Garbage collection vehicle

A garbage collection vehicle and sewage collection technology, applied in the field of garbage collection vehicles, can solve the problems of unreasonable occupation volume, pollution of sanitation workers, incomplete cleaning, etc., and achieve the effects of improving automatic operation, preventing secondary pollution, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

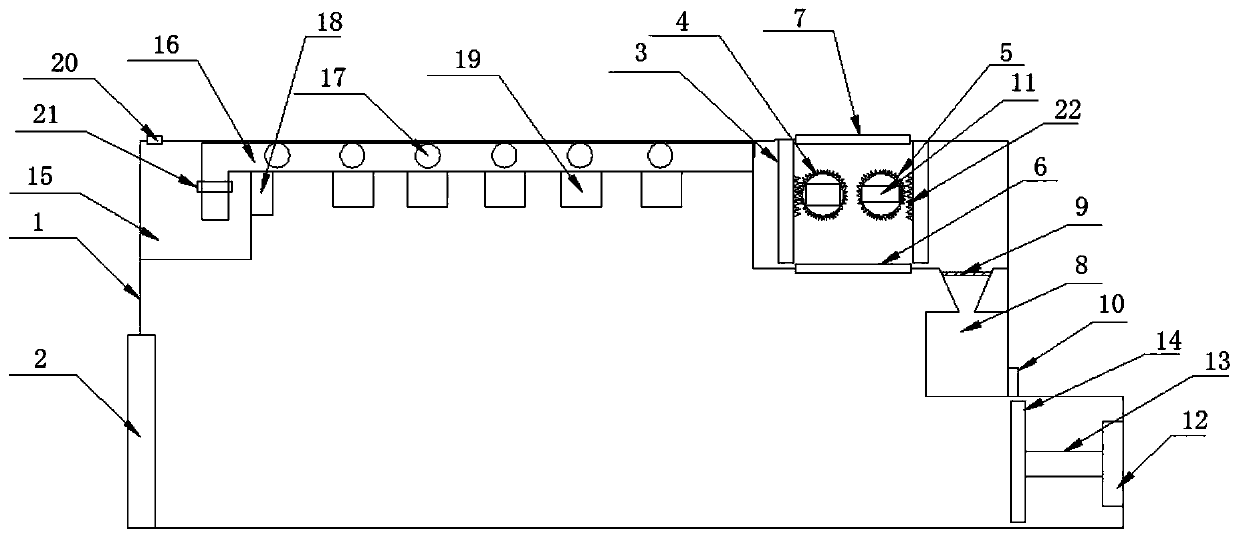

[0025] Please refer to figure 1 The schematic structural diagram of the first embodiment of a garbage collection vehicle disclosed in the present application is shown, including: a box body 1 of the garbage collection vehicle, a rolling structure and a cleaning structure arranged on the top wall of the box body 1; The cleaning structure is far away from the front of the garbage collection vehicle relative to the rolling structure;

[0026] The top of the rolling structure is provided with a feed port, the feed port is provided with a cover 7, and two baffles 3 are symmetrically arranged on both sides of the feed port; There are two rolling rollers 4 arranged in parallel and rotating in opposite directions; the side wall ring of the rolling roller 4 is provided with rolling teeth 5; the end of the rolling roller 4 is provided with a The first motor 11 that the pressing roller 4 rotates, and the rotating shaft of the first motor 11 is fixedly connected to the rolling roller 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com