Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Realize chamfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

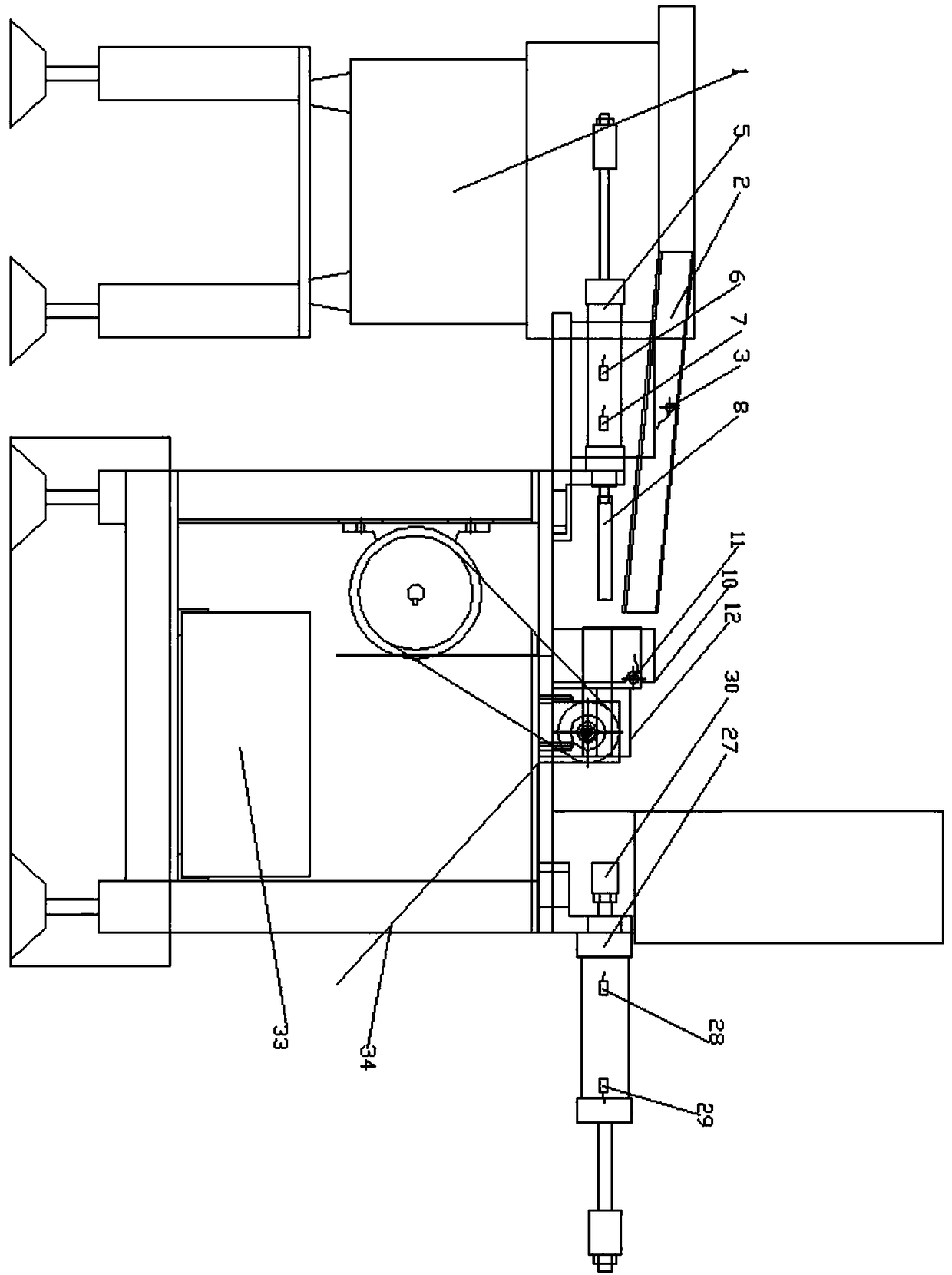

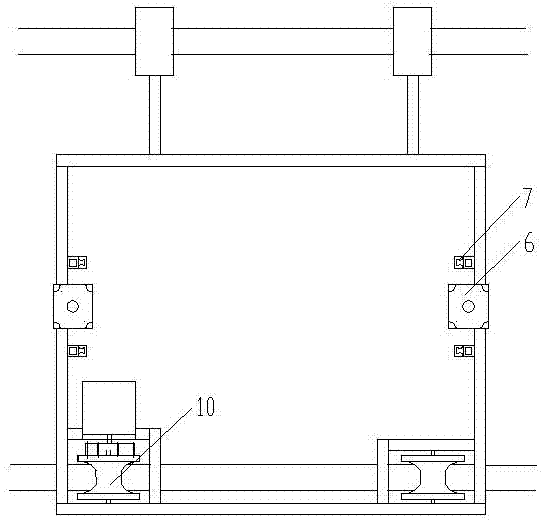

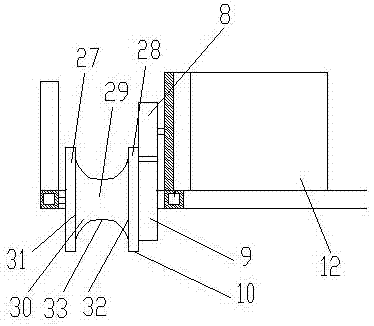

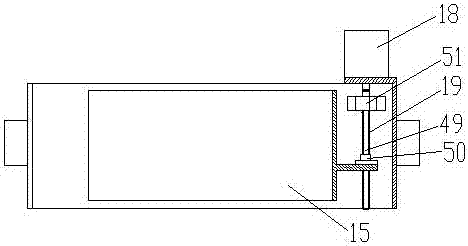

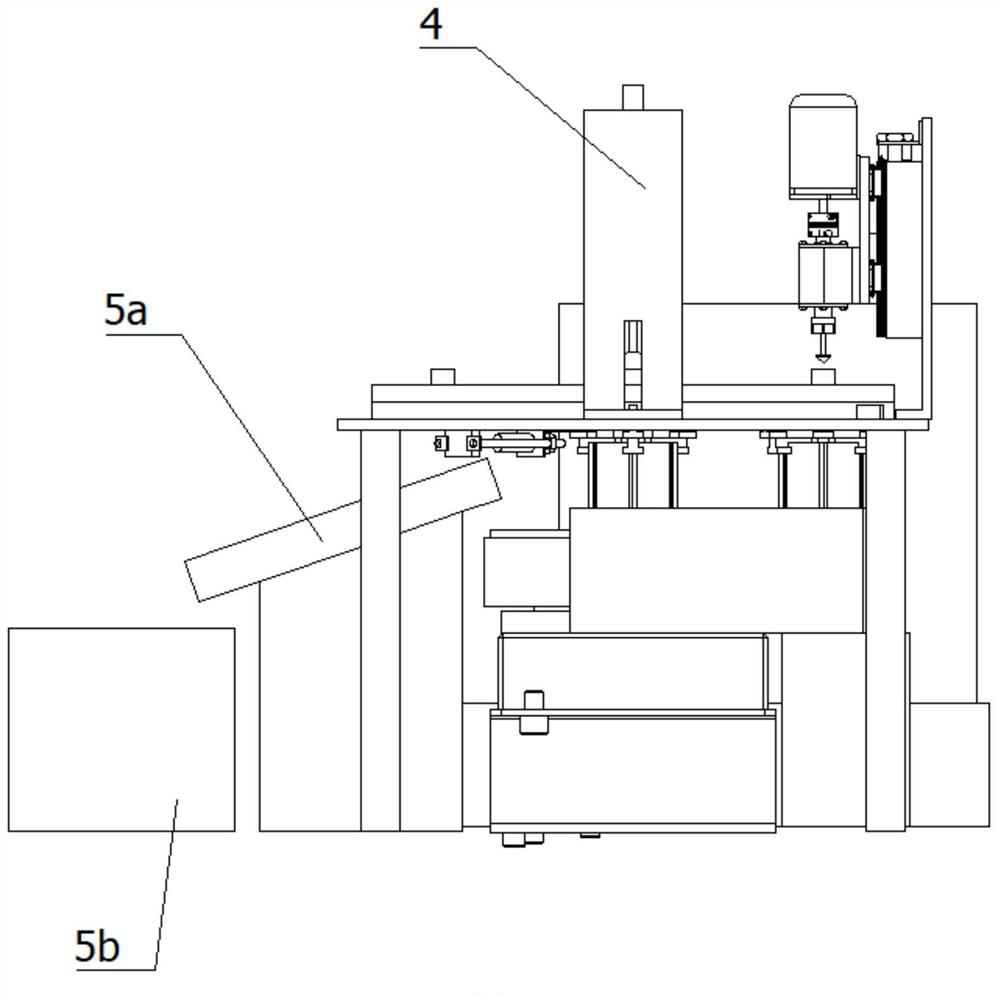

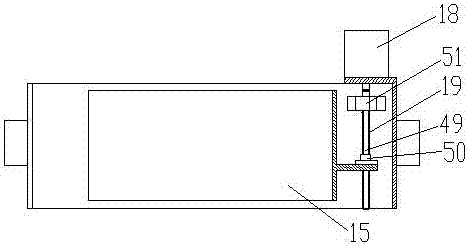

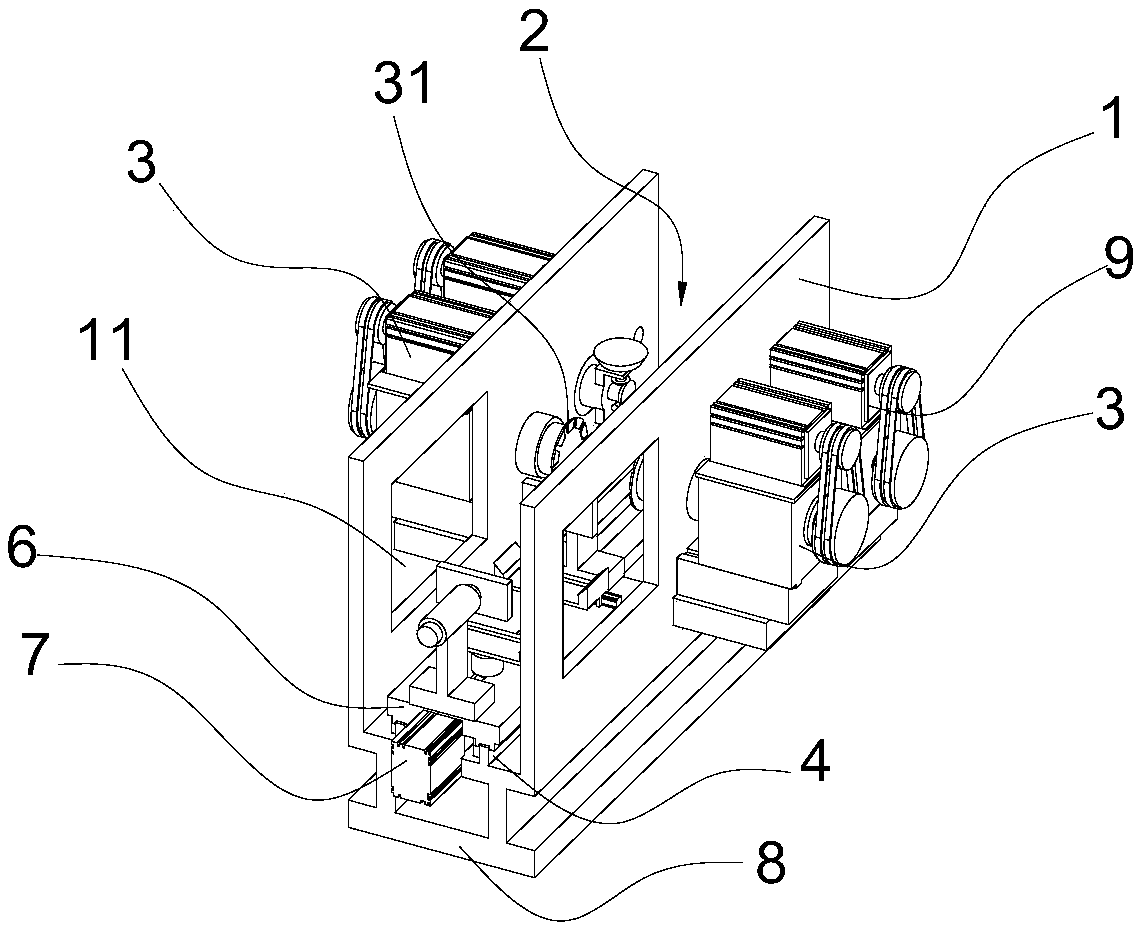

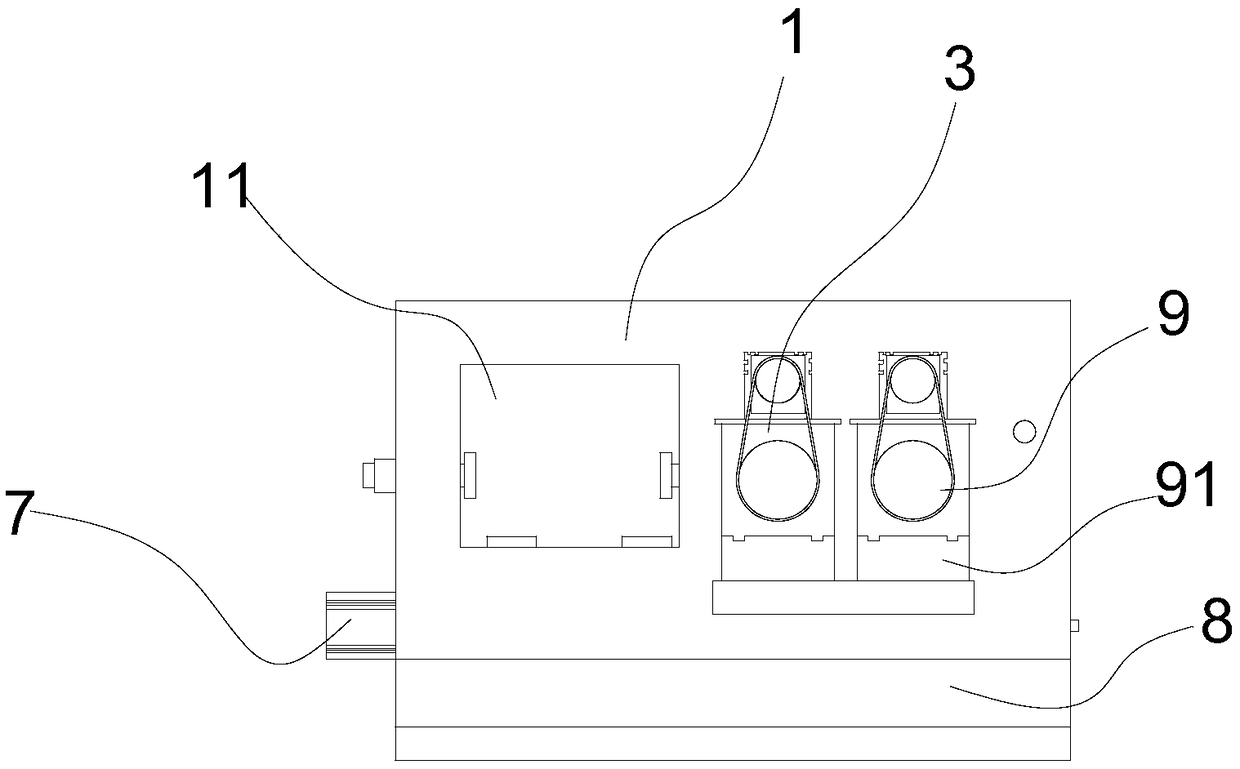

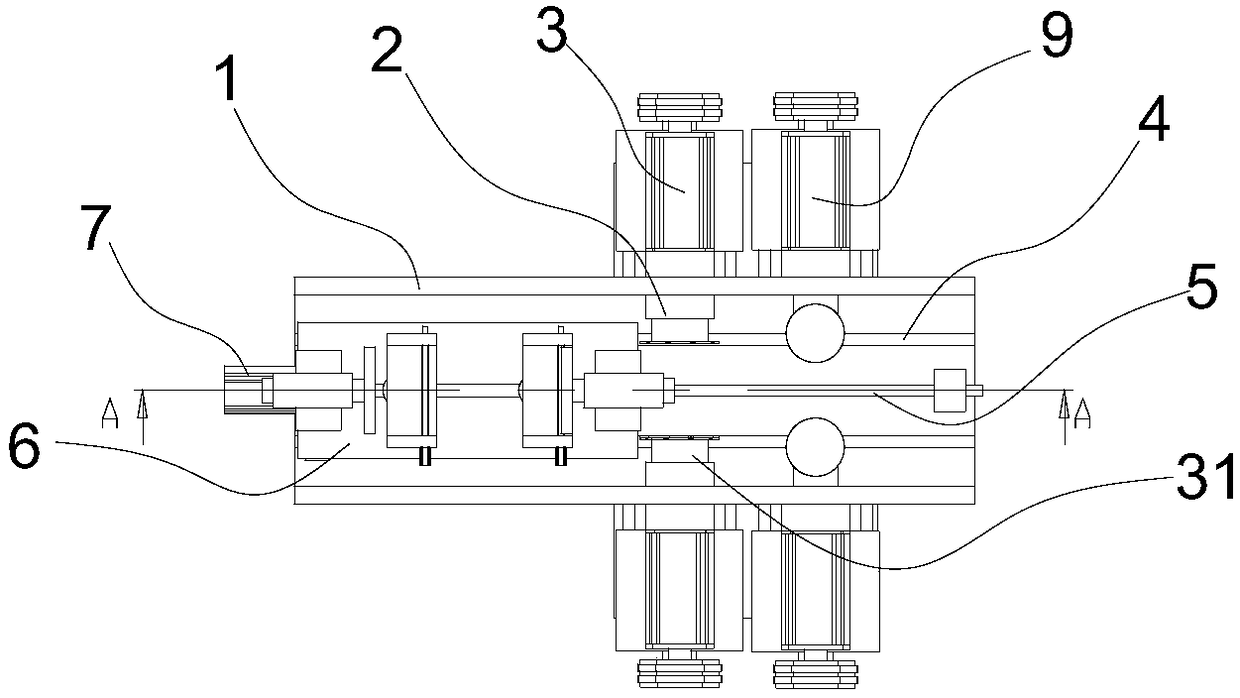

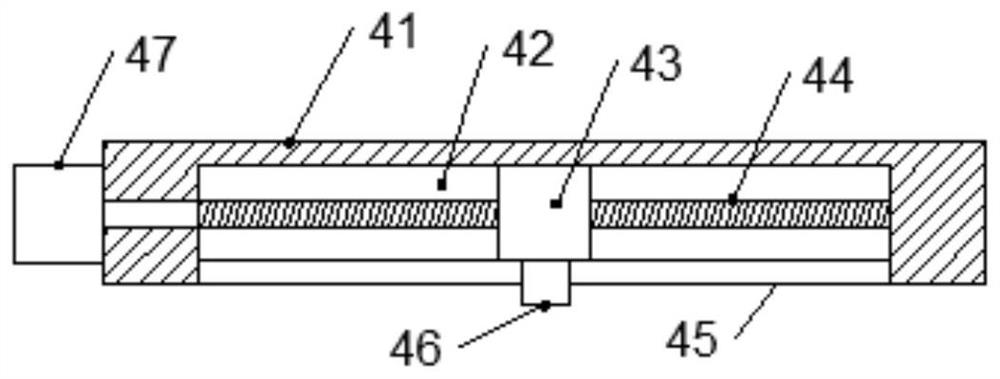

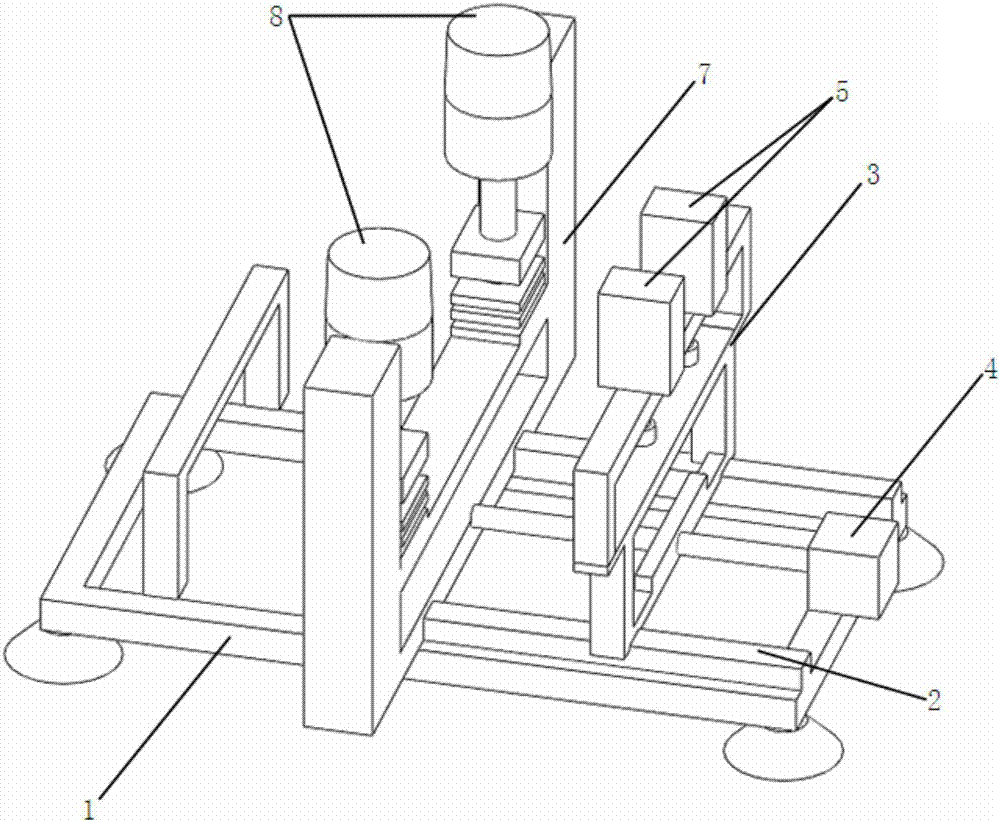

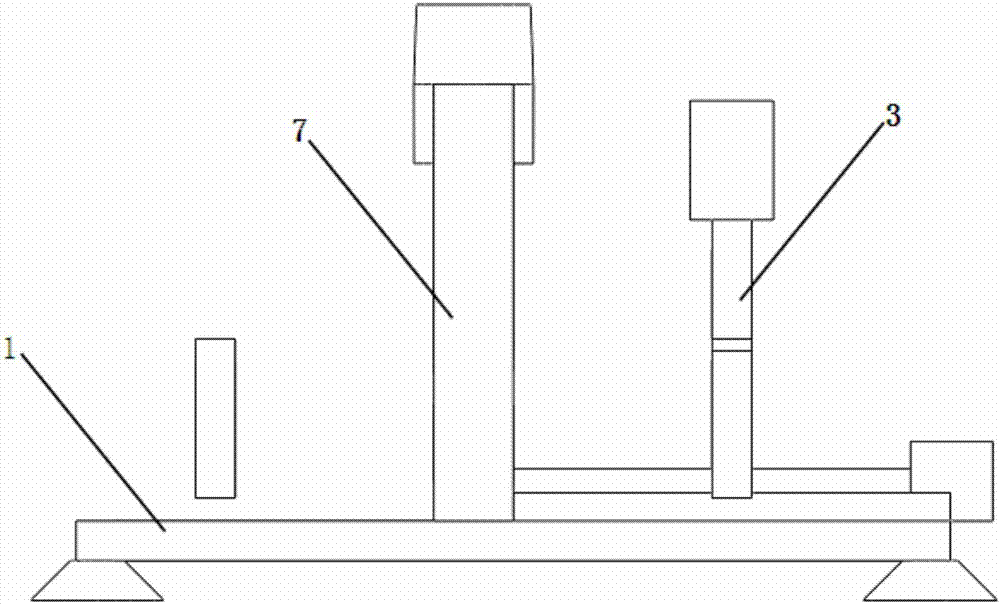

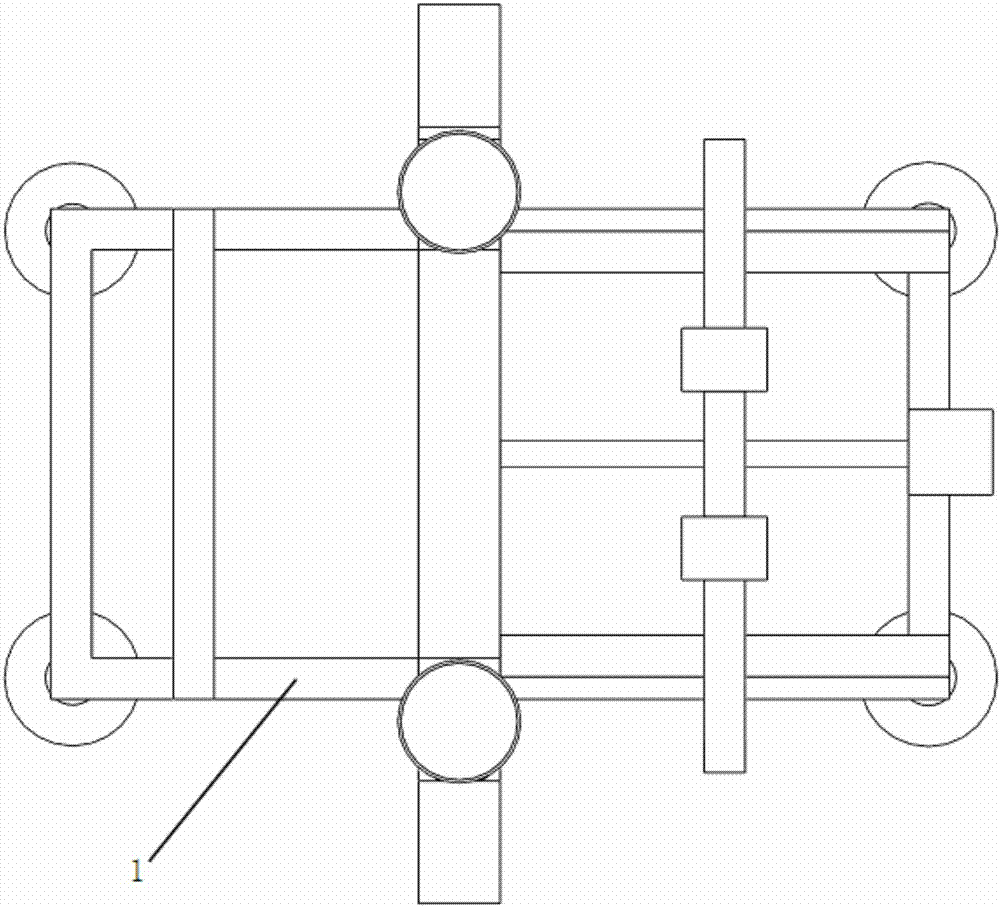

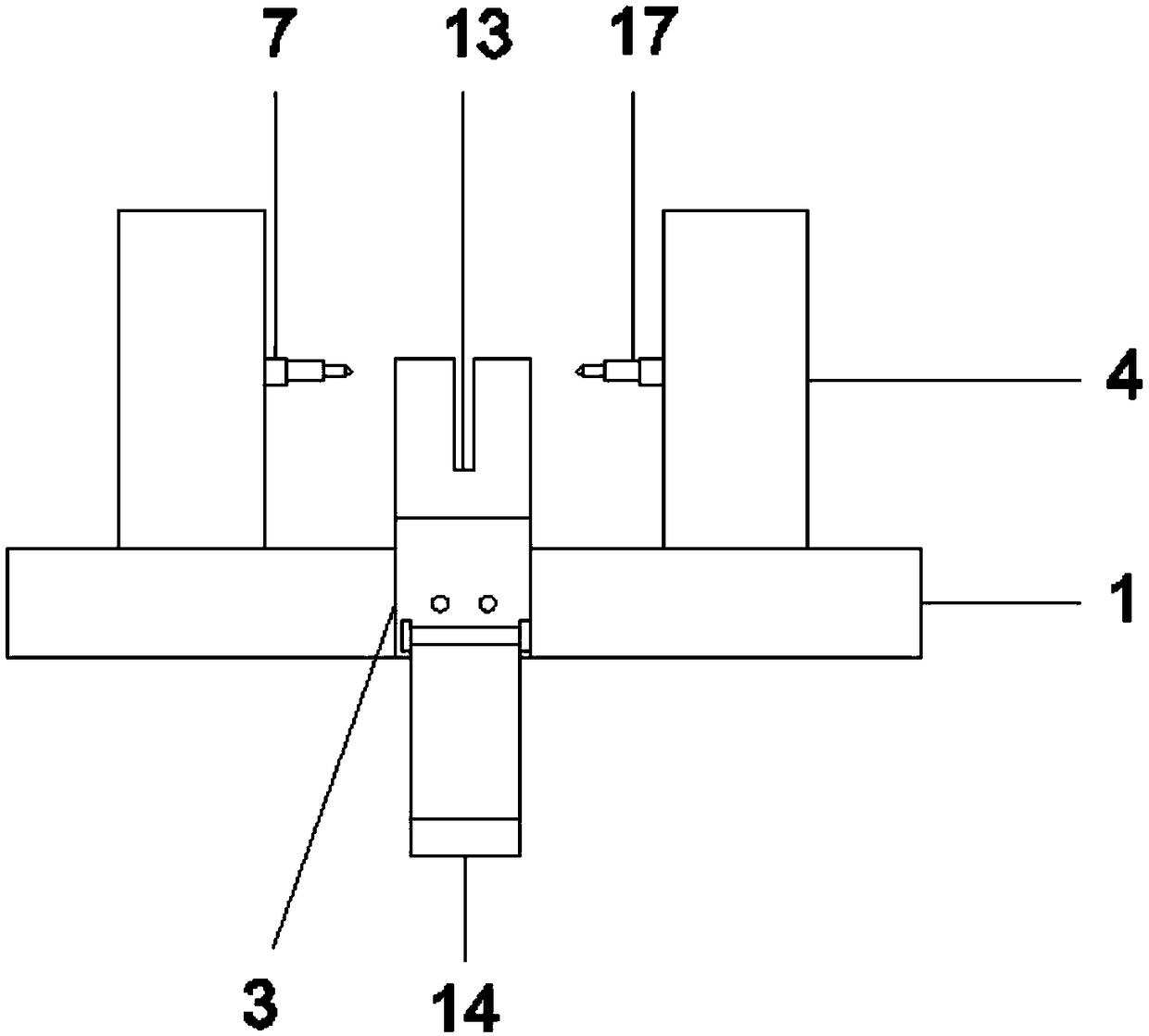

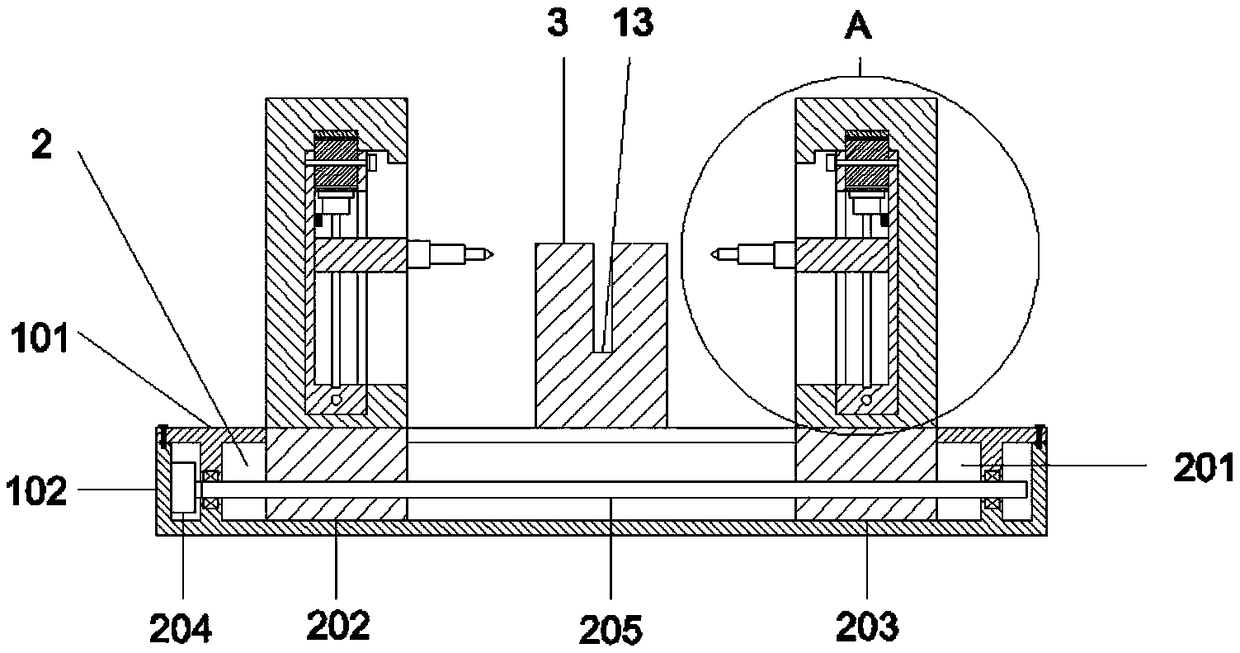

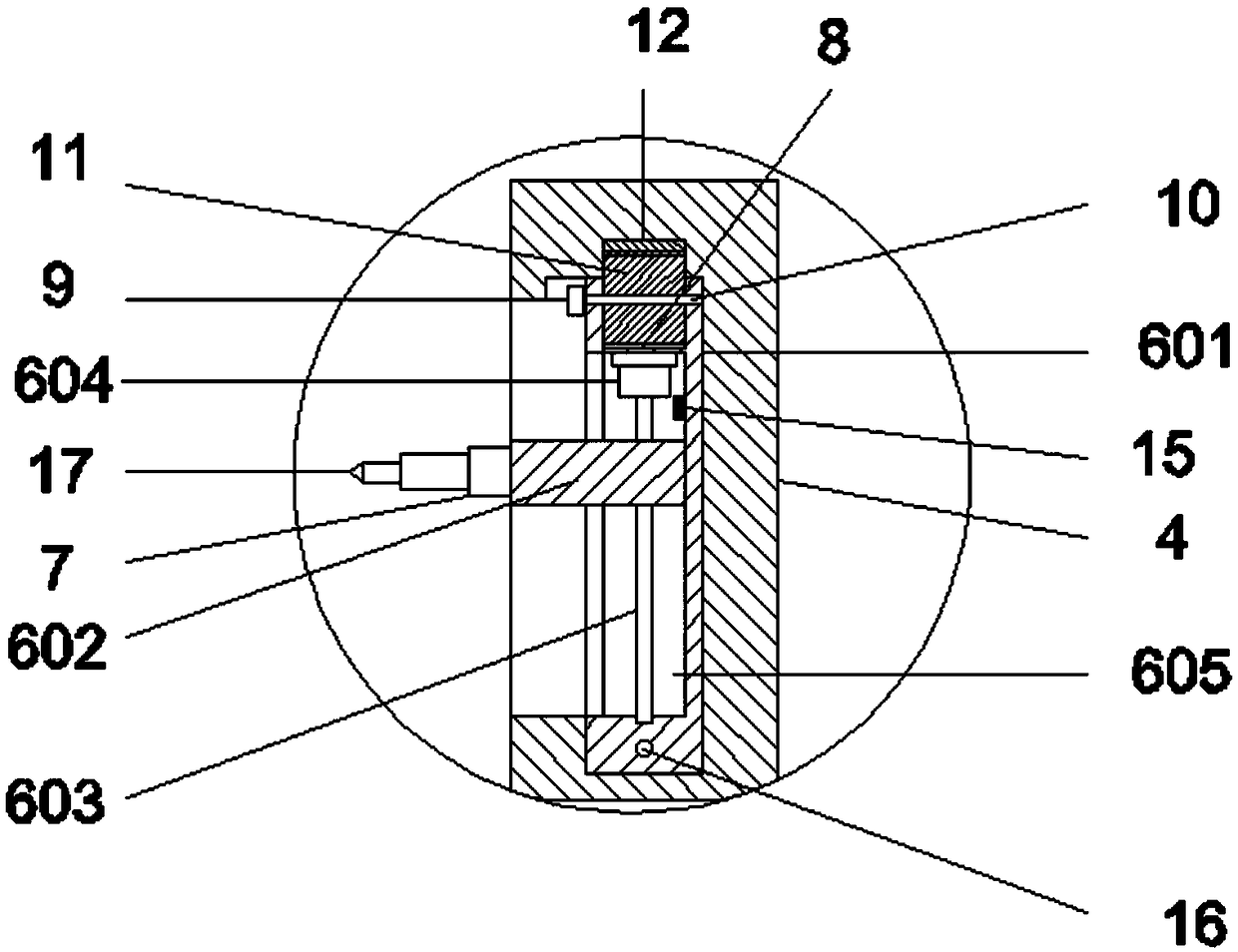

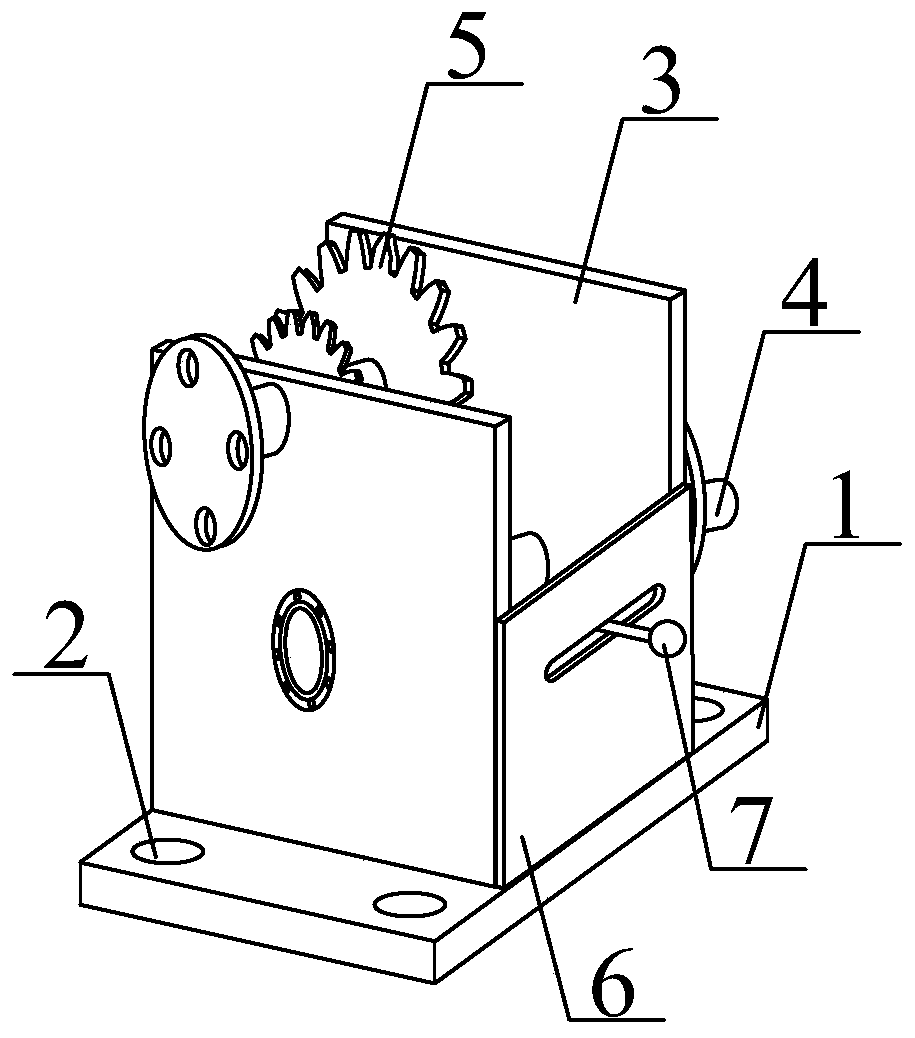

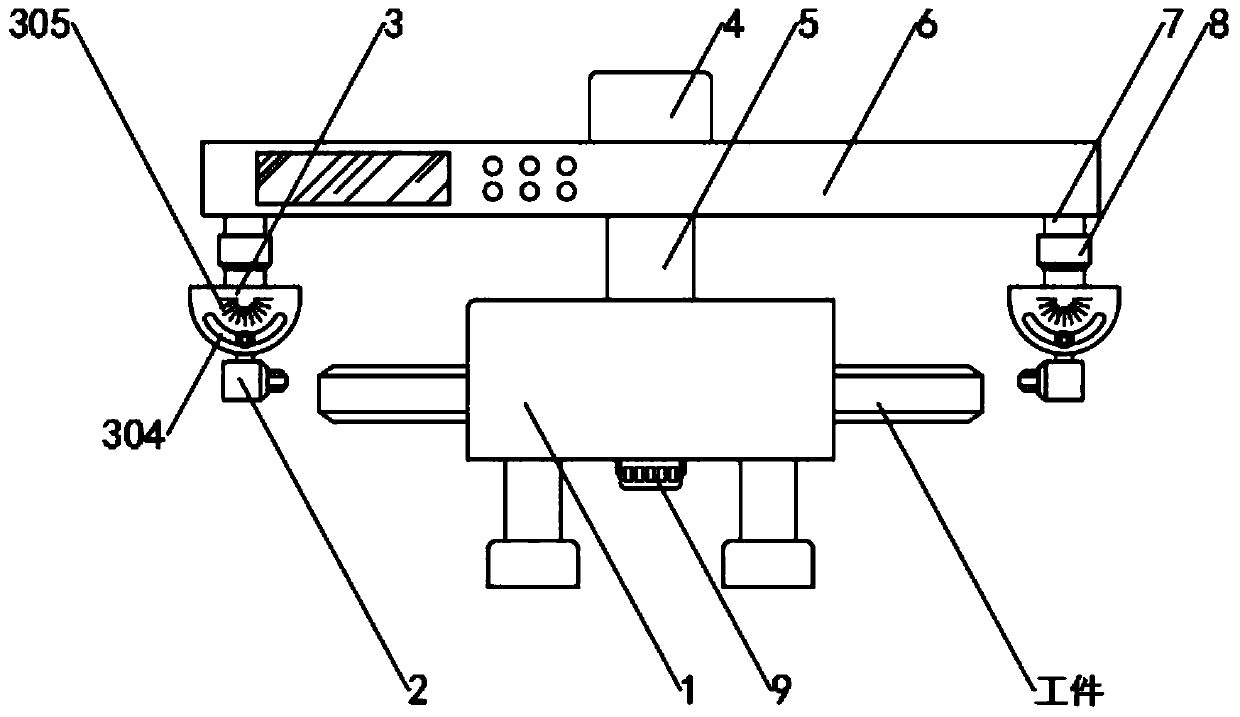

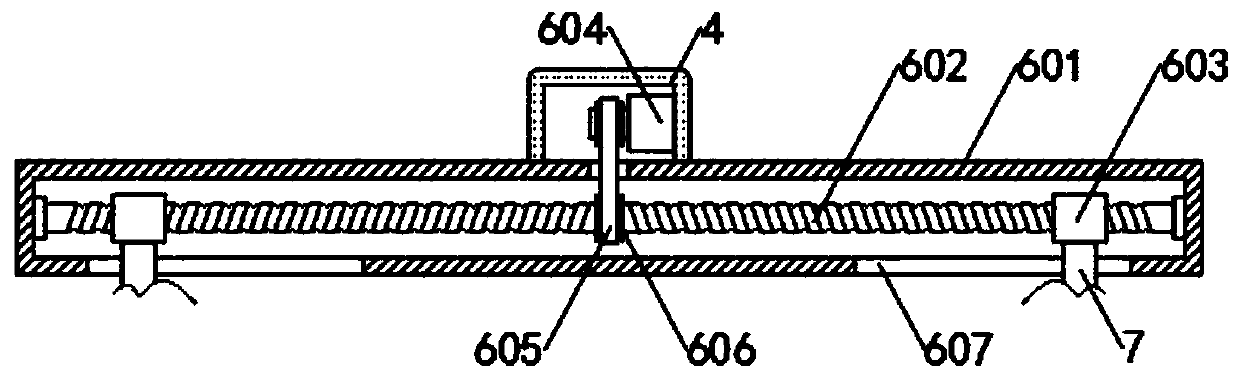

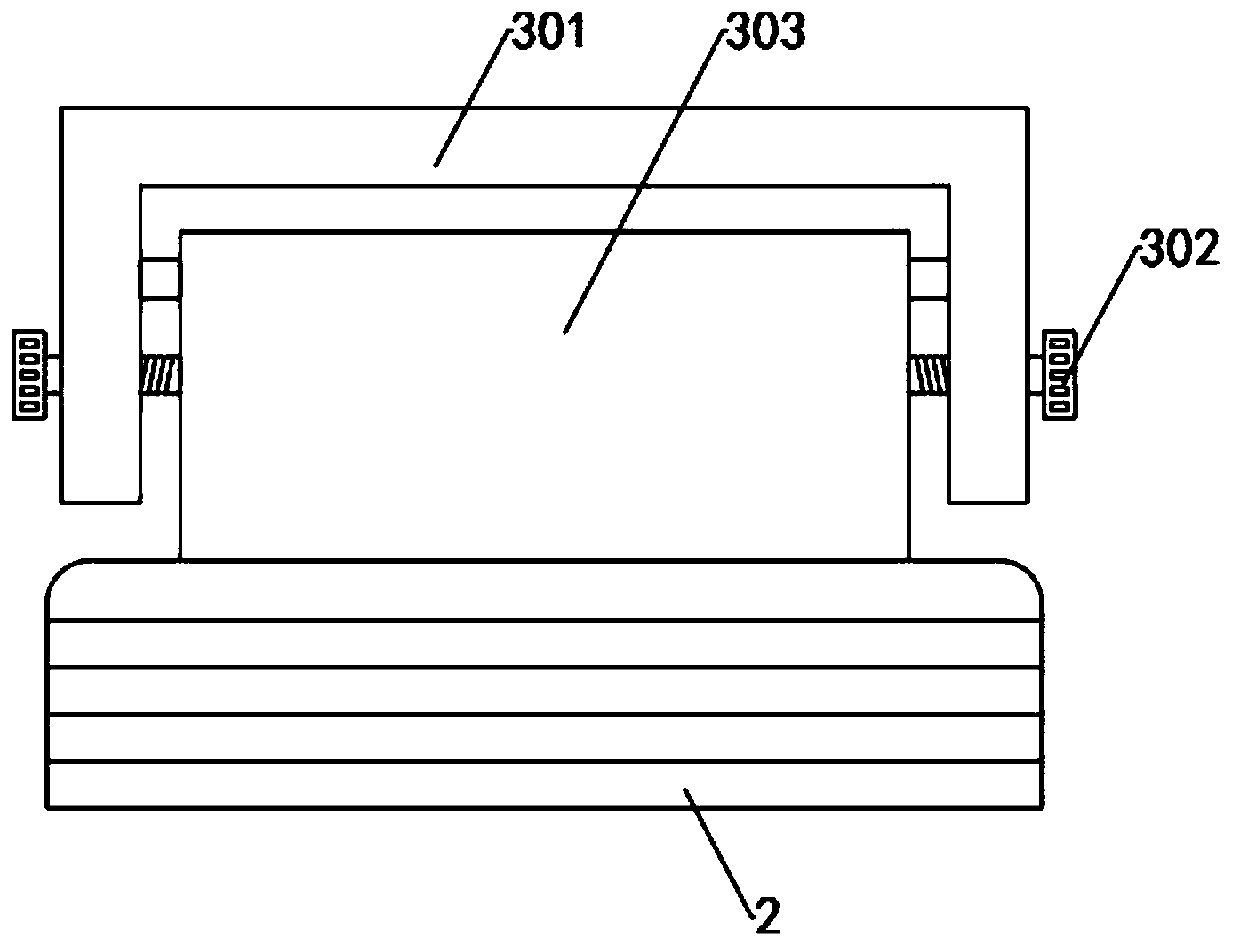

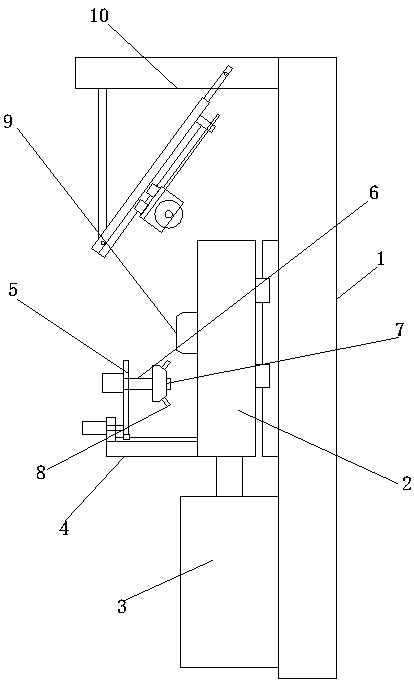

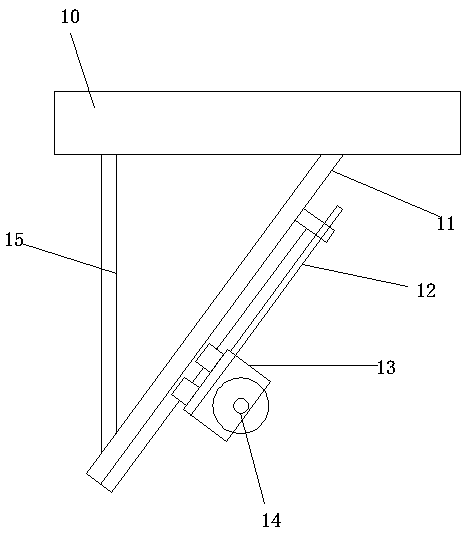

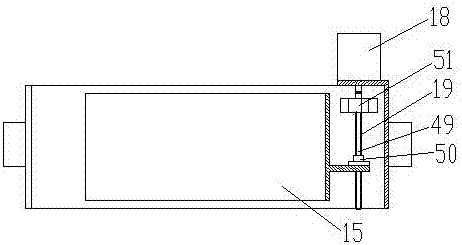

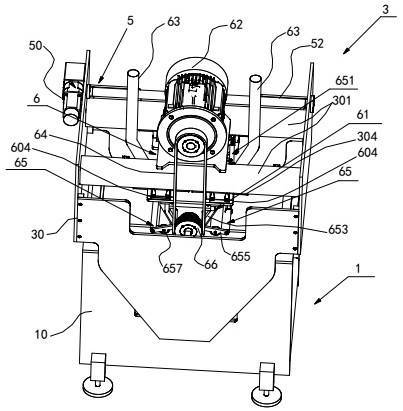

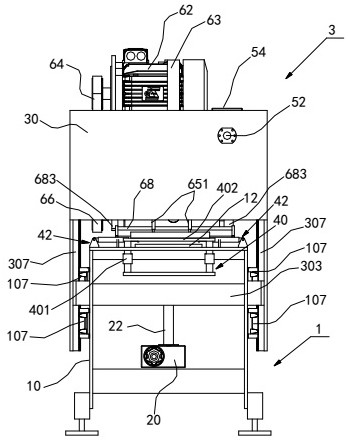

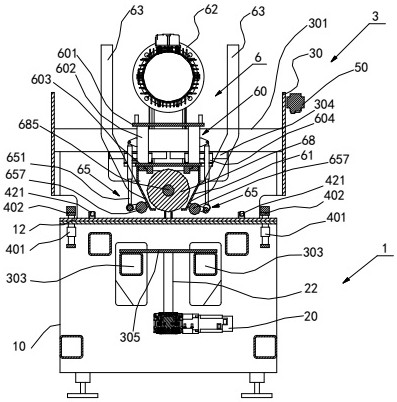

Full-automatic double-face drilling and chamfering machine

PendingCN108284321AAchieve drillingRealize chamferOther manufacturing equipments/toolsBoring/drilling machinesTransmission beltDrill

The invention relates to a full-automatic double-face drilling and chamfering machine. The machine comprises a feeding mechanism, a drilling mechanism, a limiting mechanism and an electric cabinet; the feeding mechanism is composed of a vibrating disc, a linear material channel, a material detecting sensor, a linear vibrator, a pushing air cylinder and a push rod; the drilling mechanism is composed of a material groove, a clamp, a motor, a first belt disc, a transmission belt, a first bearing, a spline sleeve, a second belt disc, a clamp spring, a shell, an air cylinder, a connecting block, asleeve, a second bearing, a spline shaft, a drill chuck and a limiting screw; the limiting mechanism is composed of a limiting air cylinder and a stop block; and the electric cabinet is used for allowing electrical equipment to be installed, the vibrating disc is arranged on a vibrating disc seat, and the rest parts are all arranged on a working table. The problem that after drilling is carried out through drilling equipment, manual face-turning needs to be carried out for chamfering and burr removing is solved, the technical innovation of full-automatic double-face drilling and chamfering isrealized, and the working efficiency of equipment is greatly improved.

Owner:金勇

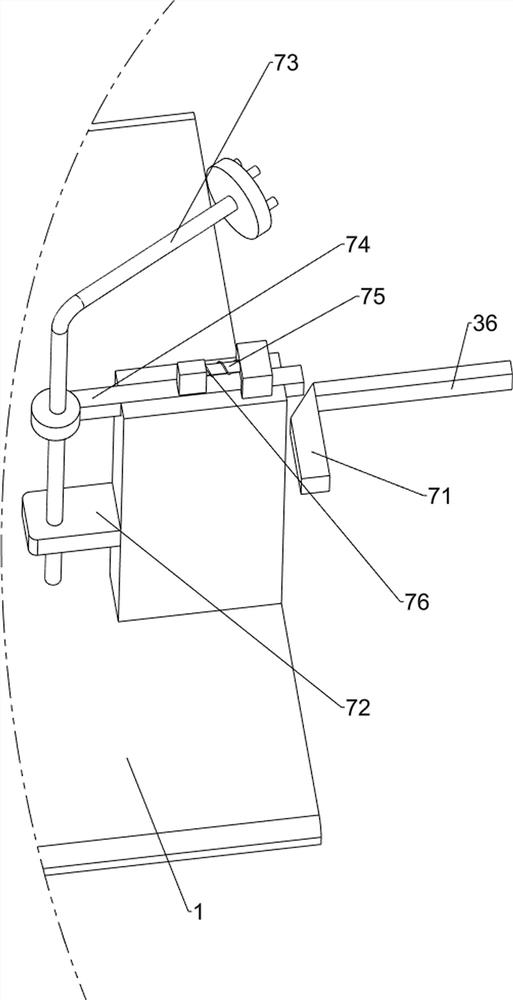

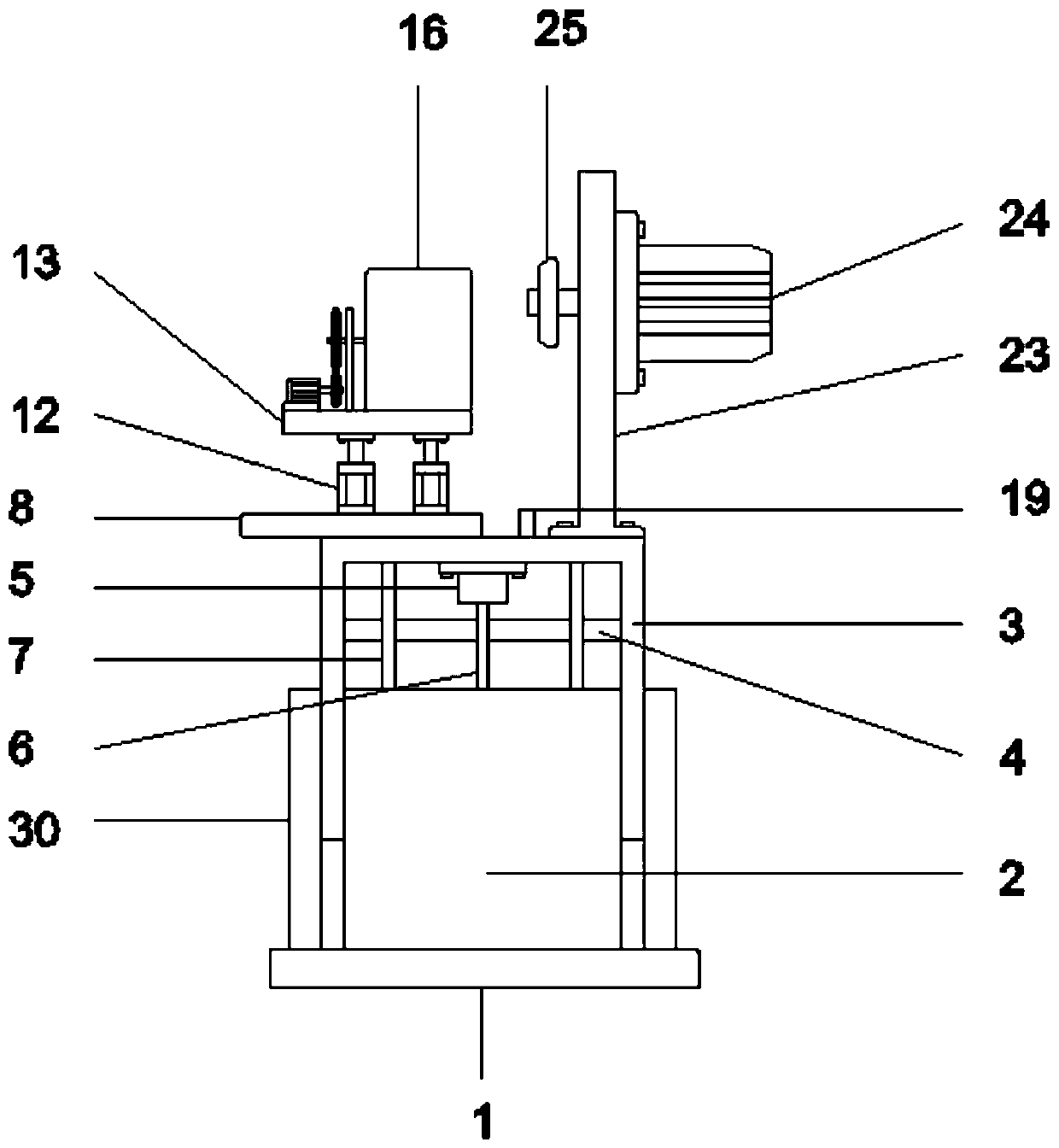

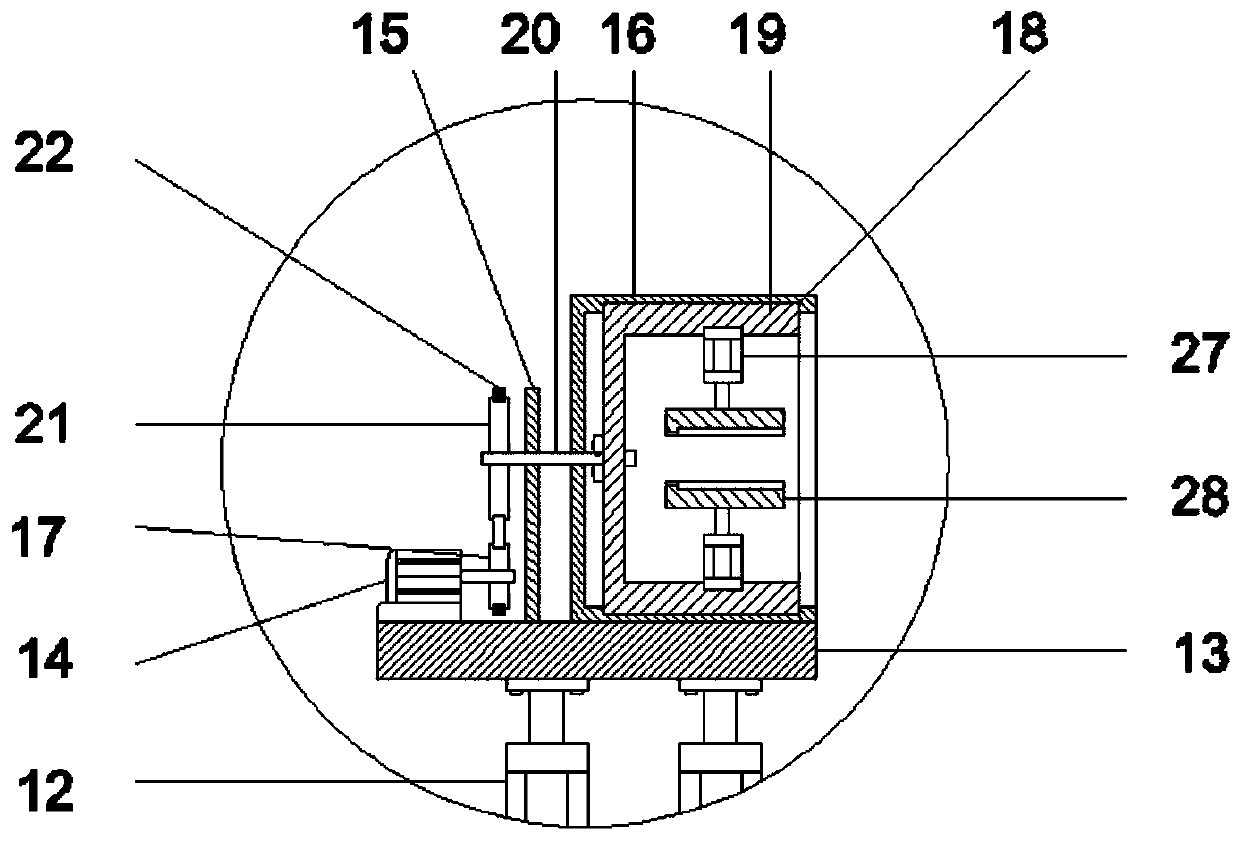

Polisher capable of adjusting polishing height of lipping of rail head

PendingCN107165008ALarge swing angleImprove swing flexibilityRailway track constructionPhysicsElectric machinery

The invention discloses a polisher capable of adjusting the polishing height of lipping of rail head, and belongs to the technical field of railway maintenance equipment. The polisher comprises a rack. The polisher is characterized by further comprising a vertically moving device and a travelling device; the vertically moving device comprises a hanging bracket, ball bearing bases, ball screws and ball nuts, stepper motors and vertically sliding blocks are arranged on the rack, and the hanging bracket is connected with the rack in a sliding mode through the vertically sliding blocks; the travelling device comprises a driving gear, a driven gear, a travelling wheel, a rolling wheel and a motor, wherein the driving gear is connected with the motor shaft of the motor, the driven gear is driven by the driving gear through gear meshing, and the travelling wheel is connected with the driven gear. According to the polisher capable of adjusting the polishing height of the lipping of the rail head, when polishing is conducted on the lipping of the rail head, the polisher can uniformly move at a low speed, and a grinding wheel is driven to automatically feed in the vertical direction, so that polishing in the vertical direction is conducted on the lipping of the rail head, and the polishing speed is uniform; moreover, the grinding wheel can vertically move, and polishing is conducted on any position of the height of the lipping of the rail head, so that the overall effect of polishing of the lipping of the rail head is improved.

Owner:西藏天仁科技发展有限公司

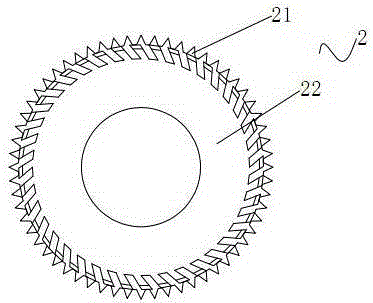

Cutting machine

InactiveCN106737945AReasonable structural designBeautiful chamfer qualityMulti-purpose machinesRotary cutting toolsBar productEngineering

The invention relates to a cutting machine comprising a rack, cutters and a feeding mechanism arranged on the rack and used for conveying a product to be cut. A rotating main shaft is further arranged on the rack. The cutters are mounted on the rotating main shaft which is connected with motors. Each cutter comprises a saw blade in the middle and chamfering blades located on the two sides of the saw blade, and the outer diameter of each chamfering blade is less than the outer diameter of each saw blade. The cutting machine is reasonable in structure design. After the saw blades cut the product to be cut with a certain depth, the chamfering blades conduct chamfering on the two ends of the cut product to be cut separately, and after chamfering is finished, the saw blades cut off the product to be cut to form a plurality of circular wood strips or circular plastic bars with chamfers. Automatic cut-off and chamfering of wooden plug bar products or plastic bar products are achieved. The cutting and chamfering are high in speed, good in quality and high in good product rate. The production cost is saved greatly, the labor intensity is reduced, and the production efficiency is improved. The circular wood strip products or the circular plastic bar products have the attractive chamfering quality.

Owner:曾胜发

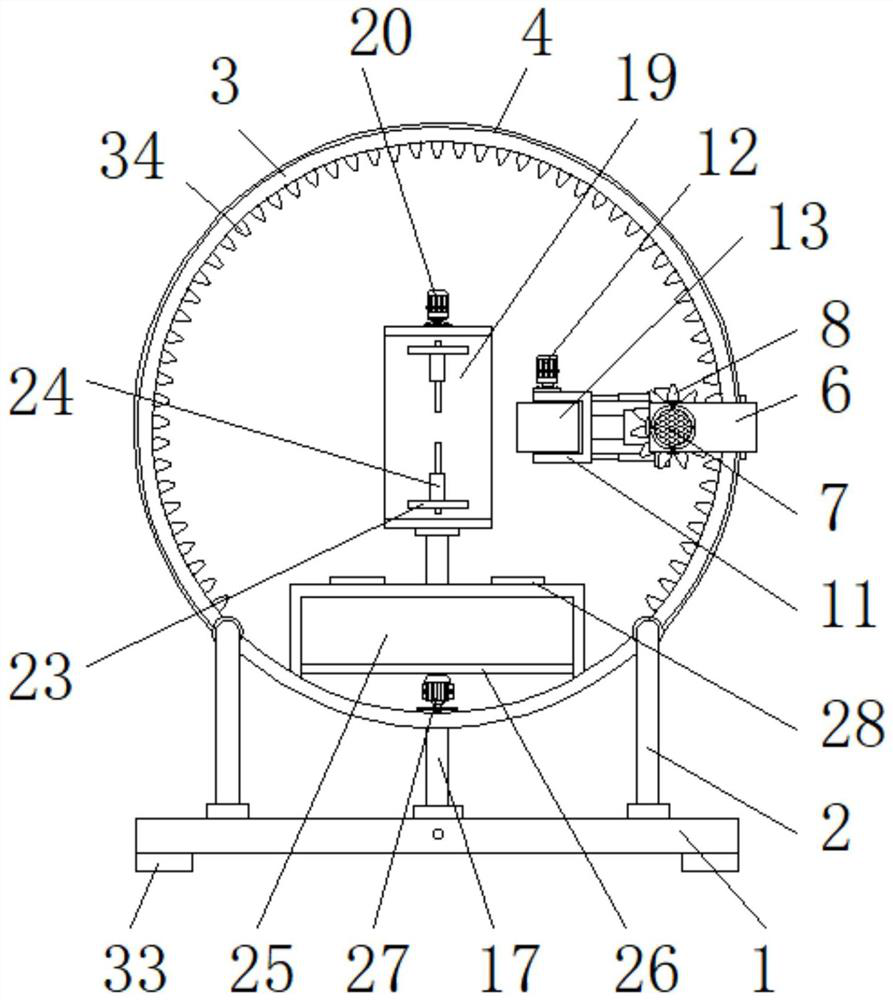

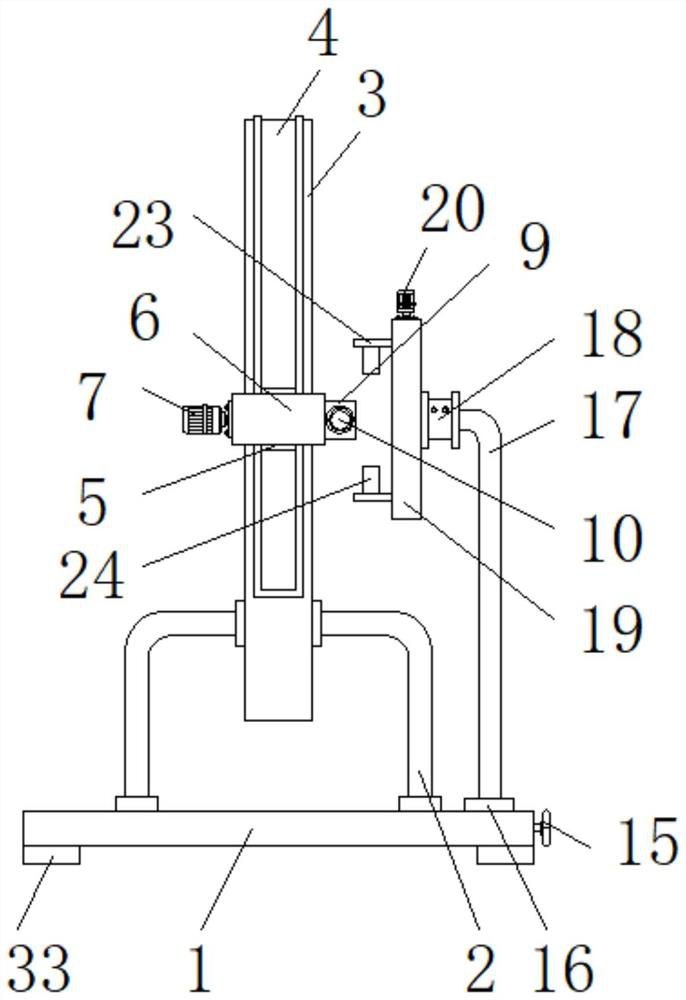

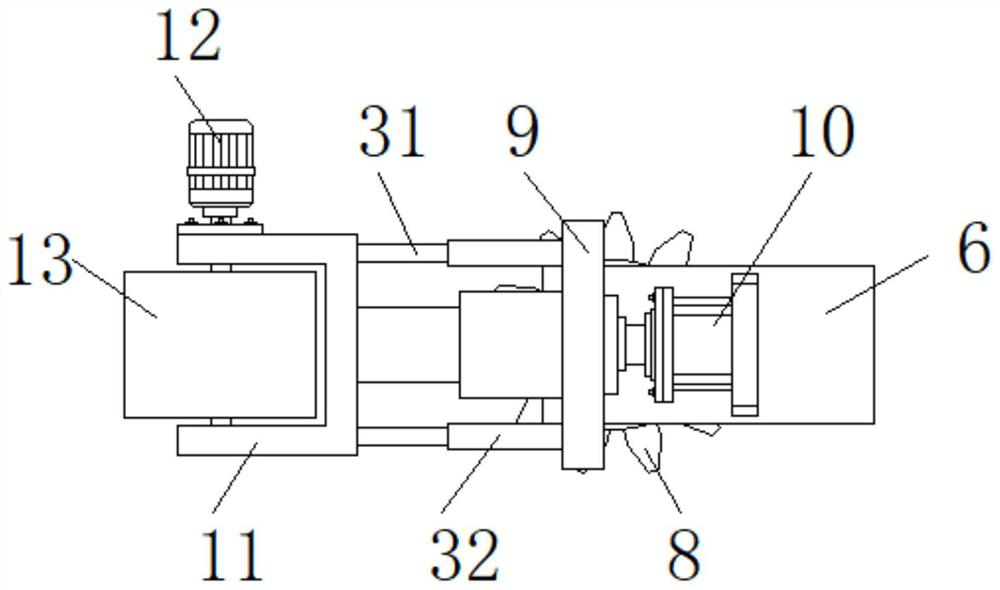

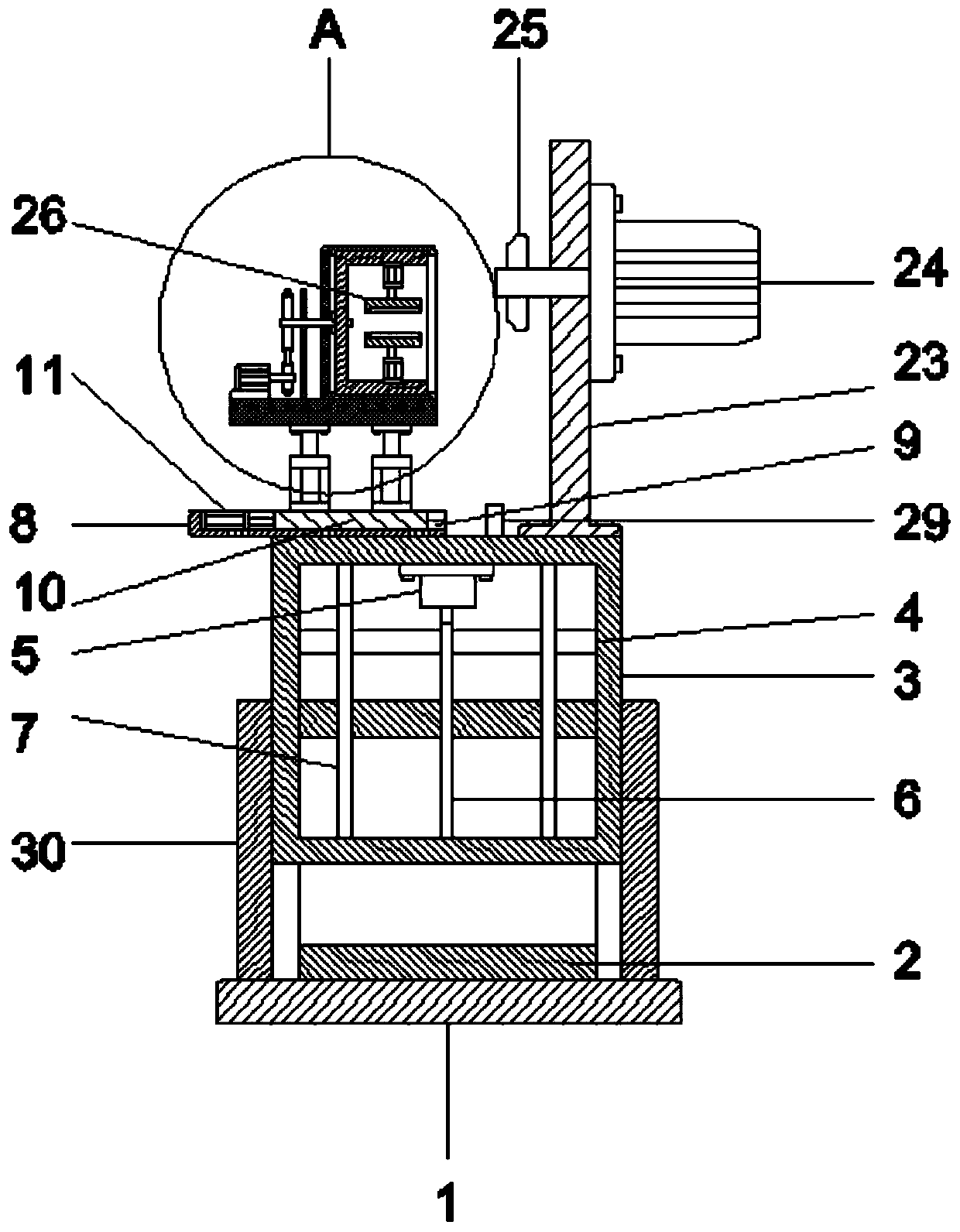

Steel rail fat edge automatic grinding machine

PendingCN107217558ALarge swing angleImprove swing flexibilityRailway track constructionBall bearingGear wheel

The invention discloses a steel rail fat edge automatic grinding machine, and belongs to the field of railway maintenance equipment. The automatic grinding machine comprises a machine frame, and is characterized by further comprising an up-down moving device, a traveling device and a horizontal feeding device; the up-down moving device comprises a hanging bracket, ball bearing seats, ball screws and ball nuts; a stepping motor and upper and lower sliding blocks are arranged on the machine frame; the traveling device comprises a driving gear, a driven gear, a traveling wheel, a roller and a motor; the horizontal feeding device comprises a grinding wheel, a gear acceleration box, a movable platform, a horizontal sliding block, a driving mechanism, a pulse motor and a ball screw pair; an output shaft of the gear acceleration box is connected with the grinding wheel, and an input shaft is connected with the driving mechanism. The grinding machine can be used for simultaneously grinding a steel rail fat edge in the transverse direction and in the longitudinal direction, different feeding amounts can be selected according to the steel rail fat edges with different thicknesses, and one-time grinding is achieved; the grinding wheel can move up and down to grind the steel rail fat edge at any position in the height direction, and the overall grinding effect of the steel rail fat edge is good.

Owner:西藏天仁科技发展有限公司

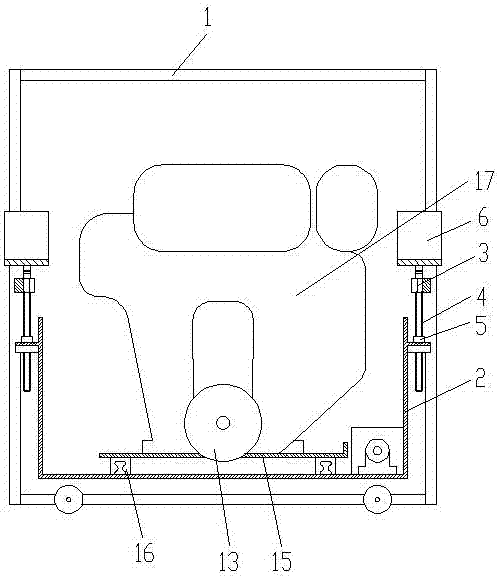

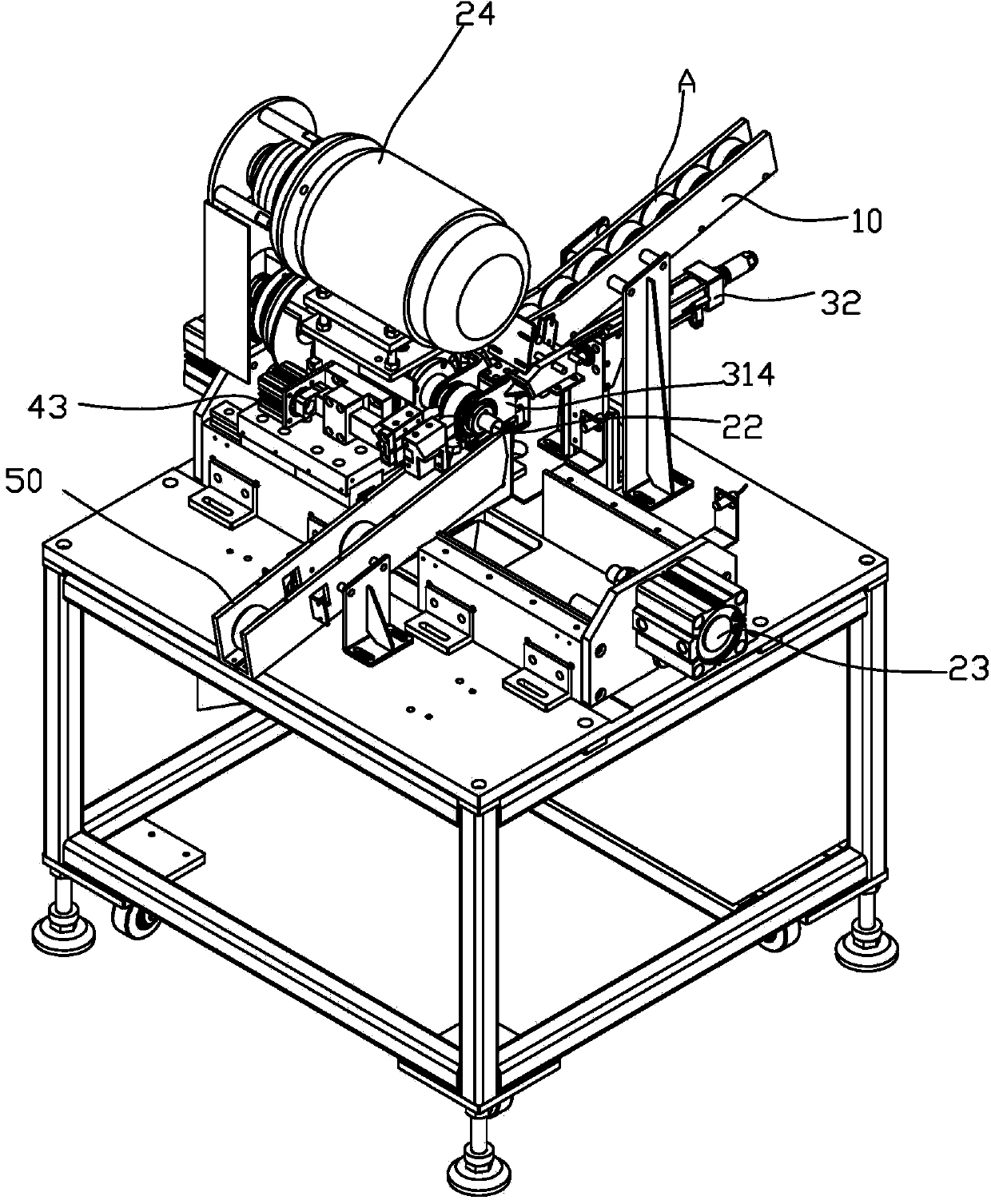

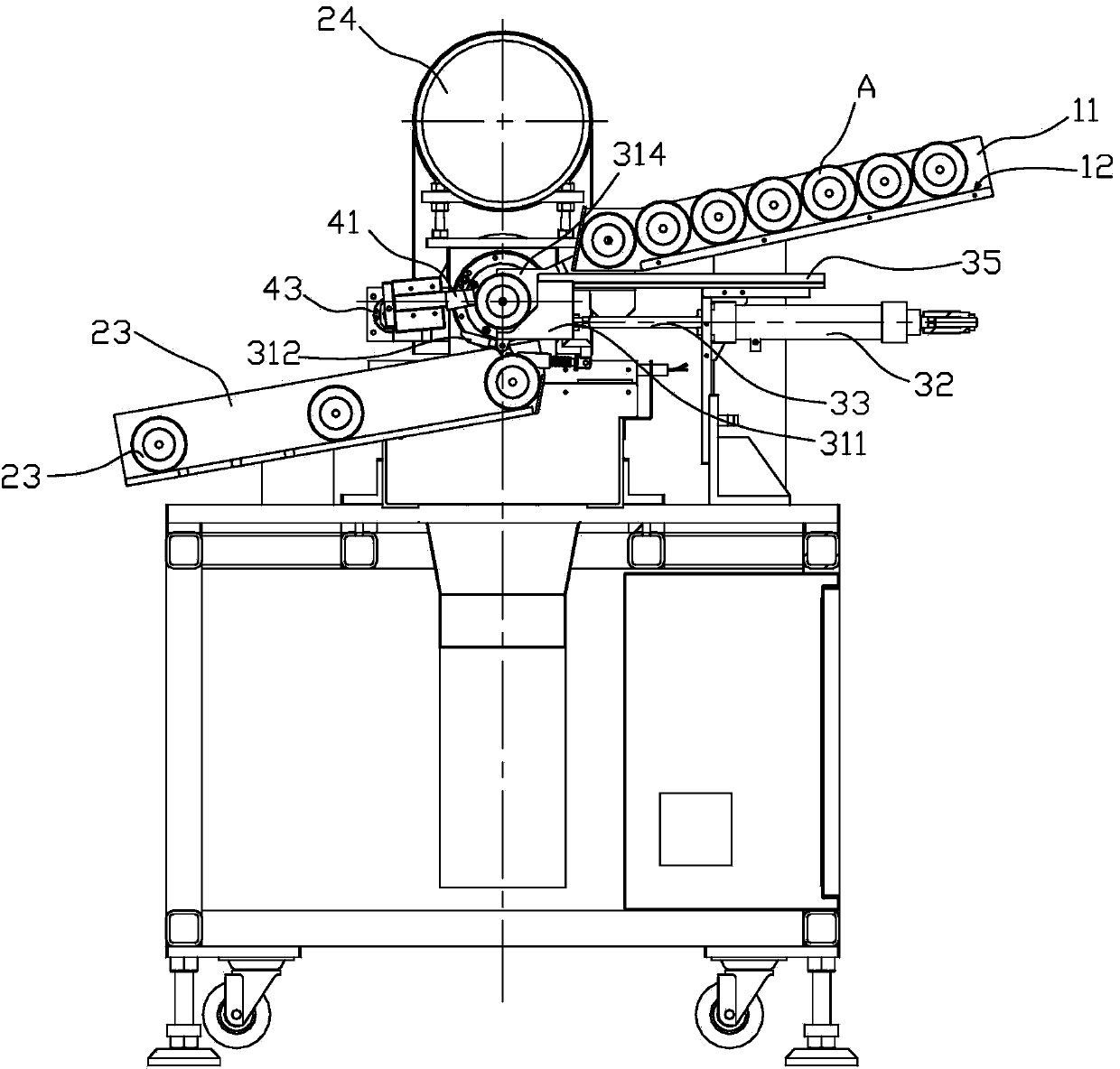

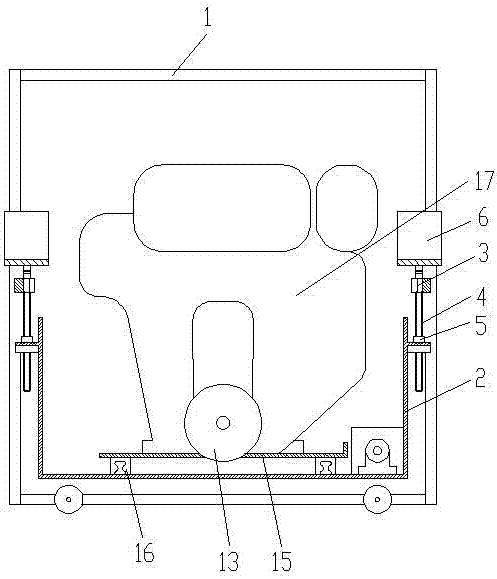

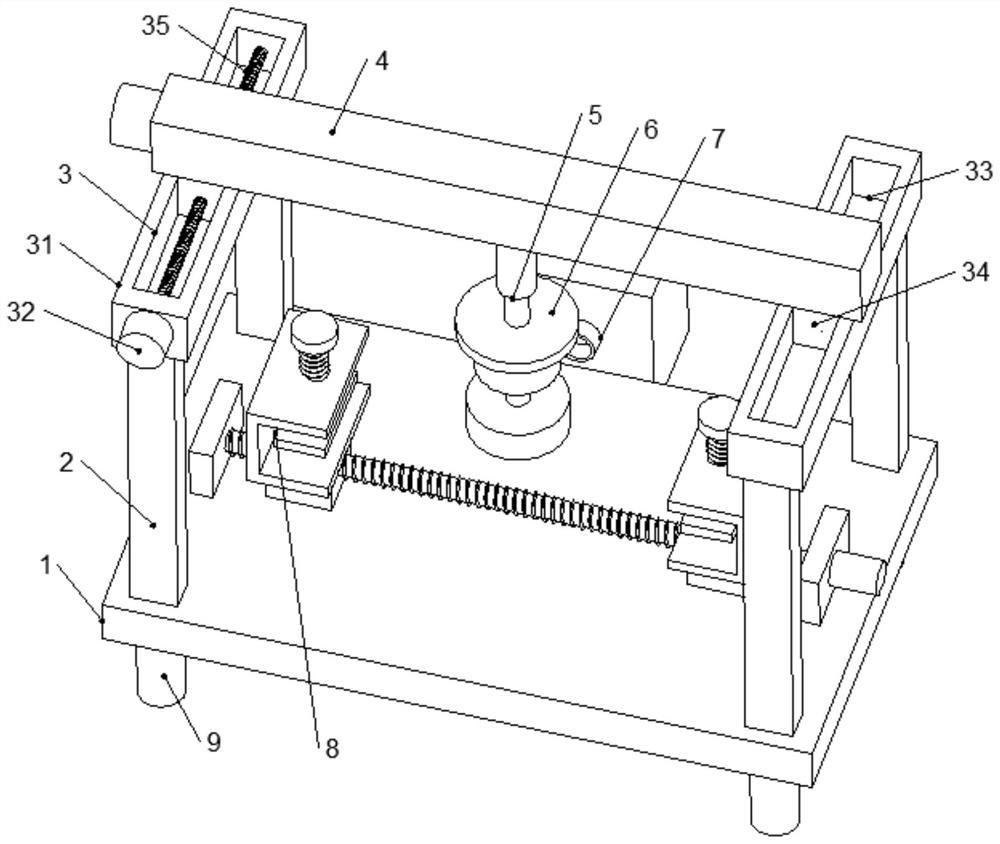

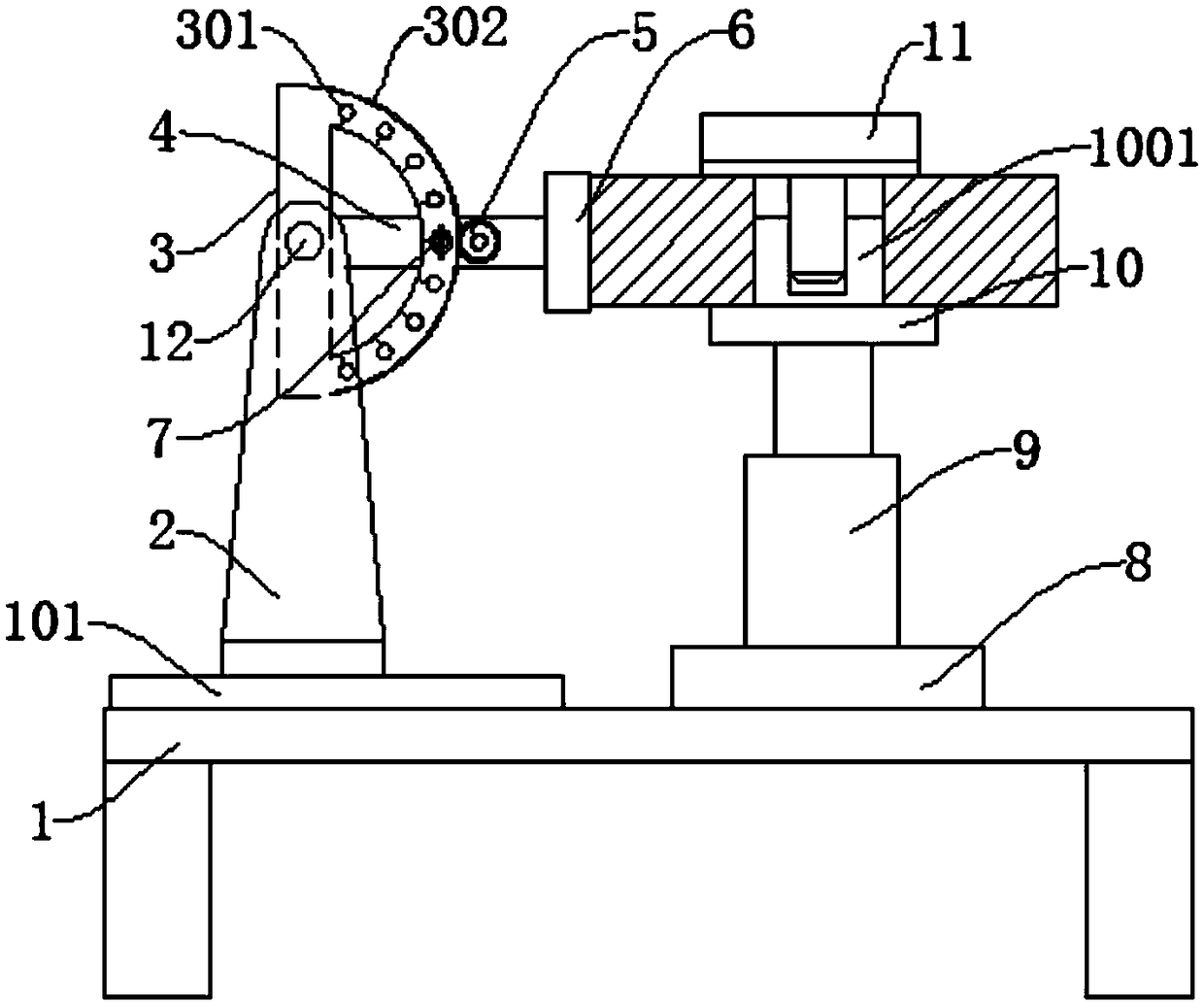

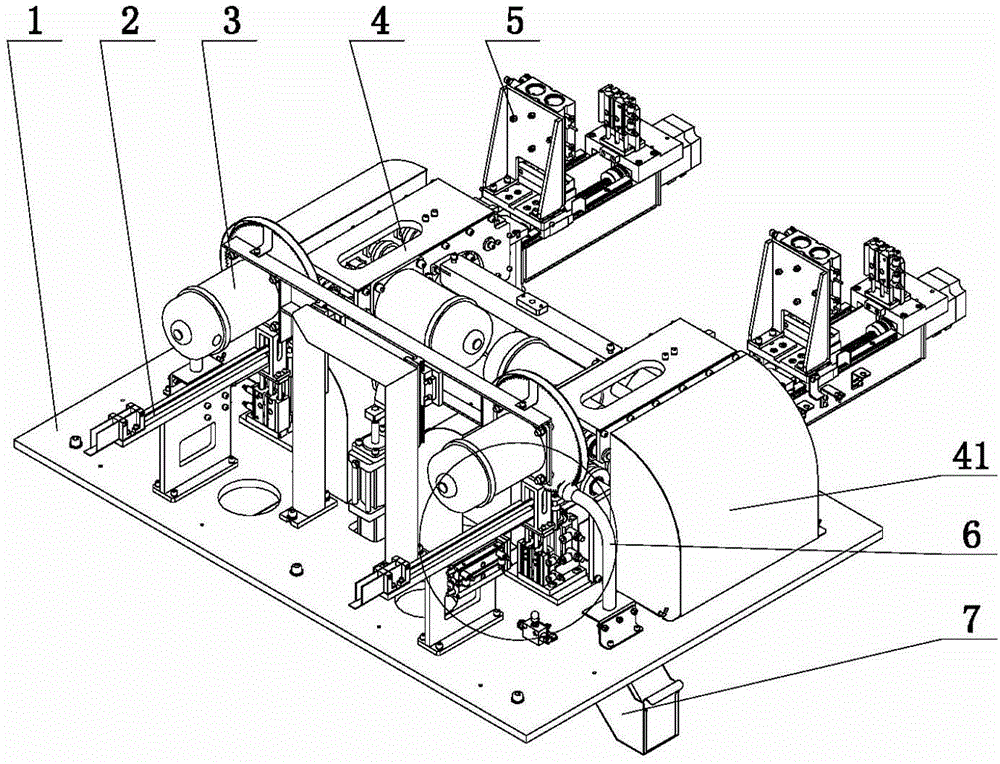

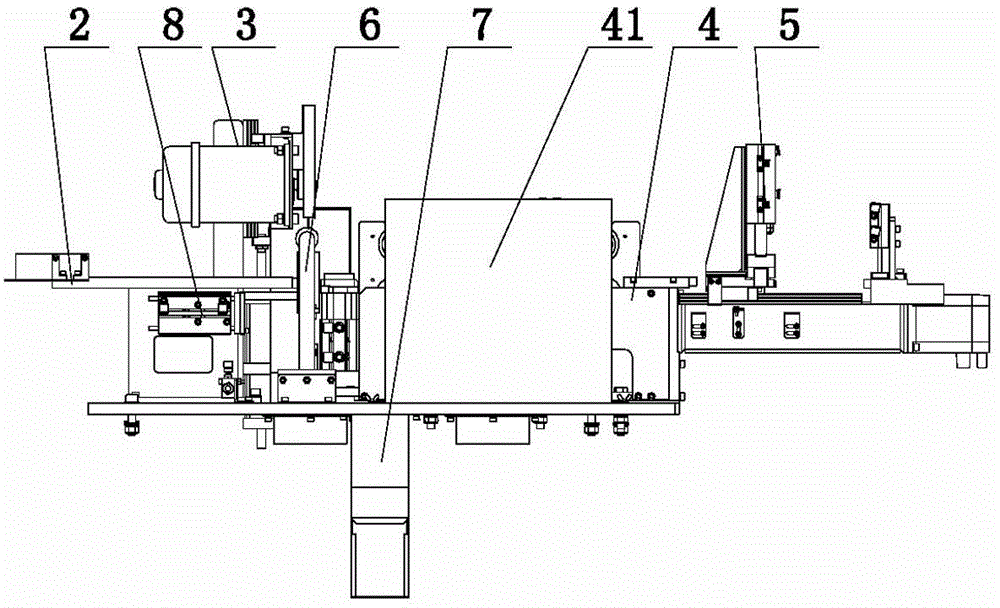

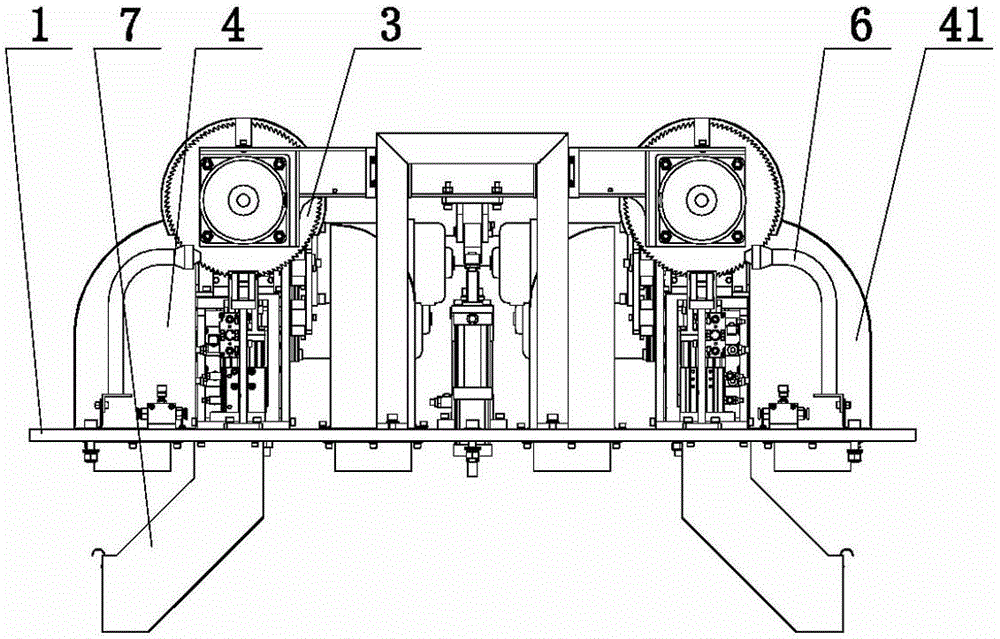

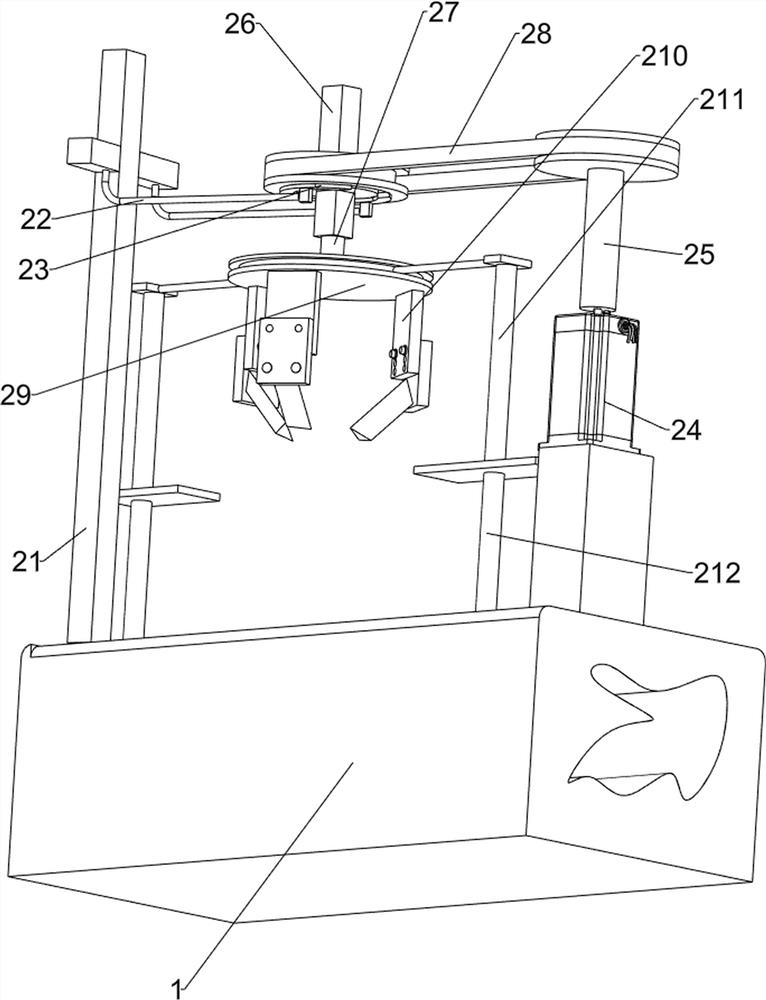

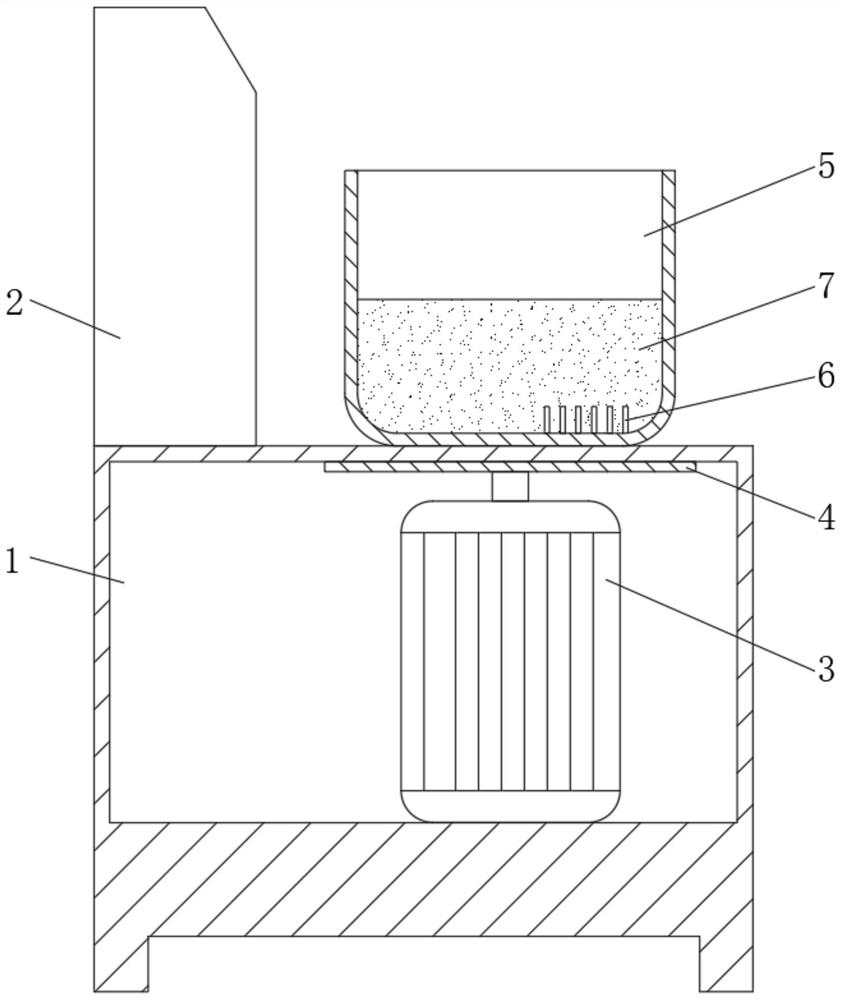

Automatic rotor chamfering machine

ActiveCN103997167ARealize chamferReduce laborManufacturing stator/rotor bodiesEngineeringTransfer mechanism

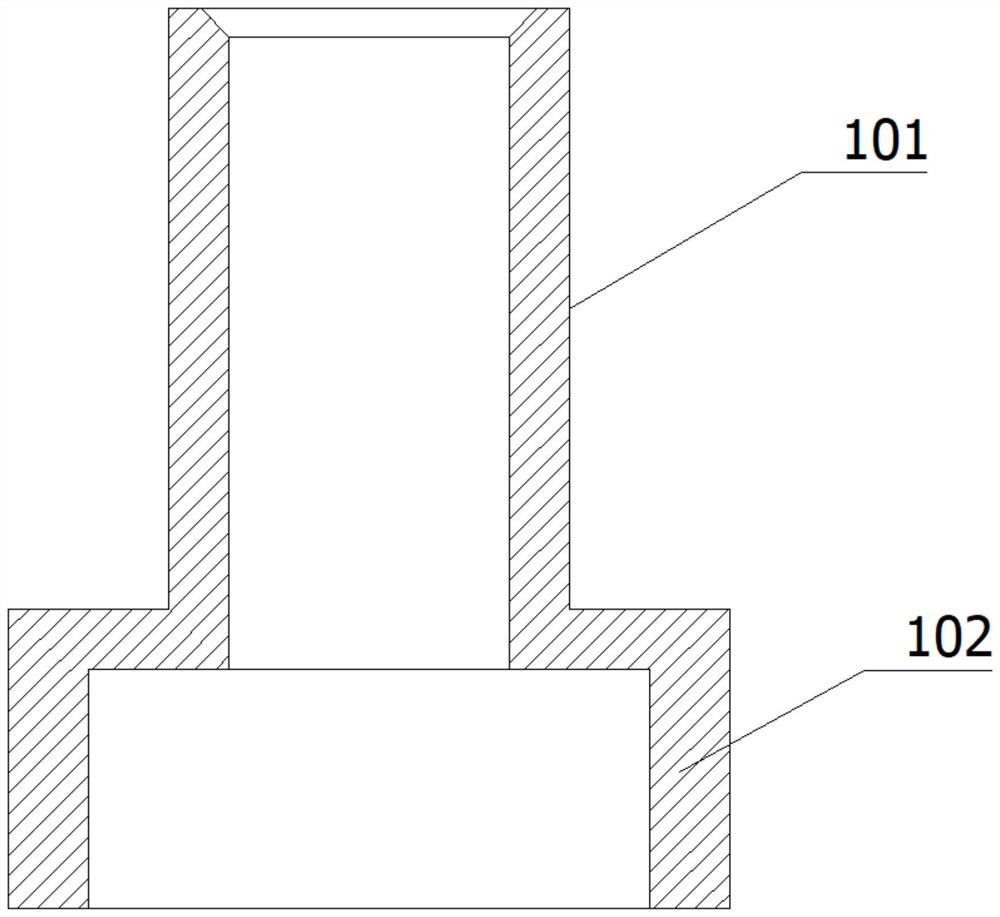

The invention relates to the field of motors, in particular to an automatic rotor chamfering machine. The automatic rotor chamfering machine comprises a guiding conveying groove arranged in an inclined mode from top to bottom. A rotor A is guided and conveyed in a rolling mode through the guiding conveying groove. A discharging opening in the lower end of the guiding conveying groove is connected with a transfer mechanism. A clamp which clamps the rotor A and drives the rotor A to rotate is arranged nearby the transfer mechanism. The transfer mechanism comprises a U-type or V-type clamping opening for supporting and being connected with the rotor A, and a driving mechanism for driving the clamping opening to move between the discharging opening of the guiding conveying groove and the clamp. A cutting tool for chamfering the rotor A is arranged nearby the clamp. The rotor rolls along the guiding conveying groove into the clamping opening. The transfer mechanism transfers the clamping opening to the clamping position of the clamp. The clamp clamps the rotor inside the clamping opening, and then the driving mechanism drives the rotor to rotate, so that the rotor and the cutting tool relatively rotate. The tool turns the end face of the rotor, and therefore the rotor is chamfered. According to the automatic rotor chamfering machine, in the chamfering process, the tool does not need to be manually operated, the amount of labor is greatly reduced, and working efficiency is improved.

Owner:合肥凯邦电机有限公司

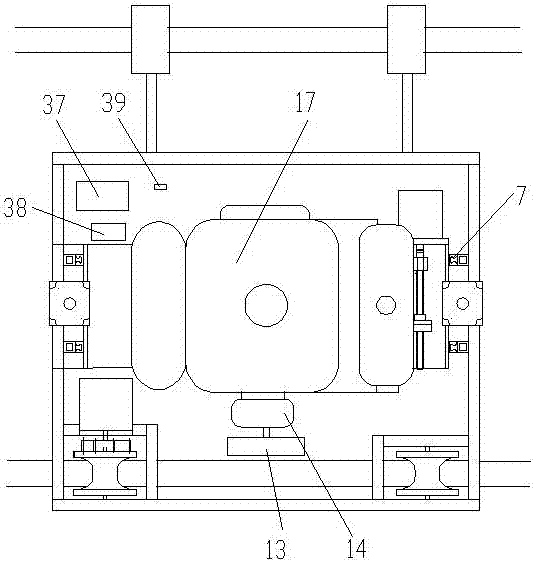

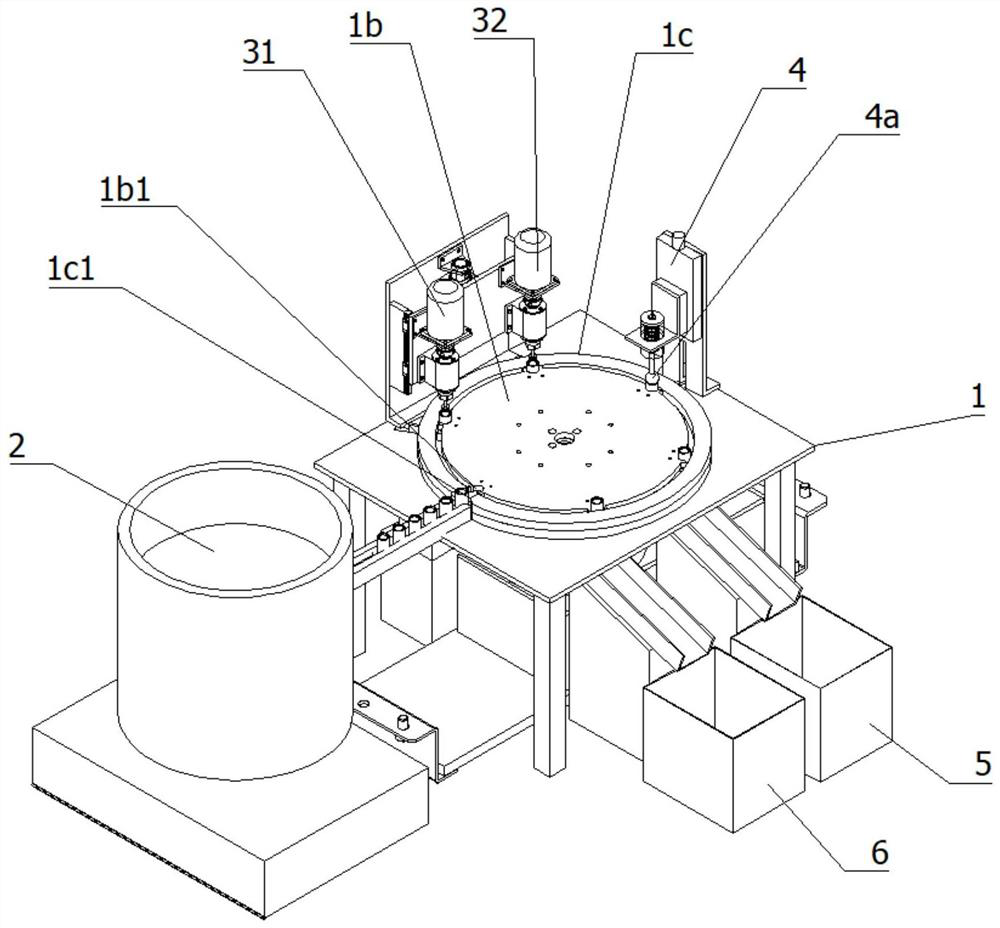

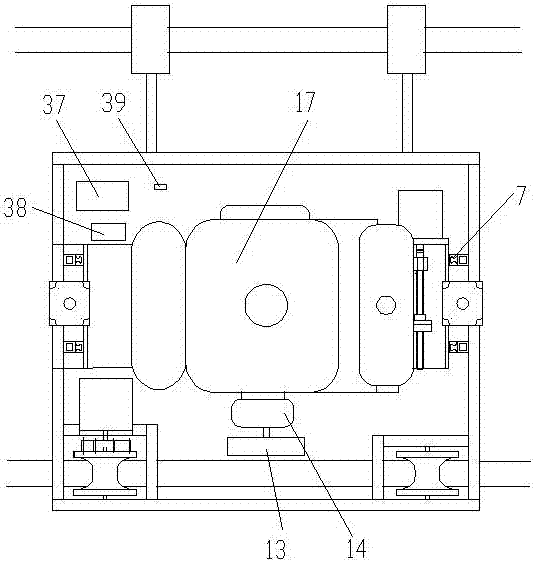

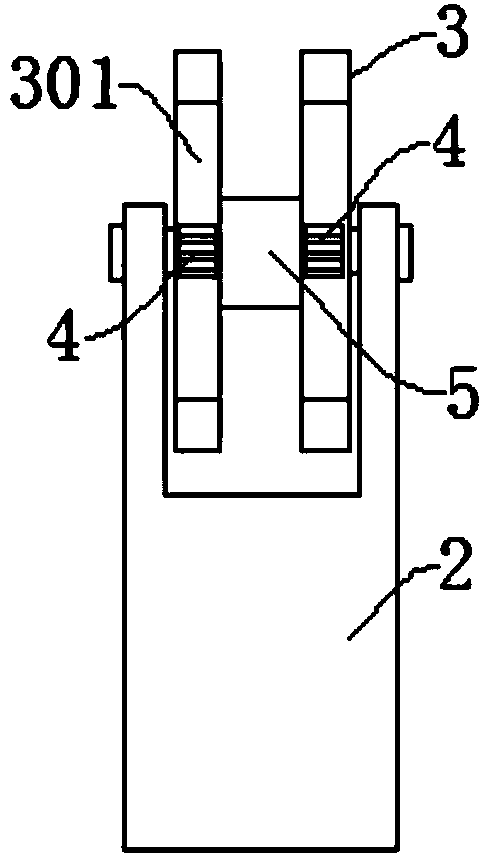

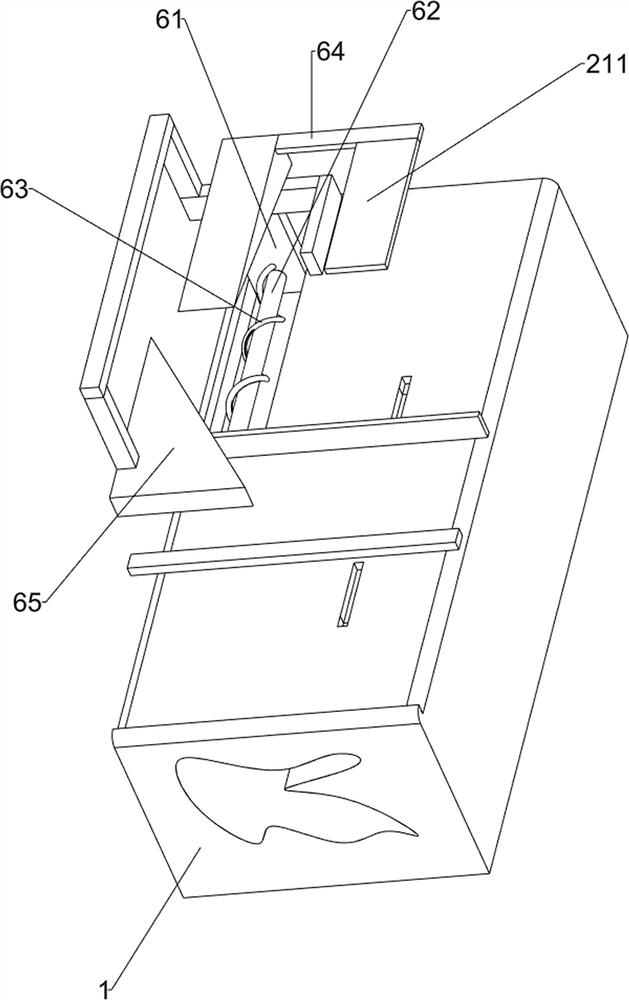

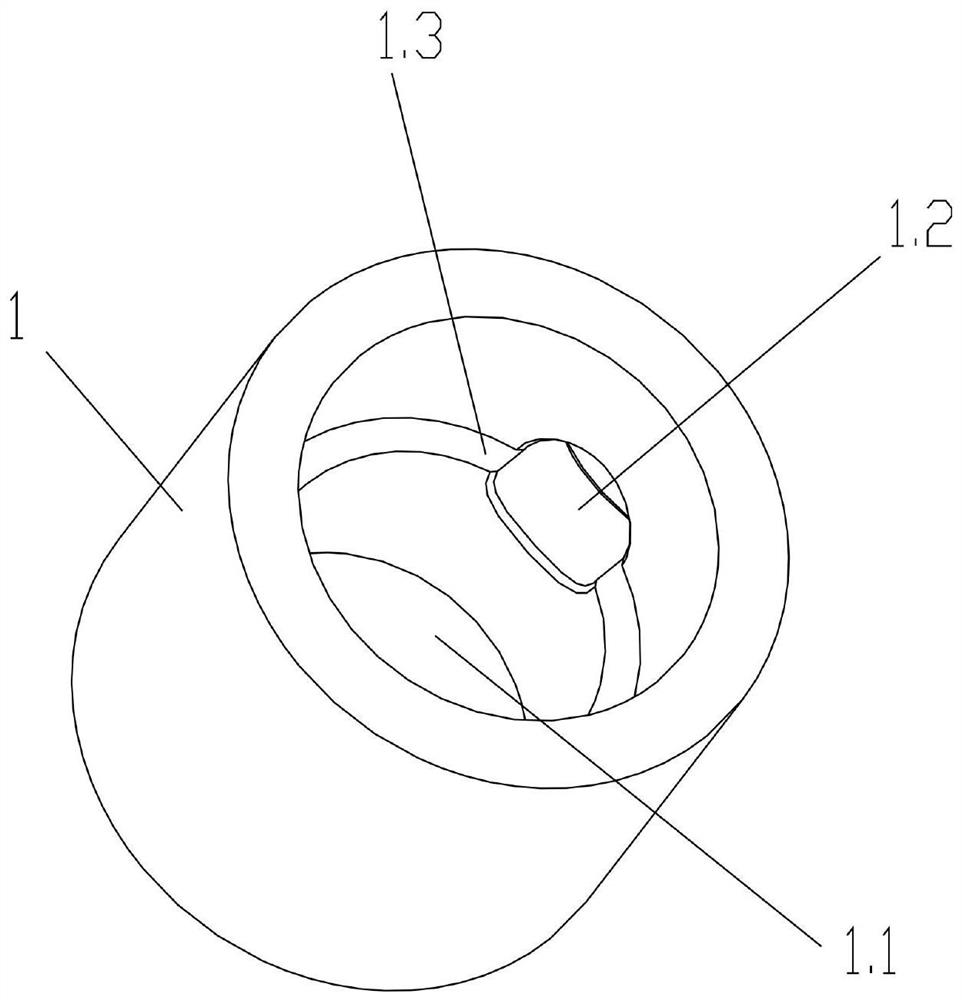

Inner chamfer machining robot for cylindrical parts

ActiveCN113210747ARealize chamferNo human intervention requiredMeasurement/indication equipmentsMetal working apparatusRotational axisVertical axis

The invention provides an inner chamfer machining robot for cylindrical parts. The inner chamfer machining robot for the cylindrical parts comprises a mounting plate, a rotating disc, a feeding assembly, a first chamfering assembly, a second chamfering assembly, a detection assembly, a first discharging assembly and a second discharging assembly; the mounting plate is horizontally arranged; the rotating disc can rotate along a vertical axis and is positioned right above the mounting plate; the feeding assembly is located on a feeding station and used for carrying out feeding on the cylindrical parts; the first chamfering assembly and the second chamfering assembly are located at a first chamfering station and a second chamfering station respectively and both supported on the mounting plate; the detection assembly is located at a detection station, is supported on the mounting plate and is used for carrying out detection on the chamfered cylindrical parts so as to judge whether chamfers are qualified or not; and the first discharging assembly and the second discharging assembly are located at a first discharging station and a second discharging station respectively and used for carrying out discharging on the cylindrical parts with qualified chamfers and the cylindrical parts with unqualified chamfers respectively, and the feeding station, the first chamfering station, the second chamfering station, the detection station, the first discharging station and the second discharging station are arranged at equal angles relative to the rotating axis of the rotating disc. By means of the robot, full-automatic inner chamfering of the cylindrical parts can be achieved.

Owner:BINZHOU UNIV

Automatic steel rail lip polishing method

InactiveCN107175554AImprove grinding efficiencyAchieve one-time grindingEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses an automatic steel rail lip polishing method, and belongs to the field of rail maintenance. The automatic steel rail lip polishing method is characterized by comprising the following steps that a, an automatic steel rail lip polishing machine is placed on a steel rail; b, the automatic steel rail lip polishing machine is driven by a traveling device of the automatic steel rail lip polishing machine to move in the longitudinal direction of the steel rail, a steel rail lip is polished longitudinally through a grinding wheel, and a horizontal feeding device drives the grinding wheel to transversely polish the steel rail lip at the same time; and c, the grinding wheel is driven by an up-down moving device to move up and down so as to polish any position of the steel rail lip in the height direction. According to the automatic steel rail lip polishing method, the steel rail lip can be polished transversely and longitudinally at the same time, manual adjustment is not needed, different feeding quantities are selected according to steel rail lips with different thicknesses, one-time polishing is achieved, and the polishing speed is constant; the grinding wheel can move up and down, and thus any position of the steel rail lip in the height direction can be polished; and the automatic steel rail lip polishing method has the characteristics of being high in polishing efficiency and good in polishing effect.

Owner:西藏天仁科技发展有限公司

Square crystal bar grinding and chamfering integrated machine

PendingCN109333290ARealize one-time chamferingSimplify the barreling processEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses a square crystal bar grinding and chamfering integrated machine capable of simultaneously finishing chamfering of four corners of a crystal bar at a time, grinding the two opposite side faces of the crystal bar at the same time, improving the work efficiency and reducing the cost. The square crystal bar grinding and chamfering integrated machine comprises a machine body internally provided with a transverse work through cavity; a crystal bar clamping device is arranged at the bottom of the transverse work through cavity, and a discharging window is arranged at one end of the machine body; and grinding devices and chamfering devices are arranged on the two sides of the other end of the machine body; the grinding devices are located between the discharging window andthe chamfering devices; the grinding devices are provided with grinding heads, and the grinding heads extend into the transverse work through cavity; and the chamfering devices are provided with chamfering grinding wheels extending into the transverse work through cavity. By adoption of the square crystal bar grinding and chamfering integrated machine, the crystal bar face grinding and chamferingefficiency can be improved, meanwhile, positioning errors can be reduced, and silicon material waste can be reduced.

Owner:LESHAN TOPRAYCELL

Automatic chamfering device for photovoltaic glass

InactiveCN113635174AEasy chamferingEasy to achieve chamfer grindingEdge grinding machinesGrinding drivesDust controlElectric machinery

The invention discloses an automatic chamfering device for photovoltaic glass. The automatic chamfering device comprises a base, supporting rods are fixedly connected to the four corners of the top of the base, a longitudinal adjusting assembly is arranged at the top ends of the supporting rods, a transverse adjusting assembly is connected to the top of the longitudinal adjusting assembly, an electric telescopic rod is connected to the bottom of the transverse adjusting assembly, a mounting plate is connected to the bottom end of the electric telescopic rod, a grinding motor is arranged at the bottom of the mounting plate, a grinding wheel is connected to the output end of the grinding motor, a clamping and fixing assembly is arranged on the top of the base, and a dust removal assembly is arranged on the rear side of the top of the base; and the longitudinal position of the grinding wheel can be adjusted through the longitudinal adjusting assembly, the transverse position of the grinding wheel can be adjusted through the transverse adjusting assembly, chamfering grinding of different positions of photovoltaic glass is conveniently achieved, the glass is fixed through the clamping and fixing assembly, the grinding wheel is driven to rotate through the grinding motor, chamfering of the photovoltaic glass is achieved, and dust generated during glass chamfering is treated through the dust removal assembly.

Owner:赫冉新能源科技扬州有限公司

Quartz glass sheet outer circle grinding and chamfering device

InactiveCN108608282AAchieve grindingRealize chamferGrinding wheel securing apparatusGrinding drivesEngineeringMechanical engineering

The invention discloses a quartz glass sheet outer circle grinding and chamfering device. The quartz glass sheet outer circle grinding and chamfering device comprises a workbench, a stand column and agrinding head. A rotary table is arranged on the upper portion of the workbench. An electric lifting rod is arranged on the upper portion of the rotary table. A supporting plate is arranged at the top of the electric lifting rod. A plug is arranged on the upper portion of the supporting plate. A detachable pressing plate is mounted on the upper portion of the plug. The stand column is further arranged on the workbench and located on one side of the rotary table. An electric guide rail is arranged at the bottom of the stand column. A U-shaped opening is formed in the top of the stand column. Aconnecting shaft is arranged in the middle of the U-shaped opening. A connecting rod is rotationally mounted on the connecting shaft. The quartz glass sheet outer circle grinding and chamfering device has the beneficial effects that by adjusting the inclined angle of the connecting rod, a quartz glass ring outer circle face is ground and chamfered, thus, multiple times of mounting and dismountingof quartz glass rings are avoided, and thus the processing efficiency is greatly improved; and the structure is simple, and adjustment is convenient.

Owner:JIANGSU JINGTAI GLASS CO LTD

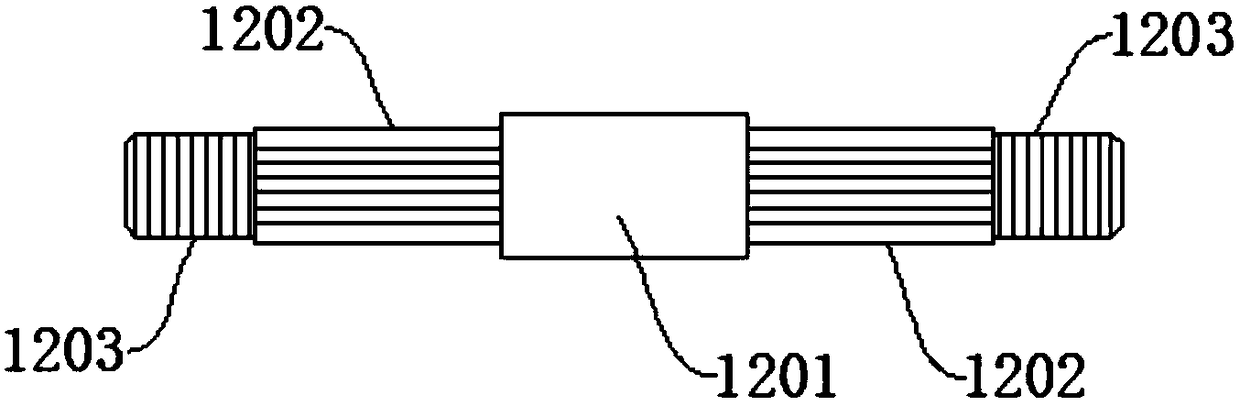

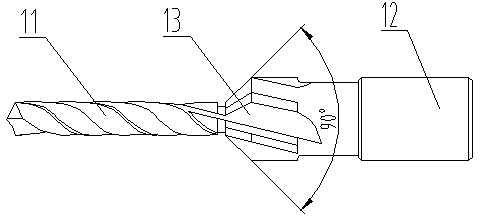

Method for machining forming hole of annular feed forming mould and reamer

ActiveCN103752884AReduce resistanceRealize chamferTransportation and packagingTrepanning drillsEngineeringReamer

The invention discloses a method for machining a forming hole of an annular feed forming mould and a reamer. The method comprises the steps that a center hole is drilled at the center of an inner-wall forming hole of an annular mould body through a center drill firstly; secondly, the forming hole is drilled roughly in the position of the center hole from the inner wall of the annular mould body to the outer wall of the annular mould body through a twist drill; thirdly, the hole is reamed through the forming hole reamer, chamfering is conducted on a hole opening, burrs of the hole opening are removed, and the machined forming hole is smooth, clean and standard. According to the forming hole reamer, a conical-surface counter bit (12) is additionally arranged between a drill bit (11) and a drill handle (13), after the forming hole is reamed, chamfering and burr removal can be conducted on the hole opening without the need for cutter replacement, and therefore machining efficiency is improved.

Owner:KUNMING GUIFENG MACHINERY

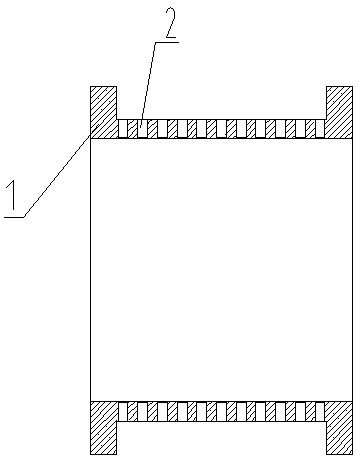

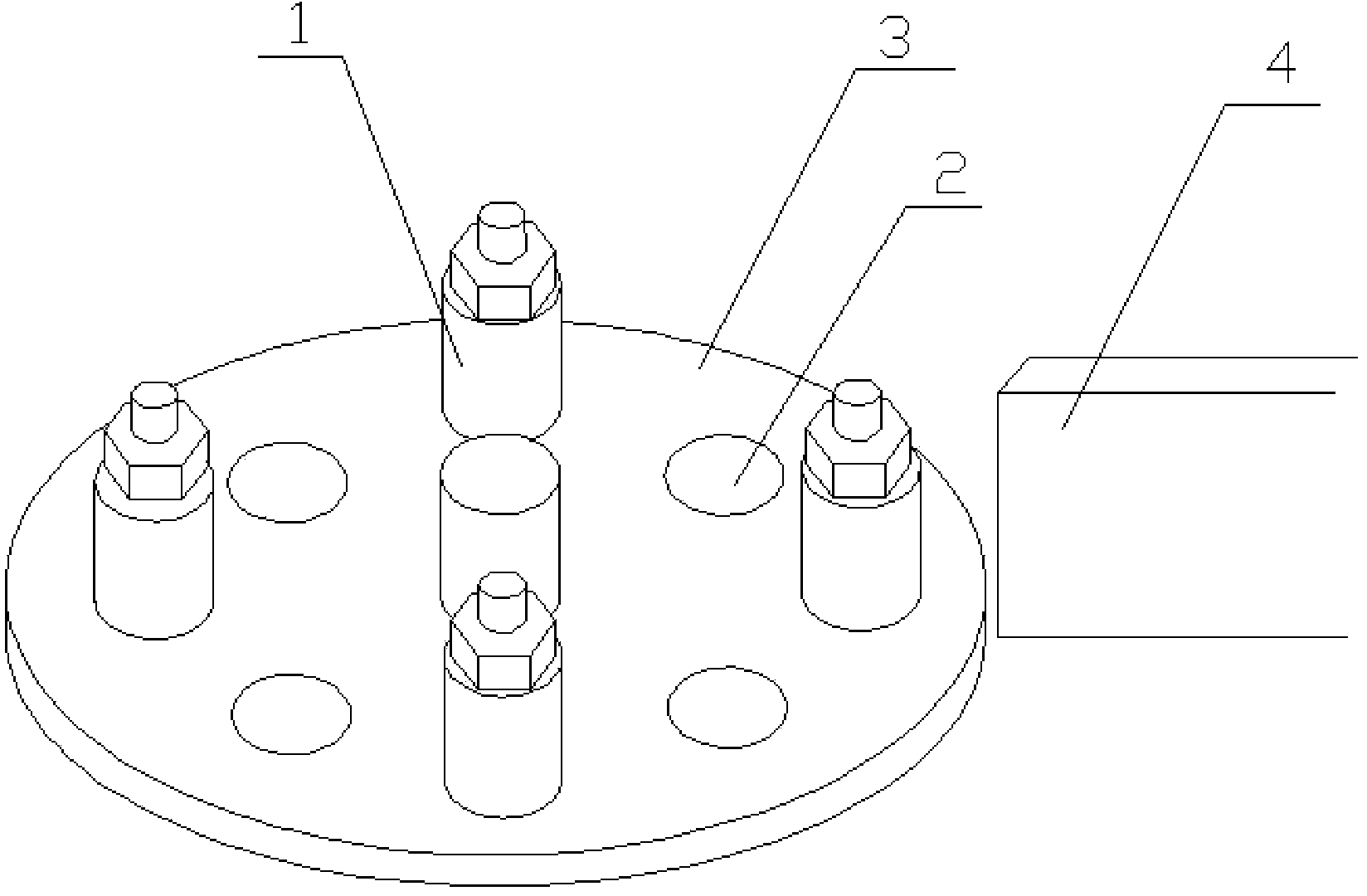

Nut processing device

InactiveCN104070238ARealize chamferConvenient and fast cutting and grindingMechanical engineeringEngineering

The invention discloses a nut processing device, comprising a rotary base plate (3), fastening rods (1) and a cutting knife (4), wherein the rotary base plate (3) is provided with a plurality of positioning through holes (2) at intervals along the peripheral direction of the rotary base plate (3), the fastening rods (1) are screwed into the rotary base plate (3) through the positioning through holes (2), nut workpieces sleeve the fastening rods (1) and fixed by nuts, the cutting knife (4) cut the nut workpieces under the guide of the edge of the rotary base plate (3), and the radius of the rotary base plate (3) is more than or equal to ten times of that of the nut workpiece. The nut processing device can cut and polish the nut workpieces more conveniently and rapidly, and thus the cylindrical nuts can be chamfered.

Owner:WUHU QIUJING FASTENER

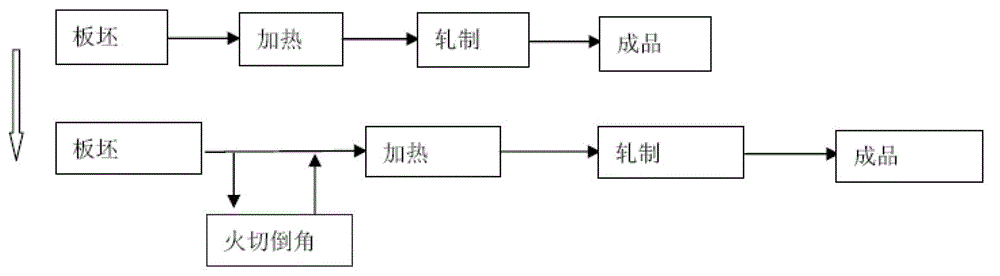

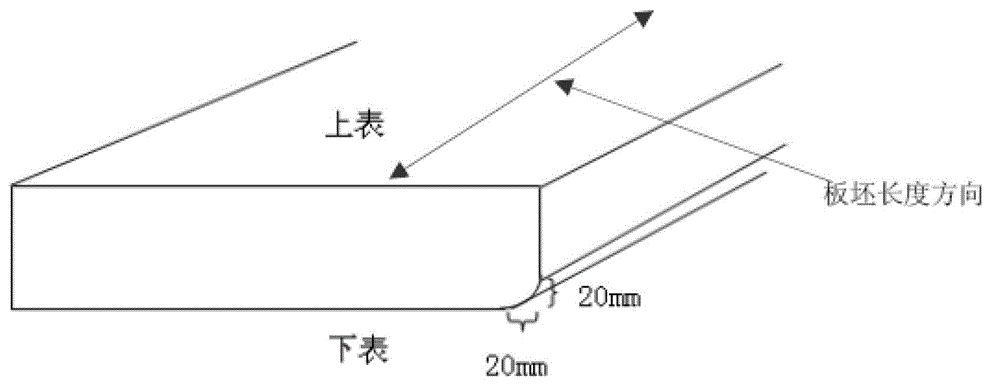

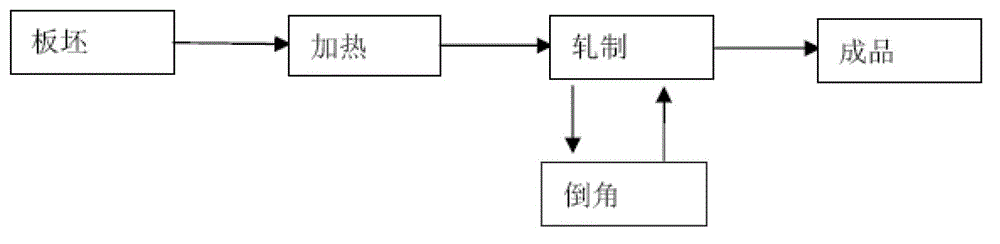

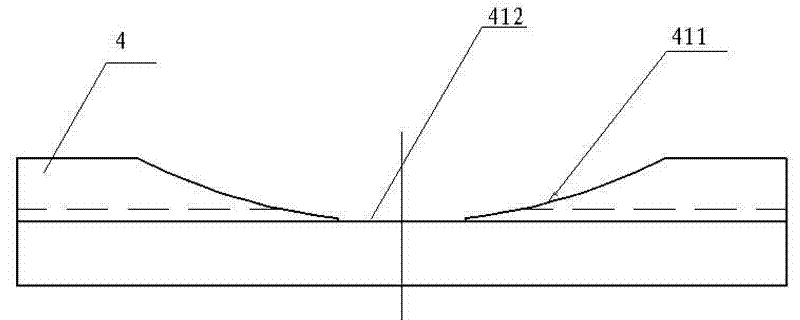

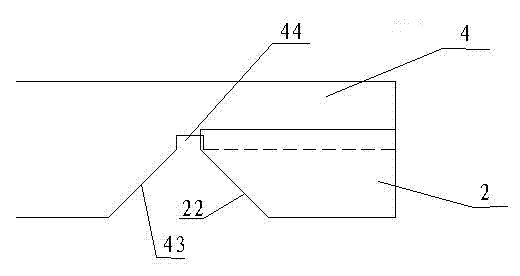

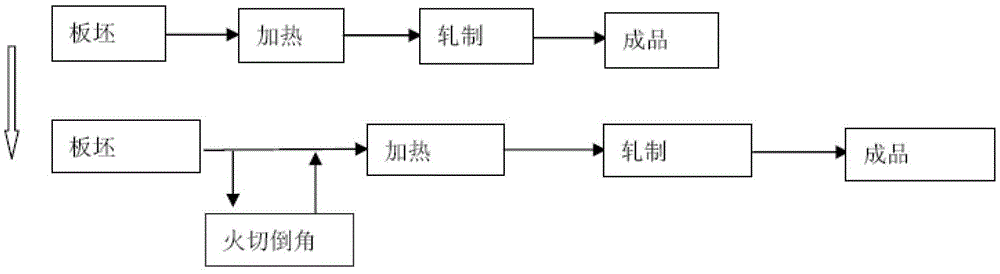

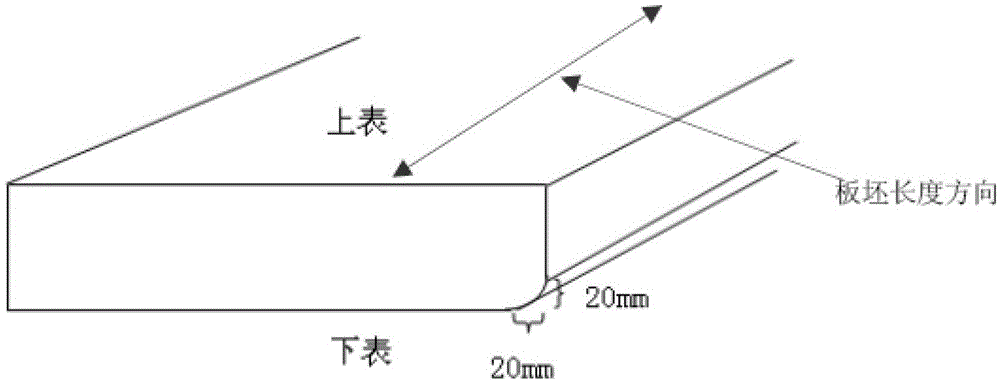

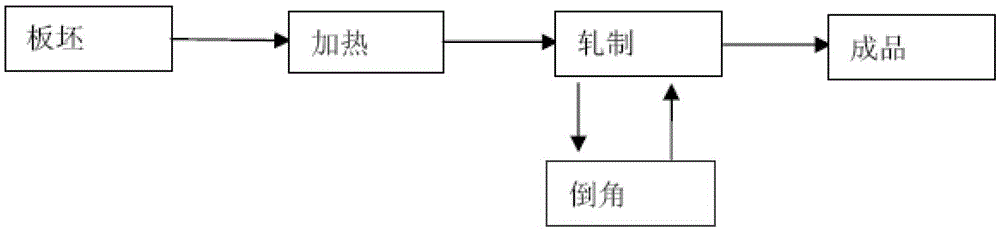

Method for chamfering slabs during rolling of rolling mill

ActiveCN104148407AChamfering effectHigh cost of cancellationRare end control deviceEngineeringRolling mill

The invention discloses a method for achieving the chamfering purpose during rolling of a slab rolling mill. According to the method, the slab chamfering effect can be achieved by accurately controlling head and tail roller gaps during slab rolling, and therefore the defects of slab fire cutting chamfering are avoided, the purposes of preventing rolling defects and omitting the slab fire cutting chamfering procedure are achieved, and chamfering can be achieved on all rolling slabs. Due to the fact that the original slab fire cutting chamfering technology is long in consumed operation time, high in logistics difficulty, low in efficiency and high in cost, the normal rolling process is adopted in the method, the slab chamfering problem is solved very well, and the purpose and effect of slab fire cutting chamfering are achieved. The method is an innovation for rolling defect controlling of plates with moderate thicknesses, the slab fire cutting technology can be completely replaced by the method, the efficiency is high, and the method has substantive characters and progress and is novel, creative and practical. The method does not have a negative effect on the environment, and can be popularized in all moderate thickness plate enterprises at home and abroad.

Owner:BAOSHAN IRON & STEEL CO LTD

Automatic feeding type aluminum plate corner cutting device

InactiveCN107159773ARealize automatic feedingRealize chamferMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention relates to an aluminum plate processing equipment, in particular to an automatic feeding type aluminum plate corner cutting device, which includes a frame, a feeding mechanism and a corner cutting mechanism arranged on the frame, and the feeding mechanism includes a The first bracket on the frame, the first bracket is connected with the lead screw motor, two cylinders are arranged at the upper end of the first bracket, and two rubber pressure blocks are connected with the cylinders; The angle-cutting mechanism includes a second bracket arranged on the frame, two hydraulic cylinders are arranged on the top of the second bracket, a pressing plate is connected with the hydraulic cylinders, and a pressing plate is connected with the pressing plate Cutting die. Preferably, the pressing plate is connected to the frame through a spring. The invention has a simple structure and is easy to realize. The automatic feeding of the aluminum plate can be realized through the feeding mechanism. When the aluminum plate passes the position of the angle cutting die of the angle cutting mechanism, the hydraulic cylinder is activated to realize the angle cutting of the aluminum plate.

Owner:HEFEI TAITONG REFRIGERATION TECH CO LTD

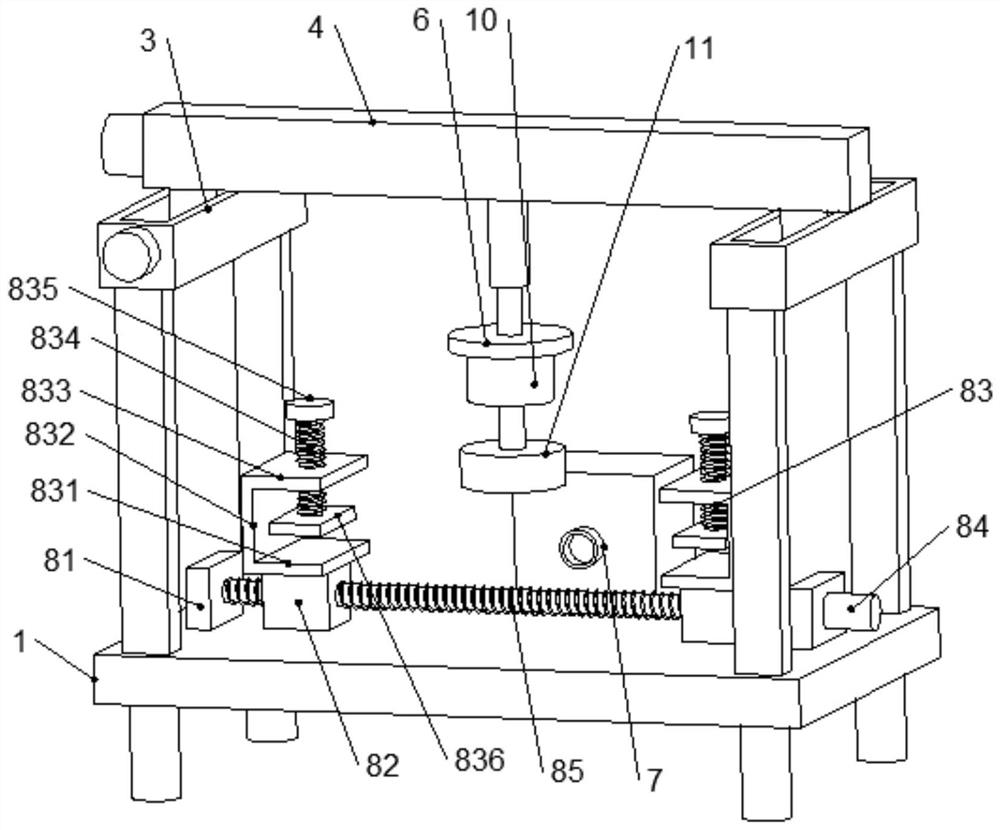

Chamfering device of automobile chassis supporting frame

PendingCN109332750AEffectively fixedRealize chamferBoring/drilling machinesManufacturing technologyRolling chassis

The invention discloses a chamfering device of an automobile chassis supporting frame and relates to the technical field of automobile manufacturing. The chamfering device comprises a base. The base is provided with a sliding and moving mechanism. The middle of the base is fixedly provided with a clamping base. Supports are symmetrically arranged on the sliding and moving mechanism leftwards and rightwards. The supports are internally provided with sliding grooves. The sliding grooves are internally connected with lifting mechanisms in a sliding manner. The lifting mechanisms are connected with rotating motors. Output shafts of the rotating motors are provided with drill rods. The chamfering device is simple in structure and convenient to operate, chamfering can be carried out on holes indifferent positions of the automobile chassis supporting frame, it does not need to repeatedly move the automobile chassis supporting frame, the production labor force is reduced, and the production efficiency is improved.

Owner:WUHU YUANSHAN MACHINERY MFG CO LTD

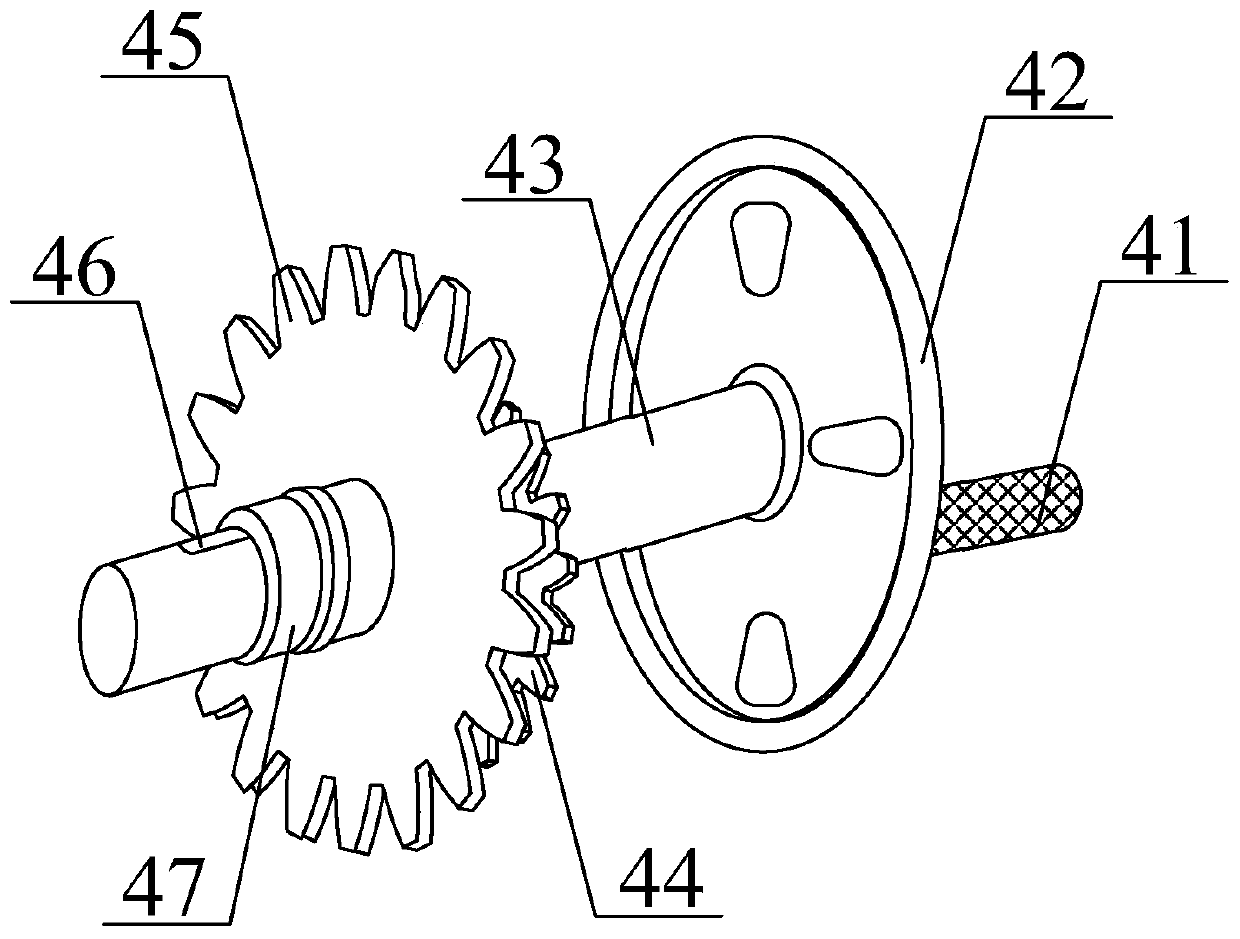

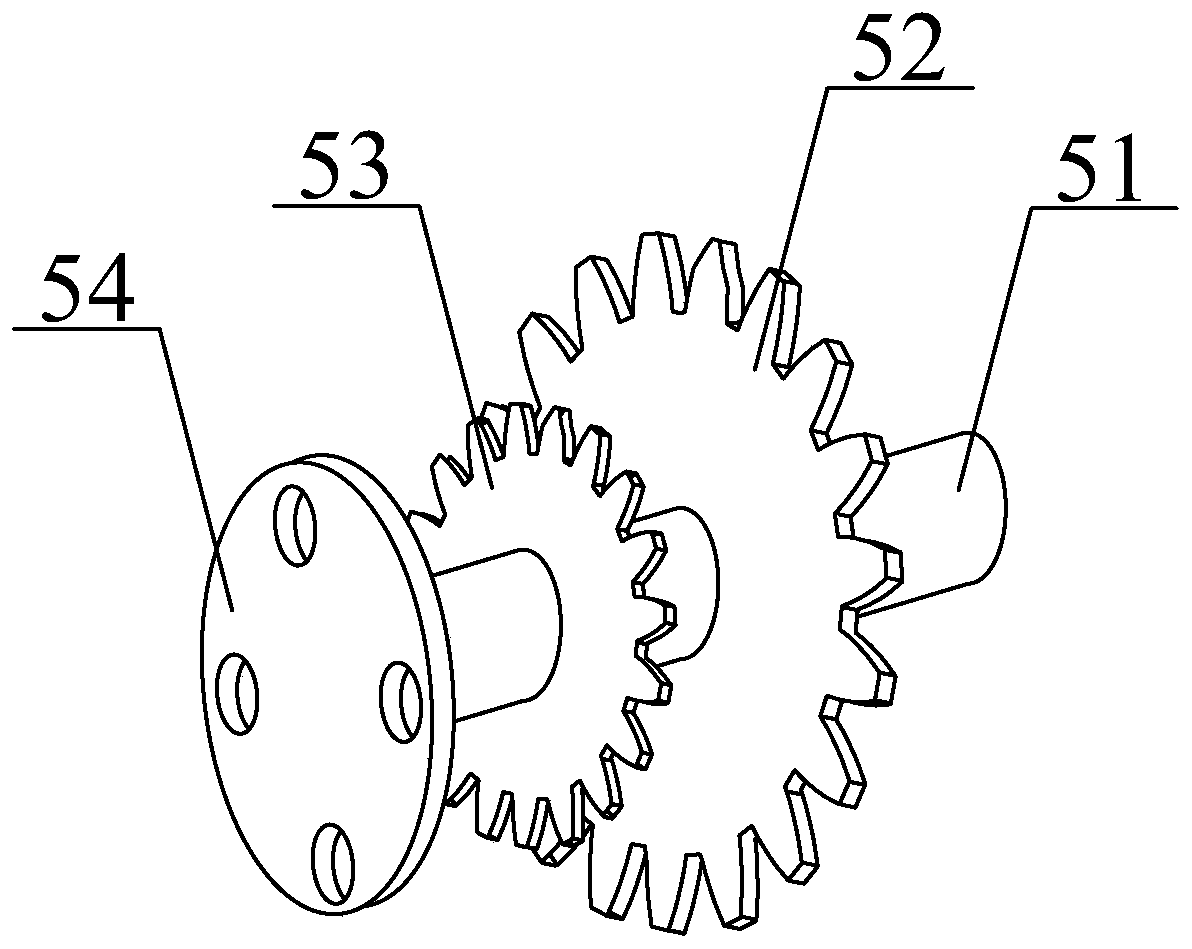

Hand-operated rotary disc brush driving device

The invention discloses a hand-operated rotary disc brush driving device. The device comprises a base, a mounting hole, a mounting plate, a hand-operated driving mechanism, a driving device, a side vertical plate and a speed change mechanism. According to the device, a sliding sleeve is arranged, an annular protrusion is arranged at the upper end of the sliding sleeve, a protruding block is arranged on the inner surface of the sliding sleeve in the axis direction of the sliding sleeve, and is matched with a key groove, the sliding sleeve can be guaranteed to drive a small main gear and a largemain gear to move on a transmission shaft, the transmission ratio is switched, and the rotating effect can be guaranteed; and the speed change mechanism is arranged, a pushing handle is moved to drive a pushing sleeve to slide on the transmission shaft, the transmission ratio between the small main gear and the large main gear and between an large auxiliary gear and a small auxiliary gear is converted, the rotating speed of the disc brush can be adjusted according to different workpieces, the labor intensity of operators is effectively reduced, and the working efficiency is improved.

Owner:安徽省潜山县志发机电配件有限公司

Resin base polishing device for resin toy processing

InactiveCN111730452AEasy to polishAffect securityEdge grinding machinesDispersed particle filtrationGear wheelEngineering

The invention discloses a resin base polishing device for resin toy processing. The device comprises a base, wherein the top of the base is fixedly connected with a first supporting rod through a bolt, one end of the first supporting rod is fixedly connected with a foxed ring through a bolt, a sliding rail is welded to the outer wall of one side of the fixed ring, and a sliding block is connectedinto the sliding rail in a sliding mode. According to the resin base polishing device for resin toy processing, through meshed connection of a gear and a gear ring, a first supporting frame can move on the fixed ring in the rotating process of the gear, on one hand, angle adjustment of a polishing disc and a resin base is achieved, and then omnibearing polishing of the resin base is achieved, andthe polishing efficiency and quality of the resin base are improved; and on the other hand, chamfering grinding of the resin base can be achieved, chamfering of the resin base is achieved, corners ofthe four corners of the resin base are prevented from affecting the use safety of subsequent resin toys, and the resin toys are prevented from scratching children in the playing process.

Owner:赣县洪顺工艺厂

Chamfering device for disc-shaped workpiece

PendingCN110666612ARealize chamferEasy to useEdge grinding machinesGrinding carriagesCircular discElectric machinery

The invention discloses a chamfering device for a disc-shaped workpiece. The chamfering device comprises an operation table and a grinding mechanism. The operation table is arranged in a square shape.The inner cavity of the operation table is provided with a rotary table which is in transmission connection with an output shaft of a first motor fixed on the lower surface wall of the operation table. According to the invention, through the arrangement of a second motor, a belt pulley, and a belt, a second threaded rod can rotate. During the rotation of the second threaded rod, a second threadedsleeve can enable an adjusting mechanism and the grinding mechanism to move horizontally through a first connecting rod, so that workpieces of different diameters are chamfered. The arrangement of ahydraulic rod allows the adjusting mechanism and the grinding mechanism to move vertically, so that workpieces of different thicknesses are ground. The device has a higher degree of automation, and isconvenient for operators to use.

Owner:湖南恒裕汽车零部件有限公司

Gear milling machine used for machining straight cone gear

ActiveCN108687409AAchieve rotation adjustmentQuick chamferGear-cutting machinesGear teethRound tableGear wheel

The invention discloses a gear milling machine used for machining a straight cone gear. The machine comprises a mounting base, a mounting plate is arranged on the upper portion of the mounting base ina sliding manner, one side of the mounting plate is provided with an air cylinder fixedly connected with the mounting base, an L-shaped connecting plate is perpendicularly welded to the position above the end, close to the air cylinder, of the mounting plate, the side, away from the air cylinder, of the L-shaped connecting plate is perpendicularly provided with a movable plate in a sliding manner, the movable plate is perpendicularly sleeved with a rotating shaft, the end, close to the mounting plate, of the rotating shaft is fixedly sleeved with a round-table-shaped rotating disc, driving levers are welded to the outer ring of the rotating disc in the axis line direction at equal distances, a positioning column is welded to the position above the mounting plate, the end, away from the air cylinder, of the mounting plate is perpendicularly welded with a supporting column, and the side, close to the mounting plate, of the supporting column is welded with an inclined guide plate. The gear which is preliminarily machined is automatically and rapidly subjected to chamfering and edge trimming operation, the gear machining efficiency is improved, manpower and material resources are saved, the gear surface is smooth and free of burrs, and the gear quality and attractiveness are improved.

Owner:CHONGQING HANYUAN MACHINERY

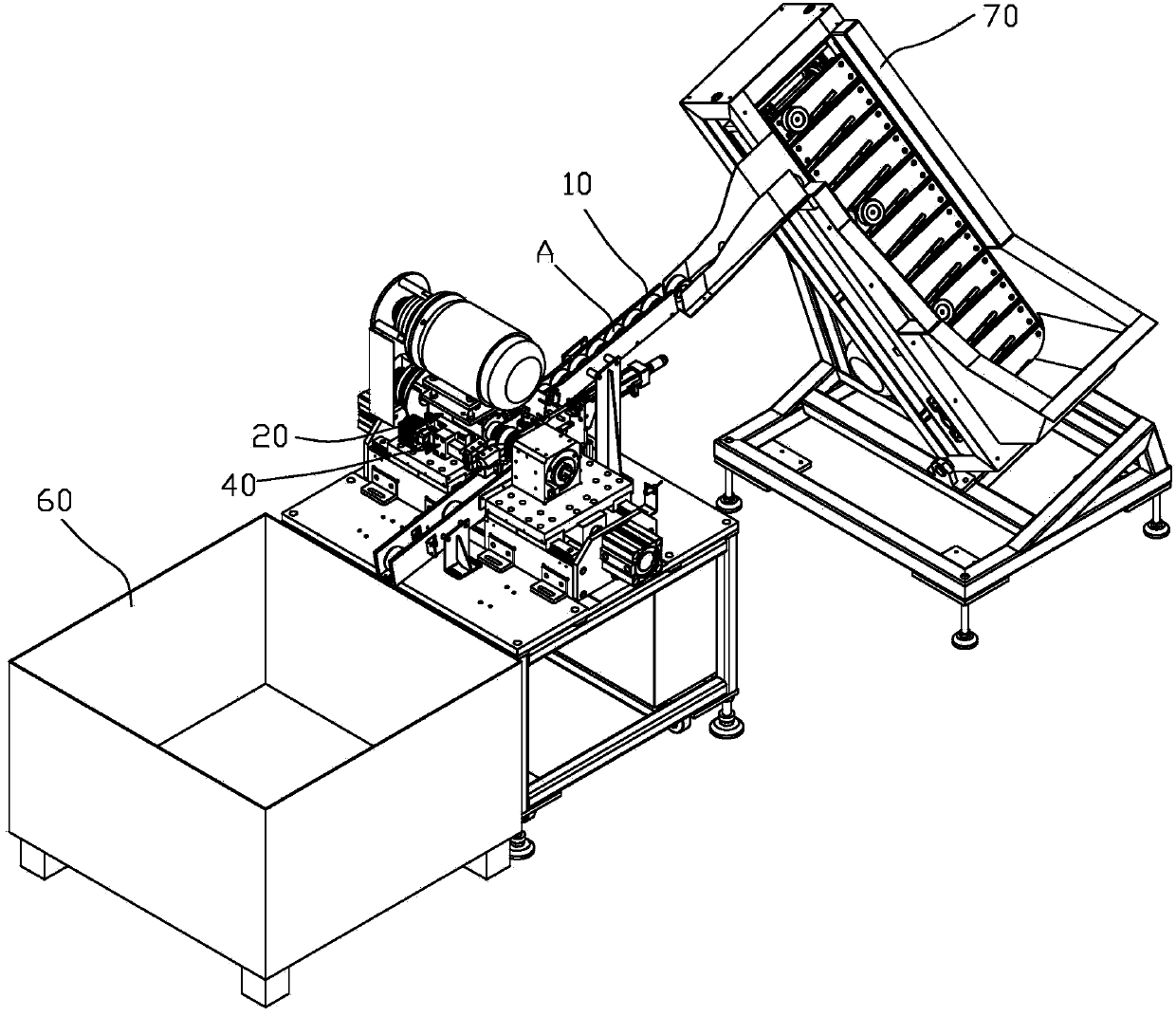

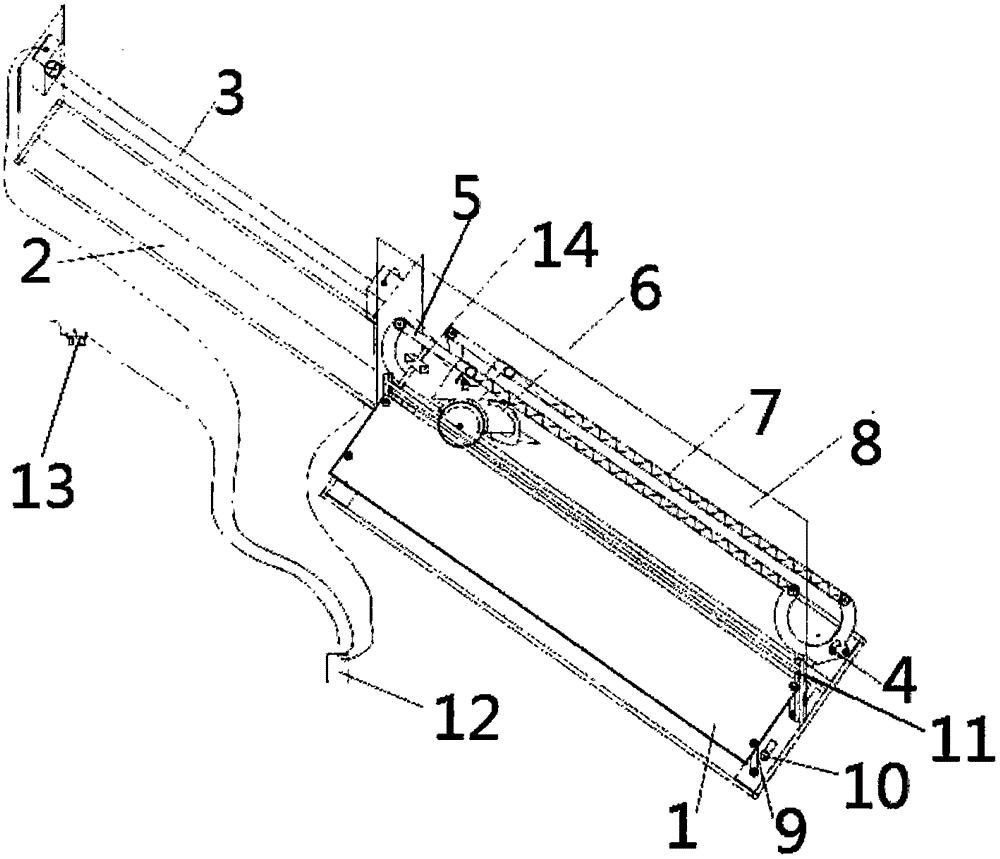

Material strip treating device

InactiveCN105082228ARealize automatic deliveryRealize chamferMetal working apparatusProduction lineEngineering

The invention discloses a material strip treating device, and relates to the technical field of automatic production equipment for cushion strips and cushion blocks used in power transmission, in particular to the material strip treating device in an automatic production line for the cushion strips and the cushion blocks. The material strip treating device provided by the invention can automatically convey, chamfer and cut off material strips, and comprises a machine base, wherein a conveying mechanism, a chamfering mechanism and a cutting mechanism which are connected in sequence are arranged on the machine base. The material strip treating device is characterized in that the conveying mechanism comprises a conveying rack, wherein a conveying servo motor with a conveying lead screw is arranged in the conveying rack; a conveying movement frame is arranged on a conveying nut of the conveying lead screw; a conveying cushion plate is arranged on the conveying movement frame; a conveying cylinder pressing plate is arranged at a position, corresponding to the conveying cushion plate, on the conveying movement frame.

Owner:YINGKOU JINCHEN AUTOMATION CO LTD

Automatic chamfering and cutting device

PendingCN106607995AEasy to adjustEasy to operateWorking accessoriesStone-like material working toolsEngineeringWorking environment

The invention relates to an automatic chamfering and cutting device. The automatic chamfering and cutting device comprises an operation platform (1). An angle adjusting plate (4) is arranged at each of the two ends of the operation platform (1). Two tracks (5) are arranged between the two angle adjusting plates (4). The tracks (5) are provided with an electric cutting machine (6). A telescopic dustproof cover (7) is arranged on one side of the electric cutting machine (6), and a transparent dustproof baffle (8) is arranged on the other side of the electric cutting machine (6). An air cylinder base (2) is arranged at one end of the operation platform (1) and provided with an air cylinder (3). A cylinder rod of the air cylinder (3) is connected with the electric cutting machine (6). The automatic chamfering and cutting device further comprises a foot control valve (12) and an automatic oil feeder (13). The foot control valve (12) is connected with the air cylinder (3), the electric cutting machine (6) and the automatic oil feeder (13). One person is enough for operating the device, simpleness and convenience are achieved, the work efficiency is improved, and cost is reduced; and meanwhile, unsafe factors can be eliminated, accidental injuries of workers are eradicated, and the work environment can be improved.

Owner:山东诺玛建材有限公司

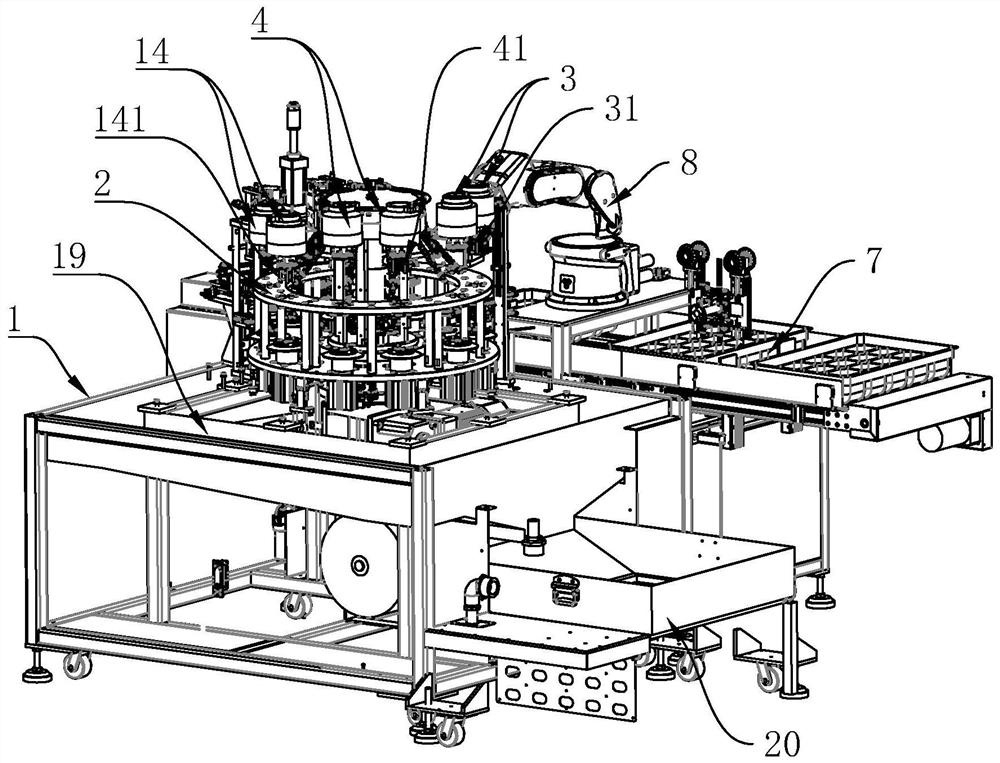

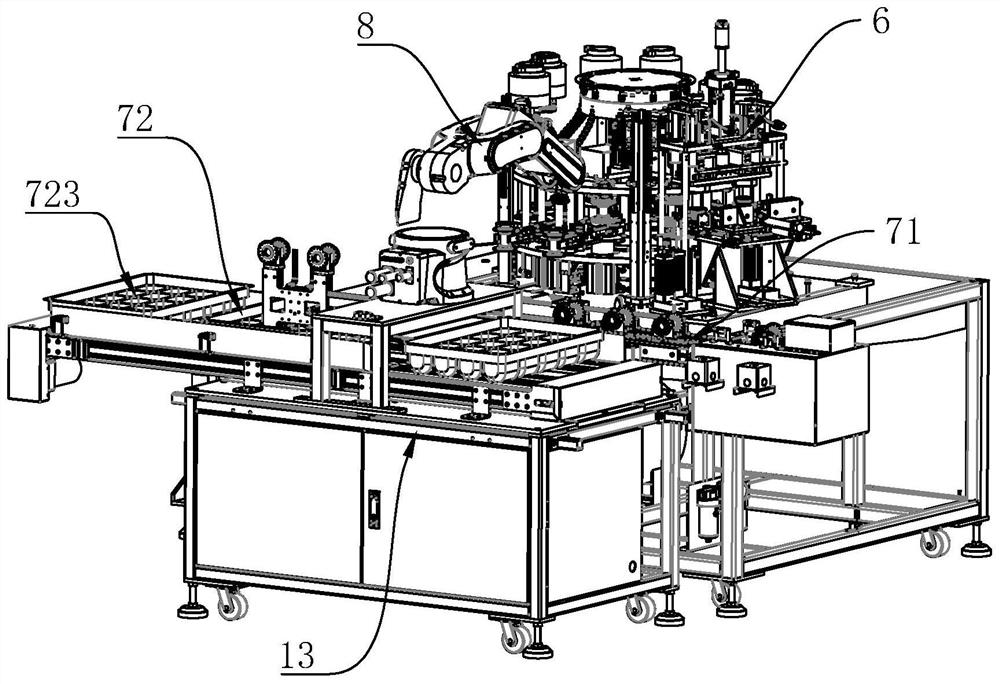

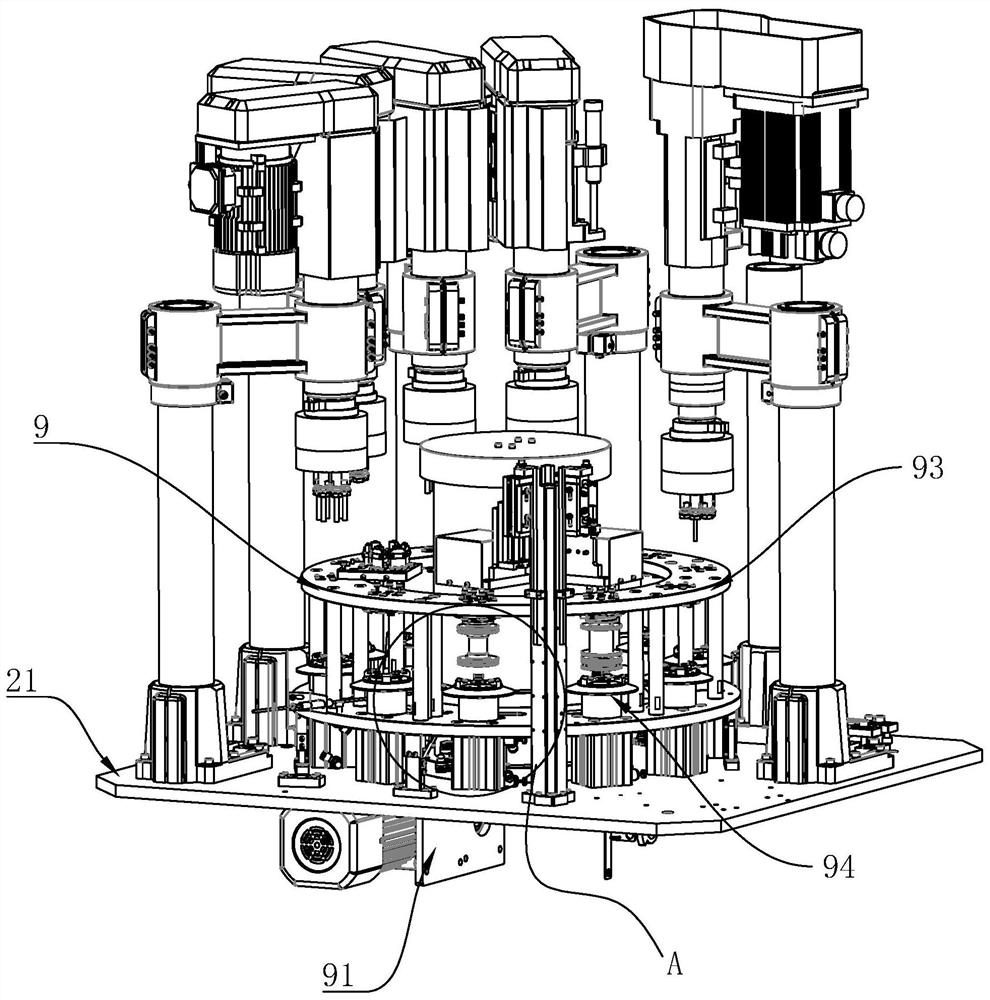

Workpiece drilling and tapping system

ActiveCN113927303ASolve automatic loading and unloadingImprove production and processing efficiencyOther manufacturing equipments/toolsRobot handWorkbench

The invention discloses a workpiece drilling and tapping system which comprises a first workbench. The workpiece drilling and tapping system is characterized in that a rotating disc output device is arranged in the center of the first workbench; a chamfering device, a drilling device, a tapping device and a deburring device are installed on the first workbench along the rotating disc output device; the drilling device, the chamfering device, the tapping device and the deburring device are correspondingly arranged above the rotating disc output device; a material conveying device is arranged on one side of the first workbench; and a mechanical arm used for feeding and discharging is arranged between the material conveying device and the first workbench. According to the workpiece drilling and tapping system provided by the invention, integrated operation of automatic feeding and discharging, chamfering, drilling, tapping and deburring of cylindrical flange pieces is achieved, double-station machining on one piece of equipment is achieved, and the production and machining efficiency is improved.

Owner:深圳市鸿富精研科技有限公司

Barrel beehive chamfering equipment for animal husbandry

PendingCN112475329ARealize chamferAchieve normal workFeeding apparatusTurning machinesAnimal scienceAgricultural science

The invention relates to chamfering equipment, in particular to barrel beehive chamfering equipment for animal husbandry. The barrel beehive chamfering equipment for animal husbandry can complete barrel beehive chamfering work without consuming large strength by workers, and meanwhile, can ensure that the chamfering strength of each time is the same, and can also fix a barrel beehive, so that thechamfering efficiency is improved. The barrel beehive chamfering equipment for animal husbandry comprises a bottom plate and a cutting mechanism, wherein the cutting mechanism is arranged at the top of the bottom plate. According to the barrel beehive chamfering equipment for animal husbandry, the cutting mechanism is arranged, the cutting mechanism is matched with a clamping and positioning mechanism, so that chamfering and clamping and positioning work of the barrel beehive can be realized; a pressing mechanism is arranged, so that a rotating block does not need to be manually pressed downwards by workers, and the chamfering efficiency of the barrel beehive is further improved; and a feeding and discharging mechanism is matched with a pushing mechanism, so that the work of automaticallypushing the barrel beehive to a designated position at intervals can be realized, and the placing time of the barrel beehive is effectively shortened.

Owner:李龙

Fatty steel rail edge polishing machine

PendingCN107178016ALarge swing angleImprove swing flexibilityRailway track constructionElectric machineryBall (bearing)

The invention discloses a fatty steel rail edge polishing machine, and belongs to the technical field of railway maintenance equipment. The fatty steel rail edge polishing machine comprises a rack. The fatty steel rail edge polishing machine is characterized by further comprising a vertical moving device and a horizontal feeding device, wherein the vertical moving device comprises a hanging rack, a ball bearing seat, a ball screw rod and a ball screw nut; a stepper motor and a vertical sliding block are arranged on the rack; the hanging rack is connected with the rack through the vertical sliding block in a sliding manner; the horizontal feeding device comprises a grinding wheel, a gear acceleration tank, a moving platform, a horizontal sliding block, a driving mechanism, a pulse electromotor and a ball screw rod pair; the output shaft of the gear acceleration tank is connected with the grinding wheel; the input shaft of the gear acceleration tank is connected with the driving mechanism; and the horizontal sliding block is connected with the hanging rack in a sliding manner. By adopting the fatty steel rail edge polishing machine, a fatty steel rail edge is polished horizontally, manual adjustment is not needed, different feeding amounts can be selected according to fatty steel rails of different thicknesses, one-time polishing is achieved, the grinding wheel can be moved up and down, any position at any height of the fatty steel rail edge can be polished, and the polishing efficiency and the polishing effects are improved.

Owner:西藏天仁科技发展有限公司

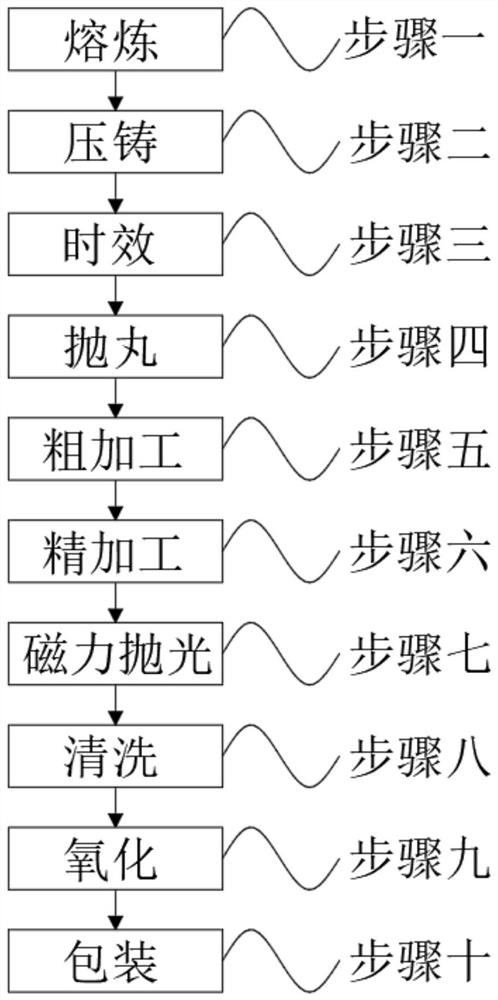

Ultra-precision machining process for aluminum alloy die-casting gearbox valve sleeve

PendingCN114227521ARealize chamferAchieve polishEdge grinding machinesPolishing machinesPolishingDie casting

The invention discloses an ultra-precision machining technology for an aluminum alloy die-casting gearbox valve sleeve. The ultra-precision machining technology comprises the following steps that firstly, smelting is conducted; step 2, die casting; step 3, aging; step 4, shot blasting; 5, rough machining; step 6, finish machining; seventhly, magnetic polishing is conducted; step 8, cleaning; step 9, oxidation; and step 10, packaging. The polishing machine has the beneficial effects that multiple effects of deburring, chamfering, polishing, cleaning, environmental protection and the like can be achieved; the grinding and polishing device is suitable for grinding and polishing nonmetal workpieces such as metal workpieces, hard plastic workpieces, ceramic workpieces and silicon wafers; irregular parts, hole-shaped parts, pipe-shaped parts, cracks and the like can be polished, polishing is free of dead angles, the ground workpieces are never deformed, the surfaces are never damaged, and the precision is never affected; customization time is short, processing speed is high, and operation is easy and convenient; variable frequency adjustment is achieved, various polishing requirements are met, and voltage, current, frequency and time can be monitored.

Owner:德阳上川科技有限公司

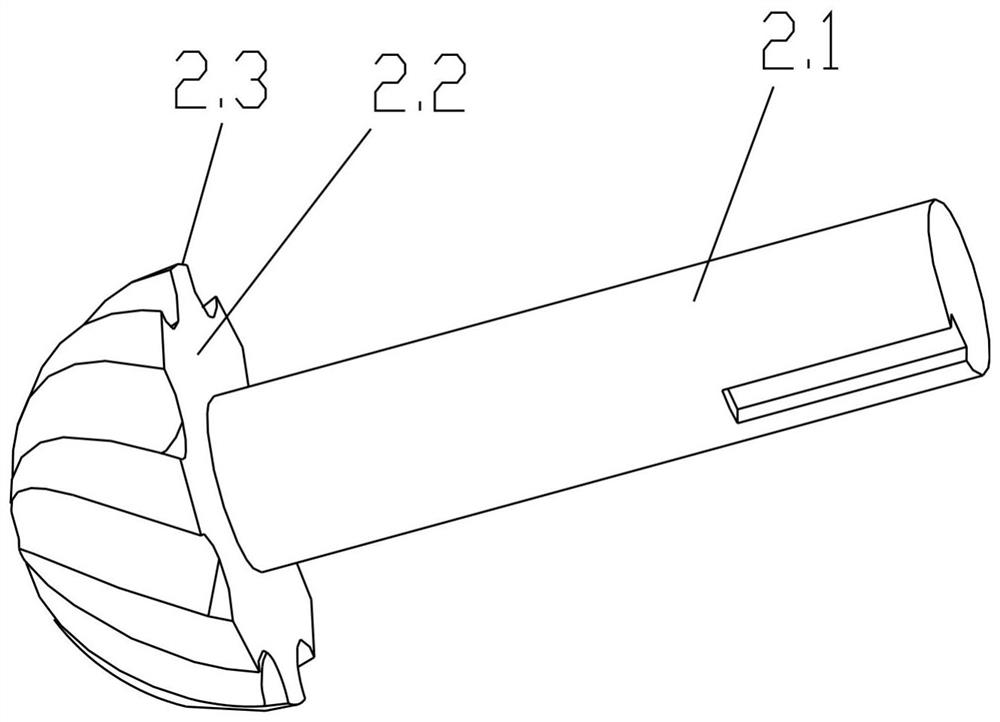

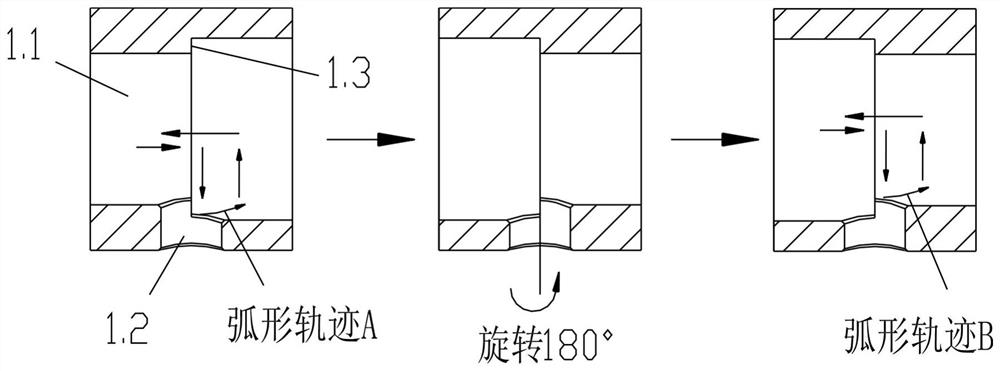

Spherical milling cutter for machining stepped hole chamfer and machining method for machining stepped hole chamfer

The invention discloses a spherical milling cutter for machining a stepped hole chamfer and a machining method for machining the stepped hole chamfer. According to the spherical milling cutter, a spherical cutter head is smaller than or equal to a half spherical surface, the diameter of a cutter handle is smaller than the outer diameter of the widest part of a maximum cutting edge, and the axis ofthe cutter handle is perpendicular to the end face of the spherical cutter head, so that a stepped hole can be chamfered. During machining, the axis of the spherical milling cutter is parallel to a center hole of a workpiece, the end face of the spherical cutter head can be attached to the interface due to the fact that the axis of the cutter handle is perpendicular to the end face of the spherical cutter head, the plane where the interface is located serves as a cutting feed starting point, and the inner wall face of the center hole can be prevented from being cut. Therefore, the stepped hole is chamfered through the feeding route, chamfering of the stepped hole can be accurately and automatically completed on machining equipment, manual polishing is not needed, labor intensity is reduced, and production efficiency is improved.

Owner:HONDA FOUNDRY (FOSHAN) CO LTD

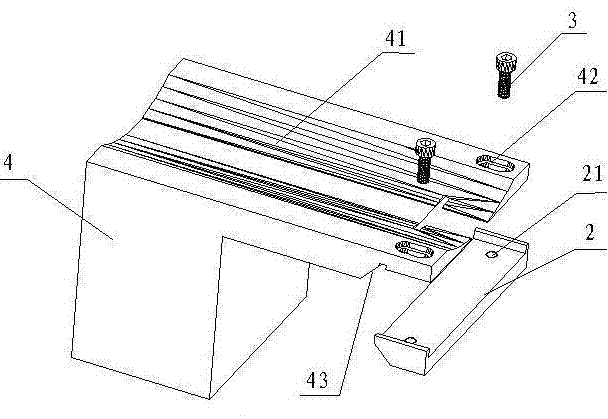

Chamfer jig for adjustable type surface grinder

ActiveCN102189451BIncrease profitRealize chamferEdge grinding machinesPlane surface grinding machinesStructural engineeringGrinding wheel

The invention discloses a chamfer jig for an adjustable type surface grinder. The jig is used in coordination with the surface grinder and is characterized by comprising a jig seat, an adjustable sliding block and a locking screw which is used for adjusting the position of the adjustable sliding block on the jig seat, wherein the upper surface of the jig seat is provided with a forming groove which is used for accommodating the lower bottom surface of a grinding wheel of the surface grinder; and a V-shaped groove of which the included angle is 90 DEG is formed between the jig seat and the adjustable sliding block, is vertical to the forming groove and is intersected with the forming groove in a communicated way. In the chamfer jig, a workpiece to be machined is put into the V-shaped groove, the right-angle edge of the workpiece is exposed out from the communicated position to the forming groove on the upper surface of the jig seat, and the exposed part is ground off by the grinding wheel, so that a chamfer is realized. The invention has the advantages that: only the bottom surface of the grinding wheel is required to be used, the grinding wheel for grinding an angle is not needed,and the chamfer jig can be used for machining the chamfer in a handheld way, and has high chamfer accuracy and high speed.

Owner:JOUDER PRECISION INDAL KUSN

A method of chamfering slabs during rolling by a rolling mill

ActiveCN104148407BRealize chamferAvoiding the disadvantages of slab fire-cutting and chamferingRare end control deviceEngineeringRolling mill

The invention discloses a method for achieving the chamfering purpose during rolling of a slab rolling mill. According to the method, the slab chamfering effect can be achieved by accurately controlling head and tail roller gaps during slab rolling, and therefore the defects of slab fire cutting chamfering are avoided, the purposes of preventing rolling defects and omitting the slab fire cutting chamfering procedure are achieved, and chamfering can be achieved on all rolling slabs. Due to the fact that the original slab fire cutting chamfering technology is long in consumed operation time, high in logistics difficulty, low in efficiency and high in cost, the normal rolling process is adopted in the method, the slab chamfering problem is solved very well, and the purpose and effect of slab fire cutting chamfering are achieved. The method is an innovation for rolling defect controlling of plates with moderate thicknesses, the slab fire cutting technology can be completely replaced by the method, the efficiency is high, and the method has substantive characters and progress and is novel, creative and practical. The method does not have a negative effect on the environment, and can be popularized in all moderate thickness plate enterprises at home and abroad.

Owner:BAOSHAN IRON & STEEL CO LTD

Carbon beam chamfering machine

PendingCN112621438ARealize chamferEdge grinding machinesGrinding drivesElectric machineryDrive motor

The invention relates to a carbon beam chamfering machine. The carbon beam chamfering machine comprises a base device and a grinding head device, wherein the base device comprises a frame base, an up-down driving mechanism, a carbon beam workbench and two sets of carbon beam fixing devices; the grinding head device comprises a grinding head frame, a horizontal driving mechanism and a grinding head assembly; the grinding head frame is connected with the up-down driving mechanism and can be installed on the frame base in an up-down moving manner; the grinding head assembly is connected with the horizontal driving mechanism and can be installed on the grinding head frame in a horizontal moving manner; the grinding head assembly comprises a grinding head support, a driving motor, a belt pulley and a grinding head; the grinding head support is connected to the grinding head frame in a horizontal sliding manner; the driving motor is installed on the grinding head support; the belt pulley is driven by the driving motor through belt transmission; and the grinding head is rotatably installed on the grinding head support and coaxially driven by the belt pulley. According to the carbon beam chamfering machine, a carbon beam can be ground through up-down feeding and left-right feeding of the grinding head, chamfering of the head and the tail of the carbon beam is achieved, the grinding precision is high, the efficiency is high, and the qualification rate is high.

Owner:上海欣庆机械有限公司

A carbon rod end chamfering device

ActiveCN109483361BAchieve clampingRealize chamferEdge grinding machinesGrinding drivesGraphite carbonHydraulic cylinder

The invention discloses a carbon rod end part chamfering device, and relates to the technical field of graphite carbon rod machining equipment. The carbon rod end part chamfering device comprises a base, the base is provided with a lower frame body, the lower frame body is slidably connected with an upper frame body, and a first motor, fixing rods and a lead screw are fixed to the inner side of the upper frame body; a first supporting plate is fixed to the top of the upper frame body, the first supporting plate is provided with a cylinder and a sliding block, and a first hydraulic cylinder isfixed to the top of the sliding block; a second supporting plate is connected to a telescopic rod of the first hydraulic cylinder, and a second motor, a support plate and a cylinder frame are sequentially arranged on the top of the second supporting plate; and a cylinder is slidably connected in the cylinder frame, a rotating shaft is fixed to the left side of the cylinder, a supporting base is arranged on the right side of the first supporting plate, the supporting base is fixed to the top of the upper frame body, a sand mill is installed on the supporting base, and clamping devices are symmetrically arranged on the inner side of the cylinder along the axis. The carbon rod end part chamfering device has a high carbon rod chamfering precision and is suitable for chamfering of carbon rods with different specifications.

Owner:亳州市亚珠新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com