A new energy transmission system and crushing system

A conveying system and new energy technology, applied in the direction of transportation and packaging, conveyor objects, grain processing, etc., can solve the problems of single structure, limited use, large power consumption, etc., and achieve the effect of ensuring effective transportation and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

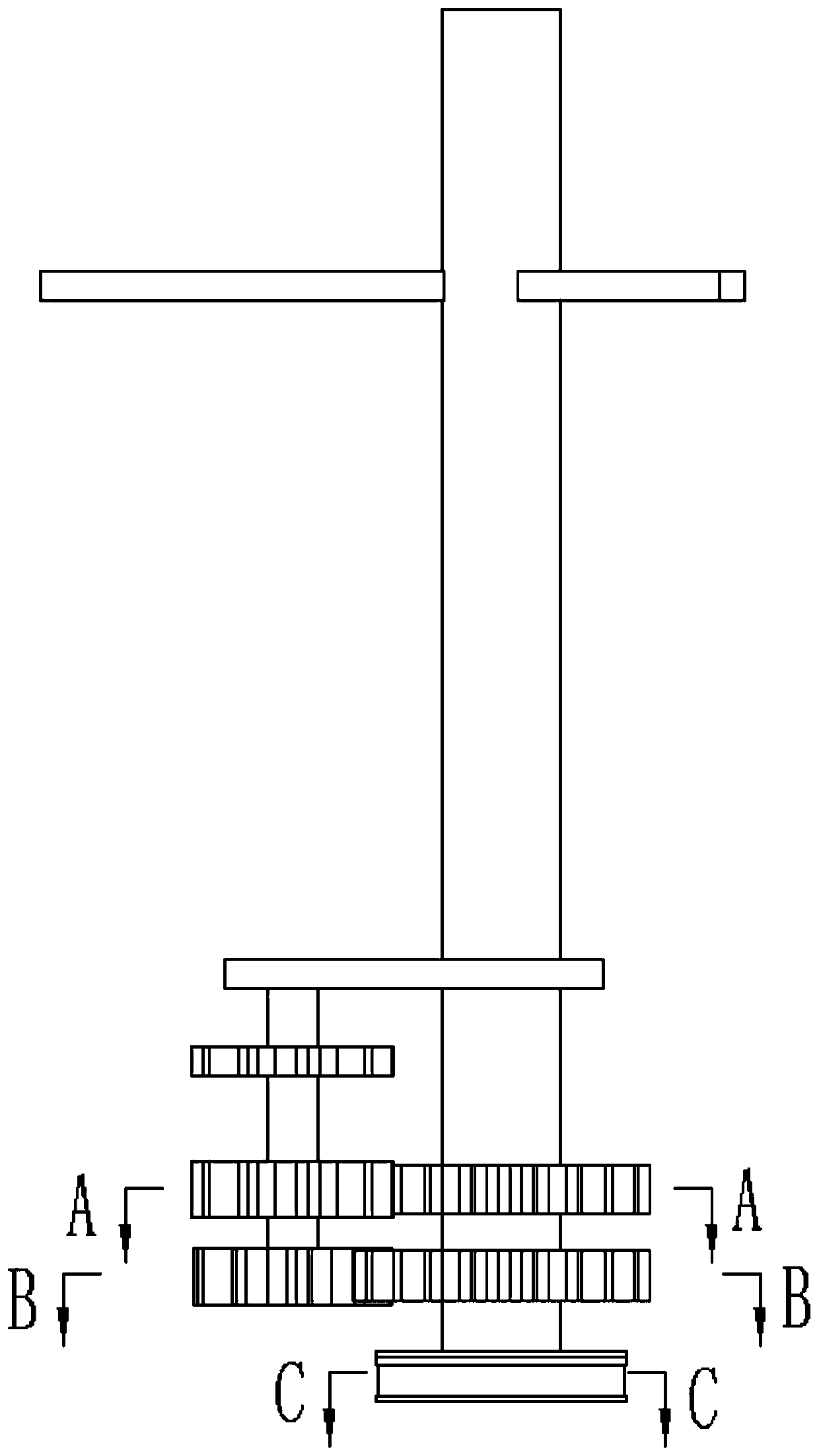

[0032] Such as Figure 1-6As shown, a new energy delivery system provided by this embodiment includes a power mechanism and a delivery mechanism; the delivery mechanism includes a first delivery assembly 1 and a second delivery assembly 2; the power mechanism includes a drive assembly 3, a one-way Transmission assembly 4, conveyor belt 5, driven pulley 6 and worm gear mechanism 7; described one-way transmission assembly 4 comprises first one-way gear 40, second one-way gear 41, first transmission gear 43, second transmission Gear 45, the third transmission gear 46, the fourth transmission gear 48, the first transmission shaft 44, the second transmission shaft 47 and the one-way driving pulley 42; the first one-way gear 40 and the second one-way gear 41 alternate Installed on the drive assembly 3; the second one-way gear 41 is connected with a drive shaft 49, specifically, the second one-way gear 41 is integrated with the drive shaft 49; the one-way driving belt The wheel 42 i...

Embodiment 2

[0047] Such as Figure 1-9 As shown, a crushing system provided in this embodiment includes the new energy transmission system described in Embodiment 1, and also includes a crushing mechanism 11 and a vibration mechanism 12; the crushing mechanism 11 is located between the first conveying assembly 1 and the second Between the two conveying components 2.

[0048] The crushing mechanism 11 includes a base plate 102, a top plate 101 disposed on the base plate 102, and a crushing pedal 103 disposed on the top plate 101; a delivery space is provided between the base plate 102 and the top plate 101; the crushing The pedal 103 can move up and down relative to the top plate 101;

[0049] The vibration mechanism 12 includes a connecting rod 122, a supporting plate 121 and a vibration feeding pedal 120; the connecting rod 122 and the supporting plate 121 are respectively connected with the bottom plate 102 and the top plate 101; the vibration feeding pedal 120 is installed on the on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com