Soil hardened block crushing treatment device for garden potted plants

A soil compaction and processing device technology, which is applied in the fields of flower pot filling, gardening, cultivation, etc., and can solve problems such as poor crushing effect and difficult manual processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

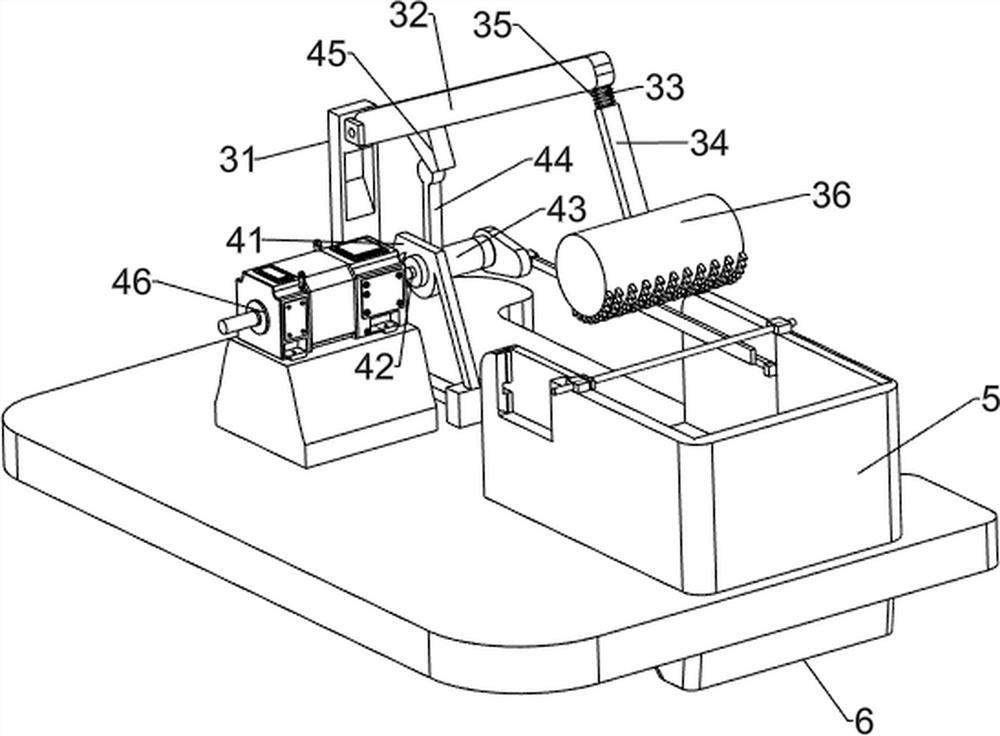

[0025] Such as figure 1 , figure 2 and image 3 As shown, a soil plate agglomeration and crushing device for garden potted plants includes a base 1, a workbench 2, a smashing device 3, a toggle device 4, a processing frame 5, a lower hopper 6 and a pushing device 7, and the top of the base 1 A workbench 2 is provided, a smashing device 3 is arranged on the right side of the top of the workbench 2, a toggle device 4 is arranged on the top of the base 1, and the toggle device 4 cooperates with the smashing device 3, and a processing frame 5 is arranged on the left side of the top of the base 1 The lower hopper 6 is arranged at the bottom of the processing frame 5, and the lower hopper 6 cooperates with the processing frame 5. A pushing device 7 is arranged in the lower hopper 6, and the pushing device 7 cooperates with the toggle device 4.

[0026] The smashing device 3 includes a mounting plate 31, a rotating plate 32, a guide column 33, a sleeve frame 34, a first elastic me...

Embodiment 2

[0031] Such as image 3 and Figure 4 As shown, on the basis of Embodiment 1, it also includes a first fixed frame 8, a rotating seat 9, a second connecting rod 10, a sleeve 11 and a second elastic member 12, and the mounting plate 31 is provided with a first fixed frame 8, the first fixed frame 8 is provided with a rotating seat 9, the rotating seat 9 is provided with a second connecting rod 10, the second connecting rod 10 is sleeved with a sleeve 11, the connection between the sleeve pipe 11 and the second connecting rod 10 A second elastic member 12 is disposed between them, and the second elastic member 12 is a compression spring.

[0032] When the push rod 44 rotates to squeeze the wedge-shaped block 45, the wedge-shaped block 45 drives the rotating plate 32 to swing upwards, and the rotating plate 32 drives all components on the rotating plate 32 to move upwards, and the sleeve 11 is slidably inserted into the second connecting rod 10, The second elastic member 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com