Automatic rotor chamfering machine

A technology of chamfering machine and rotor, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of high work intensity, low work efficiency, unstable quality, etc., and achieve the effect of reducing labor and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

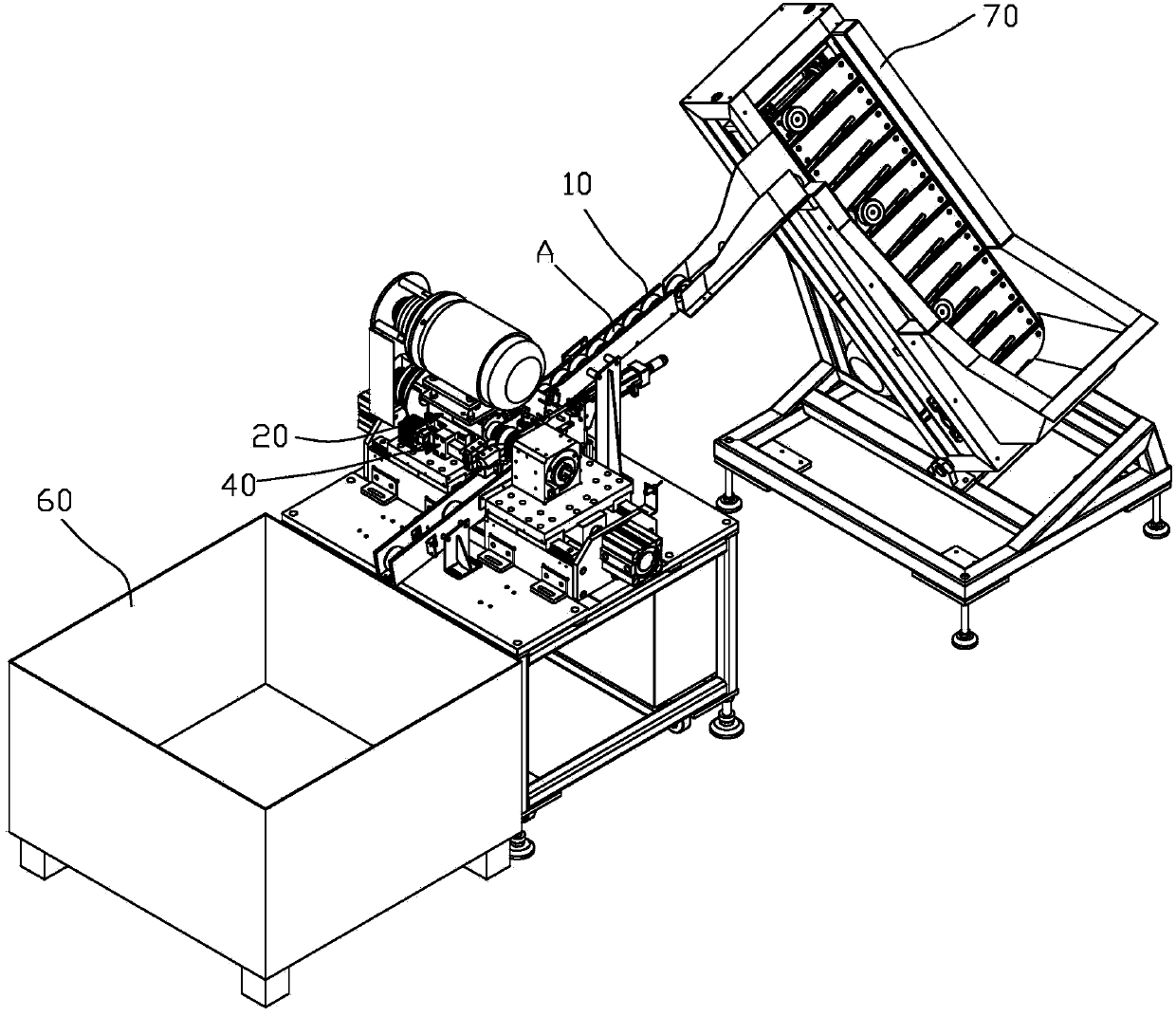

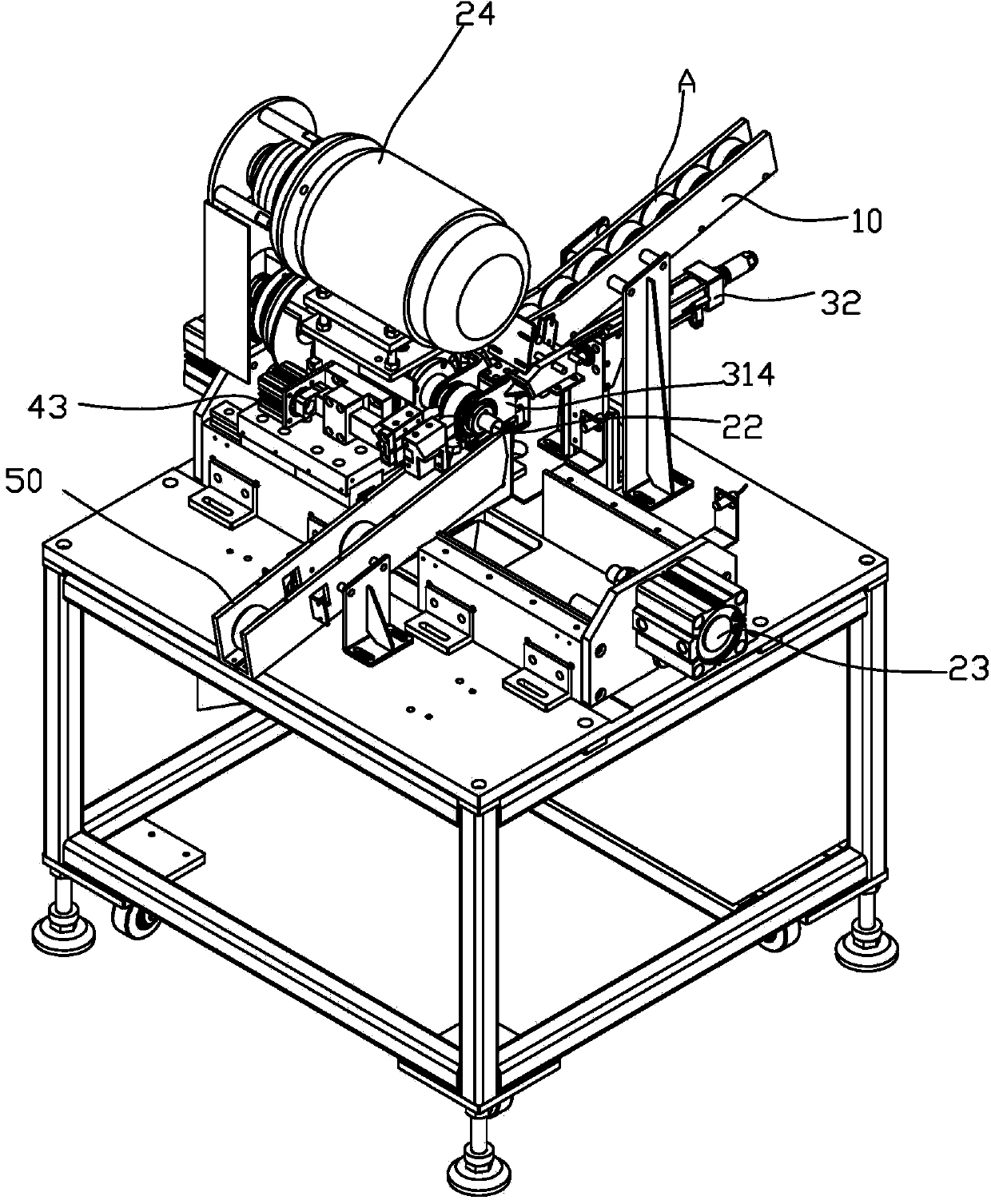

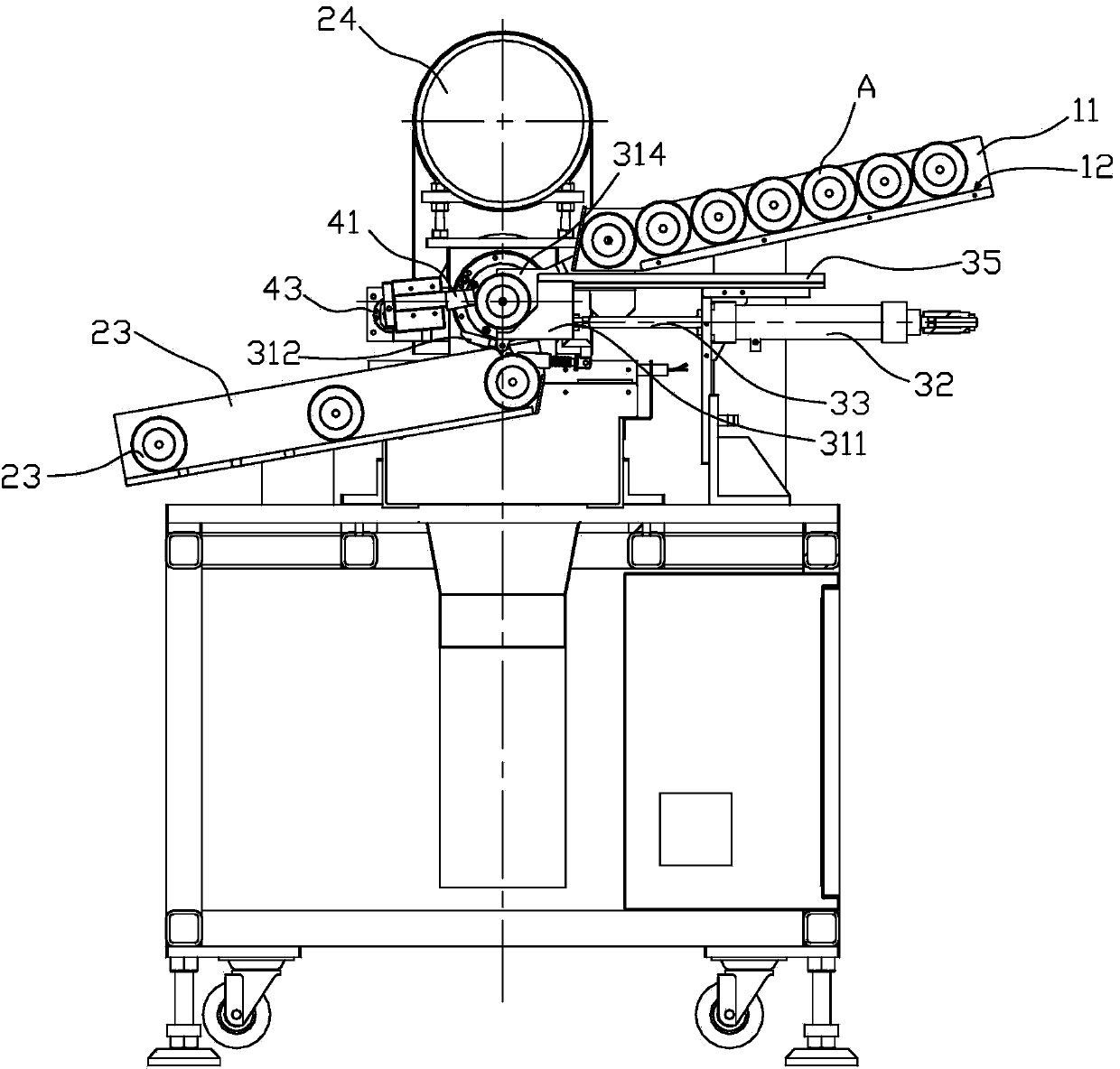

[0011] An automatic rotor chamfering machine, including a guide groove 10 arranged obliquely from top to bottom for the rolling guide of the rotor A, the lower end of the guide groove 10 is connected with a transfer mechanism 30, and the side of the transfer mechanism 30 There is a jig 20 that clamps the rotor A and drives it to rotate. The transfer mechanism 30 includes a U-shaped or V-shaped bayonet 31 that supports the rotor A, and a blanking port and a jig for driving the bayonet 31 in the guide groove 10 20, a cutting tool 40 for chamfering the rotor A is set beside the fixture 20. like figure 2 As shown, one end of the guide groove 10 is higher and the other end is lower, the high end of the guide groove 10 is connected to the automatic feeding device of the rotor, and the lower end of the feeding port corresponds to the position of the bayonet 31, ensuring that the rotor A can move from the guide groove 10 The blanking mouth of the roll rolls out and falls in the bayo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com