Split hanging machine air conditioner with filtering net automatic cleaning device

An automatic cleaning and filter technology, which is applied in the direction of cleaning methods, air conditioning systems, cleaning methods and utensils using gas flow, which can solve the problems of clogging water channels, not collecting dust, affecting the cleaning effect, etc. The effect of sweeping dead corners and increasing the length of sweeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

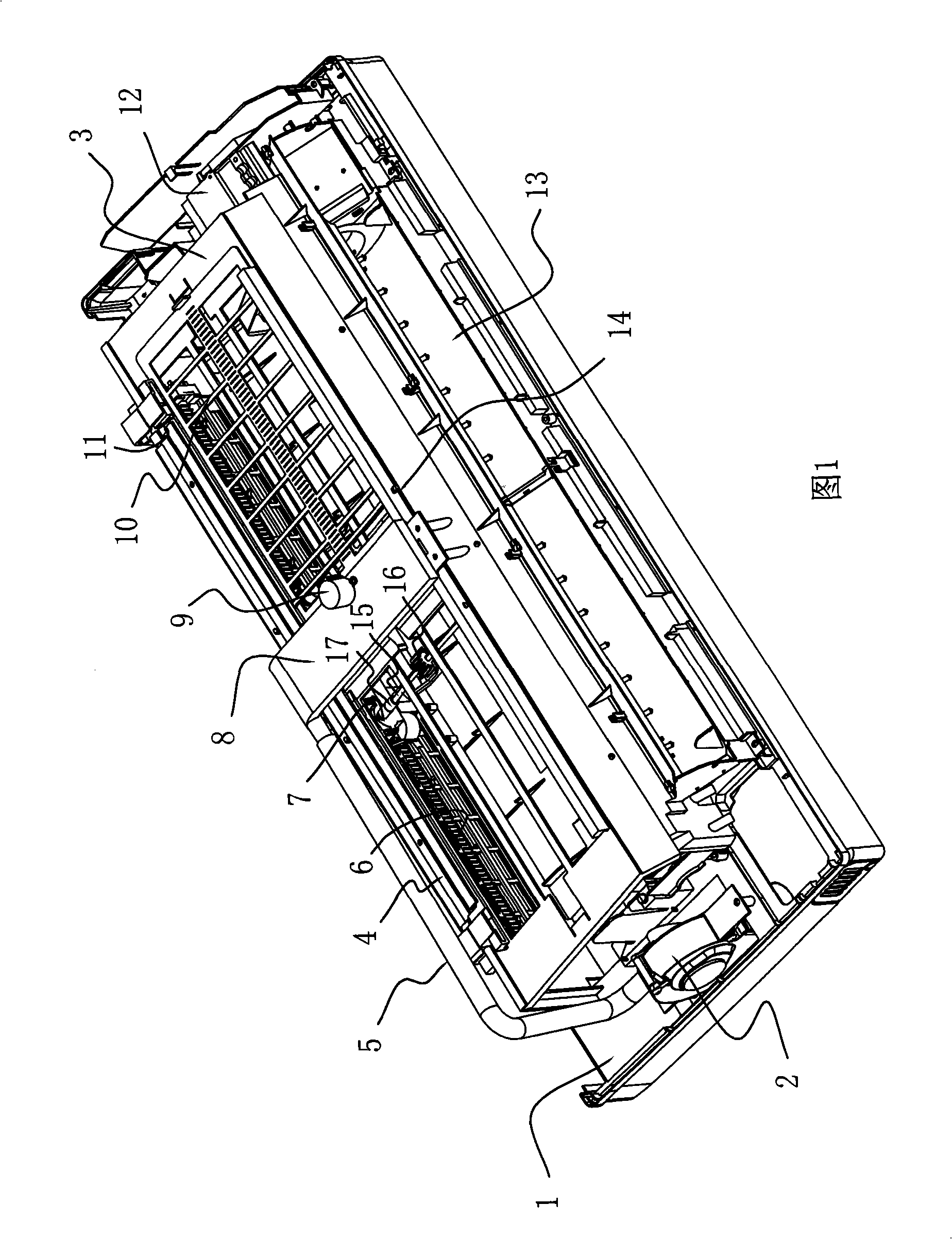

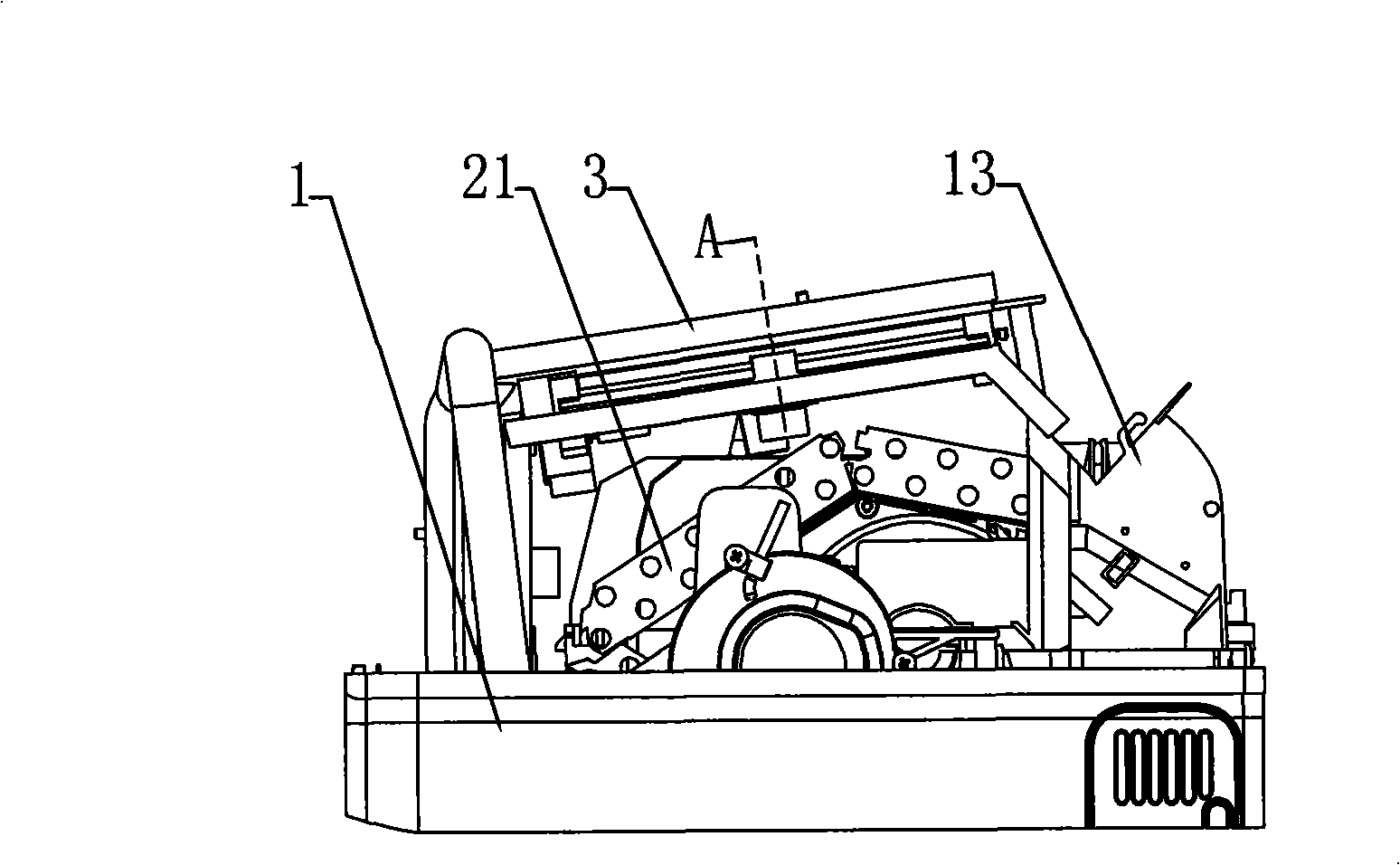

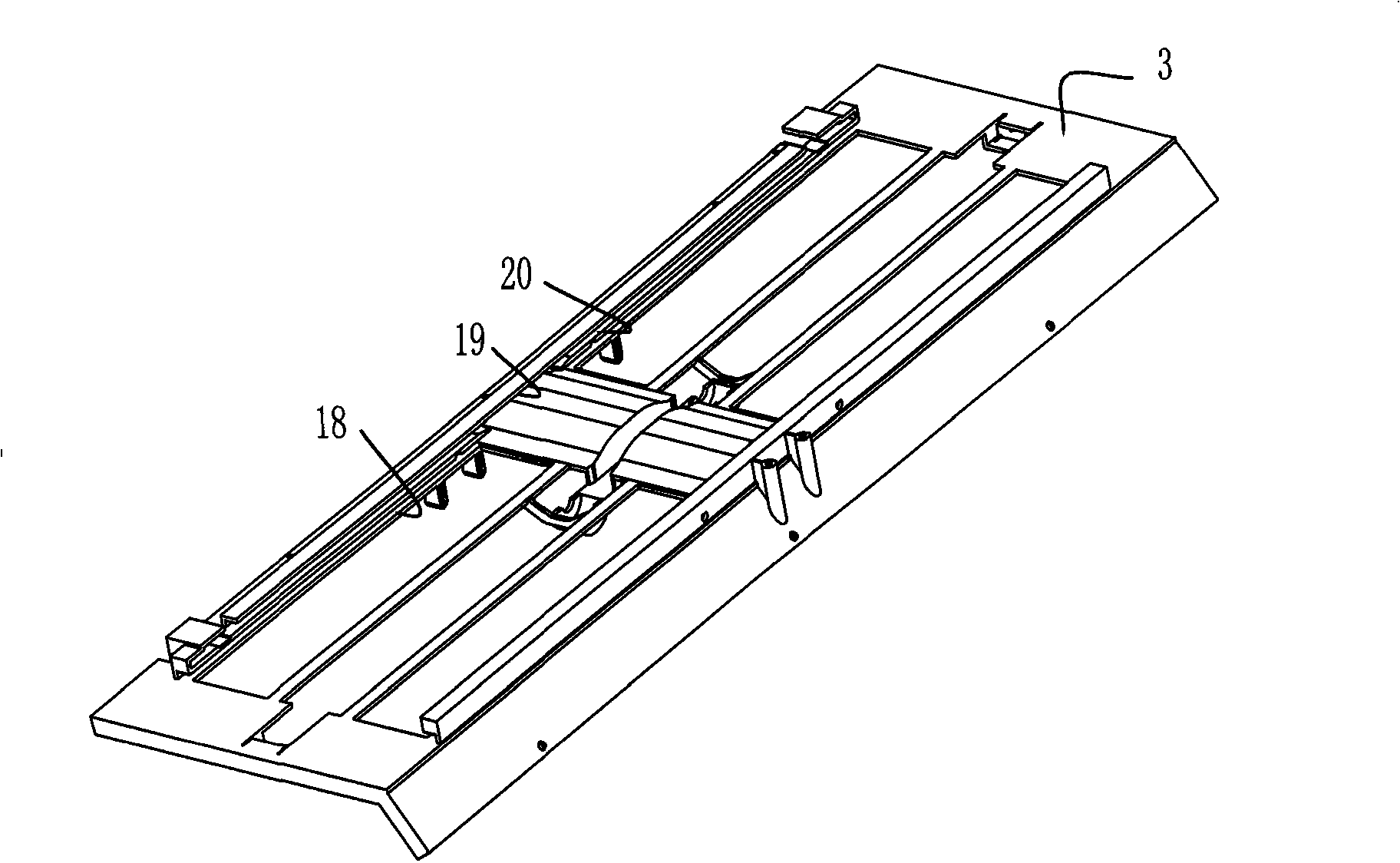

[0042] Please see Figure 1, figure 2 with Figure 5 , the split mounted air conditioner with filter screen automatic cleaning device of the present invention, which includes a base 1, an evaporator 21, an air outlet body 13, a middle frame 24 and a front grille panel installed in the middle frame 24, corresponding to the front grille panel in the middle frame (omitted among the figures) and the position of rear air intake grille 23 are provided with front fixed frame 3 and rear fixed frame 4 respectively. The evaporator 21 is installed on the base 1, and the air outlet main body 13, the rear air intake grille 23 and the front grille panel are respectively installed on the bottom, front and top of the evaporator 21, so that the air can flow from the rear air intake grille 23 And the front grille panel enters through the evaporator 21 and is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com