Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Realize automatic forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

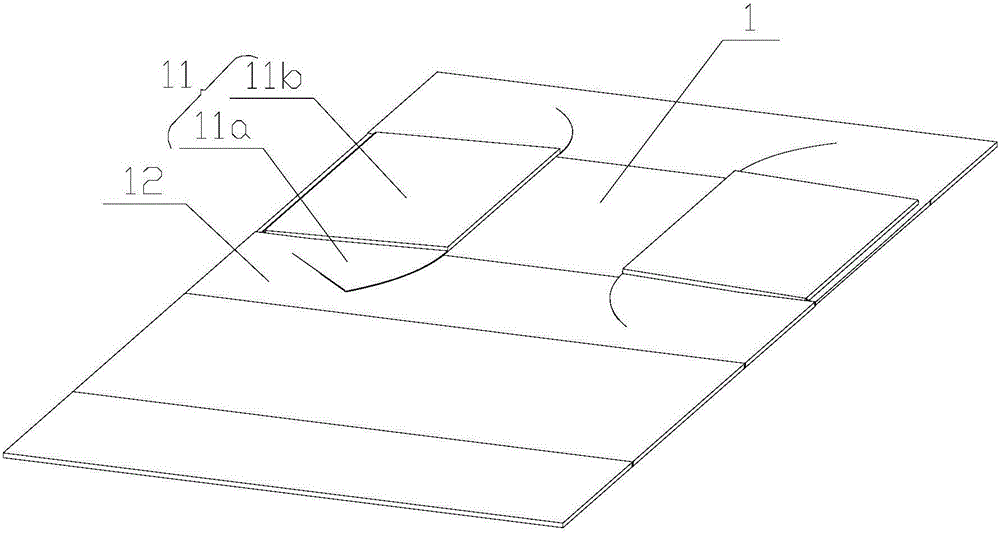

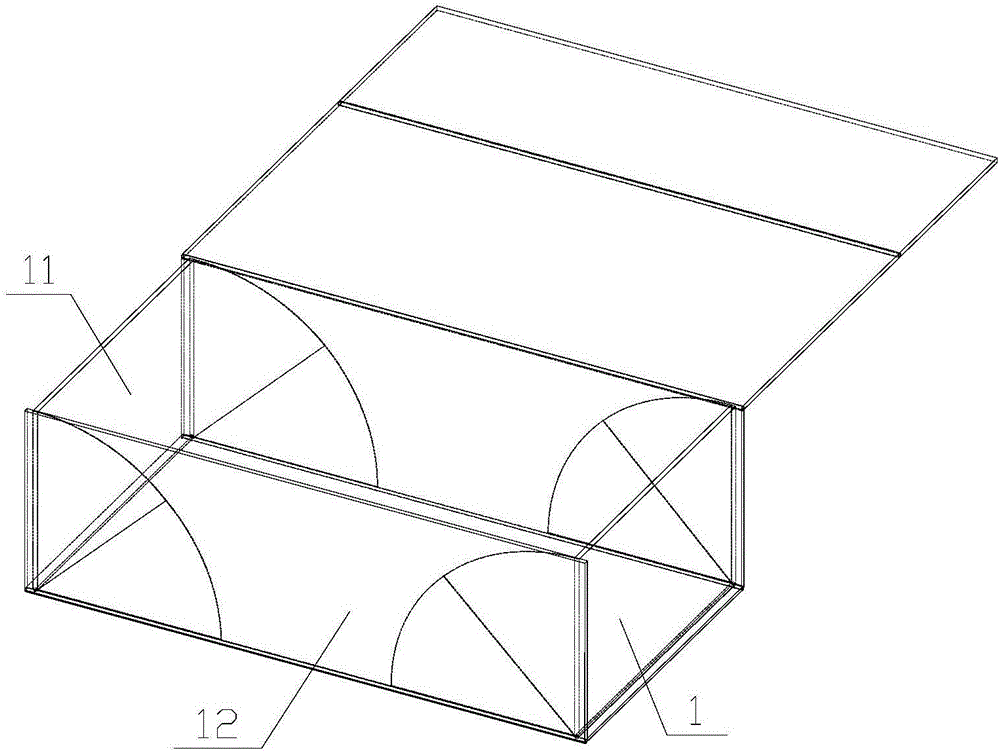

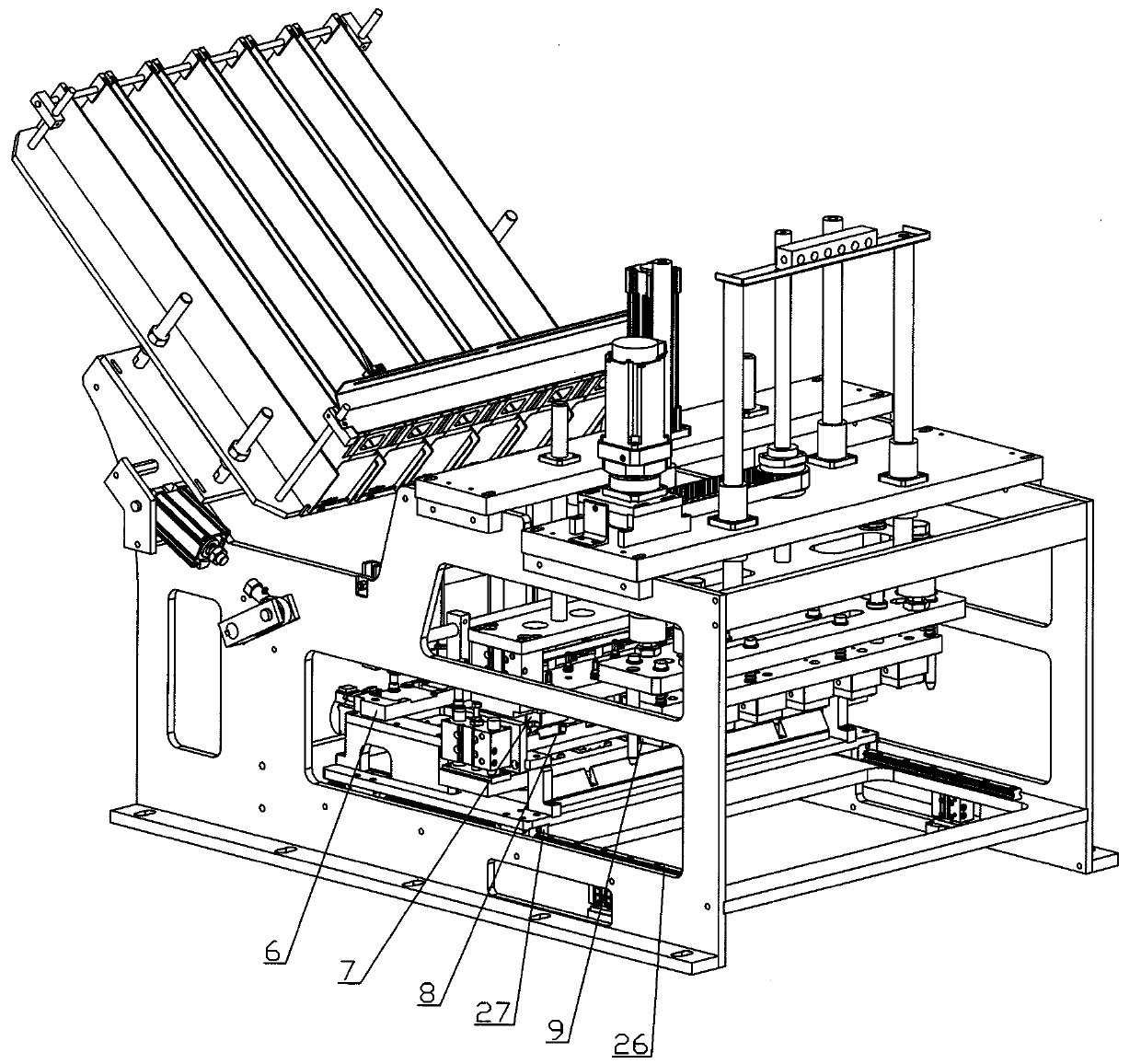

Carton folding machine

ActiveCN105128399ARealize folding box formingAchieve interconnectionBox making operationsPaper-makingMolding machineCarton

The invention provides a carton folding machine. The carton folding machine comprises a bottom board, a bracket, a paperboard feeding mechanism, a supporting mechanism, a compressing mechanism, an edge leftwards and rightwards folding mechanism, a forming mechanism, a carton push-out mechanism, an edge forwards and backwards folding mechanism and an edge forwards and backwards pressing mechanism, wherein the bracket is used for supporting the bottom of the bottom board which is provided with a forming cavity. The carton folding machine is provided with the forming cavity of the same structure as a formed package carton, the paperboard with folding lines is placed in the forming cavity, and then the bottom board of the package carton is downwards pressed to the bottom of the forming cavity and moves downwards so as to drive side boards of the package carton to be erected, so that the package carton is formed in a folded manner. According to the carton folding machine, the package carton is formed in the folded manner based on the stamping principle, and a new method is provided for folded molding of the package carton.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD

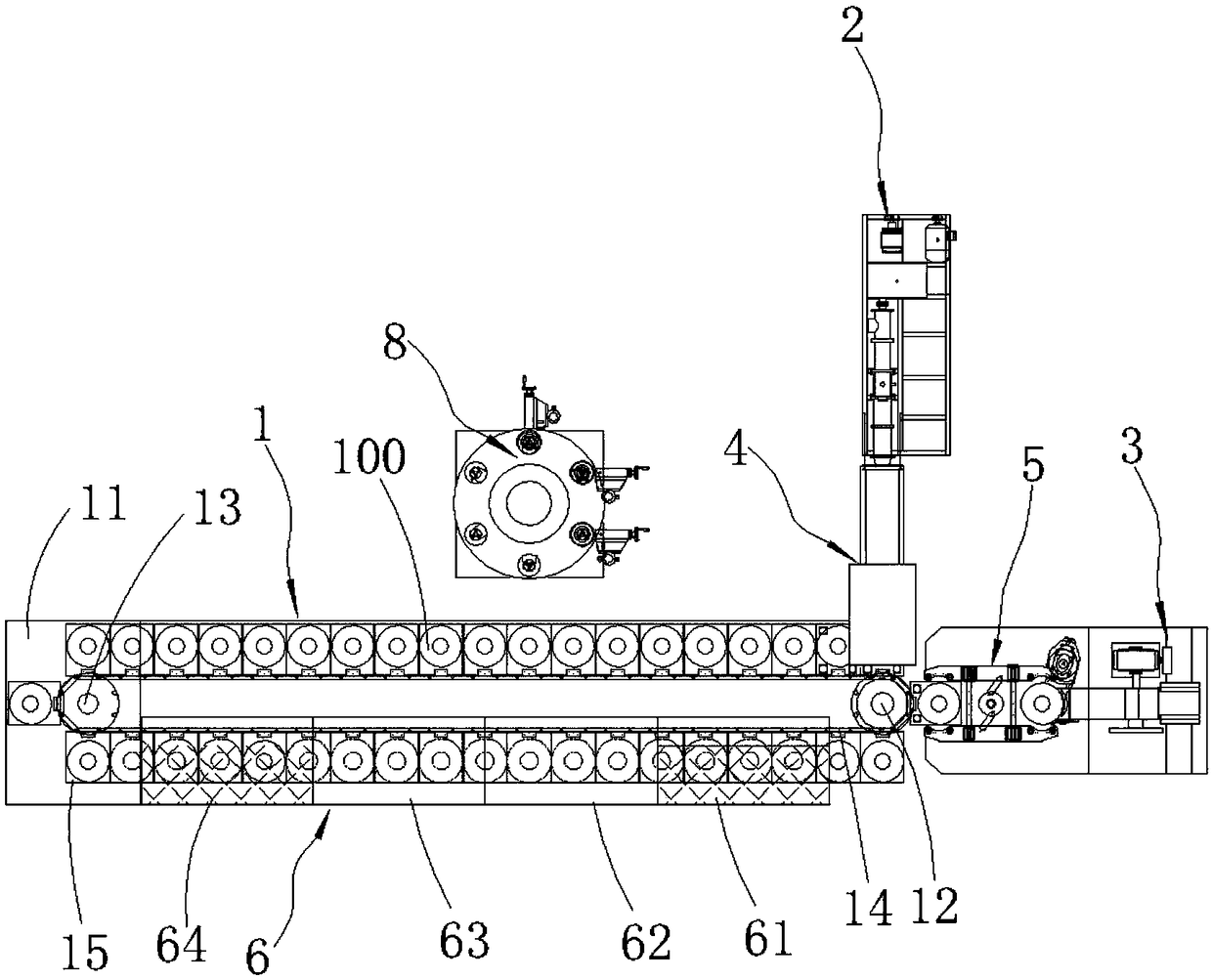

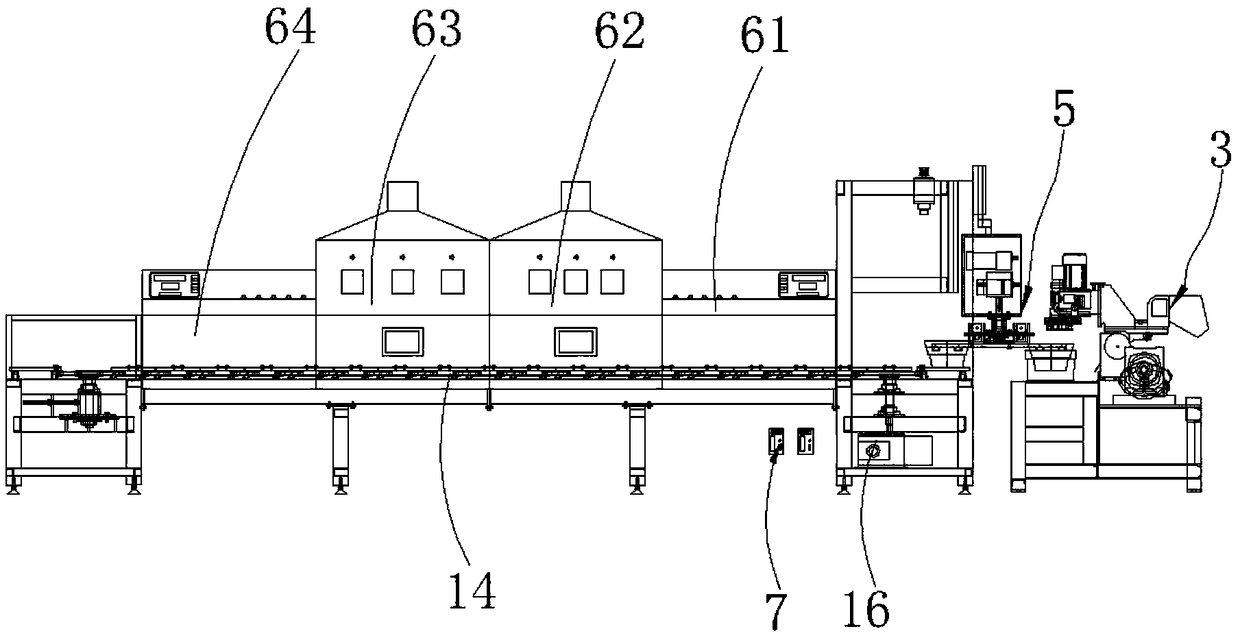

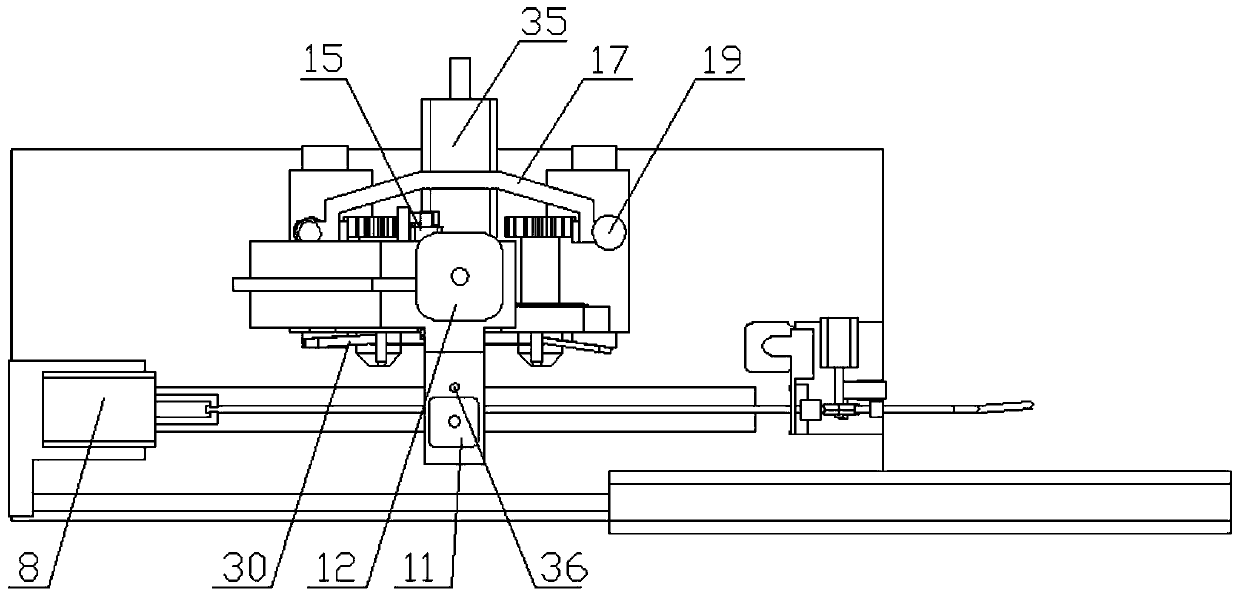

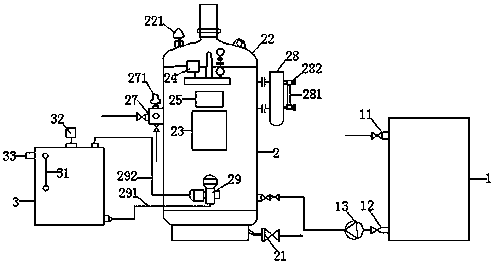

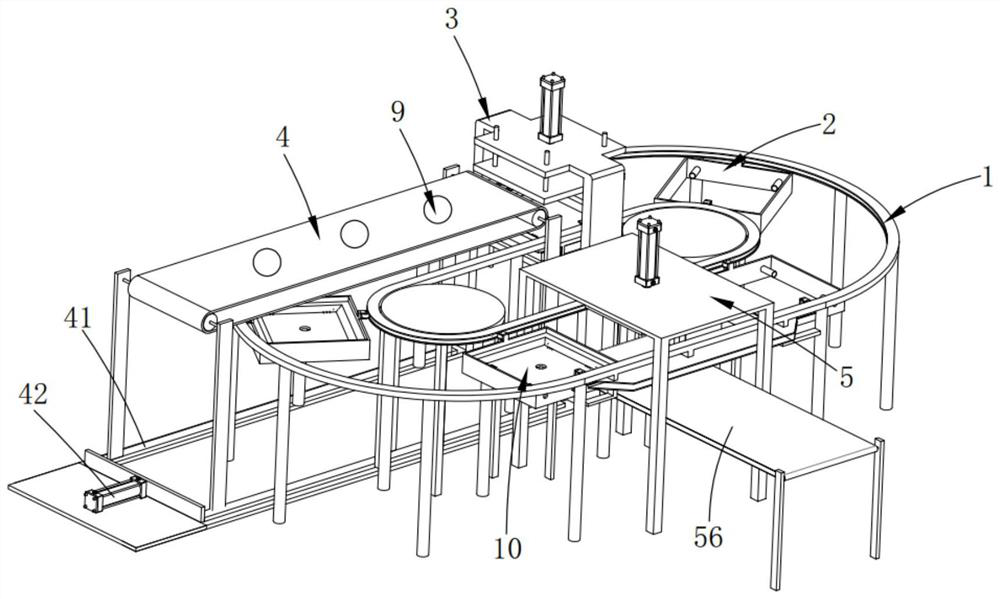

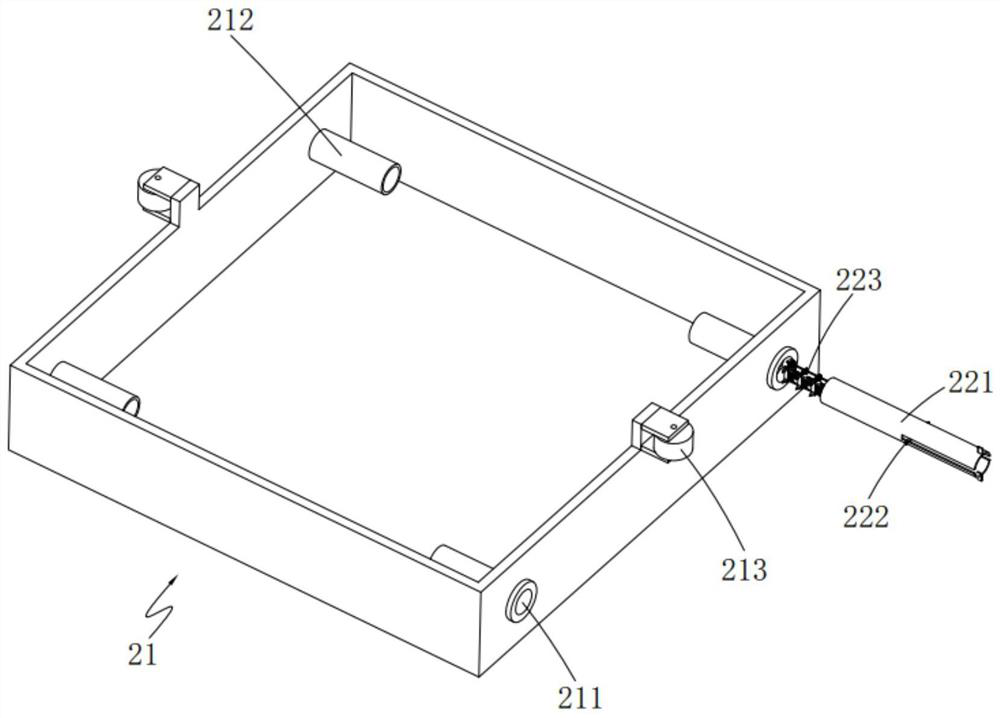

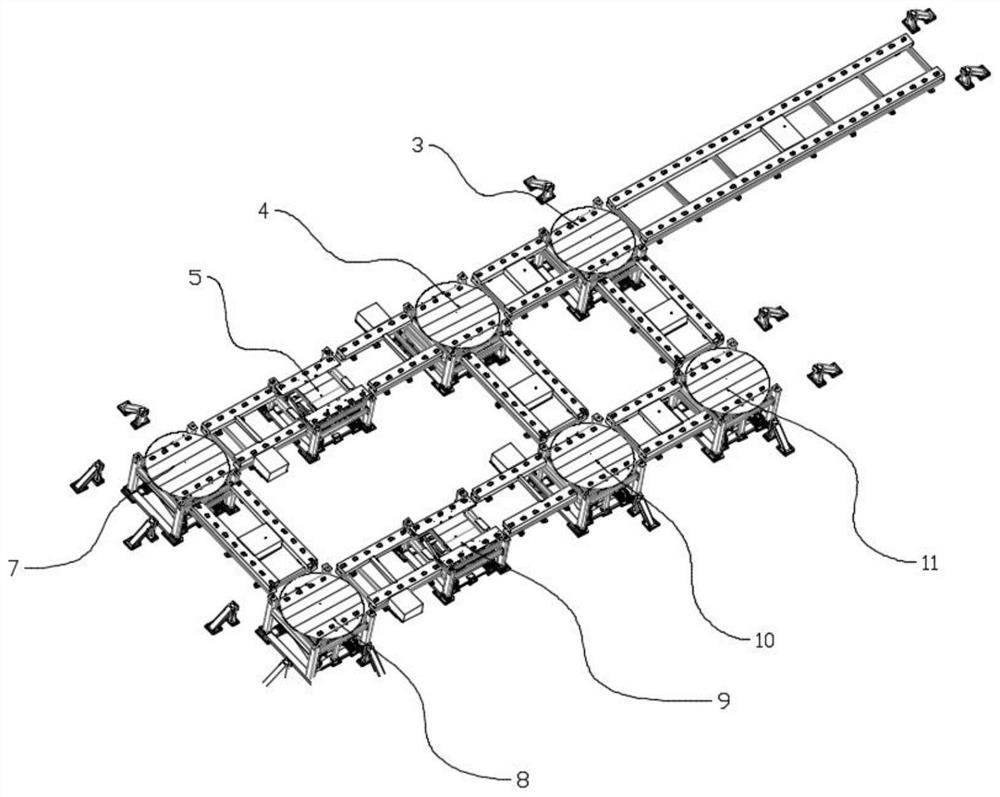

Ceramic microwave automatic forming line and ceramic forming method

InactiveCN108608567AAvoid crackingReduce labor costsCeramic shaping plantsFeeding arrangmentsProduction lineMicrowave

The invention relates to the field of ceramic microwave automatic forming lines and ceramic forming methods, in particular to a ceramic microwave automatic forming line and a ceramic forming method. The ceramic microwave automatic forming line and the ceramic forming method are characterized by comprising a circulated conveying line, an automatic pugging machine and an automatic forming machine, the circulated conveying line is sequentially provided with an automatic mud putting machine, an automatic mold clamping machine and a microwave drying box, the automatic pugging machine is connected with the circulated conveying line through the automatic mud putting machine, and the automatic forming machine is connected with the circulated conveying line through the automatic mold clamping machine. Manual transferring labor is not needed for joining parts between equipment of the ceramic microwave automatic forming line, the automatic degree is high, the production efficiency is high, and the space occupied by the equipment is small; by means of the ceramic forming method, the labor cost is saved, the operation accuracy is high, and the finished product rate is improved; and compared with a traditional drying manner, the microwave drying manner is good in drying uniformity, a blank body is not prone to cracking, the drying time is short, and the energy consumption is low.

Owner:福建省德化博龙陶瓷有限公司

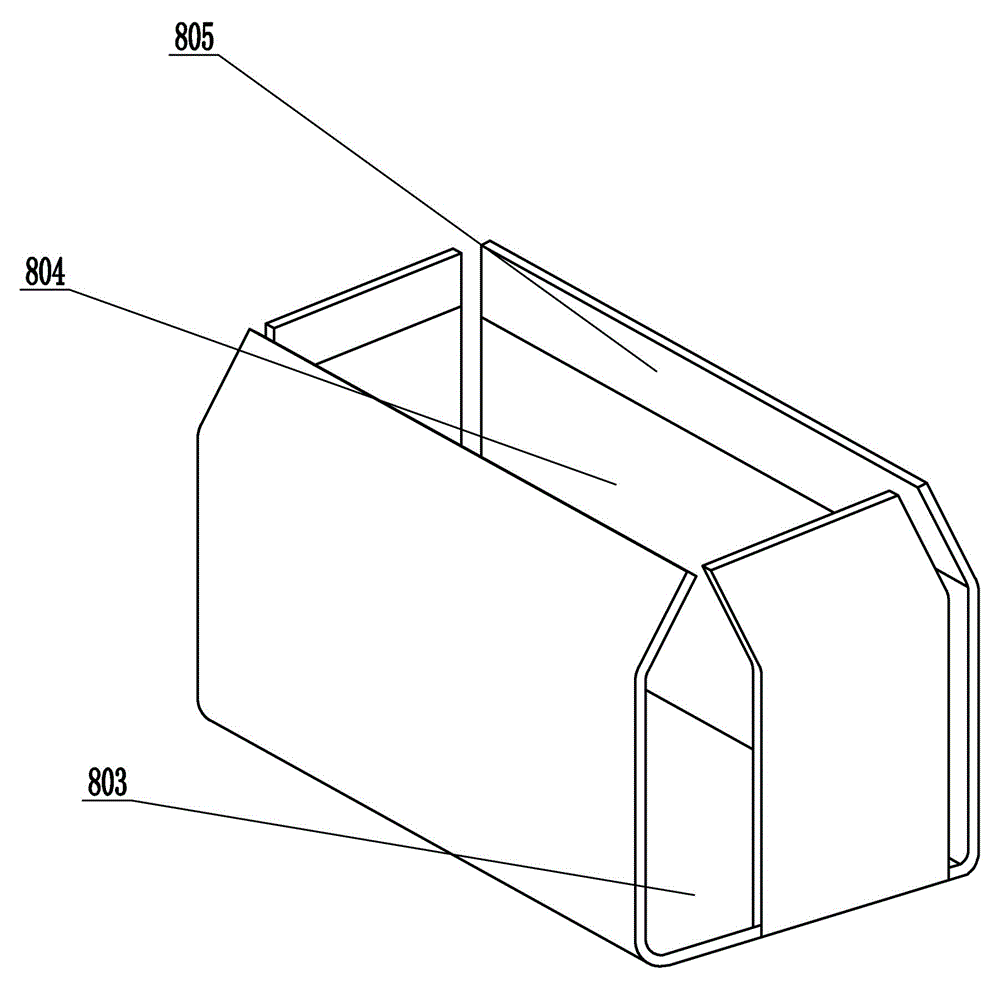

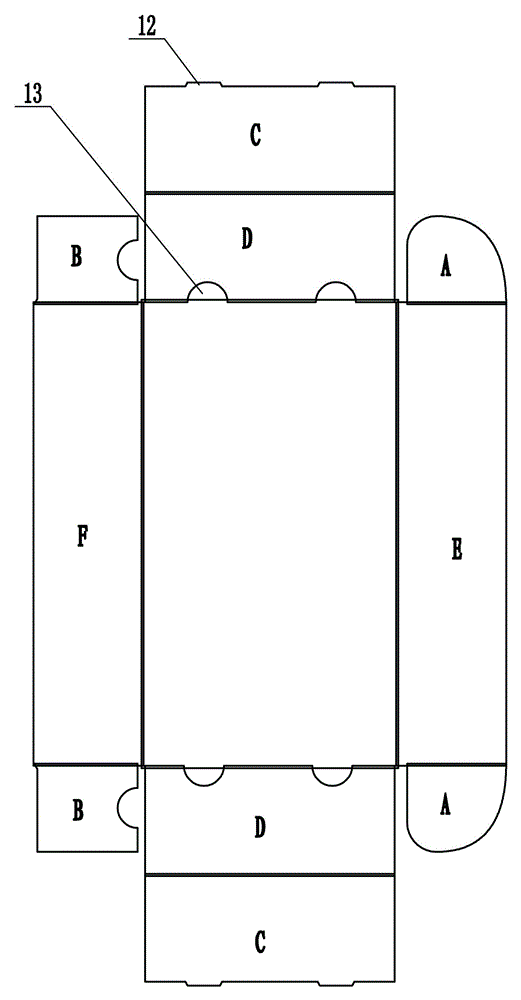

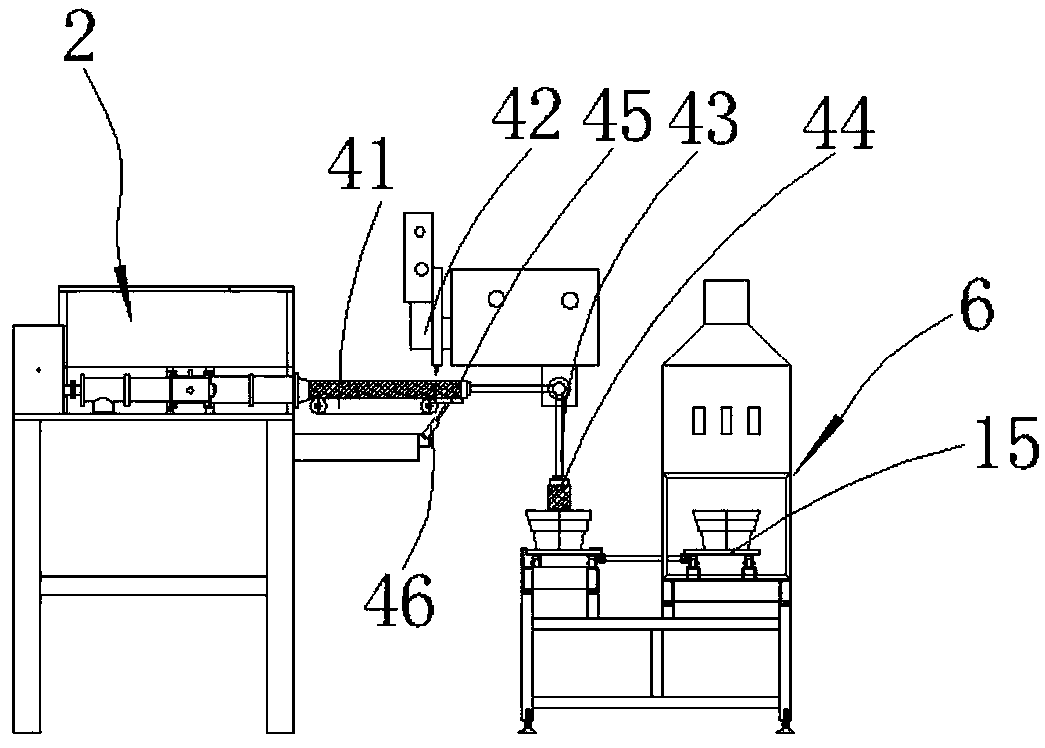

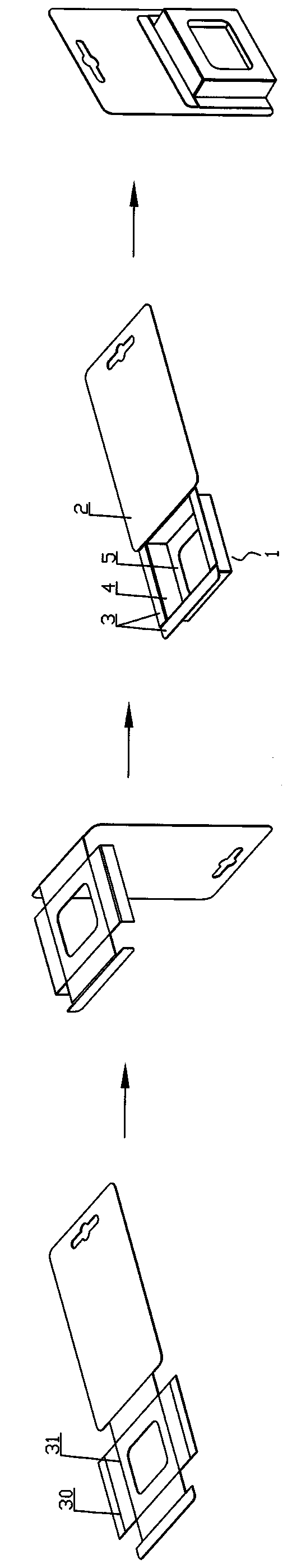

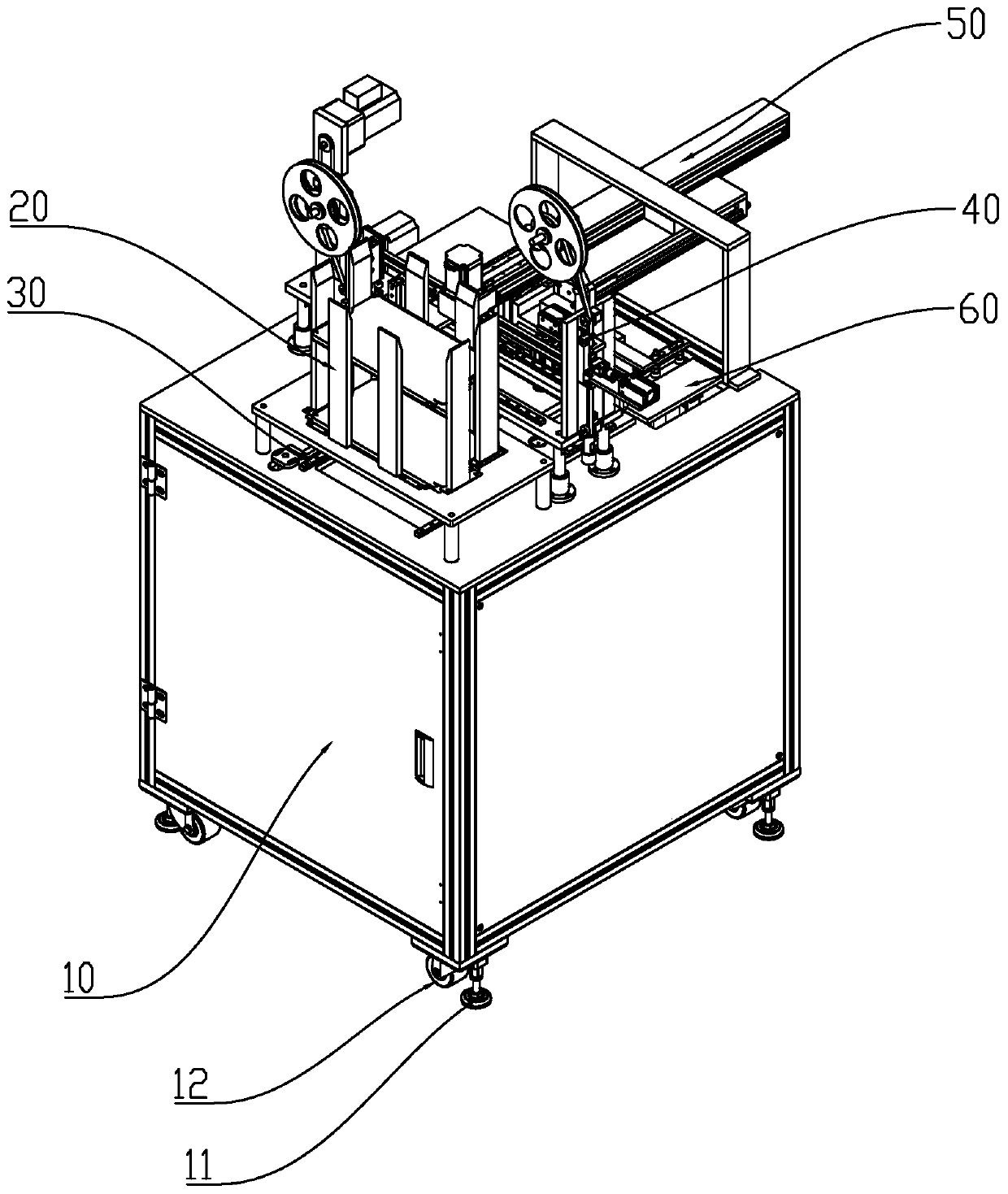

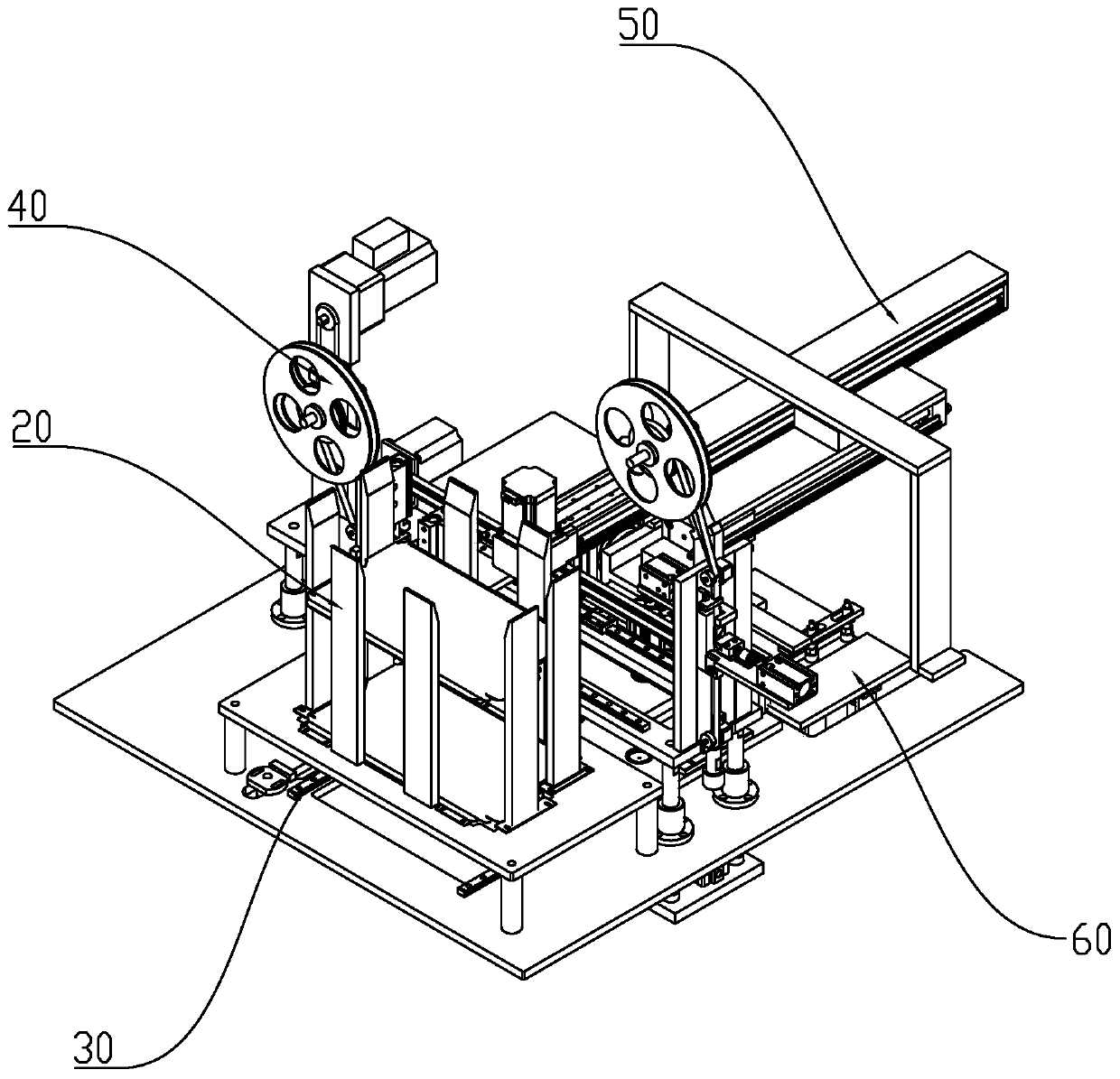

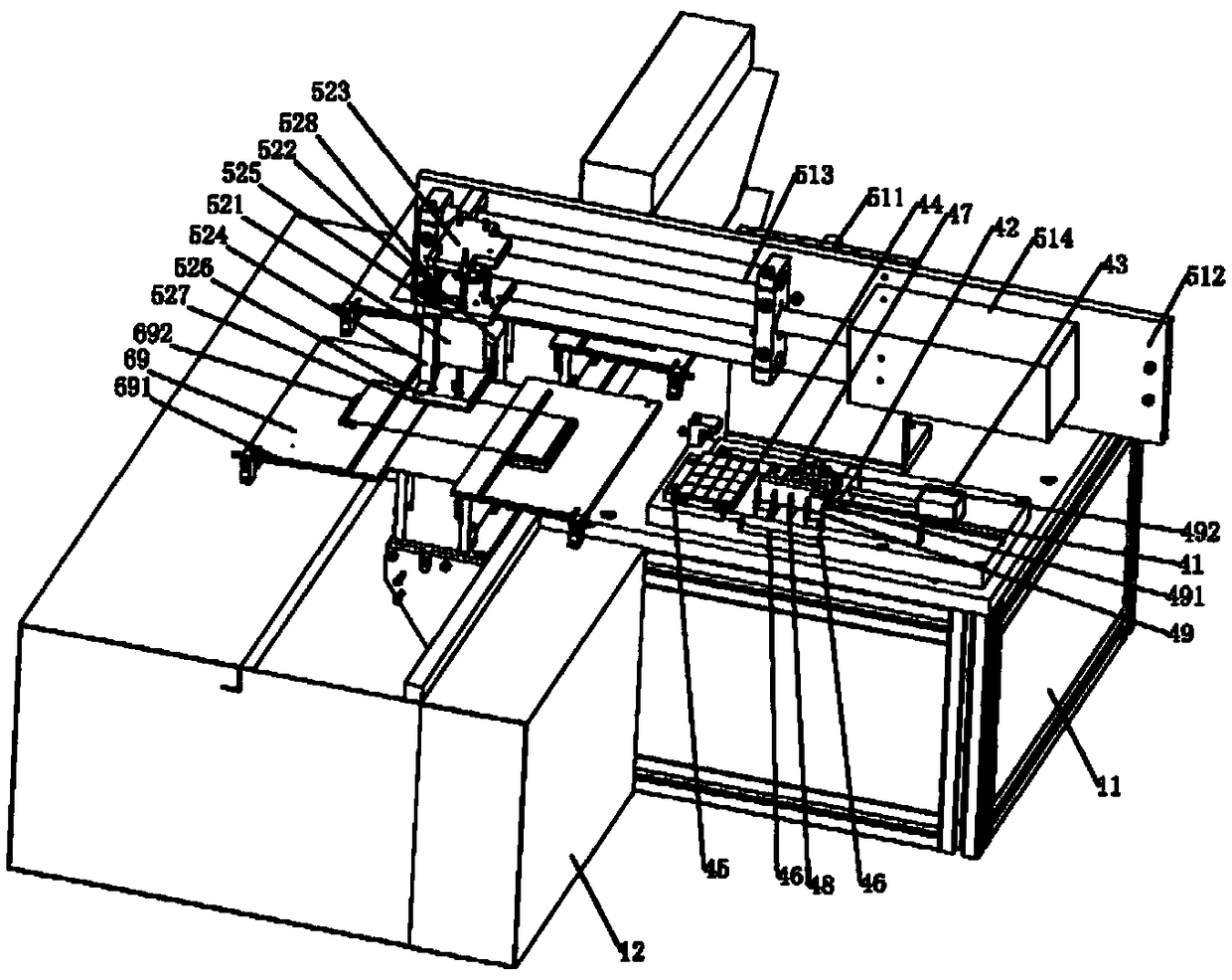

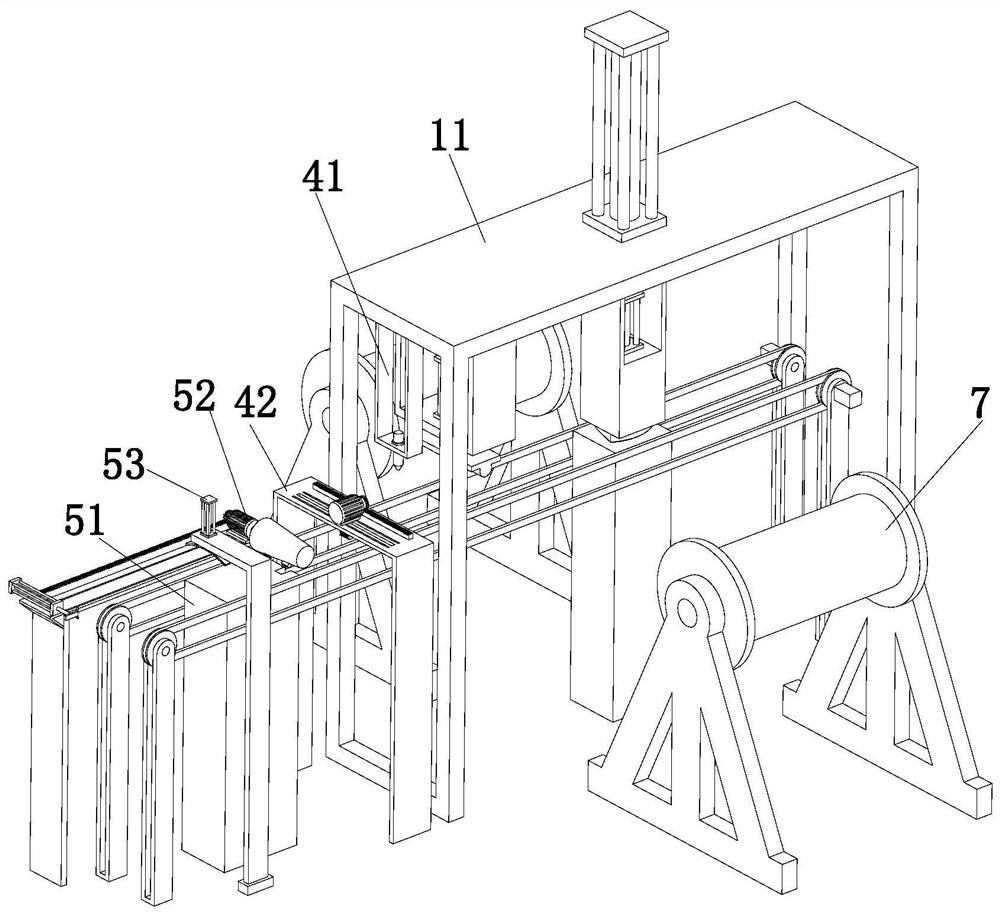

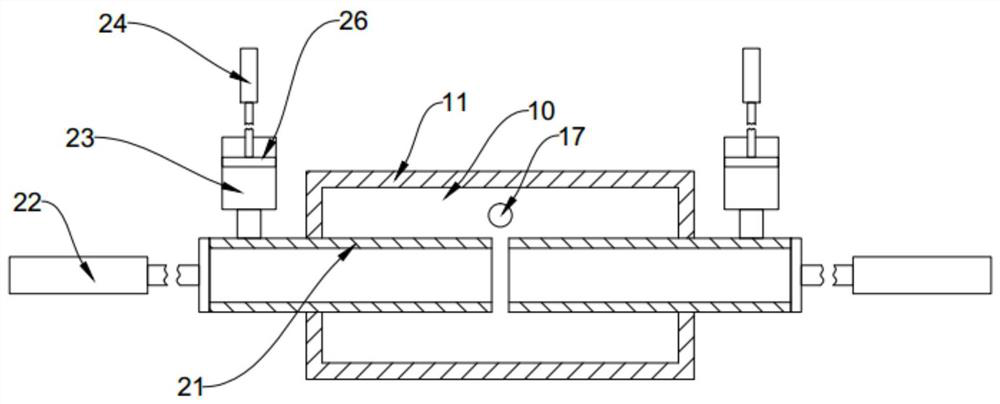

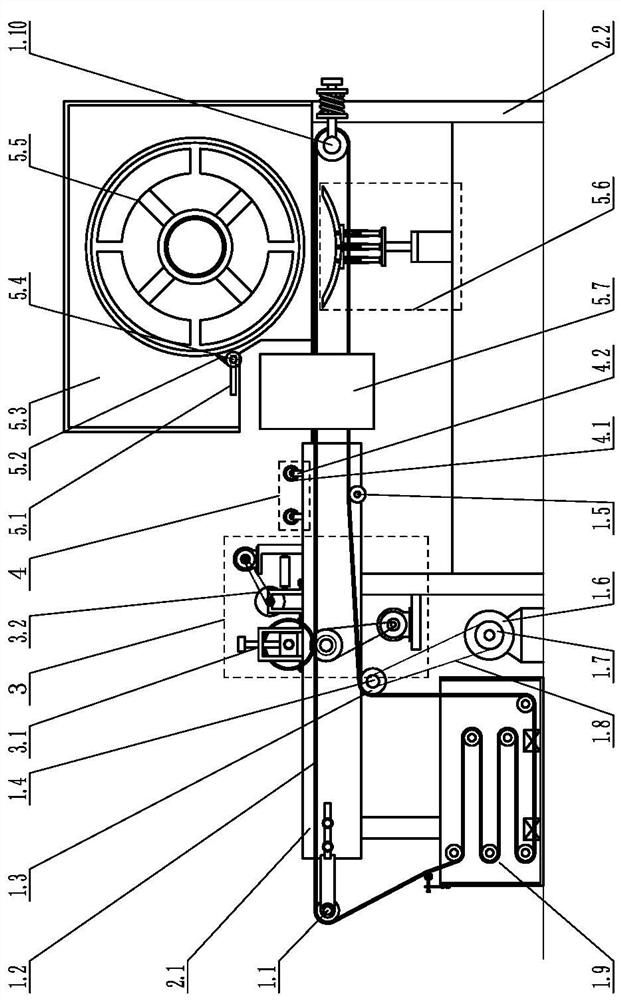

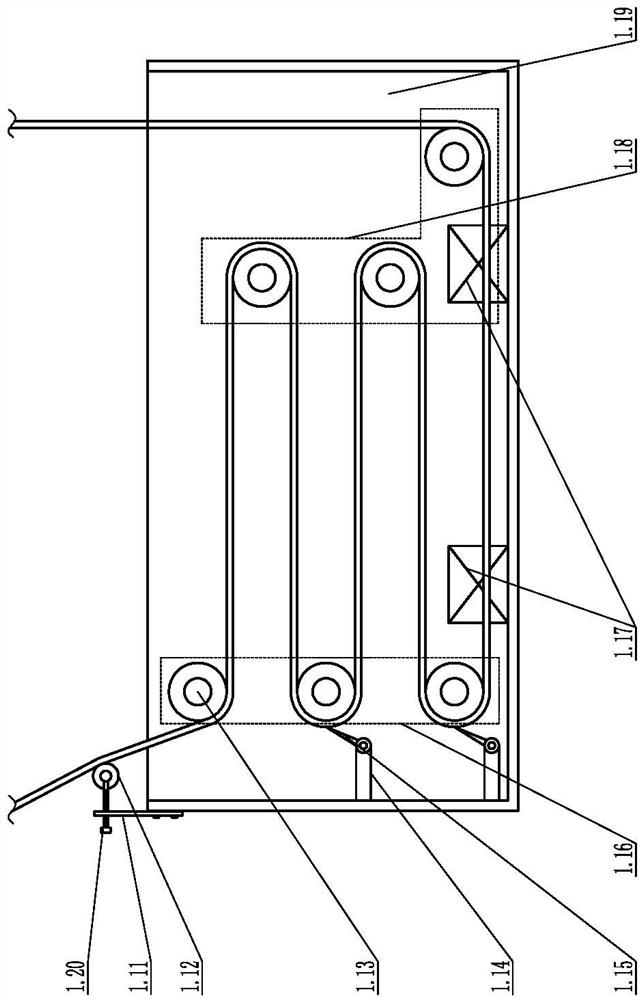

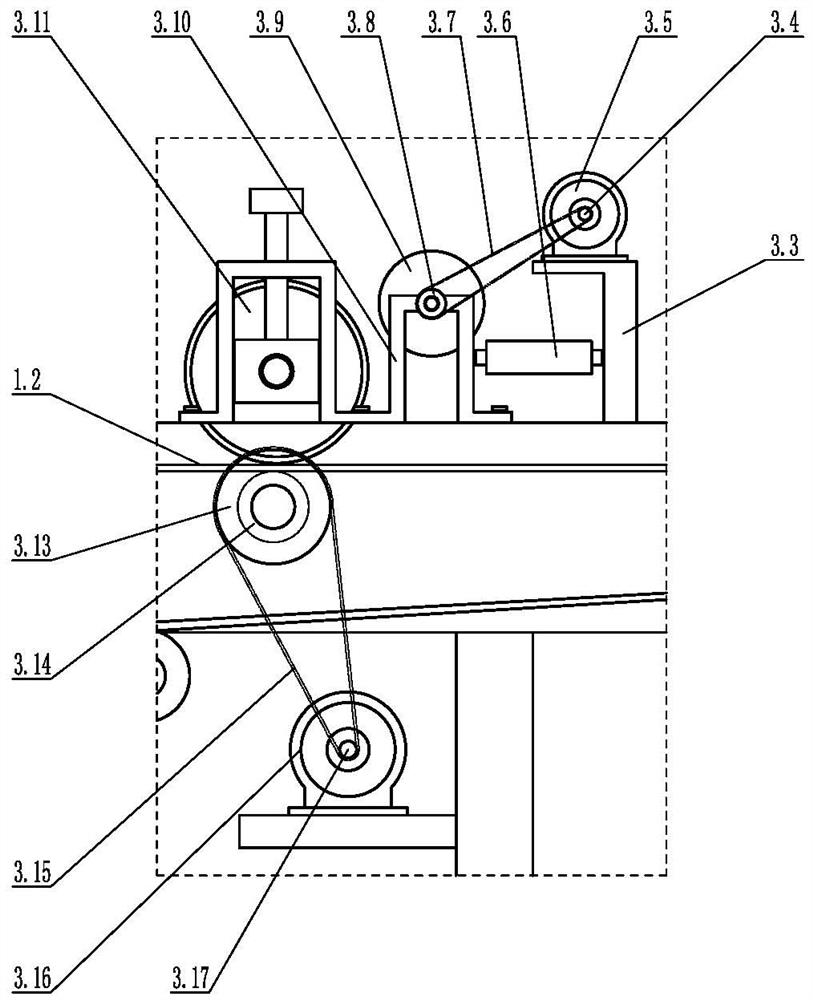

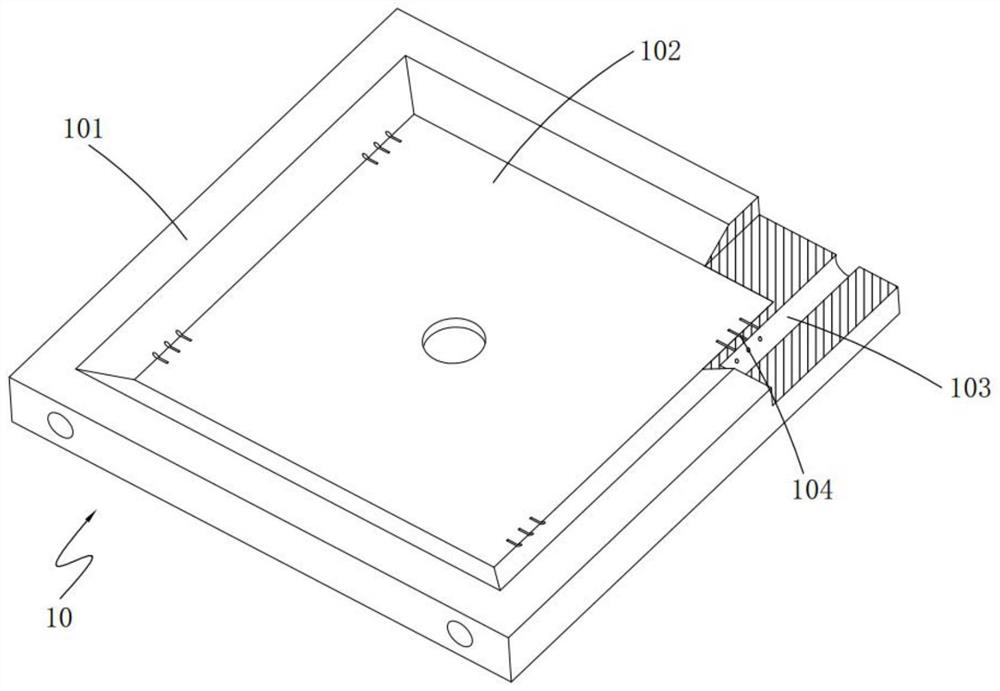

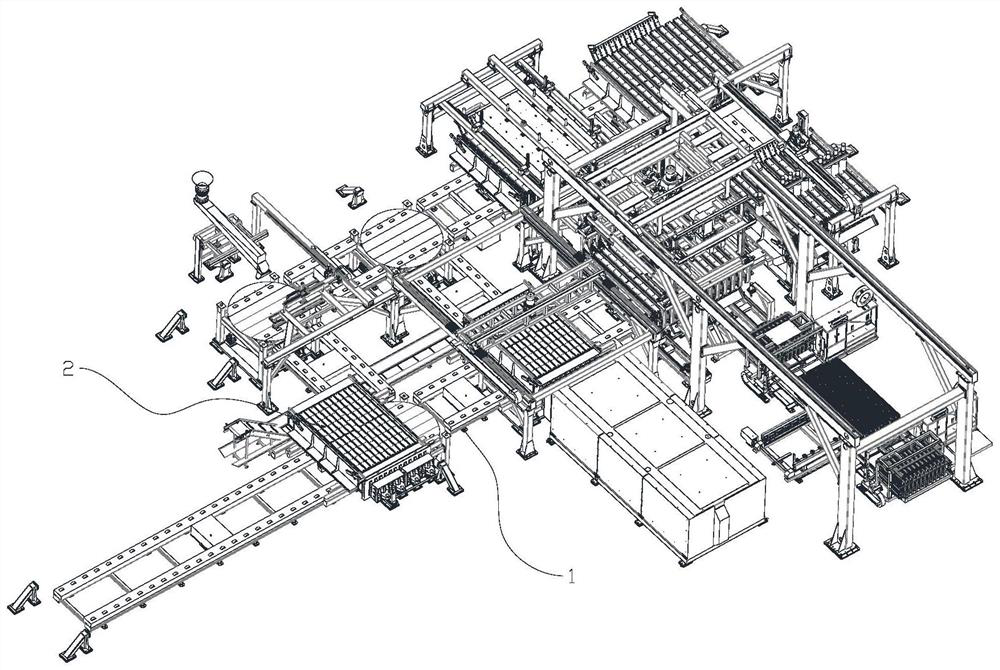

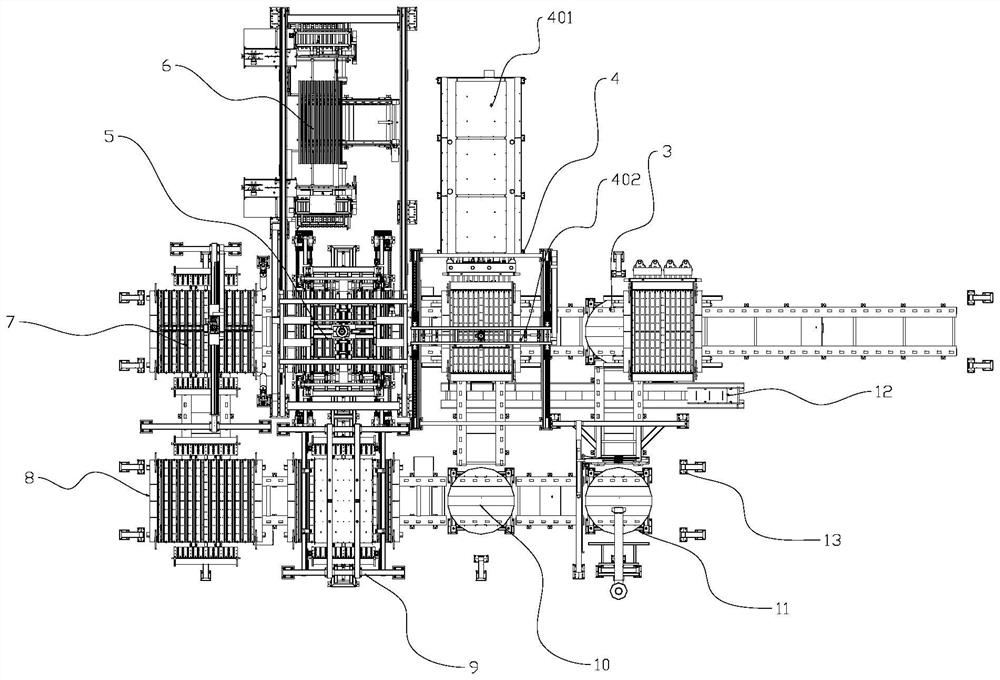

Automatic forming production line for cartons

ActiveCN106003820ARealize automatic formingIncrease productivityBox making operationsPaper-makingEngineeringSurface plate

The invention relates to an automatic forming production line for cartons. The carton has a first panel and a second panel which can be folded, and after being folded by certain angles, the first panel fits to the second panel; the production line comprises a carton feeding mechanism, a dispensing mechanism used for dispensing on the first panel and / or the second panel and a forming mechanism used for folding and fitting the first panel and the second panel; cartons fall off from the carton feeding mechanism to a carton conveying mechanism one by one; the cartons are moved by the carton conveying mechanism; and the dispensing mechanism is located above the carton conveying mechanism. The automatic forming production line for cartons can realize automatic forming of the cartons, flow line production is adopted, and the production efficiency is high.

Owner:常州节卡智能装备有限公司

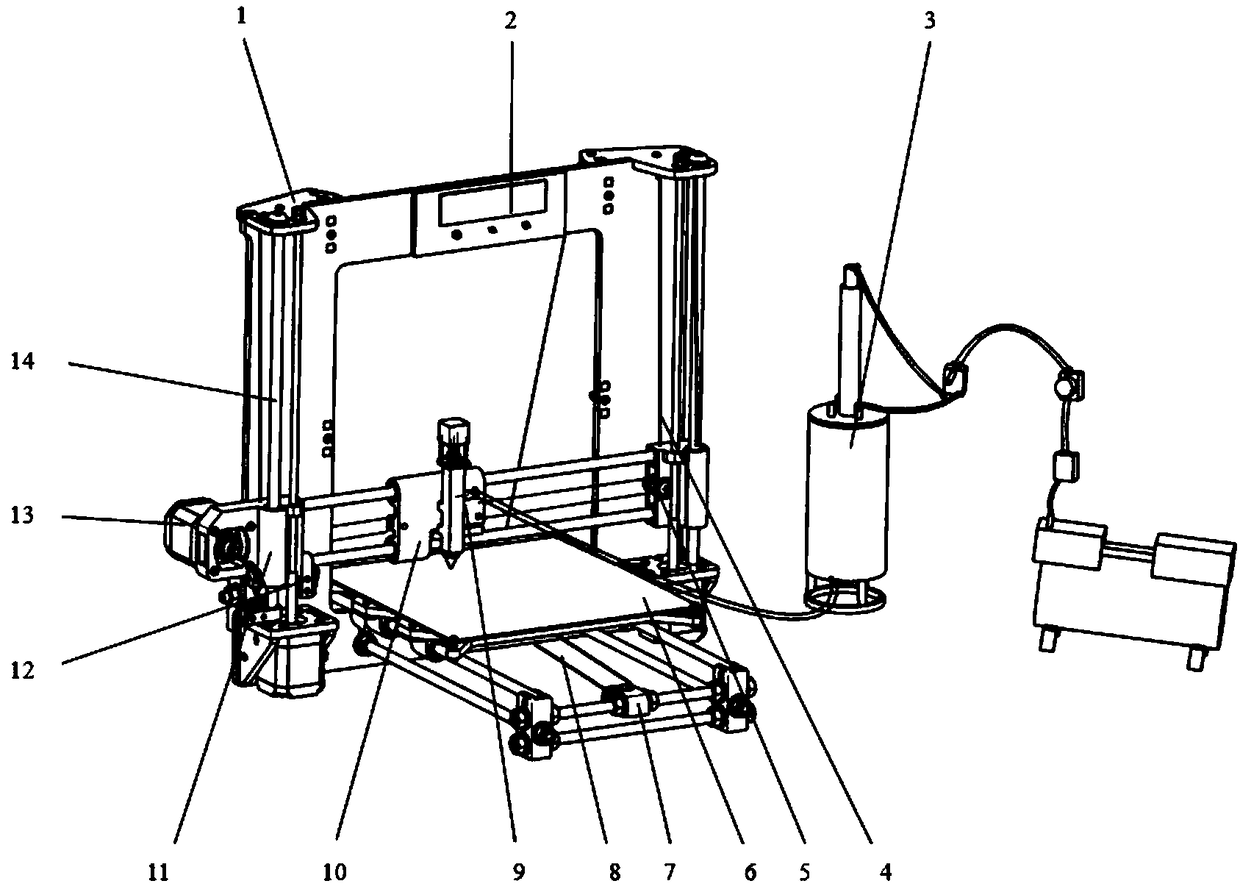

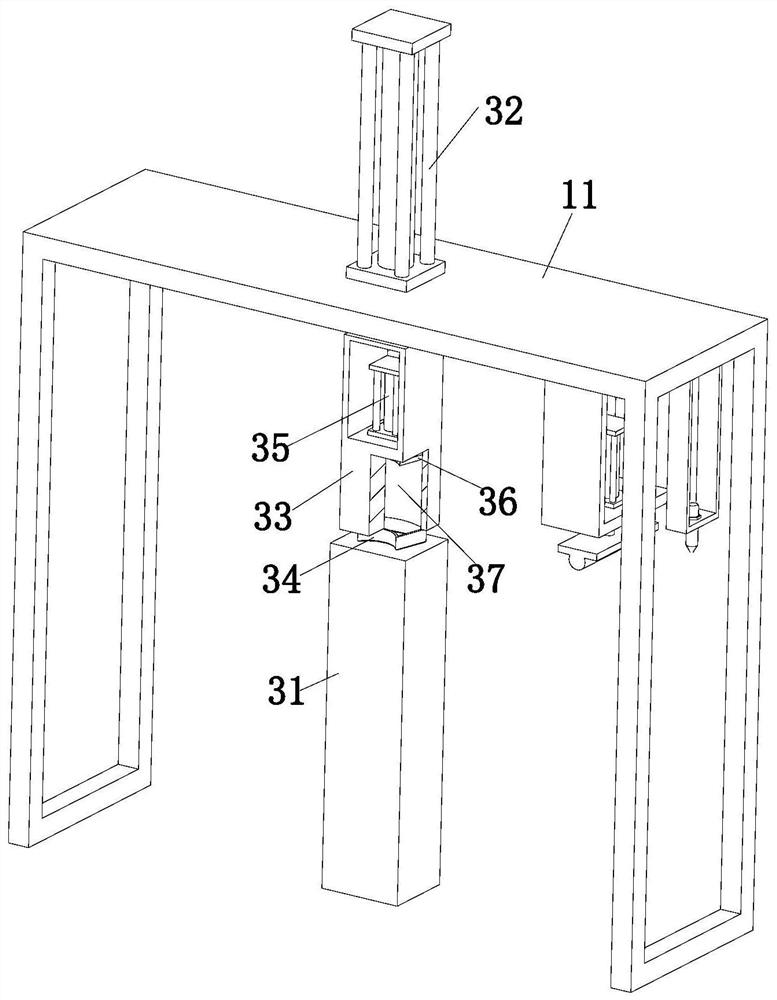

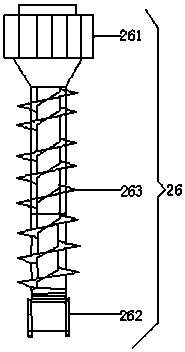

Novel ceramic forming device based on 3D printing technology

InactiveCN108297244AReduce labor costsAchieve high-precision printingAdditive manufacturing apparatusCeramic shaping apparatusCeramic compositeCeramic molding

The invention relates to the technical field of 3D printing, in particular to a novel ceramic forming device based on the 3D printing technology. The device comprises a rack, a master controller, a three-dimension motion module, a feeding device and an extrusion device; the feeding device comprises a storage tank, a piston, an air cylinder, an air compressor, a conveying pipe, an electromagnetic valve, a pressure regulating valve and a reversing valve, the extrusion device comprises a stepping motor II, a screw rod, a coupler, a screw rod sleeve and a nozzle, and the device can be applied to printing molding of ceramic composite materials, cement and other building materials; manual cost is reduced, high-precision printing of 3D ceramic printing can be achieved, the 3D printing technology,ceramic forming, mechatronics and the three dimensional model design technology are fused, automatic molding of traditional ceramic is successfully achieved, the special form difficultly achieved through the traditional ceramic blank drawing technology can be achieved, according to customer needs, individual customizing is achieved, the device can be widely applied in the culture creativity field, and new forming breakthrough is achieved.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG +1

Bowknot rope automatic forming machine for shoemaking

InactiveCN111254579ARealize automatic formingRealize clamping and feedingKnottingSevering textilesRotational axisMolding machine

The invention discloses a bowknot rope automatic forming machine for shoemaking. The bowknot rope automatic forming machine for shoemaking comprises a machine base, a cutting-off device, a rope pulling device, a sliding plate frame, two rotating shafts, and a driving device, wherein a feeding device is mounted at one end of the machine base through a support seat and is used for clamping and feeding of a bowknot rope; the cutting-off device is mounted at the part, located on one side of an outlet of the feeding device, of one end of the machine base through the support seat and used for realizing sizing cutting; the rope pulling device is longitudinally mounted on the machine base along the machine base through a reciprocating sliding mechanism and is used for clamping and pulling out theto-be-knotted bowknot rope sent out through the feeding device; the sliding plate frame is mounted on the machine base through two sliding guide rails, is connected with a feeding air cylinder mountedon the machine base, and is used for pushing the sliding plate frame to reciprocate along the sliding guide rails; the two rotating shafts are rotatably mounted on the sliding plate frame in parallel; rope winding rods are mounted on shaft shoulders, close to the front end, on the two rotating shafts, and are used for driving the bowknot rope to be wound and formed during rotation; and the driving device is mounted on the sliding plate frame and is in transmission connection with the rotating shafts. The machine has the advantages of being high in automation degree, high in manufacturing efficiency, low in labor intensity and good in product consistency.

Owner:JINHOU GRP WEIHAI SHOES

Computer readable memory medium and trimming cutter block manufacturing machine tool applied to same

ActiveCN107390642ARealize automatic formingShort and controllable processing timesProgramme controlComputer controlData preparationEngineering

The present invention relates to a computer readable memory medium and a trimming cutter block manufacturing machine tool applied to the same. The medium memory has a computer program which can be executed by the processor of the trimming cutter block manufacturing machine tool, an engineer inputs a trimming line and the type of a cutter block into the processor, the processor selects which side of the trimming line to be connect two ends of the trimming line into a closed curve through adoption of an auxiliary line according to the type of the cutter block, the closed curve is moved to construct a cutter block green body, the cutter block green body is arranged to be close to the end face of a casting model to allow the cutter block green body to be formed, after forming, a side wall taking the trimming line as a boundary is selected to process the cutter edge of the cutter block on the cutter block green body, the cutter edge is subjected to parameter setting to complete the data preparation work of the shape of the trimming cutter block and the cutter edge and generate CNC codes through adoption of the data by employing UG software to perform processing of the trimming cutter block manufacturing machine tool to perform automatic forming so as to allow the processing time of the trimming cutter block to be shortened and controllable and improve the processing efficiency.

Owner:TANGXIA BRANCH VISION TOOL & MOLD

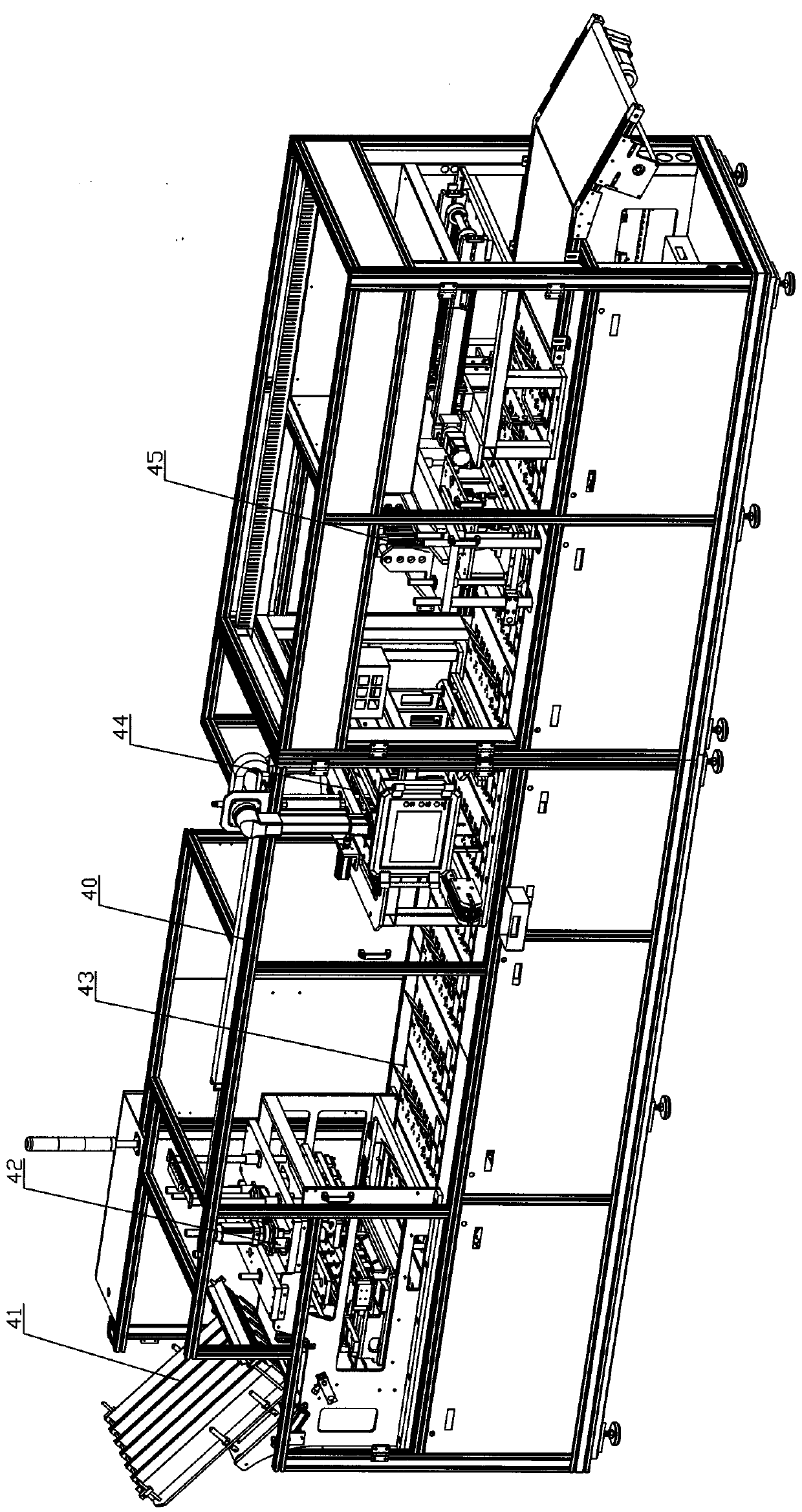

Packaging machine

PendingCN110422385ARealize automatic formingAutomate the packaging processPackaging machinesPulp and paper industryPackaging machine

The invention discloses a packaging machine. The packaging machine comprises a machine frame, a lower paper clamping mechanism, a paper box forming mechanism, a paper box conveying mechanism, a bottomplate folding mechanism and a sealing mechanism, the packaging machine is characterized in that the paper box forming mechanism comprises a first edge folding device and a second edge folding device,the first edge folding device comprises a first lower die and a first upper die and an upper paper folding piece which are lifted up and down, the second edge folding device comprises a second lowerdie and a lower paper folding piece and a second upper die which are lifted up and down, and the bottom plate folding mechanism comprises a press plate which is lifted up and down. According to the packaging machine, the paper box forming mechanism realizes automatic forming of a paper box, the bottom plate folding mechanism is used for covering the bottom plate of the paper box with the materials, so that the paper box is sealed, automatic packaging of the materials is realized, existing manual processing is replaced, the working efficiency is improved, and the production cost is reduced.

Owner:浙江诚达机械股份有限公司

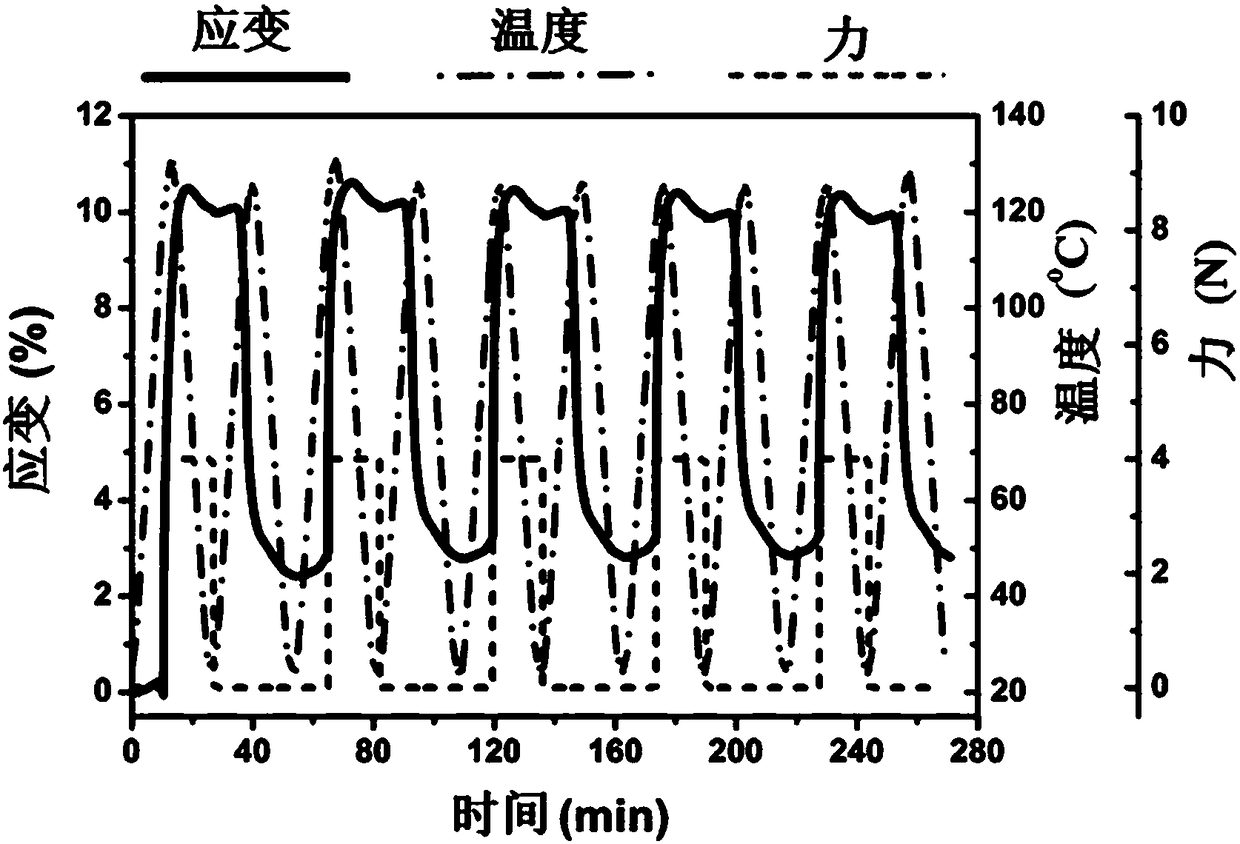

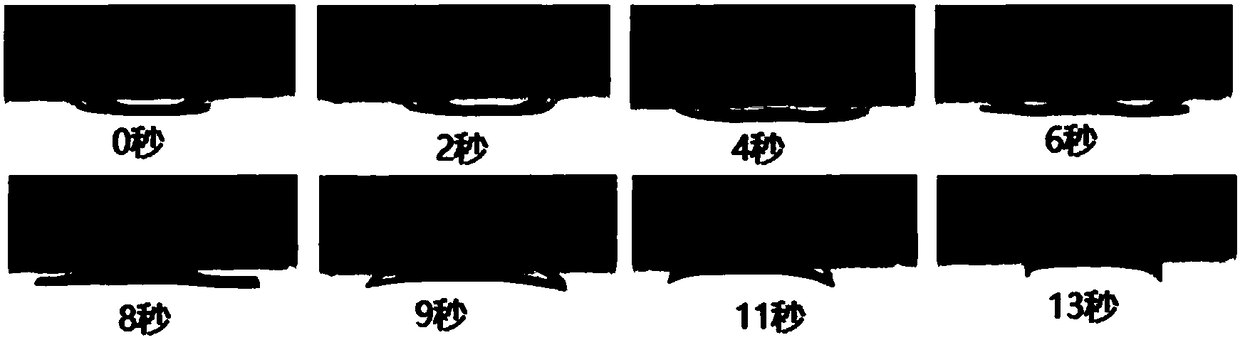

Preparation method of self-repairing reshapeable multi-deformation thermosetting shape-memory resin system

ActiveCN108559224AHas the function of self-healing micro-cracksStable shape memory propertiesEpoxyMemory effect

The invention discloses a preparation method of a self-repairing reshapeable multi-deformation thermosetting shape-memory resin system. The resin system mainly comprises the following raw materials: bismaleimide, aromatic diamine, epoxy resin, dicarboxylic anhydride and a transesterification accelerant; bismaleimide resin is subjected to a chain extension reaction by the aromatic diamine to form alinear oligomer, then the epoxy resin, the accelerant and the dicarboxylic anhydride are added, and after a certain thermal curing process is performed, a reshapeable multi-deformation thermosettingshape-memory material with self-repairing function is obtained. The material prepared with the method can not only be reshaped into a new shape, but also is good in shape memory effect when the deformation recovery cycle reaches 5 times or more than 5 times, and materials prepared therefrom are good in self-repairing capability and has the fracture toughness repairing efficiency being 62% or morethan 62%. Therefore, the prepared materials have wide application potential in high-performance structural-functional integration materials.

Owner:SUZHOU UNIV

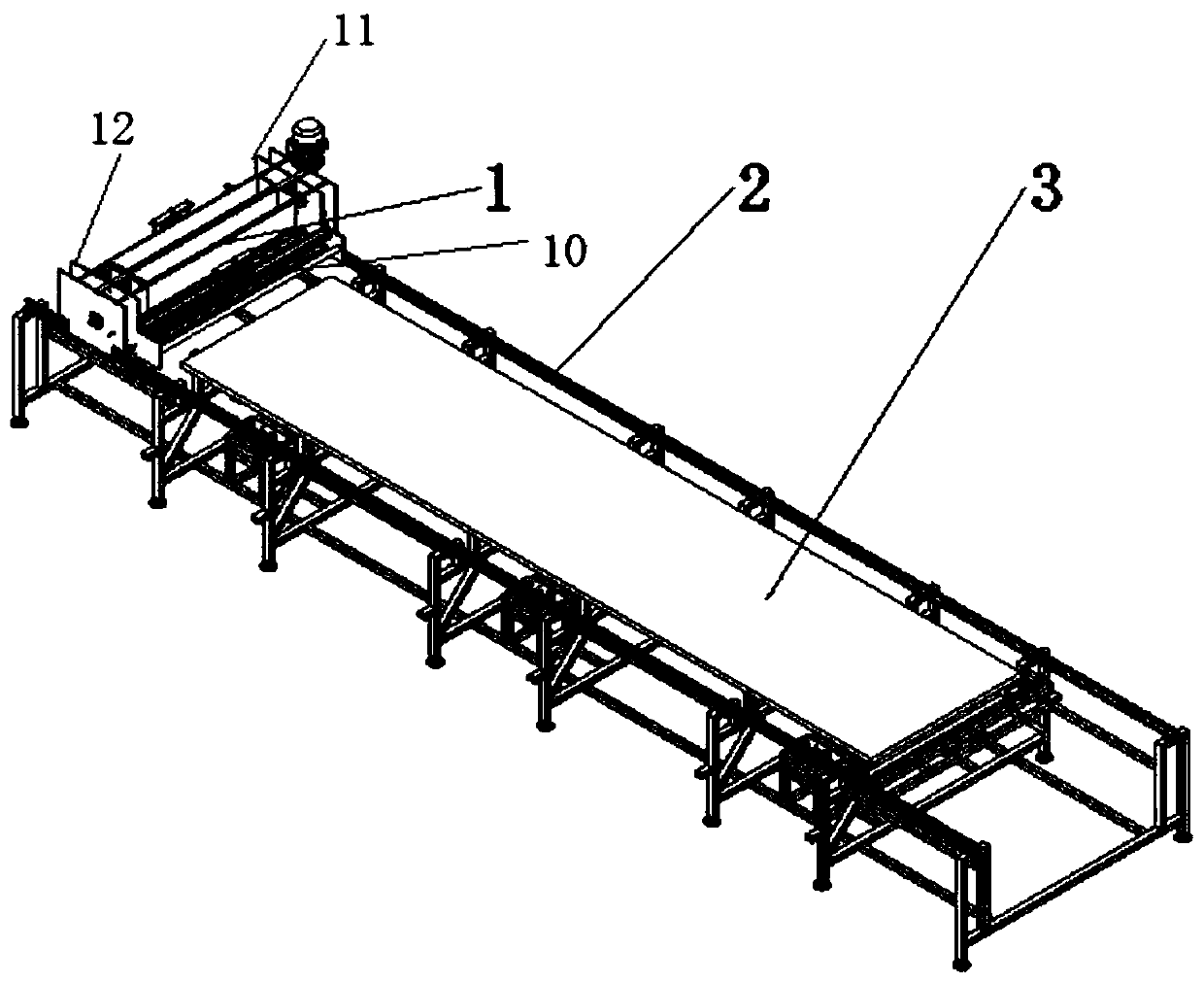

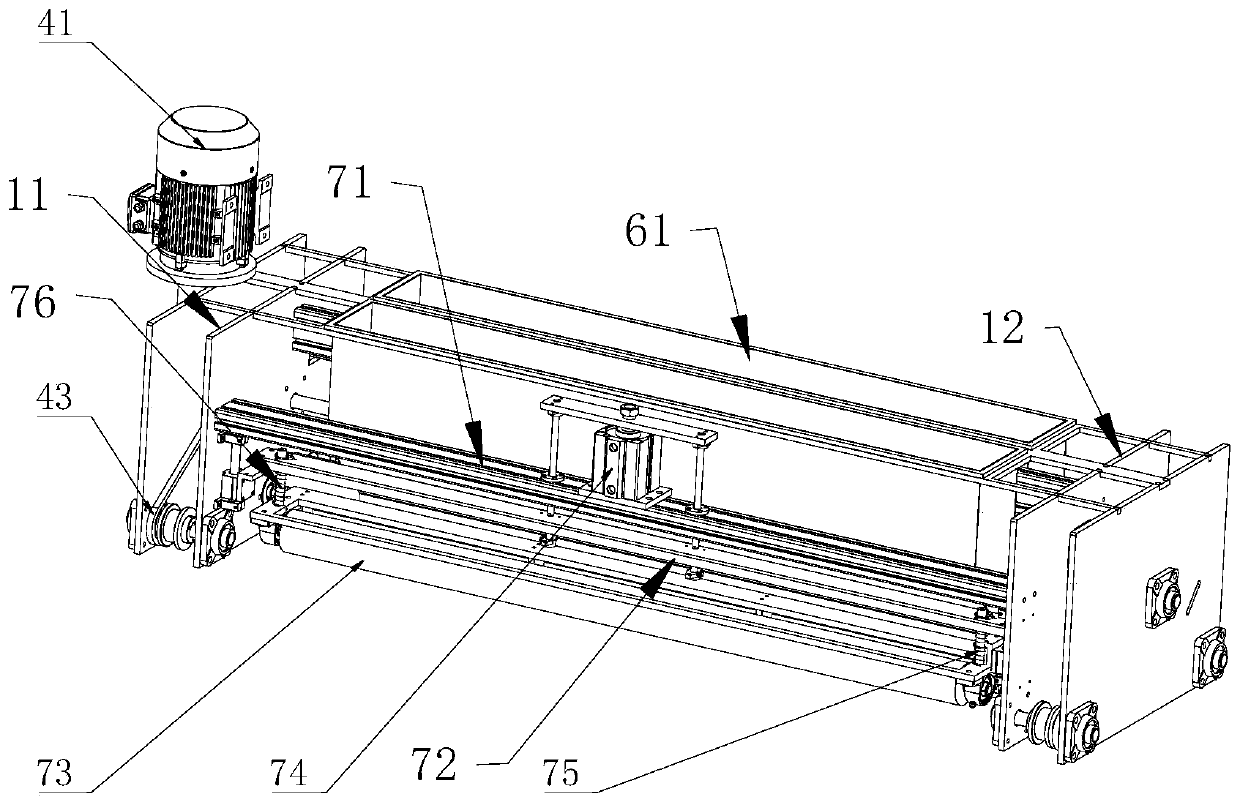

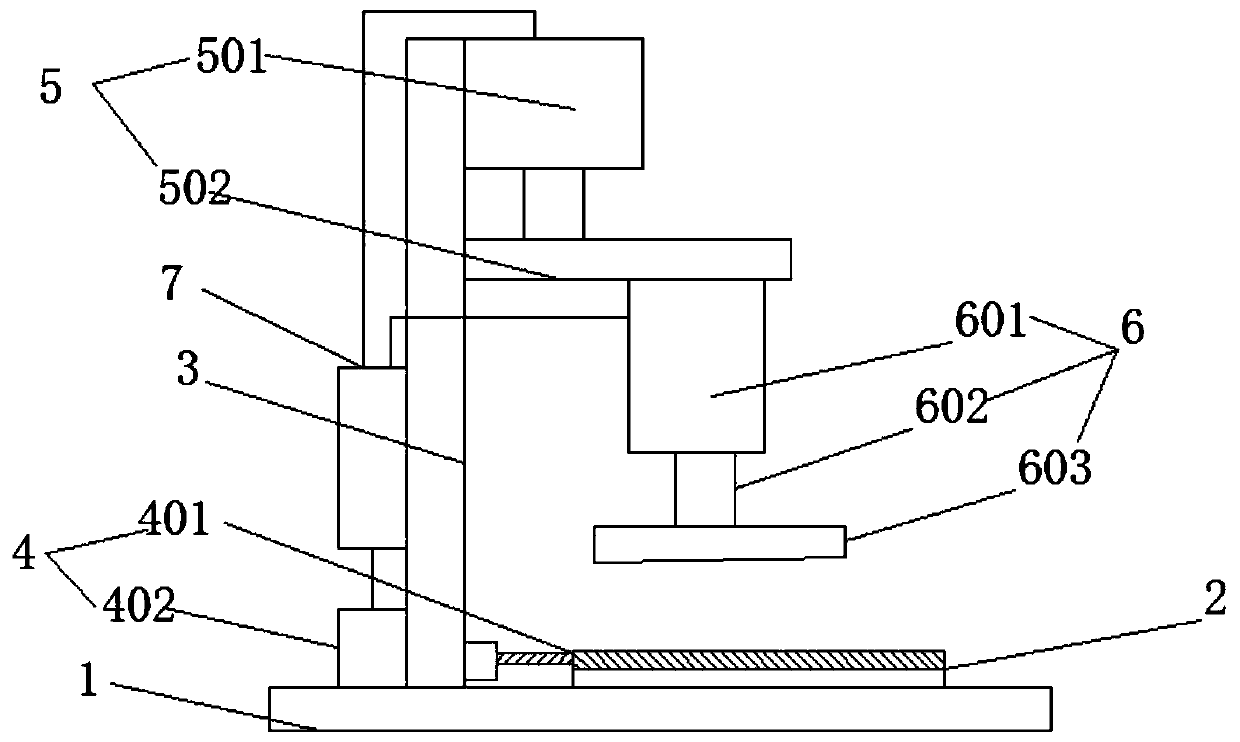

Automatic coating forming device and coating forming method for concentric-square-shaped supporting structural component

ActiveCN111016214ARealize automatic formingSolve labor shortageMechanical engineeringFiber structure

The invention discloses an automatic coating forming device for a concentric-square-shaped supporting structural component. The automatic coating forming device comprises a forming auxiliary frame anda moving support, wherein a wood mold is mounted on the upper surface of the forming auxiliary frame, guide rails are mounted on two sides of the forming auxiliary fame, the moving support is arranged on the guide rails to move in a spanning mode, the two ends of the moving support in the direction of the guide rail are respectively provided with a first mounting plate and a second mounting plate, a first mounting plate and a second mounting plate are mounted at the two ends of the moving support in the direction spanning the guide rails correspondingly, a driving device is mounted on the outer side of the first mounting plate, a pressing roller device, a feeding device and a laying device are sequentially mounted between the first mounting plate and the second mounting plate, so that theraw material laying and compacting are sequentially carried out, a clamping device is mounted on the forming auxiliary frame below the wood mold, ribbons before laying are clamped, after the liquid materials and the ribbons are laid down and completed, a first bending device and a second bending device are sequentially started, and forming of the concentric-square-shaped structure is completed. According to the automatic coating forming device and coating forming method, the complete automatic forming of the concentric-square-shaped fiber structural component can be realized, and the problemof insufficient labor force is fundamentally solved, and a single-direction coating process is adopted, so that a more smooth surface of the structural component is facilitated to be obtained.

Owner:JIANGSU UNIV OF SCI & TECH

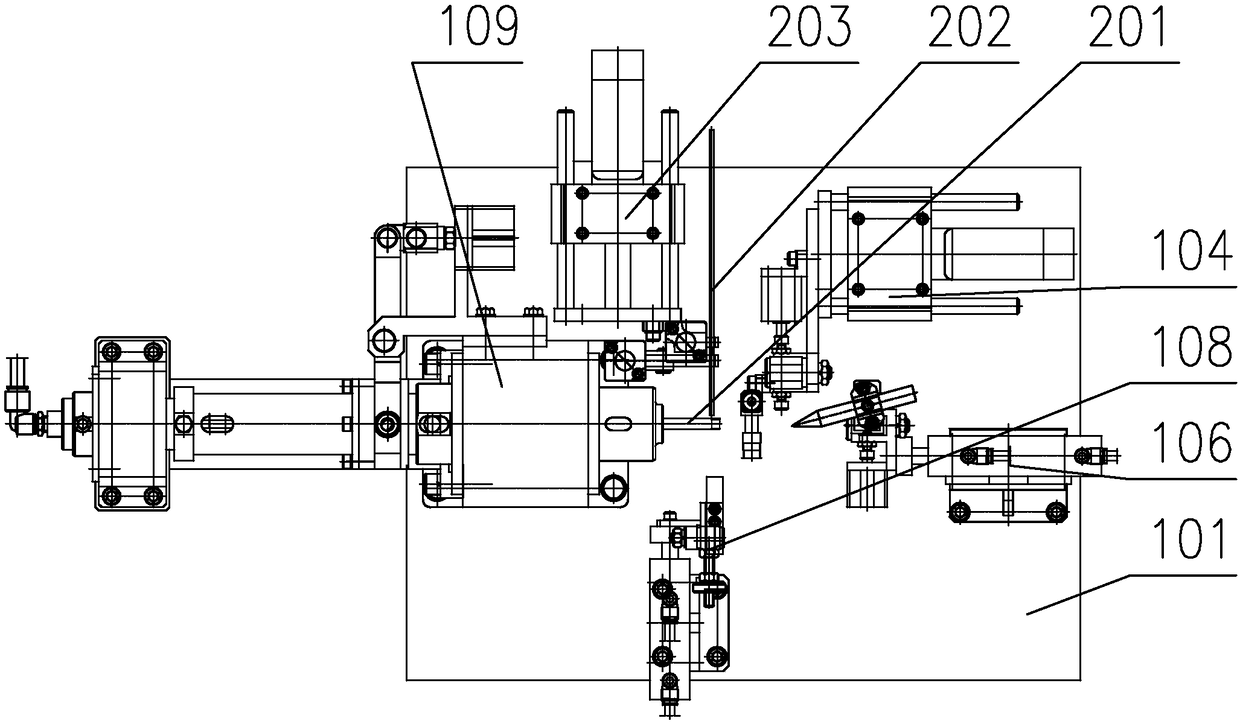

Automatic tearing and adhering type double faced adhesive tape forming device for box cover

PendingCN109795914ARealize automatic formingIncrease profitPaper-makingBox making operationsEngineeringProcessing cost

The invention relates to an automatic tearing and adhering type double faced adhesive tape forming device for a box cover. The device comprises a rack, a material groove assembly which is arranged atone side of the rack, a picking positioning assembly which is arranged at the rear end of the material groove assembly, an adhesive tape tearing and adhering mechanism which is arranged at the rear end of the material groove assembly, a transferring assembly which is arranged at the rear end of the adhesive tape tearing and adhering mechanism, a rotating assembly which is positioned at one side ofthe transferring assembly, and a forming mechanism which is arranged at the rear end of the transferring assembly. According to the device, the dead load type conveying design is carried out to realize non-stop continuous production, so that the device utilization rate is increased; an automatic tearing and adhering type double faced adhesive tape is adopted, and a double faced adhesive tape diecutting technology is replaced, so that the quantity of used double faced adhesive tape and the die cutting processing cost can be saved; and meanwhile, the box cover is automatically formed, so thatthe product quality is stable; the product quality is improved; and moreover, the labor is saved; and the practicability is high.

Owner:SHENZHEN YUTO PACKAGING TECH

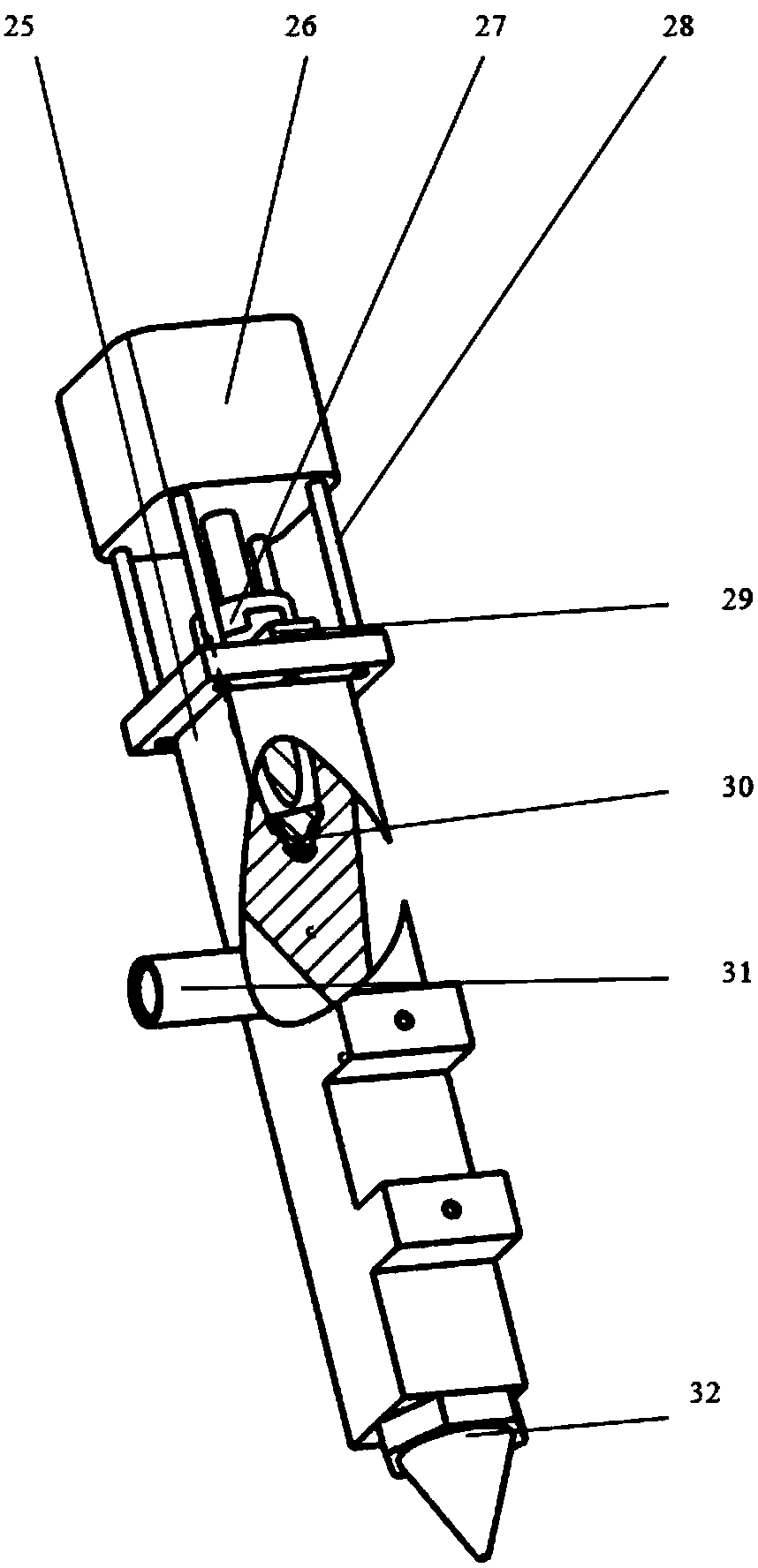

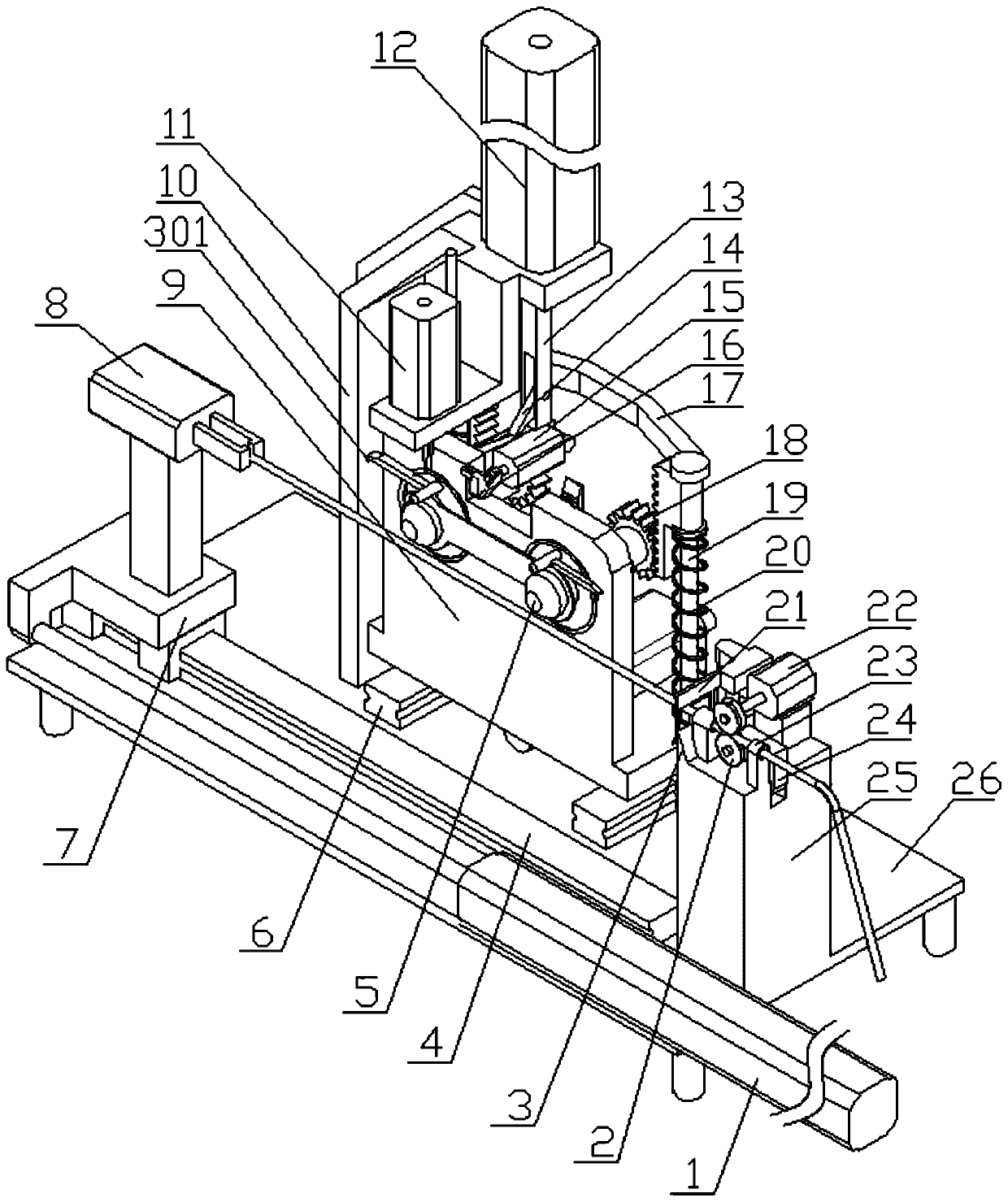

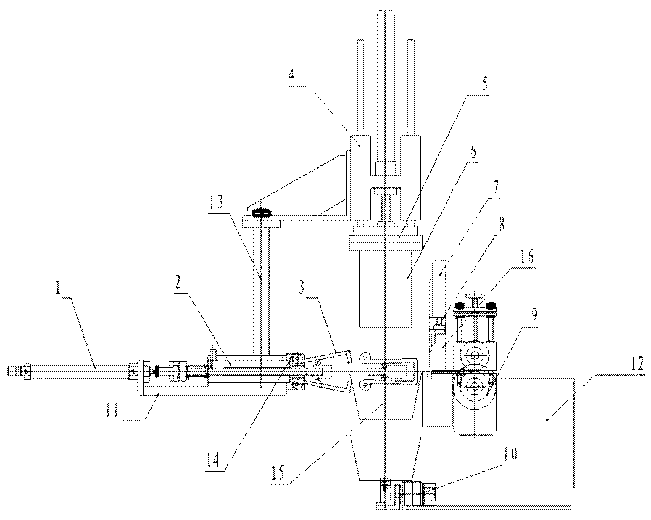

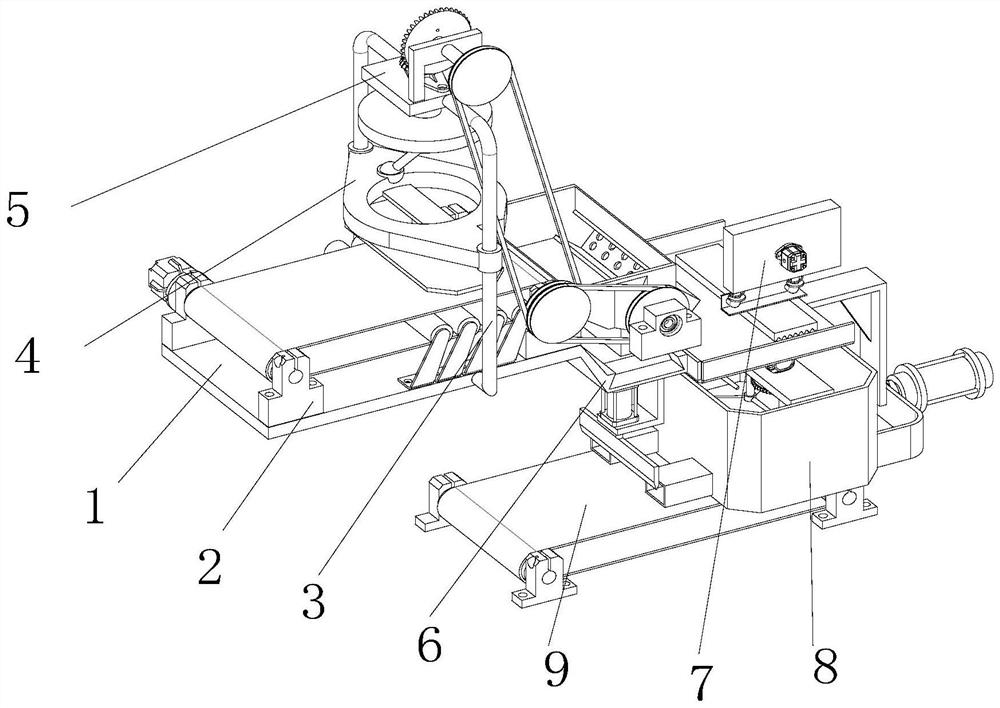

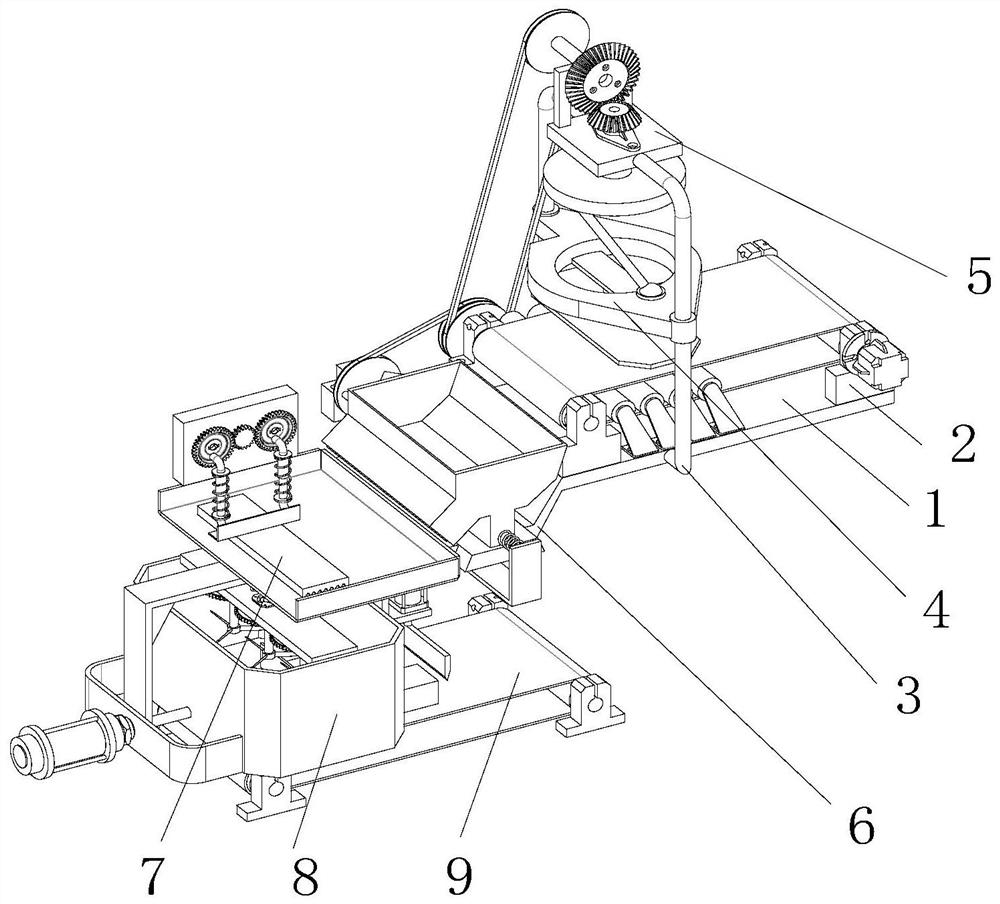

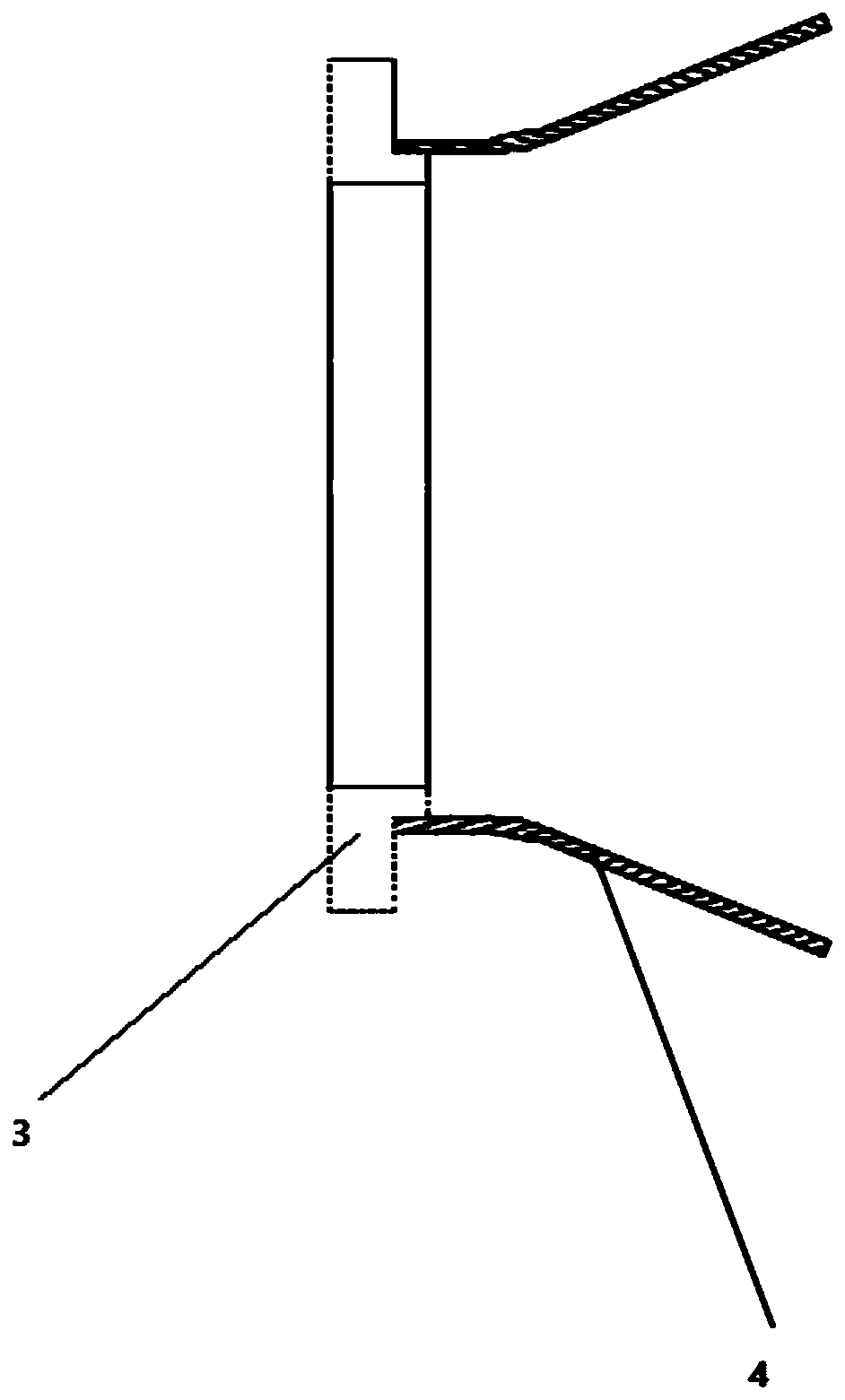

Angle line automatic forming device for nonel tube bundling

InactiveCN101717319ARealize automatic formingRealize automatic tractionFuse manufactureEngineeringManipulator

The invention provides an angle line automatic forming device for nonel tube bundling. A traction air cylinder, a movement limiting block and a forming opening are arranged on a horizontal installation bench surface of the angle line automatic forming device. A vertical installation surface is vertically connected with the horizontal installation bench surface and is provided with a support rack II and a dynamic traction mechanism. An installation support rack I is fixed on the horizontal installation bench surface, the forming air cylinder is fixedly connected with the installation support rack I, and a forming mould is arranged under a forming mechanism. A conveying mechanical arm is fixedly arranged under the left lower part of the vertical installation surface. The invention can realize the automatic traction, the automatic forming, the separate cutting and the automatic transfer of angle lines.

Owner:NO 70 INST OF CHINA NORTH IND GRP

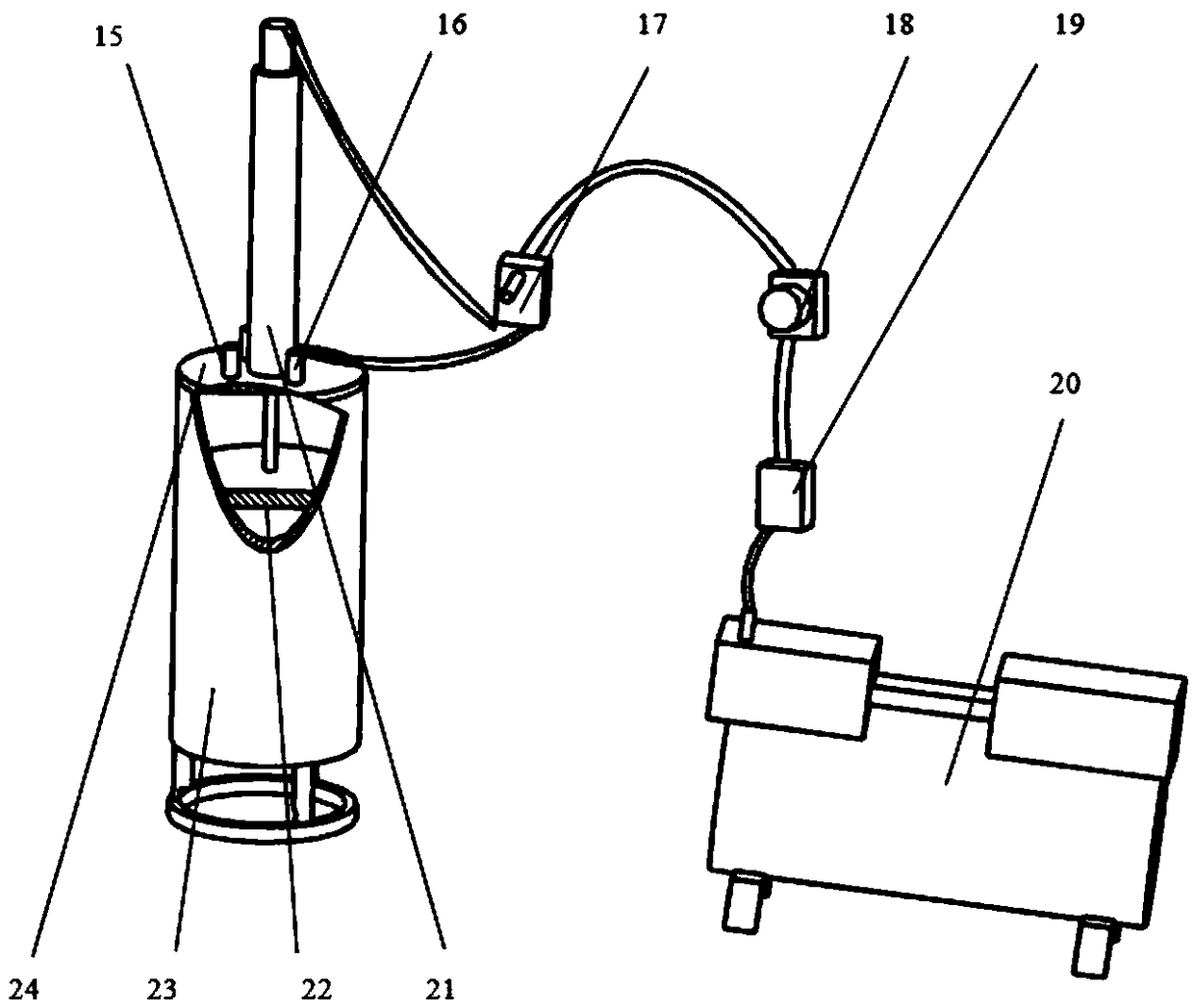

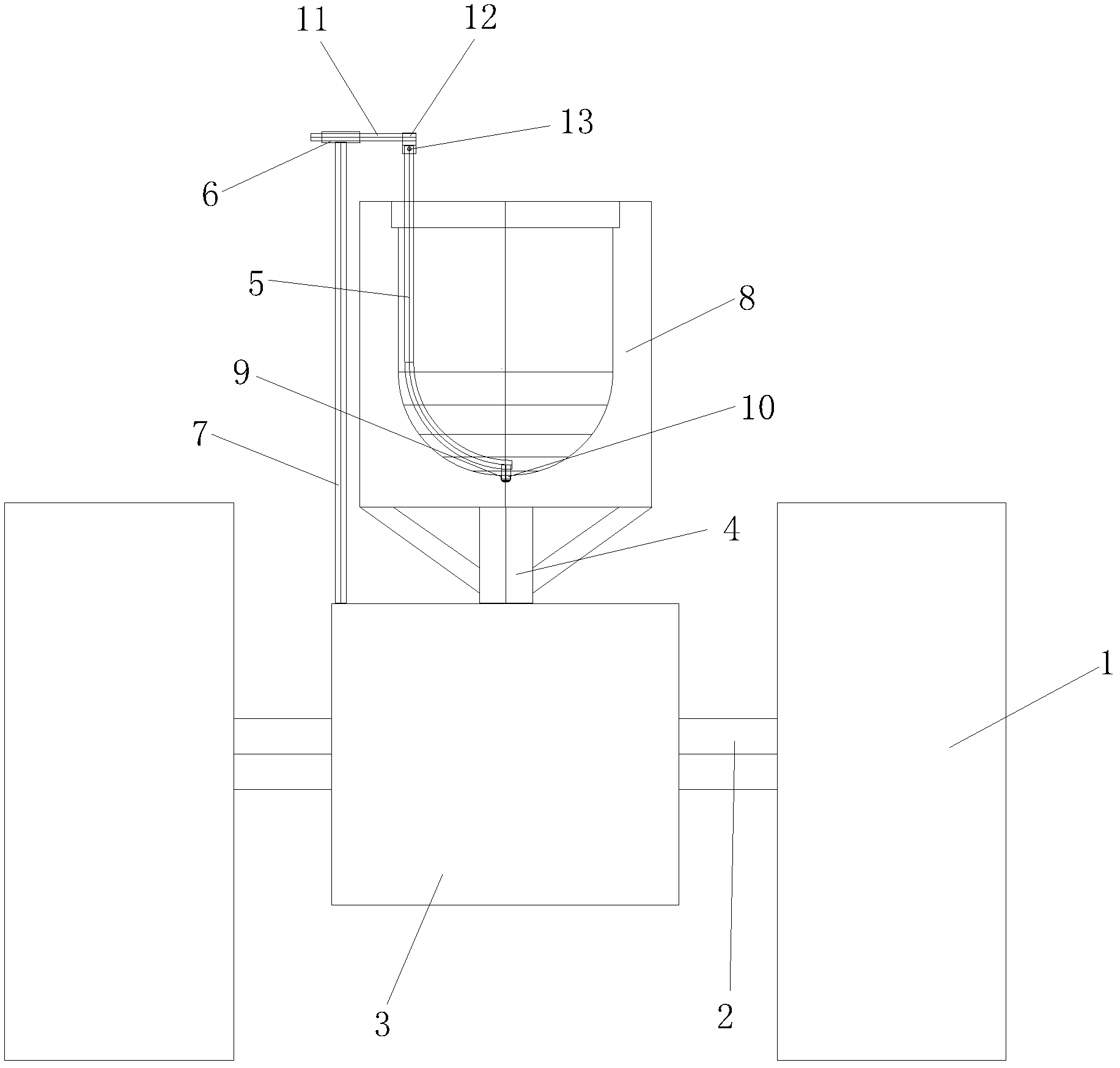

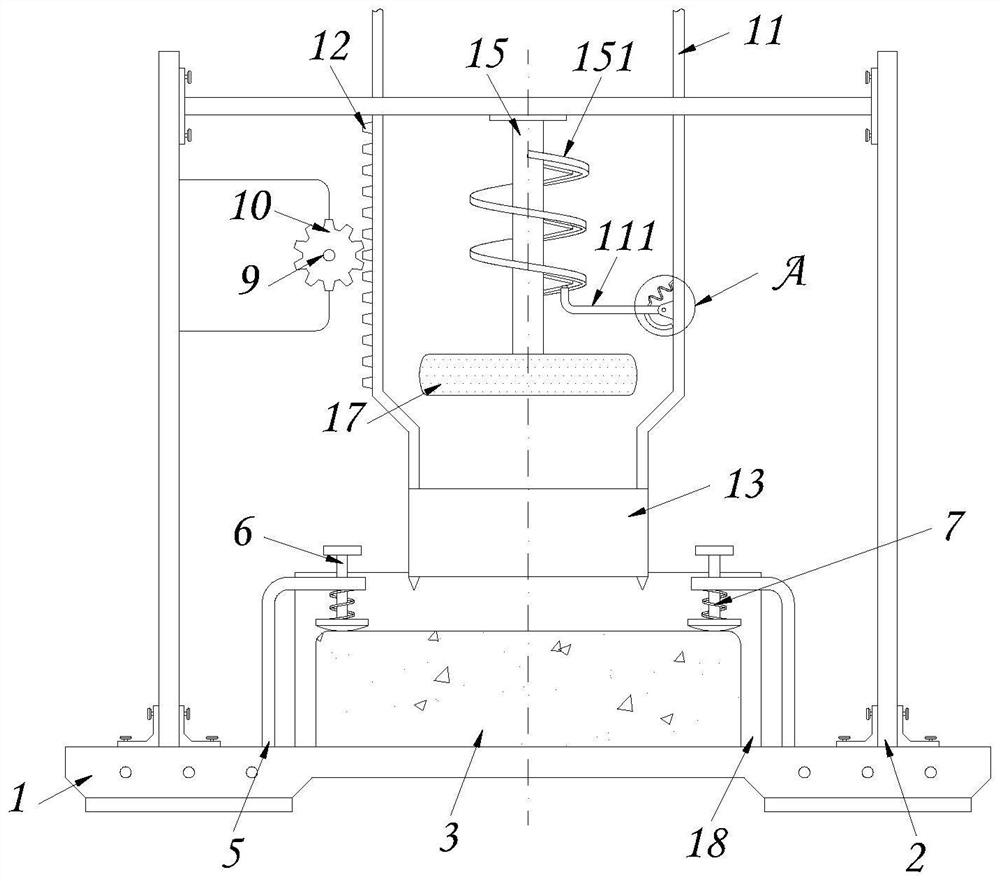

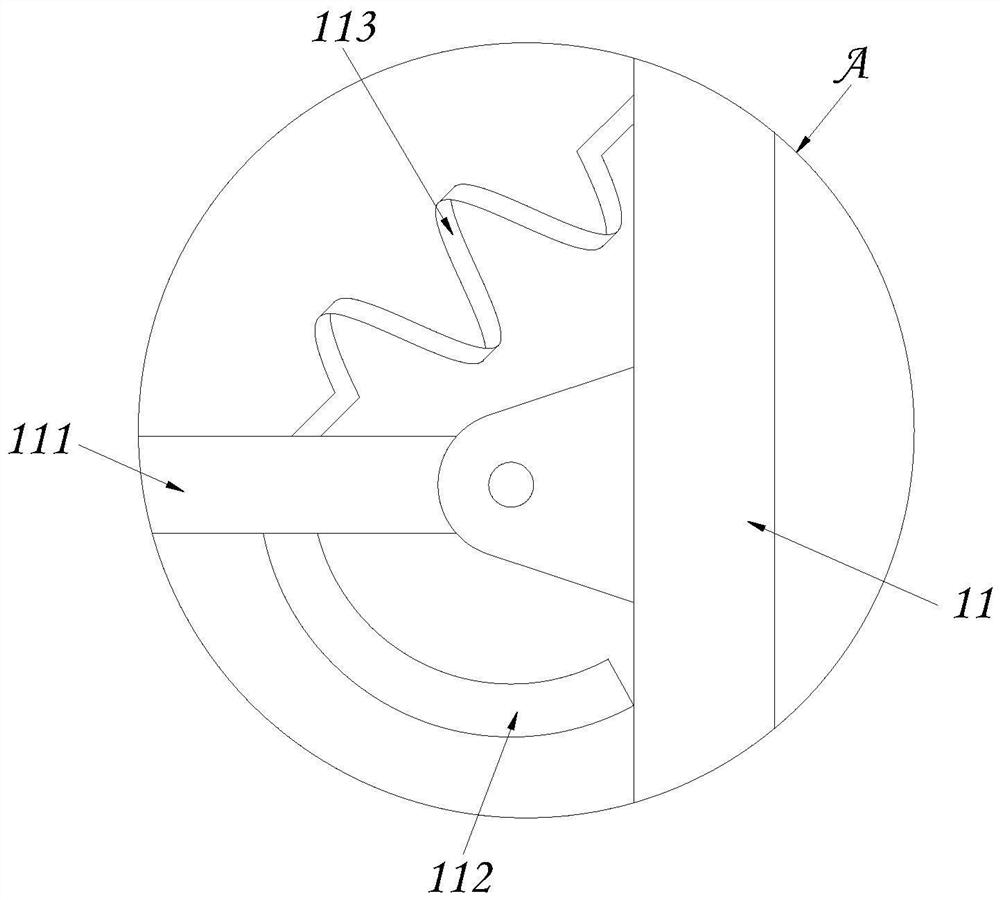

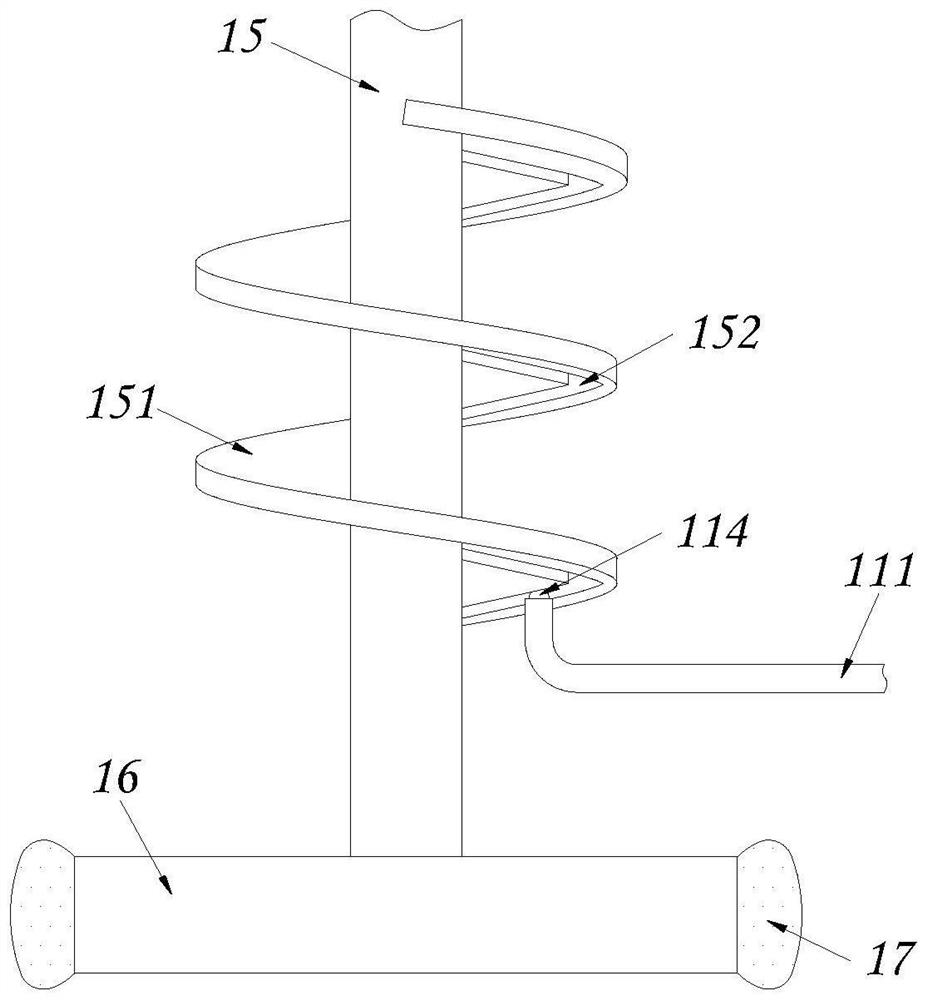

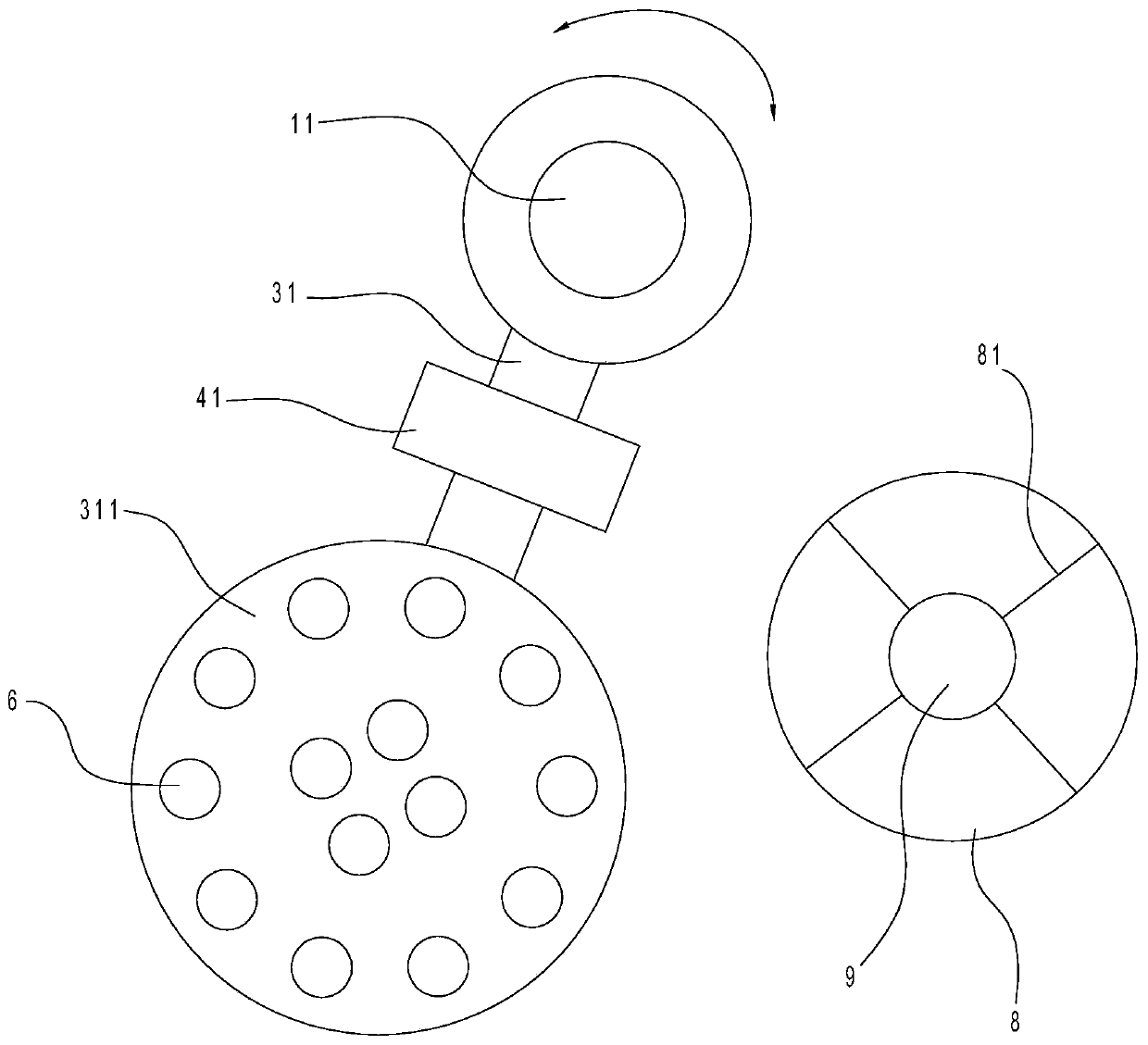

Automatic molding system of quartz crucible blank

The invention discloses an automatic molding system of quartz crucible blanks. The molding system comprises a first driving device, a second driving device, a positioning device and a second transmission shaft, wherein the second driving device is installed on the first driving device through a first transmission shaft; the positioning device and the second transmission shaft are installed on the second driving device; the positioning device comprises a mold, a positioning hole and a positioning mechanism, wherein the positioning hole is arranged at the bottom of the inner wall of the mold; the positioning mechanism is used in match with the mold and the positioning hole; the positioning mechanism comprises a horizontal guide rod and a vertical rod installed at one end of the horizontal guide rod; the horizontal guide rod and the vertical rod are fixedly connected and adjusted in positions by a regulation block and a regulation nut, the end part of the vertical rod is a positioning end, the vertical rod is matched with the inner wall of the mold; the positioning end is in match with the positioning hole; a support rod is installed on the horizontal guide rod; and the bottom of the support rod is installed on the second driving device. According to the system, coaxial reversion of the positioning device can be realized both during the whole material feeding process of the quartz crucible blanks and in the period after the material is fed completely; the efficiency and the quality of the quartz sand molding are guaranteed; and the automatic molding is realized.

Owner:XIAN JINNUO PHOTOELECTRIC TECH

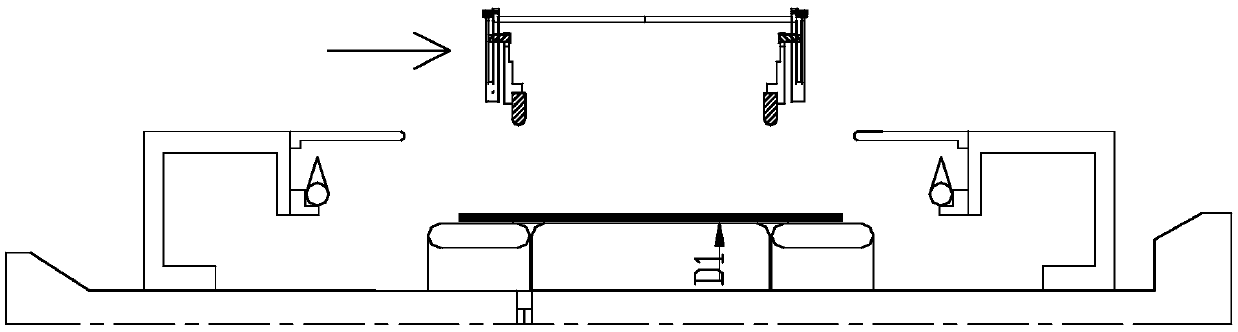

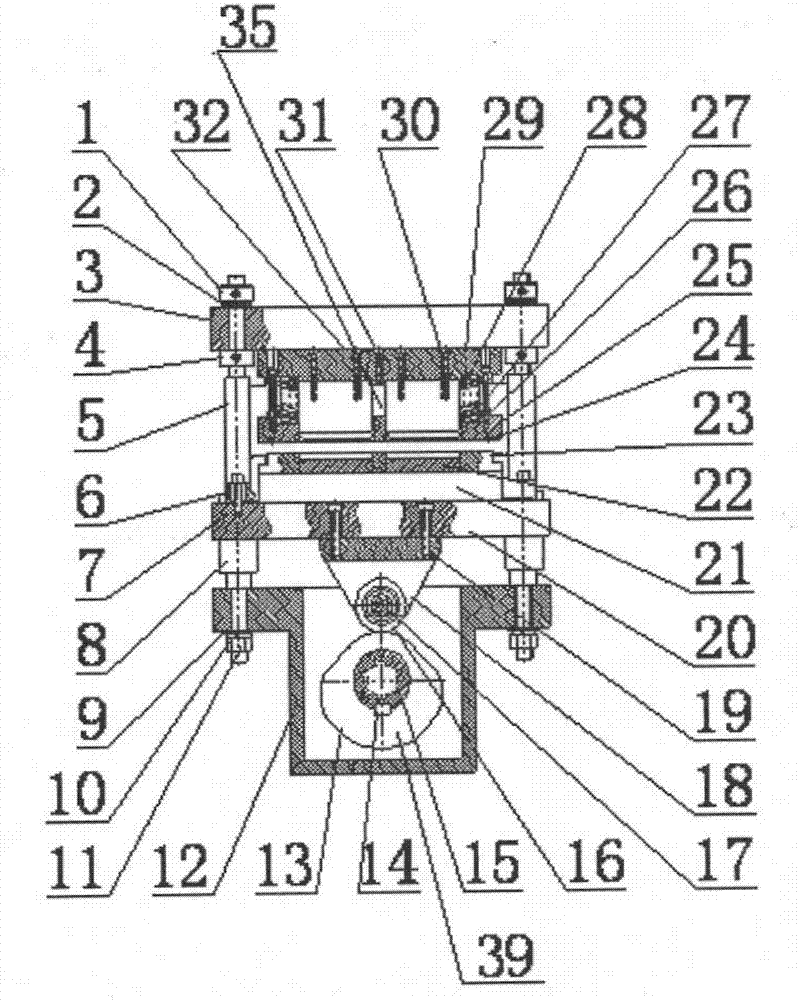

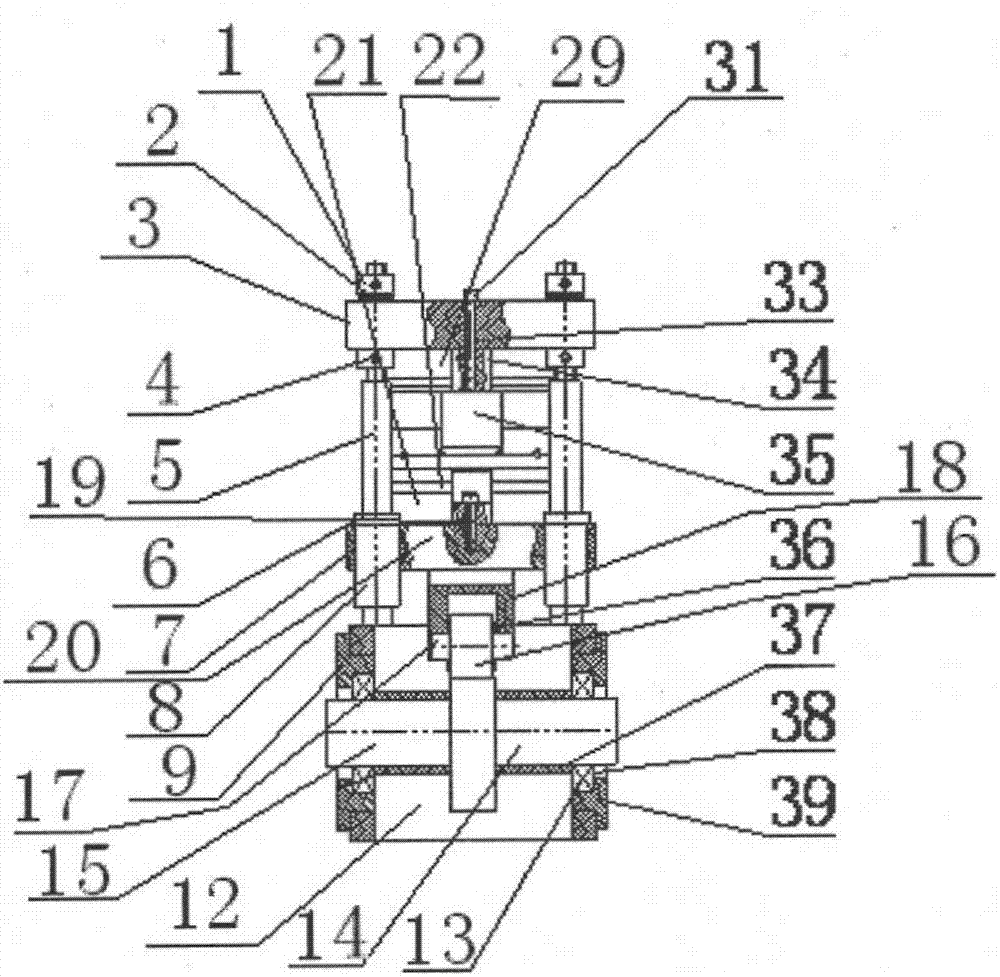

Device and method used for bead locating and turning up of aviation radial tire building machine

ActiveCN109572017AMeet the molding process requirementsRealize automatic formingTyresAviationTire bead

The invention relates to a device and method used for bead locating and turning up of an aviation radial tire building machine. The device comprises a tire body drum, a right angle forming unit, a left turning up unit and a right turning up unit; the tire body drum is arranged on a spindle, and can rotate along with the spindle; the right angle forming unit is used for pressing a carcass ply intoa right-angle structure by hooping when the tire body drum expands; the left turning up unit is arranged at the left side of the tire body drum, and comprises a left turning up bladder and a left turning up assembly; the left turning up bladder is arranged on a spindle between the left side of the tire body drum and the left turning up assembly; the left turning up assembly can be axially and movably arranged on a spindle at the left side of the tire body drum, and is used for installing a tire bead into the carcass ply in a turning up manner when the left turning up bladder is inflated to expand; the right turning up unit and the left turning up unit are symmetrically arranged at the right side of the tire body drum; and a right turning up assembly can be axially and movably arranged on aspindle at the right side of the tire body drum, and is used for installing the tire bead into the carcass ply in a turning up manner when a right turning up bladder is inflated to expand.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Automatic packaging machine for diamond tool bit

PendingCN109367883ANo need to worry about breakingNo need to worryPackaging automatic controlIndividual articlesEngineeringTransfer mechanism

The invention relates to an automatic packing machine for a diamond tool bit. The automatic packing machine comprises a machine frame, a feeding vibrating disk, a feeding channel, a stacking mechanism, a transferring mechanism and a boxing mechanism. An adsorption component comprises two air cylinders, a push plate, two air cylinder fixing plates, a permanent magnet plate, a discharging plate andfour vertical guide rods. The first air cylinder fixing plate horizontally moves above the stacking mechanism and the boxing mechanism. The second air cylinder fixing plate is arranged on the top of the first air cylinder fixing plate. The push plate and the discharge plate are connected through vertical guide rods, the second air cylinder fixing plate and the permanent magnet plate are arranged in the middle of the vertical guide rod in a sliding mode. The first cylinder is used for controlling the displacement of the permanent magnet plate. The second cylinder is used for controlling displacement of the push plate. The boxing mechanism comprises a boxing supporting seat, a boxing bottom plate, a boxing side plate and a box supporting plate. The boxing support seat is slidably connected to the machine frame. The boxing bottom plate is fixed to the boxing support seat. The four boxing side plates are fixed to the boxing bottom plate to form a box-shaped structure, and the box supporting plate moves upwards and downwards in the box-shaped structure. The automatic packing machine for a diamond tool bit has advantages that high in stability, longer in service life and low in maintenance cost.

Owner:福建南安市华天机械有限公司

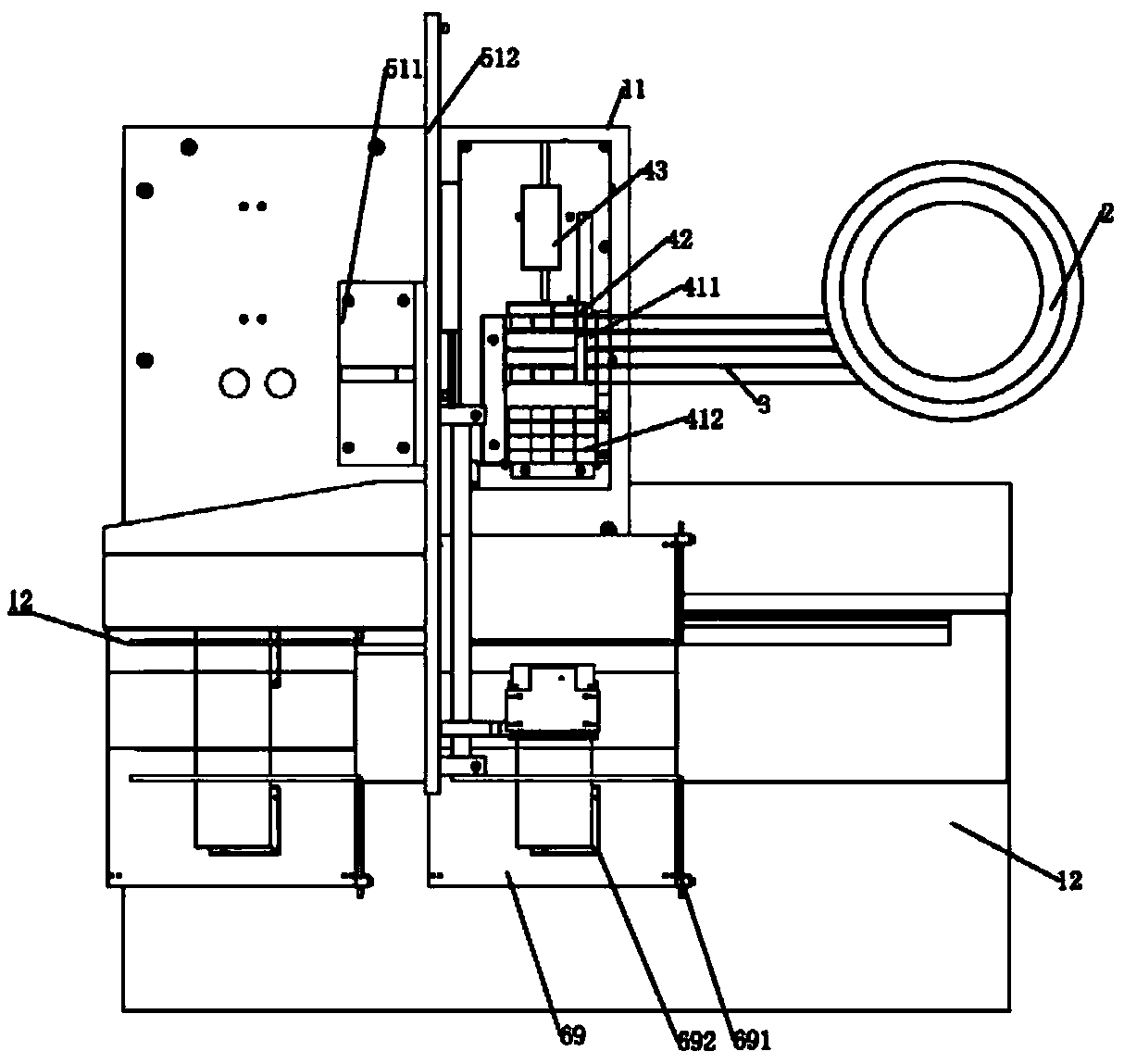

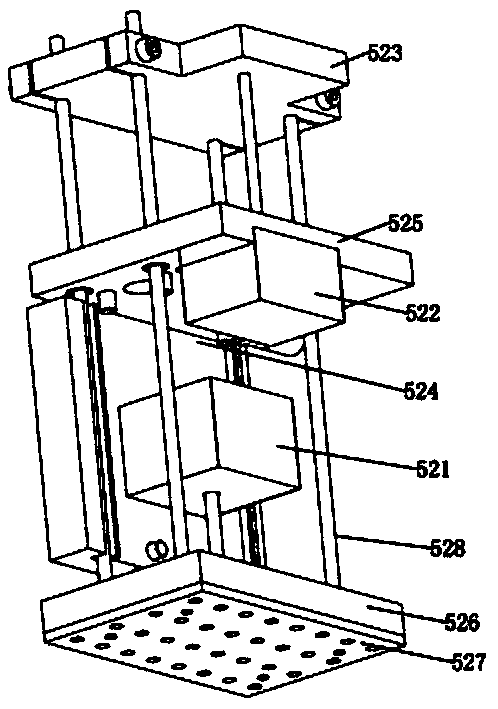

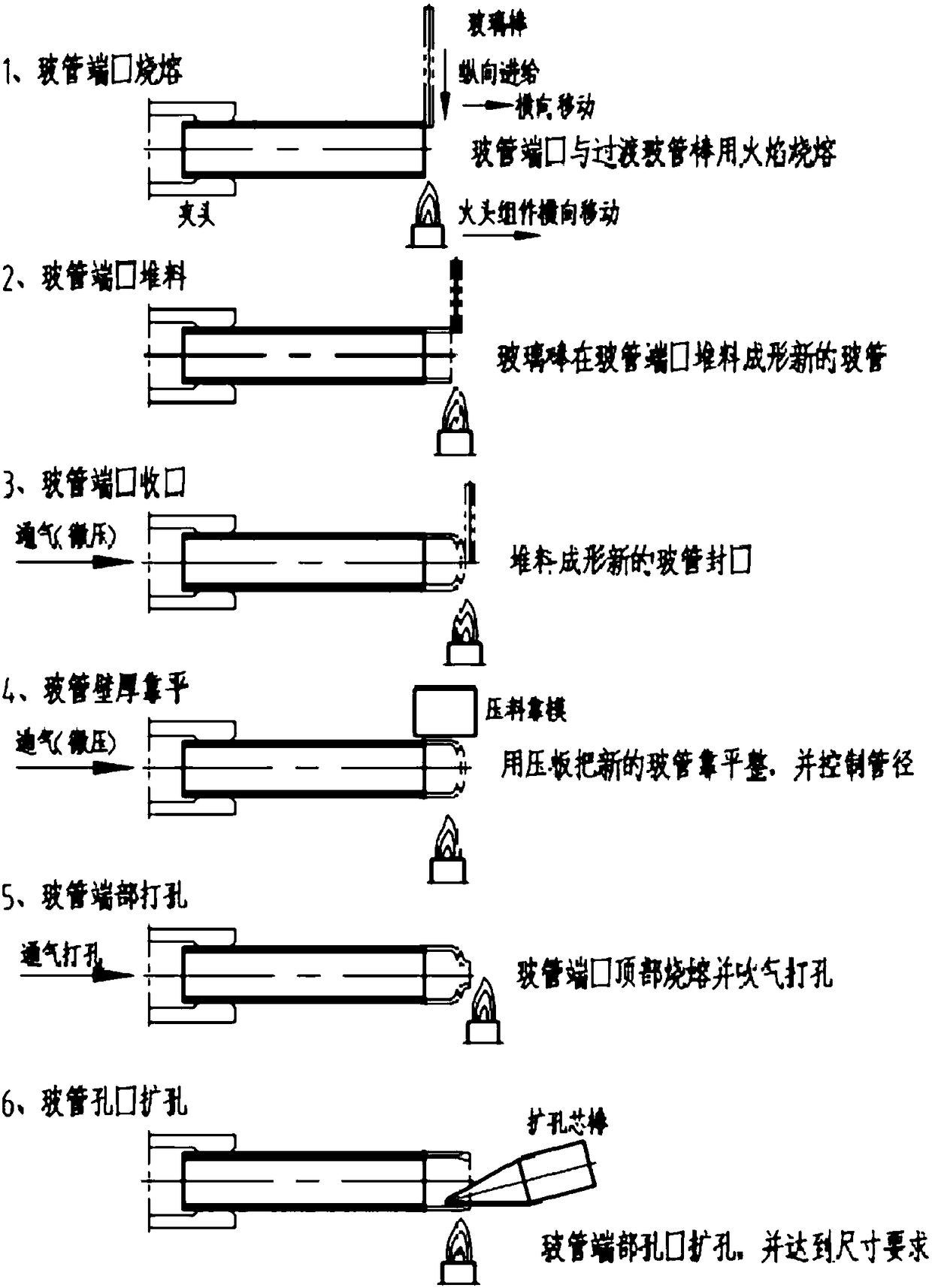

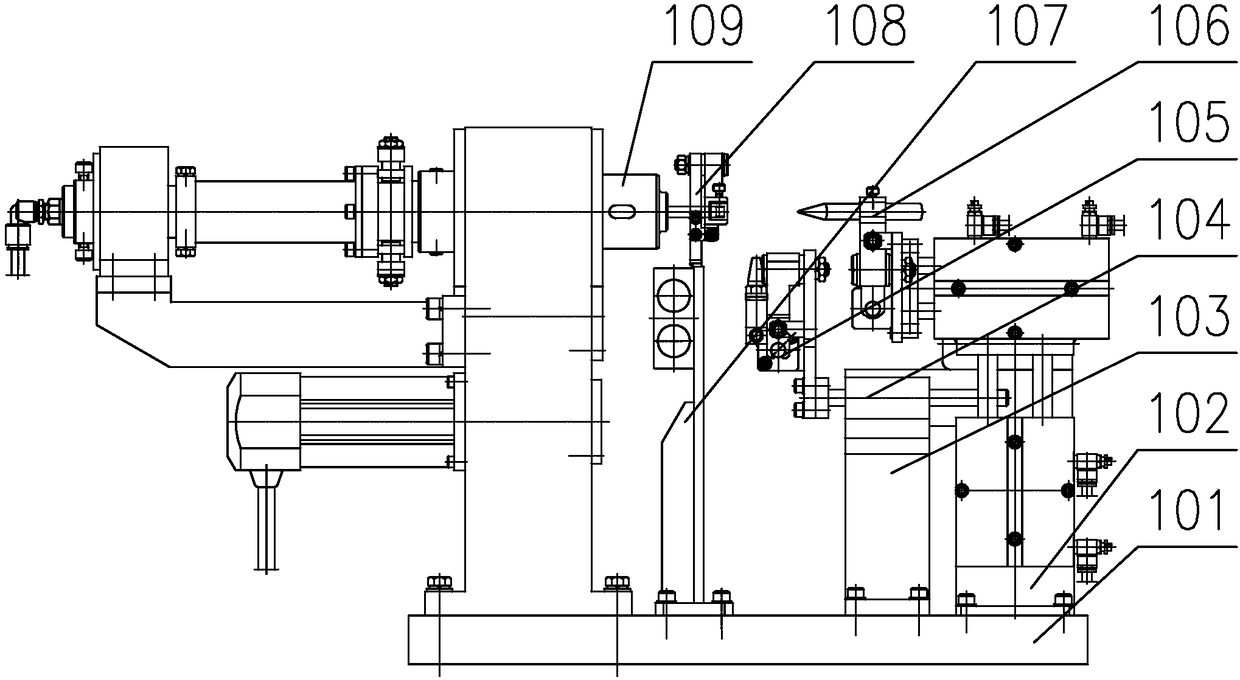

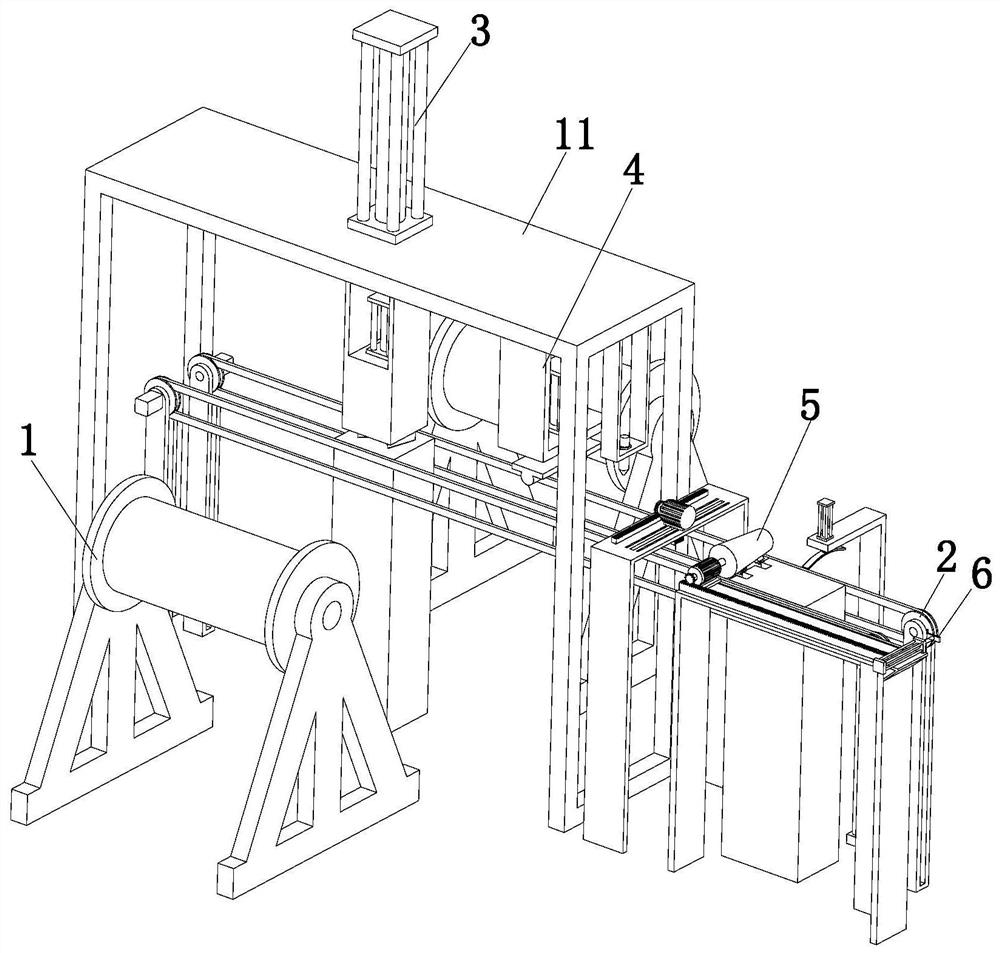

Method and equipment for automatically stacking glass to form glass tubes

InactiveCN108409116AUniform wall thicknessProduct quality consistency is goodGlass reforming apparatusGlass productionEngineeringGlass tube

The invention discloses a method and equipment for automatically stacking glass to form glass tubes. The method comprises the following steps: melting an end of a rotating glass tube with flame; aftera glass bar is melted with flame, sticking the glass bar to an end of the glass tube; and carrying out movement and feeding to form a spiral transitional glass tube at an end of the glass tube; sealing an end of the transitional glass tube, ventilating and bubbling; pressing a pressure plate against the outer wall of the transitional glass tube; controlling the diameter of the transitional glasstube; and perforating the closed end and carrying out pore broadening and forming so as to realize automatic forming of the transitional glass tube. The equipment comprises a glass tube clamping and ventilating mechanism, a glass tube outer wall pressing mechanism, a fire head device and a pore broadening mechanism. The transitional glass tube is formed automatically, the quality consistency of products is good, the labor intensity of workers is relieved, and the production efficiency is improved.

Owner:SOUTHEAST UNIV

Finishing system and finishing process for magnesium aluminate spinel brick production

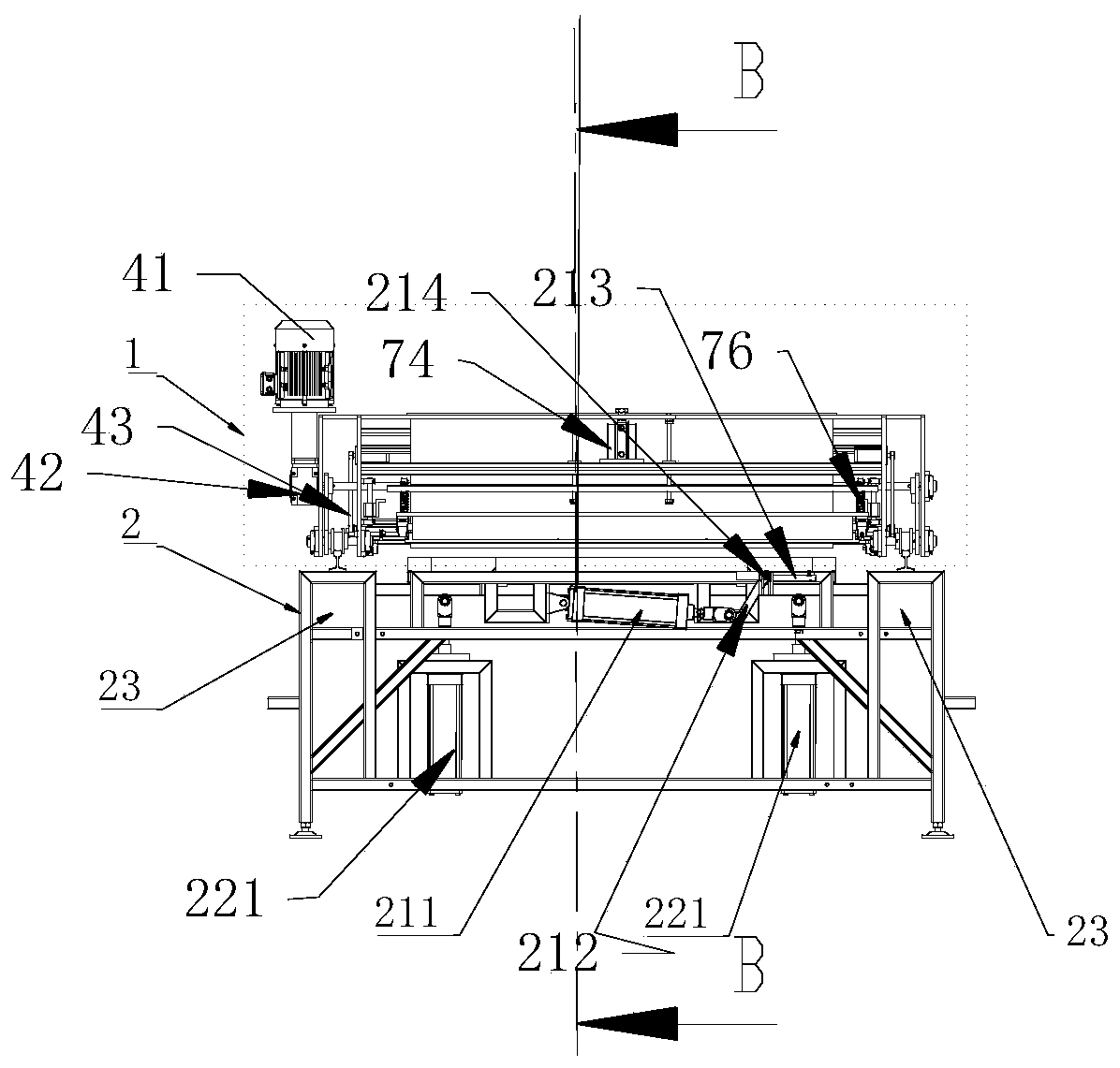

ActiveCN113618894AAvoid bendingEasy to GrindDischarging arrangementCeramic shaping plantsBrickElectric machinery

The invention discloses a finishing system and a finishing process for magnesium aluminate spinel brick production, and belongs to the field of magnesium aluminate spinel brick machining. The finishing system for magnesium aluminate spinel brick production comprises a base table plate, the base table plate is fixedly connected with a building, four carrying shaft seats are arranged at the top end of the base table plate, and every two carrying shaft seats form a group. A carrying roller is arranged in the middle of each group of carrying shaft seats, wherein a carrying motor is arranged on the side wall of one carrying shaft seat. The two carrying rollers are connected through a carrying belt, an outrigger guide rail is arranged above the base table plate, two ends of the outrigger guide rail are fixedly connected with the side wall of the base table plate, a lifting table is arranged on the outrigger guide rail in a sleeving mode, and a carrying plate is fixedly mounted at the top end of the outrigger guide rail. An extension table is arranged on one side of the base table plate, a grinding assembly is arranged on one side of the extension table, and a discharging assembly is arranged below the grinding assembly. According to the finishing system and the finishing process for magnesium aluminate spinel brick production, when the lifting table ascends and descends along the outrigger guide rail, blocky materials on the carrying belt can be crushed.

Owner:宜兴新威利成耐火材料有限公司

Automatic forming equipment for expandable polyethylene heat insulation cup sleeve

InactiveCN112971498ARealize automatic cutting operationRealize automatic glue applicationLiquid surface applicatorsCoatingsAutomatic processingMoulding device

The invention discloses automatic forming equipment for an expandable polyethylene heat insulation cup sleeve, and belongs to the technical field of automatic cup sleeve machining. The equipment comprises an expandable polyethylene unwinding frame, a mounting frame, an arc-shaped cotton moving device, an arc-shaped cutting device, an ironing and glue dispensing device, an automatic forming device and a forming and discharging device, wherein the expandable polyethylene unwinding frame is located at one end of the mounting frame, the arc-shaped cotton moving device is located below the mounting frame, the arc-shaped cutting device is arranged on the mounting frame, the ironing and glue dispensing device comprises an ironing and glue dispensing part and a glue dispensing and uniform smearing part, the ironing and glue dispensing part is arranged on the mounting frame, and the automatic forming device is arranged on the side of the arc-shaped cotton moving device. The automatic forming device comprises a supporting table, a coiling piece and a flattening piece, the coiling piece is located beside the arc-shaped cotton moving device, the flattening piece is located above the supporting table, and the forming and discharging device is located beside the automatic forming device. According to the invention, automatic processing and forming operation of the cup sleeve is realized, and the working efficiency is improved.

Owner:黄波

Egg cake processing device

InactiveCN110604139AAchieve liftingAchieve rotationBaking ovenOil/fat bakingEngineeringMechanical engineering

The invention discloses an egg cake processing device. The device comprises a base, baking trays and a rack, wherein baking trays are installed on the base, the rack is installed on the base, the number of the baking trays is two, the outer side of the baking tray located on the upper portion is connected with a turnover mechanism, a lifting mechanism is installed on the upper portion of the rack,and a rotating mechanism is installed on the lower portion of the lifting mechanism. The technical problem that in the prior art, a machining device cannot complete lifting and turnover is solved.

Owner:孙勇

Preparation method of purple sweet potato smashed bean bun

PendingCN111631348AGreat tasteIncrease the variety of flavorsDough extruding machinesDough processingHorticultureChemistry

The invention discloses a preparation method of a purple sweet potato smashed bean bun. The purple sweet potato smashed bean bun comprises a steamed stuffed bun body which is made of fermented flour dough and is provided with an inner cavity, wherein the inner cavity is filled with mashed purple sweet potatoes and mashed bean paste, each of the mashed purple sweet potatoes and the mashed bean paste occupy a half of the space of the inner cavity, and the mashed purple sweet potatoes and the mashed bean paste are not mixed with each other. The steamed stuffed bun body and the inner cavity are cylindrical, and each of the mashed purple sweet potatoes and the mashed bean paste pack the space at one end of the cylindrical inner cavity. According to the preparation method of the purple sweet potato smashed bean bun, one steamed stuffed bun is filled with the two kinds of stuffing which cannot be mixed, so that the taste and flavor types of the steamed stuffed bun are increased, and requirements of people are met.

Owner:合肥市福客多快餐食品有限公司

Cement proportioning device for construction site

PendingCN107901240ARealize automatic formingAffect the cement strengthCement mixing apparatusControl apparatusArchitectural engineeringMechanical engineering

The invention discloses a cement proportioning device for a construction site. The cement proportioning device comprises a water tank, a mixing barrel and a cement barrel, and the water tank communicates with the mixing barrel through a water pump; the body of the mixing barrel is provided with a monitoring window, a pressure controller and an electric cabinet electrically connected to a mixing device, and the mixing device is arranged in an inner cavity of the mixing barrel; an outlet of the mixing barrel is further provided with a high pressure pump which communicates with the cement barrelthrough a pipeline; according to the cement proportioning device for the construction site, the water tank and the cement barrel are separate, and mixing is performed by the mixing device; fluid is pumped by the water pump, so that cement is automatically formed and used for the construction site at any time; the cement proportioning device is simple in structure, and easy to use; labor forces arenot required to proportion the cement on the construction site, so that time and manpower are saved; the influence of long-distance transport of a mixing truck on the cementation strength of the cement is avoided, and the cost is reduced; and the service efficiency of the cement is improved.

Owner:安吉孝丰飞乐建筑材料厂

Two-way movement cam shaping mechanism

The invention discloses a two-way movement cam shaping mechanism. The two-way movement cam shaping mechanism comprises a cam case, a cam spline housing is arranged in the cam case, a punch assembly is arranged above the cam case and comprises a cover plate, and the cover plate is fixedly connected with the cam case through guide columns. A punch bottom plate is arranged below the cover plate, a duralumin punch and pressing plate dies are arranged below the punch bottom plate, the punch bottom plate is connected with a lower module through a punch locating plate, lower duralumin dies are arranged outside the lower module, the lower duralumin dies are fixedly connected with a guide plate through a lower duralumin die pressing plate, a first roller base is arranged below the guide plate, and a first roller is arranged on the first roller base. The two-way movement cam shaping mechanism is characterized in that another punch assembly is arranged below the cam case and comprises a bottom plate, a second roller base is arranged on the bottom plate, and a second roller is arranged on the second roller base; the second roller is tangent to a first cam; the first roller is tangent to a second cam. The two-way movement cam shaping mechanism can realize compacting and shaping of packing materials when a bubble cap machine runs, compaction force can be freely adjusted, and insufficient pressure or excessive pressure is avoided.

Owner:上海江南制药机械有限公司

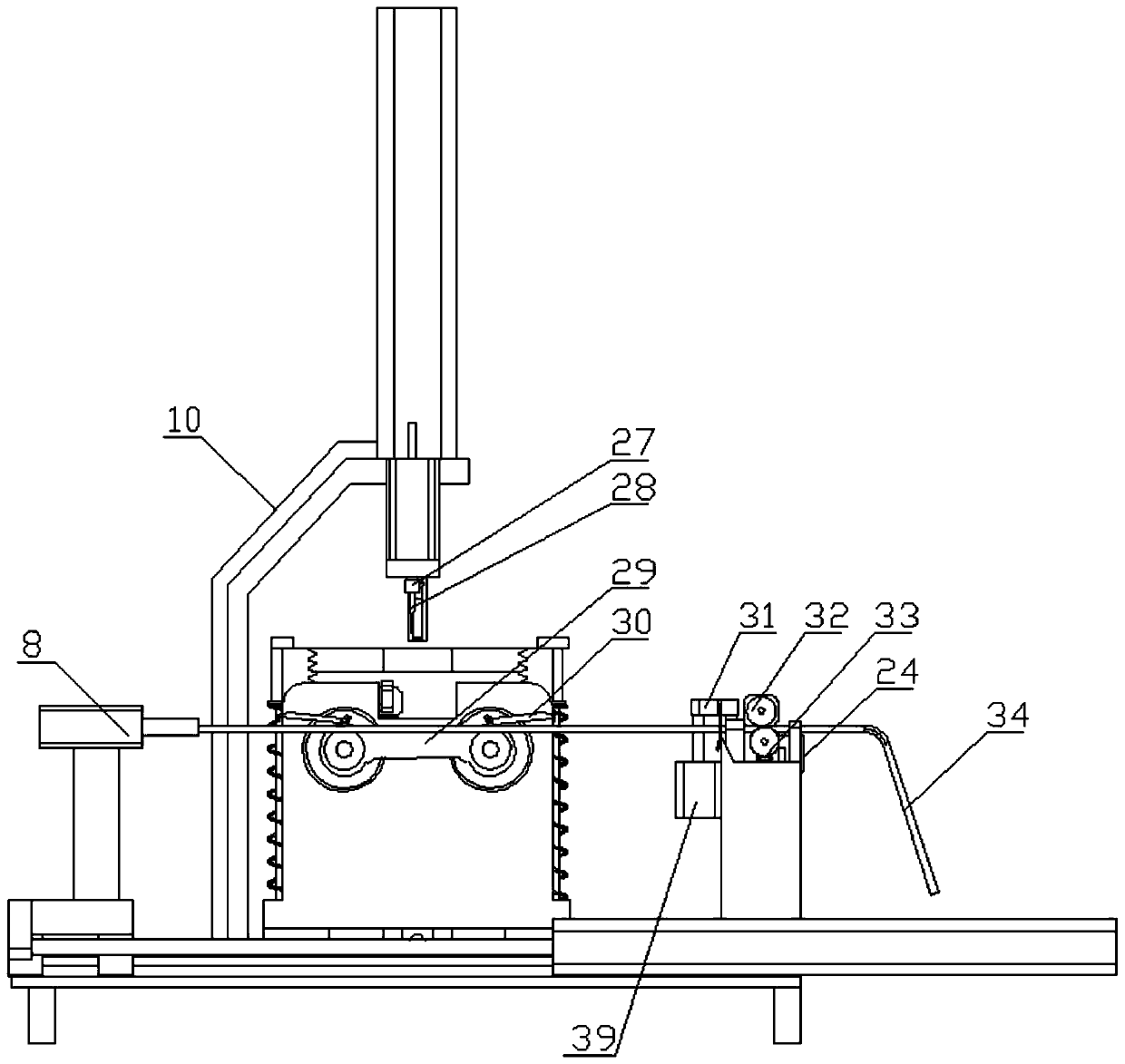

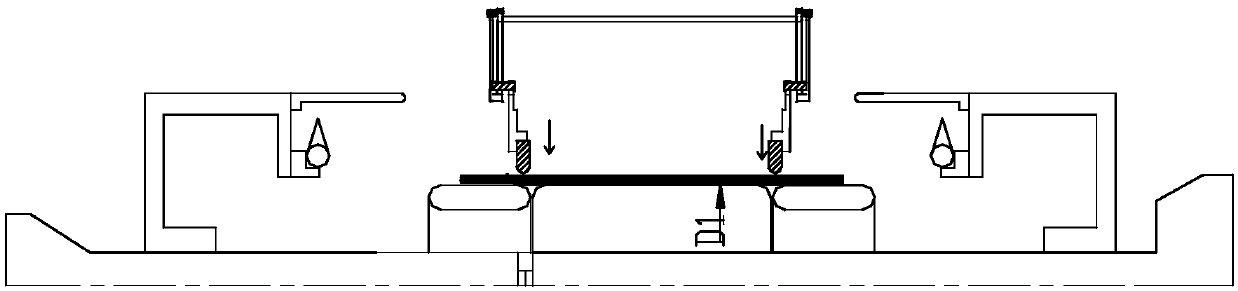

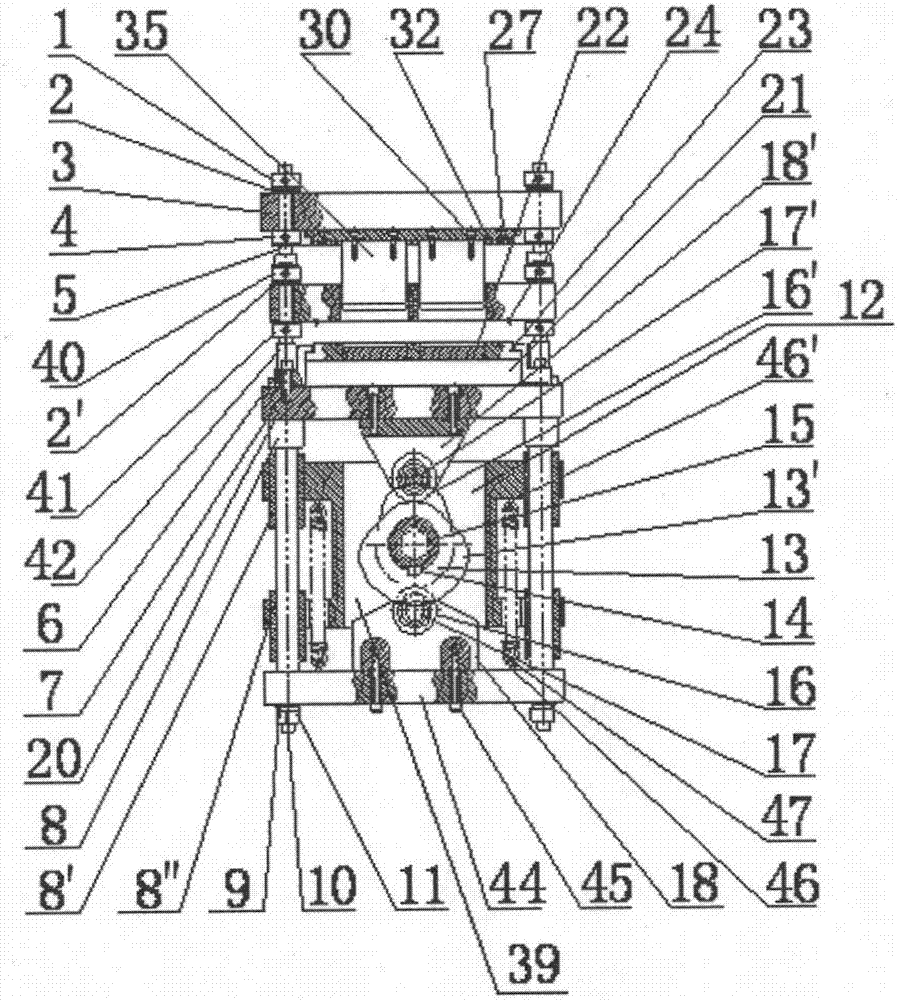

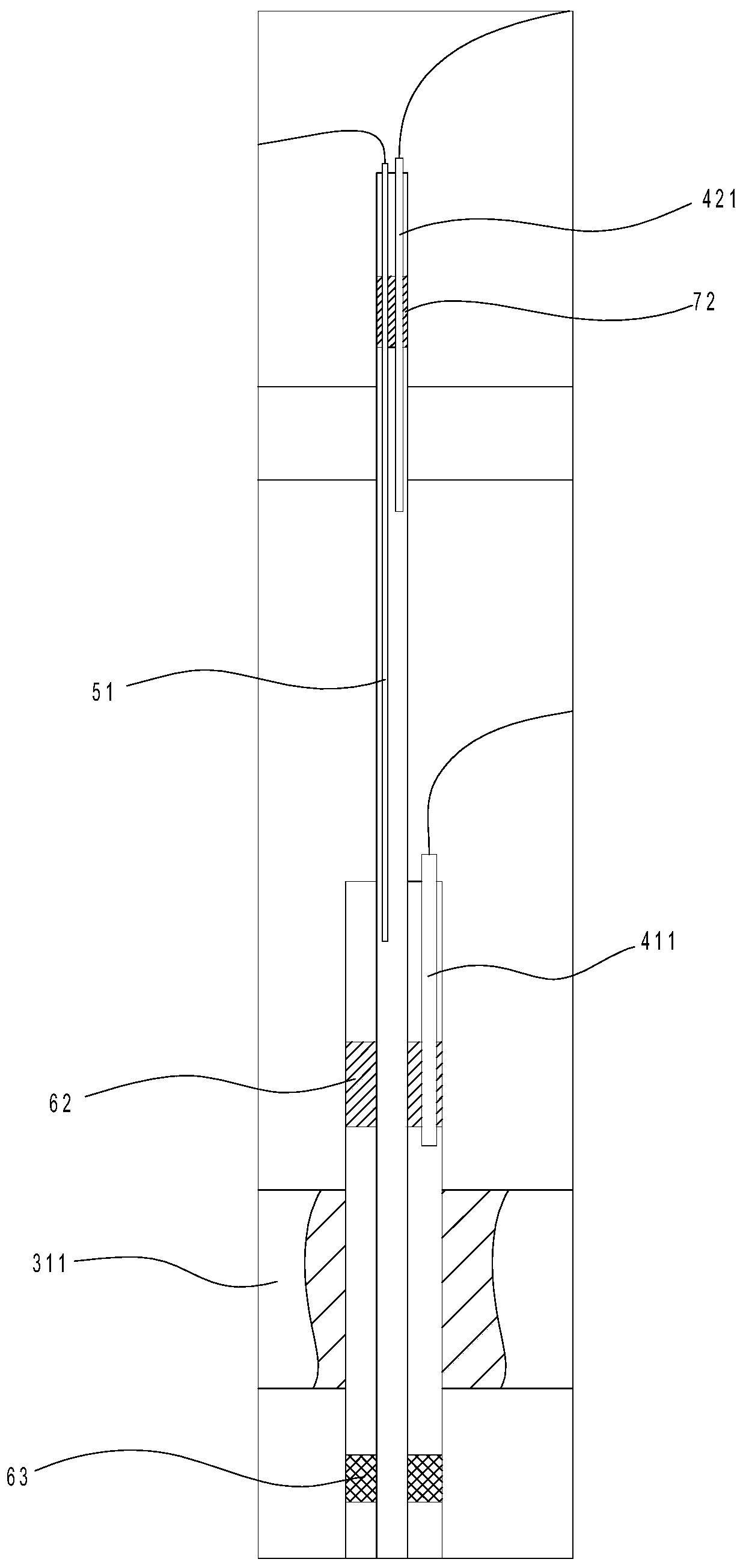

Aviation radial tire body barrel molding device and tire body drum molding process

ActiveCN110920112AMeet the molding process requirementsRealize automatic formingTyresTire beadAirbag

The invention provides an aviation radial tire body barrel molding device which includes a main shaft and a tire body drum. The main shaft is externally connected with driving force to do rotational movement; the tire body drum is installed on the main shaft and is rotated synchronously together with the main shaft, a tire body cord fabric of a tire body barrel is attached to the outer surface ofthe end, far away from the main shaft, of the tire body drum, and the two sides of the tire body drum are provided with a first reversed wrapping unit and a second reversed wrapping unit correspondingly; the first reversed wrapping unit or second reversed wrapping unit includes a reversed wrapping airbag for supporting the tire body cord fabric and a moving assembly, the reversed wrapping airbag is arranged between the moving assembly and the tire body drum, and the moving assembly is arranged on the main shaft and does rectilinear motion to synchronously get close to or be far away from the tire body drum along with rotation of the main shaft; and when the tire body drum is inflated and swells, the tire body cord fabric is hooped and pressed to be in a right angle shape through a compression assembly along the radial ends of the tire body drum, a tire bead is reversely wrapped into the tire body cord fabric through a boosting piece when the reversed wrapping airbag is inflated and swells, the problem about rubber folding at the root of the tire bead of the aviation radial tire body barrel is solved, and automatic molding of the tire body barrel is realized.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Full-automatic hotcake baking machine

ActiveCN113907101ARealize automatic formingImprove product qualityBaker's peelsDough shaping and cutting apparatusMechanical engineeringIndustrial engineering

The invention discloses a full-automatic hotcake baking machine and belongs to the technical field of automatic equipment for hotcakes. The full-automatic hotcake baking machine is characterized by comprising a machine frame, wherein the machine frame comprises a frame type supporting platform and supporting legs, and the supporting legs are mounted at the lower part of the frame type supporting platform; and a conveying device is arranged on the machine frame, a cake blank forming device and a hotcake baking device are sequentially arranged on the conveying device from right front to back, the conveying device comprises a dough cake blank conveying belt and a plurality of conveying guide rollers, and the dough cake blank conveying belt is arranged on all the conveying guide rollers in a sleeve mode. According to the full-automatic hotcake baking machine, automatic forming and baking operation of the hotcakes can be achieved, and the production efficiency is increased while the product quality is improved.

Owner:郭刚

Full-automatic filter plate production equipment and process

InactiveCN112123661AImprove molding qualityRealize automatic formingDomestic articlesMetal working apparatusFilter pressMechanical engineering

Owner:浙江金鸟压滤机有限公司

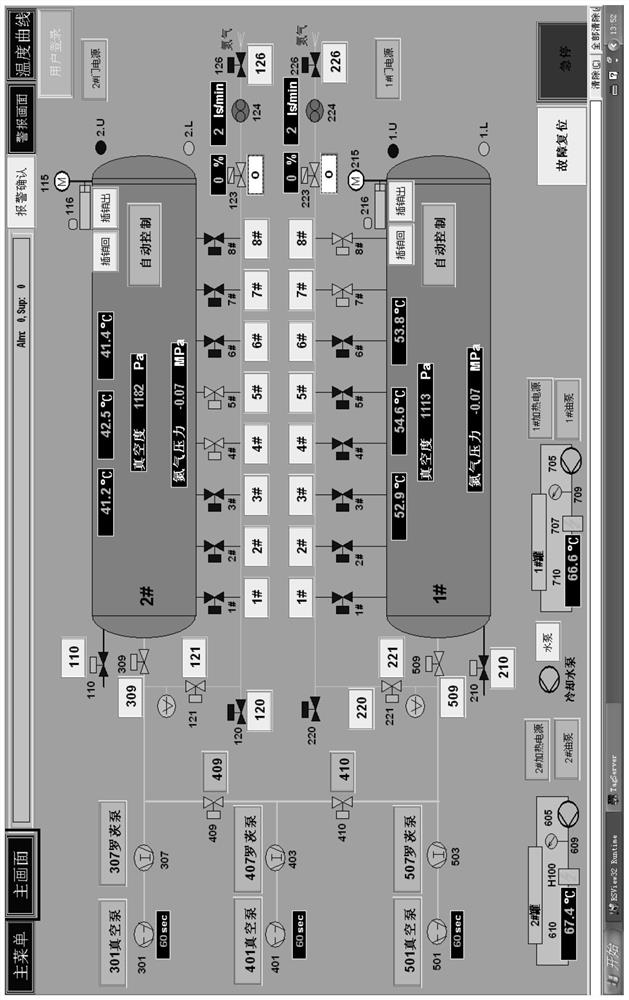

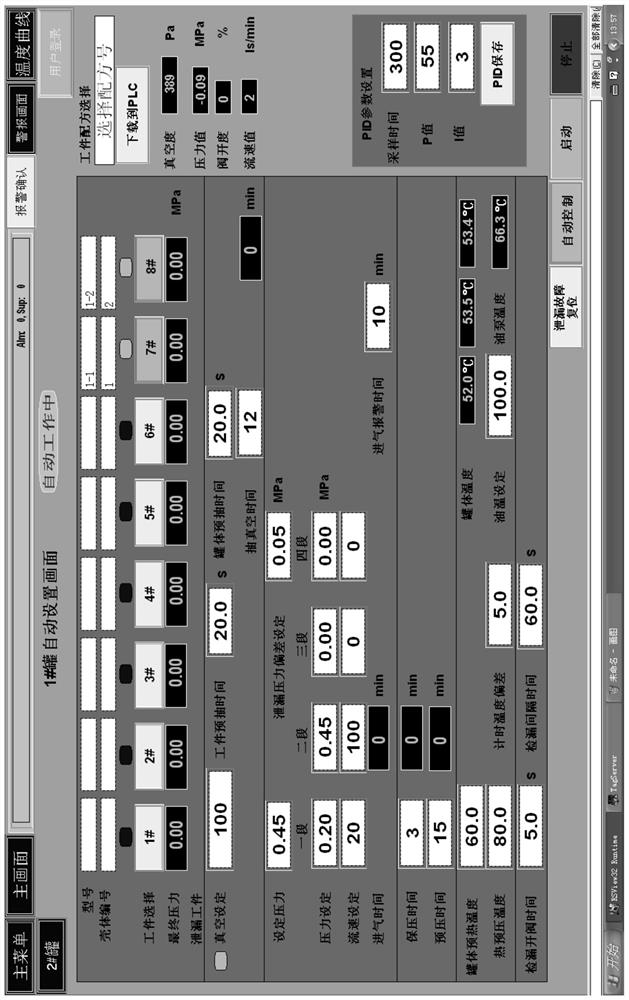

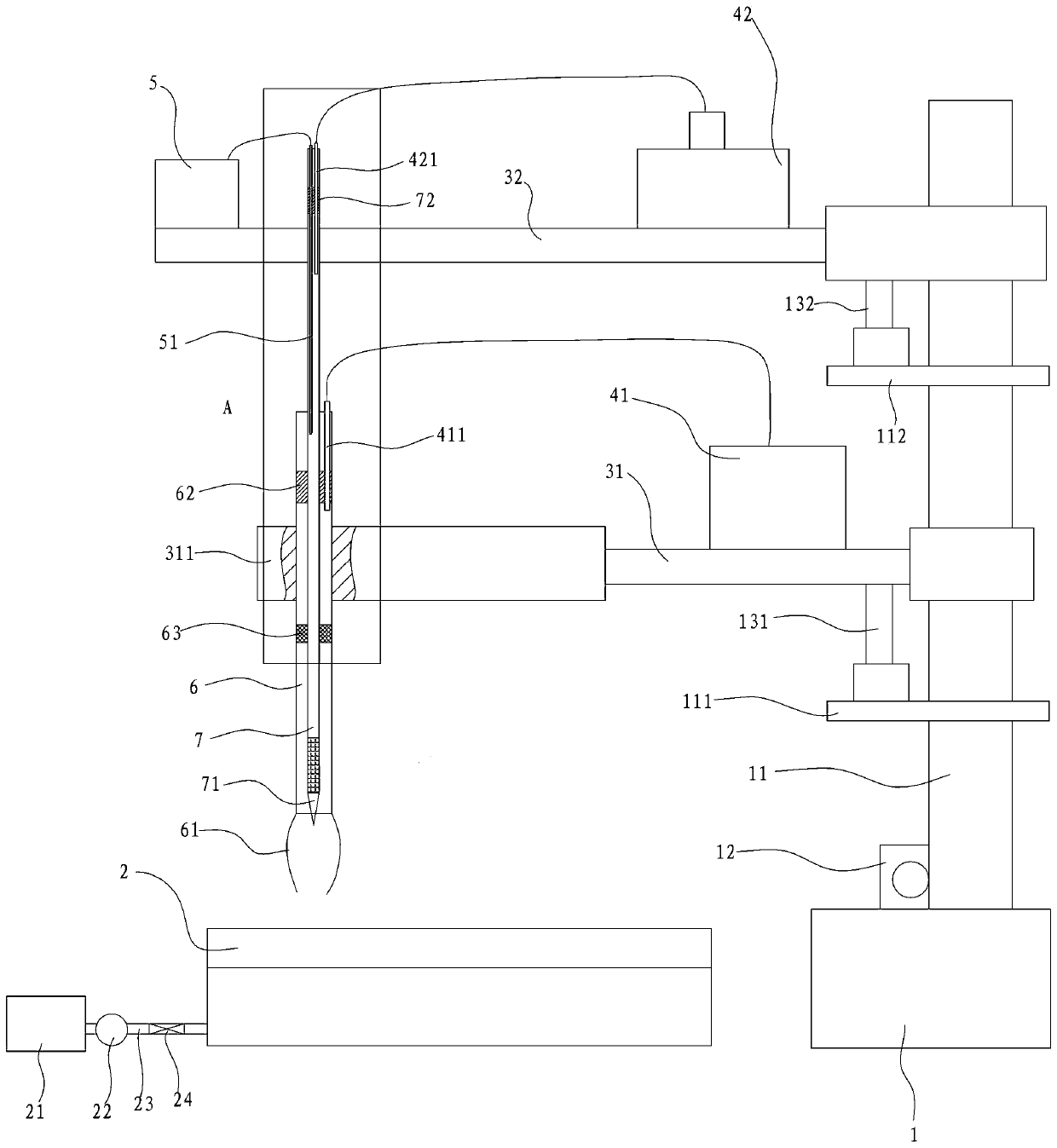

A kind of combustion chamber thermal insulation layer vacuum patch automatic control system and operation method

The invention provides an automatic control system and an operation method for a vacuum patch of a thermal insulation layer of a combustion chamber, including a large-sized temperature-controlled tank cabin, a high-efficiency vacuum protection system, a step-by-step flexible pressurization system and a full-process automatic control system; The temperature-controlled tank cabin provides the cabin space and temperature; the high-efficiency vacuum protection system provides the cabin vacuum degree; the step-by-step flexible pressurization system provides pressure for the cabin; the full-process automatic control system automatically controls the large The size and temperature control tank compartment, the high-efficiency vacuum protection system and the step-by-step flexible pressurization system are used to control and display the temperature, vacuum degree and pressure of the system, and provide real-time display alarms, reports, and record temperature after automatically matching the set parameters. Rising curve, monitoring equipment operation. The invention realizes the automatic monitoring of the whole process of forming the inner insulation layer of the solid rocket motor, and provides theoretical basis and technical support for optimizing the production process and reviewing product problems.

Owner:SHANGHAI AEROSPACE CHEM ENG INST

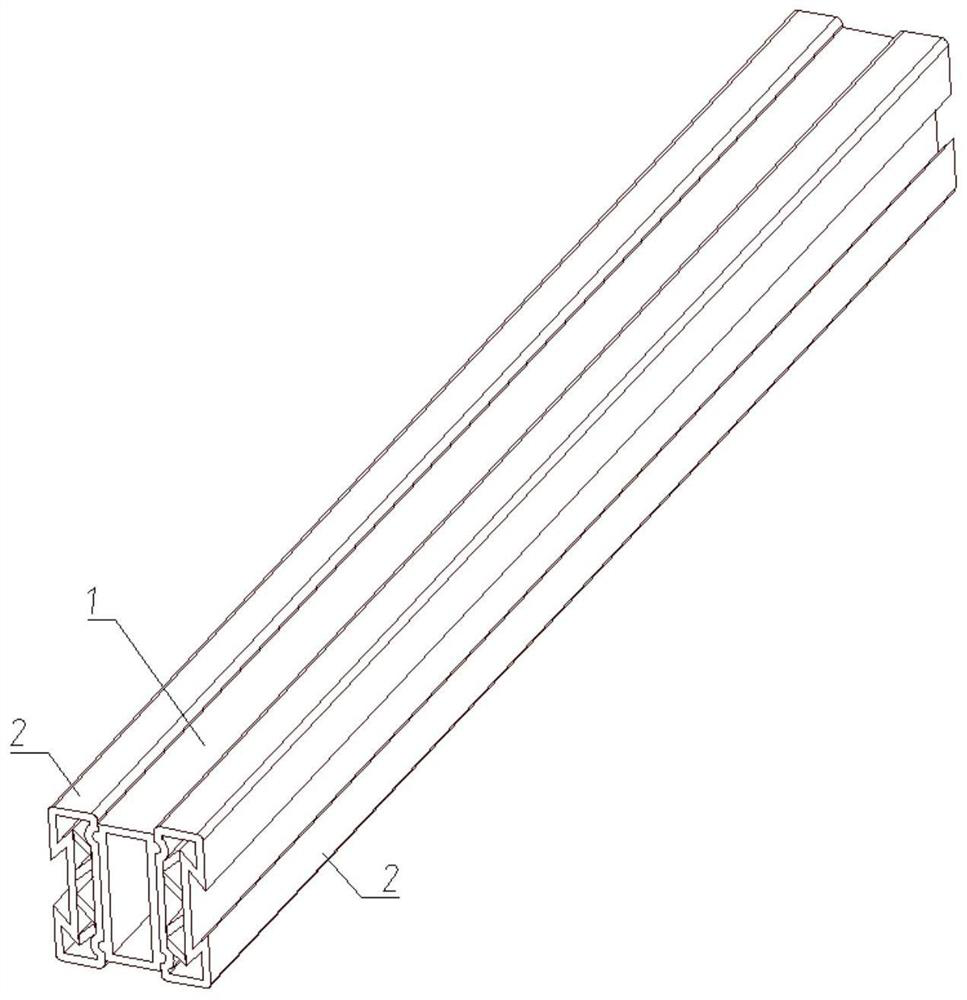

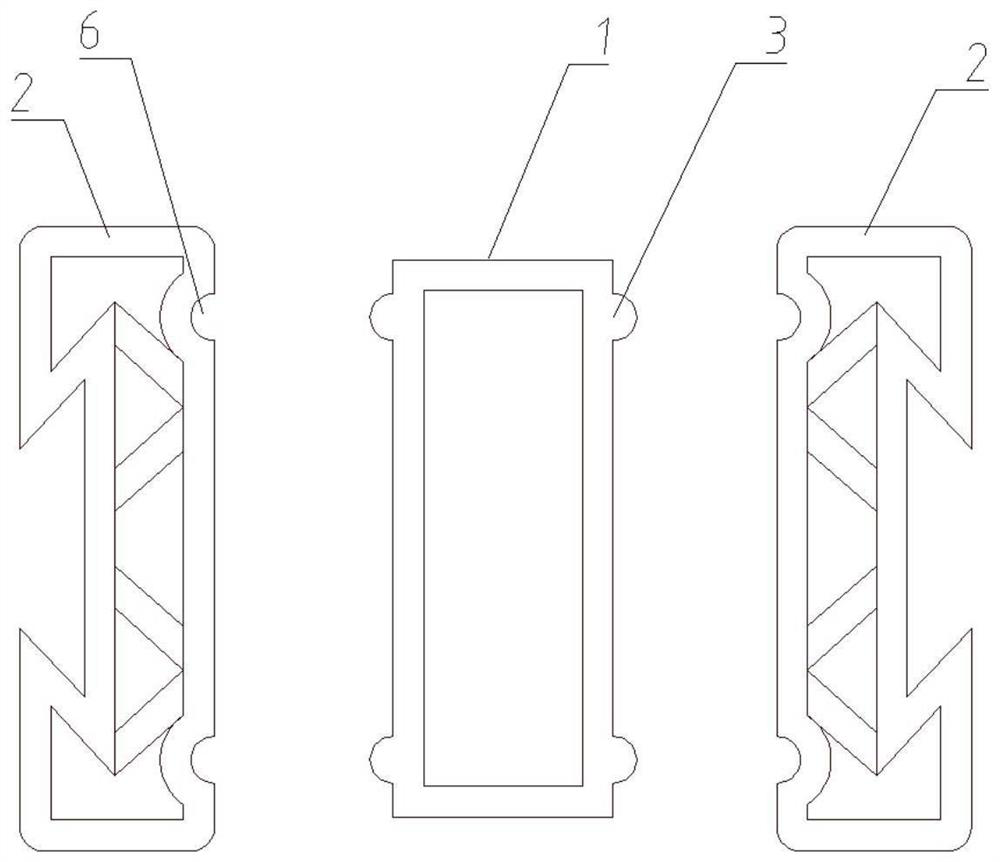

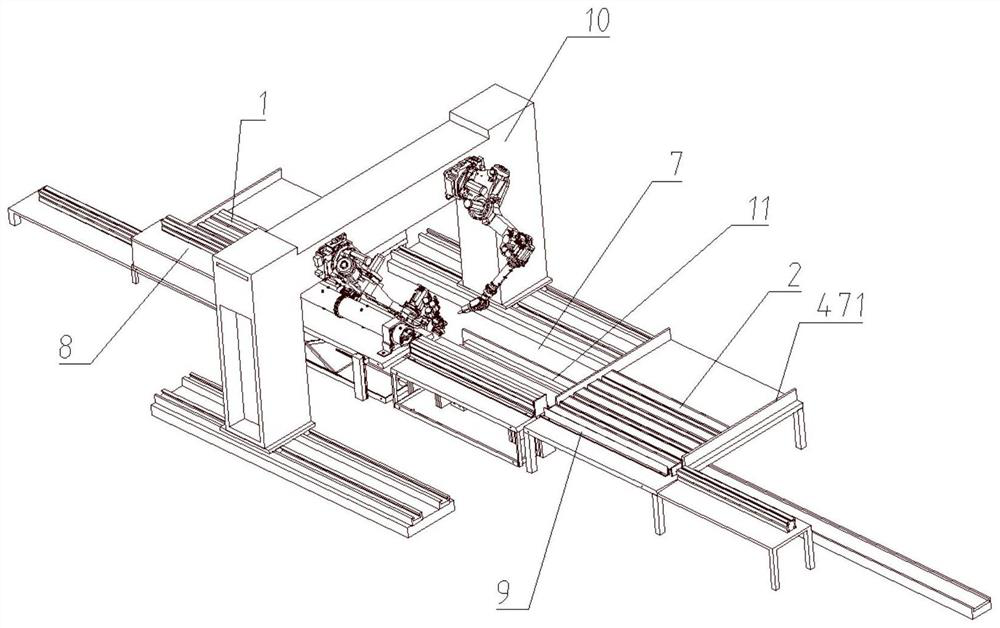

Forming robot and forming method for reinforcing back ridge of corrosion-resistant aluminum formwork

ActiveCN113182720AAchieve combinationRealize automatic formingWelding/cutting auxillary devicesAuxillary welding devicesMolding machineStructural engineering

The invention provides a forming robot for a reinforcing back ridge of a corrosion-resistant aluminum formwork. The forming robot comprises a workbench, a side pipe feeding mechanism, a middle pipe feeding mechanism and a welding mechanism; the workbench is used for supporting a middle pipe and a side pipe to be welded, a rectangular hole is formed in the table top of the workbench, and a bearing structure capable of moving up and down is arranged at the position, corresponding to the rectangular hole, of the workbench; the side pipe feeding mechanism is used for moving the side pipe to be welded to the bearing structure; the middle pipe feeding mechanism is used for moving the middle pipe to be welded to the bearing structure; the welding mechanism is used for welding the side pipe and the middle pipe which are fed; and the side pipe feeding mechanism comprises a side pipe feeding structure and a side pipe overturning structure, the side pipe feeding structure is used for feeding the side pipe into the side pipe overturning structure, and the side pipe overturning structure is used for overturning the side pipe by 180 degrees. The forming robot can achieve full-automatic forming of the reinforcing back ridge.

Owner:BINZHOU UNIV

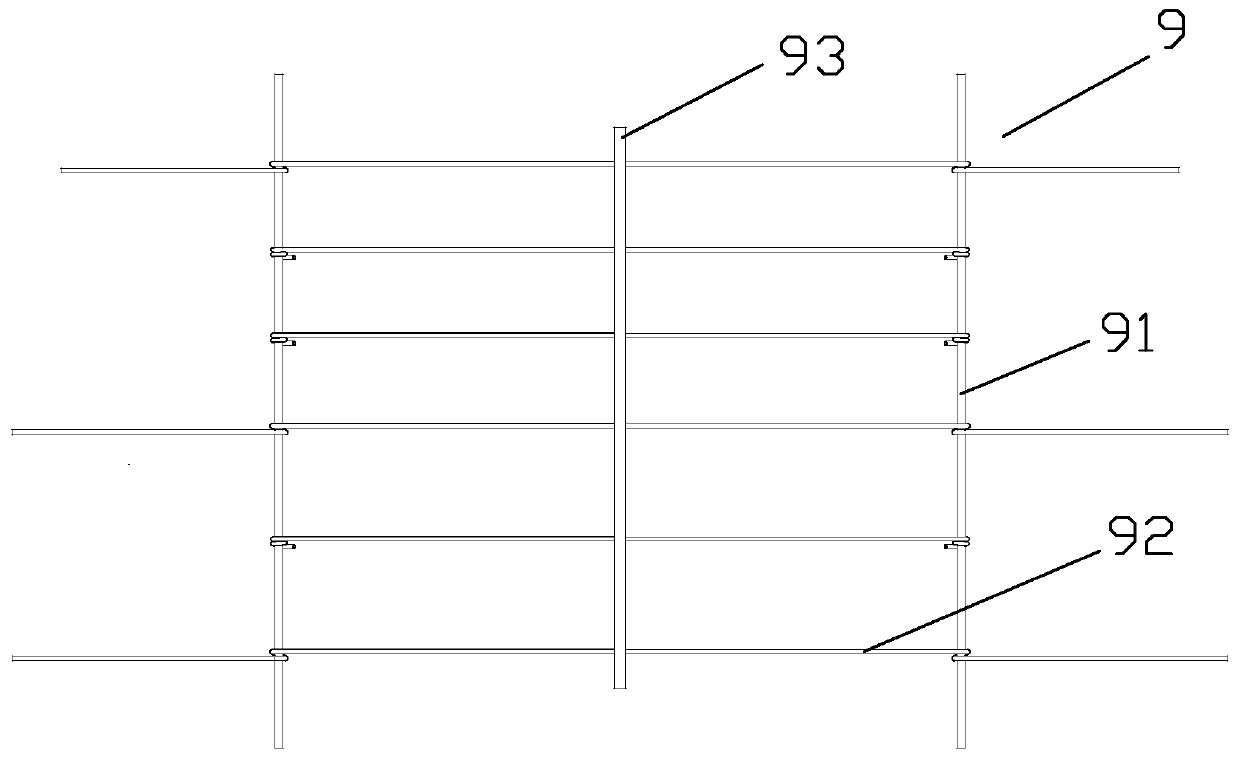

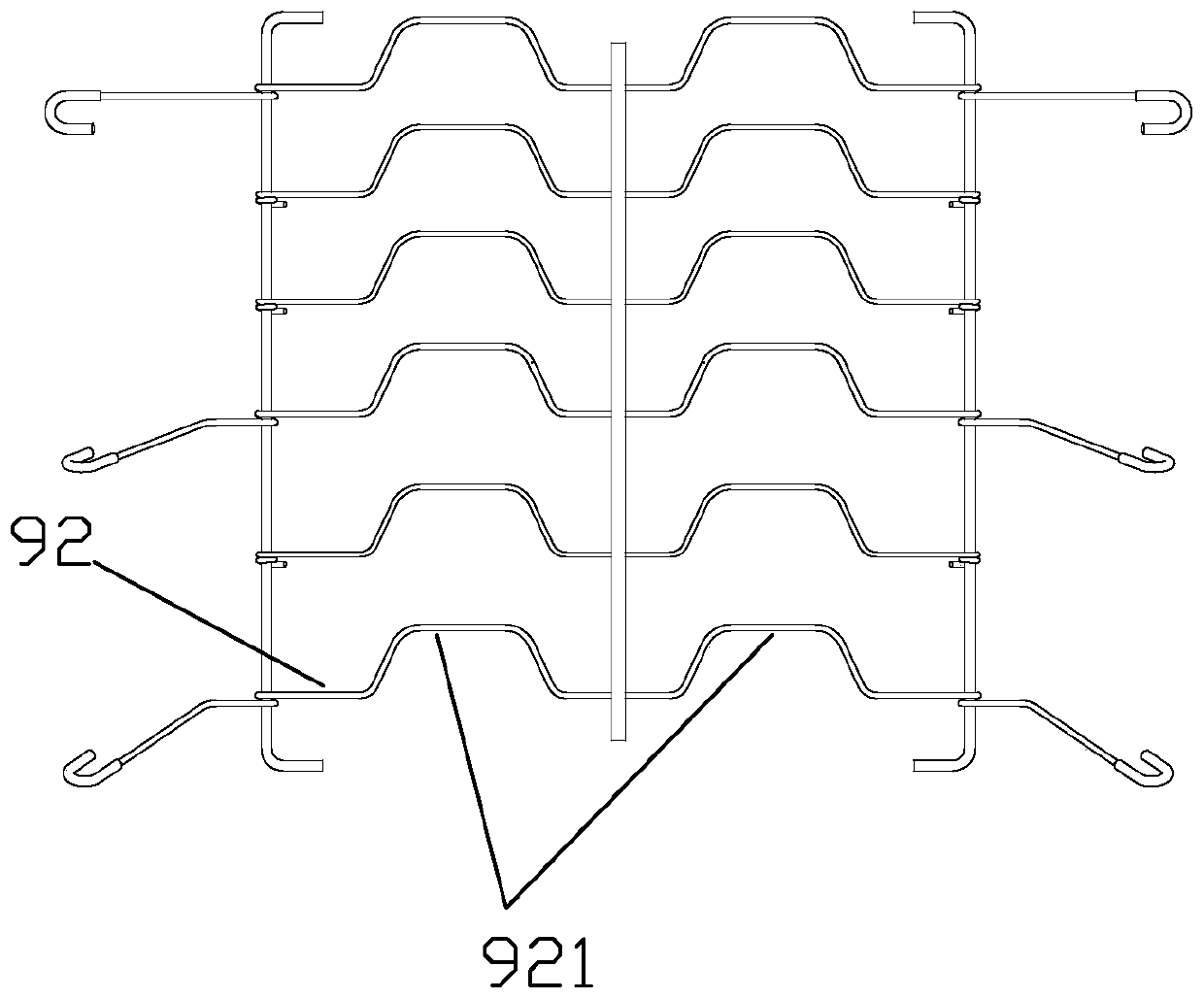

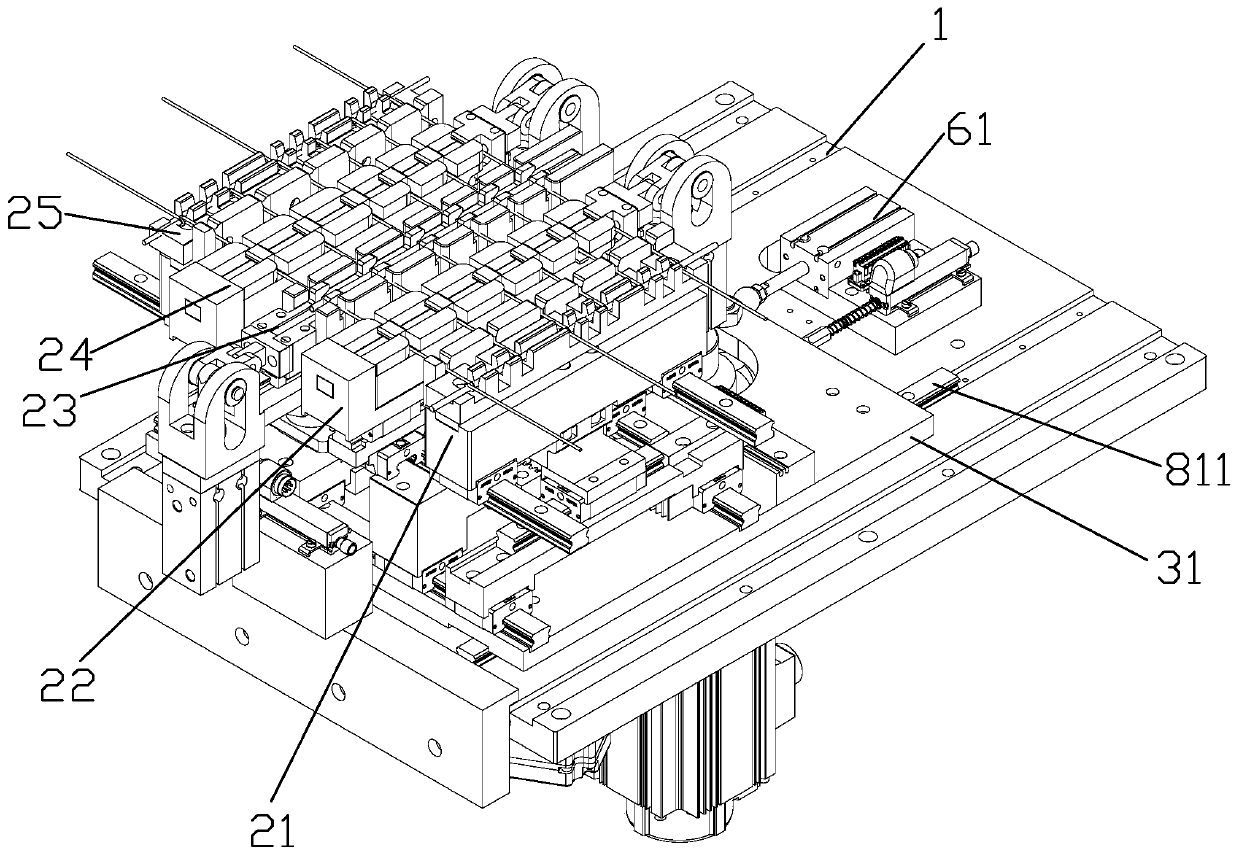

Automobile seat backrest grid forming mechanism

An automobile seat backrest grid forming mechanism comprises a frame, a forming jig, a longitudinal moving assembly, two groups of first transverse moving assemblies, two groups of second transverse moving assemblies and a driving mechanism. The forming jig comprises five rows of forming modules, wherein the five rows of forming modules sequentially comprise a first forming module to a fifth forming module from one side to the other side in the transverse direction, and the third forming module is fixedly arranged on the rack. The two groups of first transverse moving assemblies are respectively connected with the first forming module and the fifth forming module and are used for driving the first forming module and the fifth forming module to transversely move in a manner of being close to or far away from each other. The two groups of second transverse moving assemblies are respectively connected with the second forming module and the fourth forming module and are used for driving the second forming module and the fourth forming module to move together with the longitudinal moving mechanism and move transversely in a manner of being close to or far away from each other. The driving mechanism is used for driving the longitudinal moving assembly, the first transverse moving assemblies and the second transverse moving assemblies to move. The automobile seat backrest grid formingmechanism has the advantages of high automation degree, high forming speed and wide application range.

Owner:SHANGHAI SAN HUAN SPRING CO LTD

Articular cartilage repair stent forming device

PendingCN114795595AImplement automatic rolloutPrevent shape changeJoint implantsCleaning using toolsBiomedical engineeringGeneral surgery

The articular cartilage repair stent forming device is provided with a forming table, and a supporting frame is fixed to the upper end face of the forming table; the supporting plate is fixed on the side of the cartilage material; comprising a motor installed on the inner side of the supporting frame through a bolt; the movable plate movably penetrates through the top of the supporting frame, and a tooth block is fixed to the side face of the movable plate; the supporting column is movably mounted on the lower end face of the top of the supporting frame; the fixed box is fixed on the upper end surface of the forming table; and the movable cylinder movably penetrates through the interior of the fixed box. According to the articular cartilage repair stent forming device, after the articular cartilage repair stent is taken out, the repair stent can be automatically pushed out, an additional push-out tool does not need to be used, the inner wall of the cutting die can be cleaned in the push-out process, the smoothness of the surface of the subsequent repair stent is prevented from being affected, and the repair efficiency is improved. And meanwhile, the redundant thickness of the repaired stent can be cut off.

Owner:XIAN HONGHUI HOSPITAL

Gypsum board forming production line and production method thereof

ActiveCN113942106AReal-time position controlCooperate effectivelyCeramic shaping plantsAuxillary shaping apparatusControl systemEngineering

The invention discloses a gypsum board forming production line and a production method thereof. The production line comprises a PLC control system, a circulating conveying line, a machining station arranged along the circulating conveying line and a mold trolley automatically moving along the circulating conveying line; the mold trolley is provided with an RFID electronic tag; the machining station is provided with an RFID reader; the RFID reader is connected with the PLC control system; a plurality of forming cavities for forming gypsum boards are arranged in the mold trolley; and the PLC control system controls all the processing stations to work according to an RFID electronic tag content read by the RFID reader in the production process, so that automatic forming of the gypsum boards is achieved. According to the gypsum board forming production line and the production method thereof provided by the invention, automatic production of the gypsum boards can be achieved, manual intervention is not needed in the whole process, the production efficiency of the gypsum boards is effectively improved, and consumption of manpower and material resources is reduced.

Owner:四川吉浦森建材有限公司

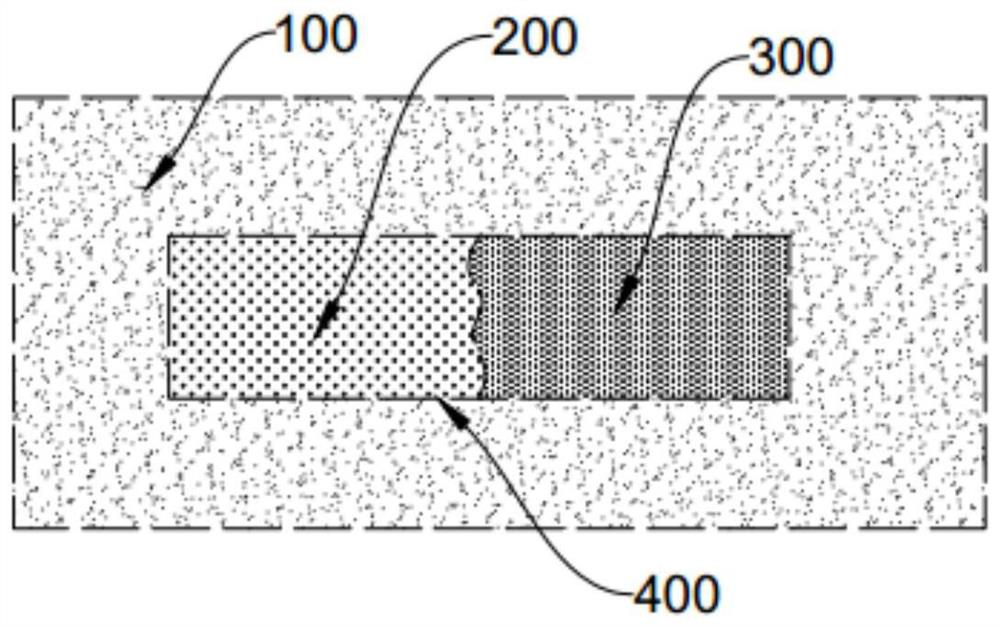

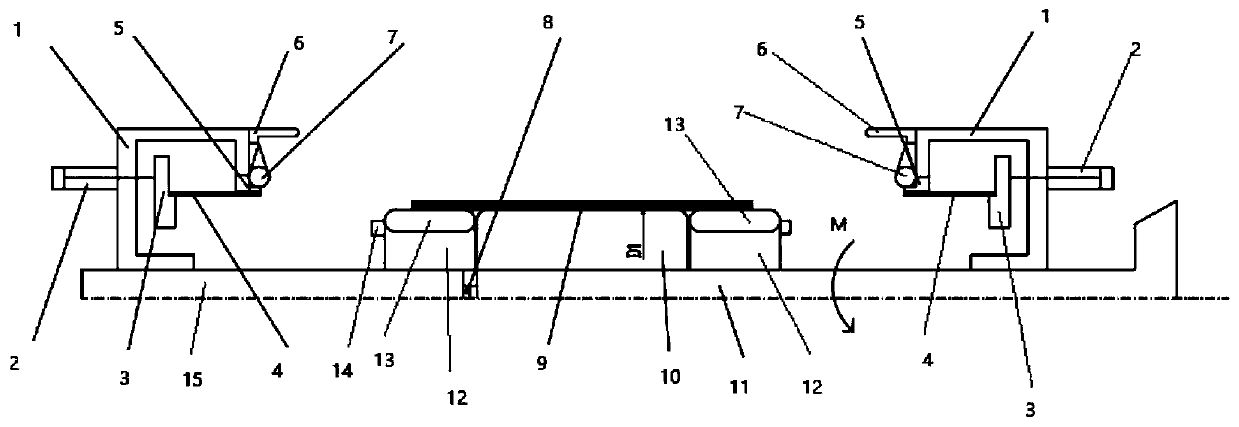

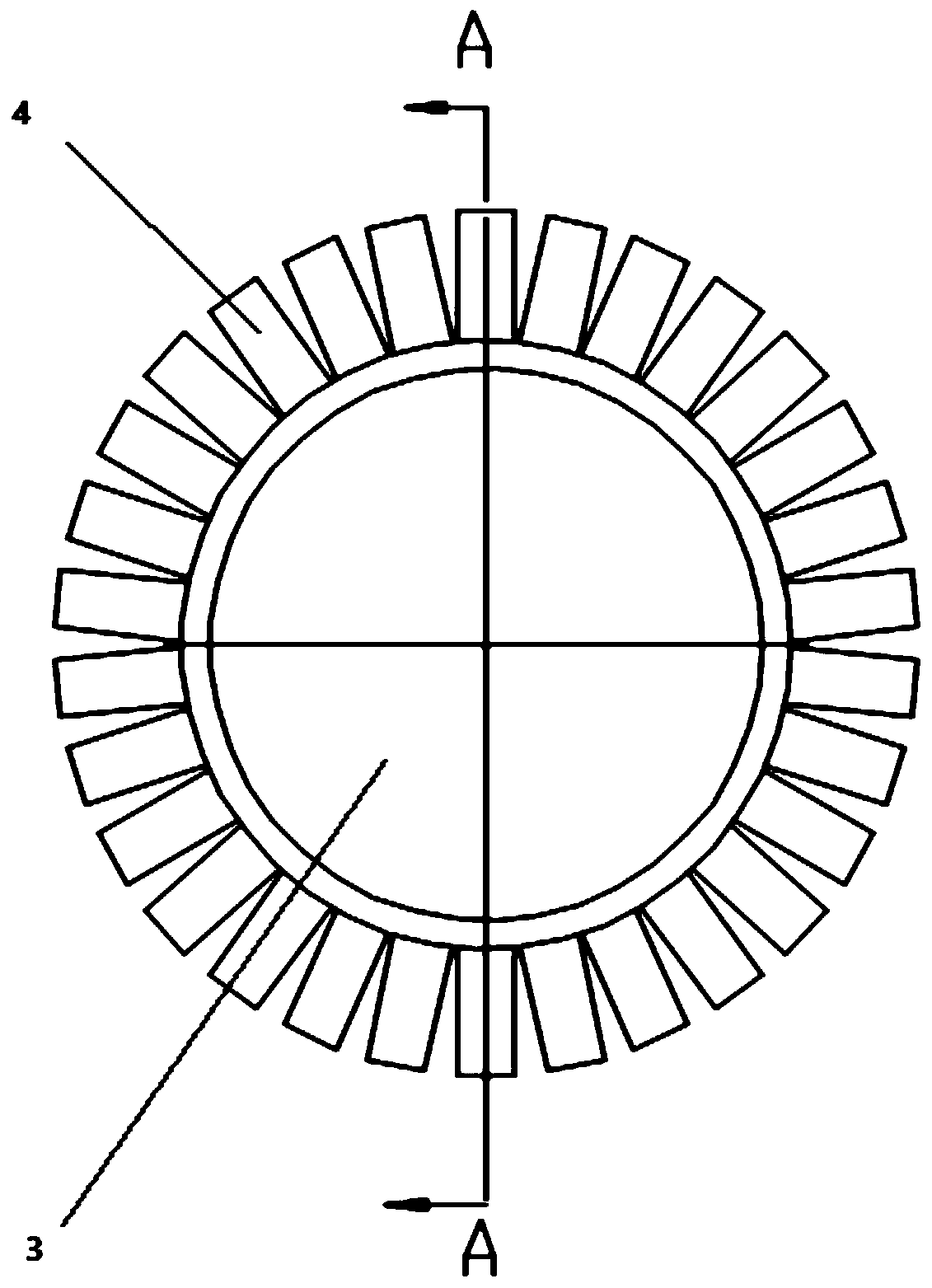

Soft capsule machine and soft capsule forming method

ActiveCN108096027BRealize automatic formingSimple structureCapsule deliveryDomestic articlesCold airSurgery

The invention discloses a soft capsule machine and a soft capsule forming method, wherein the soft capsule machine comprises a capsule shell forming component, a medicine liquid injection component and a capsule collecting box, wherein the capsule shell forming component comprises a first supporting rod, a mounting disc and a glue liquid box; a first barometric regulator is arranged on the first supporting rod; a plurality of gelatin pipes are vertically arranged on the mounting disc; elastic capsule molds are connected to the lower ends of the gelatin pipes; the medicine liquid injection component comprises a second supporting rod; a second barometric regulator and a medicine liquid box are arranged on the second supporting rod; medicine liquid pipes, which are inserted into the corresponding gelatin pipes, are arranged at the outer end of the second supporting rod; a first bracket is arranged in the capsule collecting box; and a cold air generator is arranged on the bracket. The method comprises the following steps: immersing the capsule molds by 2 / 3-4 / 5 of the heights of the capsule molds; inserting dropping liquid heads of the medicine liquid pipes into gelatin liquid in the capsule molds; generating cold air from the cold air generator; and popping soft capsules in the capsule molds out of the capsule molds.

Owner:ZHEJIANG WANLIAN PHARMA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com