Method for machining forming hole of annular feed forming mould and reamer

A processing method and forming ring technology, applied in metal processing equipment, drilling/drilling equipment, drill repairing, etc., can solve problems such as difficult to remove burrs, rough holes, irregular shapes, etc., and improve processing efficiency , Remove orifice burrs, the effect of small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples do not constitute a limitation to the present invention.

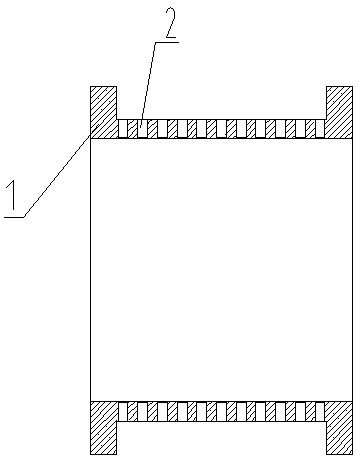

[0012] see figure 1 , the present invention a kind of processing method of feed forming ring mold forming hole comprises the following steps: first drill the center hole at the center position of the inner wall forming hole 2 of the ring mold body 1 with the center drill, then use the twist drill to drill the center hole at the position of the center hole by the ring Roughly drill the forming hole 2 from the inner wall of the mold body 1 to the outer wall of the annular mold body 1, then use the forming hole reaming drill to ream the hole, and chamfer the hole to remove the burr from the hole.

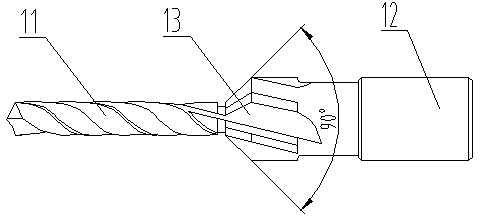

[0013] see figure 2 The forming hole reaming drill of the present invention comprises a drill bit 11 and a drill shank 12. There is also a conical surface countersink 13 between the drill b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com