Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Overcome the defect of low yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

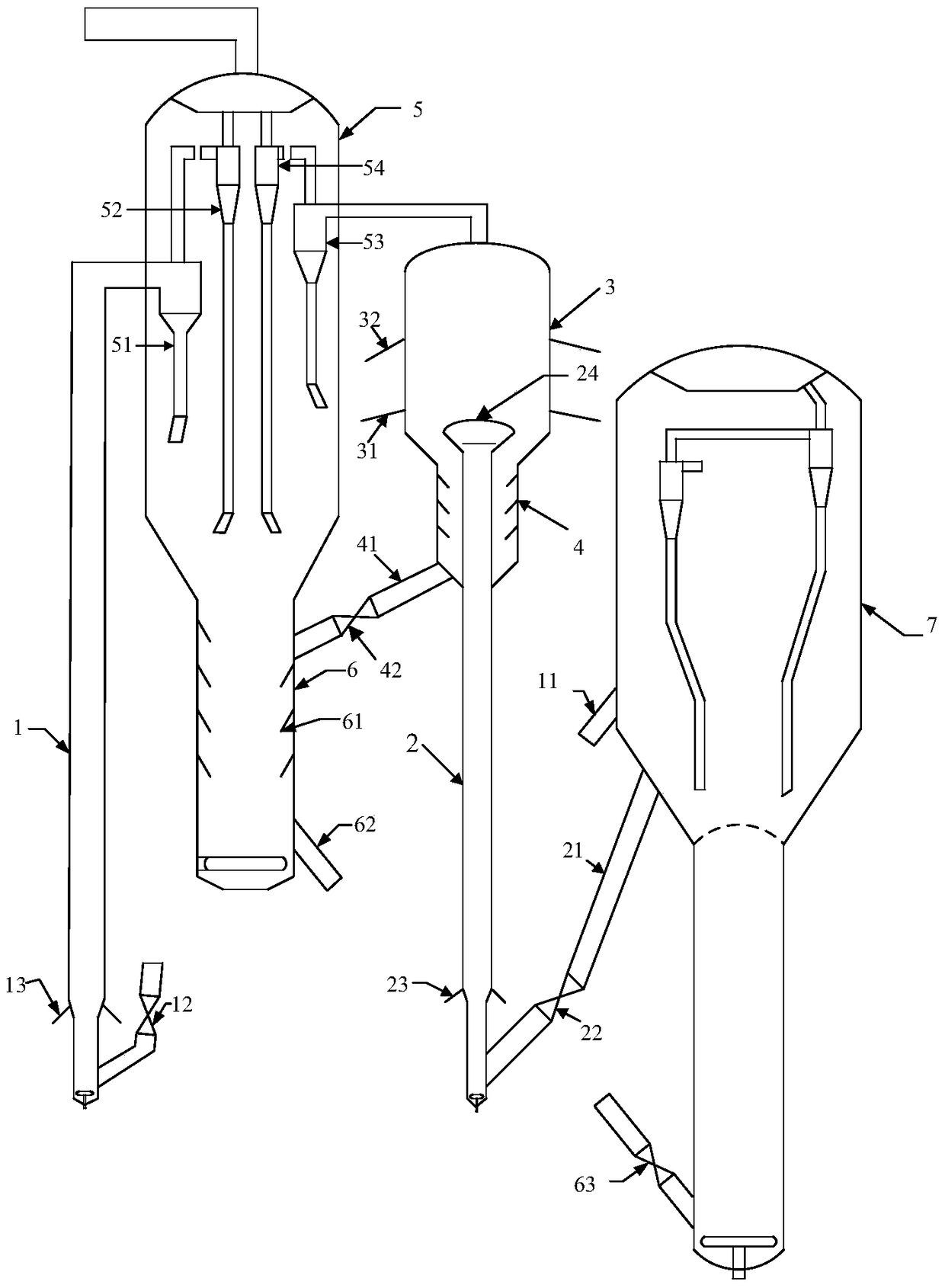

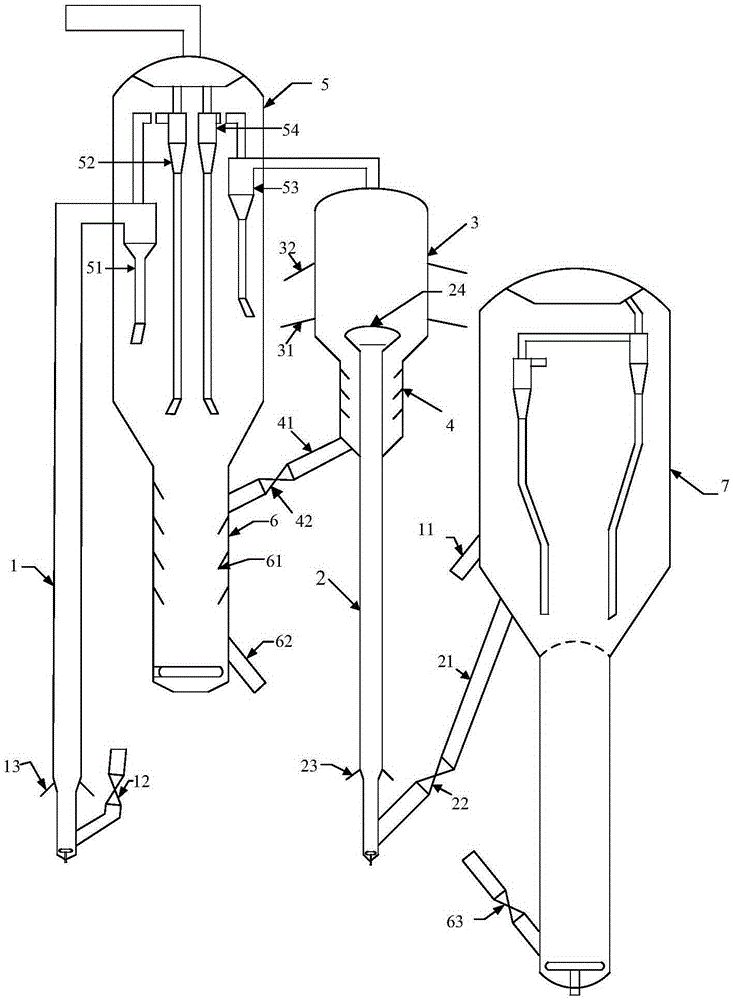

Hydrocarbon catalytic converting method with high butene and light arene yields

ActiveCN106609152AInhibition of hydrogen transfer reactionsFast carbanion cracking reactionTreatment with plural serial stages onlyHydrocarbon oils treatment productsButeneBoiling point

The invention relates to the catalytic cracking field of heavy hydrocarbon class raw materials and particularly discloses a hydrocarbon catalytic converting method with high butene and light arene yields. The method comprises the following steps: 1, enabling a heavy hydrocarbon class raw material to carry out contact reaction with a first cracking catalyst in a first reactor, and then carrying out separation so as to obtain a first carbon depositing catalyst and a first reaction product; 2, enabling light cracked gasoline of which the final boiling point does not exceed 90DEG C to carry out contact reaction with a second cracking catalyst in a second reactor; and 3, directly guiding a reaction mixture which is obtained through reaction in the second reactor into a third reactor without separating the reaction mixture, enabling the reaction mixture to carry out contact reaction with hydrogenation modified cracked light oil of which the boiling range is between 200DEG C and 390DEG C, and then carrying out separation so as to obtain a second carbon depositing catalyst and a second reaction product, wherein the hydrogenation modified cracked light oil is prepared by carrying out hydrogenation treatment on the cracked light oil. High butene yield and high light arene yield can be obtained by the method provided by the invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for granulose condensable sugar

The invention provides a preparation method for granulose condensable sugar. The preparation method comprises the following steps: mixing and stirring crystallization agent resistant, overheated and supersaturated cane sugar liquid and powdery condensable sugar seed crystals; after vacuum drying, granulating with a high speed granulator; then forced air drying and dry sieving to obtain a granulose condensable sugar product. The condensable sugar prepared by the preparation method is uniform in grain, high in flow ability and high in yield.

Owner:山东朗诺制药有限公司

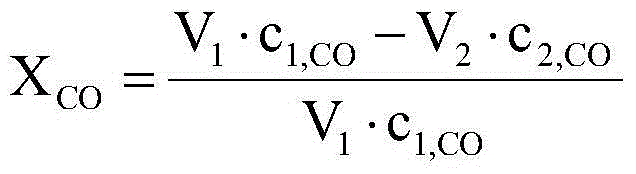

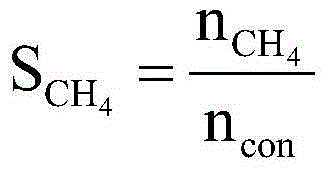

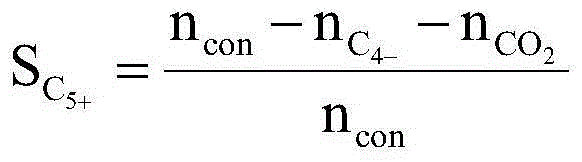

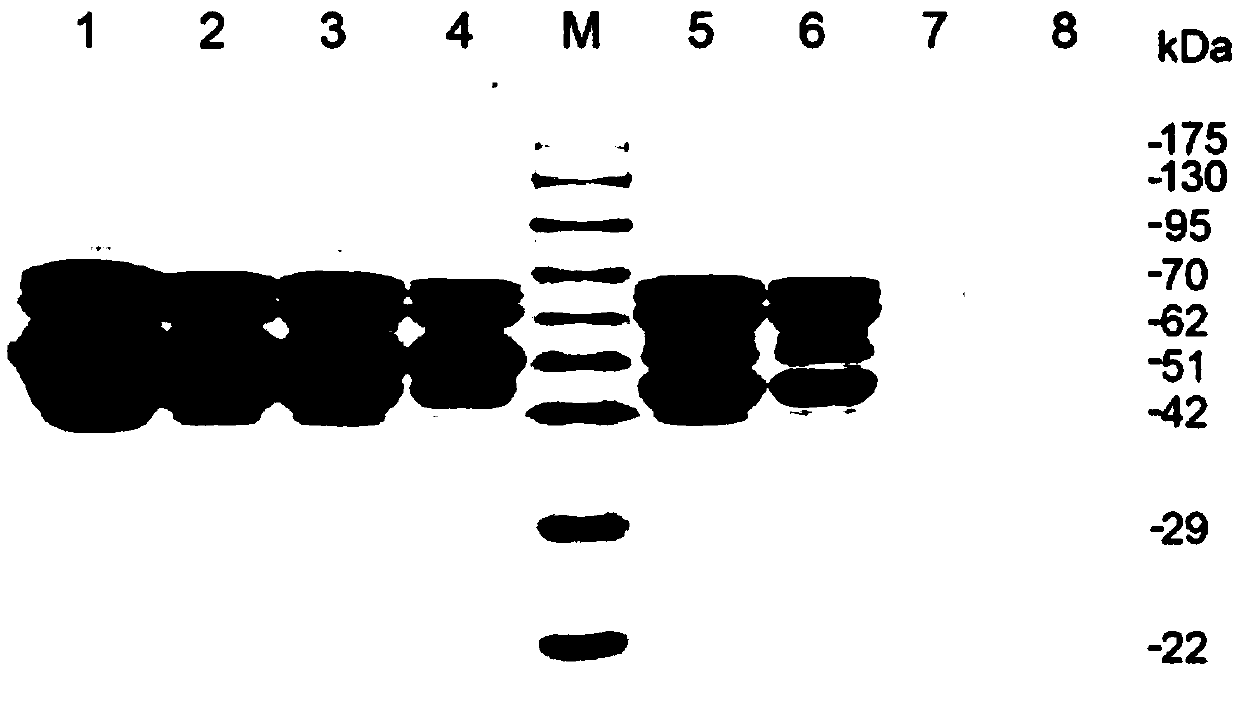

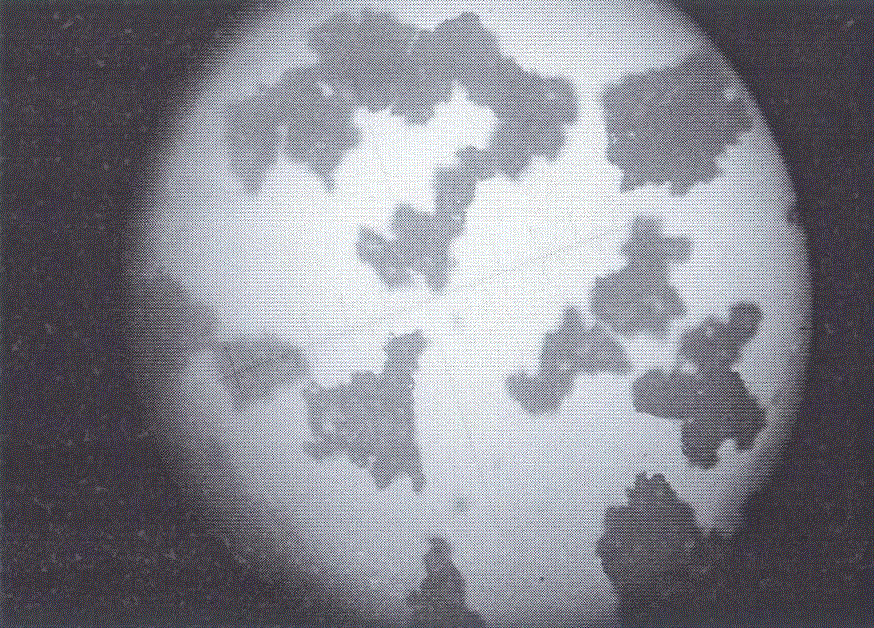

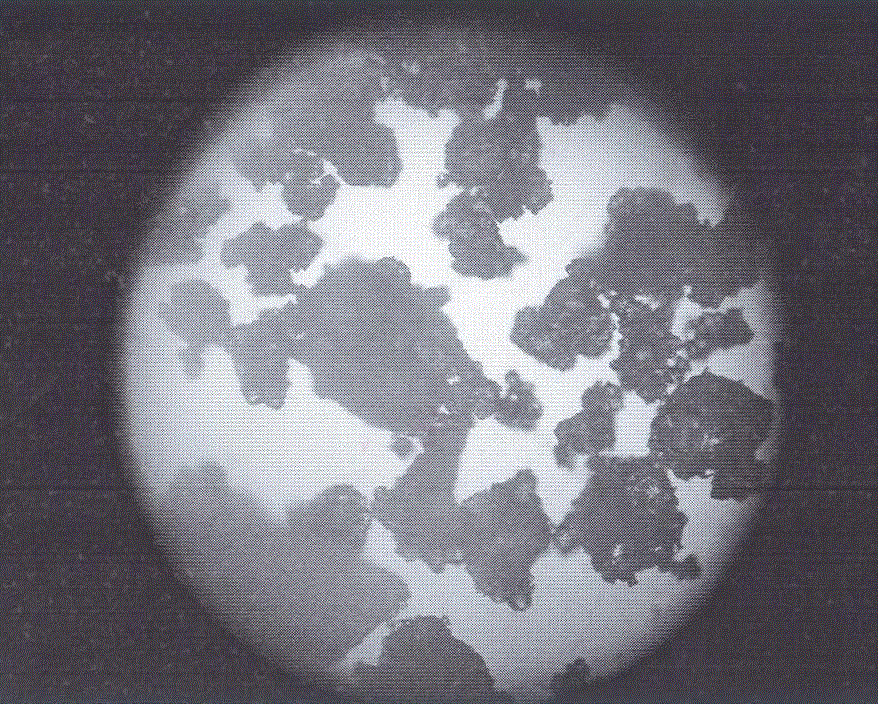

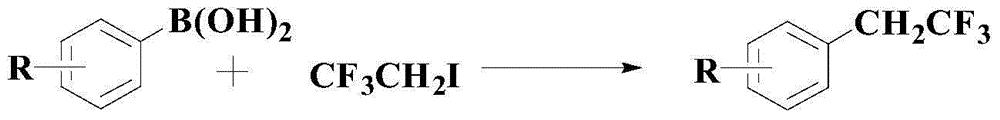

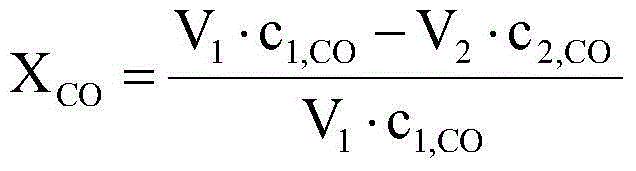

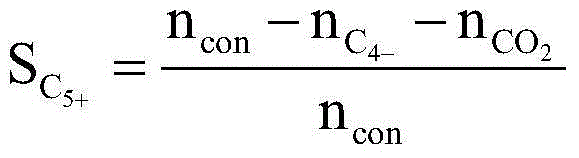

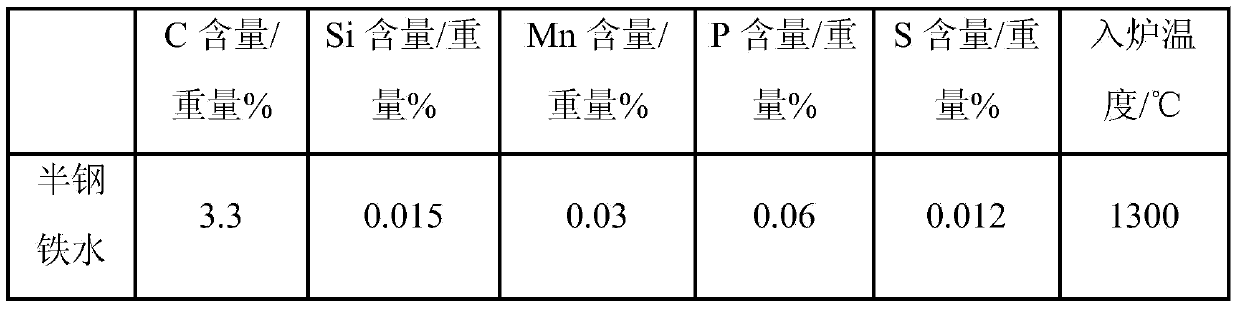

Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate

InactiveCN101973960ANo significant increase in costOvercome the defect of low yieldOrganic chemistryBromineChemistry

The invention relates to a synthesis method of benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate. The synthesis method comprises the following main steps of: performing esterification on m-aminobenzoic acid serving as an initiative raw material and methanol so as to obtain m-aminobenzoic acid methyl ester; in the presence of a surfactant, reacting the m-aminobenzoic acid methyl ester and thiocyanate so as to obtain N-(3-carbomethoxy phenyl)-thiourea; adding bromine into the N-(3-carbomethoxy phenyl)-thiourea in chlorobenzene or glacial acetic acid to perform a cyclization reaction so as to obtain 2-amino-7-carbomethoxy benzothiazole; performing heating and loop opening on the 2-amino-7-carbomethoxy benzothiazole in aqueous solution of KOH and performing diazotization and loop closing under an acid condition so as to obtain 7-carboxylic acid-[1,2,3] diazosulfide; and in the presence of oxalyl chloride, performing an esterification reaction on the 7-carboxylic acid-[1,2,3] diazosulfide and trifluoroethanol so as to obtain a target product. Compared with the prior art, the method increases the yield of the benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate.

Owner:EAST CHINA UNIV OF SCI & TECH

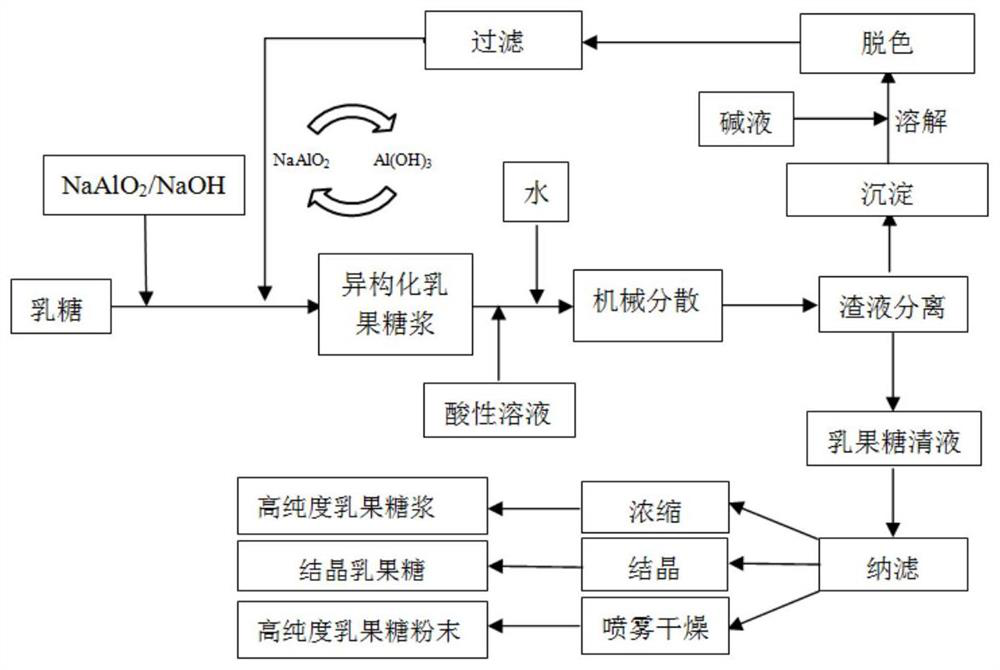

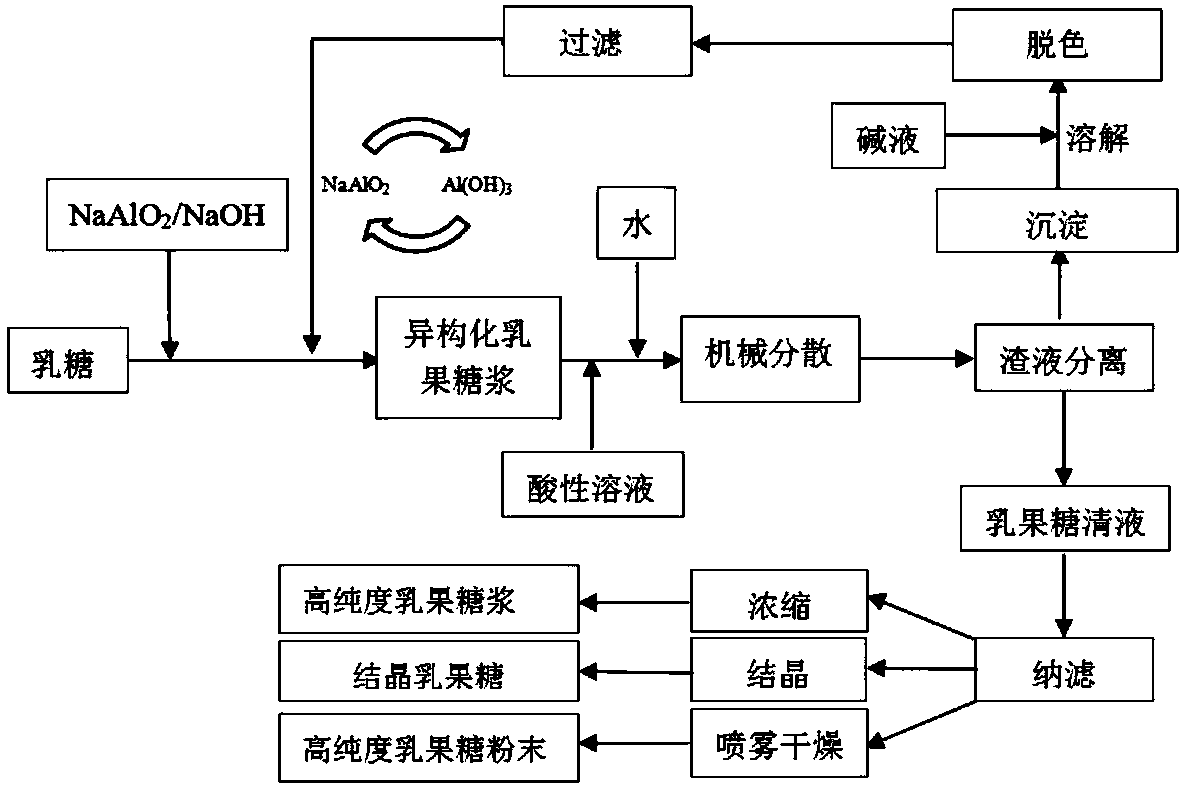

Continuous cyclic preparation method of high-purity lactulose solution and product thereof

ActiveCN108148099AIncrease concentrationRealize repeated useSugar derivativesDisaccharidesHigh concentrationResource saving

The invention belongs to the technical field of oligosaccharide preparation, and relates to a continuous cyclic preparation method of a high-purity lactulose solution and a product thereof. Specifically speaking, the preparation method comprises the following steps: (1) performing lactulose isomerisation; (2) performing acidity adjustment; (3) diluting, dispersing and separating; (4) purifying clear lactulose liquid; (5) performing cyclic utilization of a catalyst. Through the preparation method, high-concentration lactulose solution and a subsequent product thereof can be prepared. Accordingto the continuous cyclic preparation method of the high-purity lactulose solution and the product thereof, sodium metaaluminate / an alkaline matter is taken as an alkaline complexing catalyst for the first time in China, and the conversion rate and lactulose concentration achieved by preparing the lactulose by taking the sodium metaaluminate / an alkaline matter as the alkaline complexing catalyst are far higher than those achieved by adopting a boracic acid / sodium hydroxide system; repeated cyclic use of a sodium metaaluminate catalyst is realized; the defect that precipitate wraps the lactuloseis overcome. The preparation method provided by the invention meets resource-saving and environment-friendly production requirements, and provides beneficial experience and reference for promoting clean, high-efficiency and environment-friendly lactulose industrial production.

Owner:JIANGNAN UNIV

Catalyst and preparation method and application thereof

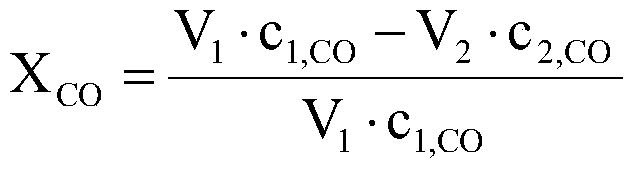

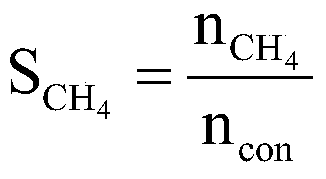

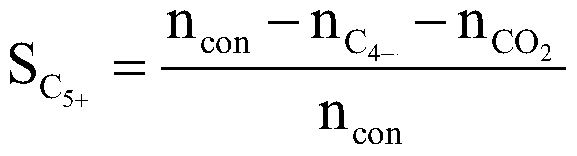

ActiveCN105080568AOvercome the defect of low yieldHydrocarbon from carbon oxidesOrganic compound preparationActivated carbonAlcohol

The invention provides a catalyst and its preparation method and application. The catalyst comprises a carrier and an active component and an auxiliary agent which are loaded on the carrier, wherein the carrier is an activated carbon carrier which has undergone acid pickling and oxidation and has particle size of 200-2000 microns; the active component is the Group VIII metal component; and the auxiliary agent is the Group IVB metal component. When the catalyst provided by the invention is used in preparation of low carbon alcohols from synthesis gas, low carbon alcohols can be prepared at low temperature, and contents of low carbon alcohols, especially methanol and ethanol, in an oil-phase product are high. The preparation method has advantages of mild condition, high conversion per pass and low energy consumption, and is beneficial to industrial popularization.

Owner:CHINA PETROLEUM & CHEM CORP +1

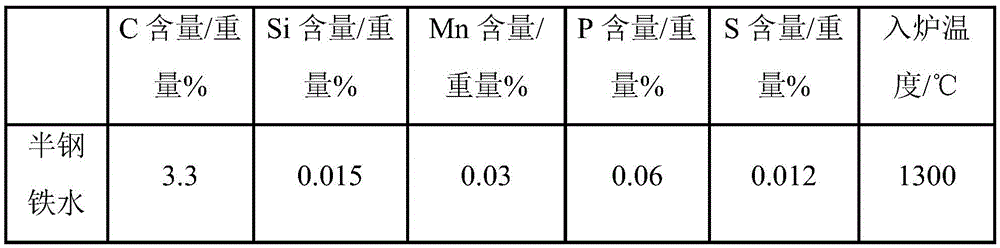

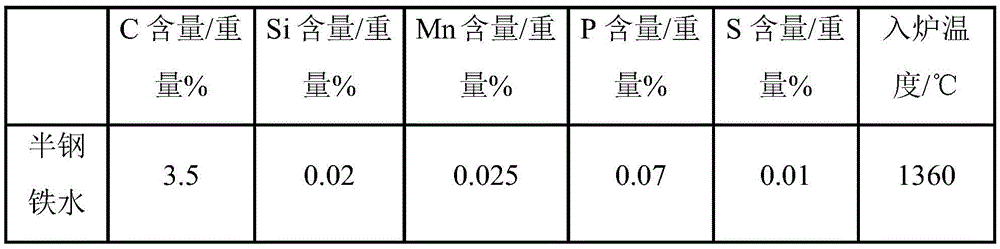

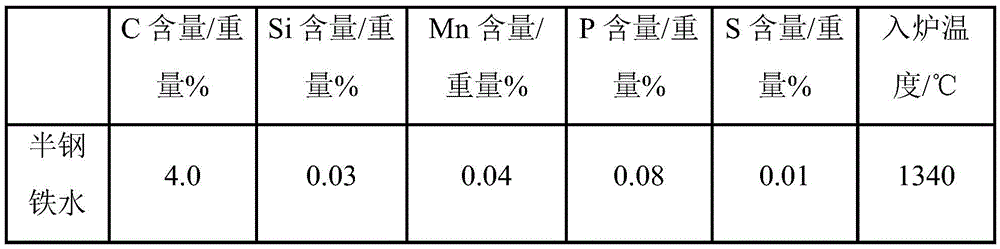

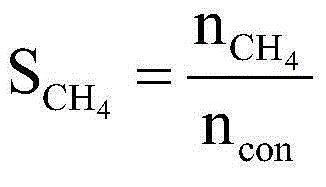

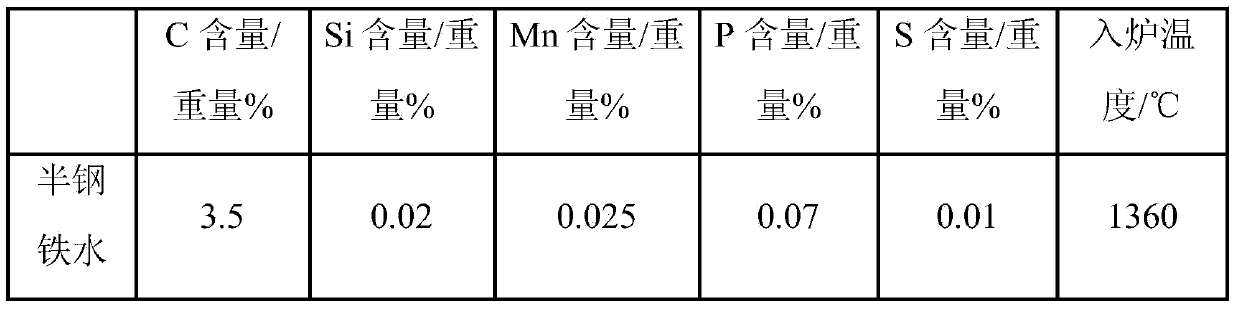

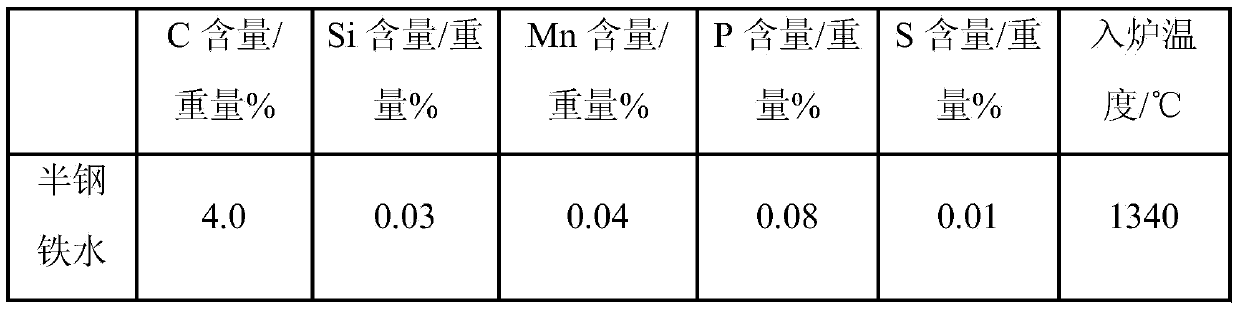

Method for improving Mn alloy yield in semisteel steel-making

ActiveCN104004878AOvercome the defect of low yieldHigh yieldManufacturing convertersHigh magnesiumFerrosilicon

The invention discloses a method for improving Mn alloy yield in semisteel steel-making. The method comprises the following steps: adding semisteel in a converter and adding slag making materials to perform converter smelting; and then performing the converter smelting terminal control and tapping. In the tapping process, middle carbon manganese iron alloy is added to increase the manganese of the semisteel, wherein the slag making material comprises ferrosilicon, active lime and high-magnesium lime, the adding amount of the slag making material enables the slag basicity to be 3-4, and the adding amount of the ferrosilicon is 4-6kg / ton of steel. By adopting the method disclosed by the invention, the high catch carbon tapping can be realized, the terminal oxygen activity is effectively reduced so as to effectively improve the Mn alloy yield.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

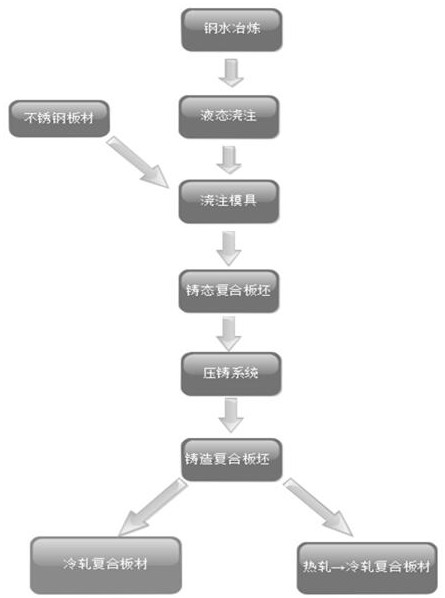

Bimetal composite plate and preparation method thereof

InactiveCN113523240ACorrosion and corrosion resistanceImprove structural performanceComposite strengthDie casting

The invention belongs to the technical field of bimetal composite plate preparation, and particularly relates to a bimetal composite plate and a preparation method thereof. According to the bimetal composite plate, by adopting a solid-liquid composite matched die-casting process, a bimetal composite plate blank with metallurgical composite strength is obtained by casting liquid carbon steel and solid stainless steel / nickel-based alloy for metallurgical composite, and then the composite plate blank is subjected to die-casting forming, so that the bonding quality and the wall thickness of the bimetal metallurgical composite plate blank meet preset requirements; and finally, a finished composite plate is obtained through hot rolling and cold rolling or cold rolling. According to the preparation method, the forging composite plate blank is directly prepared with the cooperation of casting forming and die casting processes, the quality of the composite plate blank is better than that of an as-cast composite plate blank, the process is simple, efficiency is high, and time and labor are saved.

Owner:青岛力晨新材料科技有限公司

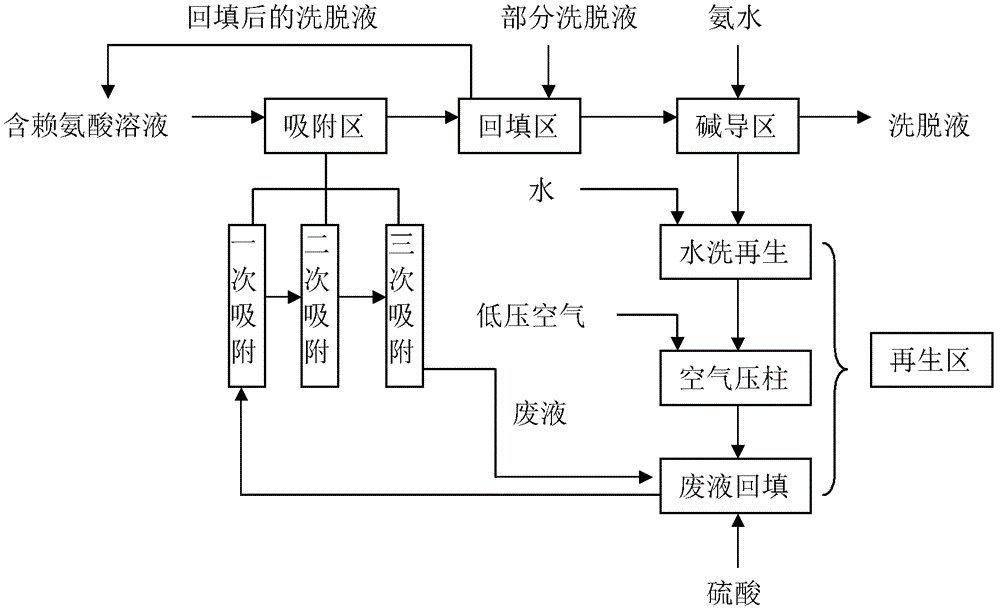

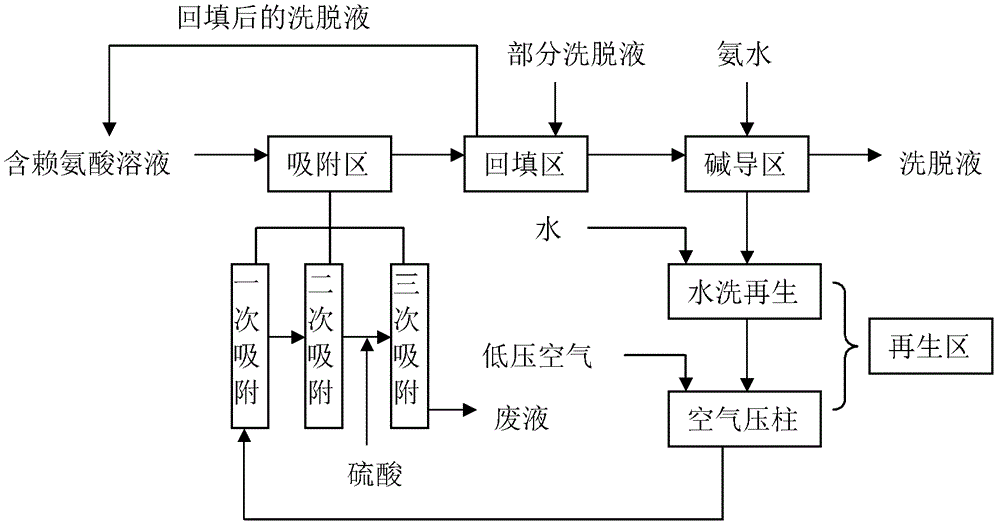

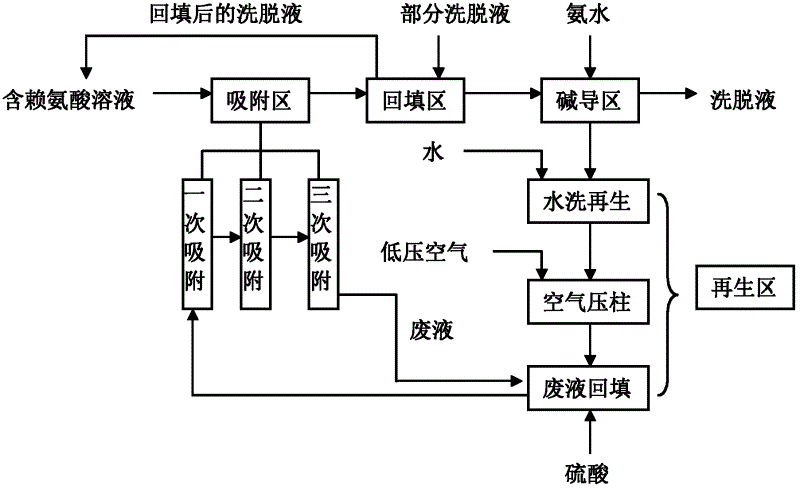

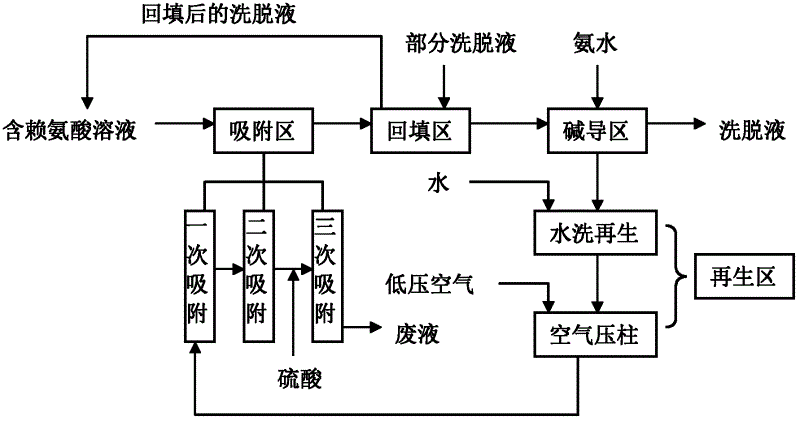

Processing method for lysine-containing solution

ActiveCN102617379AOvercome the defect of low yieldHigh yieldOrganic compound preparationAmino-carboxyl compound preparationElutionIon-exchange resin

The invention discloses a processing method for a lysine-containing solution. The processing method includes that the lysine-containing solution is enabled to sequentially pass one or more groups of positive ion exchange resin column groups which are in serial connection sequentially until the concentration of lysine in liquid flowed from ends of the one or more groups of positive ion exchange resin column groups is not larger than 0.1g / dL, each group of positive ion exchange resin column groups comprises one or more positive ion exchange resin columns which are in a parallel connection, and positive ion exchange resin columns with lysine are subjected to elution with an alkaline solution to obtain a lysine-containing elution. The processing method for the lysine-containing solution is characterized in that the lysine-containing solution passes the positive ion exchange resin column groups under the condition that the pH is 1.0-2.0 or the concentration of lysine is not lower than 1.0g / dL. The invention further discloses a circulating processing method for the lysine-containing solution. The processing method can improve the yield of the lysine, and be widely applied to industrial production.

Owner:COFCO BIOTECHNOLOGY CO LTD

Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate

InactiveCN101973960BNo significant increase in costOvercome the defect of low yieldOrganic chemistryThioureaCarboxylic acid

The invention relates to a synthesis method of benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate. The synthesis method comprises the following main steps of: performing esterification on m-aminobenzoic acid serving as an initiative raw material and methanol so as to obtain m-aminobenzoic acid methyl ester; in the presence of a surfactant, reacting the m-aminobenzoic acid methyl ester andthiocyanate so as to obtain N-(3-carbomethoxy phenyl)-thiourea; adding bromine into the N-(3-carbomethoxy phenyl)-thiourea in chlorobenzene or glacial acetic acid to perform a cyclization reaction soas to obtain 2-amino-7-carbomethoxy benzothiazole; performing heating and loop opening on the 2-amino-7-carbomethoxy benzothiazole in aqueous solution of KOH and performing diazotization and loop closing under an acid condition so as to obtain 7-carboxylic acid-[1,2,3] diazosulfide; and in the presence of oxalyl chloride, performing an esterification reaction on the 7-carboxylic acid-[1,2,3] diazosulfide and trifluoroethanol so as to obtain a target product. Compared with the prior art, the method increases the yield of the benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for screening high-yield bacterial strain of vitamin B2

InactiveCN107475240AIncrease contentOvercome the defect of low yieldMutant preparationMicroorganism based processesChemical compoundScreening method

The invention discloses a method for screening high-yield vitamin B2 strains. The vitamin B2 high-yield strains are obtained through the following steps: the original strains are pretreated, subjected to ultraviolet and chemical mutagenesis, and then domesticated by metabolic substrate analogues, and finally re-treated. It is obtained by screening nutrient medium and fermentation medium. The present invention comprehensively utilizes physical and chemical compound mutagenesis and domestication of metabolic substrate analogues, thereby screening out a stable and high-yielding vitamin B2 strain, which overcomes the defect of low vitamin B2 production in the prior art compared with the original strains , under the condition that the fermentation cycle remains unchanged, its vitamin B2 synthesis ability is increased by about 6g / L, and the fermentation cost is greatly reduced.

Owner:SHANGHAI ACEBRIGHT PHARMA CO LTD +2

Catalyst and preparation method and application thereof

ActiveCN105080569AOvercome the defect of low yieldHydrocarbon from carbon oxidesOrganic compound preparationActivated carbonAlcohol

The invention provides a catalyst and its preparation method and application. The catalyst comprises a carrier and an active component and an auxiliary agent which are loaded on the carrier, wherein the carrier is an activated carbon carrier which has undergone acid pickling and oxidation and has particle size of being greater than or equal to 30 microns and less than 200 microns; the active component is the Group VIII metal component; and the auxiliary agent is the Group IVB metal component. When the catalyst provided by the invention is used in preparation of low carbon alcohols from synthesis gas, low carbon alcohols can be prepared at low temperature, and contents of low carbon alcohols, especially methanol and ethanol, in an oil-phase product are high. The preparation method has advantages of mild condition, high conversion per pass and low energy consumption, and is beneficial to industrial popularization.

Owner:CHINA PETROLEUM & CHEM CORP +1

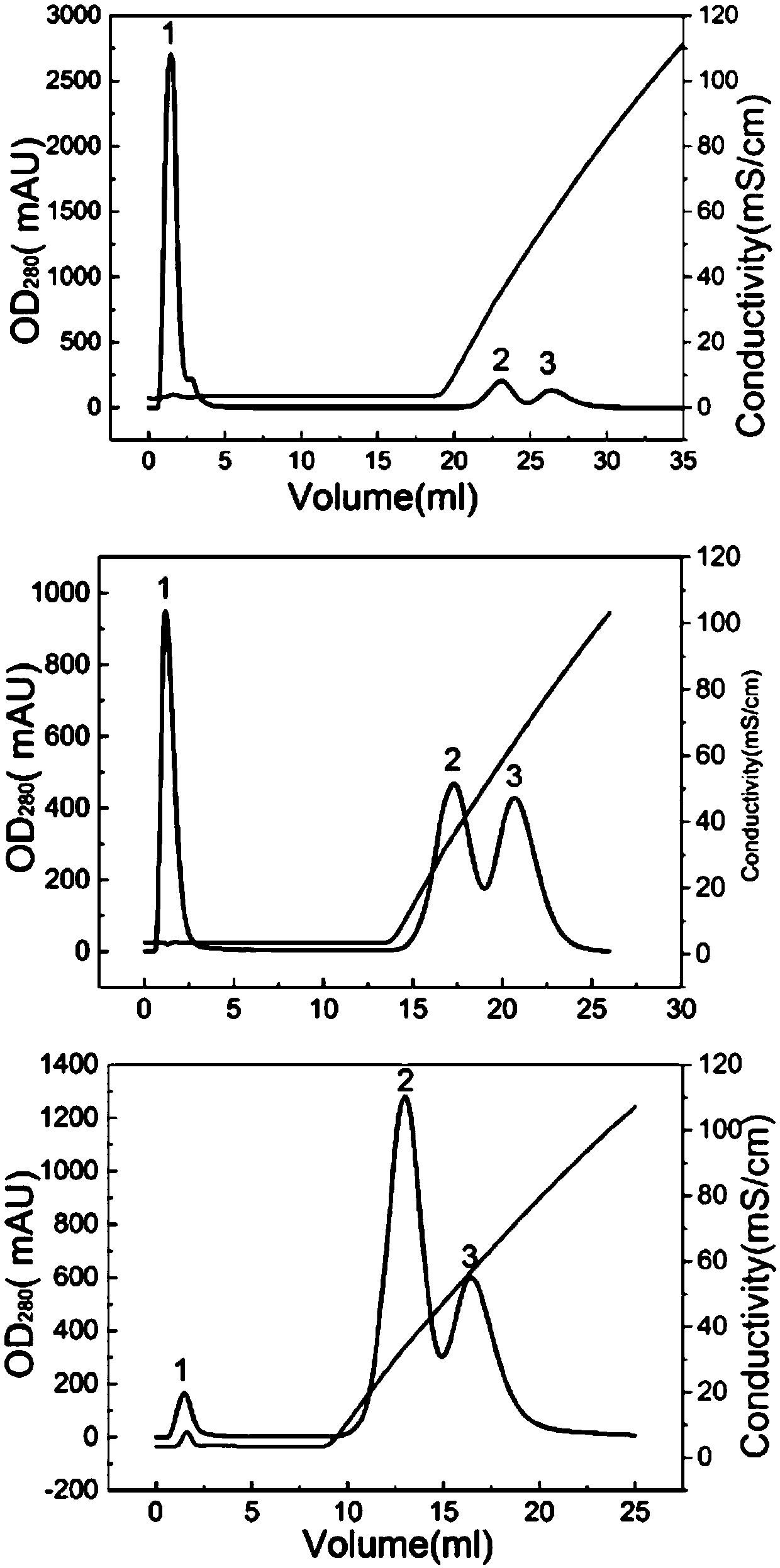

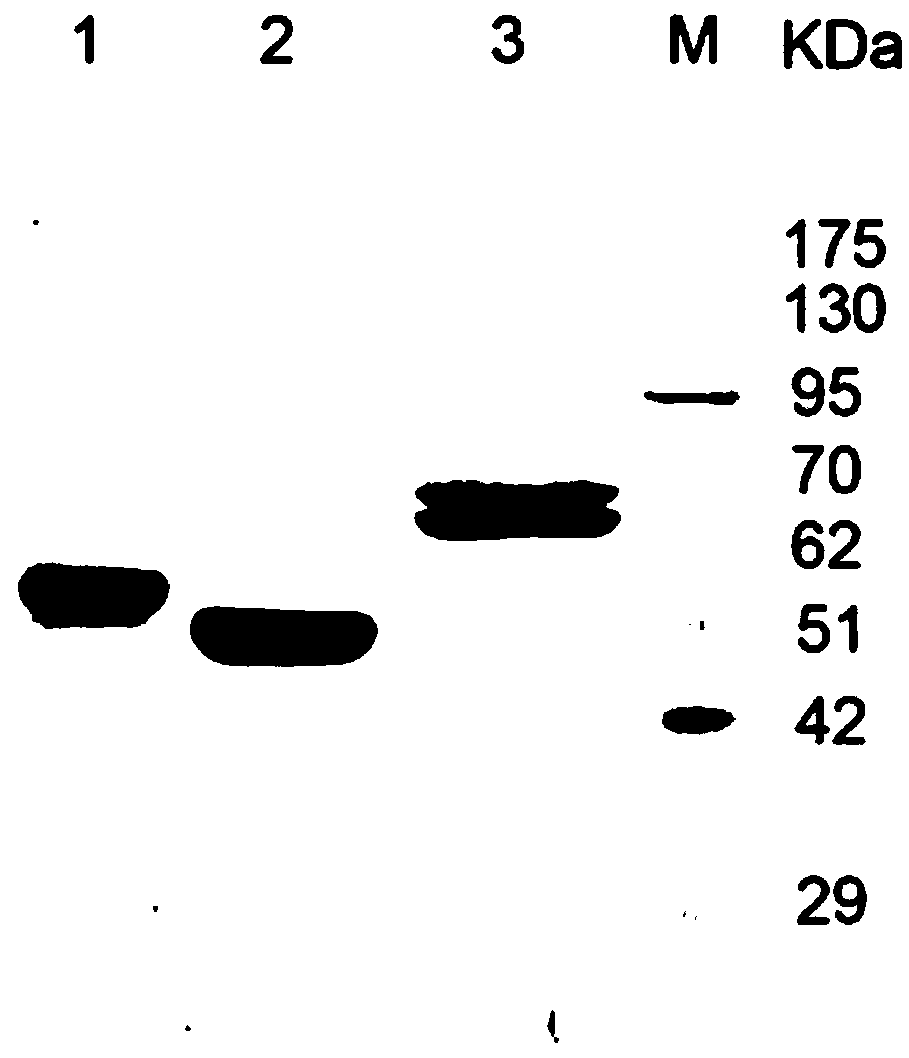

Method for increasing yield of major proteins 2 and 3 in royal jelly by liquid chromatography purification

ActiveCN109535239AIncrease productionIncrease abundancePeptide preparation methodsAnimals/human peptidesCentrifugationUltrafiltration

The invention provides a method for increasing yield of major proteins 2 and 3 in royal jelly by liquid chromatography purification. The method comprises steps as follows: royal jelly is dissolved inan extraction buffer solution, the mixture is mixed uniformly and centrifuged, a supernatant is taken, saturated ammonium sulfate is added to the supernatant for precipitation, a supernatant is takenafter centrifugation, filtering is performed by a filter membrane, and a sample buffer solution is obtained; the sample buffer solution is replaced with a buffer solution A with pH being 7.0 by an ultrafiltration centrifuge tube; a royal jelly sample is loaded to a pre-assembled weak cationic chromatographic column balanced by the buffer solution A; the column is subjected to gradient elution by amixed solution of the buffer solution A and a buffer solution B, the ratio of the buffer solution B is gradually increased from 0 to 100%, and major proteins 2 and 3 in the royal jelly are separatedand purified in sequence. According to the method for increasing the yield of the major proteins 2 and 3 in the royal jelly by liquid chromatography purification, abundance of the major proteins 2 and3 in the royal jelly is increased, yield of the major proteins 2 and 3 in the royal jelly is increased, repeatability is good, the yield is high, and the major proteins 2 and 3 in the royal jelly canbe produced on a large scale.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

A kind of preparation method of granular compressible sugar

The invention provides a preparation method for granulose condensable sugar. The preparation method comprises the following steps: mixing and stirring crystallization agent resistant, overheated and supersaturated cane sugar liquid and powdery condensable sugar seed crystals; after vacuum drying, granulating with a high speed granulator; then forced air drying and dry sieving to obtain a granulose condensable sugar product. The condensable sugar prepared by the preparation method is uniform in grain, high in flow ability and high in yield.

Owner:山东朗诺制药有限公司

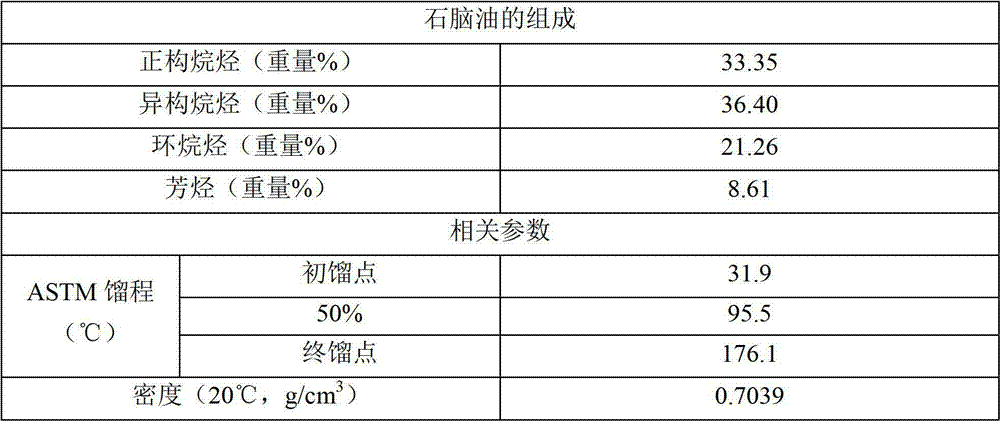

Butadiene preparation method

InactiveCN103588608AOvercome the defect of low yieldHydrocarbon by hydrocarbon crackingCracking reactionChemistry

The invention discloses a butadiene preparation method. The method comprises a step that a cracking raw material is subjected to a steam cracking reaction, the cracking raw material contains 5-100wt% of cyclohexene. The butadiene preparation method can substantially improve the butadiene yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

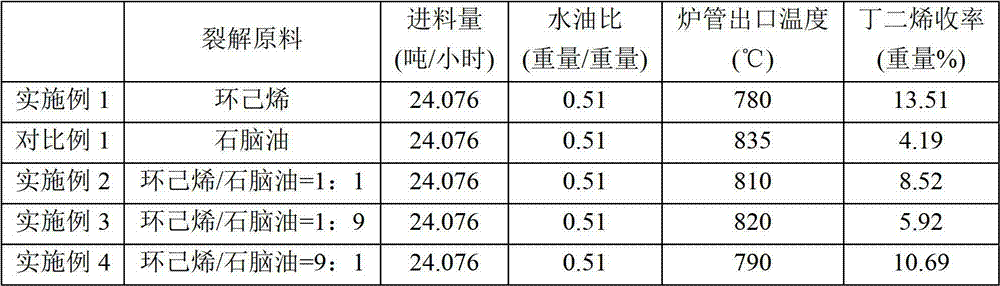

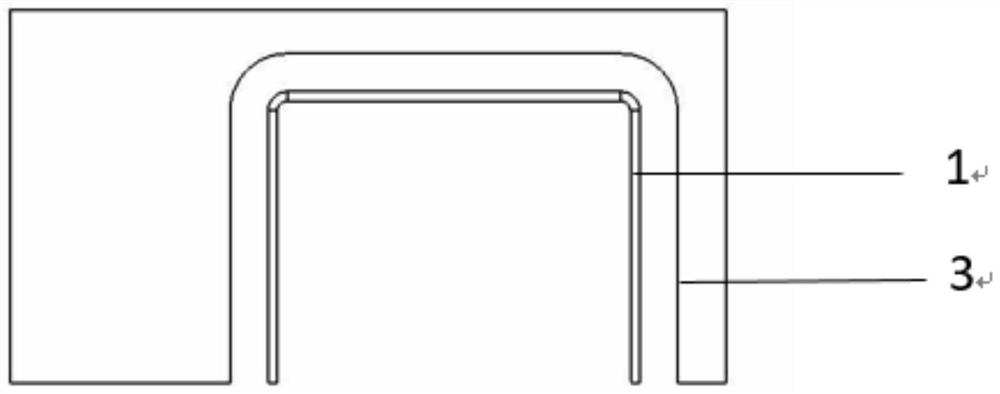

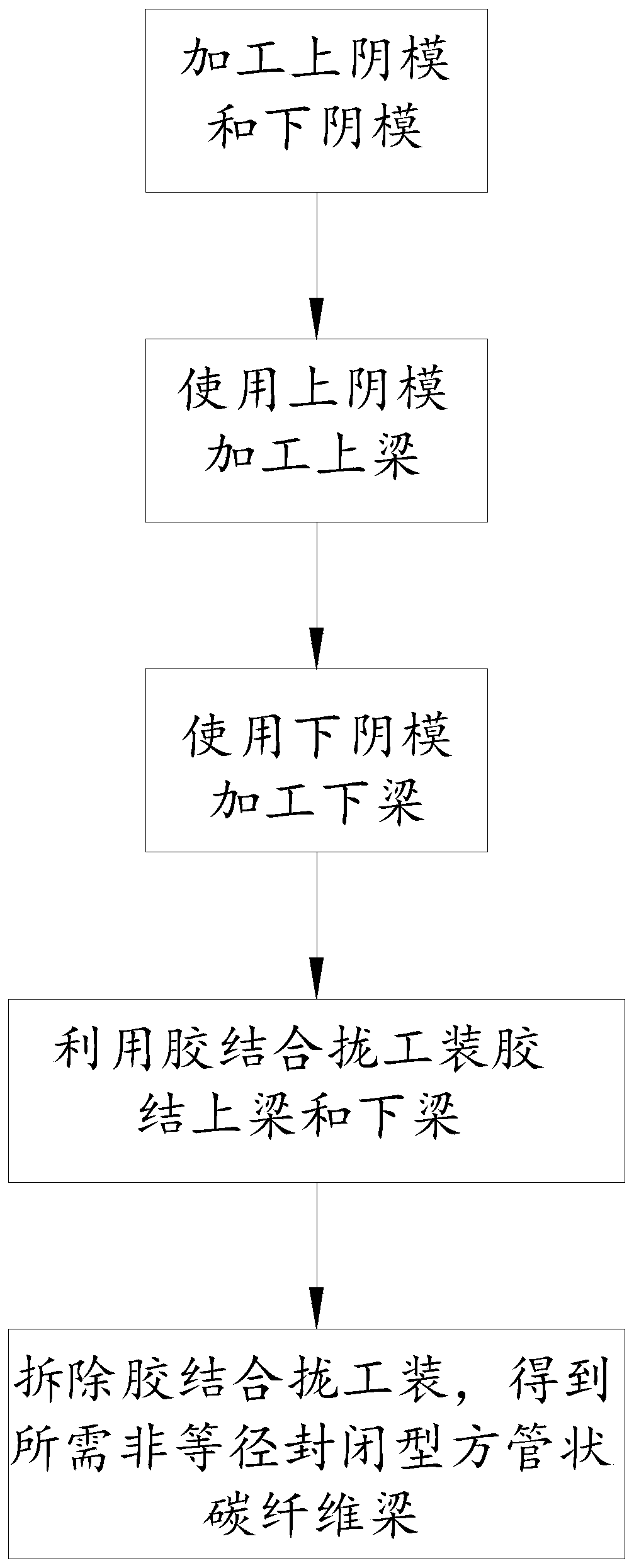

A method for manufacturing a non-equal-diameter closed square tubular carbon fiber beam for an unmanned aerial vehicle

ActiveCN110654039BSolve the difficulty of demouldingOvercome the defect of low yieldDomestic articlesFiberCarbon fibers

In order to effectively solve the technical problems of narrow application range, difficult demoulding, low yield of airbag core film, short service life, complicated process and high cost of the existing manufacturing method of non-equal-diameter closed square tubular carbon fiber beams of unmanned aerial vehicles, the present invention A method for manufacturing a UAV non-equal closed square tubular carbon fiber beam is proposed, including steps: 1) processing an upper die and a lower die; step 2) using the upper die to process an upper beam; step 3) Using the lower female mold to process the lower beam; step 4) gluing the upper beam and the lower beam with the gluing and joining tool; step 5) removing the gluing and joining tool to obtain the required non-equal diameter closed square tubular carbon fiber beam. The invention divides the integral component into two parts and forms them separately. Compared with integral forming, the requirements for forming process and forming tooling are lower, and the problem of difficult demoulding of non-equal-diameter closed square tube beams is solved.

Owner:西安爱生无人机技术有限公司

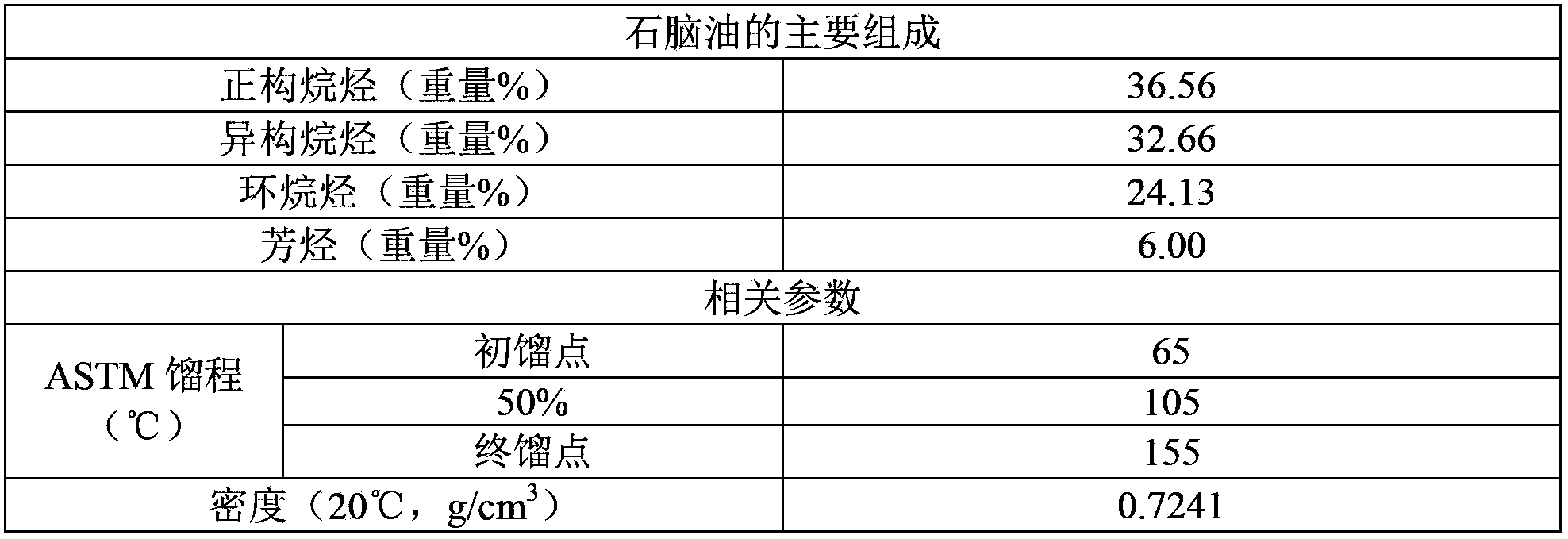

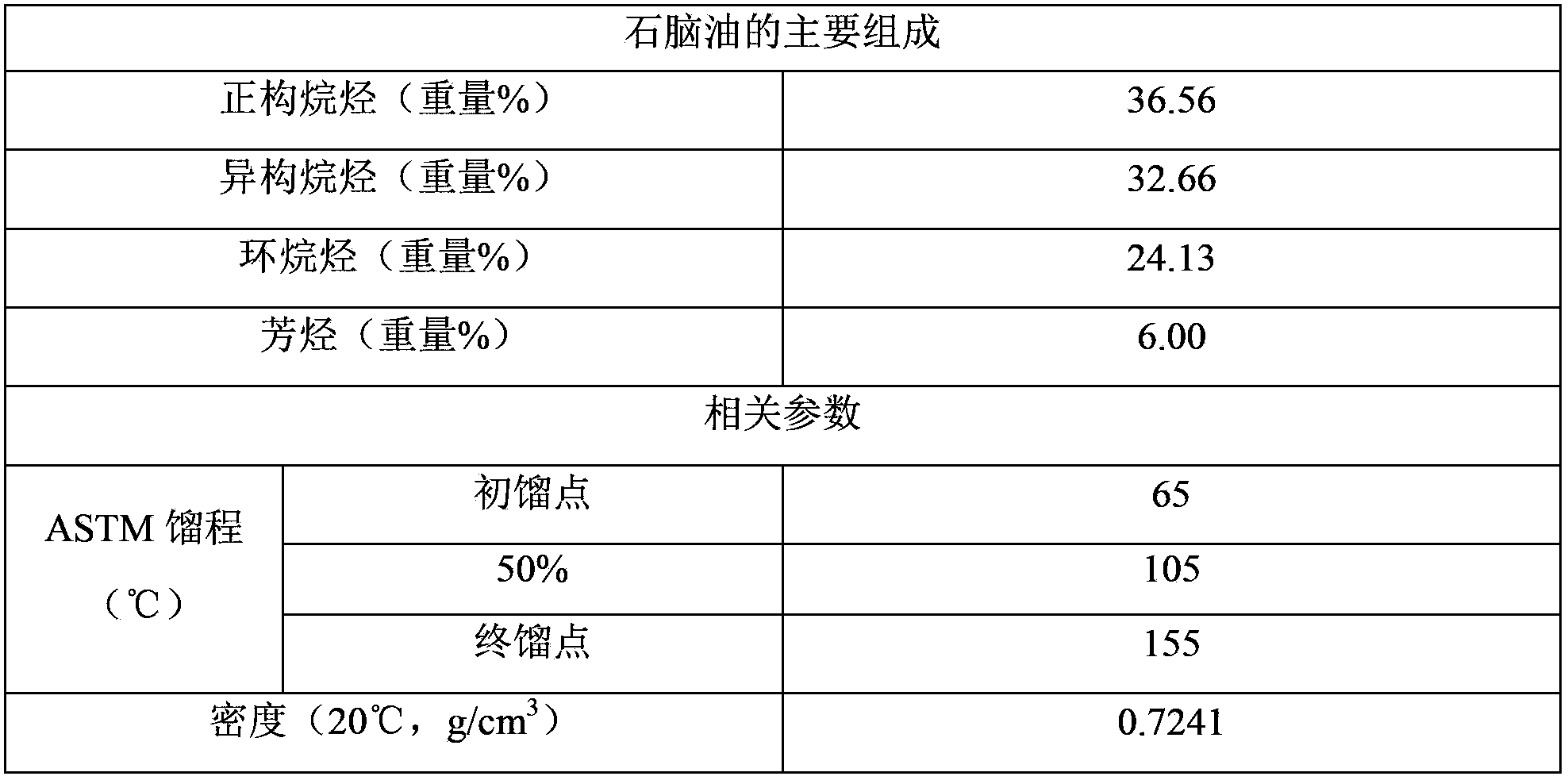

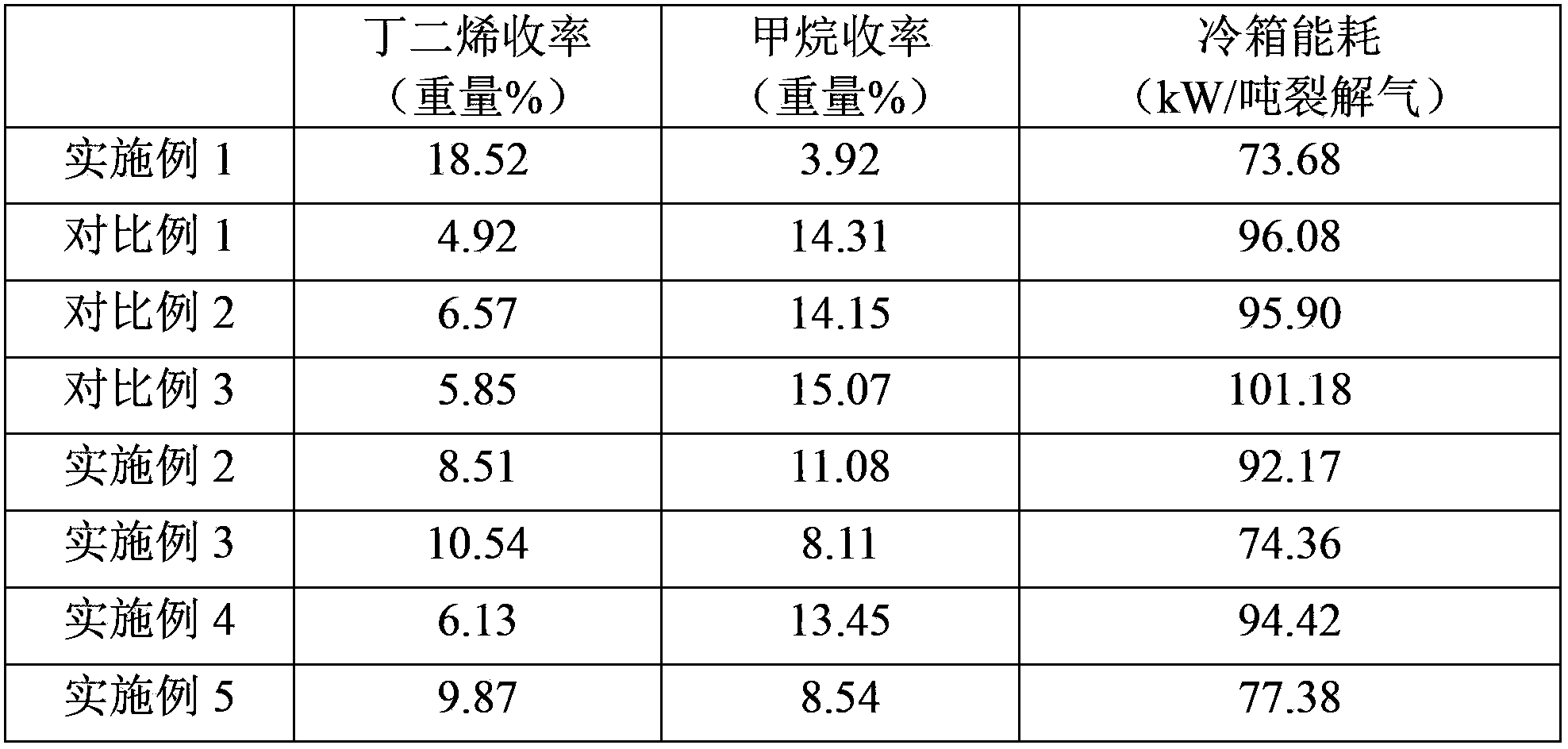

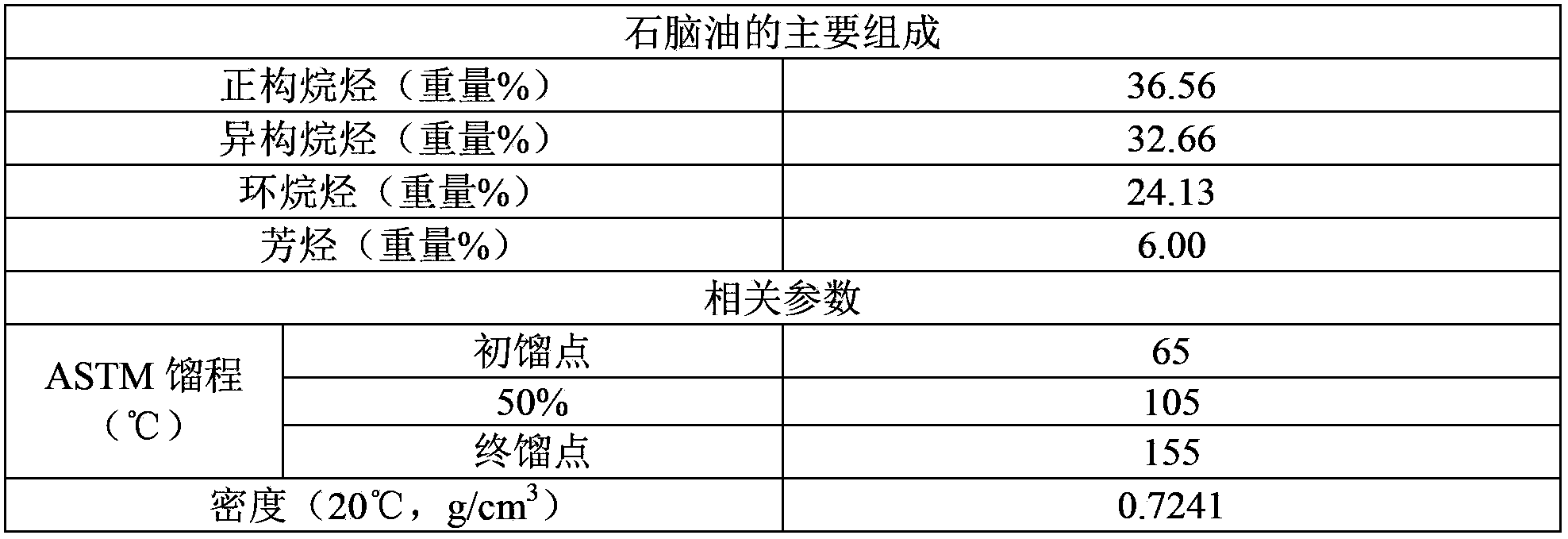

Method of preparing butadiene from gasoline

ActiveCN103483121BOvercome the defect of low yieldHydrocarbon by hydrocarbon crackingHydrogenation reactionGasoline

The method discloses a method of preparing butadiene from gasoline. The method takes a hydrogenation reaction product as at least part of a cracking raw material to carry out steam cracking reactions, wherein the hydrogenation product is prepared according to at least one method picked from following two methods: (1) method one, carrying out hydrogenation reactions with gasoline, whose aromatic hydrocarbon mass content is larger than 12%; (2) method two, separating at least one component of a C6 fraction, a C7 fraction, and a C8 fraction from gasoline, whose aromatic hydrocarbon mass content is larger than 12%, and then subjecting the separated fraction to carry out hydrogenation reactions. The method provided by the invention of preparing butadiene from gasoline has a high yield of butadiene and a low yield of methane, and thus the energy consumption of the cooling box in the separation process of cracking gas is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of processing method containing lysine solution

ActiveCN102617379BOvercome the defect of low yieldHigh yieldOrganic compound preparationAmino-carboxyl compound preparationElutionIon-exchange resin

The invention discloses a processing method for a lysine-containing solution. The processing method includes that the lysine-containing solution is enabled to sequentially pass one or more groups of positive ion exchange resin column groups which are in serial connection sequentially until the concentration of lysine in liquid flowed from ends of the one or more groups of positive ion exchange resin column groups is not larger than 0.1g / dL, each group of positive ion exchange resin column groups comprises one or more positive ion exchange resin columns which are in a parallel connection, and positive ion exchange resin columns with lysine are subjected to elution with an alkaline solution to obtain a lysine-containing elution. The processing method for the lysine-containing solution is characterized in that the lysine-containing solution passes the positive ion exchange resin column groups under the condition that the pH is 1.0-2.0 or the concentration of lysine is not lower than 1.0g / dL. The invention further discloses a circulating processing method for the lysine-containing solution. The processing method can improve the yield of the lysine, and be widely applied to industrial production.

Owner:COFCO BIOTECHNOLOGY CO LTD

Preparation method of butadiene

ActiveCN103483126AOvercome the defect of low yieldBulk chemical productionHydrocarbon by hydrocarbon crackingBenzeneHydrogenation reaction

The invention provides a preparation method of butadiene. The method comprises following steps: carrying out hydrogenation reactions with hydrocarbon raw materials, which contain benzene and / or alkyl benzene, in the presence of a hydrogenation catalyst, and then carrying out steam cracking reactions by taking the obtained hydrogenation reaction products as part of the cracking reaction raw material. The preparation method of butadiene is capable of obtaining a high yield of butadiene and a low yield of methane, and thus reduces the energy consumption of a cooling cabinet during the separation process of cracking gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

A continuous circulation preparation method and product of high-purity lactulose solution

ActiveCN108148099BIncrease concentrationRealize repeated useSugar derivativesDisaccharidesPtru catalystBiochemical engineering

A method for preparing high-purity lactulose by efficient removal of sodium meta-aluminate, pertaining to the technical field of oligosaccharide preparation. The method comprises preparing a high-purity lactulose syrup and a product thereof by pretreatment of a syrup, removal of a catalyst, removal of a monosaccharide and a salt, and posttreatment of the syrup. The efficient removal and recycling of the catalyst sodium meta-aluminate is realized. In the final product, Al residue is < 10 ppm (with respect to lactulose) and the purity of lactulose is > 95%. The preparation process meets resource-saving and environmentally-friendly production requirements, and facilitates clean, efficient, and environmentally-friendly industrial production of high-purity lactulose.

Owner:JIANGNAN UNIV

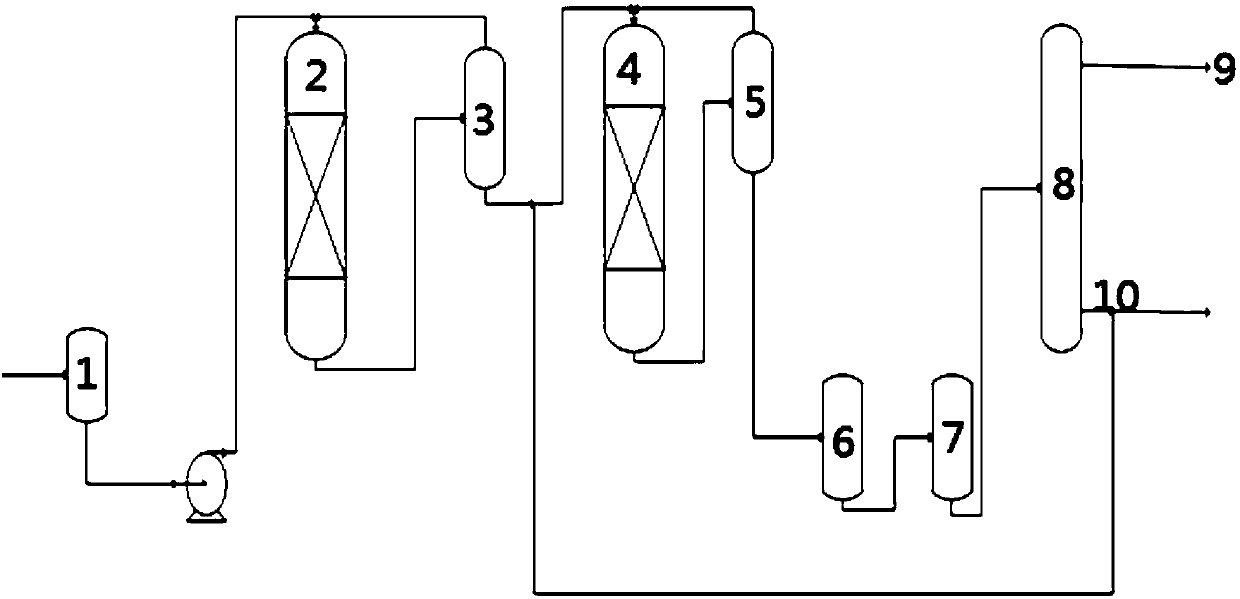

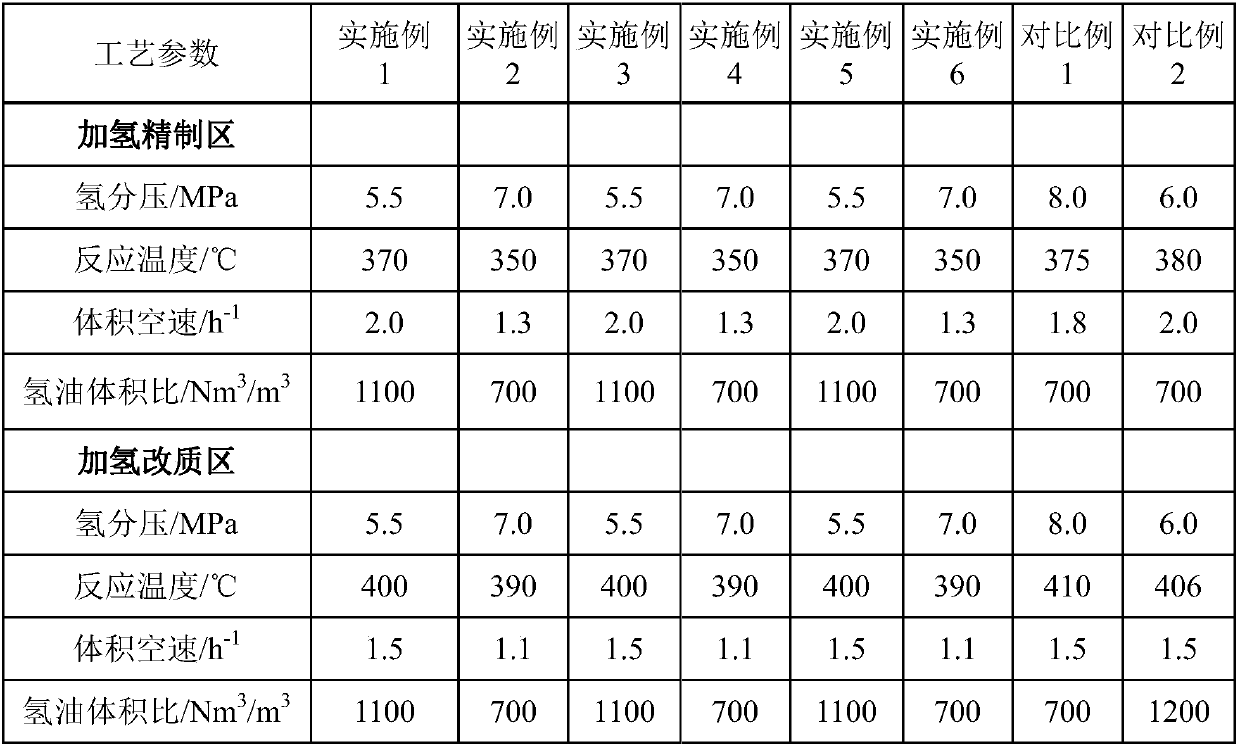

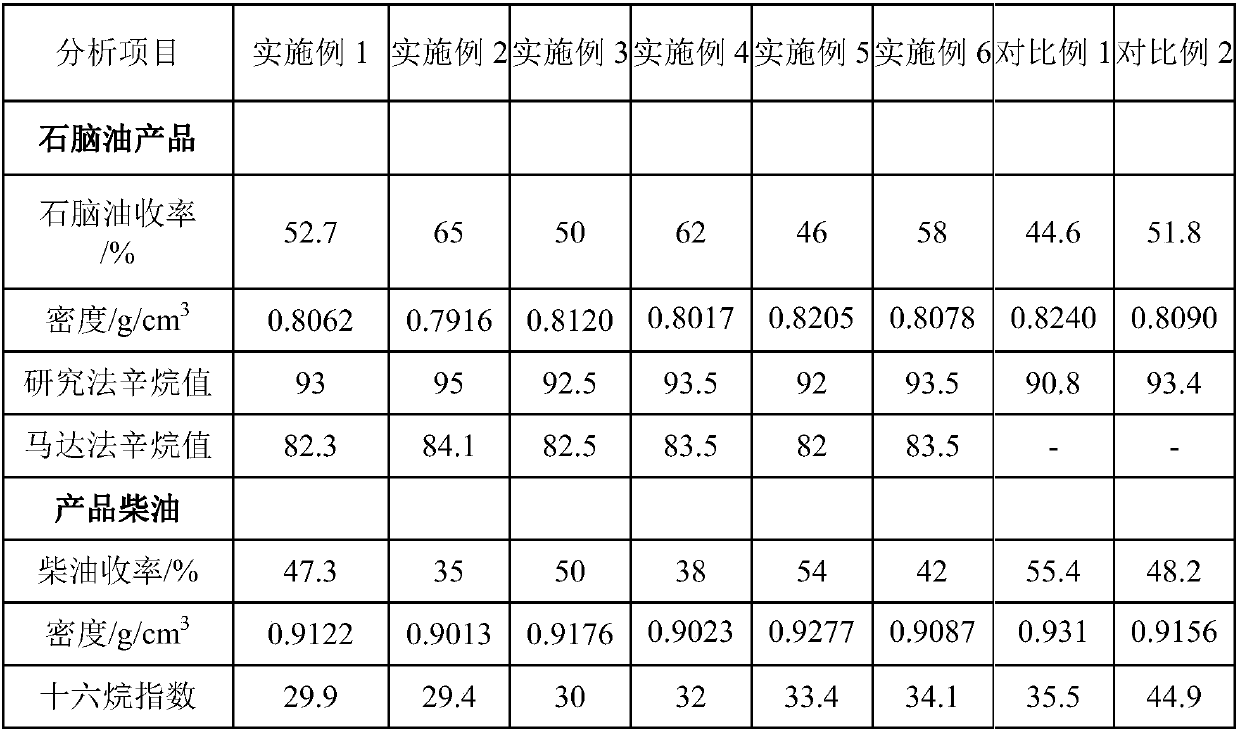

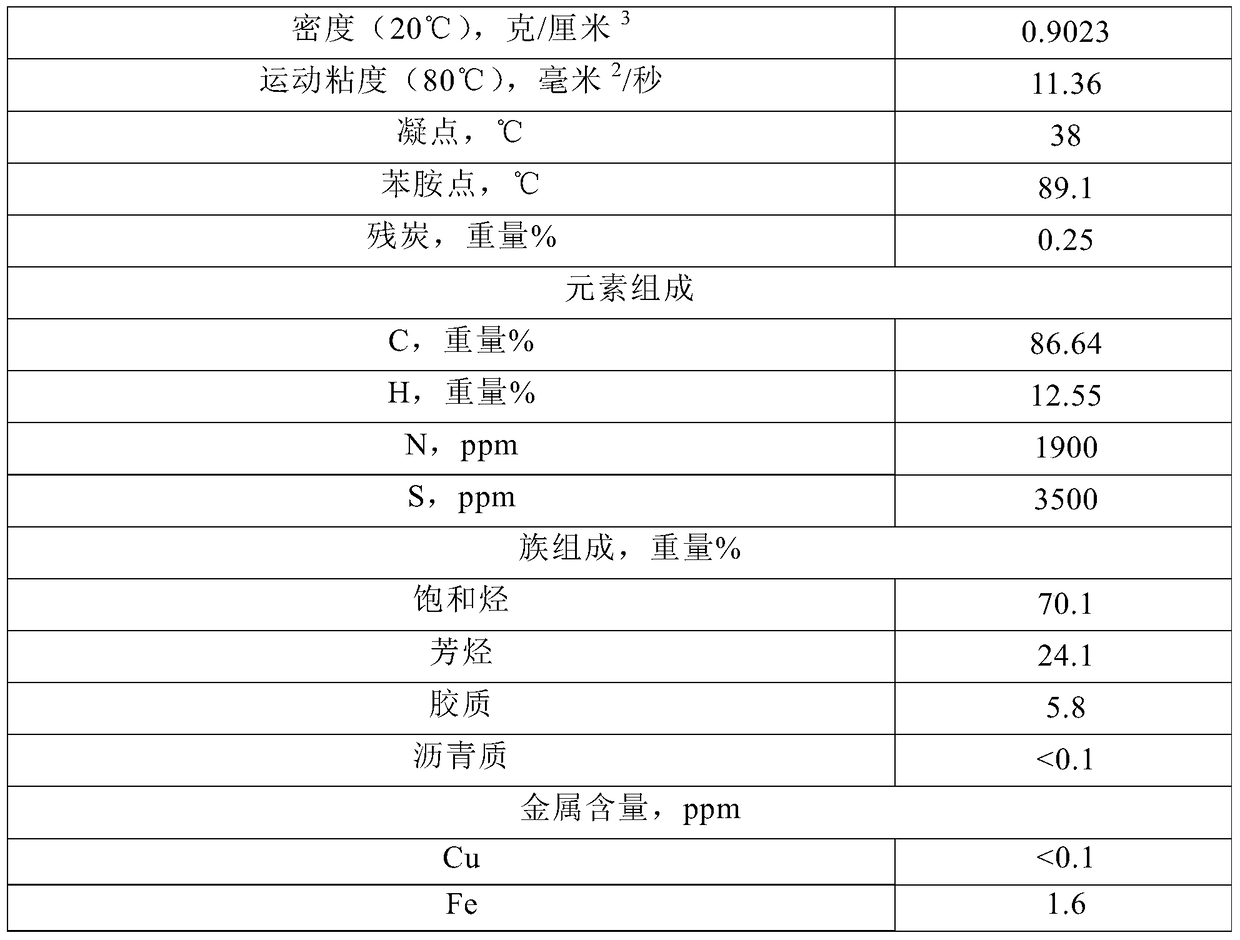

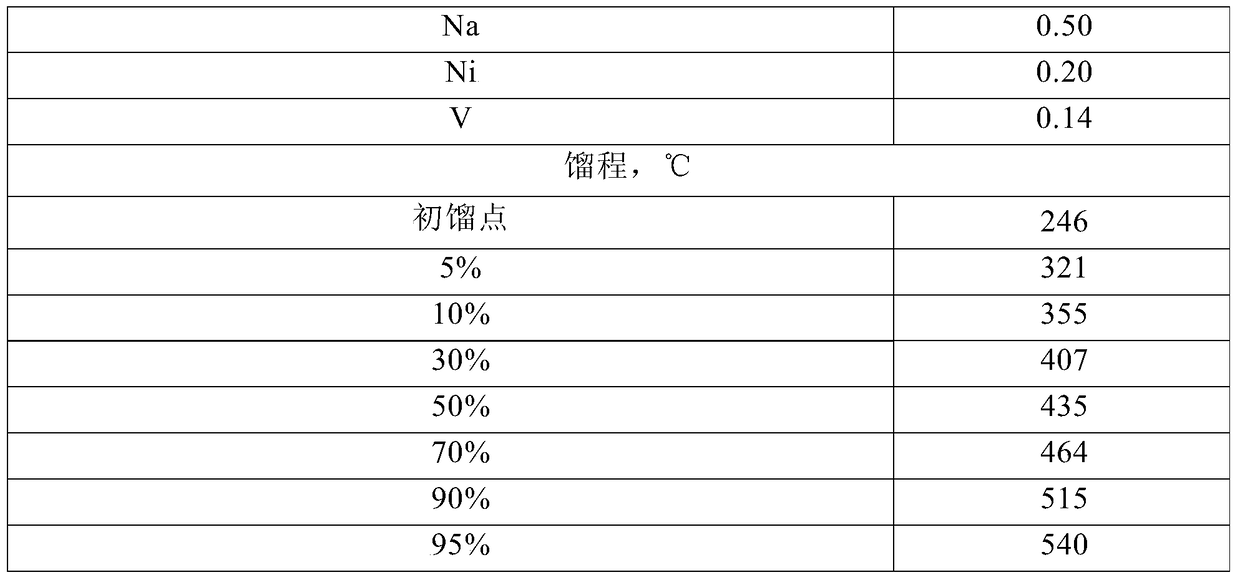

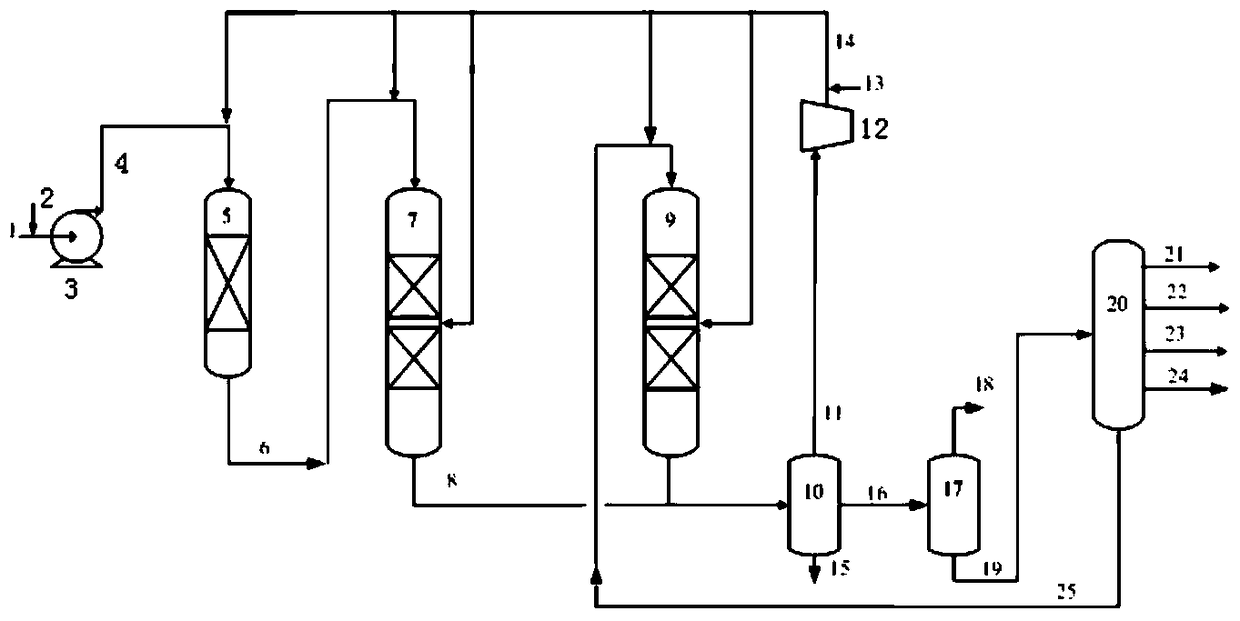

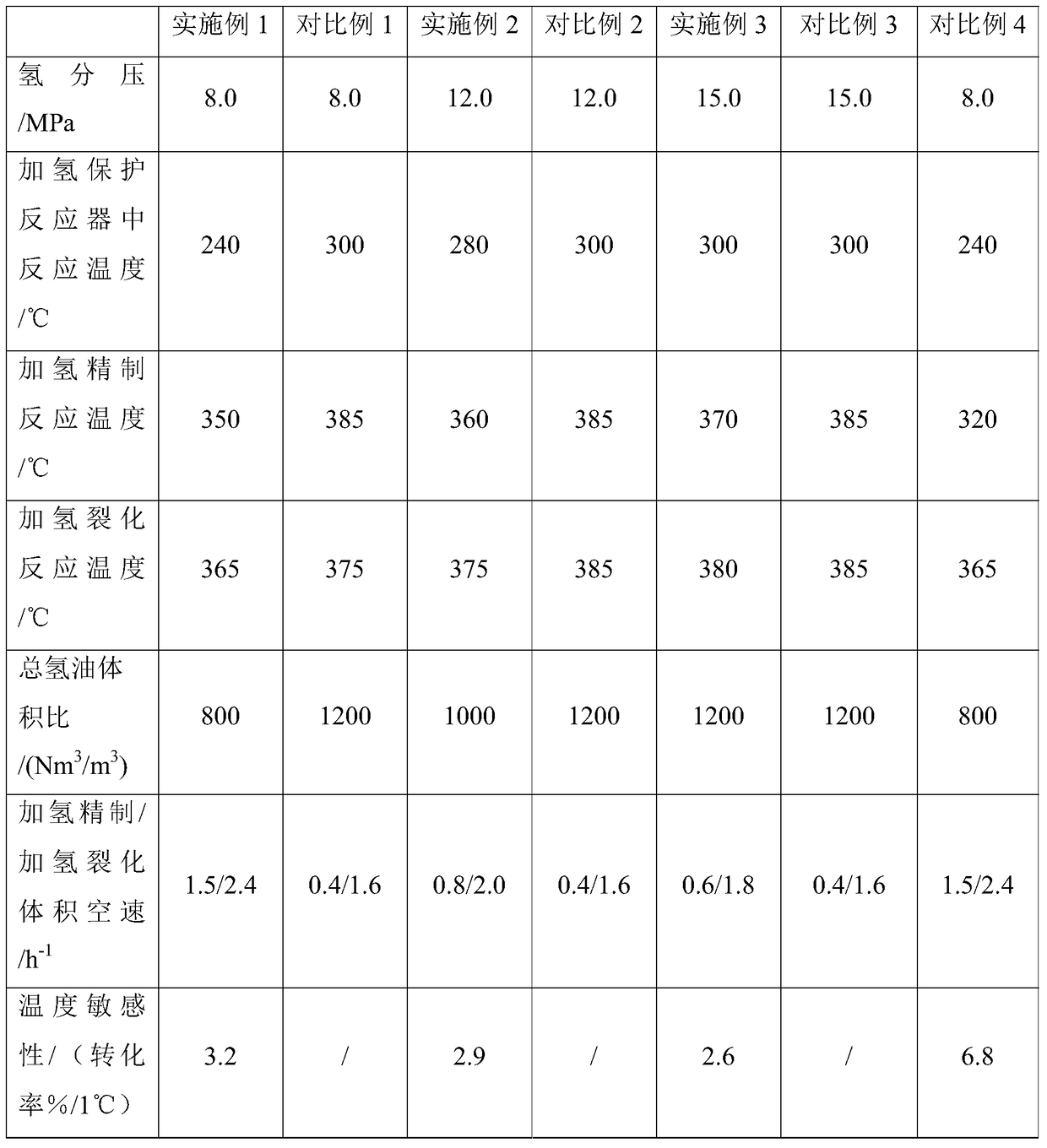

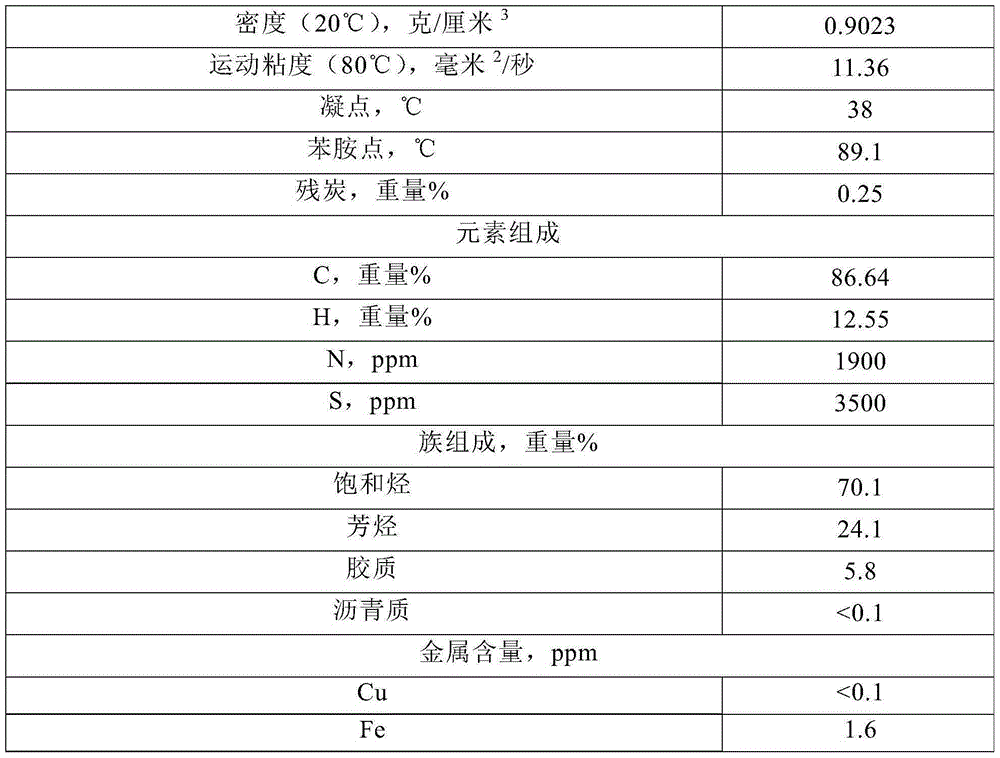

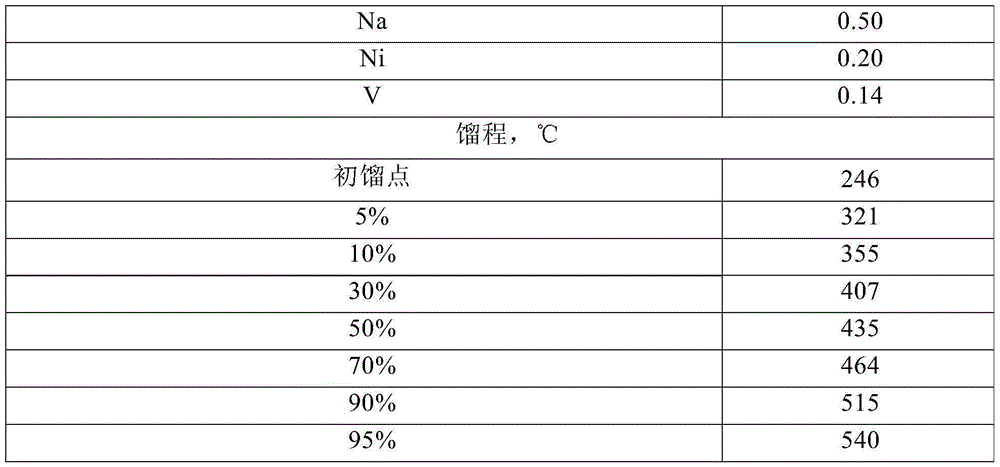

Method for processing inferior diesel oil raw material through moving bed hydrogenation

ActiveCN109694731ARealize flexible operationOvercome the defect of low yieldTreatment with hydrotreatment processesHydrocarbon oils refiningChemistryNaphtha

The invention relates to the field of production of high-value oil products by processing inferior diesel oil, and discloses a method for processing an inferior diesel oil raw material through movingbed hydrogenation. The method comprises: in the presence of hydrogen, introducing an inferior diesel oil raw material into a moving bed hydrorefining reaction unit, and carrying out a first contact reaction with the hydrorefining catalyst contained in the moving bed hydrorefining reaction unit; introducing the hydrogen and the remaining hydrorefining catalyst-separated material into a moving bed hydro-upgrading reaction unit, and carrying out a second contact reaction with the hydro-upgrading catalyst contained in the moving bed hydro-upgrading reaction unit; and separating and fractionating the remaining hydro-upgrading catalyst-separated material to obtain a naphtha product and a product diesel oil. With the method of the present invention, the disadvantages that the use of the fixed bedhydrogenation reactor as the main device can cause the short service life of the catalyst, and the insufficient contact between the oil and gas can cause the low yield of the product oil can be overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing butadiene from gasoline

ActiveCN103483121AHigh yieldLow yieldHydrocarbon by hydrocarbon crackingHydrogenation reactionGasoline

The method discloses a method of preparing butadiene from gasoline. The method takes a hydrogenation reaction product as at least part of a cracking raw material to carry out steam cracking reactions, wherein the hydrogenation product is prepared according to at least one method picked from following two methods: (1) method one, carrying out hydrogenation reactions with gasoline, whose aromatic hydrocarbon mass content is larger than 12%; (2) method two, separating at least one component of a C6 fraction, a C7 fraction, and a C8 fraction from gasoline, whose aromatic hydrocarbon mass content is larger than 12%, and then subjecting the separated fraction to carry out hydrogenation reactions. The method provided by the invention of preparing butadiene from gasoline has a high yield of butadiene and a low yield of methane, and thus the energy consumption of the cooling box in the separation process of cracking gas is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

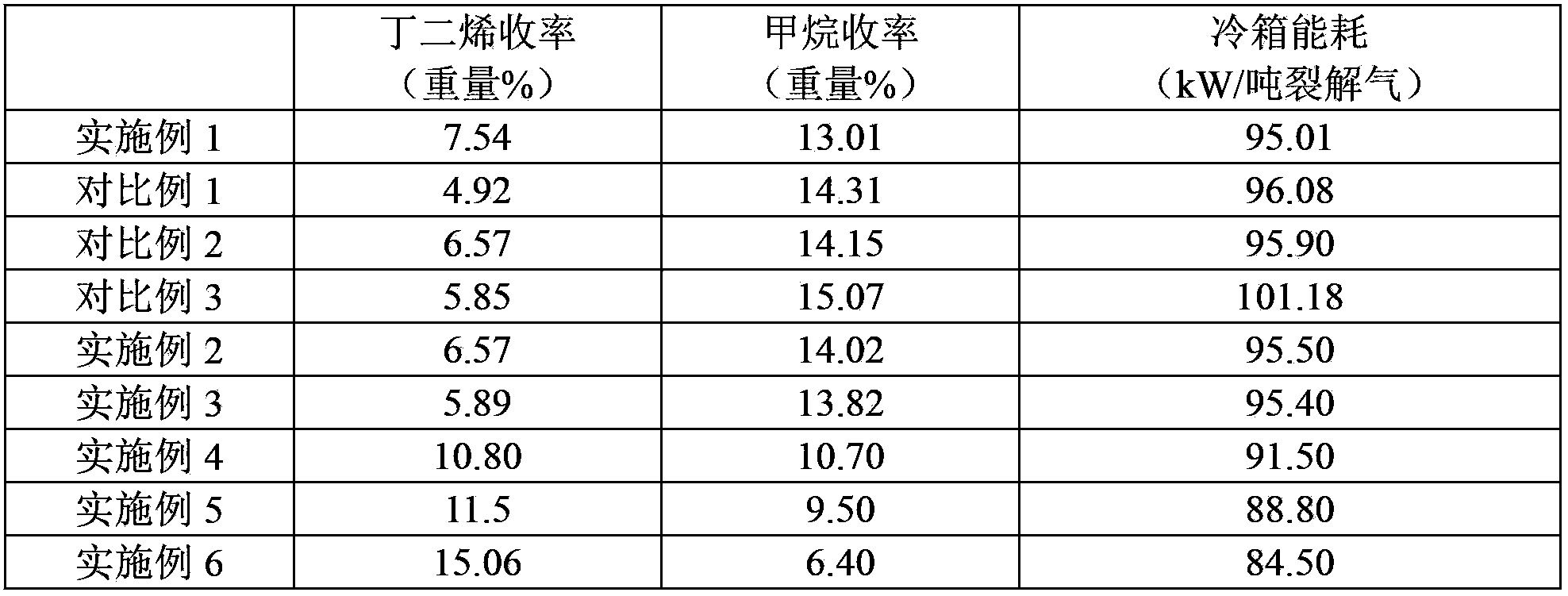

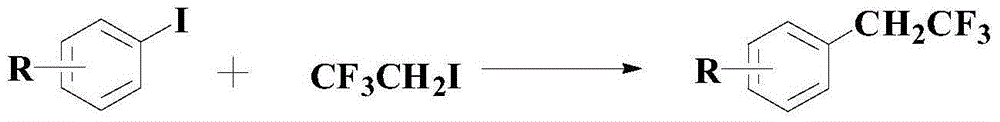

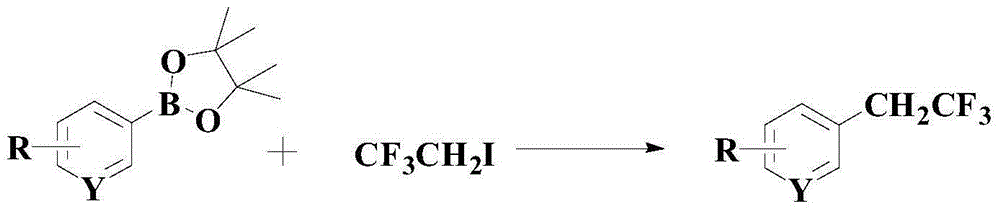

A kind of synthetic method of the medicine intermediate compound containing trifluoroethyl

ActiveCN103965012BOvercome the defect of low yieldChange the reaction environmentCarboxylic acid nitrile preparationOrganic compound preparationArylSynthesis methods

The invention relates to a synthesis method of a pharmaceutical intermediate compound containing trifluoromethyl, which directly implements a coupling reaction between aryl iodine and 1,1,1-trifluoro-2-ethyl iodide. According to the method, a copper powder / additive system serves as a multi-composite catalysis system to realize efficient coupling between aryl iodine and 1,1,1-trifluoro-2-ethyl iodide; reaction time is shortened on the basis of improving a reaction yield. Dimethyl formamide (DMF) in the process is an optimum reaction solvent, and various components of additive are selected according to an optimum industrial formula; the compound shows outstanding industrial application potential and theoretical research value.

Owner:BTC PHARMA TECH CO LTD

A method for catalytic conversion of hydrocarbons with high yield of butene and light aromatics

ActiveCN106609152BOvercome the defect of low yieldTreatment with plural serial stages onlyHydrocarbon oils treatment productsButeneBoiling point

The invention relates to the catalytic cracking field of heavy hydrocarbon class raw materials and particularly discloses a hydrocarbon catalytic converting method with high butene and light arene yields. The method comprises the following steps: 1, enabling a heavy hydrocarbon class raw material to carry out contact reaction with a first cracking catalyst in a first reactor, and then carrying out separation so as to obtain a first carbon depositing catalyst and a first reaction product; 2, enabling light cracked gasoline of which the final boiling point does not exceed 90DEG C to carry out contact reaction with a second cracking catalyst in a second reactor; and 3, directly guiding a reaction mixture which is obtained through reaction in the second reactor into a third reactor without separating the reaction mixture, enabling the reaction mixture to carry out contact reaction with hydrogenation modified cracked light oil of which the boiling range is between 200DEG C and 390DEG C, and then carrying out separation so as to obtain a second carbon depositing catalyst and a second reaction product, wherein the hydrogenation modified cracked light oil is prepared by carrying out hydrogenation treatment on the cracked light oil. High butene yield and high light arene yield can be obtained by the method provided by the invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

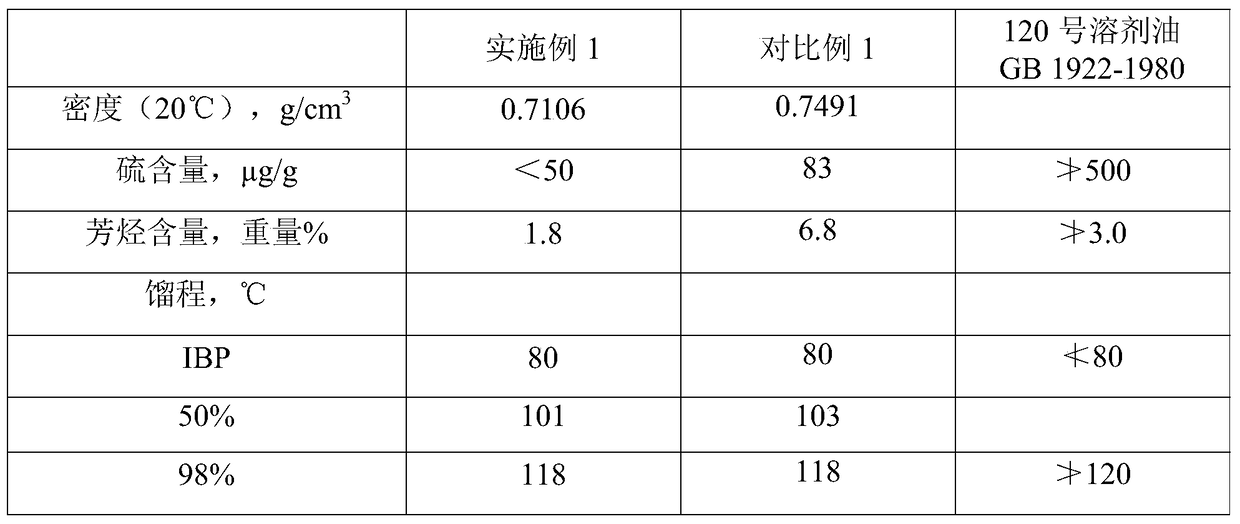

A method of mixing and processing coal tar and Fischer-Tropsch synthetic oil

ActiveCN106147855BHigh temperature sensitivityOvercome the defect of low yieldTreatment with hydrotreatment processesNaphthaHydrogenation reaction

The invention relates to the field of petrochemical industry, and discloses a method for mixing and processing coal tar and Fischer-Tropsch synthetic oil. Reaction in the refining reaction zone to obtain the hydrofining reaction effluent, wherein the weight ratio of the Fischer-Tropsch synthetic oil and coal tar is 1:0.01-1.50; (2) separating the hydrofining reaction effluent and any Selected mixture with the effluent from the hydrocracking reaction zone to obtain a liquid effluent; (3) fractionating the liquid effluent to obtain the target product and naphtha and tail oil, optionally the tail Oil is introduced into the hydrocracking reaction zone for reaction. The method can overcome the defects of high temperature sensitivity and low product yield caused by secondary cracking in the process of processing Fischer-Tropsch synthetic oil in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

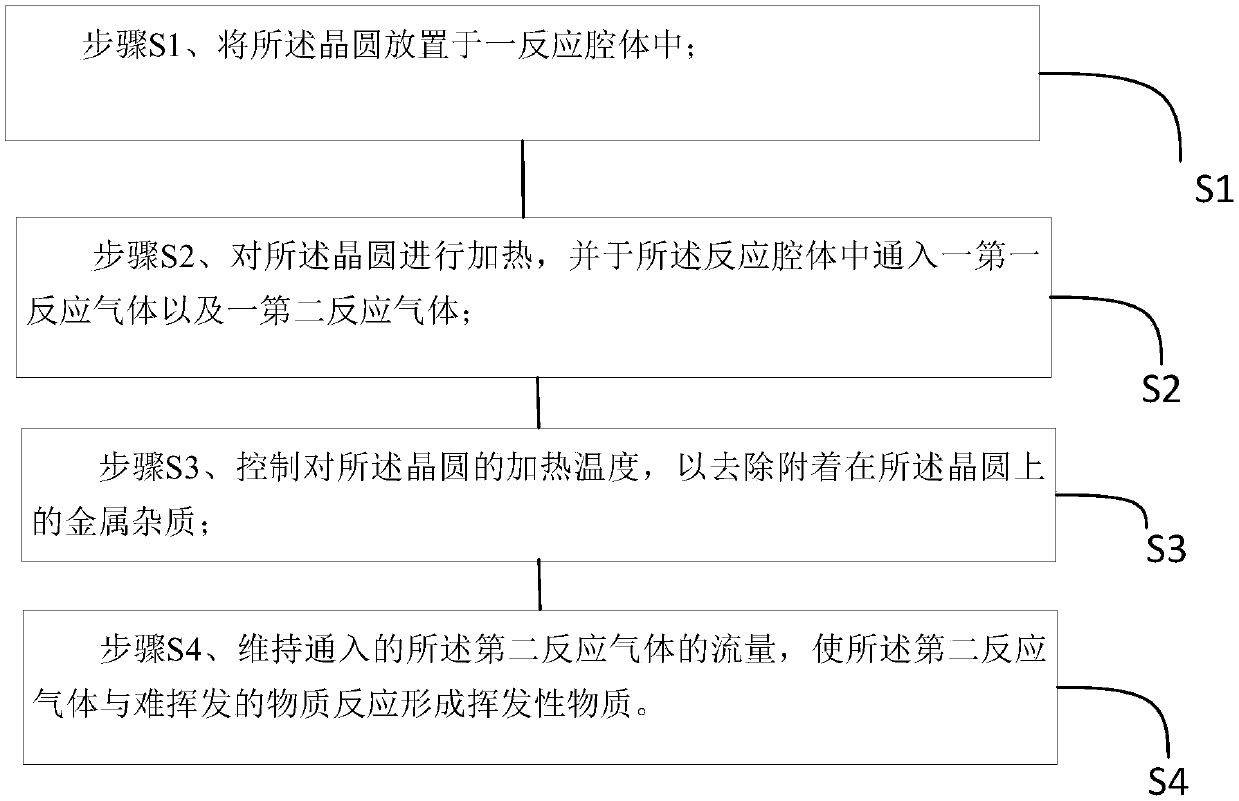

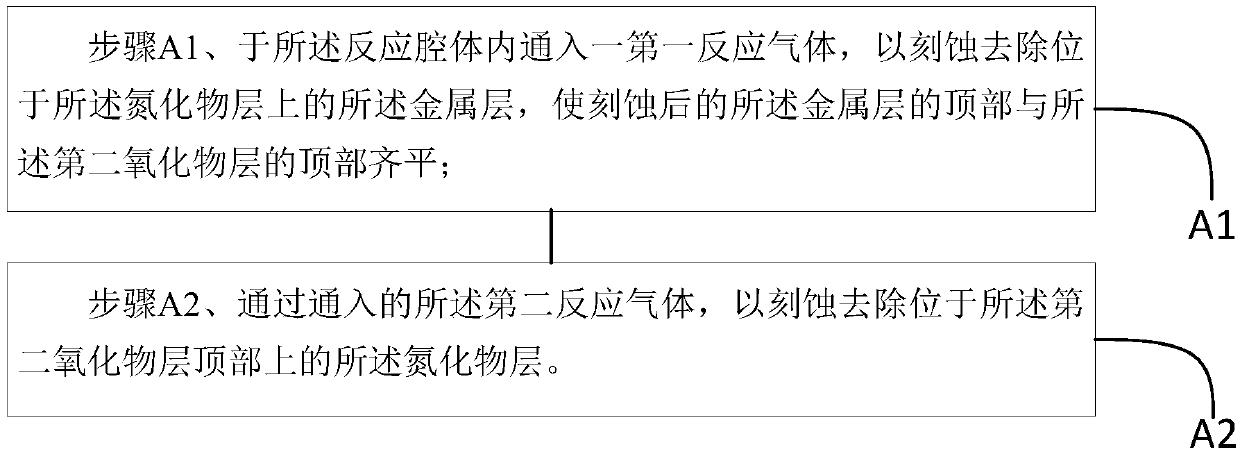

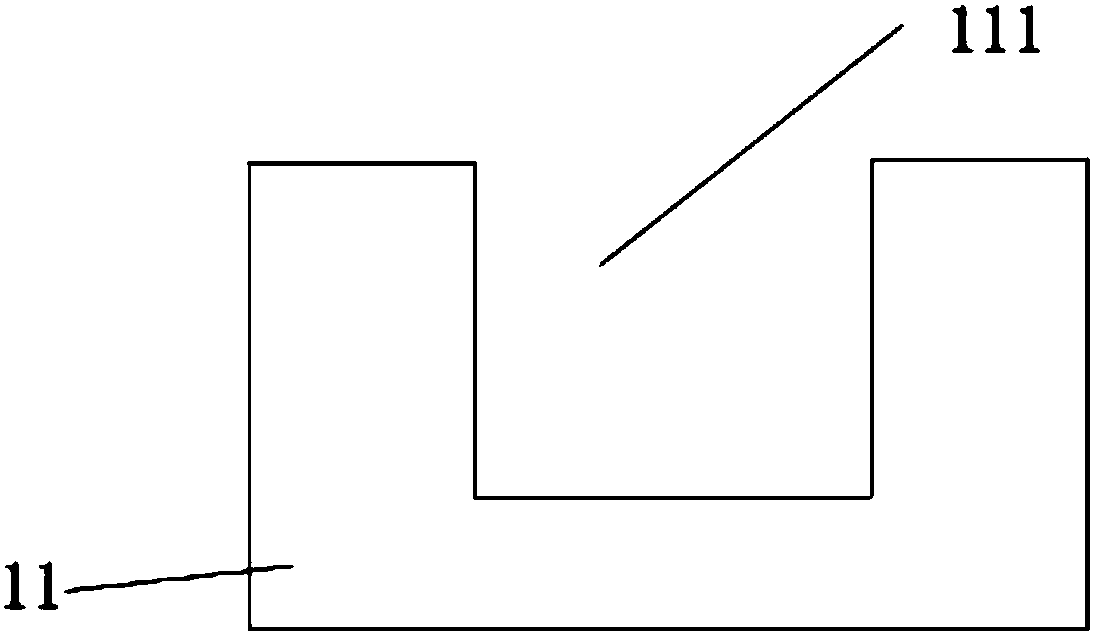

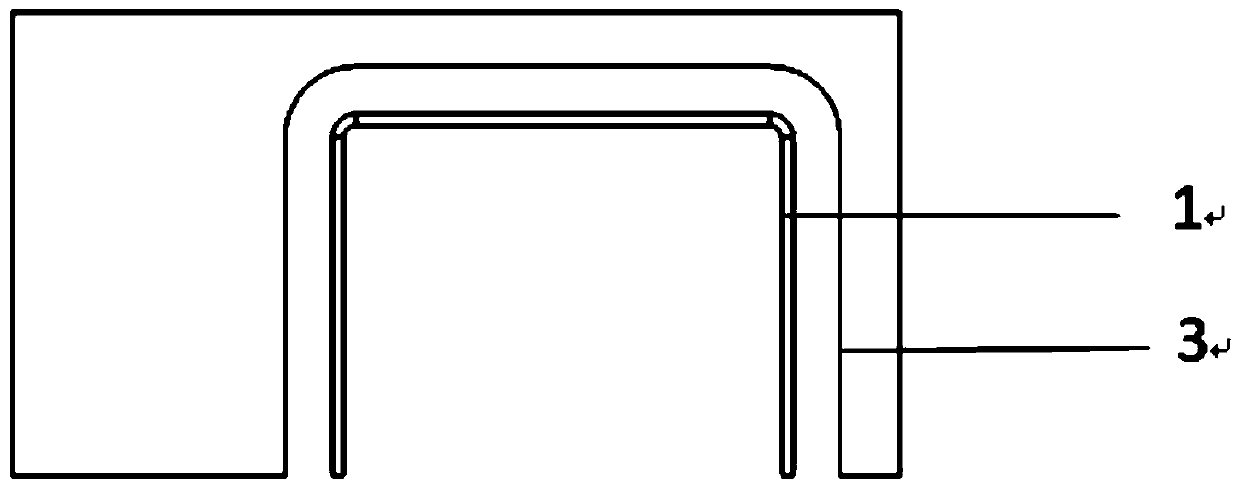

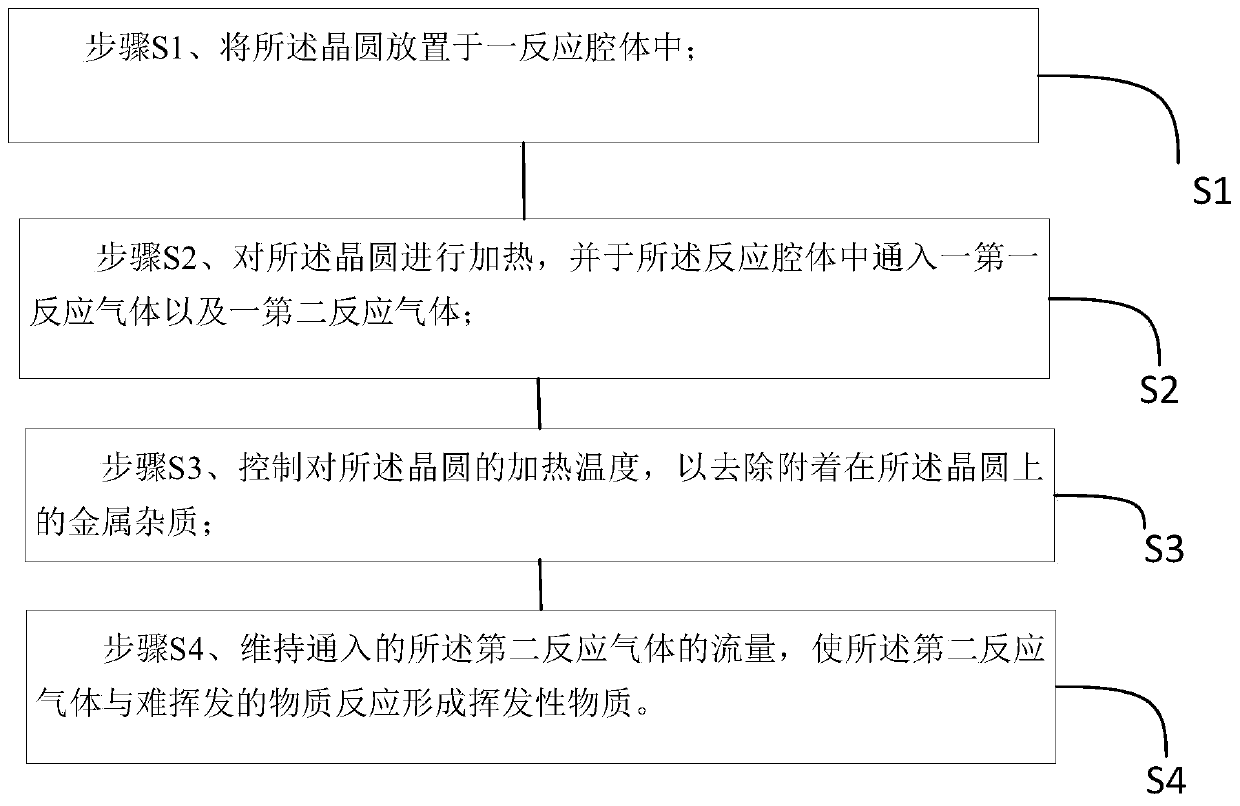

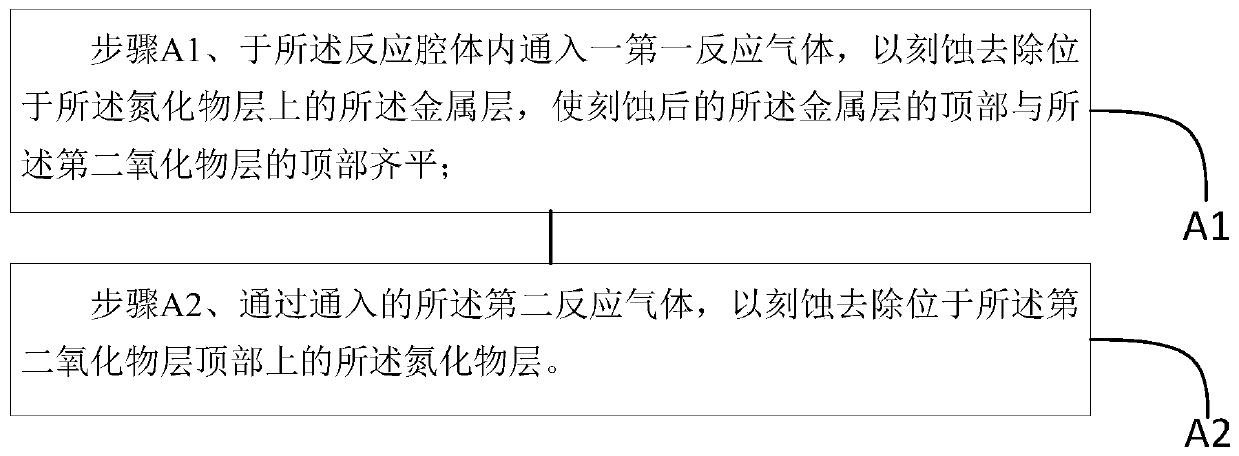

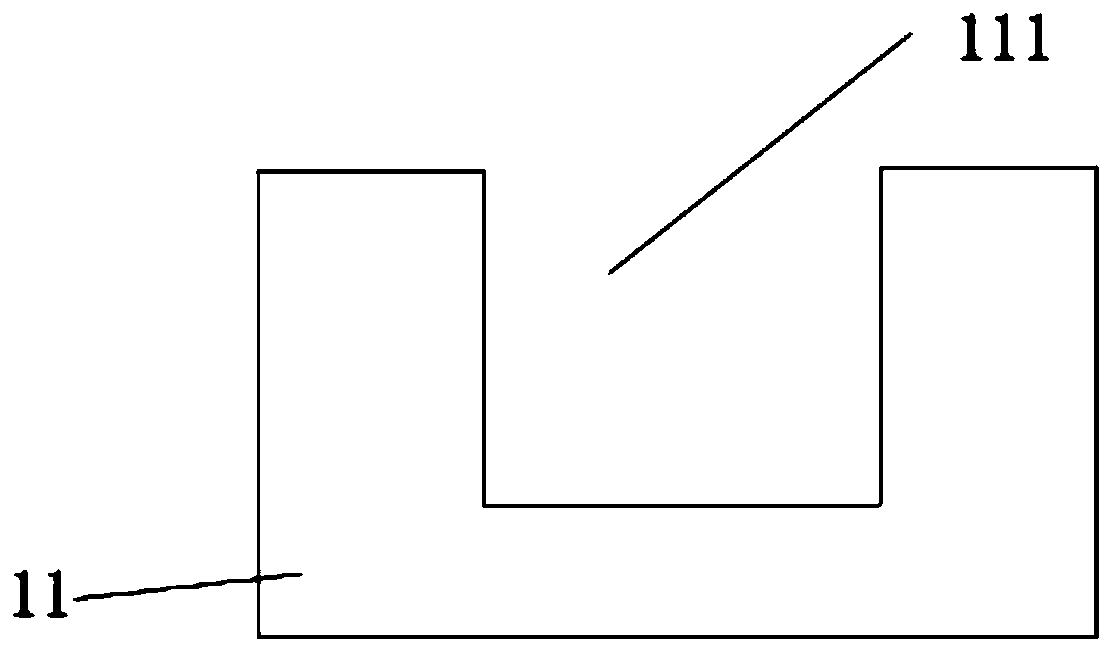

Method for removing substance difficult to volatilize from wafer

ActiveCN107680902AOvercome the defect of low yieldSemiconductor/solid-state device manufacturingTungstenMetal impurities

The invention provides a method for removing a substance difficult to volatilize from a wafer, applied to a tungsten etching back process of a deep trench isolation processing process; in the deep trench isolation processing process, the substance difficult to volatilize is generated easily, and the substance difficult to volatilize is attached to the wafer; the method comprises the following steps of S1, putting the wafer into a reaction cavity; S2, heating the wafer, and pumping first reaction gas and second reaction gas to the reaction cavity; S3, controlling the heating temperature on thewafer to remove metal impurities attached on the wafer; and S4, maintaining the flow of the pumped second reaction gas to enable the second reaction gas to be reacted with the substance difficult to volatilize so as to form a volatile substance. The technical scheme has the beneficial effects that the shortcoming of relatively low wafer yield caused by the fact that the substance difficult to volatilize and metal impurities are attached on the wafer in the prior art can be overcome.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Manufacturing method for unmanned aerial vehicle non-equal-diameter closed square pipe shaped carbon fiber beam

ActiveCN110654039ASolve the difficulty of demouldingOvercome the defect of low yieldDomestic articlesFiberCarbon fibers

The invention provides a manufacturing method for an unmanned aerial vehicle non-equal-diameter closed square pipe shaped carbon fiber beam so as to effectively solve the technical problems that an existing manufacturing method for the unmanned aerial vehicle non-equal-diameter closed square pipe shaped carbon fiber beam is narrow in application range, demolding is difficult, the airbag core filmyield is low, the service life is short, the flow is complicated, and the cost is relatively high. The manufacturing method for the unmanned aerial vehicle non-equal-diameter closed square pipe shapedcarbon fiber beam comprises the following steps that 1) an upper female die and a lower female die are machined; 2) an upper beam is machined by using the upper female die; 3) a lower beam is machined by using the lower female die; 4) the upper beam and the lower beam are bonded by using a bonding combining tool; and 5) the bonding combining tool is removed to obtain the required non-equal-diameter closed square pipe shaped carbon fiber beam. According to the manufacturing method, an integral component is divided into two parts to be separately formed, compared with integral forming, the requirements on a forming process and a forming tool are relatively low, and the problem of difficult demolding of the non-equal-diameter closed square pipe beam is solved.

Owner:西安爱生无人机技术有限公司

Plastic formula with high rate of finished products

The invention discloses a plastic formula with high rate of finished products. The plastic formula comprises the following components in parts by weight: 69-88 parts of polypropylene, 1.3-1.5 parts ofstannous octoate, 0.2-1 part of monomer resin, 5-6.2 parts of calcium carbonate, 1.3-1.5 parts of a preservative, 0.2-1 part of a plasticizer, 1.1 parts of an alumina powder and 1.3 parts of magnesium stearate; the raw materials are fully mixed and then put in an injection molding machine for die-cast molding. Compared with the prior art, the plastic formula disclosed by the invention has the advantages of being low in price, high in rate of finished products and excellent in performance.

Owner:XUZHOU CURRENCY MAGNETOELECTRICITY

A method for removing difficult-to-volatile substances on wafers

ActiveCN107680902BOvercome the defect of low yieldSemiconductor/solid-state device manufacturingWaferPhysical chemistry

Owner:WUHAN XINXIN SEMICON MFG CO LTD

A kind of catalyst and its preparation method and application

ActiveCN105080568BOvercome the defect of low yieldHydrocarbon from carbon oxidesOrganic compound preparationActivated carbonAlcohol

The invention provides a catalyst and its preparation method and application. The catalyst comprises a carrier and an active component and an auxiliary agent which are loaded on the carrier, wherein the carrier is an activated carbon carrier which has undergone acid pickling and oxidation and has particle size of 200-2000 microns; the active component is the Group VIII metal component; and the auxiliary agent is the Group IVB metal component. When the catalyst provided by the invention is used in preparation of low carbon alcohols from synthesis gas, low carbon alcohols can be prepared at low temperature, and contents of low carbon alcohols, especially methanol and ethanol, in an oil-phase product are high. The preparation method has advantages of mild condition, high conversion per pass and low energy consumption, and is beneficial to industrial popularization.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for improving the yield rate of semi-steelmaking mn alloy

ActiveCN104004878BOvercome the defect of low yieldHigh yieldManufacturing convertersSteelmakingHigh magnesium

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ce3022ab-8482-4ecb-a12b-ab2f73846741/BSA00000268271500021.PNG)

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ce3022ab-8482-4ecb-a12b-ab2f73846741/BSA00000268271500022.PNG)

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ce3022ab-8482-4ecb-a12b-ab2f73846741/BSA00000268271500031.PNG)

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ce37175a-38e9-459c-8b0c-1c007c24fa21/BSA00000268271500021.PNG)

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ce37175a-38e9-459c-8b0c-1c007c24fa21/BSA00000268271500022.PNG)

![Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate Improved method for preparing benzo[d][1,2,3] thiadiazole-7-formic acid trifluoroacetate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/ce37175a-38e9-459c-8b0c-1c007c24fa21/BSA00000268271500031.PNG)