Medical waste crushing device

A crushing device, a technology of medical waste, applied in water supply devices, waste disinfection or sterilization methods, sanitary equipment for toilets, etc., can solve problems such as air pollution, surface water and groundwater pollution, and environmental impact, and achieve environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

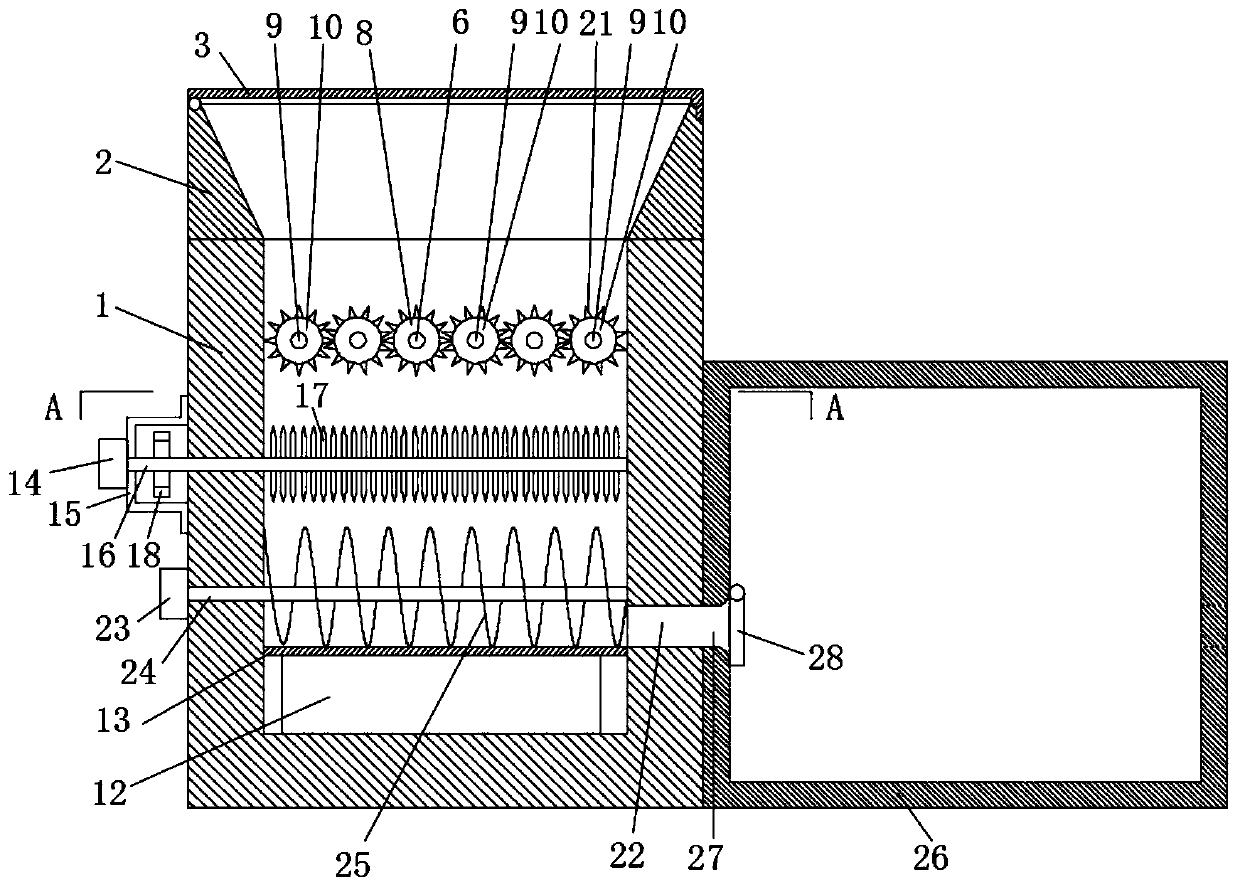

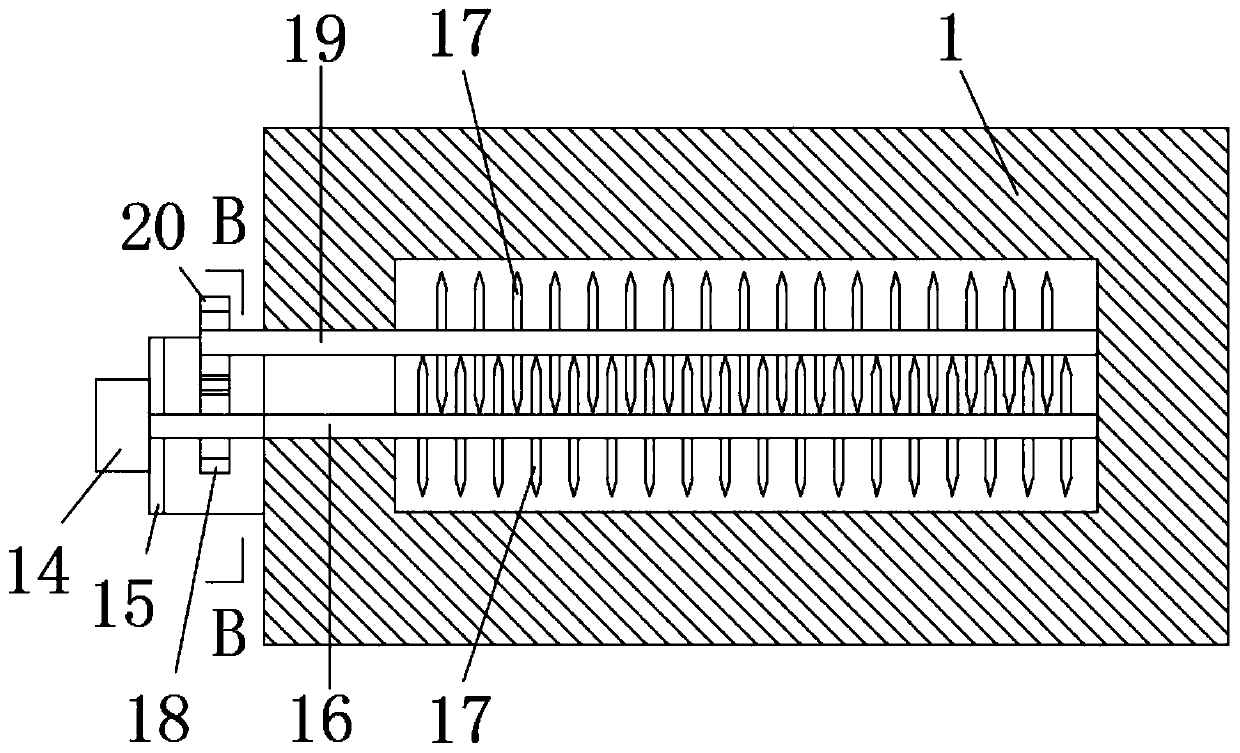

Embodiment 1

[0026] see Figure 1-5 , a medical waste crushing device, comprising a crushing box 1, a feed hopper 2 fixedly installed on the top of the crushing box 1, a flip cover 3 rotatably mounted on the top of the feeding port, and a sterilization and disinfection device, the crushing box 1 is A crushing device is provided, and the crushing device includes a crushing motor 4 and a first motor support 5 for fixedly installing the crushing motor 4, and the first motor support 5 is fixedly mounted on the crushing box 1, and the crushing The first driving shaft 6 is fixedly installed on the crushing motor 4, and the first driving shaft 6 is rotatably mounted on the crushing box 1, and the first driving shaft 6 inside the crushing box 1 is fixedly installed with crushing teeth. The driving roller 8 of 21, the first driving gear 7 is fixedly installed on the first driving shaft 6 outside the crushing box 1, and the crushing box 1 is provided with several rollers located on both sides of the...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that: the side wall of the crushing box 1 is provided with a discharge port 22, and the crushing box 1 is provided with an output device, and the specific structure of the output device is not added. Limitation, in this embodiment, preferably, the output device includes an output motor 23 fixedly installed on the outer wall of the crushing box 1, an output shaft 24 is fixedly installed on the output motor 23, and the output shaft 24 is rotatably installed on the crushing box 1. On the box body 1, the output shaft 24 is provided with a delivery screw blade 25; by setting the output motor 23 and the delivery screw blade 25, the delivery motor 23 rotates and drives the output shaft 24 to rotate, thereby driving the delivery screw on the output shaft 24 The blades 25 rotate, so that the sterilized broken medical waste is effectively cleaned out from the discharge port 22 on the broken box body 1 .

[0032] Further, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com