Material strip treating device

A processing device and strip technology, applied in metal processing, etc., can solve the problems of low production efficiency, unstable product quality, harmful chemicals, etc., and achieve the effect of high work efficiency, good product precision and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

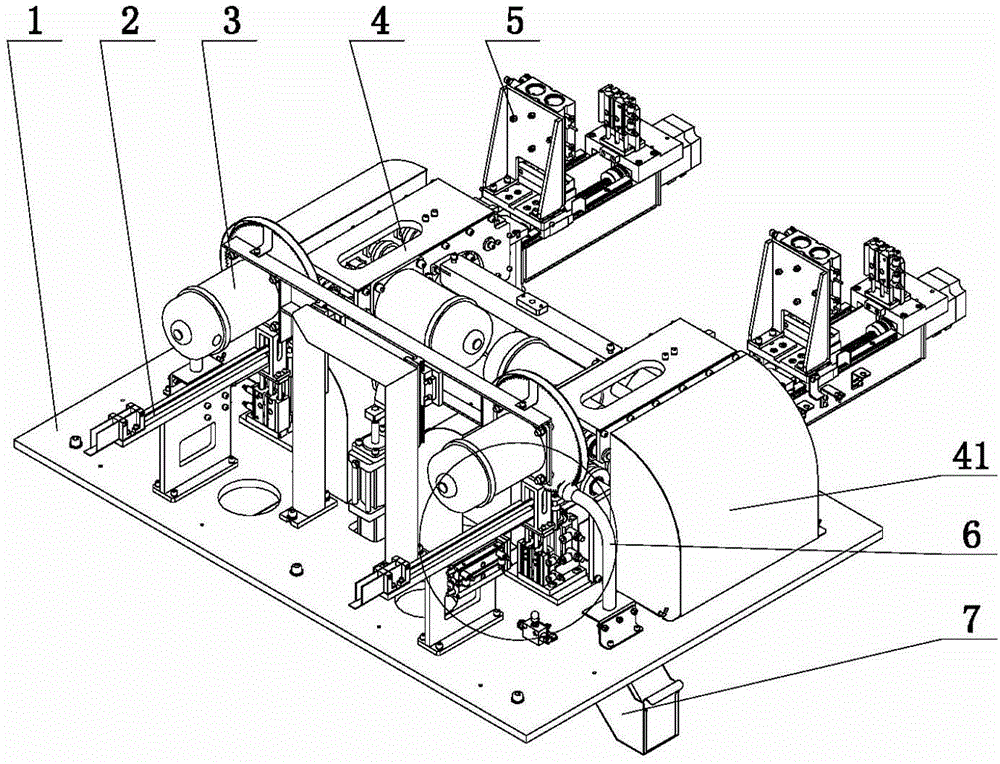

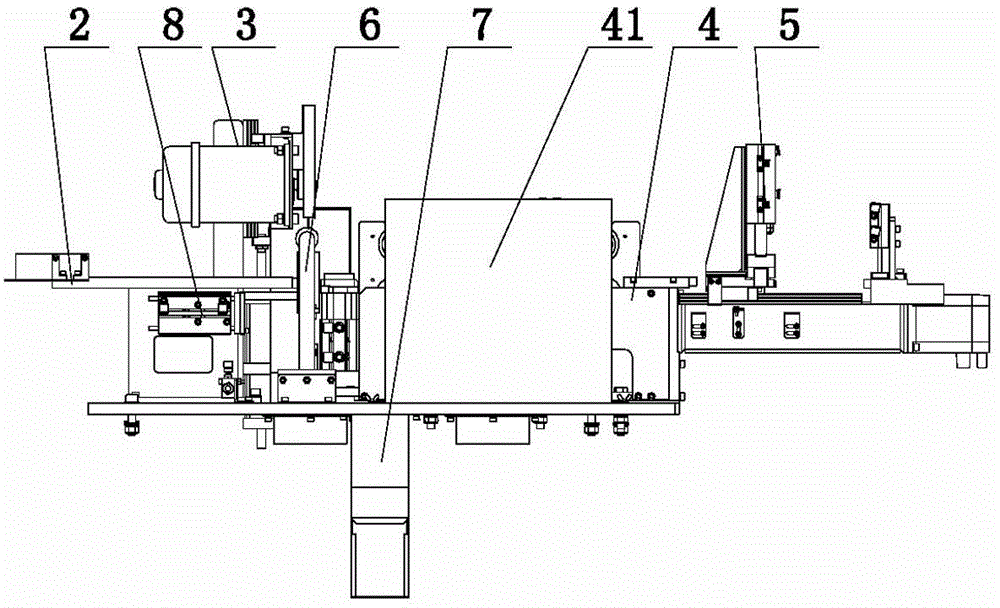

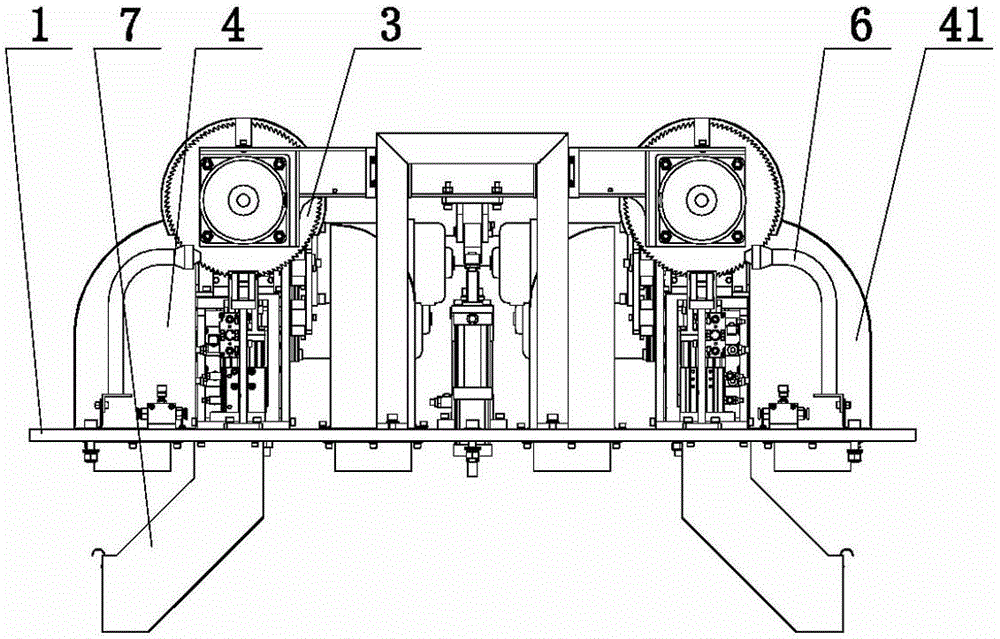

[0033] The present invention includes a machine base 1, which is provided with a conveying mechanism 5, a chamfering mechanism 4, and a cutting mechanism 3 which are sequentially connected, and is characterized in that: the conveying mechanism 5 includes a conveying frame 54 in which the conveying frame 54 is arranged A conveying servo motor 57 with a conveying screw 58 is provided with a conveying moving frame 51 on the conveying nut 59 of the conveying screw 58, a conveying backing plate 53 is provided on the conveying moving frame 51, and the conveying moving frame 51 corresponds to the conveying backing plate 53 is provided with a conveying cylinder pressing plate 52; the chamfering mechanism 4 includes a chamfering frame 47, the chamfering frame 47 is provided with a chamfered track 412 corresponding to the conveying pad 53, corresponding to the chamfered track 412 There are at least two sets of guide wheels 42, between which are provided an upper chamfering knife 44 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com