Optical fiber Fabry-Perot temperature sensing head based on PDMS arc-shaped reflecting surface and preparation method of optical fiber Fabry-Perot temperature sensing head

A reflective surface, sensor head technology, applied to thermometers with physical/chemical changes, using optical devices to transmit sensing components, thermometers, etc., can solve the problem of increasing deformation, not too high temperature sensitivity, poor interference contrast, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

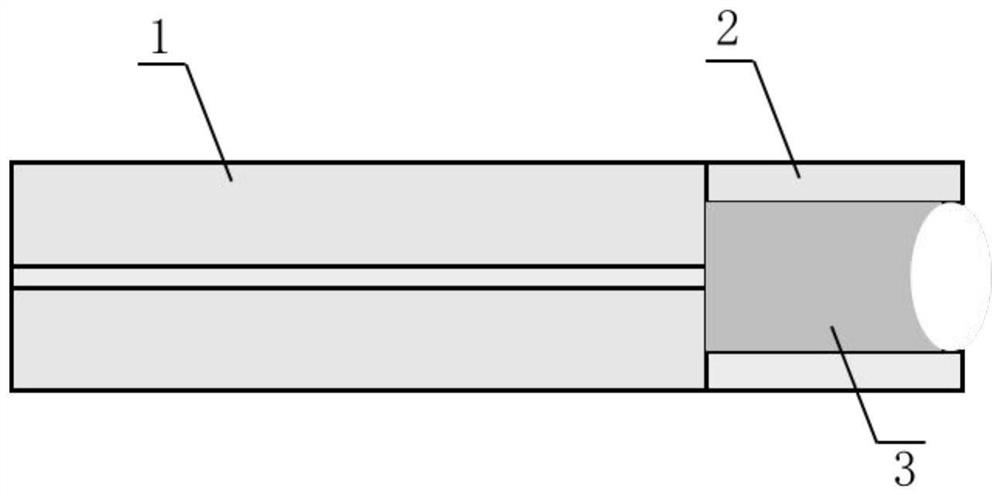

[0032] Such as figure 1As shown, it is a structural schematic diagram of a fiber-optic F-P temperature sensor head based on a PDMS arc reflective surface of the present invention. The structure of the sensing head is composed of single-mode optical fiber 1, microtube 2, and polymer PDMS 3. The sensing head 4 is mainly composed of a single-mode fiber 1, a microtube 2 and PDMS 3; a small section of microtube 2 is welded at the end of the single-mode fiber 1 to act as a container, and then the polymer is filled inside the microtube 2 by capillary phenomenon. The substance PDMS 3, and then using the preparation method proposed by the present invention, can form an arc-shaped reflective surface at the end of the PDMS solution. The polymer PDMS 3 filled in the microtube 2 constitutes the Fappel cavity of the sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com