Cutting machine

A cutting machine and cutting tool technology, applied in the direction of rotary cutting tools, multi-purpose machinery, metal processing, etc., can solve the problems of unsightly overall appearance, low production efficiency, high production cost, etc., and achieve beautiful chamfering quality and high yield rate , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate the understanding of those skilled in the art, the working principle of the present invention will be further described in detail below with reference to the drawings and embodiments.

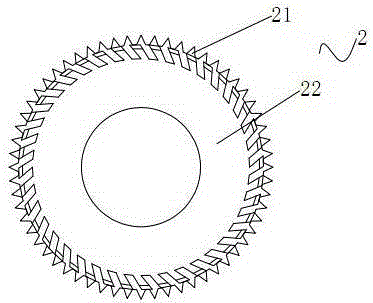

[0014] like Figure 2-4 As shown, the cutting machine disclosed in this embodiment is mainly used for cutting and chamfering the round wooden strips or round plastic sticks to be cut into several sections. The cutting machine includes a frame 1 , a cutting tool 2 and a feeding mechanism 3 arranged on the frame 1 for transferring products 10 to be cut. Wherein, the frame 1 is also provided with a rotating main shaft 4, the cutting tool 2 is installed on the rotating main shaft 4, the rotating main shaft 4 is connected with the motor 5, and is driven to rotate by the motor 5, and the rotating main shaft 4 drives the cutting tool 2 to rotate; the cutting tool 2 includes a saw blade 21 in the middle and chamfering blades 22 on both sides of the saw blade 21, the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com