A method of mixing and processing coal tar and Fischer-Tropsch synthetic oil

A technology for Fischer-Tropsch synthetic oil and coal tar, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment, and can solve the problems of low product yield and high temperature sensitivity of Fischer-Tropsch synthetic oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

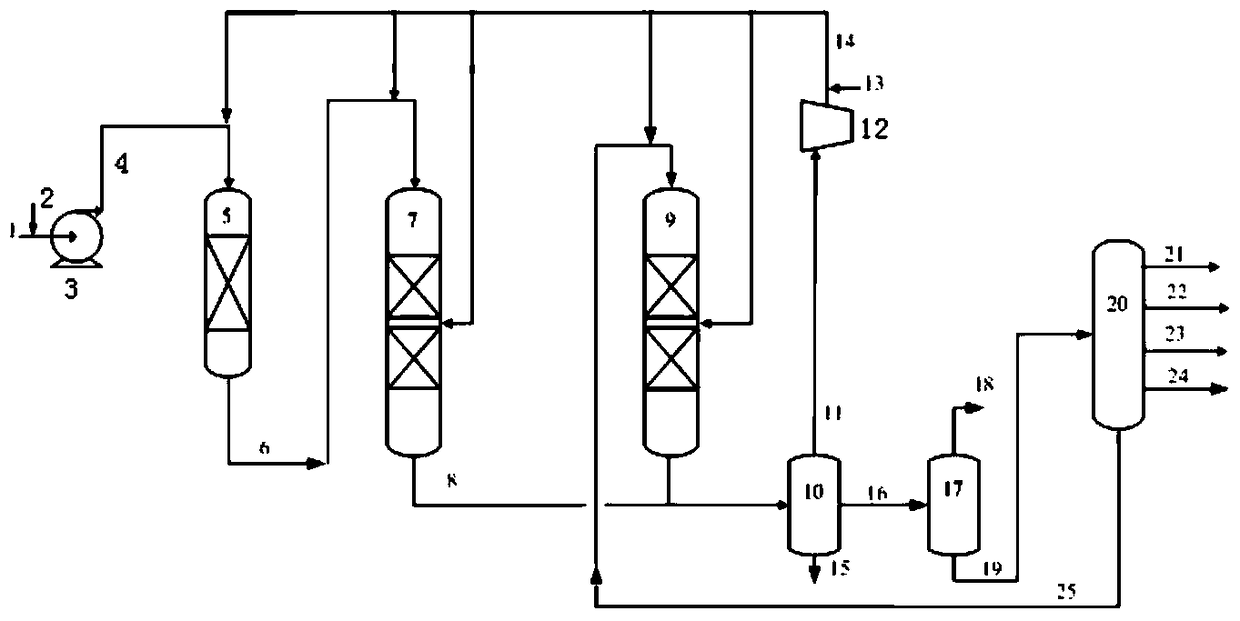

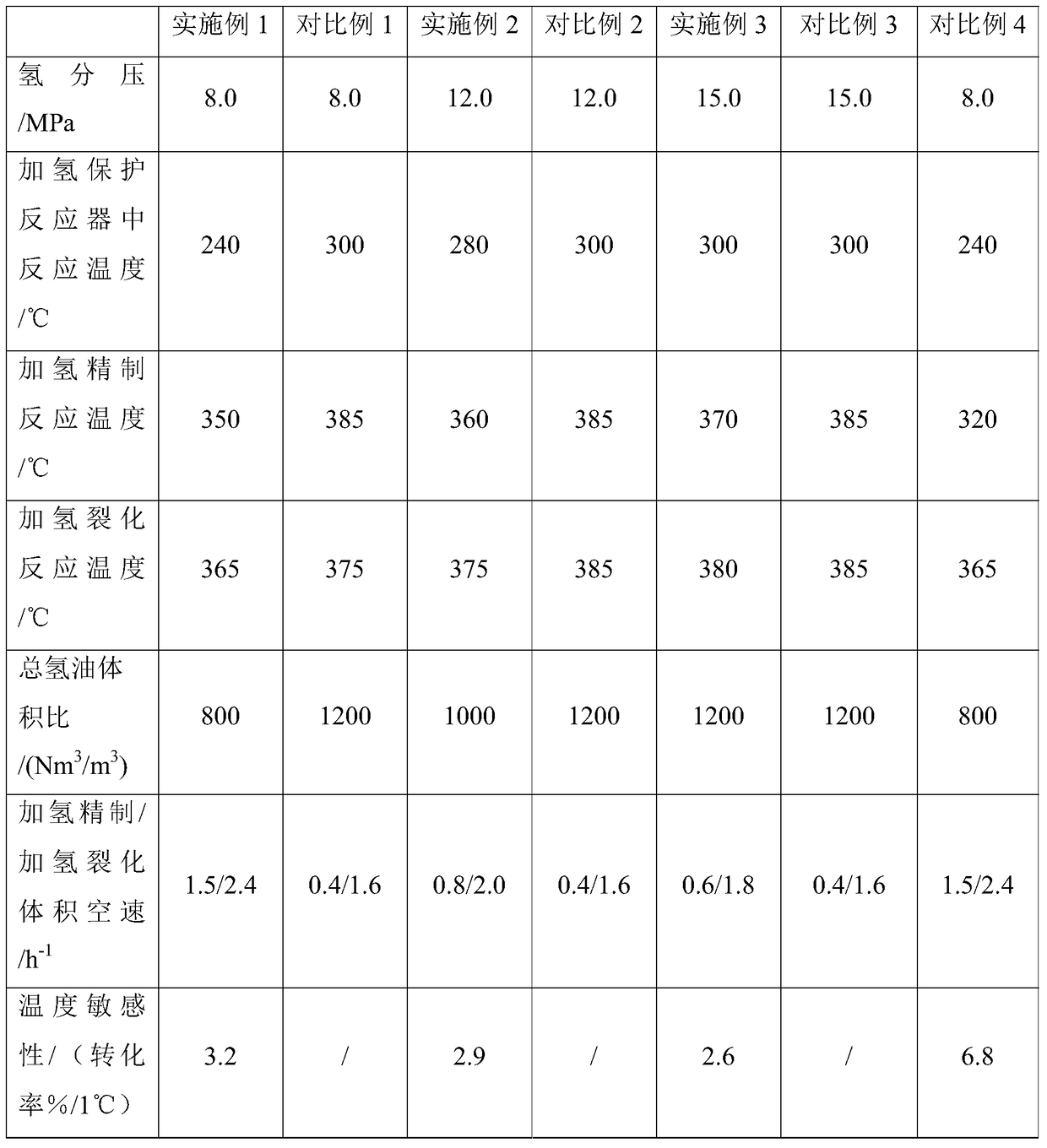

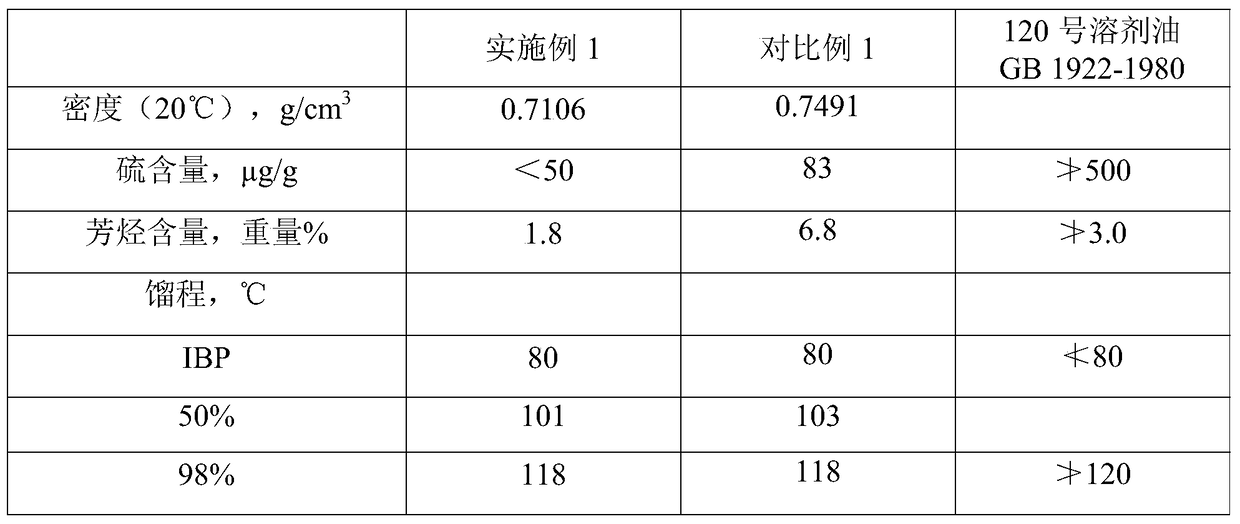

[0102] This embodiment is used to illustrate the method for the mixed processing coal tar and Fischer-Tropsch synthetic oil of the present invention, produces solvent oil, and the method of this embodiment is based on figure 1 The flowchart shown proceeds, specifically, as follows:

[0103] In this example, mixed oil 1 is used as the raw material oil, which enters the hydrogenation protection reactor and the hydrofinishing reactor successively, and is sequentially combined with the hydrogenation protection catalysts RGC-20, RGC-30E, RGC-30A, RGC-30B, RGC-1 Contact and react with the hydrofining catalyst RTC-2, the hydrofinishing reaction effluent enters the separation system for separation, and the separated liquid effluent enters the fractionation tower to cut out naphtha fraction, solvent oil fraction and tail oil. The tail oil fraction enters the hydrocracking reactor as the raw material of the hydrocracking reaction and contacts with the hydrocracking catalyst RCF-1 for fu...

Embodiment 2

[0119]This embodiment is used to illustrate the method for the mixed processing coal tar and Fischer-Tropsch synthetic oil of the present invention, produces jet fuel, and the method of this embodiment is based on figure 1 The flowchart shown proceeds, specifically, as follows:

[0120] In this example, the mixed oil 2 is used as the raw material oil, which enters the hydrogenation protection reactor and the hydrofinishing reactor in turn, and is sequentially combined with the hydrogenation protection catalysts RGC-20, RGC-30E, RGC-30A, RGC-30B, RGC-1 Contact and react with the hydrofining catalyst RTC-2, the hydrofinishing reaction effluent enters the separation system for separation, and the separated liquid effluent enters the fractionation tower to cut naphtha fraction, jet fuel and tail oil. The tail oil fraction enters the hydrocracking reactor as the raw material for hydrocracking and contacts with the hydrocracking catalyst RCF-1 for further hydroconversion. The hydroc...

Embodiment 3

[0131] This embodiment is used to illustrate the method for the mixed processing coal tar and Fischer-Tropsch synthetic oil of the present invention, produces diesel product, and the method of this embodiment is based on figure 1 The flowchart shown proceeds, specifically, as follows:

[0132] In this example, the mixed oil 3 is used as the raw material oil, which enters the hydrogenation protection reactor and the hydrofinishing reactor in turn, and is sequentially combined with the hydrogenation protection catalysts RGC-20, RGC-30E, RGC-30A, RGC-30B, RGC-1 Contact and react with the hydrofining catalyst RTC-2, the hydrofinishing reaction effluent enters the separation system for separation, and the separated liquid effluent enters the fractionation tower to cut naphtha fraction, diesel fraction and tail oil. The tail oil fraction enters the hydrocracking reactor as the raw material for hydrocracking and contacts with the hydrocracking catalyst RHC-131 for further hydroconver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com