rear wheel are arranged on the rear side of the bottom of the bottom frame, and the bottom frame comprises a mounting base and a supporting rod. A second driven chain wheel is fixedly installed at the position, close to the left end, of a second shaft rod, a first chain is arranged on the second driven chain wheel, two sets of smashing fan blades are arranged on the second shaft rod, the two sets of smashing fan blades continuously rotate, grass roots in the soil turned over by a break shovel are smashed, the situation that the grass roots connect the soil into blocks is effectively prevented, and the soil loosening effect is further improved.

Owner:张莉莉

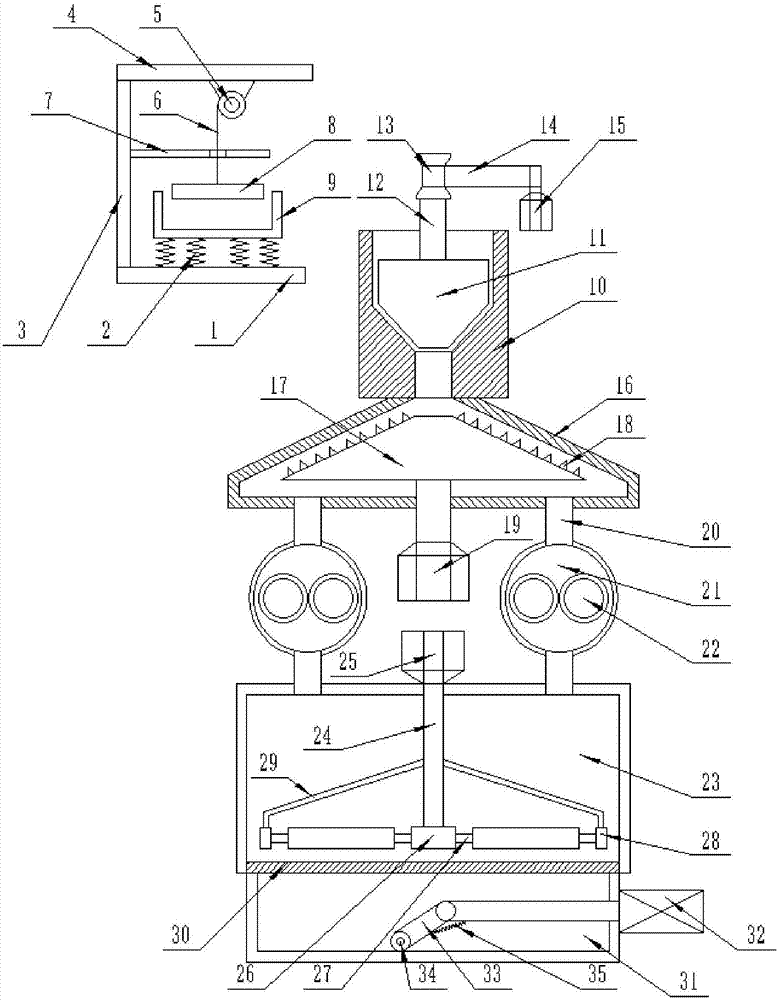

Cob pulverizing machine

The invention discloses a cob pulverizing machine which comprises a bottom supporting plate body, a bottom frame body, a lower pulverizing shell, an upper pulverizing shell, a cob feeding bin, a discharging pipe, a pulverizing shaft, a smashing roller, multiple pulverizing hammers, pulverizing cutter teeth, a zigzag bracket, an oblique grinding plate A, a longitudinal grinding plate, an adjustablesupporting plate frame, a supporting plate and an oblique grinding plate B. The end faces of the oblique grinding plate A, the longitudinal grinding plate and the oblique grinding plate B are machined with sawteeth. The cob pulverizing machine also comprises an arc-shaped adjustable narrow strip plate, an arc-shaped blanking grille grinding plate, a transitional delivery hopper, a round lifting delivery cylinder, a lifting shaft and delivery slurry, wherein a discharging buckle bag opening is formed in the upper end of the round lifting delivery cylinder. The cob pulverizing machine is novelin structural design, good in pulverizing effect, high in pulverizing efficiency, reliable in work and easy to popularize, can be adjusted according to the granule fineness of pulverized cobs and canmeet different operation requirements.

Owner:杨春

Ore feeding and screening device

PendingCN113333292ARealize crushingAchieve extrusionSievingGas current separationMining engineeringStructural engineering

The invention belongs to the technical field of ore mining, and particularly relates to an ore feeding and screening device. According to the following scheme, the ore feeding and screening device comprises a screening box, wherein a feeding port is formed in one side of the top end of the screening box, and a primary feeding screen is fixedly installed on the inner wall of the feeding port through bolts; a steel wire mesh hopper is welded to the inner wall of the end, close to the primary feeding screen, of the screening box, and a material breaking hopper barrel is welded to the bottom end of the steel wire mesh hopper; notches which are distributed at equal intervals are formed in the material breaking hopper barrel, and wall thorns which are distributed in a staggered mode with the notches are welded to the inner wall of the material breaking hopper barrel; and fixing cross rods penetrating through the steel wire mesh hopper are horizontally welded to the two sides of the inner wall, close to the top end, of the screening box. According to the ore feeding and screening device, through an arranged electric telescopic rod, when an extension rod of the electric telescopic rod is drawn back, a second piston plate can be pushed by utilizing an L-shaped driving rod, so that a first piston plate and a driven side rod are pushed to move upwards by utilizing the hydraulic principle; and otherwise, the electric telescopic rod extends and extends, so that the driven side rod moves downwards, and then a screen disc swings back and forth.

Owner:六安中科聚盆机械有限公司

Stone crusher with energy-saving and noise-reducing functions used for mine construction

InactiveCN112892654ARealize crushingWith energy saving effectGrain treatmentsCrushed stoneStructural engineering

The invention discloses a stone crusher with energy-saving and noise-reducing functions used for mine construction. The stone crusher comprises a rectangular frame, a U-shaped guide plate, a door-shaped frame, an H-shaped hanging plate, a multi-section telescopic rod, a balance weight circular truncated cone, an upper pressing plate, a lower pressing groove seat and a driving part. According to the stone crusher, the rectangular frame, the U-shaped guide plate, the door-shaped frame, the H-shaped hanging plate, the multi-section telescopic rod, the balance weight circular truncated cone, the upper pressing plate, the lower pressing groove seat and the driving piece are arranged, the upper pressing plate and the lower pressing groove seat are used for crushing stones, an L-shaped plate is arranged at the bottom of the multi-section telescopic rod, the top of the multi-section telescopic rod is connected with the balance weight circular truncated cone, the H-shaped hanging plate ascends to carry the balance weight circular truncated cone and one end of the U-shaped guide plate to ascend, when the H-shaped hanging plate ascends to a certain height and pushes away the balance weight circular truncated cone, the balance weight circular truncated cone moves outwards along the inclined U-shaped guide plate and then drives the L-shaped plate to rotate, the L-shaped plate rotates to push the upper pressing plate to move downwards, and therefore crushing machining of the stones can be achieved, potential energy is utilized for crushing machining, and the energy-saving effect is achieved.

Owner:王倍倍

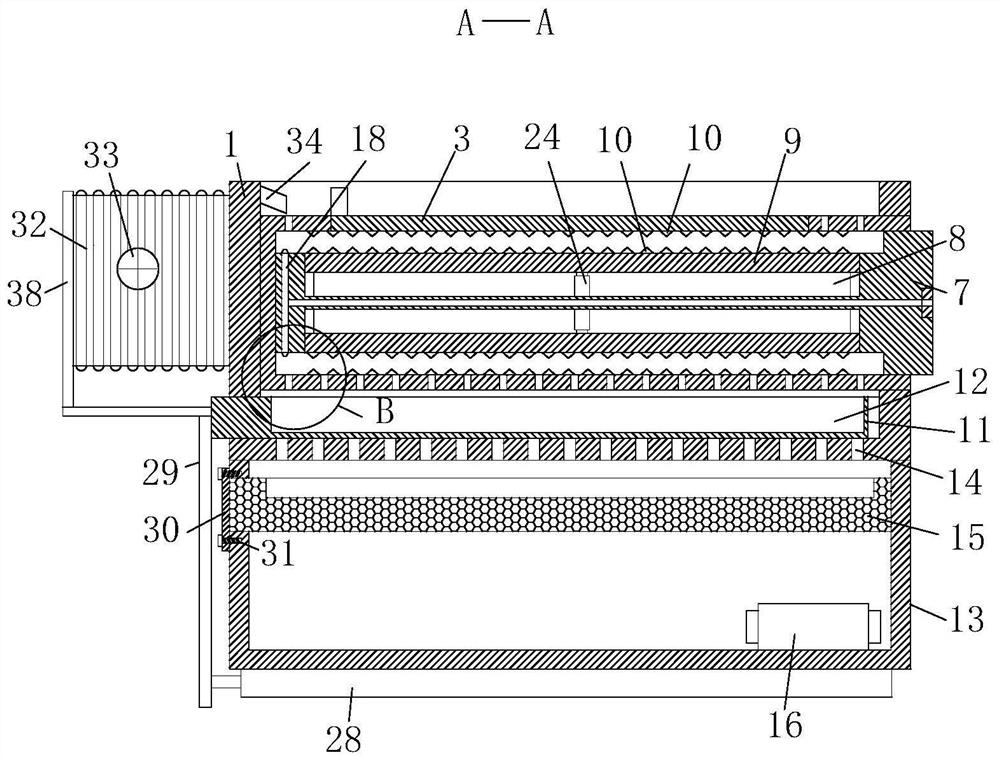

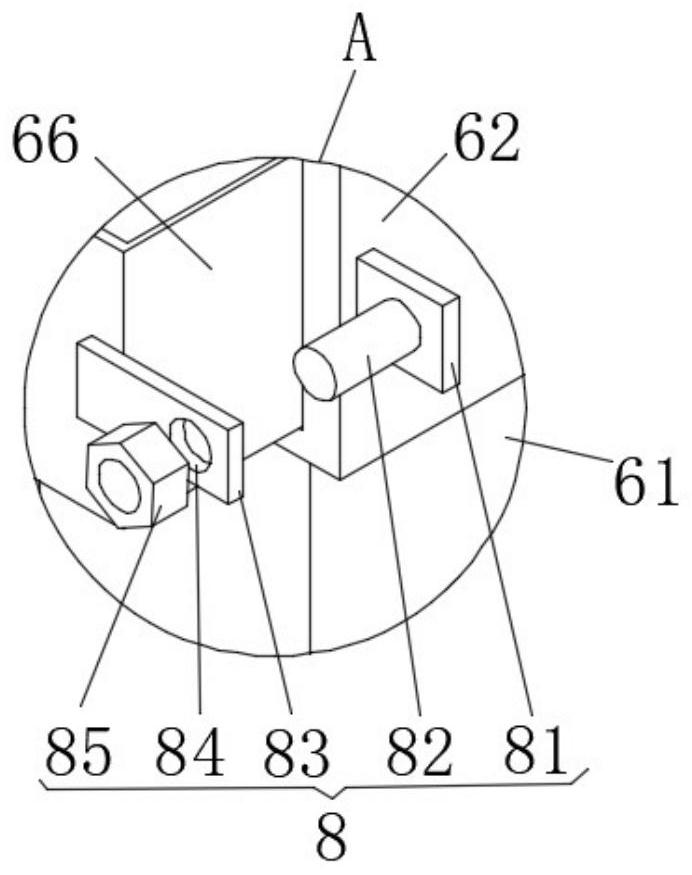

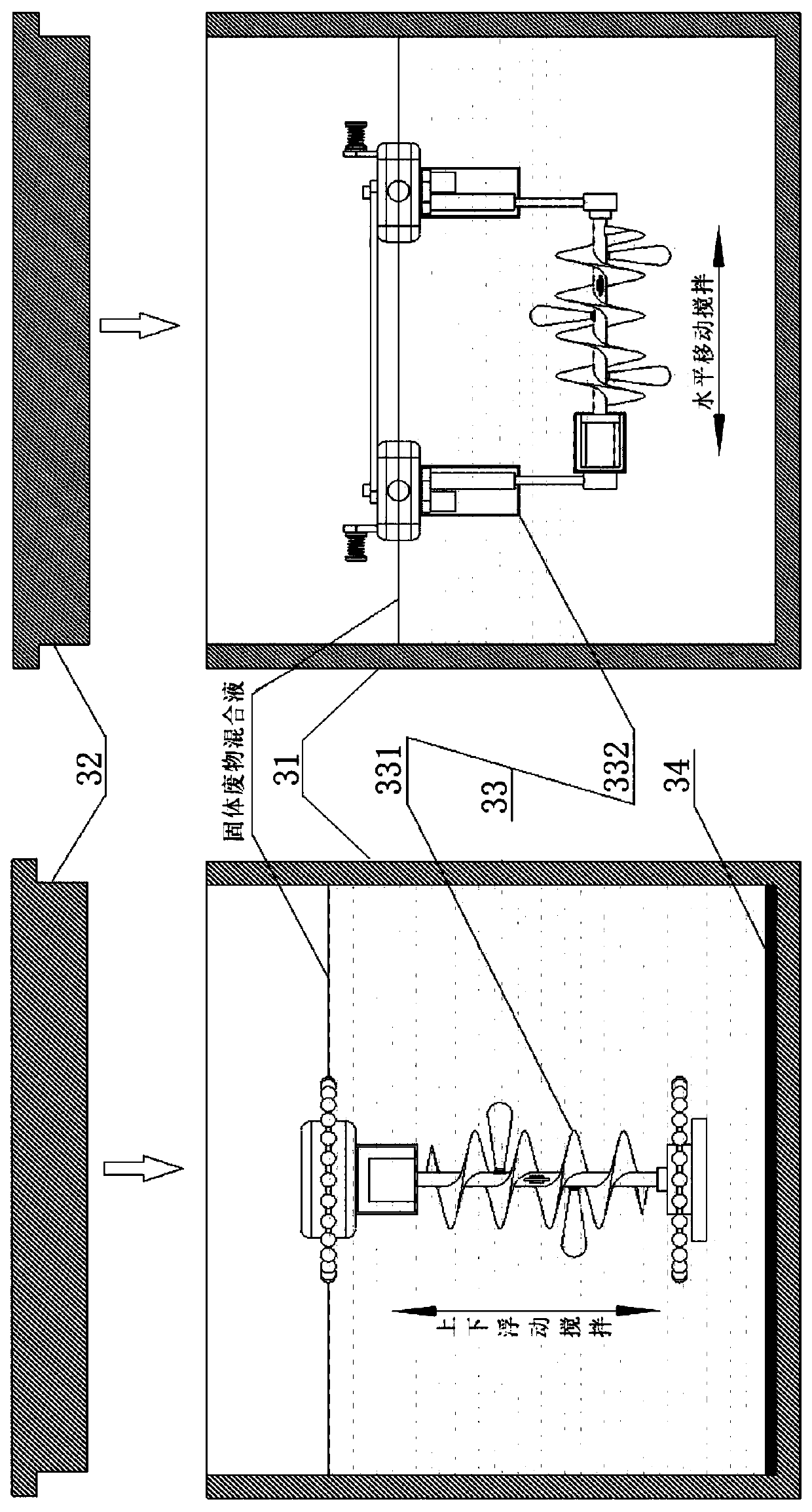

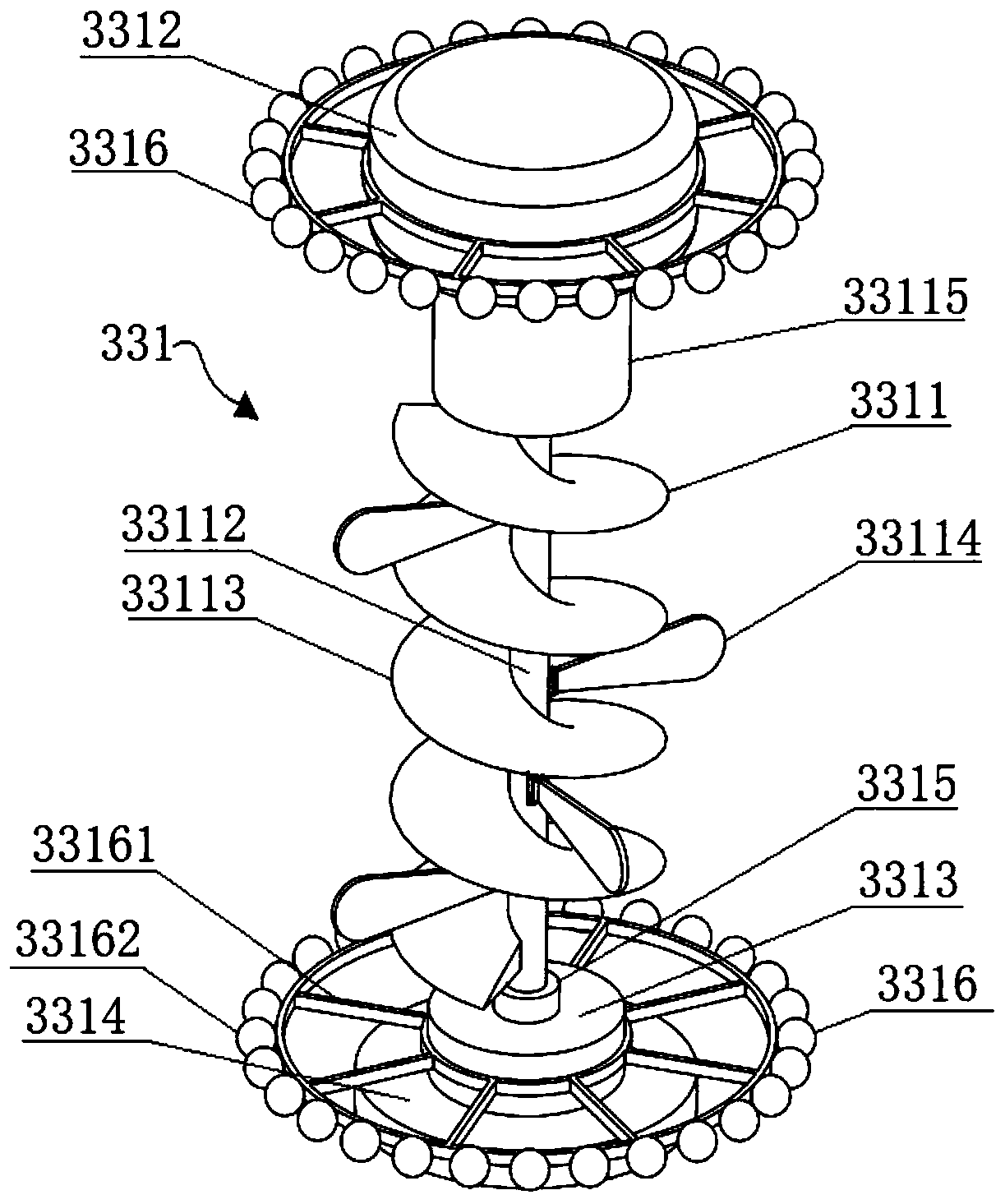

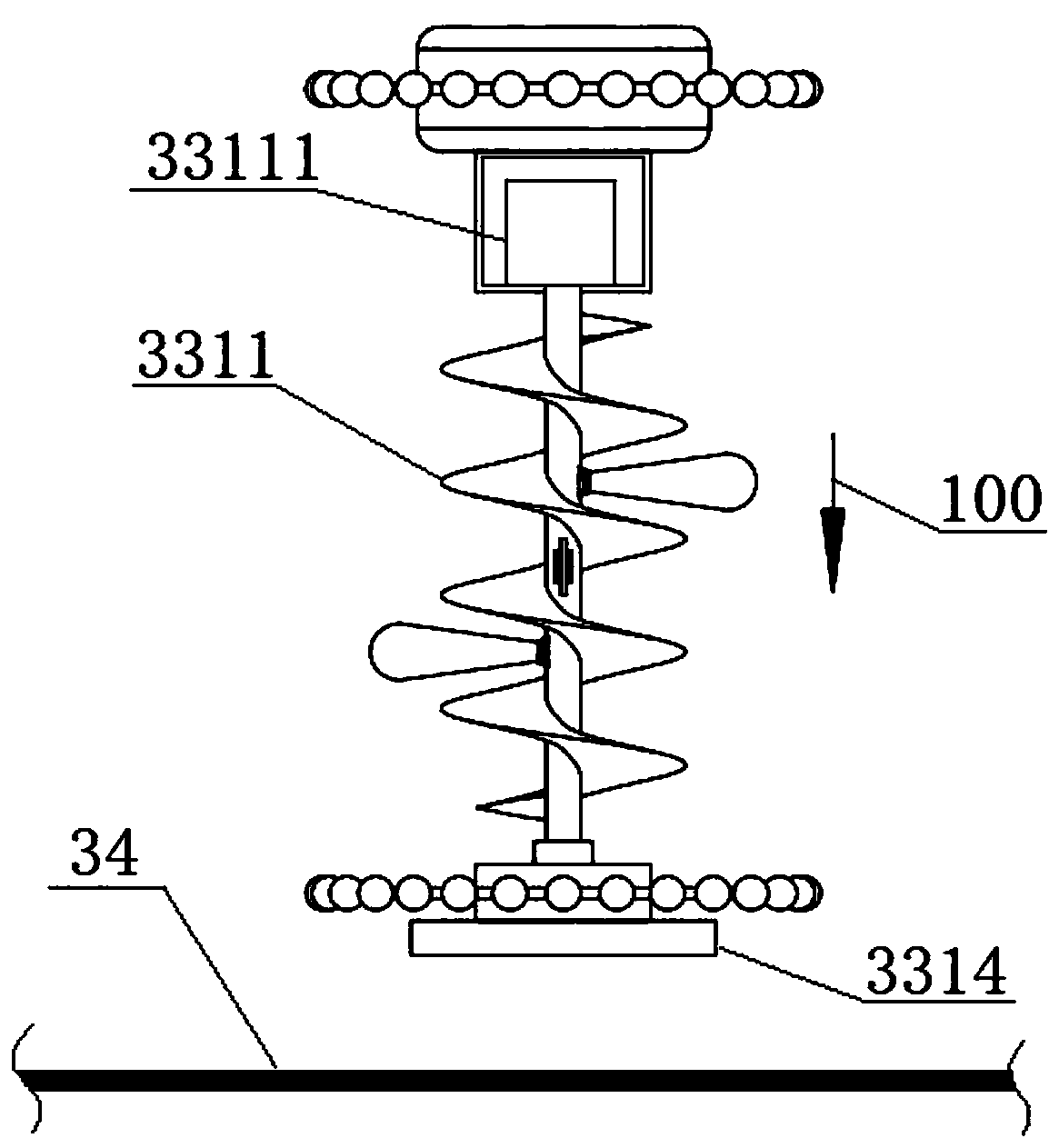

Wet type ultrasonic refining equipment for solid waste, comprehensive treatment system and method

ActiveCN111085525ARealize crushingImprove crushing effectTransportation and packagingSolid waste disposalProcess engineeringEnvironmental engineering

The invention discloses wet type ultrasonic refining equipment for solid waste, a comprehensive treatment system and a method. The wet type ultrasonic refining equipment for solid waste comprises a wet type ultrasonic refining facility which comprises a floating type stirring unit, wherein the floating type stirring unit floats on the liquid surface of a solid waste mixed liquid in an ultrasonic crushing container, and a stirring part of the floating type stirring unit is buried in the solid waste mixed liquid; and the floating type stirring unit is in a movable stirring state in the solid waste mixed liquid under reverse thrust action produced when the stirring part of the floating type stirring unit stirs the solid waste mixed liquid. The wet ultrasonic refining equipment can thoroughlycrush solid waste and is good in crushing effect and high in efficiency; and the comprehensive treatment system can effectively transfer and remove pollutants carried by the solid waste, so that comparatively thorough pollutant removal treatment of the solid waste is realized, and the system is suitable for large-scale promotion.

Owner:溧阳中材环保有限公司

A device for removing waste fabric accessories

The invention discloses a waste fabric auxiliary material removing device, and belongs to the field of waste fabric recycling equipment. The device comprises a feeding bin and two hobbing cutters; the two hobbing cutters are arranged in the feeding bin side by side, one ends of the two hobbing cutters stretch out of the feeding bin and are connected with gears correspondingly, the two gears are engaged and connected with a speed reduction motor so as to be driven to rotate, two extrusion rollers which are arranged side by side are further arranged in the feeding bin, and are arranged on the hobbing cutters, one ends of the two extrusion rollers are each provided with a drive device, an air way is arranged below the hobbing cutters, a plurality of lower air openings are formed in the bottom of the air way, and a side air opening is formed in one side of the air way; an auxiliary material vibration conveying way is arranged in the air way, the side, provided with the side air opening, of the air way is provided with an air way side opening, the auxiliary material vibration conveying way is placed obliquely and upwards and stretches out of the air way side opening, and a linear vibrator is arranged at the bottom of the auxiliary material vibration conveying way; a bottom frame is arranged at the bottom of the linear vibrator, and the bottom frame is fixed to the inner side of the bottom of the air way.

Owner:山东孚润机械科技有限公司

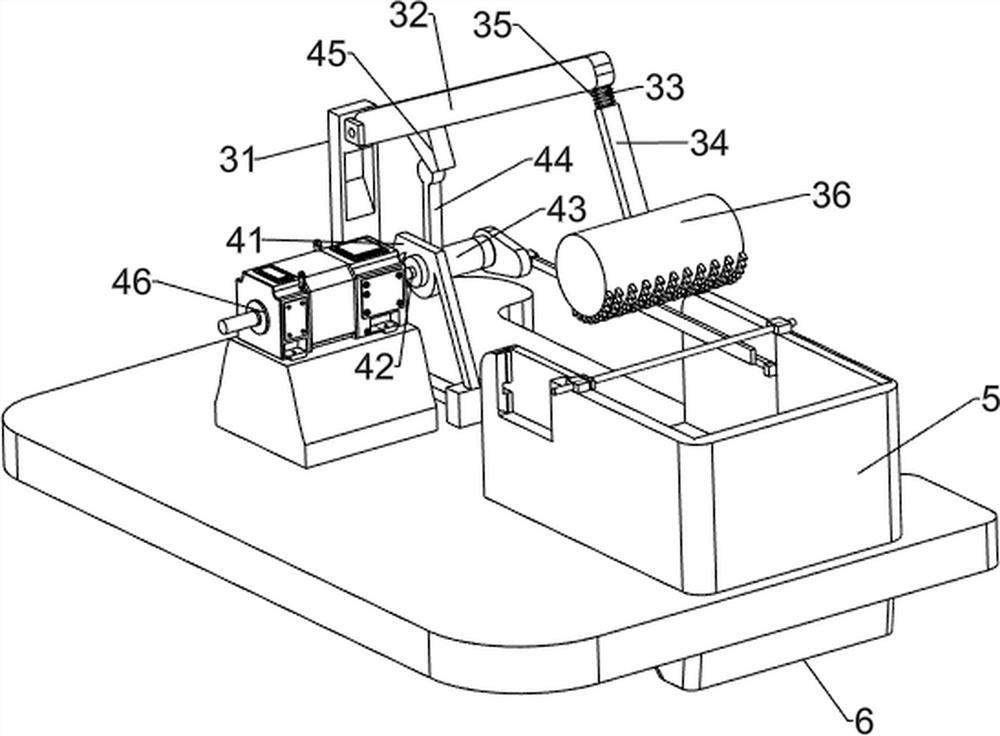

Garbage collection vehicle

InactiveCN110937290ASmall footprintLarge capacityRefuse cleaningRefuse vehiclesGarbage collectionEnvironmental geology

The invention discloses a garbage collection vehicle. The garbage collection vehicle comprises a box body of the garbage collection vehicle, and a rolling structure and a cleaning structure arranged on the top wall of the box body. According to the garbage collection vehicle, the rolling structure is arranged on the top wall of the box body for crushing garbage, so that the garbage occupies a reasonable volume, and the box body can load and transport more garbage; a cleaning device is arranged on the top wall of the box body for cleaning the interior of the box body regularly, so that the situations of mess and peculiar smell are avoided; a sewage collection box is arranged at the bottom of the rolling structure for separating sewage from solid garbage, so that pollution caused by sewage leakage is avoided; a pushing and pressing structure is arranged on the side wall of the box body for pressing the garbage, so that the capacity of the box body is increased, and the rolling structureis prevented from being blocked; a sealing cover is arranged at a feeding port, and a box door is arranged on the side wall of the box body, so that the odor of the garbage is prevented from spreading, and the garbage is prevented from leaking to cause secondary pollution; and a can holding turnover structure is arranged on the side wall of a hopper, so that a garbage can can be mechanically controlled. Therefore, the garbage collection vehicle has the advantages that the box body of the garbage vehicle can reasonably load and transport the garbage, and the box body can be cleaned regularly.

Owner:天津精鸿智装科技有限公司

A sewage discharge detection device for environmental monitoring and its detection method

ActiveCN110657844BAchieve cleanupAvoid cloggingVolume/mass flow by mechanical effectsVolume meteringWater dischargeAir blower

The invention discloses a sewage discharge capacity detection device which comprises a water inlet pipe, a water discharging tank, a water discharging pipe, an air blower and a transparent long pipe,one end of the water inlet pipe is connected with the water discharging tank, the sidewall of the water discharging tank is connected with the water discharging pipe, and a power source is installed in one side of the water inlet pipe. The problems that a traditional detection device is difficult in detection when the sewage discharge amount is large in the sewage discharge amount detection process, a detection result is inaccurate, the detection difficulty is high, too many tasks are included, a series of complex detection instruments are needed, and the production and using, event maintenance, cost of the whole detection device is high are solved; and further, the problem that sewage water with large amount and high flowing speed main damage internal assemblies of the detection device isalso solved.

Owner:安徽世纪科技咨询服务有限公司

Experimental method for studying the source mechanism and disappearance mechanism of CO in underground coal mines

ActiveCN104880543BSimple structureNovel and reasonable designFuel testingExperimental methodsNitrogen

The invention discloses an experiment device for underground coal mine CO source mechanism and disappearing mechanism research. The experiment device comprises a sealed box, wherein a cutting tool is arranged in the sealed box, a crusher is arranged in the sealed box, a crushing chamber is arranged on the crusher, a heating device is arranged on the crushing chamber, and an exhaust pipe, a gas taking pipe and two gas inlet pipes are arranged on the sealed box. The experiment device is used for providing a necessary and sufficient experiment environment for underground coal mine CO source mechanism and disappearing mechanism research. The invention further discloses an experiment method for underground coal mine CO source mechanism and disappearing mechanism research. Crushing treatment is conducted on a coal sample in an anaerobic environment under certain temperature condition, the CO gas concentration of the gas released out of the crushing chamber is detected, and the experiment method is simple and convenient. According to the experiment method for underground coal mine CO source mechanism and disappearing mechanism research, the coal sample is subjected to crushing treatment in the anaerobic environment, the crushing chamber is filled with nitrogen, then the coal sample is heated, then the concentration of the gas released out of the crushing chamber is detected, and the experiment method is simple and convenient.

Owner:XIAN UNIV OF SCI & TECH

A recycling process for waste plastic bottles

ActiveCN108274656BRealize crushingReduce noisePlastic recyclingMechanical material recoveryProcess engineeringMachine press

The invention relates to the field of plastic bottle recycling treatment, in particular to a waste plastic bottle recycling treatment technology. The technology includes the following steps that a plastic bottle is put into a label removing machine, and the label removing machine is used for removing a label on the surface of the plastic bottle; the plastic bottle obtained after label removing isput into a breaking device, and the breaking device is used for breaking the plastic bottle; the broken plastic bottle is collected and put into a pressure machine, and the pressure machine is used for pressing plastic into blocks; the plastic which is pressed into blocks is put into a slicing machine, and the slicing machine is used for slicing the block-shaped plastic; the above steps are repeated till the cut plastic is in a slice shape; and the particle-shaped plastic in the fifth step is collected. By means of the waste plastic bottle recycling treatment technology, a static pressure breaking manner is adopted for achieving breaking of the plastic bottle, compared with a traditional breaking manner, the waste plastic bottle recycling treatment technology has the beneficial effects ofbeing low in noise and good in breaking effect.

Owner:山东省易斯特环境科技有限公司

A new energy transmission system and crushing system

ActiveCN110194363BEfficient deliveryRealize crushingGrain treatmentsConveyor partsDrive shaftNew energy

The invention discloses a new energy delivery system, which includes a power mechanism and a delivery mechanism; the delivery mechanism includes a first delivery assembly and a second delivery assembly; Drive pulley and worm and worm gear mechanism; the one-way transmission assembly includes the first one-way gear, the second one-way gear, the first transmission gear, the second transmission gear, the third transmission gear, the fourth transmission gear, the first transmission gear shaft, second transmission shaft and one-way drive pulley. The present invention also provides a crushing system, including the new energy transmission system, and also includes a crushing mechanism and a vibration mechanism. The invention has flexible structural design, convenient use, energy saving and environmental protection, and improves production efficiency.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

Mashing device for agricultural processing

ActiveCN112473988AImplement shreddingRealize crushingFood processingGrain treatmentsAgricultural scienceReciprocating motion

The invention belongs to the technical field of agricultural processing, particularly relates to a mashing device for agricultural processing, and aims to solve the problems that a conventional mashing device for agricultural processing is generally simple in structural design, and materials are not crushed, so that when mashing treatment is directly performed, the processing efficiency is low, and the processing period is long. The invention provides the following scheme that the mashing device comprises a fixed frame, wherein a feeding hopper is fixedly mounted on one side close to the top end, of the fixed frame, and a driving mechanism is mounted on one side of the feeding hopper. In the vertical movement process of a clamping ring, an L-shaped vertical rod can be used for driving a mashing block to do reciprocating motion, and therefore, mashing treatment on materials is achieved through cooperation with a mashing basin. Through the arrangement of a refrigerator, the mashing basincan be subjected to temperature lowering and cooling treatment, so that bottom temperature can be utilized to cool materials to prevent the condition that the materials are overheated, and nutrient substances of the materials are influenced; and low temperature can be utilized to harder the texture of the materials, so that the mashing effect is conveniently improved.

Owner:黑龙江省日火新能源科技有限公司

Novel energy conveying system and crushing system

ActiveCN110194363AEfficient deliveryRealize crushingGrain treatmentsConveyor partsDrive shaftNew energy

The invention discloses a novel energy conveying system. The novel energy conveying system comprises a power mechanism and a conveying mechanism, wherein the conveying mechanism comprises a first conveying assembly and a second conveying assembly; the power mechanism comprises a drive assembly, a one-way transmission assembly, a conveyor belt, a driven belt wheel and a worm gear mechanism; and theone-way transmission assembly comprises a first one-way gear, a second one-way gear, a first transmission gear, a second transmission gear, a third transmission gear, a fourth transmission gear, a first transmission shaft, a second transmission shaft and a one-way drive belt wheel. The invention further provides a crushing system which comprises the novel energy conveying system, and further comprises a crushing mechanism and a vibrating mechanism. The novel energy conveying system is flexible in structural design, is convenient in use, is energy-saving and environmentally friendly, and improves production efficiency.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

Soil hardened block crushing treatment device for garden potted plants

InactiveCN112772224ARealize crushingRealize the collectionCultivating equipmentsFlower-pot fillingAgricultural engineeringMechanical engineering

The invention relates to a crushing treatment device, in particular to a soil hardened block crushing treatment device for garden potted plants. The soil hardened block crushing treatment device for garden potted plants can realize automatic crushing and automatic discharging. The soil hardened block crushing treatment device for the garden potted plants comprises a base, a smashing device, a toggling device, a treatment frame and a discharging hopper, wherein a workbench is arranged at the top of the base, the smashing device is arranged on one side of the top of the workbench, the toggling device is arranged at the top of the base, the toggling device is matched with the smashing device, the treatment frame is arranged on the other side of the top of the base, and the discharging hopper is arranged at the bottom of the treatment frame, and the discharging hopper is matched with the treatment frame in a penetrating mode. Through cooperation of the toggling device and the smashing device, crushing treatment of hardened soil blocks can be achieved, and meanwhile through cooperation of a material pushing device, soil collection is achieved.

Owner:宋娟利

A pulverizing device for biomass particle production with a pulverizing fine powder collecting mechanism

ActiveCN110918224BAchieve rotationAchieve rollingGrain treatmentsElectric machineProcess engineering

The invention belongs to the field of crushing devices, in particular, a crushing device for biomass particle production with a crushing fines collection mechanism. The existing biological particles are not provided with a collection device after being crushed, so it is inconvenient to dispose of them after processing. The problem that the particles are removed from the crushing device is now proposed as follows, which includes a crushing box, an installation cover is rotatably connected to the inner wall of the crushing box, and a drive motor located above the installation cover is fixedly installed in the crushing box, and the drive motor The output shaft is fixedly connected to the top of the installation cover. The present invention applies pressure to the pressure rollers by starting the rotating motors respectively, and then starts the drive motor to drive the pressure rollers to move circularly and rotate at the same time, so that the biological particles can be crushed and crushed , and the pressing plate can be easily taken out after the crushing is completed, so that the biological particles can be collected conveniently, so it will be more convenient when used, and has a strong market promotion prospect.

Owner:MENGCHENG SHENGYAN STRAW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com