Hand-operated rotary disc brush driving device

A technology of driving device and manual rotation, which is applied in the direction of grinding driving device, parts of grinding machine tools, metal processing equipment, etc. It can solve the problems of high labor intensity, low transmission efficiency, and inability to adjust the rotation speed, etc., and achieve reduction The degree of labor, the improvement of work efficiency, and the effect of ensuring the rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

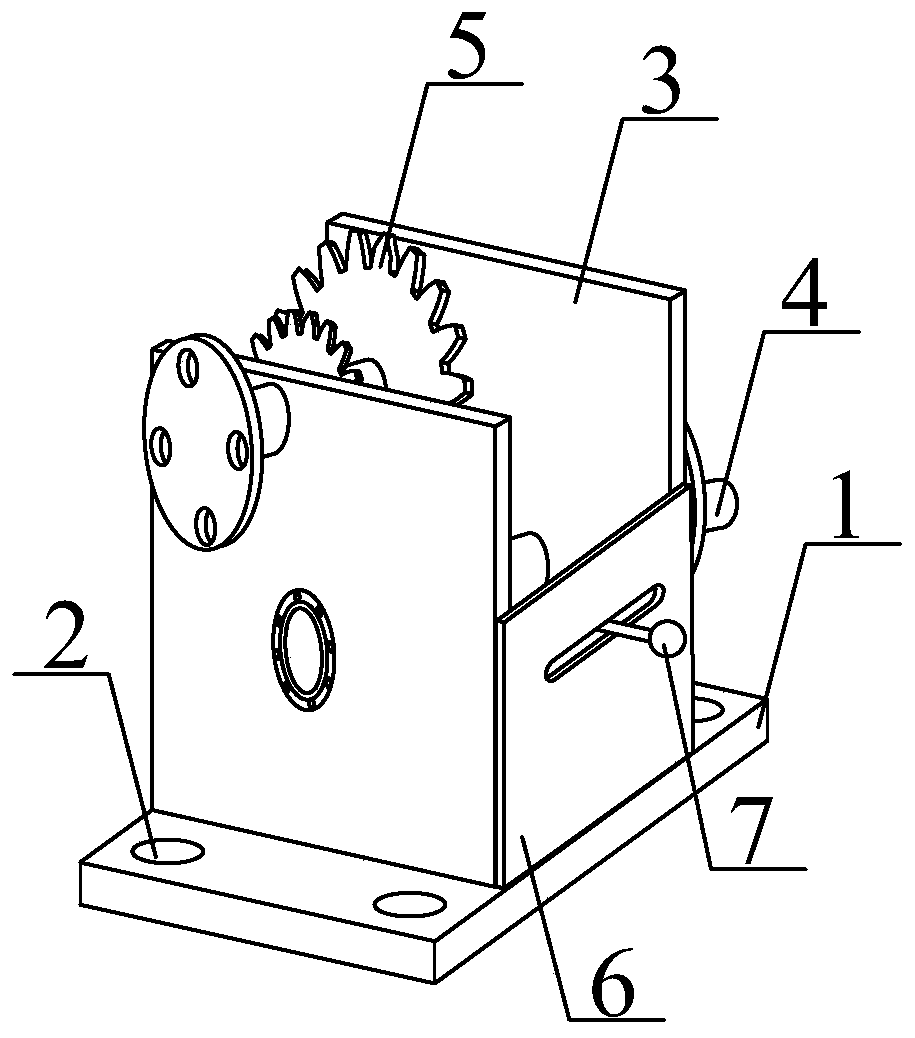

[0022] as attached figure 1 To attach Figure 4 shown

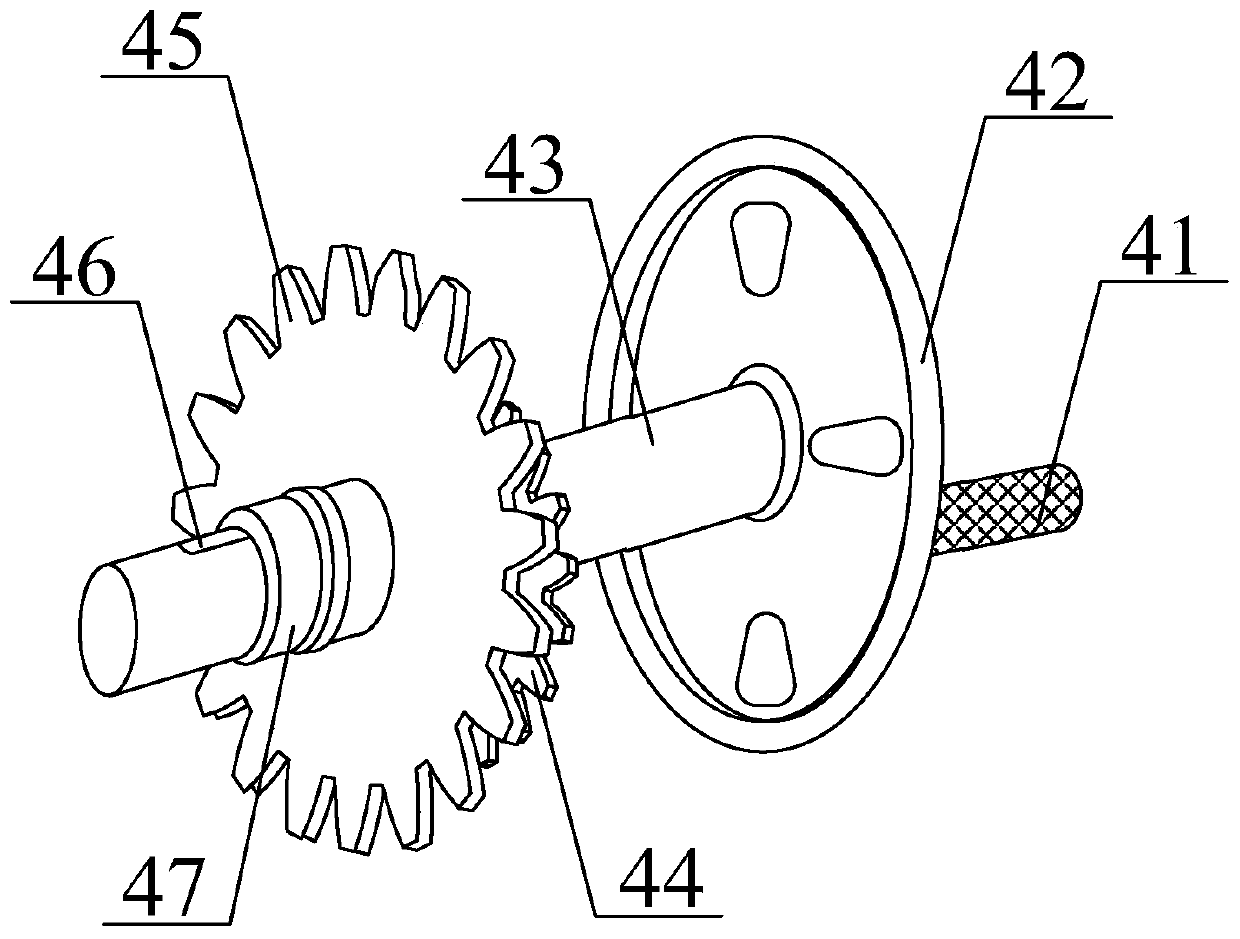

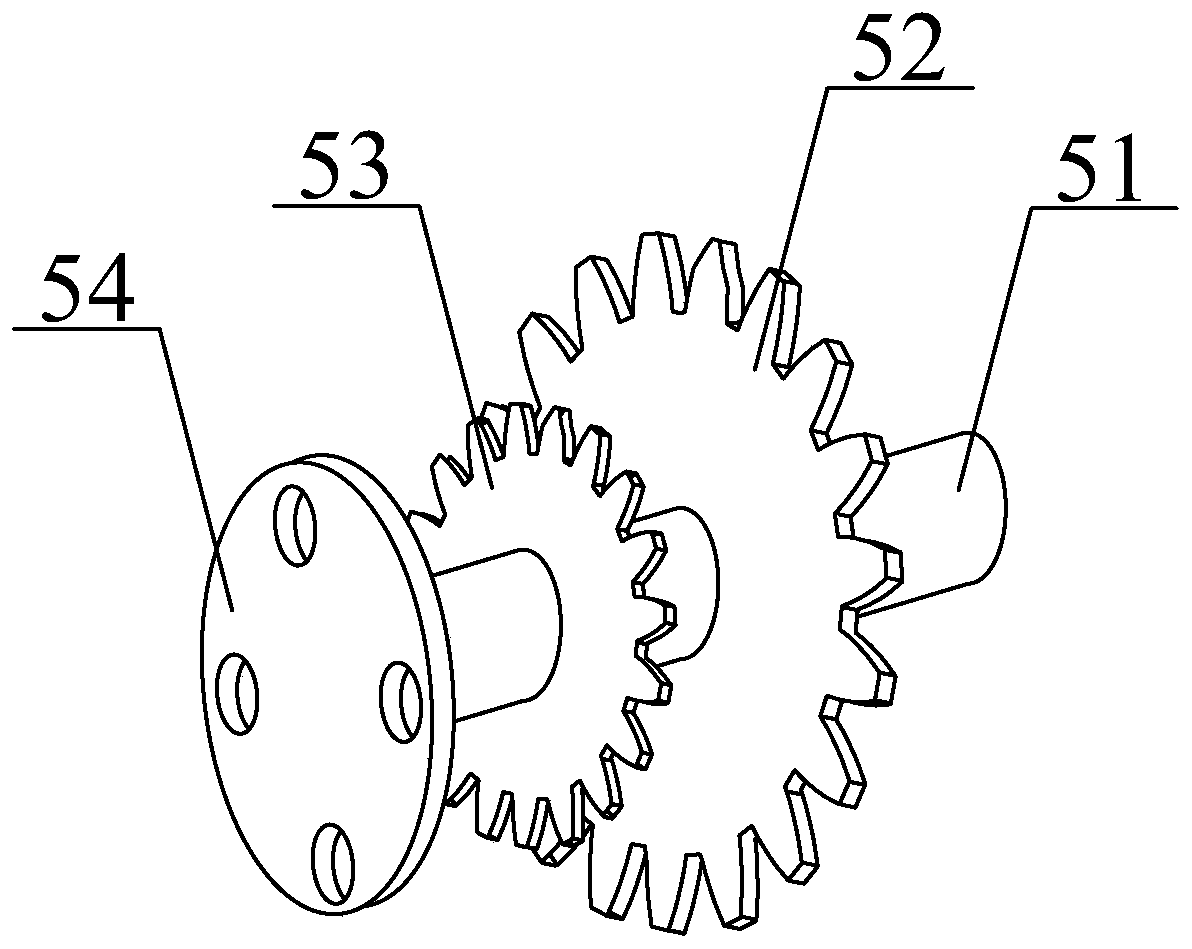

[0023] see figure 1 , a hand-operated rotary disc brush drive device, including a base 1, a mounting hole 2, a mounting plate 3, a hand-operated drive mechanism 4, a drive device 5, a side vertical plate 6 and a speed change mechanism 7, and the base 1 is arranged in a rectangular shape ; 4 mounting holes 2 are used, which are set at the four corners of the base 1 respectively; 2 mounting plates 3 are used, which are arranged on both sides of the base 1 and welded vertically with the base 1; the hand drive mechanism 4 is flexibly connected with the mounting plate 3 ; The driving device 5 is movably connected with the mounting plate 3, and is meshed with the hand drive mechanism 4; the side vertical plate 6 is welded vertically with the base 1 and the mounting plate 3 respectively; on axis 43.

[0024] In the present invention, the upper end of the side vertical plate 6 is provided with a double round head through groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com