Automatic steel rail lip polishing method

A fat edge and rail technology, applied in the field of automatic grinding of the fat edge of the rail, can solve the problems of the larger size of the equipment, the unstable speed of the grinding wheel, and the inability to maintain the transmission ratio, so as to improve the swing flexibility, improve the overall effect, and improve the grinding effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A method for automatically grinding rail fat edges, comprising the following steps:

[0068] a. Place the rail fat edge automatic grinding machine on the rail;

[0069] b. Drive the automatic rail fat edge grinding machine to move longitudinally along the rail through the running device of the rail fat edge automatic grinding machine, and the grinding wheel 13 performs longitudinal grinding on the rail fat edge, and simultaneously drives the grinding wheel 13 through the horizontal feeding device of the rail fat edge automatic grinding machine Transverse grinding of rail fat edge;

[0070] c. Drive the grinding wheel 13 to move up and down through the up and down moving device of the rail fat edge automatic grinding machine to grind any position in the height direction of the rail fat edge.

[0071]This embodiment is the most basic implementation mode, "a, the rail fat edge automatic grinding machine is placed on the rail; b, the rail fat edge automatic grinding machin...

Embodiment 2

[0073] A method for automatically grinding rail fat edges, comprising the following steps:

[0074] a. Place the rail fat edge automatic grinding machine on the rail;

[0075] b. Drive the automatic rail fat edge grinding machine to move longitudinally along the rail through the running device of the rail fat edge automatic grinding machine, and the grinding wheel 13 performs longitudinal grinding on the rail fat edge, and simultaneously drives the grinding wheel 13 through the horizontal feeding device of the rail fat edge automatic grinding machine Transverse grinding of rail fat edge;

[0076] c. Drive the grinding wheel 13 to move up and down through the up and down moving device of the rail fat edge automatic grinding machine to grind any position in the height direction of the rail fat edge.

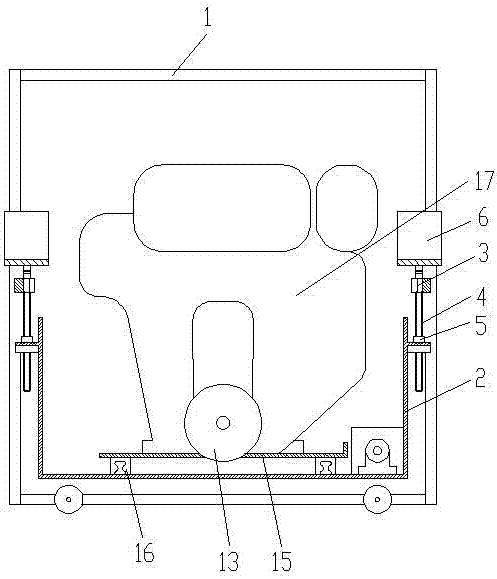

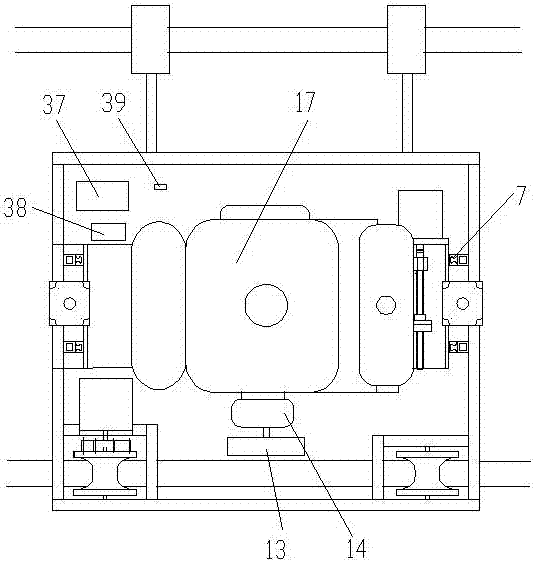

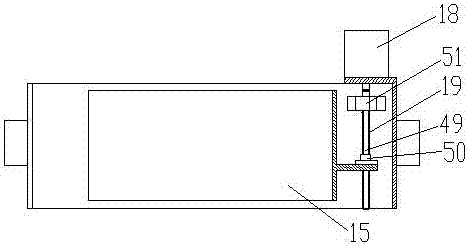

[0077] The rail fat edge automatic grinding machine includes a frame 1, an up and down moving device, a running device and a horizontal feeding device; the up and down moving devi...

Embodiment 3

[0080] A method for automatically grinding rail fat edges, comprising the following steps:

[0081] a. Place the rail fat edge automatic grinding machine on the rail;

[0082] b. Drive the automatic rail fat edge grinding machine to move longitudinally along the rail through the running device of the rail fat edge automatic grinding machine, and the grinding wheel 13 performs longitudinal grinding on the rail fat edge, and simultaneously drives the grinding wheel 13 through the horizontal feeding device of the rail fat edge automatic grinding machine Transverse grinding of rail fat edge;

[0083] c. Drive the grinding wheel 13 to move up and down through the up and down moving device of the rail fat edge automatic grinding machine to grind any position in the height direction of the rail fat edge.

[0084] The rail fat edge automatic grinding machine includes a frame 1, an up and down moving device, a running device and a horizontal feeding device; the up and down moving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com