Polisher capable of adjusting polishing height of lipping of rail head

An adjustable grinding machine technology, applied in the direction of track, laying track, track maintenance, etc., can solve the problem that the relative position of the grinding wheel and the rail fat edge cannot be adjusted up and down, the overall grinding effect of the rail fat edge cannot be guaranteed, and the grinding of the rail fat edge cannot be guaranteed. Overall effect and other issues, to achieve the effect of improving swing flexibility, improving overall effect, and preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

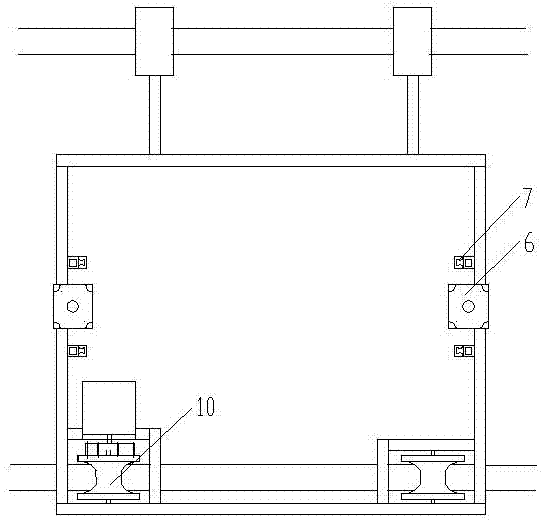

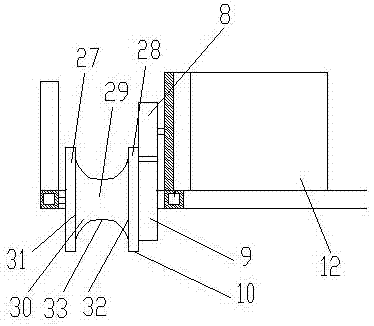

[0046] A grinding machine that can adjust the grinding height of the fat edge of the rail, including a frame 1, and also includes a vertical moving device and a walking device, and the vertical moving device includes a hanger 2, a ball bearing seat 3, a ball screw 4 and a ball mounted on a The ball nut 5 on the screw rod 4, the frame 1 is provided with a stepping motor 6 and an upper and lower slider 7, the hanger 2 is slidably connected with the frame 1 through the upper and lower sliders 7, the motor shaft of the stepping motor 6 and the ball bearing The seat 3 is connected, one end of the ball screw 4 is connected with the ball bearing seat 3, and the other end runs through the hanger 2, and the hanger 2 is connected with the ball screw 4 through the ball nut 5; Driven gear 9, travel wheel 10, roller 11 and the motor 12 that is arranged on the frame 1, drive gear 8 is connected with the motor shaft of motor 12, and driven gear 9 and drive gear 8 pass through gear engagement ...

Embodiment 2

[0049] A grinding machine that can adjust the grinding height of the fat edge of the rail, including a frame 1, and also includes a vertical moving device and a walking device, and the vertical moving device includes a hanger 2, a ball bearing seat 3, a ball screw 4 and a ball mounted on a The ball nut 5 on the screw rod 4, the frame 1 is provided with a stepping motor 6 and an upper and lower slider 7, the hanger 2 is slidably connected with the frame 1 through the upper and lower sliders 7, the motor shaft of the stepping motor 6 and the ball bearing The seat 3 is connected, one end of the ball screw 4 is connected with the ball bearing seat 3, and the other end runs through the hanger 2, and the hanger 2 is connected with the ball screw 4 through the ball nut 5; Driven gear 9, travel wheel 10, roller 11 and the motor 12 that is arranged on the frame 1, drive gear 8 is connected with the motor shaft of motor 12, and driven gear 9 and drive gear 8 pass through gear engagement ...

Embodiment 3

[0057] A grinding machine that can adjust the grinding height of the fat edge of the rail, including a frame 1, and also includes a vertical moving device and a walking device, and the vertical moving device includes a hanger 2, a ball bearing seat 3, a ball screw 4 and a ball mounted on a The ball nut 5 on the screw rod 4, the frame 1 is provided with a stepping motor 6 and an upper and lower slider 7, the hanger 2 is slidably connected with the frame 1 through the upper and lower sliders 7, the motor shaft of the stepping motor 6 and the ball bearing The seat 3 is connected, one end of the ball screw 4 is connected with the ball bearing seat 3, and the other end runs through the hanger 2, and the hanger 2 is connected with the ball screw 4 through the ball nut 5; Driven gear 9, travel wheel 10, roller 11 and the motor 12 that is arranged on the frame 1, drive gear 8 is connected with the motor shaft of motor 12, and driven gear 9 and drive gear 8 pass through gear engagement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com