A kind of processing method containing lysine solution

A treatment method, lysine technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low lysine yield, reduce production cost, increase yield, and save sulfuric acid The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

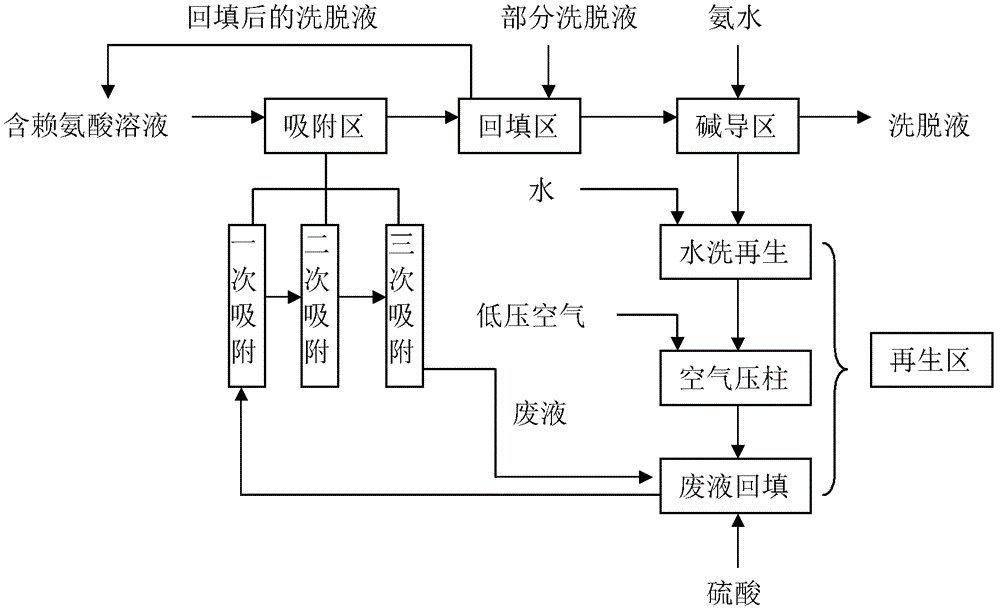

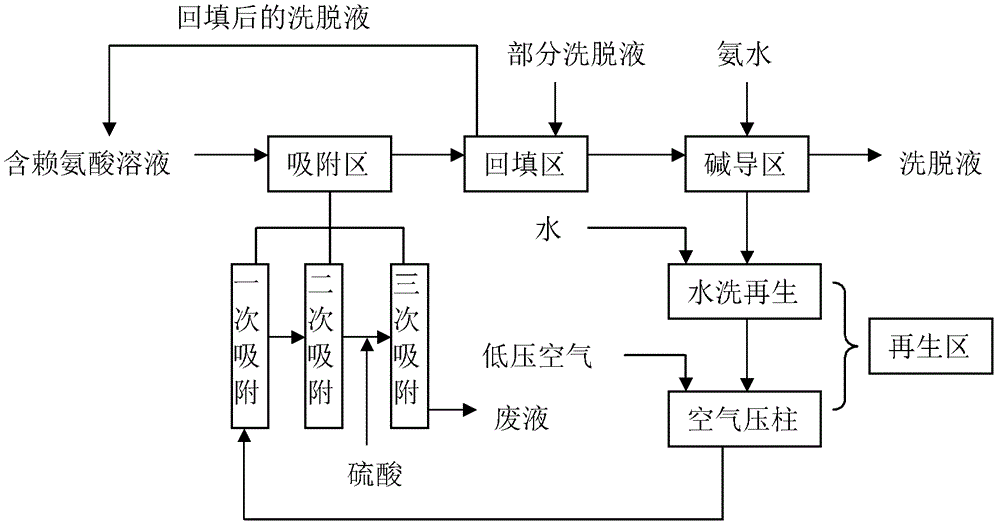

[0055] use figure 2 In the process shown, the lysine-containing solution is contacted with multiple groups of cation-exchange resin column groups for ion-exchange chromatographic separation, and each group of cation-exchange resin column groups sequentially and cyclically passes through the adsorption zone, backfill zone, alkali conduction zone and regeneration zone , so that the cation exchange resin column group sequentially and cyclically performs exchange adsorption, purification and re-adsorption, desorption and regeneration, and obtains an eluent after desorption, wherein,

[0056] Three sets of cation exchange resin columns connected in series are in the adsorption area at the same time, each set of cation exchange resin columns is composed of 4 parallel cation exchange resin columns, and the cation exchange resin in the cation exchange resin column is WD-2 type lysine Special strong acid type cation exchange resin, the total exchange capacity of the cation exchange re...

Embodiment 2

[0061] use figure 2 In the process shown, the lysine-containing solution is contacted with multiple groups of cation-exchange resin column groups for ion-exchange chromatographic separation, and each group of cation-exchange resin column groups sequentially and cyclically passes through the adsorption zone, backfill zone, alkali conduction zone and regeneration zone , so that the cation exchange resin column group sequentially and cyclically performs exchange adsorption, purification and re-adsorption, desorption and regeneration, and obtains an eluent after desorption, wherein,

[0062] Three sets of cation exchange resin columns connected in series are in the adsorption area at the same time, each set of cation exchange resin columns is composed of 3 parallel cation exchange resin columns, and the cation exchange resin in the cation exchange resin column is WD-2 type lysine Special strong acid type cation exchange resin, the total exchange capacity of the cation exchange re...

Embodiment 3

[0067] use figure 2 In the process shown, the lysine-containing solution is contacted with multiple groups of cation-exchange resin column groups for ion-exchange chromatographic separation, and each group of cation-exchange resin column groups sequentially and cyclically passes through the adsorption zone, backfill zone, alkali conduction zone and regeneration zone , so that the cation exchange resin column group sequentially and cyclically performs exchange adsorption, purification and re-adsorption, desorption and regeneration, and obtains an eluent after desorption, wherein,

[0068] Three sets of cation exchange resin columns connected in series are in the adsorption area at the same time, each set of cation exchange resin columns is composed of 6 parallel cation exchange resin columns, and the cation exchange resin in the cation exchange resin column is WD-2 type lysine Special strong acid type cation exchange resin, the total exchange capacity of the cation exchange re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com