Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Realize automatic dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

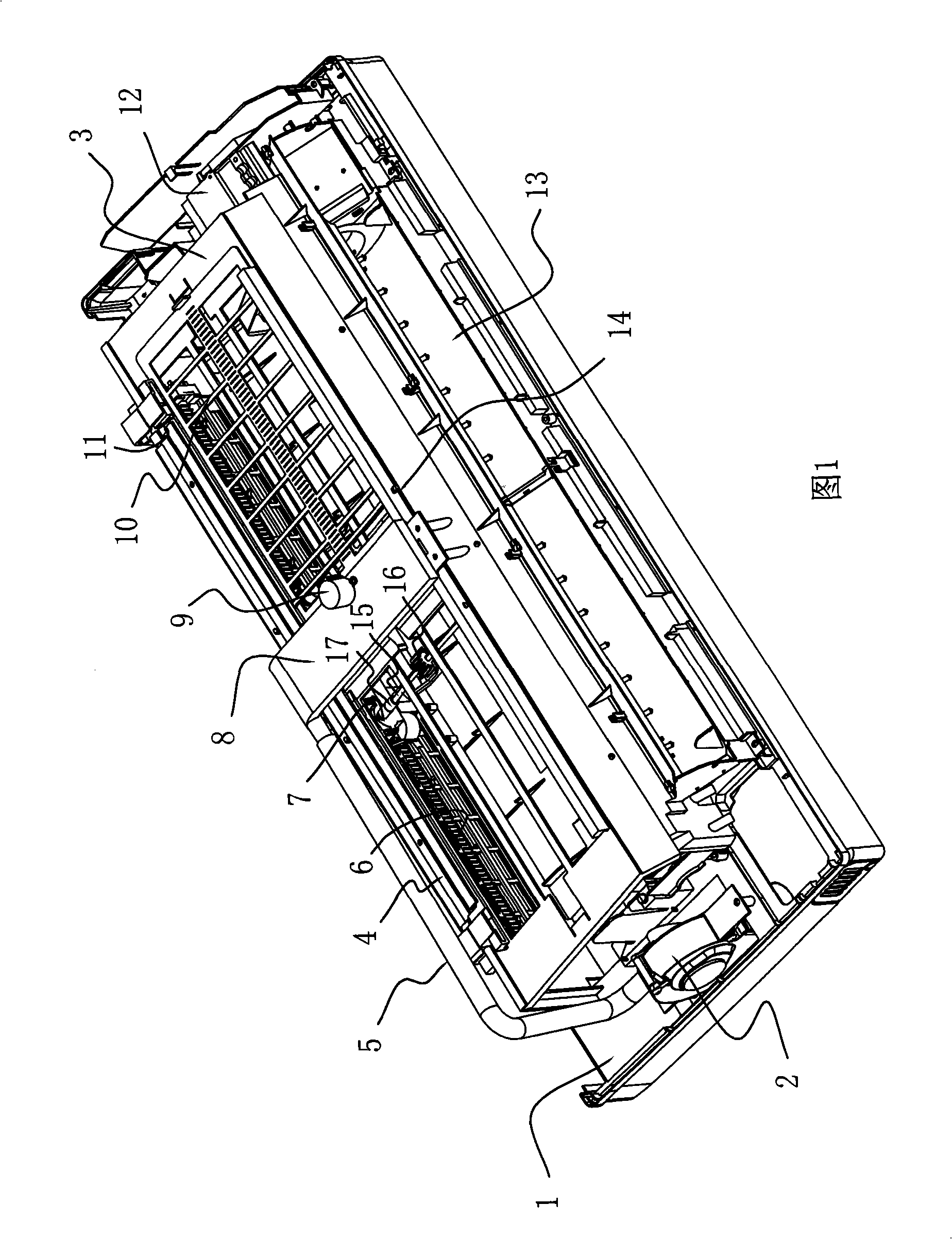

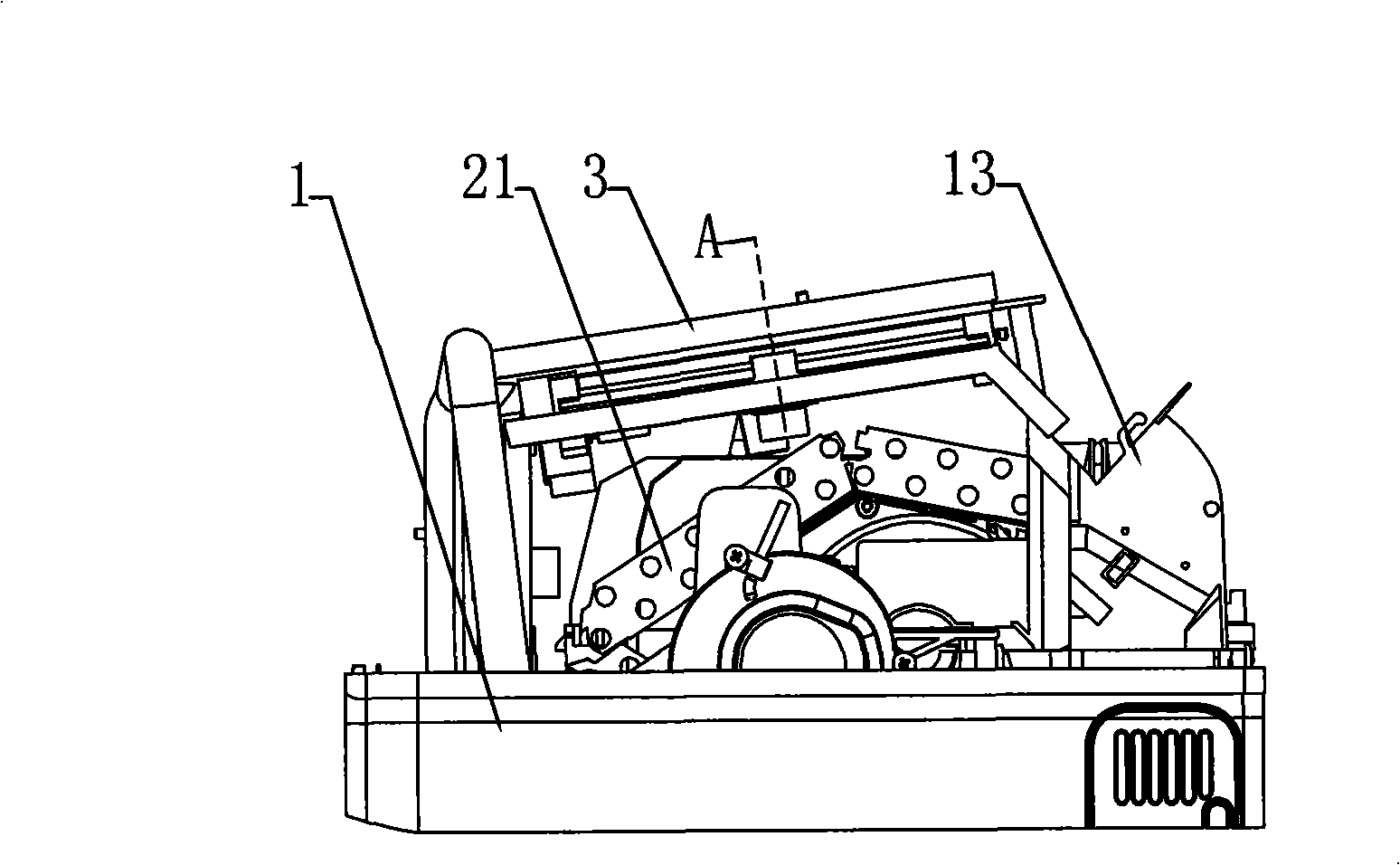

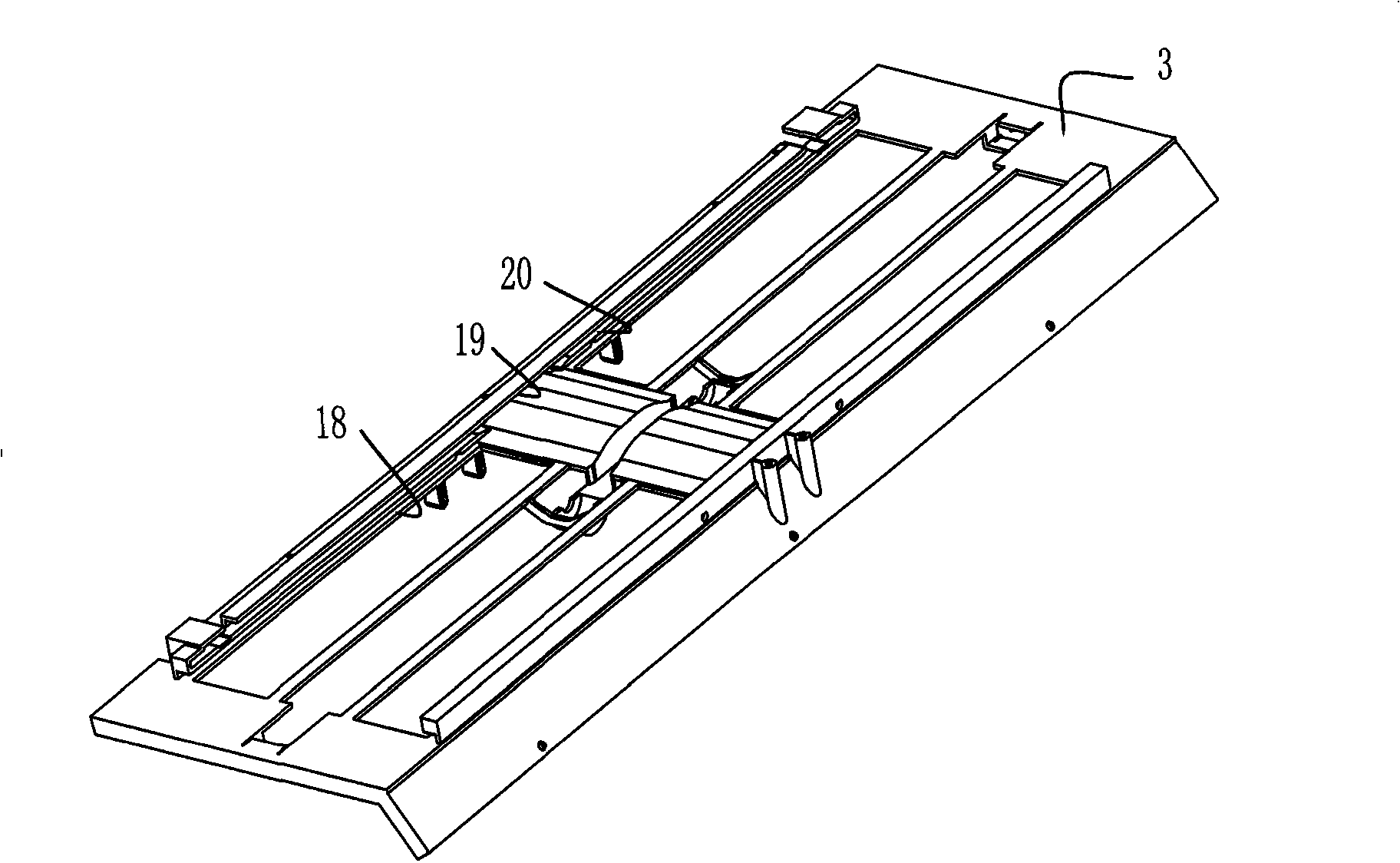

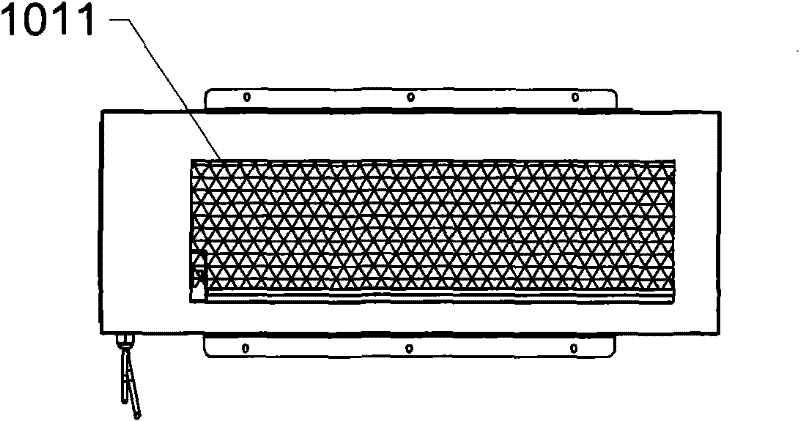

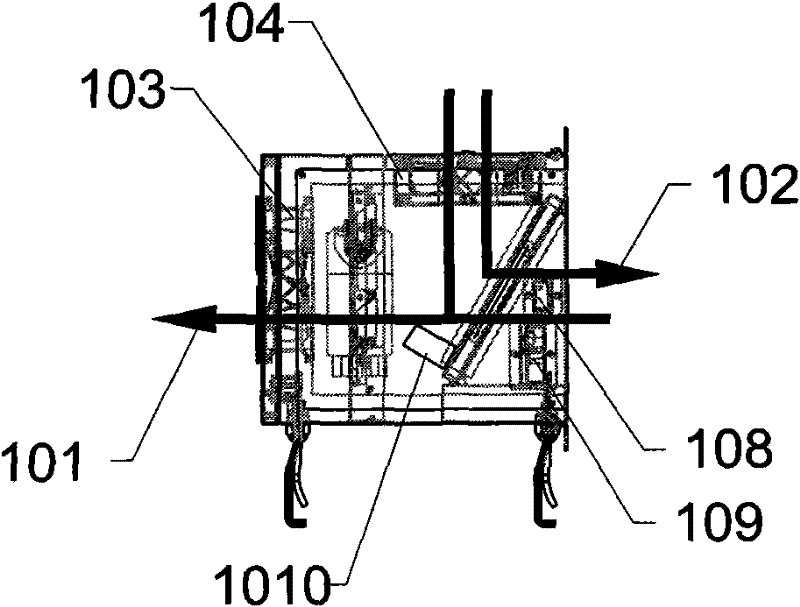

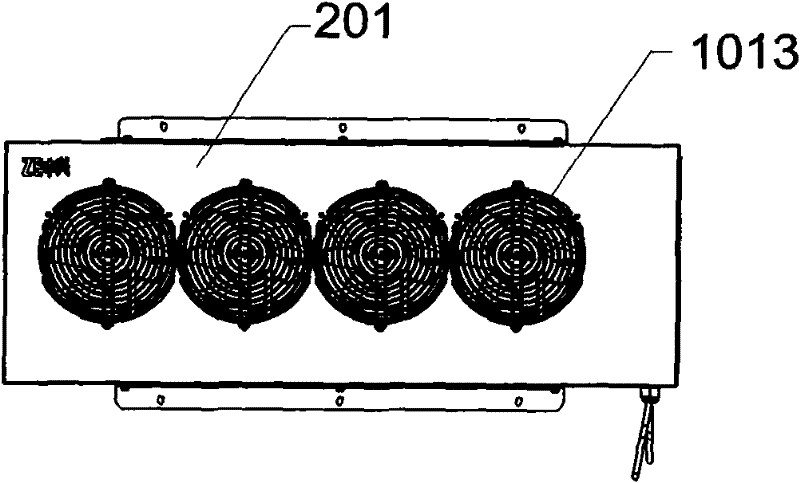

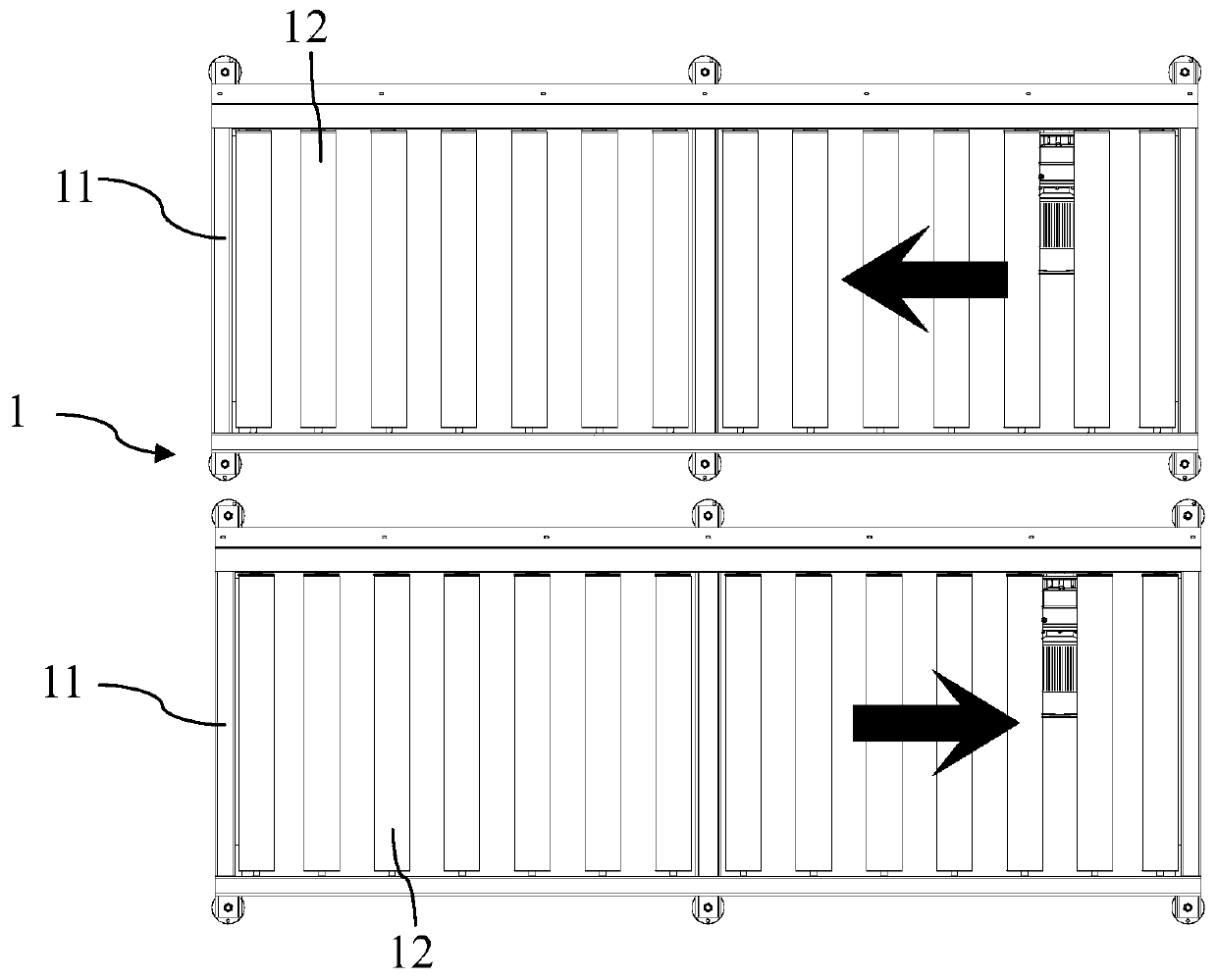

Split hanging machine air conditioner with filtering net automatic cleaning device

ActiveCN101338924AIncrease travel distanceIncrease sweep lengthLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

The invention discloses an split type on-hook air conditioner with an automatic cleaning device of a filter screen, including the filter screen and a fixing framework. The filter screens are respectively arranged at the left and the right sides in the air inlet of the air conditioner and are embedded in guide slots arranged on the two sides of the fixing framework. The guide slots of the left and the right filter screens are respectively provided with a lower guide slot and an upper guide slot which are connected by a transition guide slot. Each filter screen can move left and right along the lower guide slot, the transition guide slot and the upper guide slot thereof. The automatic cleaning device includes a filter screen driving device which drives the filter screen to move left and right and a suction component. The suction component includes a suction box and a suction fan. The suction box is arranged above the transition guide slot and spans the fixing framework. The suction box is connected with the suction fan by a suction pipe. Compared with the prior technology, the split type on-hook air conditioner of the invention has simple structure, which can remove dust automatically and clean the dust of the filter screen thoroughly.

Owner:GUANGDONG CHIGO AIR CONDITIONING

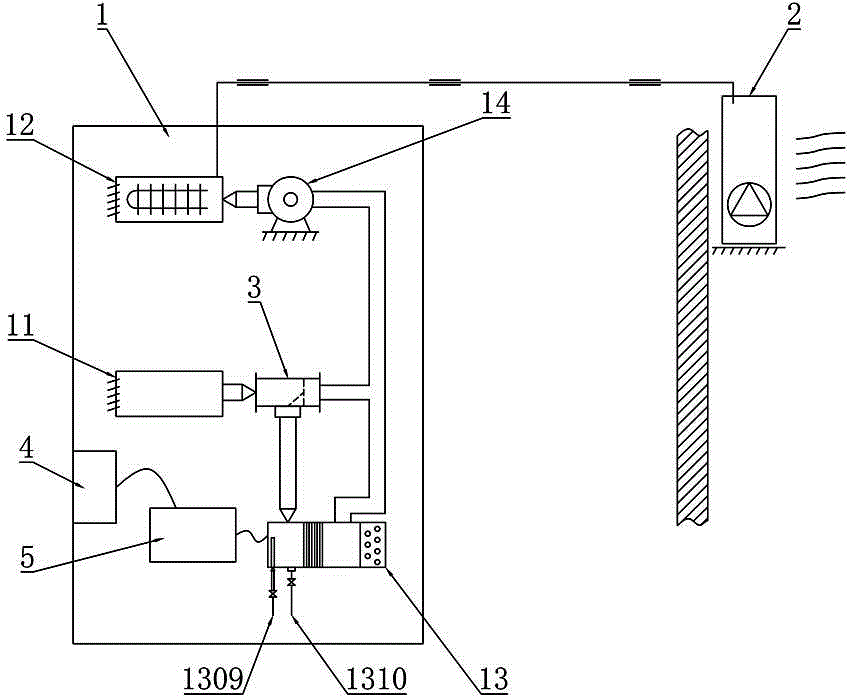

Automatic dust removal and intelligent ventilation system of fireproof linkage

ActiveCN102175055AExtend the intervalExtended service lifeSpace heating and ventilation safety systemsLighting and heating apparatusSmokeMoisture sensor

The invention relates to the field of ventilation and heat exchange systems, in particular to an automatic dust removal and intelligent ventilation system of fireproof linkage. The system comprises an intelligent energy-saving ventilation system shell; the intelligent energy-saving ventilation system shell comprises a mixed air flue, a dust discharge air flue, an air door, a dust screen, temperature and humidity sensors, a dust sensor and an intelligent energy-saving ventilation system shell component; the dust screen filters the outdoor air; the temperature and humidity sensors are used for controlling start and stop of an indoor air conditioner and an intelligent energy-saving ventilation system; and the dust sensor is used for feeding the outdoor air cleanliness condition back to a control system, and the control system controls the start and stop of the intelligent ventilation system according to the feedback condition. The system has the advantages that: the intelligent ventilation system is associated with machine room safety key equipment such as a machine room power environment monitoring system, a machine room air conditioner, a smoke sensor and the like, so that new ignition points caused by electric faults of the air conditioner under the fire condition are prevented; and the air door of the intelligent ventilation system is closed to cut off the supply source of fresh oxygen so as to prevent supporting flames.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

Dust removal system and controller thereof

InactiveCN102921247ALow running costImprove dust removal efficiencyDispersed particle filtrationControl modeSmart control

The invention discloses a dust removal system and a controller of the dust removal system. The dust removal system and the controller of the dust removal system detect the temperature and pressure of dust gas in a production process room at an inlet of a bag-type dust remover, and the pressure of the gas at an outlet of the bag-type dust remover, and the pressure or the temperature of the dust gas at the inlet or a work mode of a control system in the process of production is set as a set value to control a frequency converter to achieve control of the rotation speed of a draught fan. The controller can be connected with an online or off-line air purification detector to achieve closed-loop control of the air speed. The controller controls opening and closing of an impulse dust removal valve through differential pressure at the inlet and the outlet of the dust removal gas and the time of variation of the differential pressure, and achieves high-intelligent control modes of the bag-type dust removal, such as on line, off line, chamber division and cascade connection. The dust removal system and the controller of the dust removal system have the advantages of integration of dust removal series, modularization of the internal structure, diversification of functions, intelligentization of the control modes and optimization of cost performance, thereby being suitable for various occasions.

Owner:UNIV OF JINAN

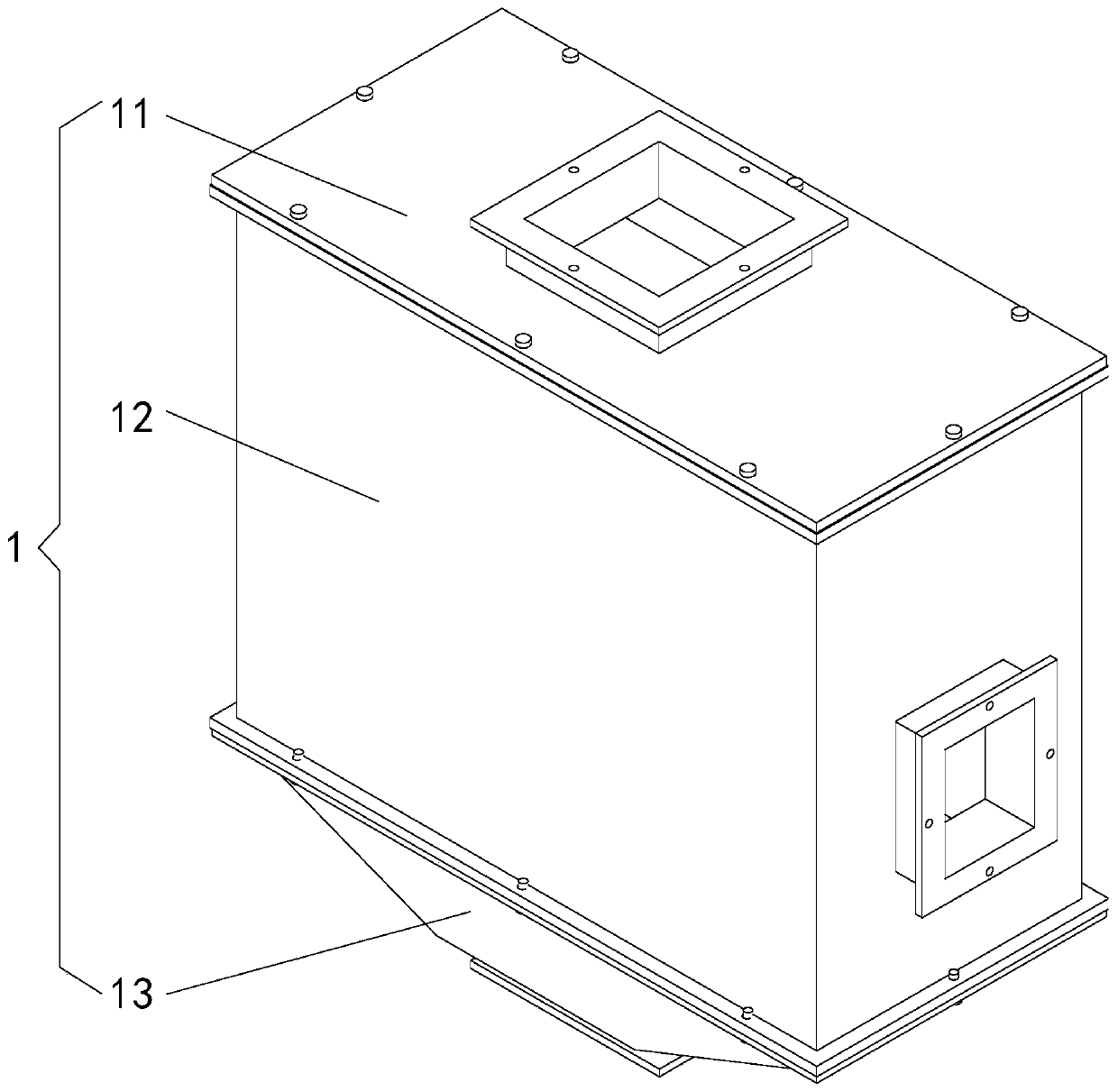

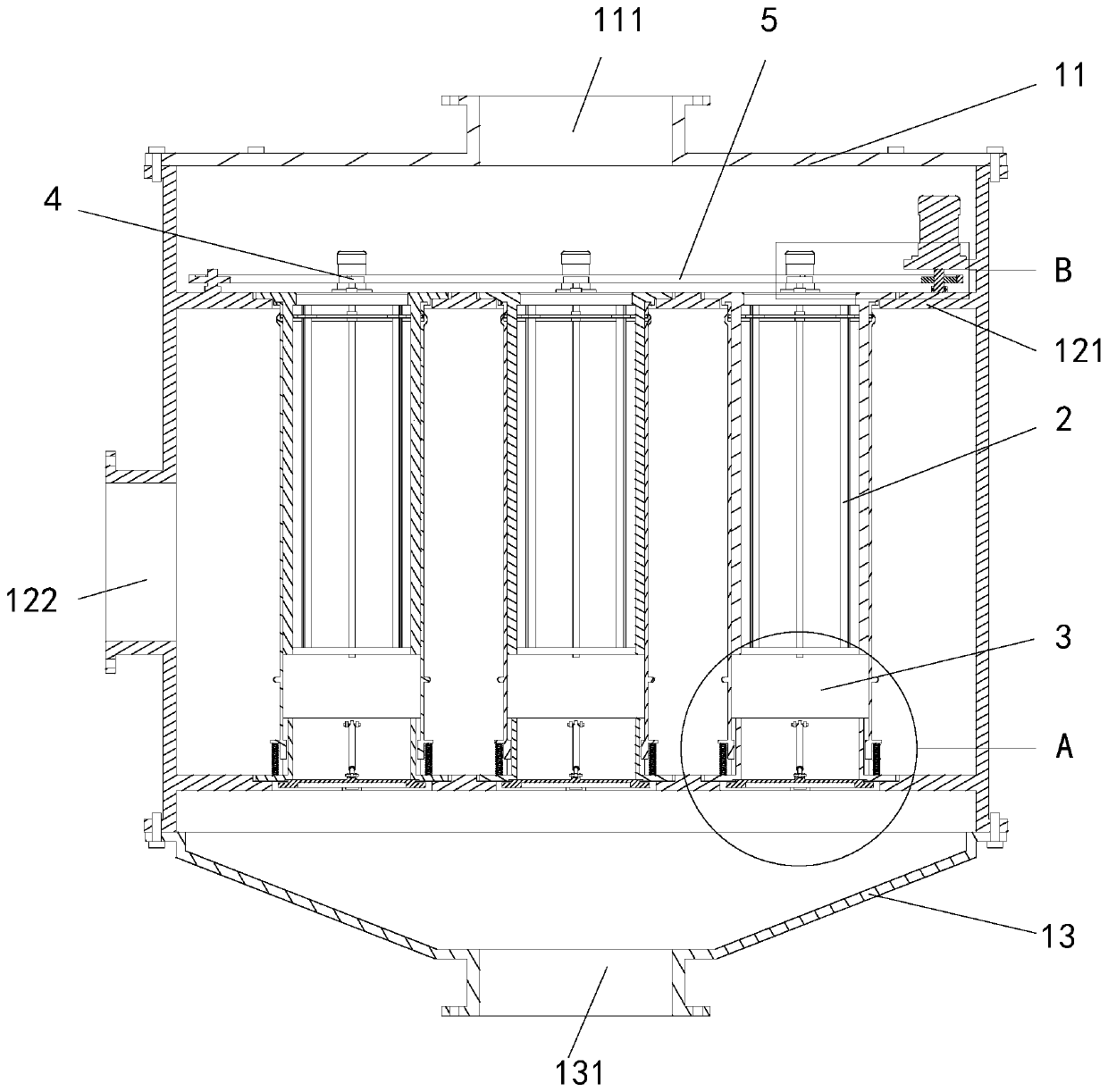

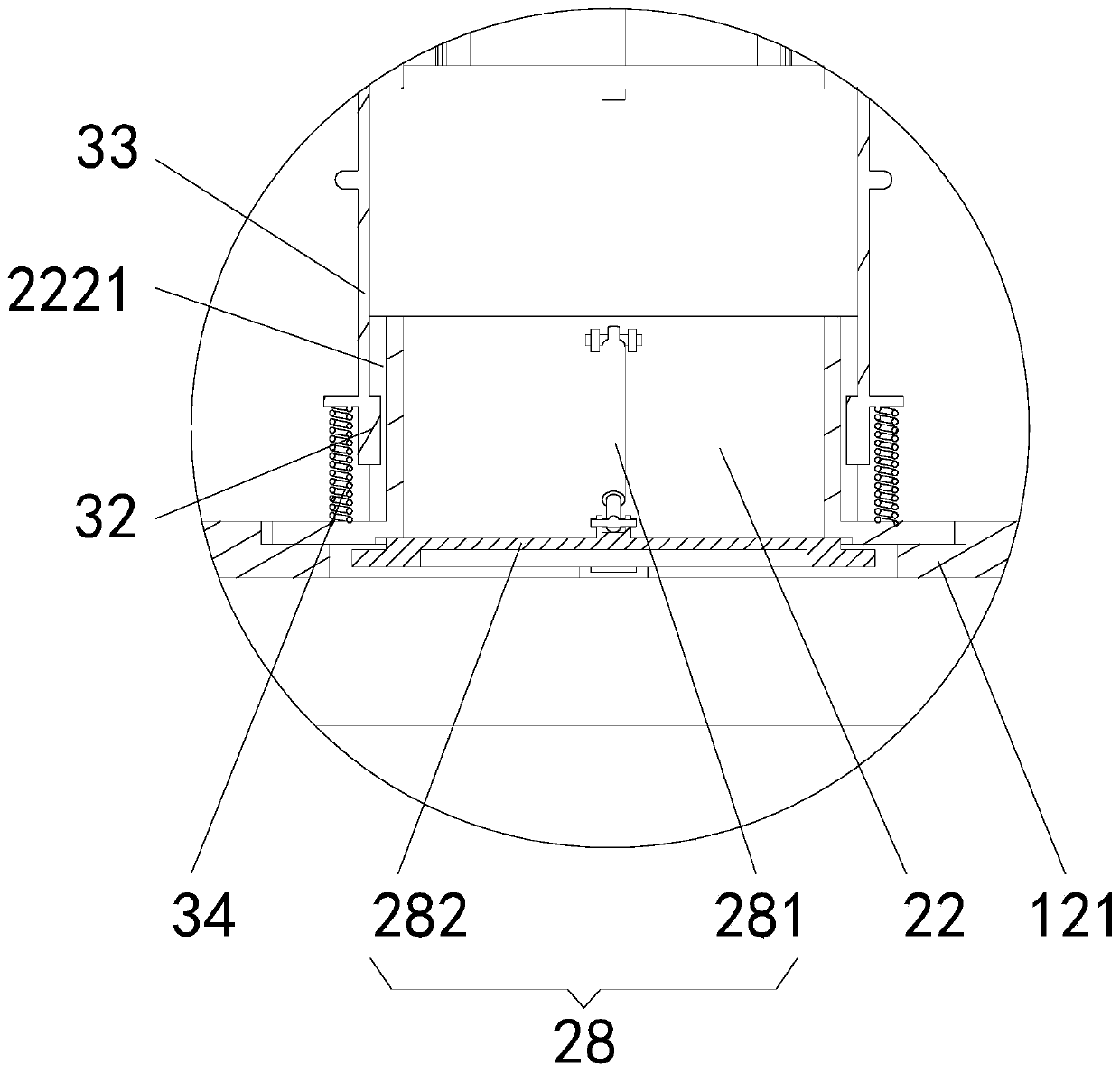

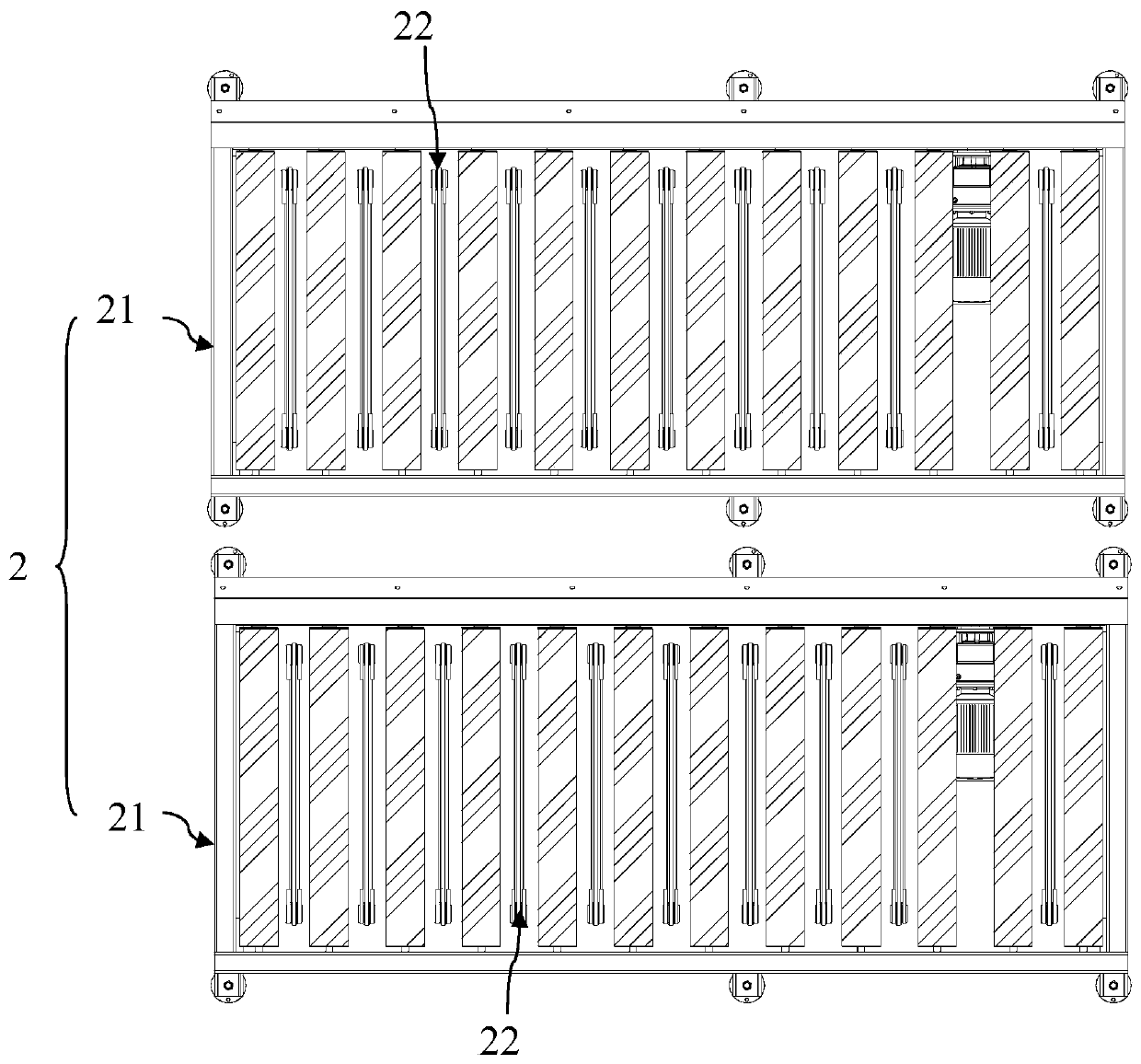

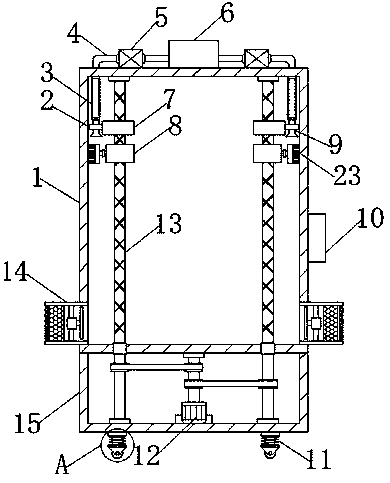

Industrial bag-type dust collector

The invention relates to an industrial bag-type dust collector. The dust removal device comprises a shell, a plurality of keel frame assemblies, a plurality of dust removal bags, a plurality of bag tying mechanisms and a dust scraping ring driving mechanism, the shell comprises an upper sealing plate, a middle shell and a dust discharging bin, two horizontal keel fixing partition plates are arranged in the middle shell, the keel frame assemblies are vertically and fixedly installed on the two keel fixing partition plates in a linear arrangement mode, each keel frame assembly is sleeved with one dust removal bag, each keel frame assembly is provided with one bag tying mechanism used for tying the middle of the corresponding dust removal bag, and the dust scraping ring driving mechanism is arranged above the keel fixing partition plate at the upper position. The industrial bag-type dust collector can regularly and automatically remove dusts, has no vibration damages to the dust removal bags and small dust removal abrasion, can prolong the service life of the dust removal bags and reduce the maintenance and replacement frequency, and can online realize automatic complete removal of accumulated dusts in the dust removal bags without influencing the processing and production.

Owner:NANTONG ANIMATE MACHINERY

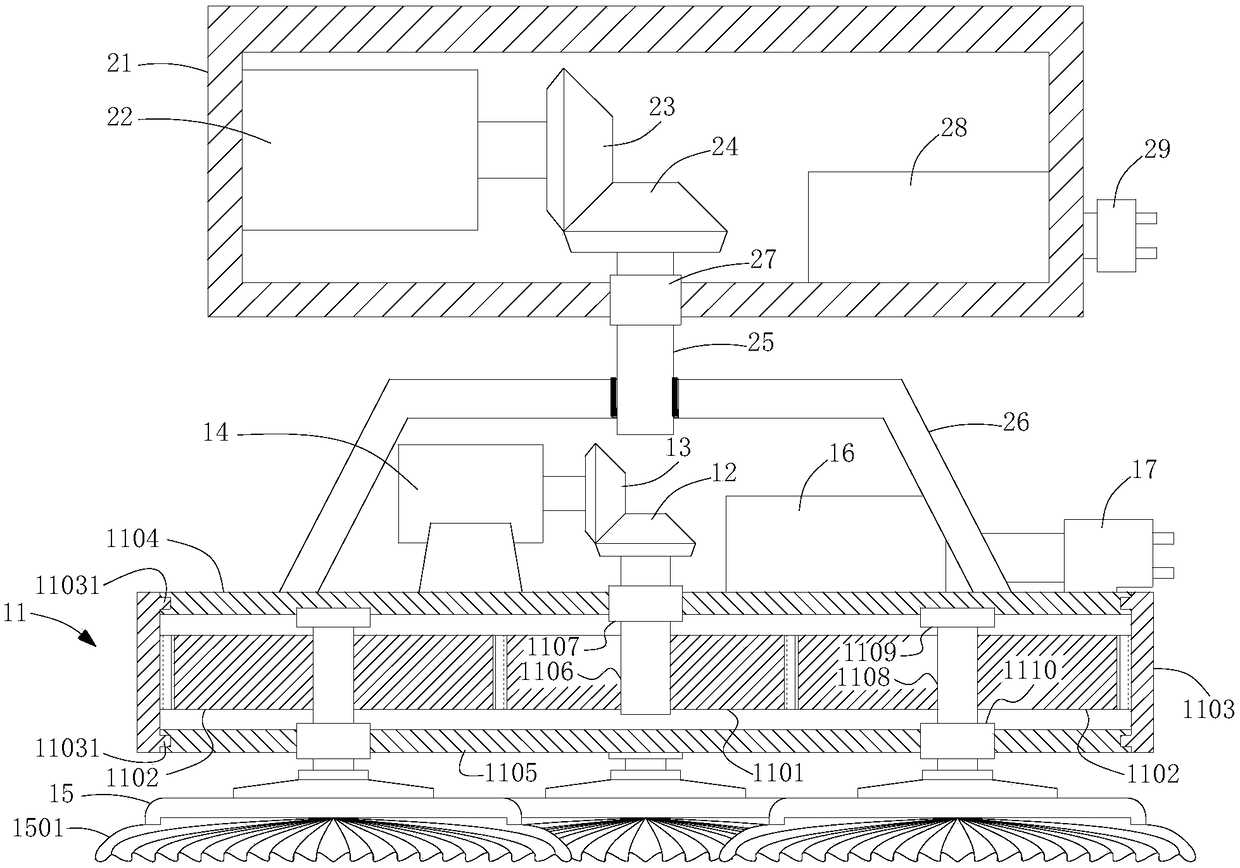

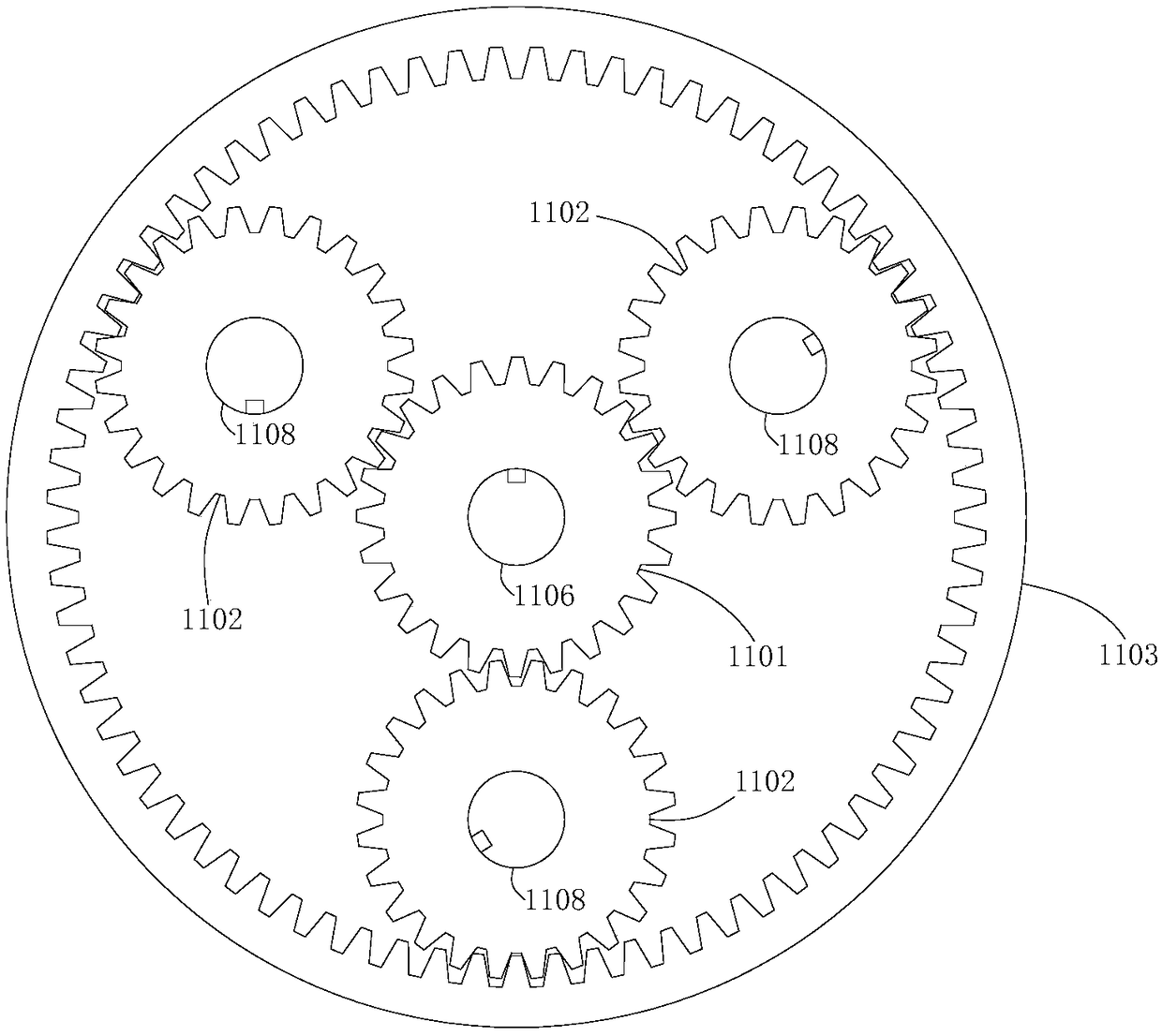

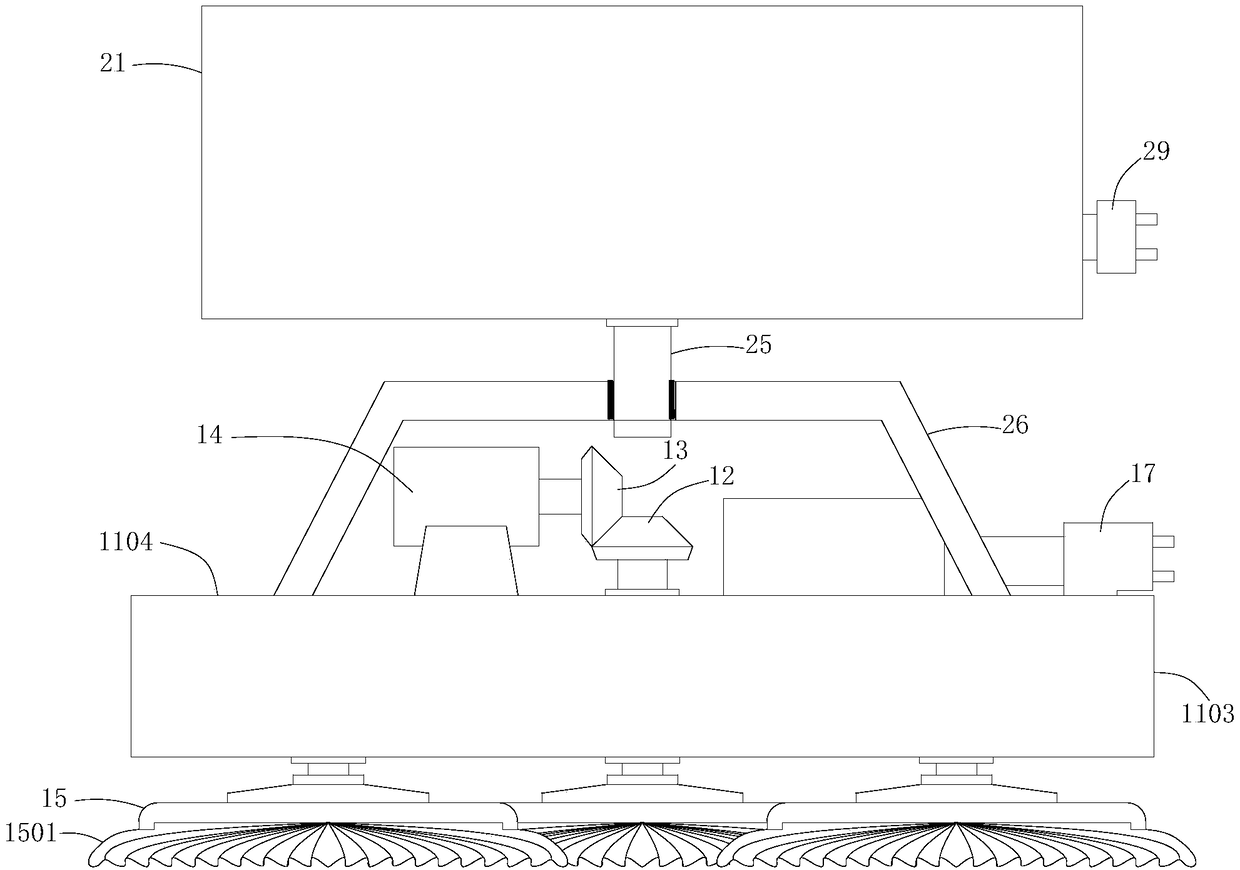

Automatic outdoor LED screen ash removal machine

PendingCN108435616AAct quicklyImprove cleanlinessCleaning using toolsMechanical componentsEngineering

The invention discloses an automatic outdoor LED screen ash removal machine. The automatic outdoor LED screen ash removal machine comprises an ash removal assembly, an ash removal assembly rotation mechanism, a first movable mechanism and a second movable mechanism. The ash removal assembly comprises a planet gear set, a first motor and three ash removal brush discs, wherein the first motor can drive the three ash removal brush discs to rotate around the respective axes through the planet gear set. The ash removal assembly rotation mechanism comprises a second motor, and the second motor can drive the three ash removal brush discs to revolve around the common center of the three ash removal brush discs through corresponding components. The first movable mechanism can drive the ash removalassembly and the ash removal assembly rotation mechanism to move in the transverse direction of an LED screen. The second movable mechanism can drive the ash removal assembly and the ash removal assembly rotation mechanism to move in the vertical direction of the LED screen. According to the automatic outdoor LED screen ash removal machine, through a series of mechanical components and mechanicalstructures, automatic outdoor LED screen ash removal can be achieved, current manual ash removal can be replaced, and the beneficial effects that the ash removal efficiency is high, and the human costis low are achieved.

Owner:四川益泽丰信息科技有限公司

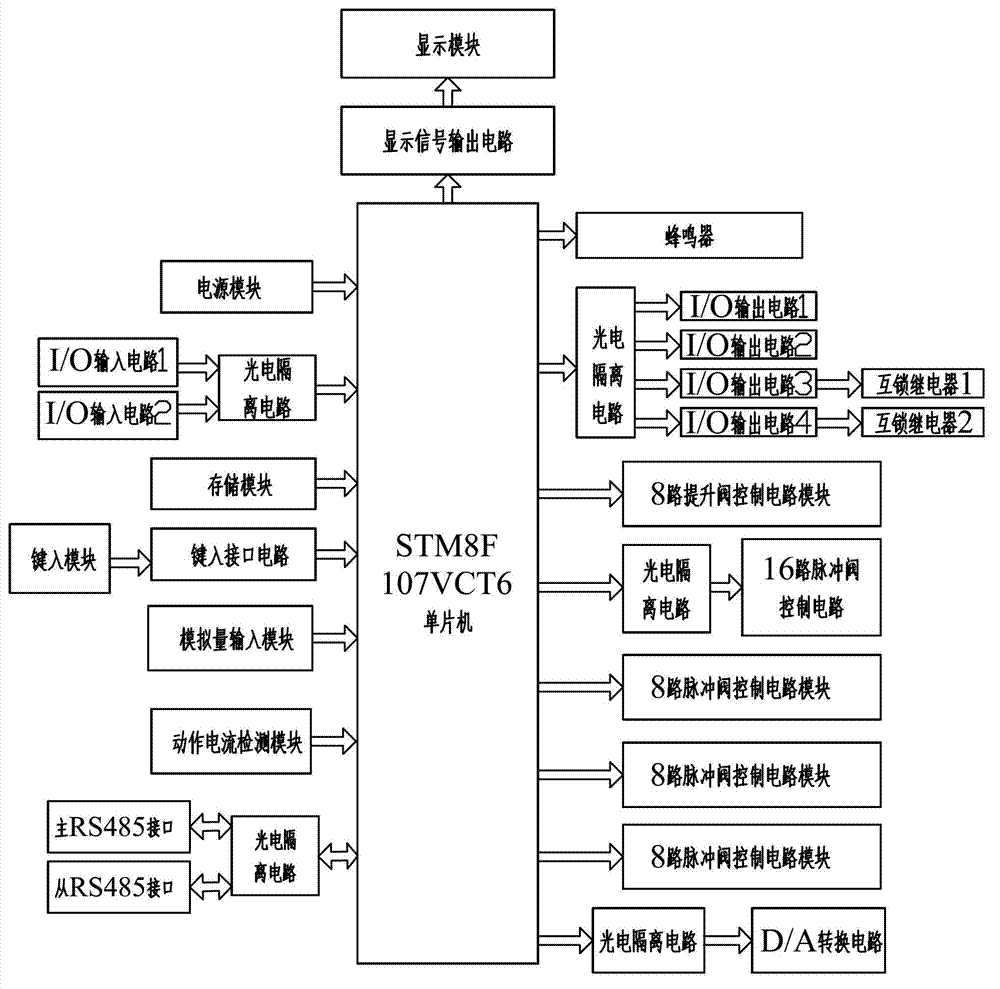

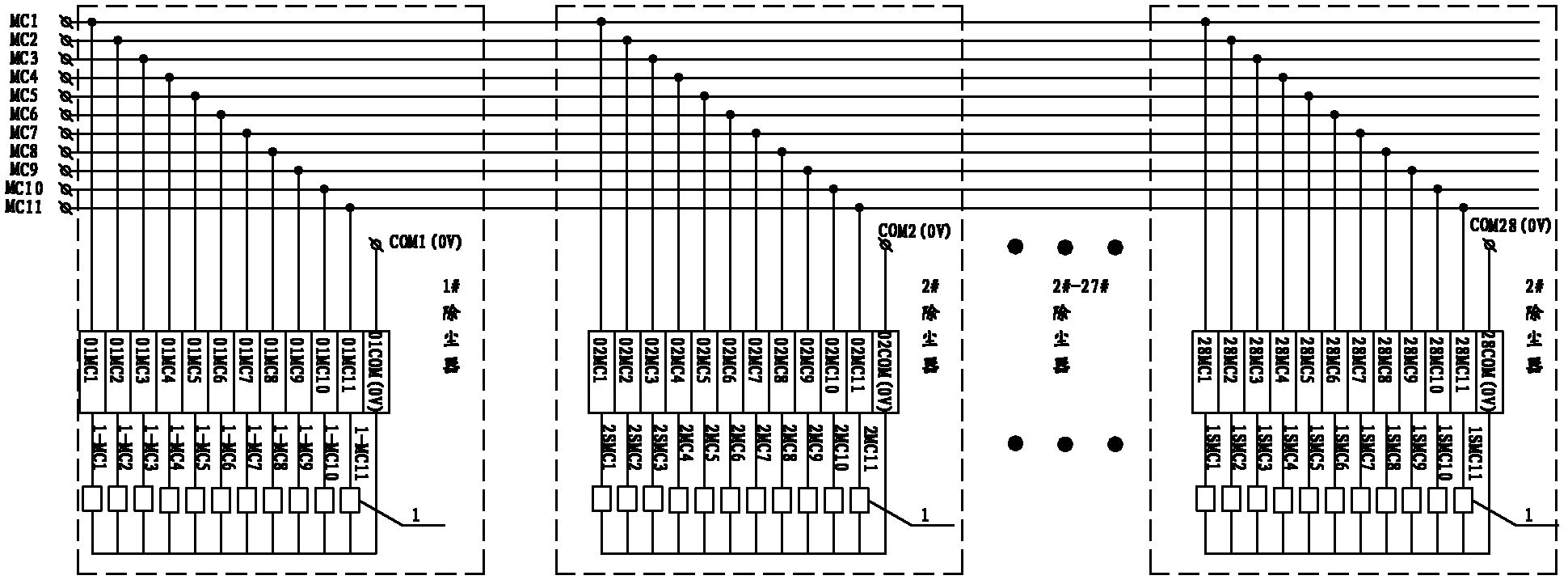

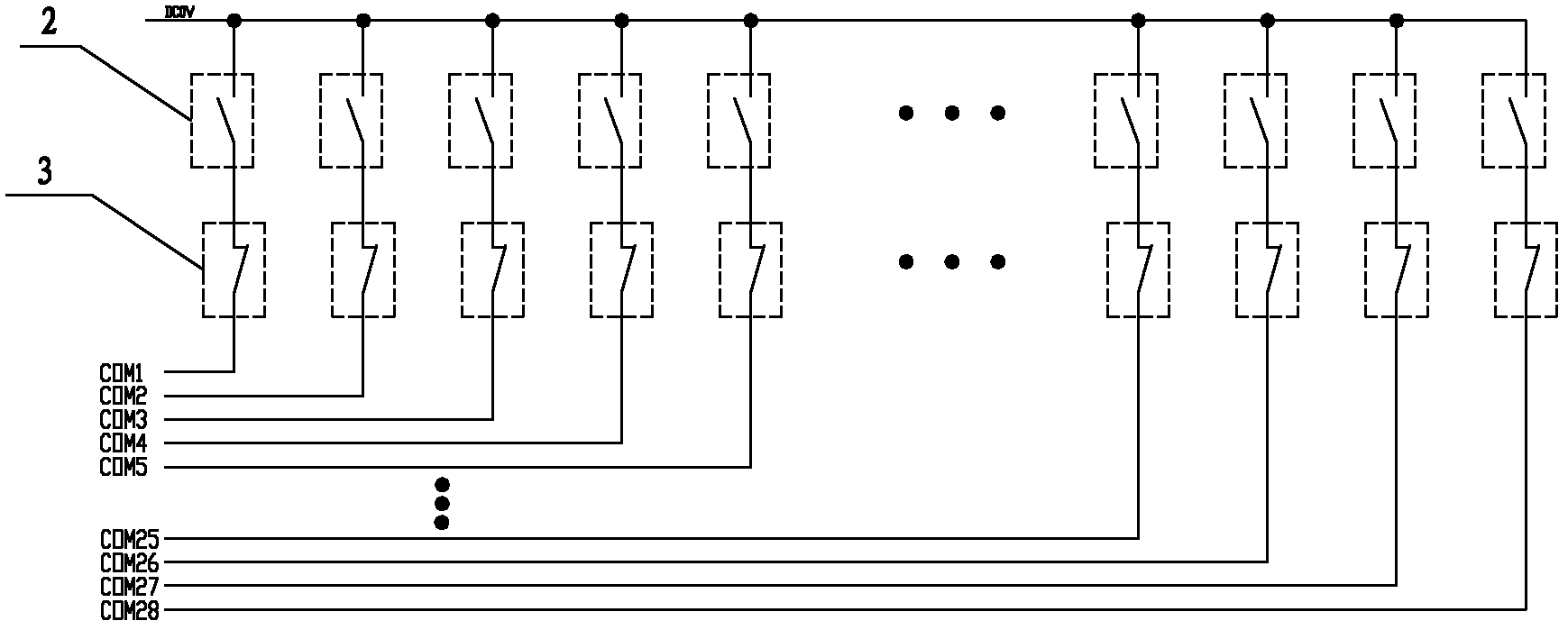

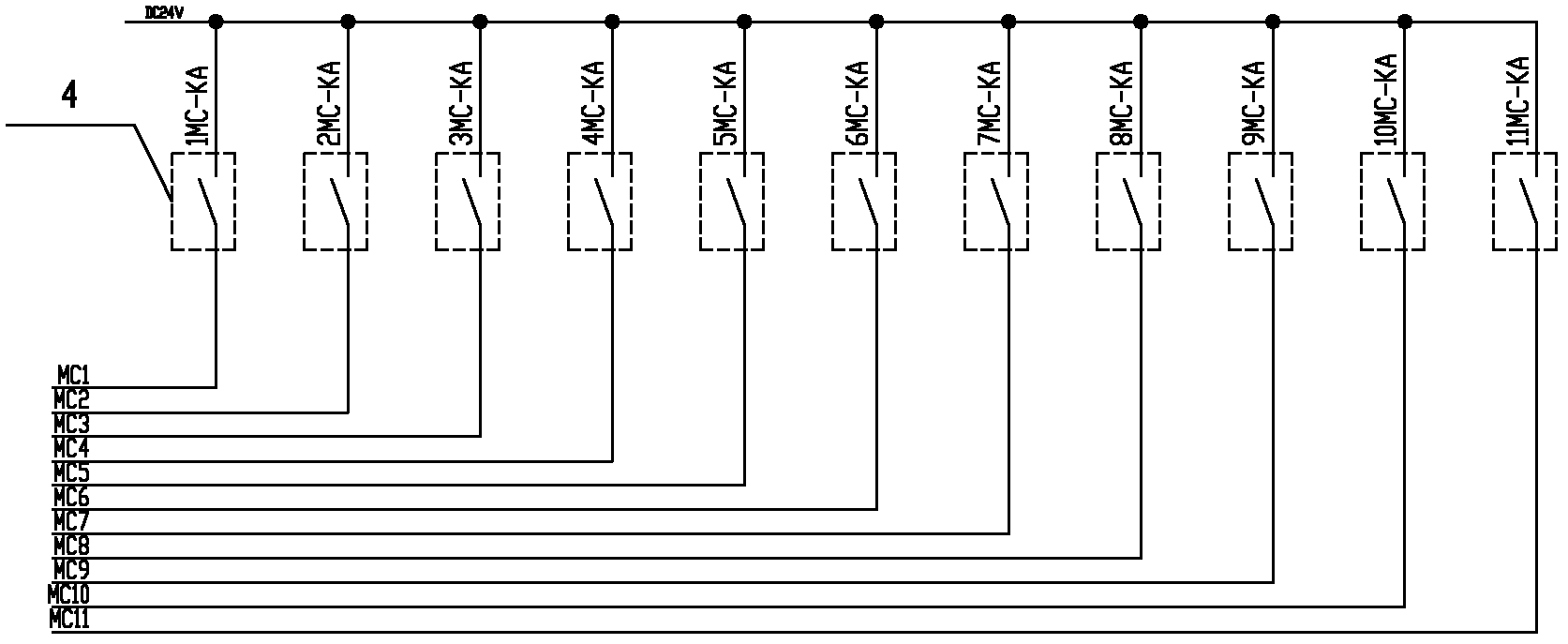

Pulsed blowing ash-removal control system of large-scale bag-type deduster, and control method therefor

InactiveCN102430298ARealize automatic dust removalRealize reasonable chainDispersed particle filtrationControl powerLow voltage

The invention provides a pulsed blowing ash-removal control system of a large-scale bag-type deduster, and a control method therefor. The pulsed blowing ash-removal control system of a large-scale bag-type deduster comprises a control power supply, a pulse valve, a blowing-out valve relay and a storehouse change relay. A negative pole of the pulse valve is connected orderly to a normally closed contact of the storehouse change relay and a normally opened contact of the blowing-out valve relay in series, and then is connected to a low-voltage port of the control power supply. A positive pole of the pulse valve is connected to a pulse valve relay normally-opened contact in series and then is connected to a high-voltage port of the control power supply. The control method adopts a fully automatic ash removal control mode, a centralized maintenance control mode and a deduster body safety interlock control mode. The pulsed blowing ash-removal control system of a large-scale bag-type deduster, and the control method therefor realize automatic ash removal of a dedusting system and ash removal of a standby storehouse used for storehouse change, guarantee intelligentization and rationalization of an ash removal process, and realize switching of various maintenance modes.

Owner:WISDRI ENG & RES INC LTD

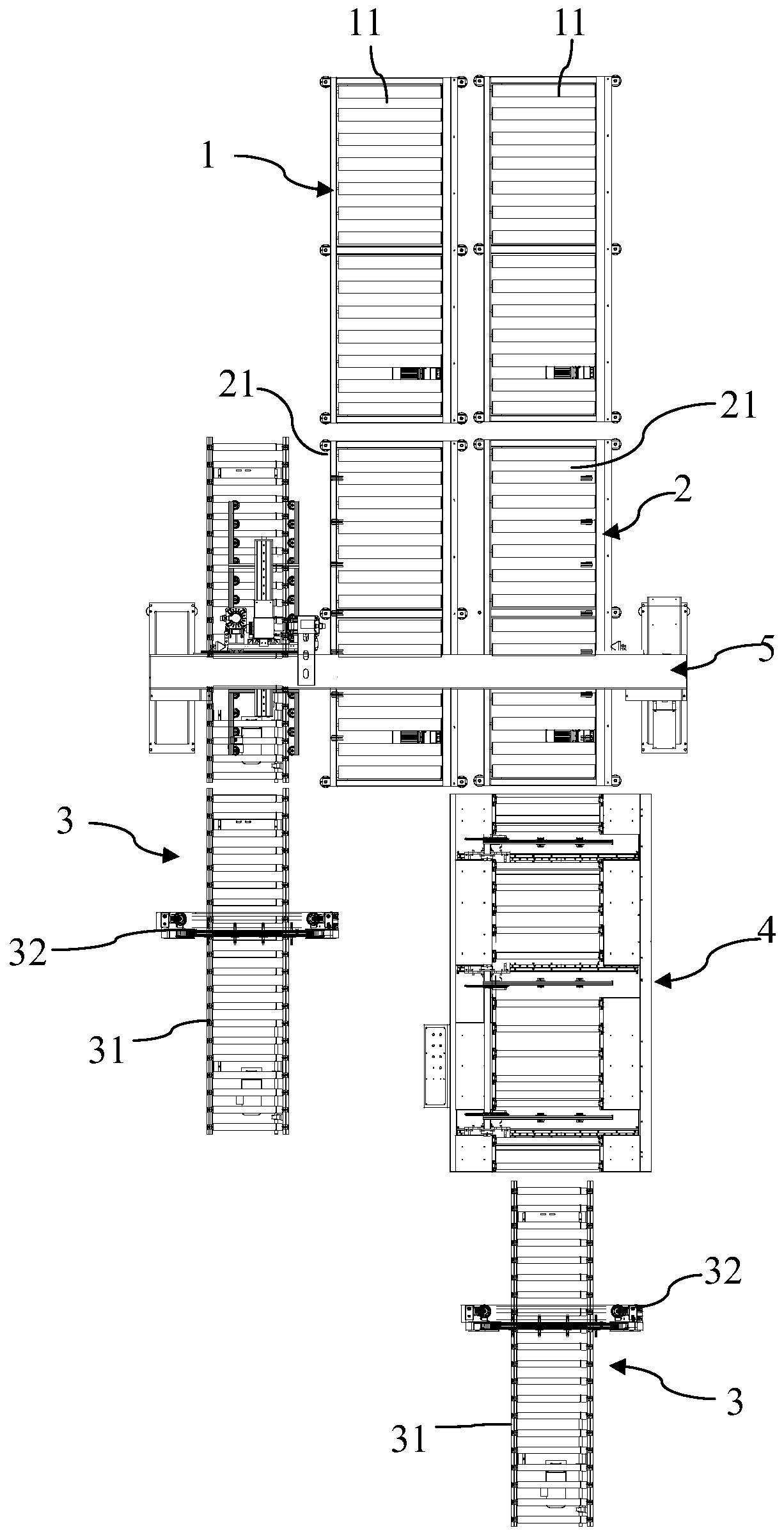

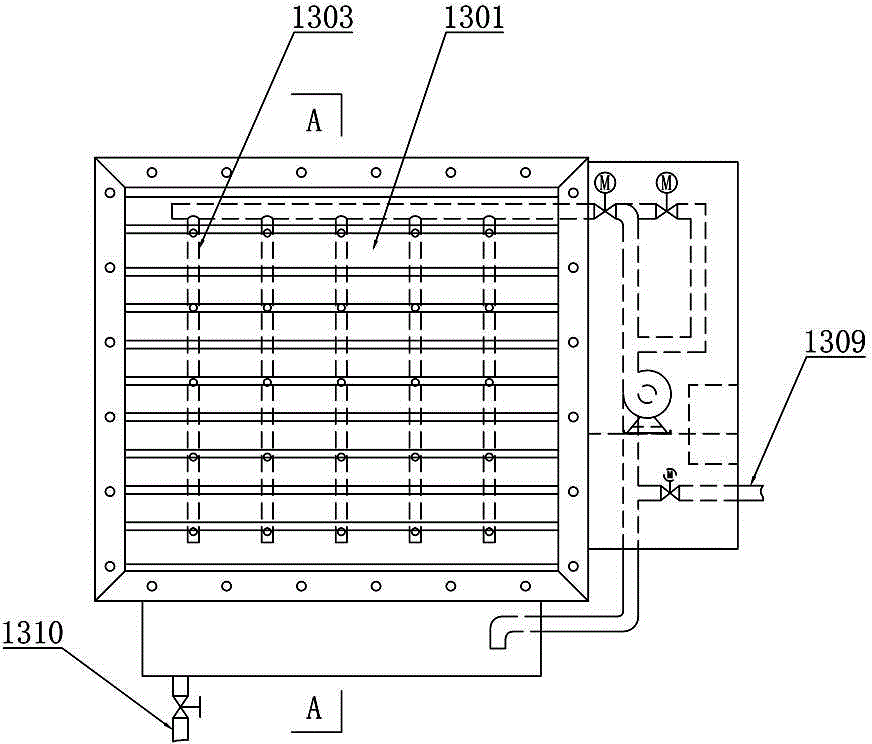

Plate transportation and ash removal system and plate transportation and ash removal method

PendingCN111056276ARealize automatic dust removalImprove cleaning efficiencyConveyorsCleaning using toolsRobot handProcess engineering

The invention discloses a plate transportation and ash removal system and a plate transportation and ash removal method. The system comprises first conveying equipment, second conveying equipment, ashremoval equipment, plate overturning equipment and a gantry manipulator; the first conveying equipment comprises two first conveying devices which are arranged side by side; the second conveying equipment comprises two second conveying devices which are arranged side by side, and a transverse conveying device is further arranged in each second conveying device; and the ash removal equipment is arranged on one side of one second conveying device, the plate overturning equipment is arranged on the front side of the other second conveying device, and the ash removal equipment is arranged on thefront side of the plate overturning device. According to the plate transportation and ash removal system and the plate transportation and ash removal method, automatic ash removal is achieved, the ashremoval efficiency is improved, ash removal can be conducted on the upper machining face and the lower machining face of a plate, full-automatic conveying or backflow can be conducted on the plate and a tray, and the production efficiency is improved.

Owner:ZHEJIANG YASHA DECORATION

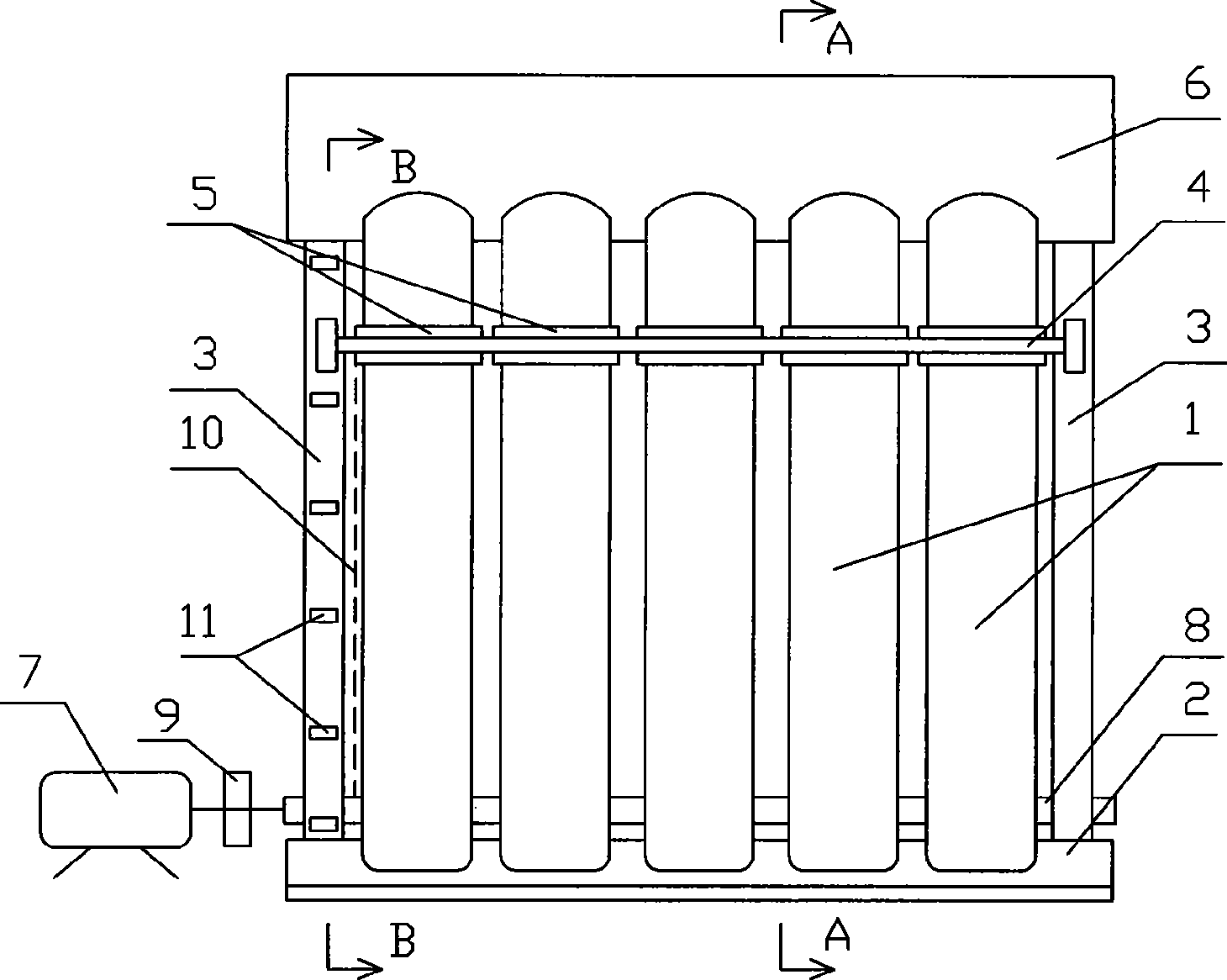

Automatic dedusting solar water heater

InactiveCN101498509ARealize automatic dust removalHigh thermal efficiencySolar heating energySolar heat devicesSolar waterSolar heater

The invention relates to a solar water heater, in particular to an automatic dust removal solar water heater which comprises a bracket provided with a vacuum pipe. The bracket is also provided with a water tank. The automatic dust removal solar heater is characterized in that the bracket is provided with a dust remover, the dust remover comprises a guide rail which is parallel to the vacuum pipe and a cross bar installed on the guide rail in a sliding way, a brush body is fixedly installed on the position of the cross bar corresponding to the vacuum pipe, and the cross bar is connected with a drive device in a transmission way through a transmission mechanism. The dust remover of the solar water heater has simple structure, and can realize automatic dust removal to the solar vacuum pipe, thereby the heat efficiency of the vacuum pipe is enhanced, and the vacuum pipe keeps the optimal working state.

Owner:宋志新

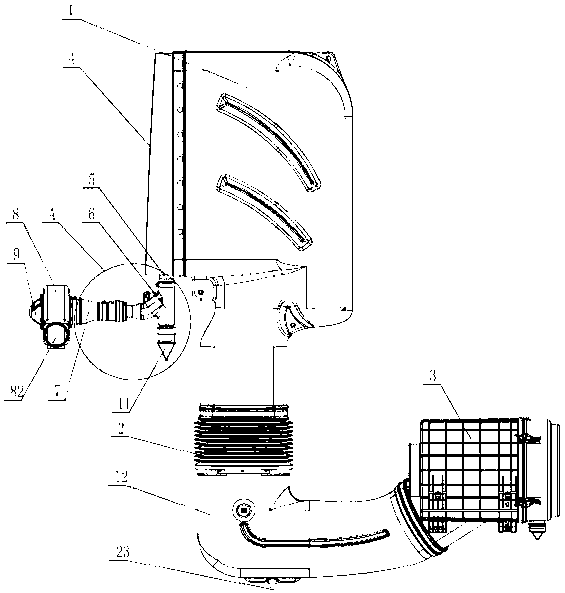

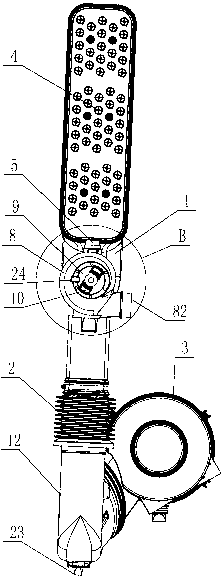

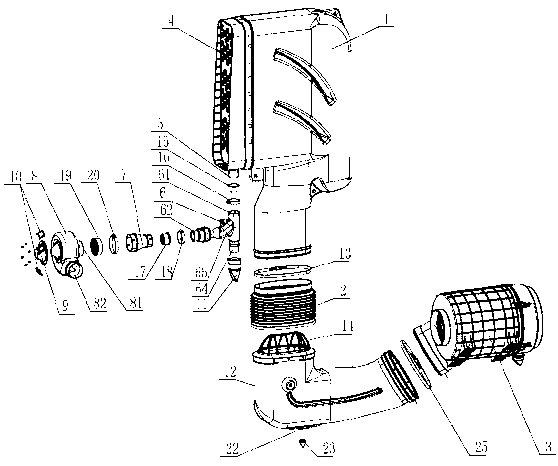

Vehicle engine intake system with fan-ejected dust removal device

ActiveCN103321797ARealize automatic dust removalImprove filtering effectMachines/enginesAir cleaners for fuelAir filterEngineering

A vehicle engine intake system with a fan-ejected dust removal device comprises an intake pipe. The gas outlet end of the intake pipe is fixedly connected with a bellows. The outlet end of the bellows is connected with the gas inlet end of an air filter through a transition bend. A pre-filter is disposed at a gas inlet of the intake pipe. The bottom of the pre-filter is provided with an ash outlet which is hermetically connected with an inlet of a one-way flow divider. A first outlet of the one-way flow divider is hermetically connected with a joint, and the other end of the joint is hermetically connected with a gas inlet of a direct-current fan. A gas outlet of the direct-current fan is a dust removal hole. A one-way valve core is disposed in the one-way flow divider. Opening direction of the one-way valve core is the same as intake direction of the direct-current fan. The one-way valve core is used for controlling opening and closing of a connecting pipeline for the one-way flow divider and the direct-current fan. The vehicle engine intake system allows for automatic dust removal of the pre-filter so that filtering effect of the pre-filter is improved and the service life of the air filter is prolonged, and is simple in structure and easy to arrange.

Owner:DONALDSON (WUXI) FILTERS CO LTD

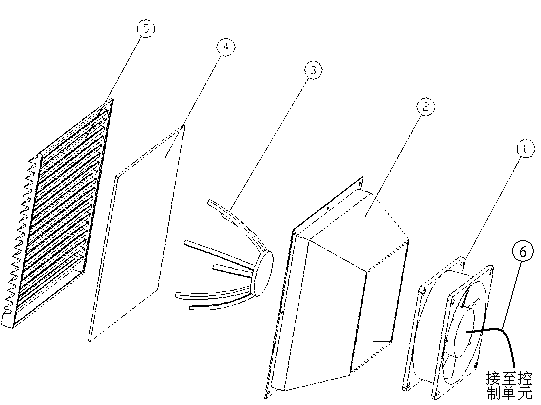

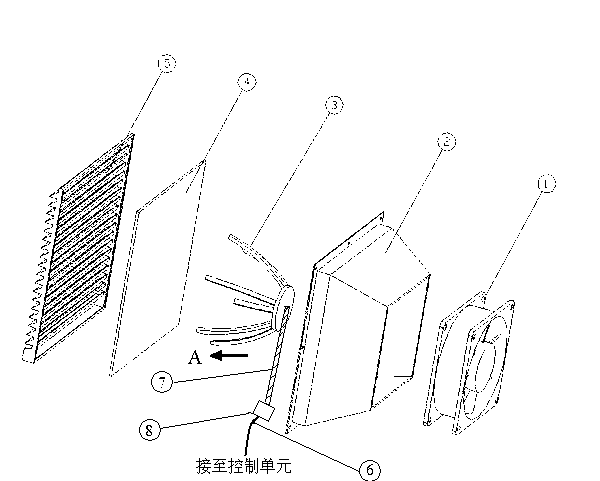

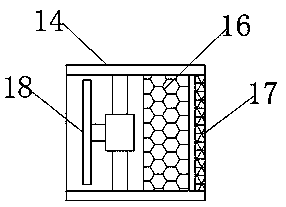

Automatic dust removing ventilation filter screen set

ActiveCN102728158ARealize automatic dust removalReasonable dust removal durationDispersed particle filtrationIndustrial equipmentEngineering

The invention discloses an automatic dust removing ventilation filter screen set and relates to ventilation accessories of electric cabinets or industrial equipment cabinets and aims at overcoming the problems in prior art that time and labor are wasted, and the cost is high in eliminating the accumulated dust inside a ventilation filter screen set. The technical points of the automatic dust removing ventilation filter screen set is that the automatic dust removing ventilation filter screen set comprises an outer screen hood, a filtering sponge, an inner screen hood shell, a dust remover and a fan, wherein the filtering sponge and the outer screen hood are covered at the opening of one end of the inner screen hood from inside to outside; the fan is arranged at the opening at the other end of the inner screen hood shell; the fan is a bidirectional rotatable fan; and the dust remover is arranged inside the inner screen hood shell.

Owner:四川科陆新能电气有限公司

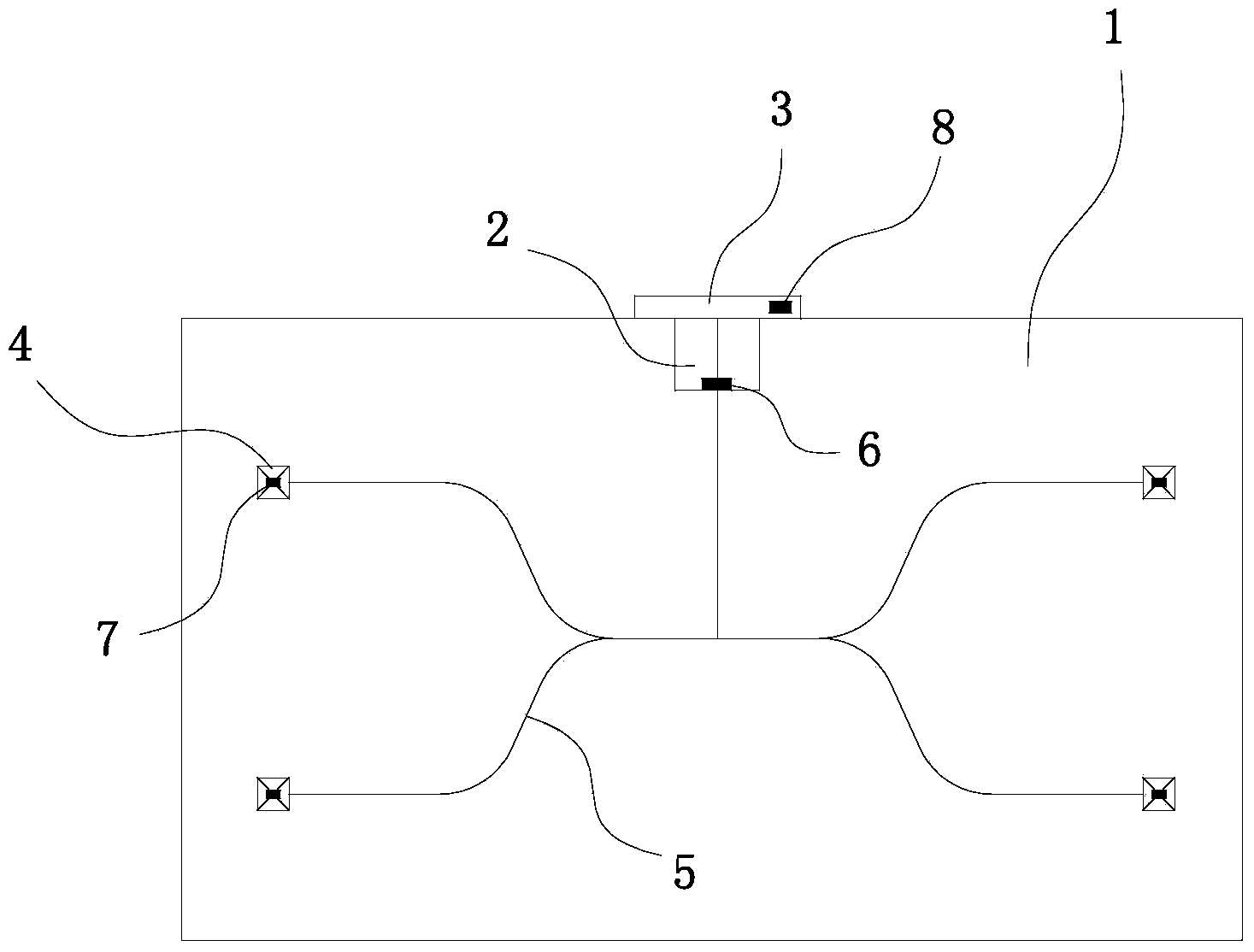

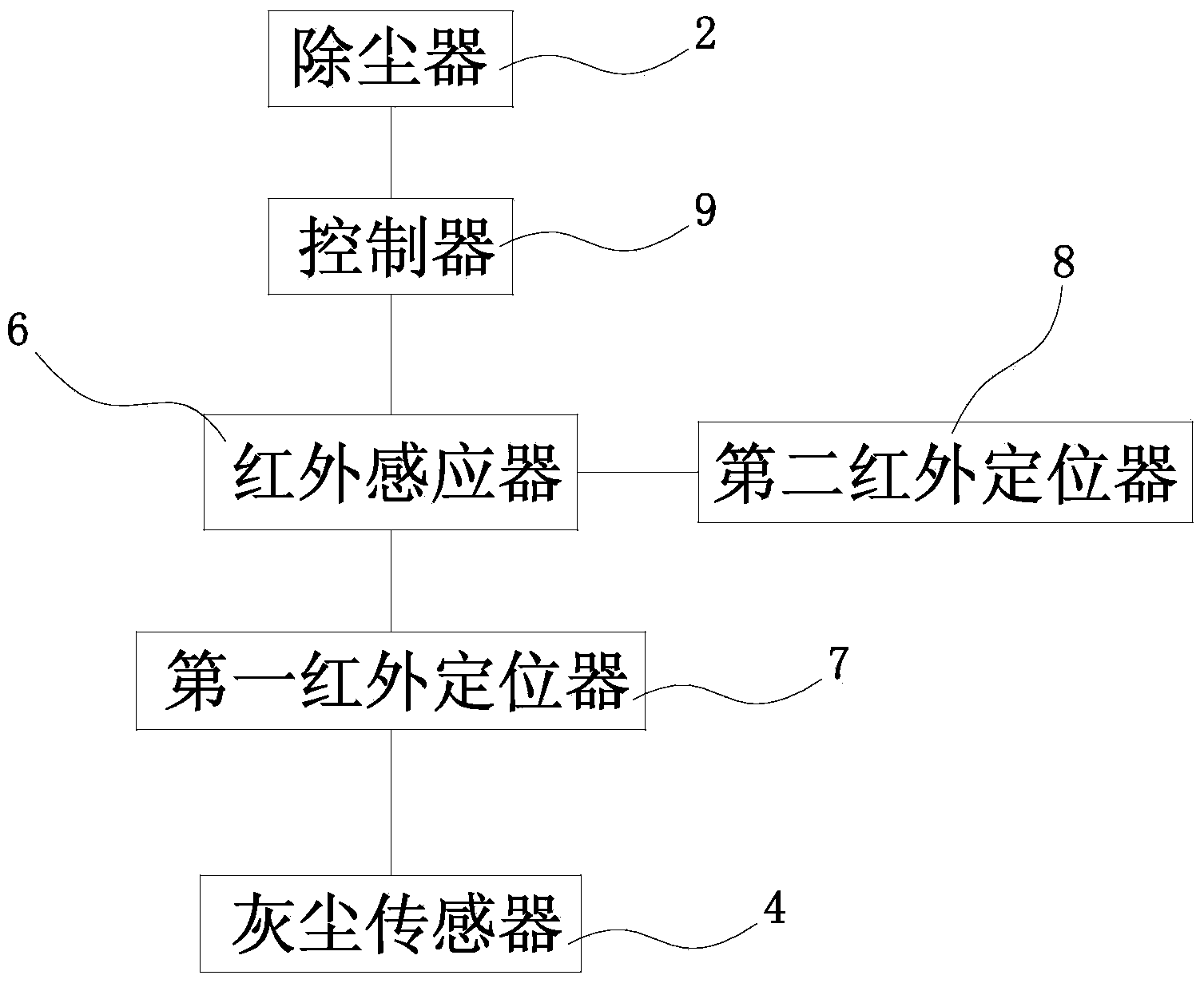

Movable dedusting device in textile workshop

InactiveCN104164717ARealize automatic dust removalTake advantage ofTextiles and paperSolar cellEnergy consumption

The invention relates to a movable dedusting device in a textile workshop. The movable dedusting device comprises a plurality of guide rails arranged on the top face of the textile workshop, and branched ends of the guide rails are respectively provided with a dust sensor and a first infrared locator. The device further comprises a deduster capable of moving on the guide rails and a solar cell panel arranged on the outer side face of the textile workshop, the deduster is provided with an infrared sensor, the solar cell panel is provided with a second infrared locator, and a controller used for controlling the deduster to move on the guide rails to remove dust is arranged in the deduster. By means of automatic detection and location of the dust sensors and the infrared locators, the deduster can automatically remove the dust in various areas, the dedusting effect is good, the dust can be removed in time, the deduster can be charged through the solar cell panel, natural energy is fully used and the movable dedusting device is low in energy consumption and environmentally friendly.

Owner:SUZHOU KAIFENGRUI ELECTRONICS SCI & TECHCO

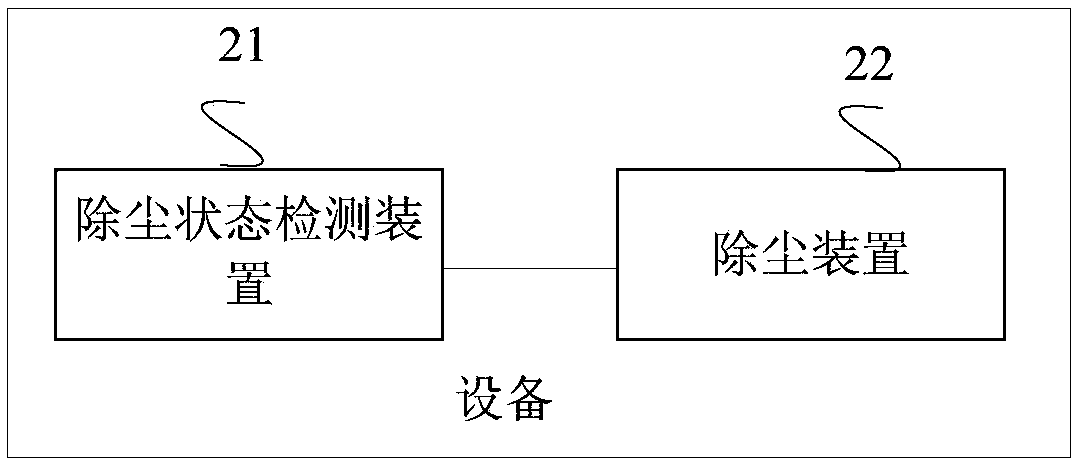

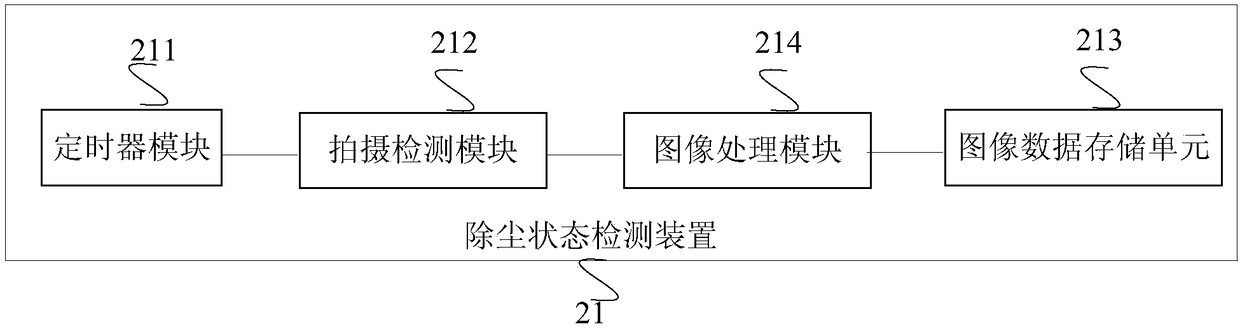

Dust-removing method, device, apparatus and computer storage medium for dust-proof net of equipment

ActiveCN109325932AEasy maintenanceAccurate detectionImage analysisDispersed particle filtrationComputer scienceComputer engineering

The present application provides a dust removing method, device, apparatus and computer storage medium for a dust screen of an apparatus. The device is provided with at least two dust-proof nets and aphotographing device. The method comprises the following steps: acquiring a first image when the dust-proof nets are dust-free by the photographing device; Acquiring, by the photographing device, a second image at the time of arrival of the predetermined photographing period; Determining whether the dust screen reaches a dust removing state according to the first image and the second image; If so, dust the dust net. By setting a simple photographing device, and by comparing the first image and the second image, The invention can accurately detect whether the dust-proof net reaches the dust-removing state at present, the detection cost is low, and the photographing device is easy to maintain, meanwhile, the problem of artificially cleaning the dust-proof net blindly caused by the blockagestate of the dust-proof net which can not be detected by the equipment in the prior art is avoided, and the timeliness and accuracy of cleaning the dust-proof net are improved.

Owner:HUAWEI TECH CO LTD

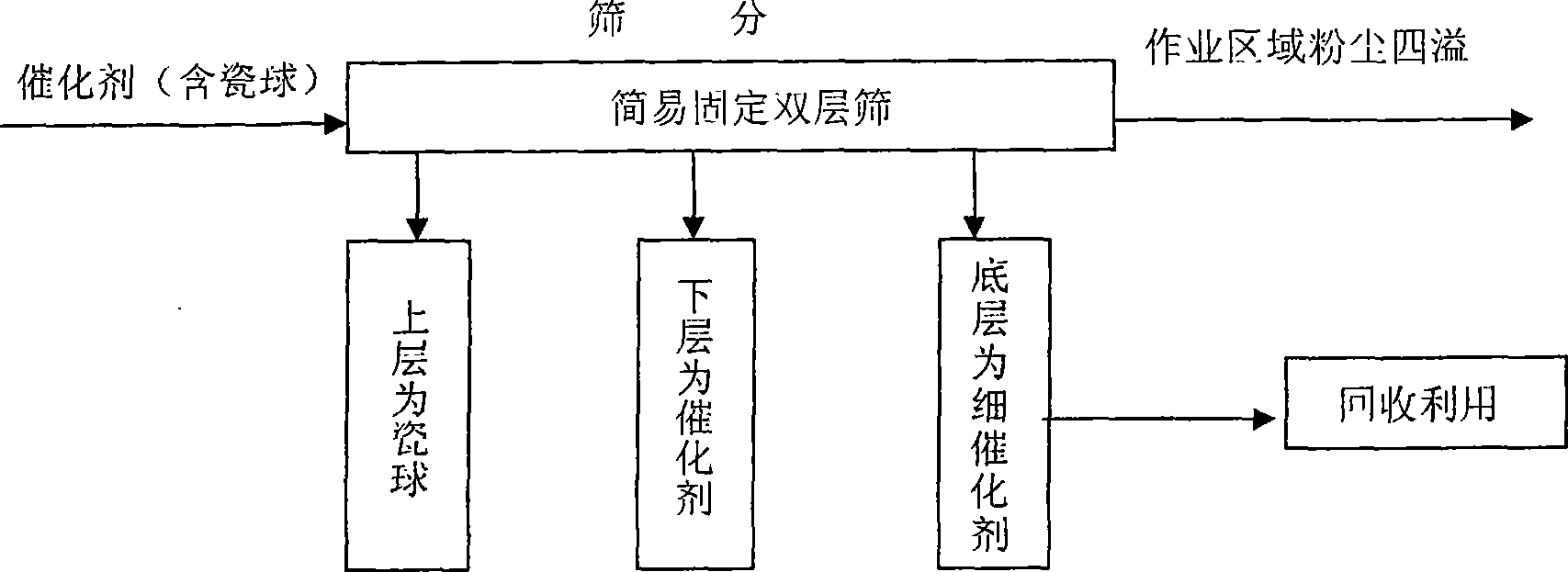

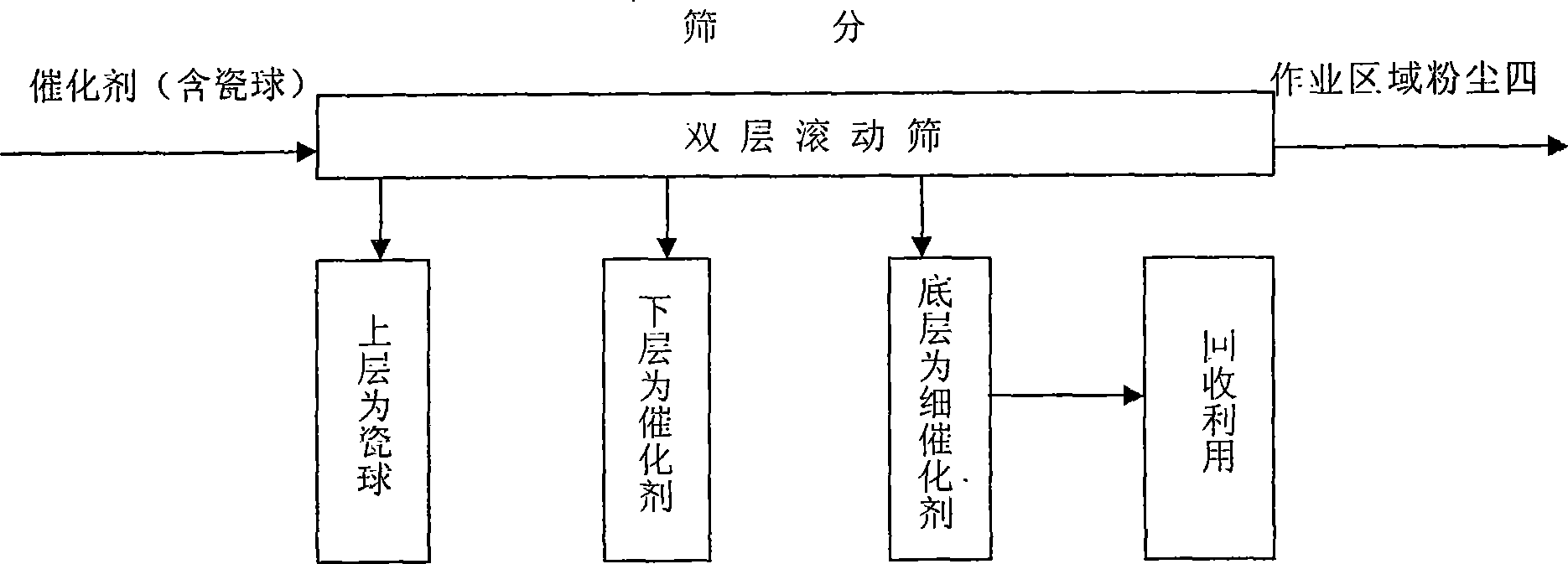

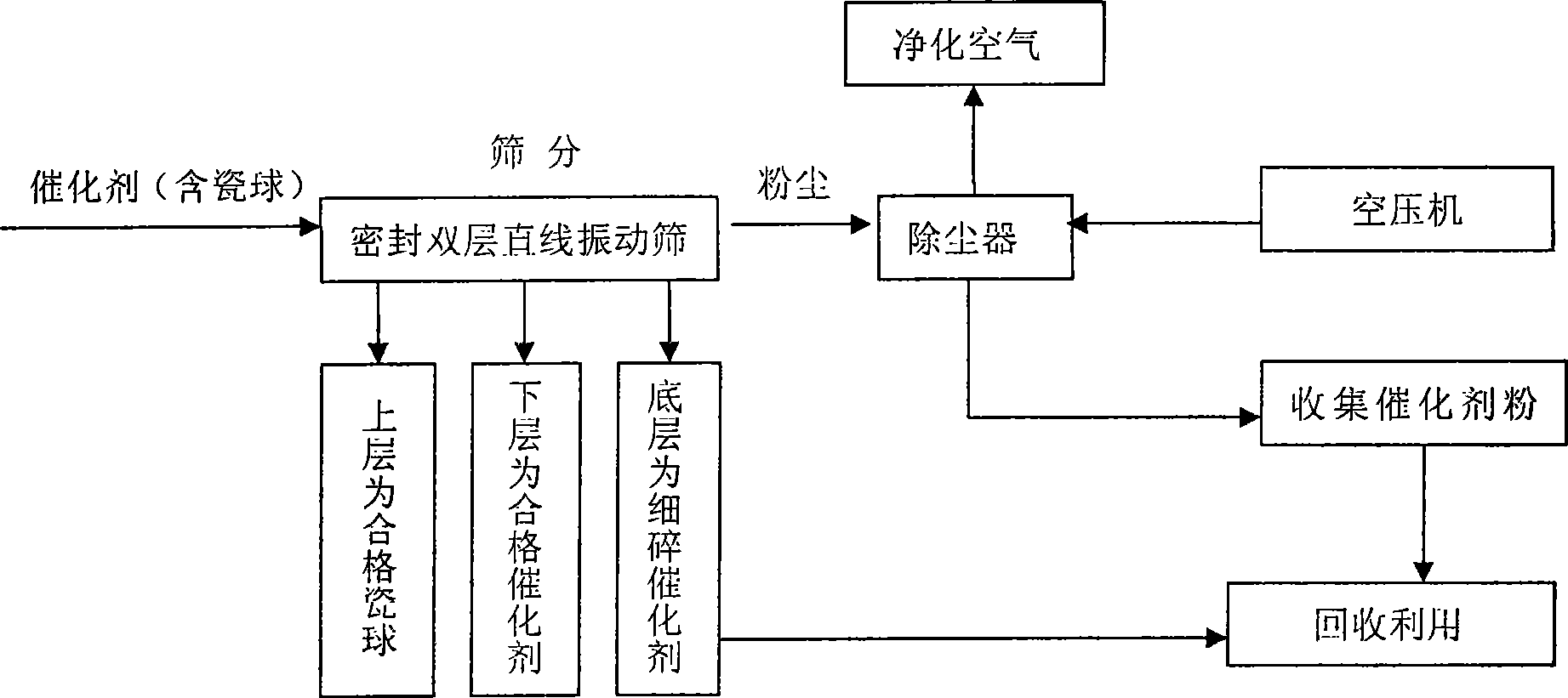

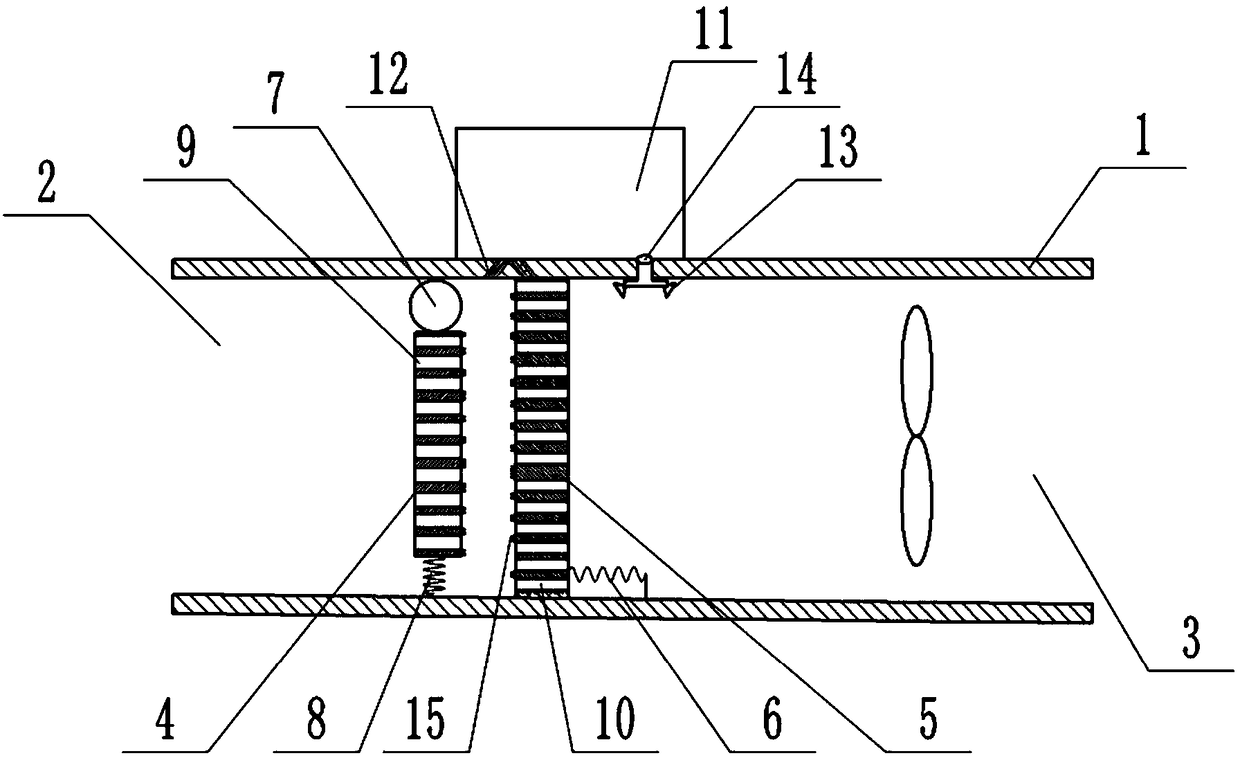

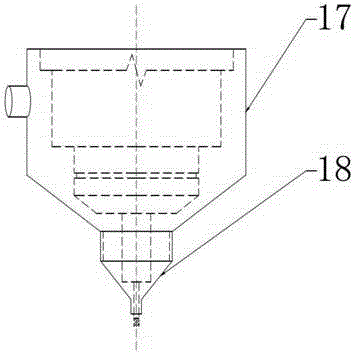

Catalyst screening method during preparation of sulphuric acid

InactiveCN101391755AReduce energy consumptionImprove efficiencySulfur-trioxide/sulfuric-acidWorking environmentEconomic benefits

The invention discloses a sulfuric acid catalyst screening method, which comprises: the catalyst is placed in a sealed double-layer linear mechanical vibrating screen to be screened level by level and the dusts generated during screening are filtered by a dust catcher; the screened thin catalyst grains and the catalyst dusts collected by the dust catcher are bagged respectively for later recycling. The application of the method can dramatically enhance the work environment and the dust density of the screening work zone is less than 3mg / m<3>, thus effectively protecting the health of workers. The improvement of environment can reduce the investment cost and the total screening cost can be saved by 5 to 10 percent, thus enhancing the economic benefit. The screening time can be dramatically shortened so as to obtain more time for the starting of sulfuric acid apparatus and guarantee smooth completion of the manufacturing task, thus having positive practical meaning and high popularization and application value.

Owner:云南云天化股份有限公司三环分公司 +1

Intelligent dust-removal and ventilating system

InactiveCN108692418APromote exchangeAchieve coolingLighting and heating apparatusSpace heating and ventilation detailsEngineeringAirbag

The invention discloses an intelligent dust-removal and ventilating system and relates to the field of air purification devices. The intelligent dust-removal and ventilating system comprises a channel. A first filtering plate and a second filtering plate which can be attached are arranged in the channel, and the first filtering plate is slidably connected with the inner wall of the channel in thevertical direction. The second filtering plate is slidably connected with the inner wall of the channel in the horizontal direction. An airbag is fixedly connected to the top of the first filtering plate, and the other side of the airbag is fixedly connected with the top wall of the channel. An elastic piece is arranged between the bottom of the first filtering plate and the bottom wall of the channel, and a through hole is formed in the first filtering plate. A slim hole is formed in the second filtering plate, and the communicating area of the through hole and the slim hole is increased gradually in the process of downward moving of the first filtering plate. A water tank is arranged on the upper portion of the channel, a plurality of spray holes communicating with the water tank are formed in the top wall of the channel, and when the second filtering plate and the first filtering plate are attached, the spray holes can be shielded. The problems that an existing ventilating device isprone to being blocked and cannot automatically adjust the ventilation quantity according to the environment temperature are solved, and the intelligent dust-removal and ventilating system is mainlyused for ventilating and dust removal of a factory.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

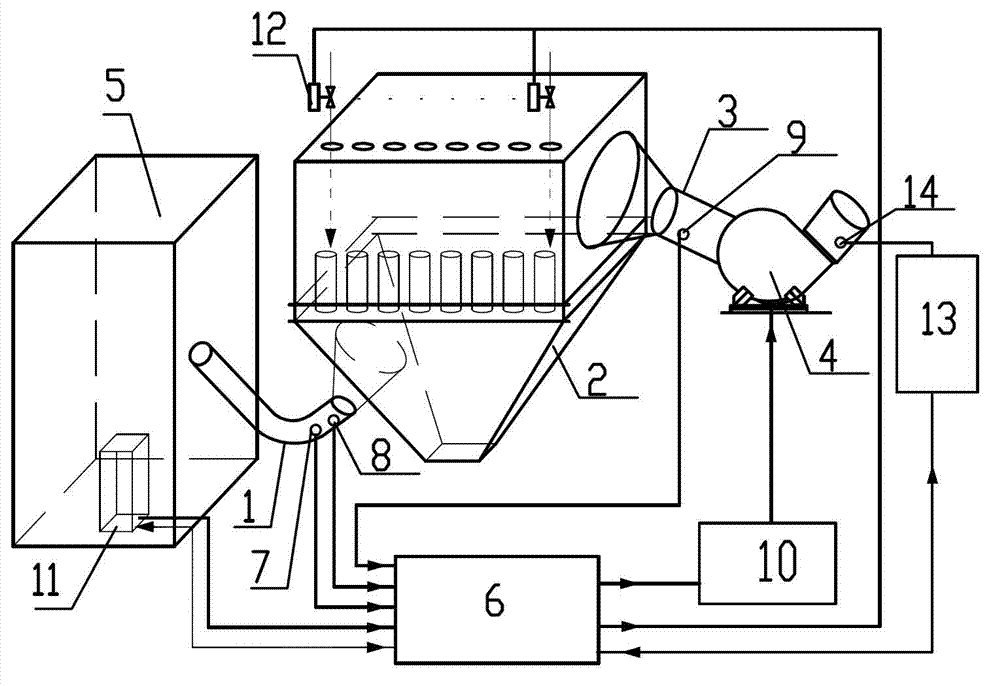

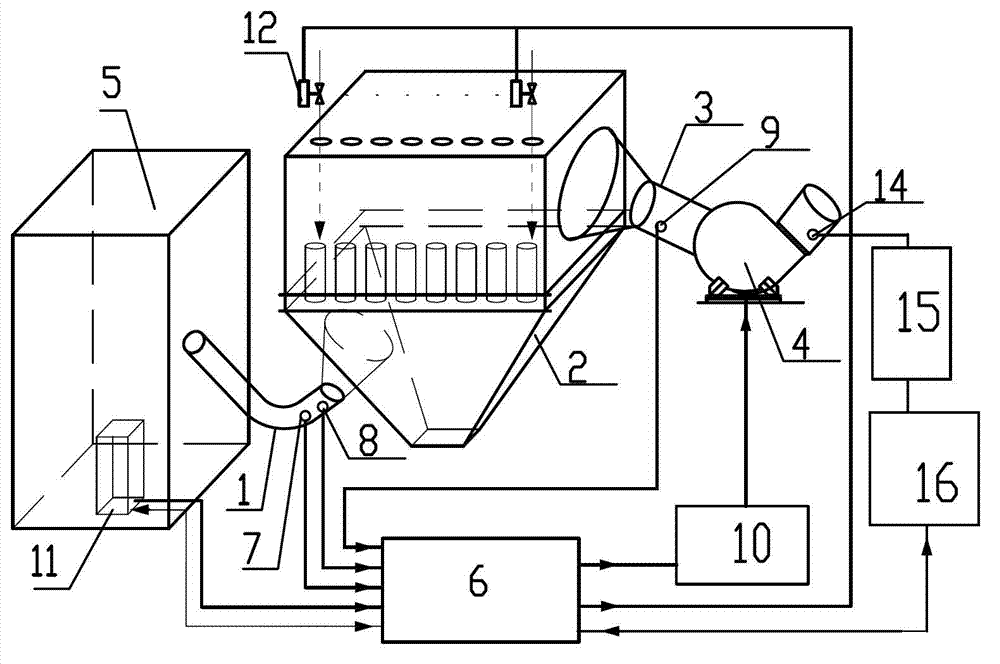

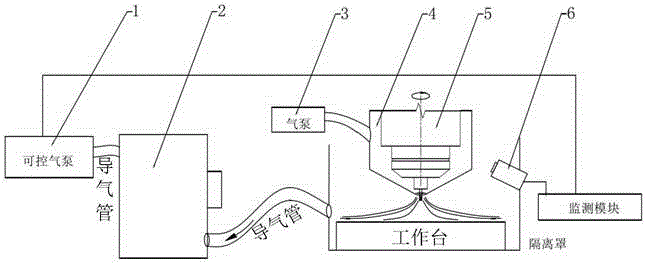

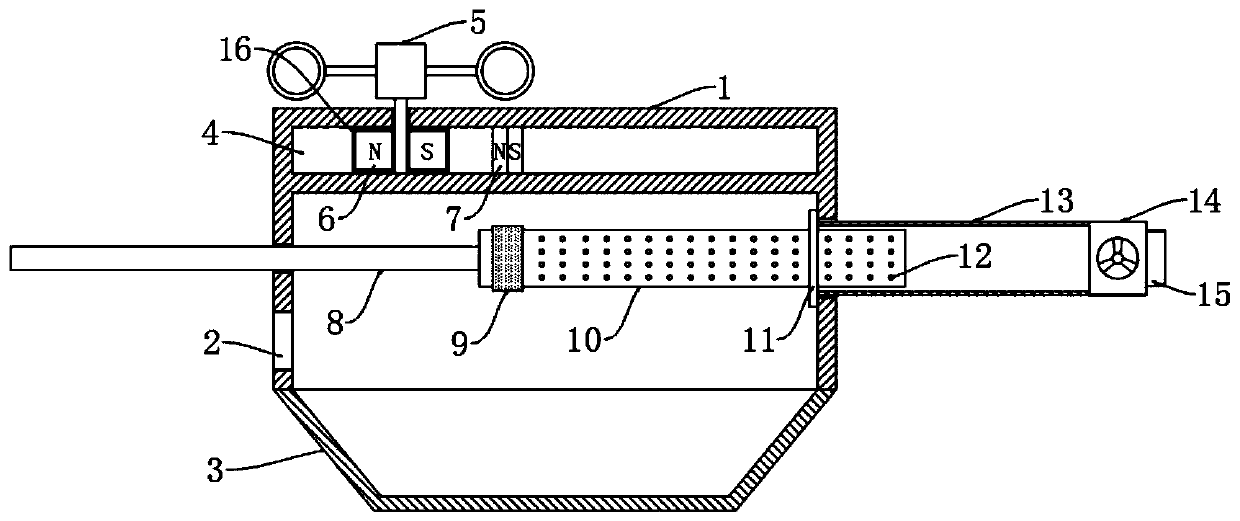

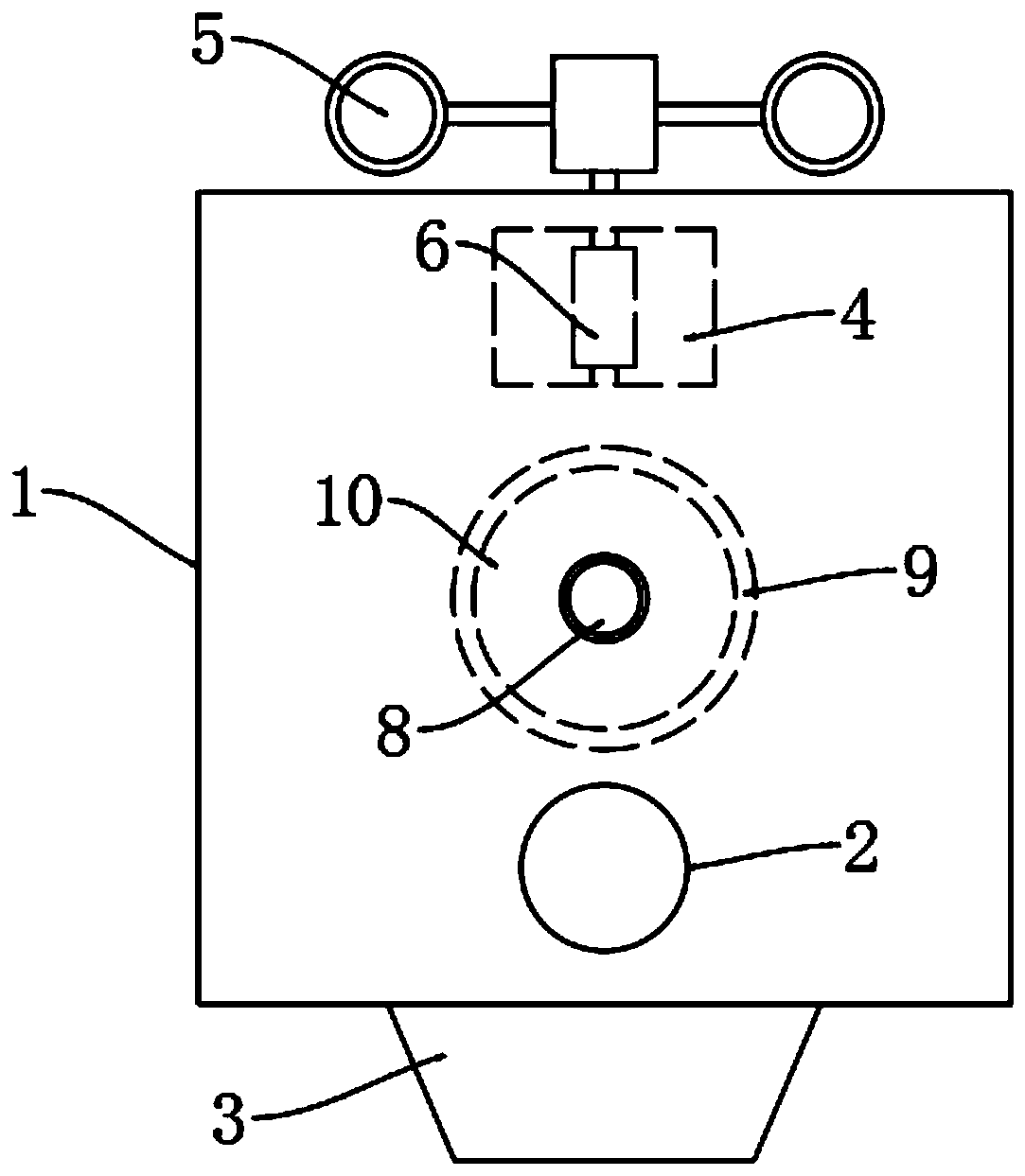

Dust monitoring device for composite material dry cutting machining

ActiveCN106393253AImprove efficiencyAvoid enteringDispersed particle filtrationTransportation and packagingMechanical designEngineering

The embodiment of the invention discloses a dust monitoring device for composite material dry cutting machining, and relates to the field of mechanical design and manufacturing. The dust monitoring device for the composite material dry cutting machining can remove dust automatically in a machining process, and comprises a controllable air pump which is connected with an air outlet of a dust removal box 2 through an air guide pipe and exhausts air from the dust removal box 2. An air inlet of the dust removal box 2 is connected with an air outlet of an isolating cover of a worktable on which a machine tool main shaft 5 is positioned through an air guide pipe. An air pump is connected with an air inlet of a main shaft protective cover 4 through an air guide pipe, and blows air into the main shaft protective cover 4. The main shaft protective cover 4 is of a semi-seal structure and is fixed to the machine tool main shaft 5; a tool which is mounted on the machine tool main shaft 5 extends through an air outlet of the main shaft protective cover 4. A dust concentration sensor 6 is mounted on the isolating cover of the worktable on which the machine tool main shaft 5 is positioned; a probe of the dust concentration sensor 6 extends into the inside of the isolating cover to detect the concentration of the dust inside the isolating cover. The dust monitoring device for the composite material dry cutting machining is applicable to dust removal of the composite material dry cutting machining.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

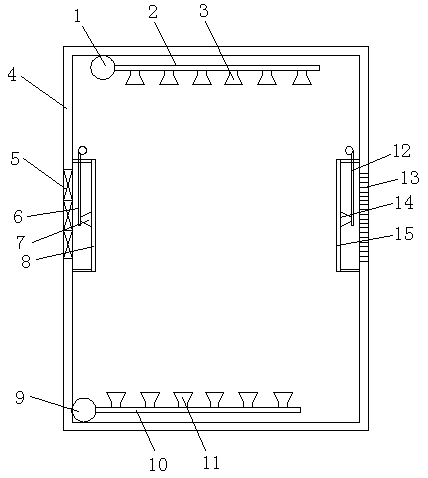

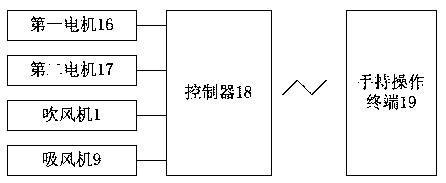

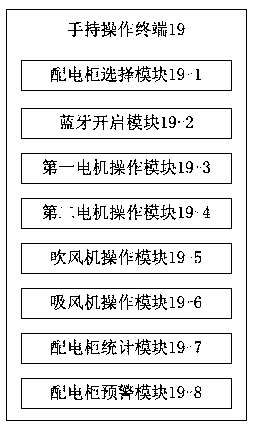

Automatic dust removal electric power distribution cabinet

InactiveCN109672093ARealize automatic dust removalMaster the dust removal situationDispersed particle filtrationTransportation and packagingElectric power distributionEngineering

The invention discloses an automatic dust removal electric power distribution cabinet. A first dust filtering screen is arranged in a ventilation window position in a cabinet body; a second dust filtering screen is arranged in an exhaust fan position in the cabinet body; a first rolling curtain plate driven by a first motor is arranged between the ventilation window and the first dust filtering screen; a first hair brush facing the first dust filtering screen is arranged at the bottom end of the first rolling curtain plate; a second rolling curtain plate driven by a second motor is arranged between the exhaust fan and the second dust filtering screen; a second hair brush facing the second dust filtering screen is arranged at the bottom end of the second rolling curtain plate; the top end in the cabinet body is provided with a blower fan; the bottom end of the cabinet body is provided with an air suction fan; a controller which is respectively and electrically connected with the first motor, the second motor, the blower fan and the air suction fan is also installed; a handheld operating terminal in wireless communication with the controller is also used. The structure is simple; theoperation is convenient; the automatic dust removal of the power distribution cabinet can be realized; the dust removal effect is relatively good; by using the handheld operating terminal, the dust removal state of a plurality of power distribution cabinets can be monitored at any time; the dust removal condition of the power distribution cabinet is mastered; the timely dust removal of the powerdistribution cabinet is convenient.

Owner:刘垚鑫

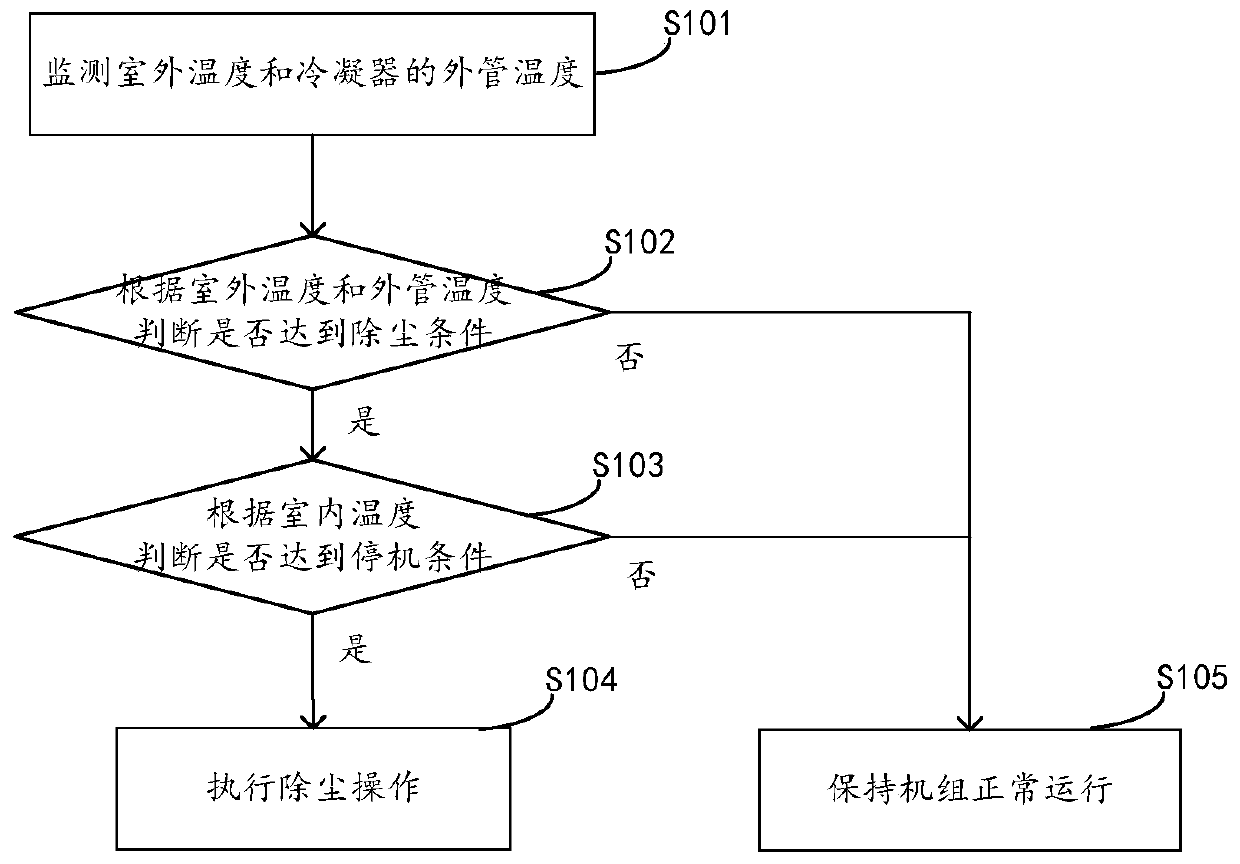

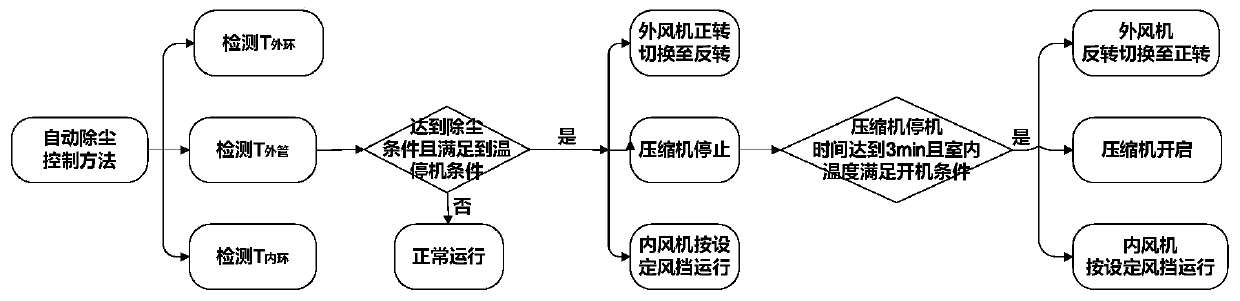

Automatic unit dust removal method and device and unit

ActiveCN110567118AAvoid cooling capacity decayImprove reliabilityMechanical apparatusUltrasound attenuationOutdoor temperature

The invention discloses an automatic unit dust removal method and device and a unit. The method includes the steps of monitoring the outdoor temperature and the temperature of an outer pipe of a condenser, judging whether the dust removal conditions are met or not according to the outdoor temperature and the temperature of the outer pipe, if yes, further judging whether shutdown conditions are metor not according to the indoor temperature, and executing the dust removal operation after the shutdown conditions are met. By combining various temperature parameters, the dust removal conditions and the shutdown conditions are sequentially judged, and the dust removal operation is executed when the two types of conditions are both met. Thus, by combining environment factors, the automatic unitdust removal is realized, the problems of refrigerating capacity attenuation and poor reliability caused by the dust accumulation or dirt blockage of the condenser are avoided, the reliability of theunit is improved, and the service life is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

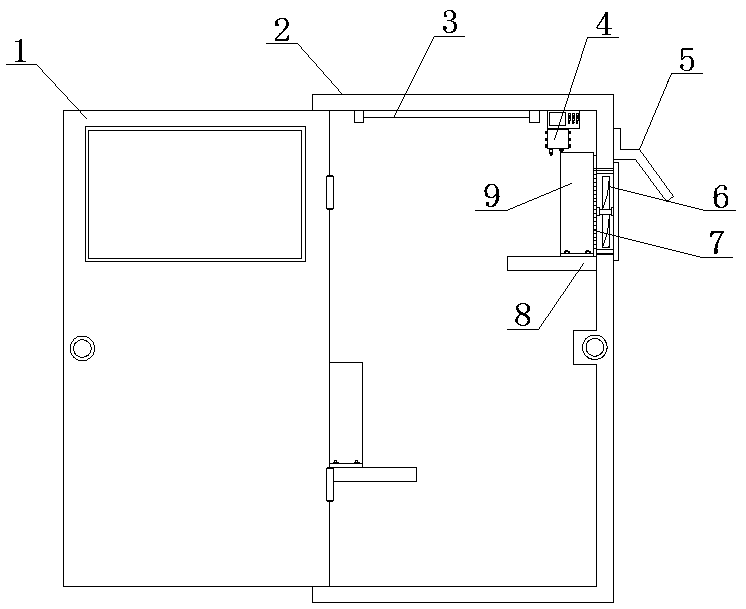

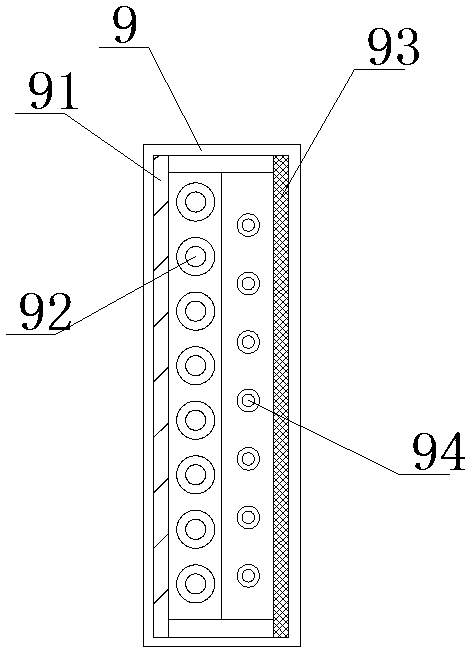

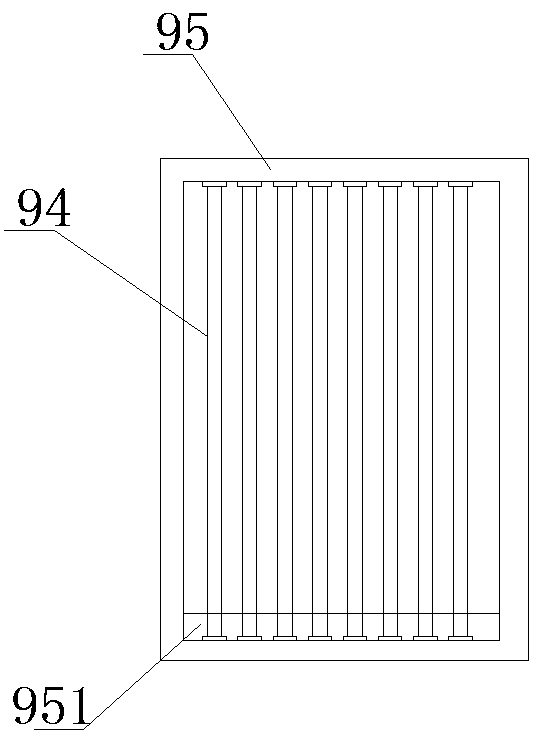

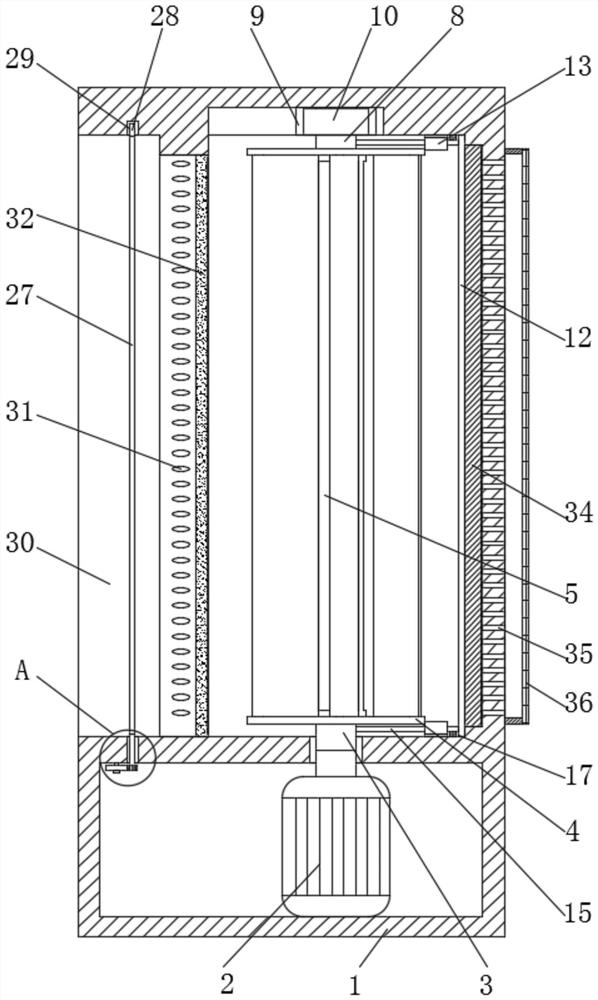

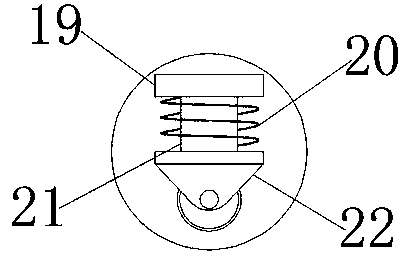

Automatic intermittent cleaning type filter of heating ventilation air conditioner

InactiveCN111530188AImprove practicalityRealize automatic dust removalDispersed particle filtrationTransportation and packagingEnvironmental engineeringWaste management

The invention discloses an automatic intermittent cleaning type filter of a heating ventilation air conditioner, the automatic intermittent cleaning type filter comprises an air inlet device; a filtering device is arranged in the air inlet device; by a drive device, the automatic intermittent cleaning type filter can utilize the kinetic energy of airflow; a force storage device is matched with a transmission device to realize kinetic energy storage; by a filter device, the filter can monitor the air resistance in real time and can make corresponding action changes according to the change of the air resistance; the air inlet device, the filtering device, a limiting device, the transmission device and a clamping device are matched, so that the kinetic energy stored by the force storage device can be continuously transmitted to a cleaning device to rotate the cleaning device, the filtering device is subjected to ash removal treatment through the cleaning device, the purpose of automatic ash removal is achieved, the ash removal speed is high, time and labor are saved, manual operation is not needed, the maintenance cost is low, and the practicability of the filter is improved.

Owner:胡玉平

Electric appliance cabinet with dust removal function

InactiveCN107592775ARealize automatic dust removalHigh hardnessFouling preventionElectrostatic separationUltraviolet lightsEngineering

The invention discloses an electric appliance cabinet with a dust removal function. The electric appliance cabinet comprises an electric appliance cabinet; the electric appliance cabinet is hinged with a cabinet door through a hinge; an ultraviolet light searchlight is mounted on the top of the interior of the electric appliance cabinet; a temperature and humidity sensor is mounted on the inner wall of the electric appliance cabinet; two air flow guiding plates are fixedly arranged in the electric appliance cabinet; the two air flow guiding plates are perpendicular to the inner wall of the electric appliance cabinet, and the two air flow guiding plates are parallel to each other; and electric appliance dust collectors are mounted above the two air flow guiding plates. By virtue of an observation window, the internal condition of the electric appliance cabinet can be observed conveniently without opening the cabinet door; an induced draft fan is mounted in each ventilating hole, so thatcirculation and ventilation of air in the cabinet can be ensured, thereby improving uniform heat dissipation performance of the electric appliance; and impurities in the air are subjected to electrostatic adsorption, so that the problem of dust accumulation can be solved; and in addition, the electric appliance cabinet is relatively low in cost, and can be cleaned by water washing and can be reused.

Owner:江阴多高自动化科技有限公司

Environment-friendly window type fresh air ventilator capable of ascending and descending

InactiveCN112212454AEfficient removalImprove satisfactionMechanical apparatusLighting and heating apparatusActivated carbon filtrationHazardous substance

The invention discloses an environment-friendly window type fresh air ventilator capable of ascending and descending. The environment-friendly window type fresh air ventilator comprises a machine body, a motor, a first rotating shaft, a cross-flow fan, a filter element, a notch, a lysozyme filter column, a second rotating shaft, a bearing seat, a bearing, a dust outlet, a baffle, a first mountingseat, a brush, a limiting groove, a second mounting seat, a second electric push rod, a rack, a sliding groove, a guide rod, a stop block, a heating piece, an activated carbon filter screen, sound-absorbing cotton, a high efficiency filter screen, an air inlet and a primary effect filter screen. Compared with the prior window type fresh air ventilator, designed louver can automatically adjust theopening and closing angle, control the air direction and is convenient to use, designed air purification system adopts the multi-stage treatment design, harmful substances in air can be effectively removed, and real clean air is exhausted. According to the environment-friendly window type fresh air ventilator capable of ascending and descending, an automatic cleaning function is designed, automatic dust removal in the equipment can be achieved, the maintenance cost is reduced, and the user satisfaction is improved.

Owner:DONGGUAN EXCEL IND

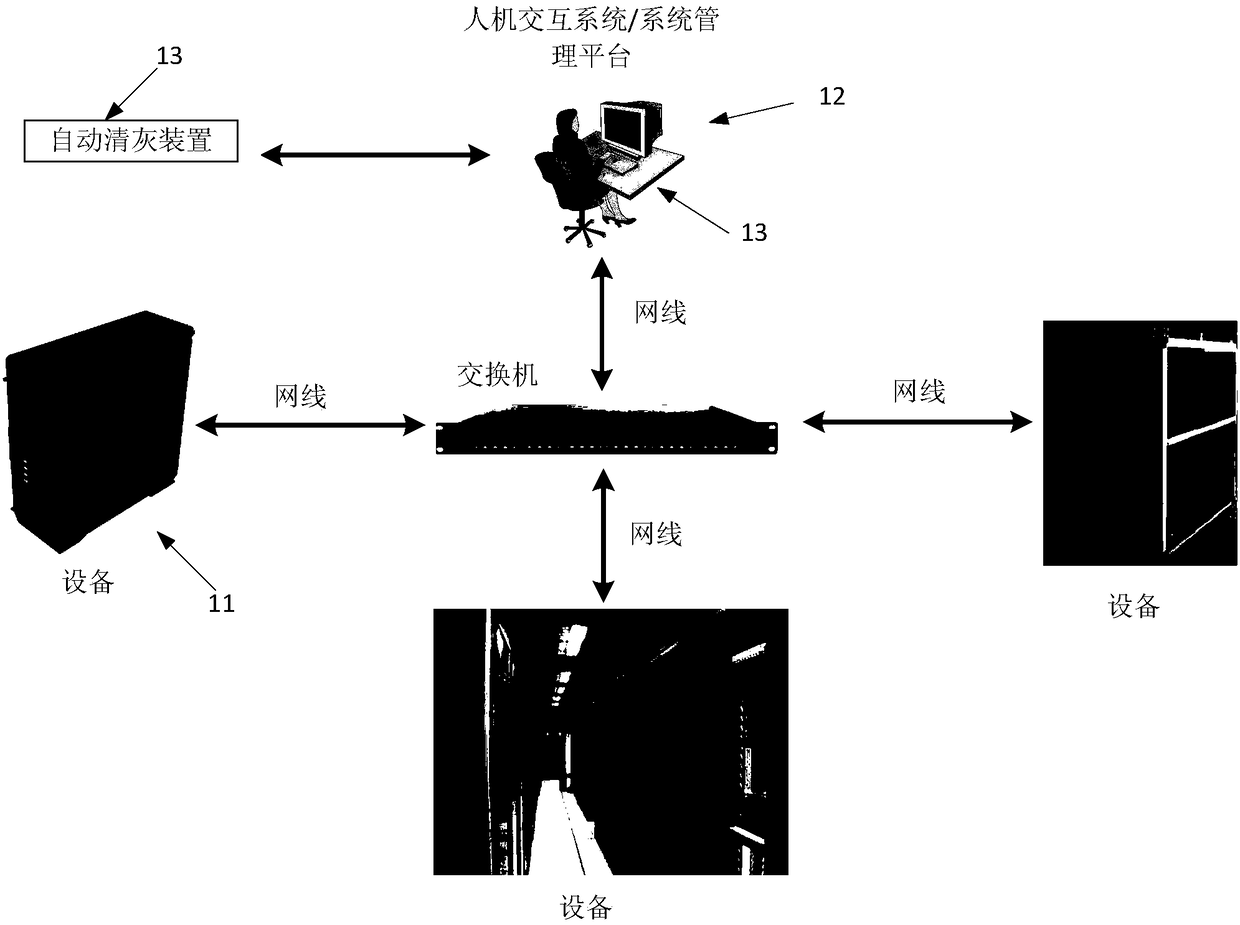

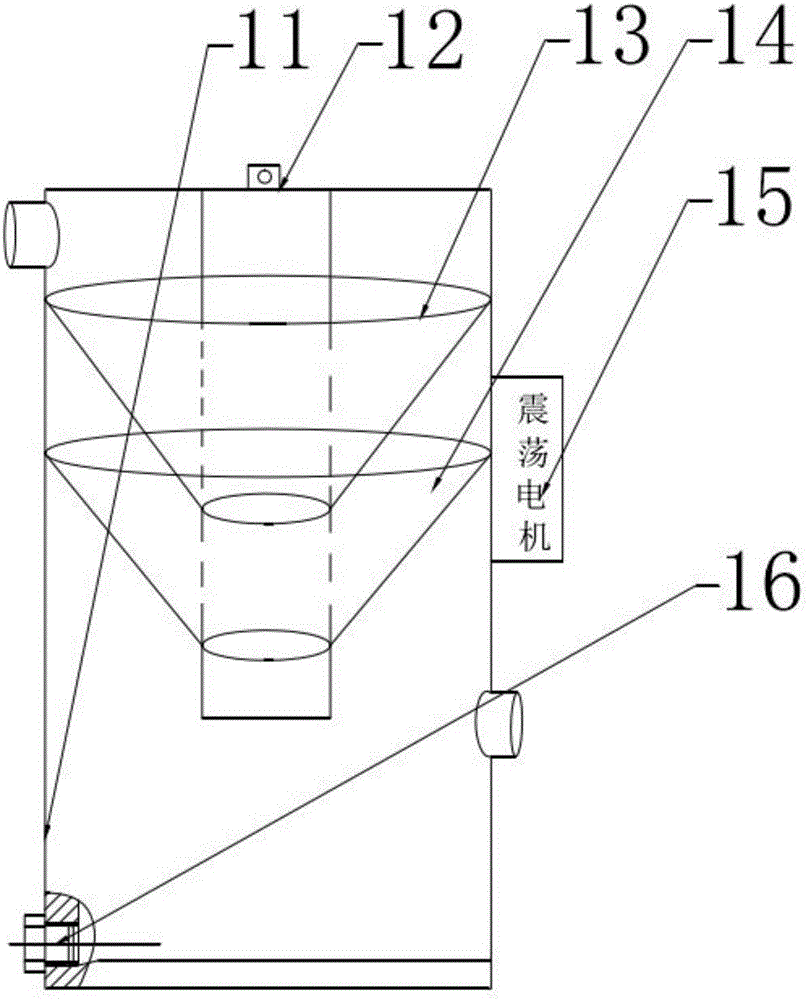

Remote controllable dust removal system

InactiveCN104759176AMeet the purpose of dust removalRealize automatic dust removalCombination devicesMicrocontrollerOpen water

The invention relates to a remote controllable dust removal system, which includes dust removal equipment and a remote control terminal. The dust removal equipment comprises a box body and a fan. The box body is provided with a dust inlet hole, and is internally equipped with an open water holding container, dust inlet pipes, a central processor, a GSM communication module, a WIFI module, a vibration plate and a vibration motor. The central processor is respectively connected to the fan, the GSM communication module, the WIFI module, the vibration plate and the vibration motor, a dust collection filter plate is disposed below the vibration plate, the dust inlet hole is equipped with a dust detector and a filter net, the water holding container is provided with a microcontroller, a stirring device, a liquid concentration detection device and an alarm device, the stirring device and the liquid concentration detection device are respectively connected to the microcontroller, the microcontroller, the dust detector and the alarm device are respectively connected to the central processor, one end of a dust inlet pipe is connected into the dust inlet hole, and the other end of a dust inlet pipe is under the water of the water holding container, and the remote control terminal is connected to the central processor, thus realizing automatic dust removal of equipment, and also meeting remote dust removal.

Owner:孙盼峰

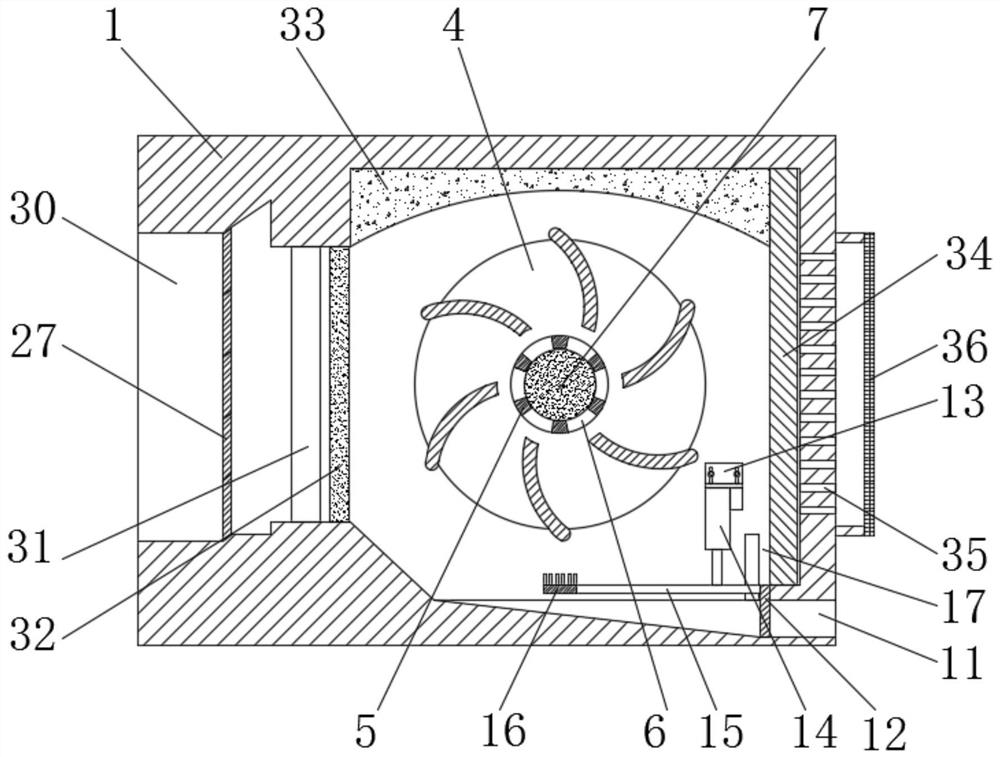

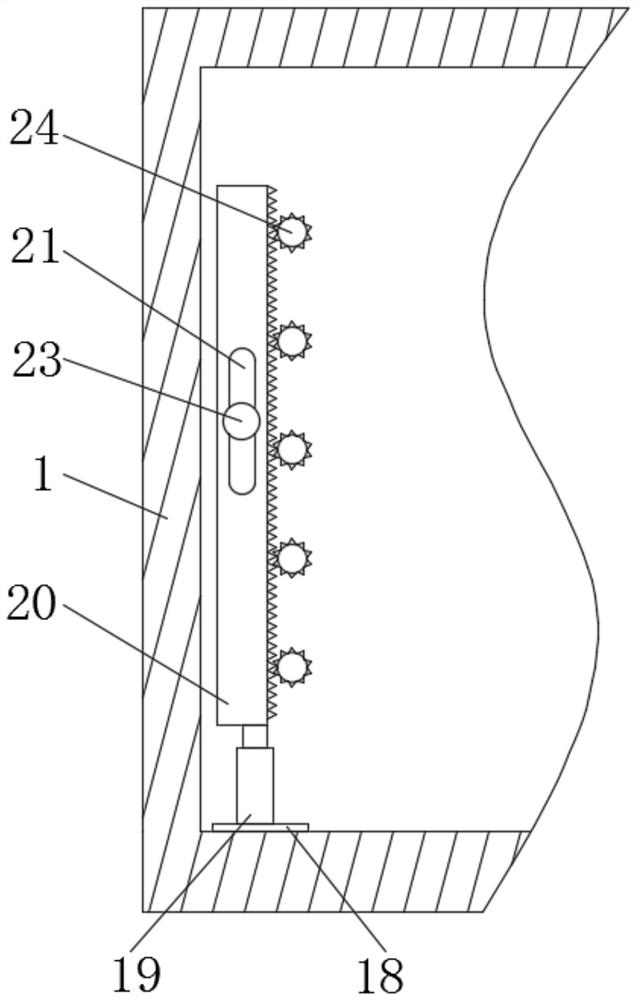

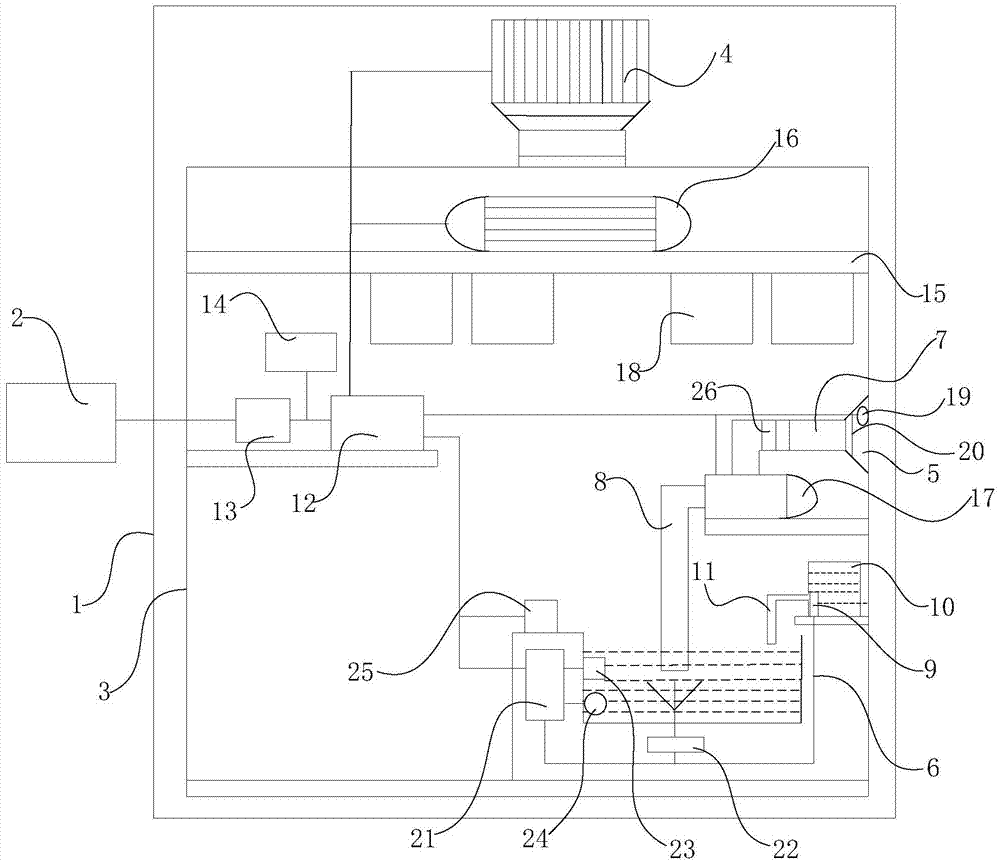

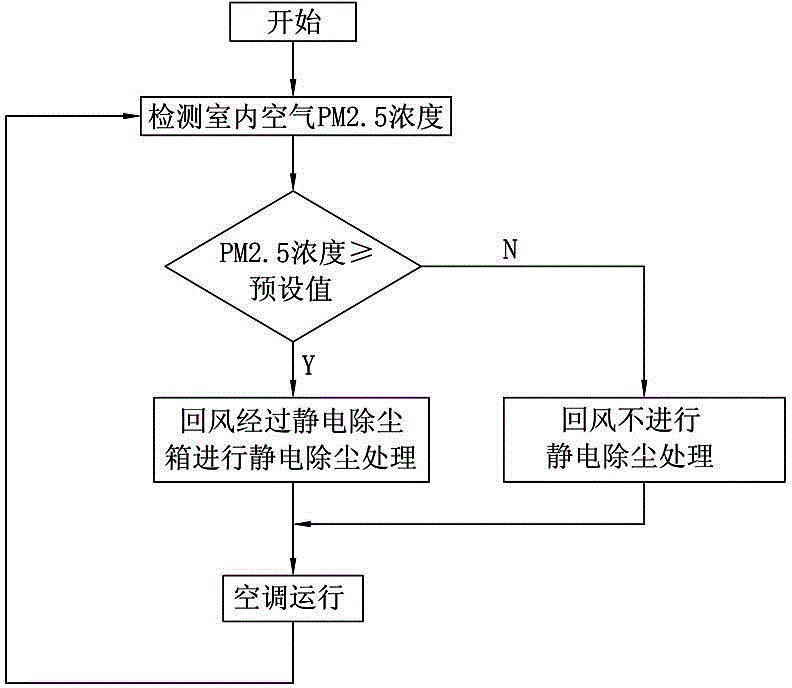

Air-conditioning returned air dust removing control method and dust removing air conditioner

ActiveCN104654453ARealize automatic dust removalAchieve purificationMechanical apparatusSpace heating and ventilation safety systemsDust controlEnvironmental engineering

The invention discloses an air-conditioning returned air dust removing control method. The air-conditioning returned air dust removing control method comprises the following steps: (1) detecting a PM2.5 actual concentration value X of indoor air when an air conditioner is started or normally operated; (2) comparing the detected PM2.5 actual concentration value X of the indoor air with a pre-set value X1; when X is more than or equal to X1, carrying out electrostatic dust removing treatment on air-conditioning returned air by using an electrostatic dust removing filtering tank; and when the X is less than the X1, not carrying out the electrostatic dust removing treatment on the returned air. The invention further discloses a dust removing air conditioner. The dust removing air conditioner comprises a detection piece for detecting the PM2.5 concentration of the indoor air, the electrostatic dust removing filtering tank capable of being washed with water and a controller; the detection piece and the electrostatic dust removing filtering tank are electrically connected with the controller; the controller is used for controlling the opening and closing of the electrostatic dust removing filtering tank according to the PM2.5 concentration value detected by the detection piece. The method and the dust removing air conditioner have the advantage of automatically purifying the indoor air.

Owner:临泉县卡天下电子商务有限公司

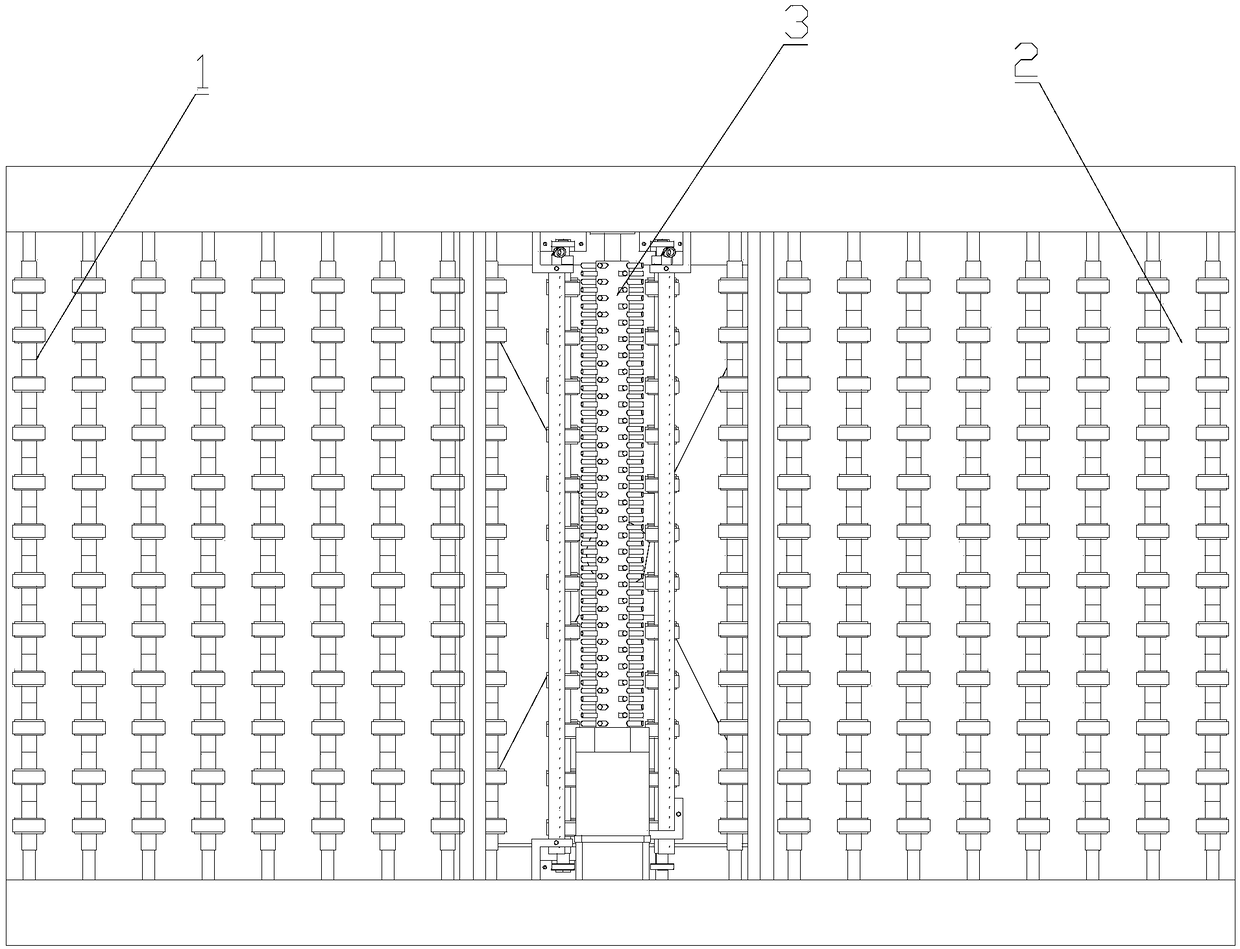

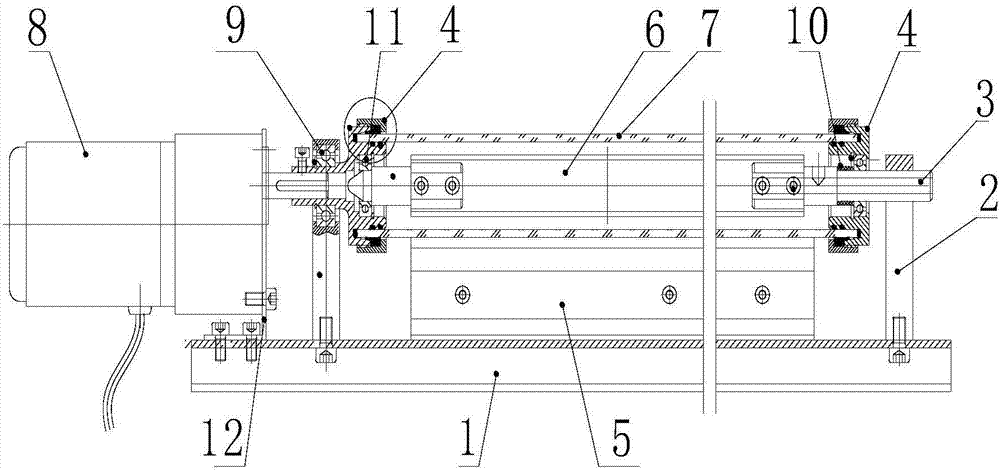

Reciprocating type dust removal device and method used after PCB drilling

InactiveCN108326944AReduce the number of manual operationsHigh precisionInsulating layers/substrates workingCleaning using gasesEngineeringManipulator

The invention discloses a reciprocating type dust removal device used after PCB drilling. The device comprises a reciprocating type dust removal mechanism, a drilling cleaning mechanism, a turnover plate cooling mechanism, a hole site precision testing mechanism and an automatic plate collection machine which are sequentially connected. The dust removal mechanism is connected with a dust removal feeding mechanical hand, and the hole site precision testing machine is connected with a testing feeding mechanical hand. Automatic dust removal and cleaning operation after drilling is achieved, the manual operation frequency of personnel in the cleaning and detection process is reduced, the processing efficiency is improved, the processing period is shortened, and the problem that a plate face isscraped in the manual repeated carrying process is solved. The reciprocating type dust removal mechanism can carry out dust removal treatment on plates repeatedly back and forth, the cleaning effectis more thorough, dust in holes can be effectively removed, and therefore follow-up hole site precision detection results are higher in accuracy. The invention further discloses a dust removal method.The dust removal method is wired type automatic dust removal method and is high in dust removal efficiency, good in cleaning effect and applicable to batch treatment on dilled plates.

Owner:江西景旺精密电路有限公司

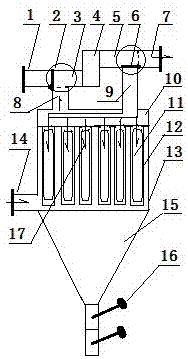

Bag dust collector

InactiveCN107137990ASimple controlFlexible operationDispersed particle filtrationEngineeringRelay valve

The invention relates to a bag dust collector. The bag dust collector comprises an air pipe, an air-intake three-way valve plate, an air suction pipe, a blower, a blower air outlet pipe, an air-outtake three-way valve plate, an air outtake pipe, an exhaust pipe, a back blowing pipe, an upper air chamber, in-bag frames, dust collecting bags, a dust collector shell, a dust air pipe, a lower air chamber, relay valves and back blowing branch pipes. The bag dust collector is characterized in that the dust collector is provided the upper air chamber and the lower air chamber, the exhaust pipe of the dust collector is connected with an air intake pipe of an air-intake three-way valve plate chamber, when the dust collector operates, the air-intake three-way valve plate closes the air pipe, and the blower air suction pipe is opened; the dust collection bags are installed in the lower air chamber, the frames are arranged inside the dust collection bags, and the dust air pipe is connected into a workroom; dust is discharged from a tapered hopper via the relay valves; during back blowing and dust clearing, the air-outtake three-way valve plate opens the air pipe, the blower air suction pipe is closed, the air-outtake three-way valve plate opens the back blowing pipe, and the air outtake pipe is closed; a negative pressure chamber turns into a positive pressure chamber quickly, dust adsorbed on the outer surfaces of the dust collection bags is blown off, and the bag dust collector returns to the dust collection state quickly.

Owner:杨朴

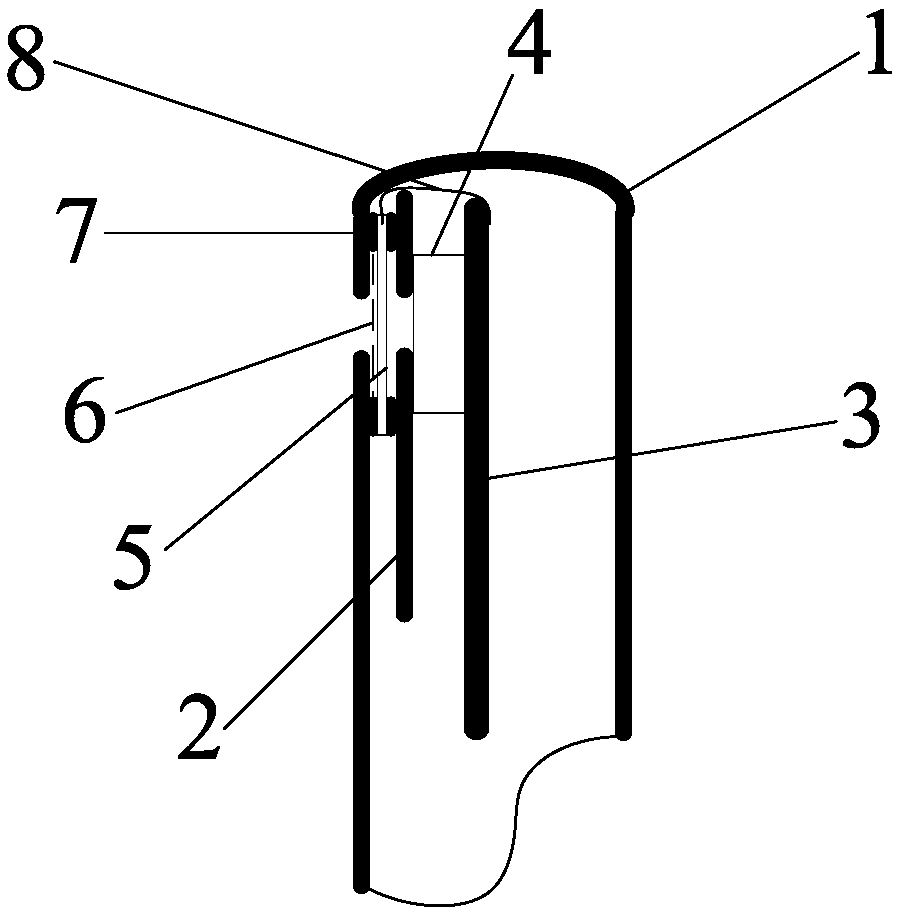

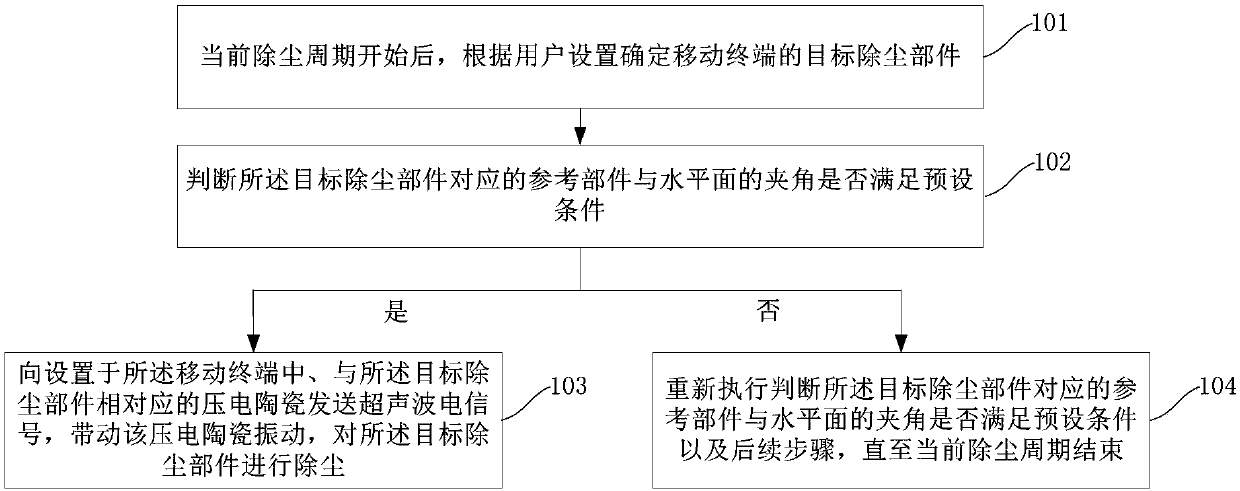

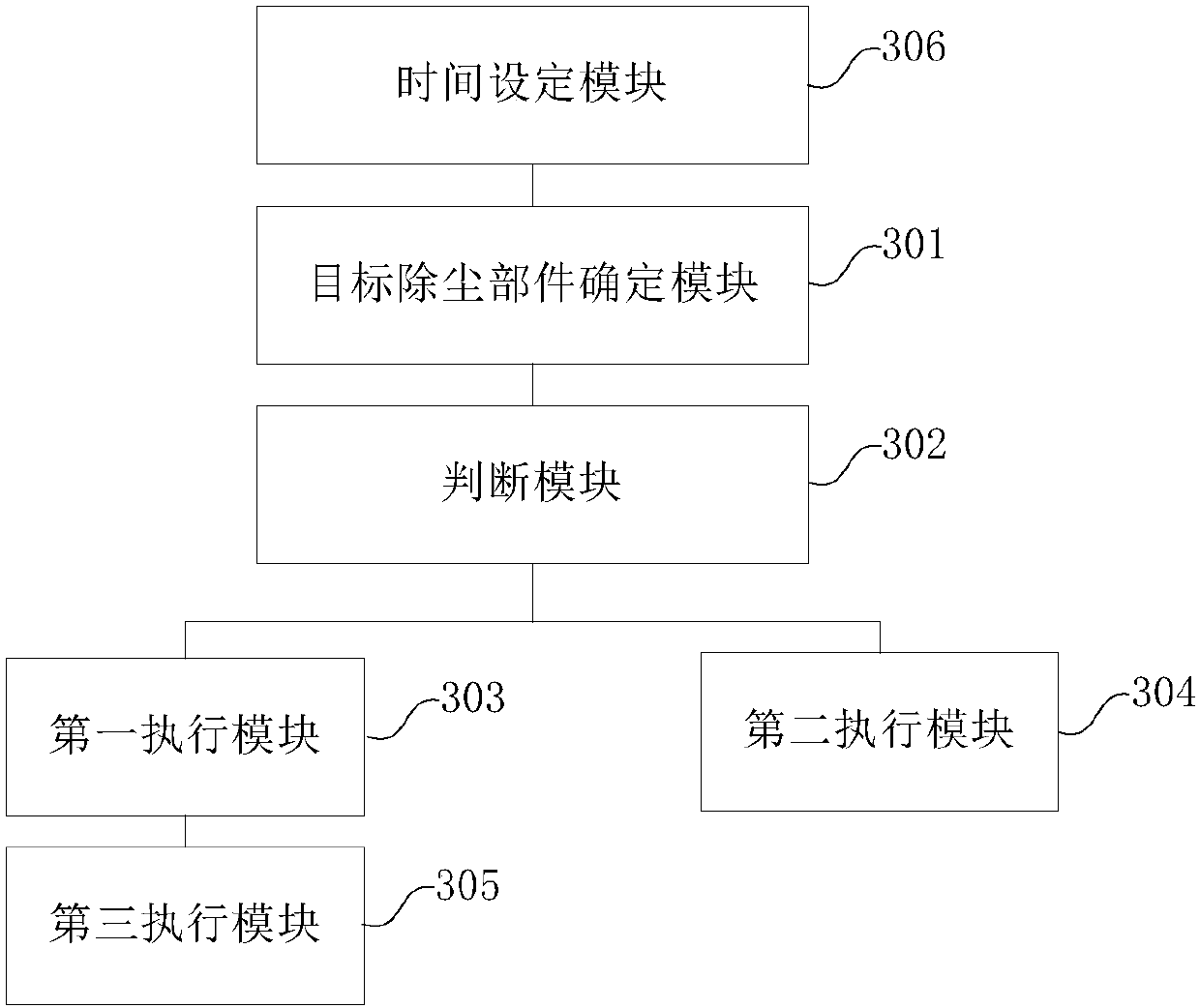

Dust-removing method and dust-removing device for mobile terminal

ActiveCN107684787ARealize automatic dust removalSmooth dischargeDispersed particle filtrationTransportation and packagingElectricityElectric signal

The invention discloses a dust-removing method and a dust-removing device for a mobile terminal. The dust-removing method comprises the following steps: after the current dust-removing cycle starts, determining a target dust-removing part of the mobile terminal according to user settings; judging the included angle between a reference part corresponding to the target dust-removing part and a horizontal plane meets a preset condition or not; if the included angle between the reference part corresponding to the target dust-removing part and the horizontal plane meets the preset condition, transmitting an ultrasonic electric signal to piezoelectric ceramic corresponding to the target dust-removing part and arranged in the mobile terminal, driving the piezoelectric ceramic to vibrate and performing dust removal on the target dust-removing part; and if the included angle between the reference part corresponding to the target dust-removing part and the horizontal plane does not meet the preset condition, executing the step of judging the included angle between the reference part corresponding to the target dust-removing part and the horizontal plane meets the preset condition or not as well as the subsequent step again until the current dust-removing cycle ends up. The dust-removing part of the mobile terminal is subjected to dust-removing treatment by the dust-removing method, so that better dust-removing effect and higher dust-removing efficiency can be removed.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Mobile electric cabinet for construction site

InactiveCN109699136ARealize automatic dust removalLow failure rateCasings/cabinets/drawers detailsElectrostatic cleaningFailure rateElectric machine

The invention belongs to the technical field of electrical cabinet equipment and particularly relates to a movable electrical cabinet for a construction site. The mobile electric cabinet comprises a cabinet body. A bottom end of the cabinet body is provided with an equipment box, a driving motor is installed in the equipment box, an output shaft of the driving motor is rotatingly connected to an inner wall of a top end of the equipment box, two sides of the driving motor are provided with vertical screws, top ends of the screws pass through the equipment box and extend into the cabinet body, an output shaft of the driving motor is drivingly connected to the screw through a belt, the screw is provided with a first moving block and a second moving block, the first moving block is above the second moving block, one end of the second moving block close to a side wall of the cabinet body is fixedly connected to a brush, the other end of the brush is in contact with the side wall of the cabinet body, and a dust-sucking head is disposed directly above the brush. The deficiencies in the prior art are overcome, the automatic dust removal in the electric cabinet is achieved, no manual cleaning is required, safety hazards are avoided, and the failure rate of the electrical cabinet is reduced.

Owner:ANHUI KANGYU HYDROPOWER MACHINERY COMPLETE EQUIP CO LTD

Tubular dust collector for construction site

InactiveCN111530193ARealize automatic dust removalAvoid cloggingCombination devicesDispersed particle filtrationReciprocating motionDust control

The invention discloses a tubular dust collector for a construction site. The tubular dust collector comprises a shell, an ash hopper fixedly connected to the lower end of the shell and communicated with the shell, and an exhaust pipe fixedly connected to the side wall of the shell and communicated with the shell, an air inlet is formed in the side wall, away from the exhaust pipe, of the shell, anegative pressure fan is installed at the tail end of the exhaust pipe, an exhaust port is formed in the side wall of the negative pressure fan, and a hollow dust removing pipe is mounted in the shell. By arranging a dust removing pipe, a dust removing brush, the negative pressure fan and a driving mechanism, power supply of the negative pressure fan can be achieved through a rotating permanent magnet and a spiral coil, so that air is sucked into the shell, real-time dust removing and dust removing operation is conducted under the action of a dust removing barrel, and meanwhile the dust removing barrel can reciprocate under the action of a magnetic sliding block and an iron ring; dust attached to the surface of the dust removing barrel is brushed away through the dust removing brush, local dust accumulation is effectively prevented, and the dust removing and purification safety is improved.

Owner:毛嘉豪

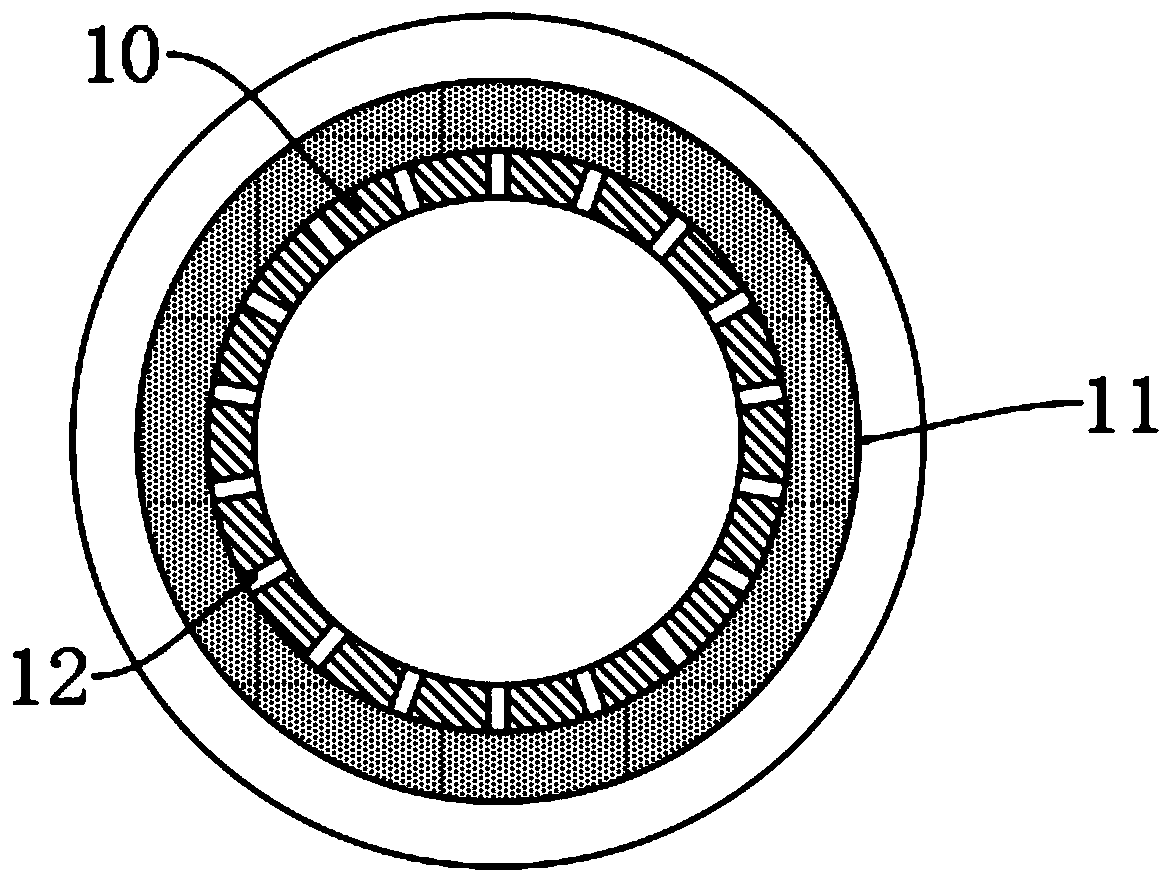

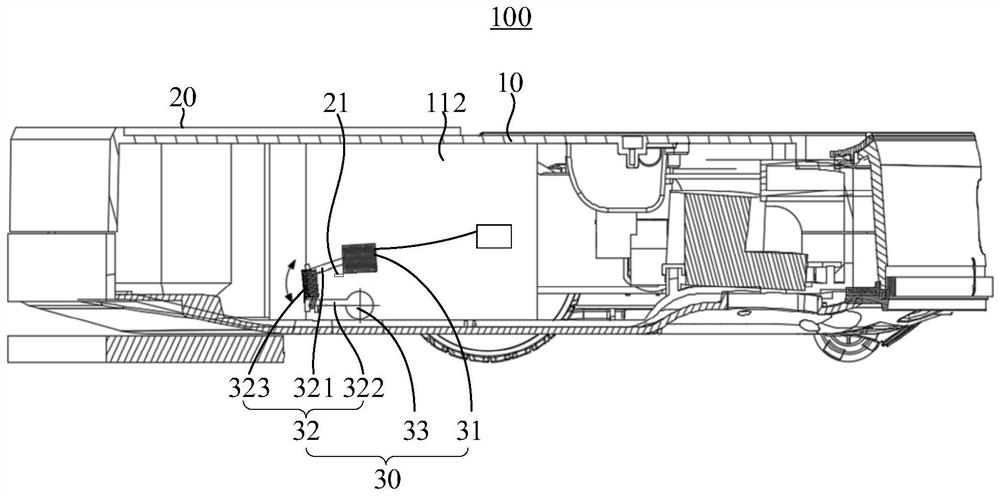

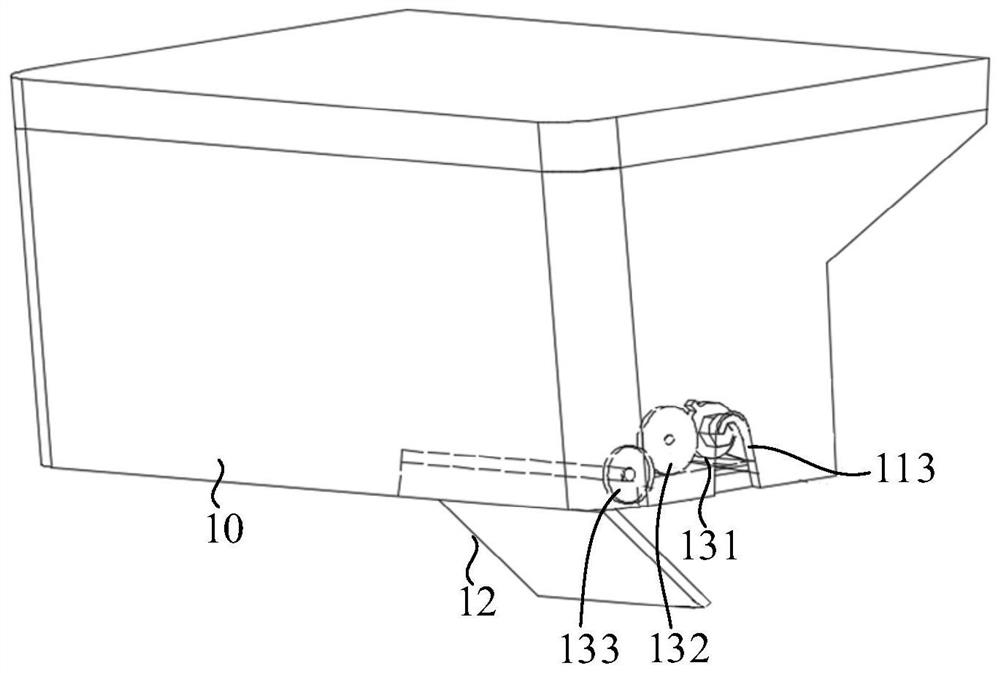

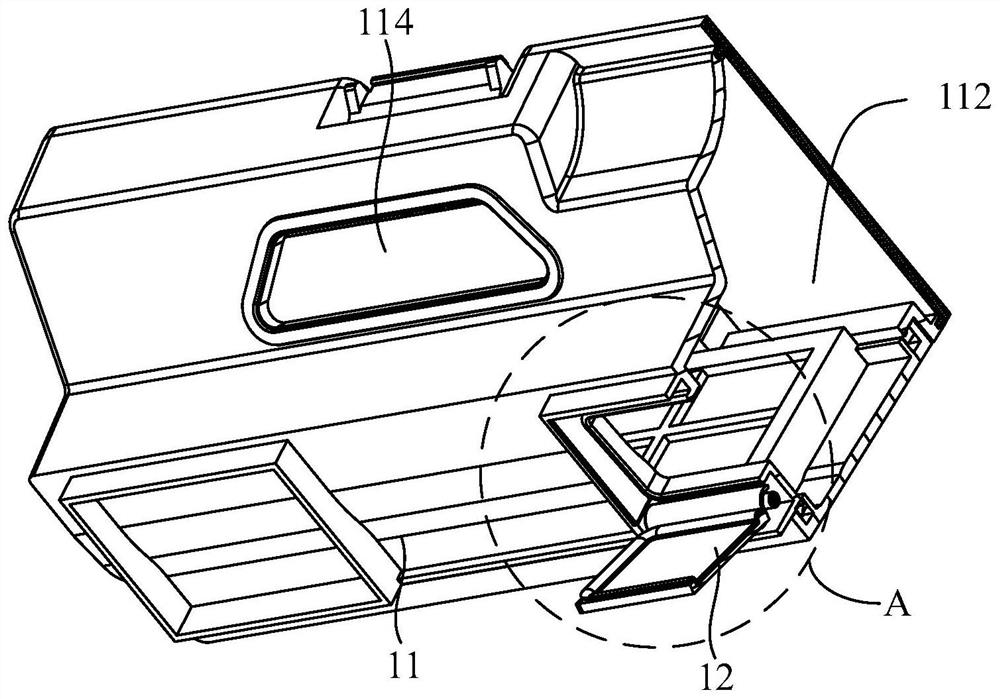

Dust box assembly, cleaning robot and cleaning system

PendingCN112515531ARealize automatic dust removalSuction filtersCarpet cleanersDust controlEnvironmental engineering

The invention discloses a dust box assembly, a cleaning robot and a cleaning system. The dust box assembly comprises a dust box main body which is provided with a dust inlet, a dust outlet and a dustcollection cavity communicated with the dust inlet and the dust outlet; a movable plate which is rotatably connected with the dust box main body, and can open or cover the dust discharge port; and a transmission assembly which is connected with the dust box main body and the movable plate, and used for receiving external drive to drive the movable plate to turn over relative to the dust box main body to open or close the dust discharge port. According to the cleaning robot, the movable plate can be automatically opened and closed, so that a user does not need to manually open and close the movable plate, meanwhile, the cleaning robot is matched with other equipment in the cleaning system, automatic dust removal of the cleaning robot can be achieved, and therefore the user does not need toclean the dust collection cavity.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

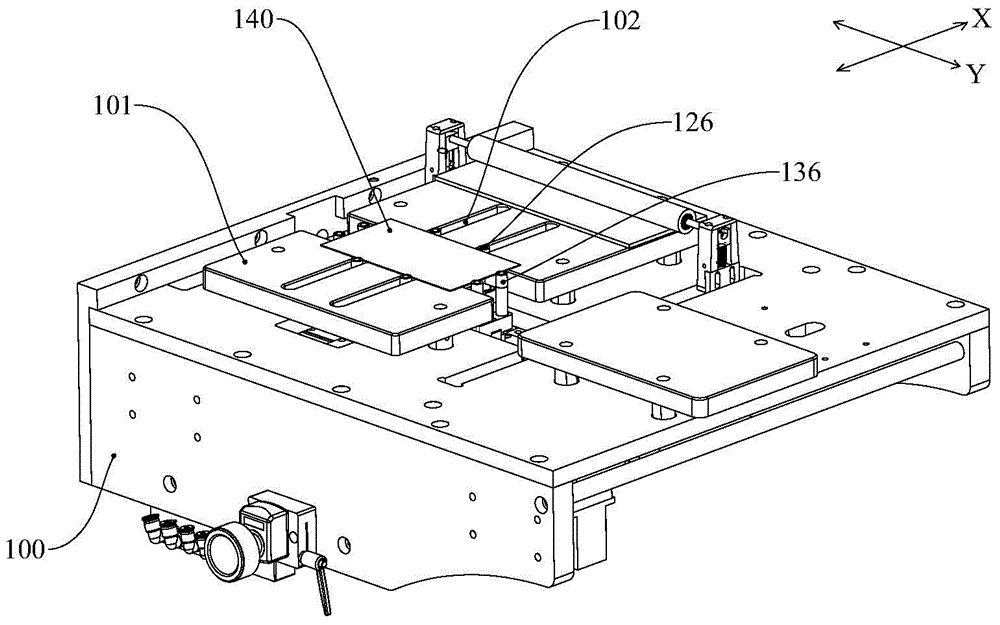

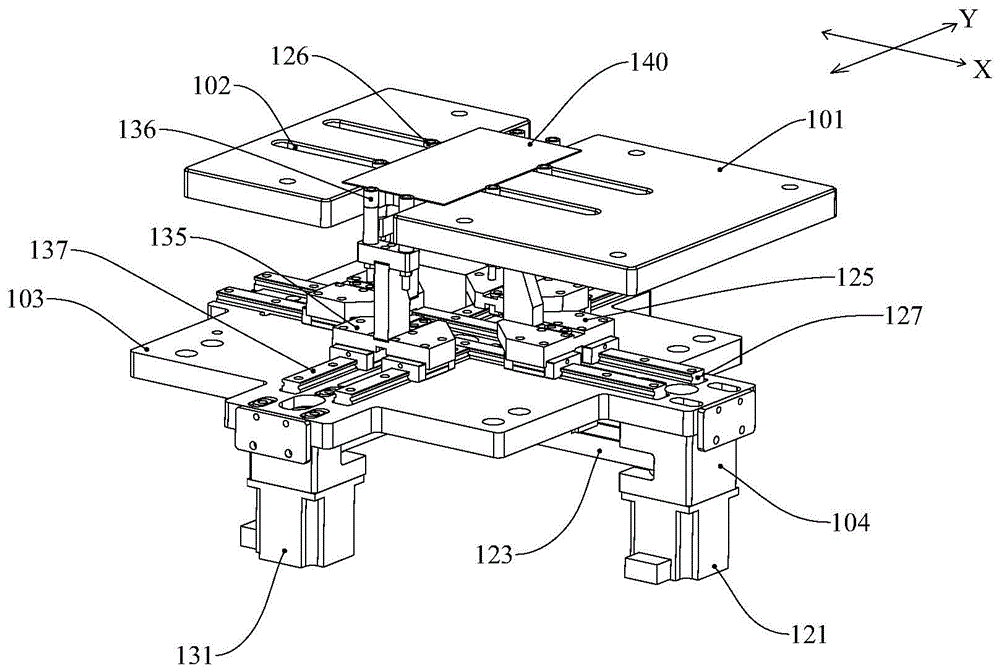

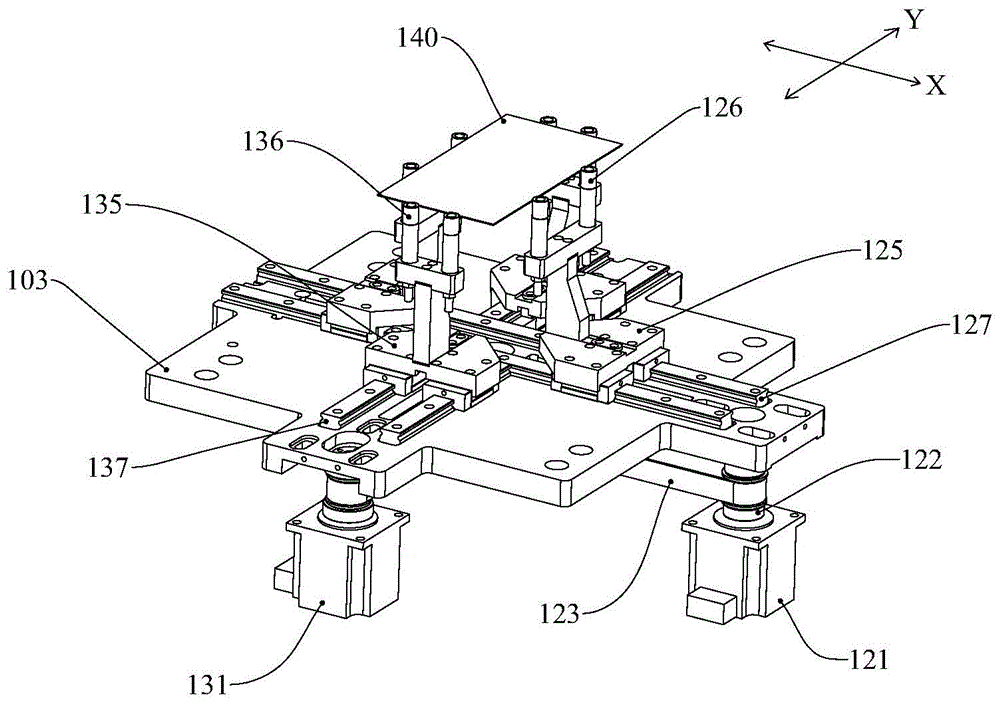

Panel material positioning and dust-removing device

ActiveCN104129157AAchieve positioningRealize automatic dust removalCylinder pressesPlaten pressesEngineeringSurface plate

The invention relates to a panel material positioning and dust-removing device which comprises a base, a carrier platform, an installation plate, an automatic positioning mechanism and an automatic dust-removing mechanism. The automatic positioning mechanism clamps and positions a panel through a first positioning assembly and a second positioning assembly, wherein the first positioning assembly and the second positioning assembly independently work. The automatic dust-removing mechanism drives a dust adhering assembly to act through a driving assembly. The dust adhering assembly comprises a roller and dust adhering paper, wherein the roller takes away the dust on the panel through surface adhesive force, and the dust adhering paper takes away the dust on the roller through surface adhesive force. The dust adhering paper is arranged on the carrier platform. The driving assembly drives the roller to roll between the dust adhering paper and the panel. According to the panel material positioning and dust-removing device, the automatic positioning mechanism and the automatic dust-removing mechanism are combined to be installed in the same device, automatic positioning and automatic dust removing can be achieved for the materials on the panel, the manual operation quantity is reduced, production efficiency is improved, and production requirements can be met.

Owner:湖南三兴精密工业股份有限公司

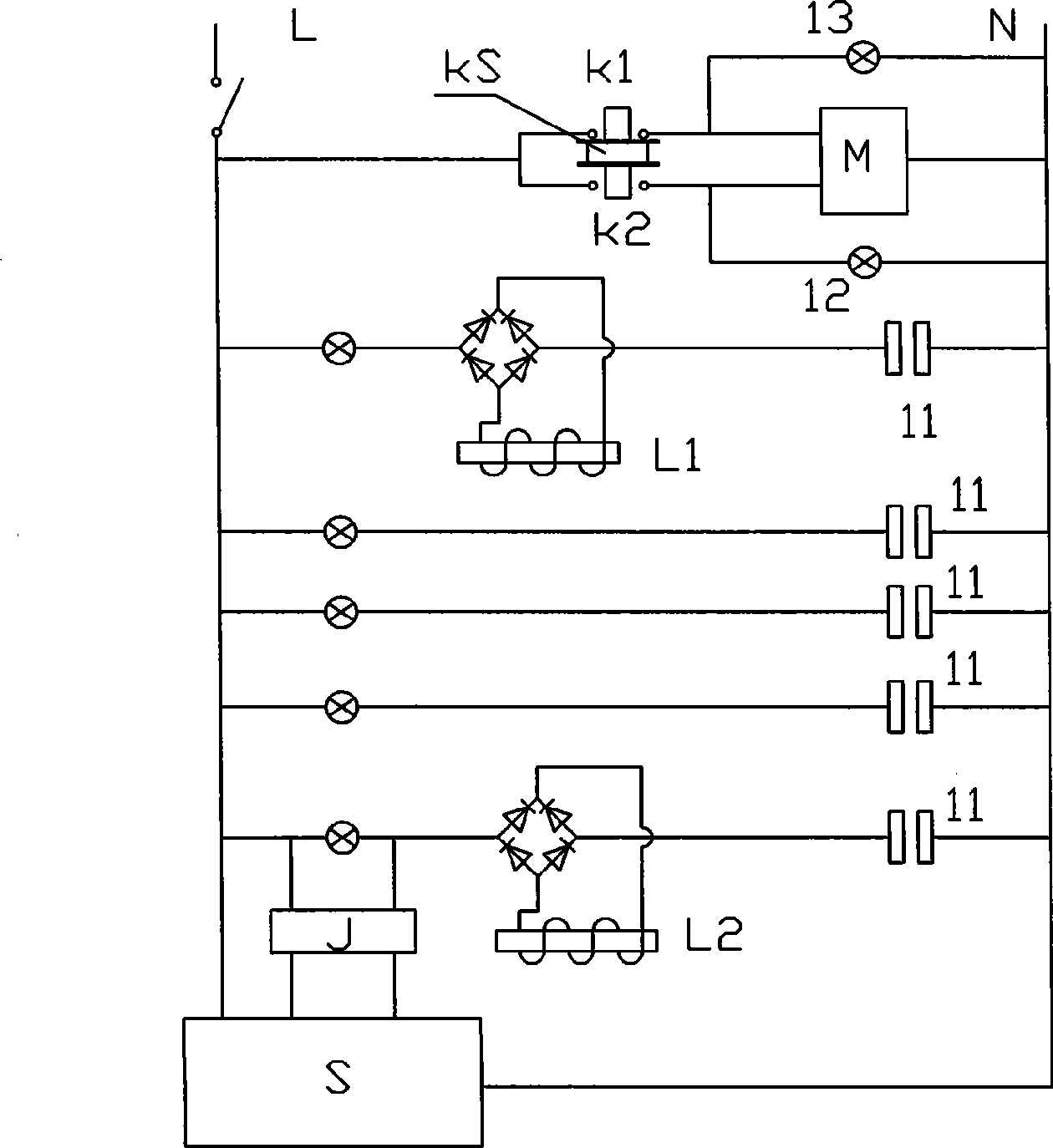

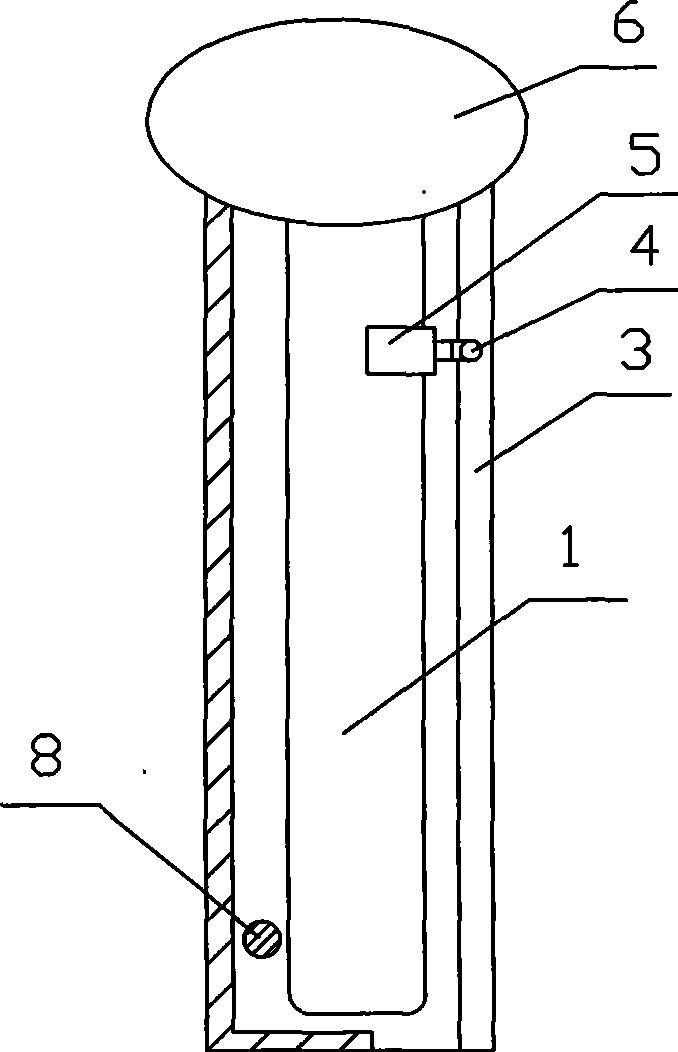

Rotating type automatic ash removing lamp assembly of caterpillar machine

PendingCN106958768ARealize automatic dust removalLighting applicationsMechanical apparatusElectric machineryStructural engineering

The invention discloses a rotating type automatic ash removing lamp assembly of a caterpillar machine. The rotating type automatic ash removing lamp assembly comprises a base plate, a lamp tube and a motor; the motor is arranged on the base plate in a supported mode through a motor support and drives an end shaft, the end shaft is supported by two shaft bases connected to the base plate and cooperatively rotates on the shaft base close to the motor side through a first bearing, the driven lamp tube is arranged in the middle of the end shaft, a glass tube is fixed to the two sides of the lamp tube through end covers, and a scraper blade is arranged on the outer side of the glass tube. Accordingly, automatic ash removing of the caterpillar machine lamp assembly is achieved.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com