Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "No slack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

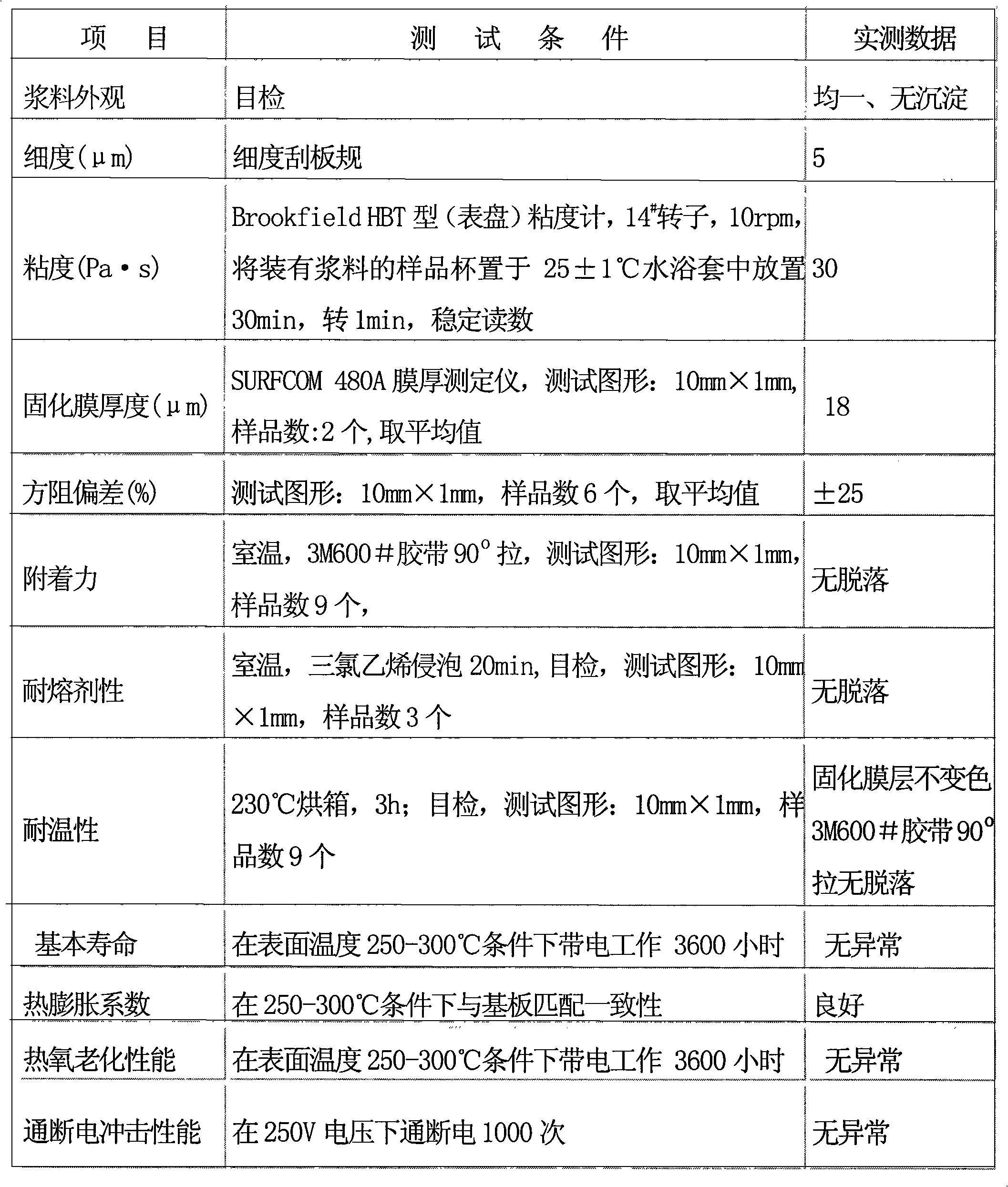

Electrothermal organic power resistance slurry for heater

InactiveCN101735561ALow temperature curingWith high temperature useHeating element materialsLow temperature curingUltra fine

The invention relates to an electrothermal organic power resistance slurry for a heater. The main formula of the slurry comprises the following components by weight percent: 28%-60% of resin I, 5%-13% of flame-retardant heat-resistant polymer containing boron element, 3%-6% of latent curing agent, 1%-2% of latent curing accelerator, 0-30% of resin II, 10%-15% of nano-carbon series conductive filler, 4%-5% of temperature coefficient adjustment additive, 0-5% of ultra-fine base metal alloy powder conductive filler, 0-3% of silicon series far infrared radiating material and 0-4% of ultra-fine mica powder, in addition to the main formula, the slurry further contains a small amount of function auxiliary phase. The slurry can solve the problems that the ordinary slurry is difficult to realize thinness, light weight or special shape; furthermore, the slurry has the properties of low temperature curing and high temperature use and can be directly used for printing or spraying and meet the technical development requirements of an electric heater on the trends of miniature, thinness, light weight and (shape and purpose) special shape.

Owner:西安宏星电子浆料科技股份有限公司

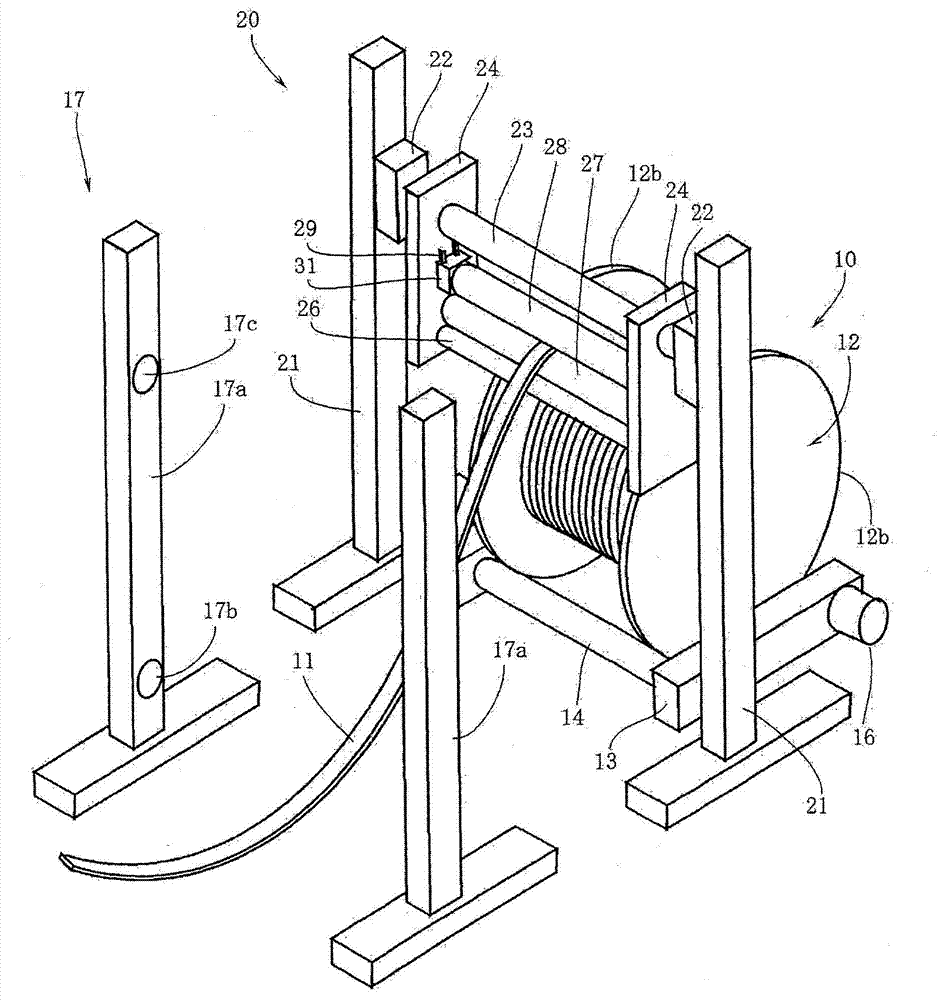

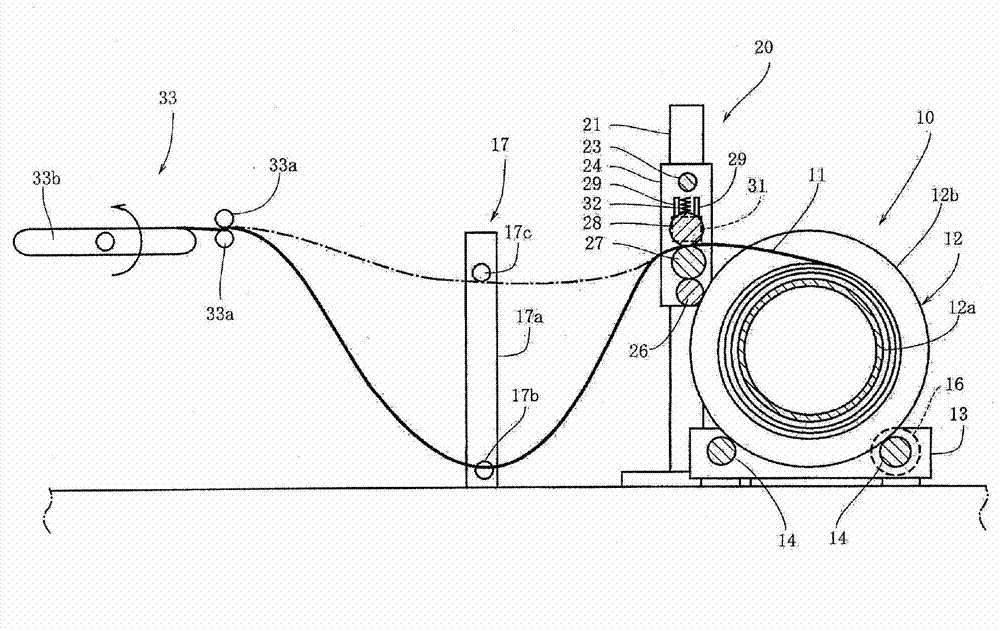

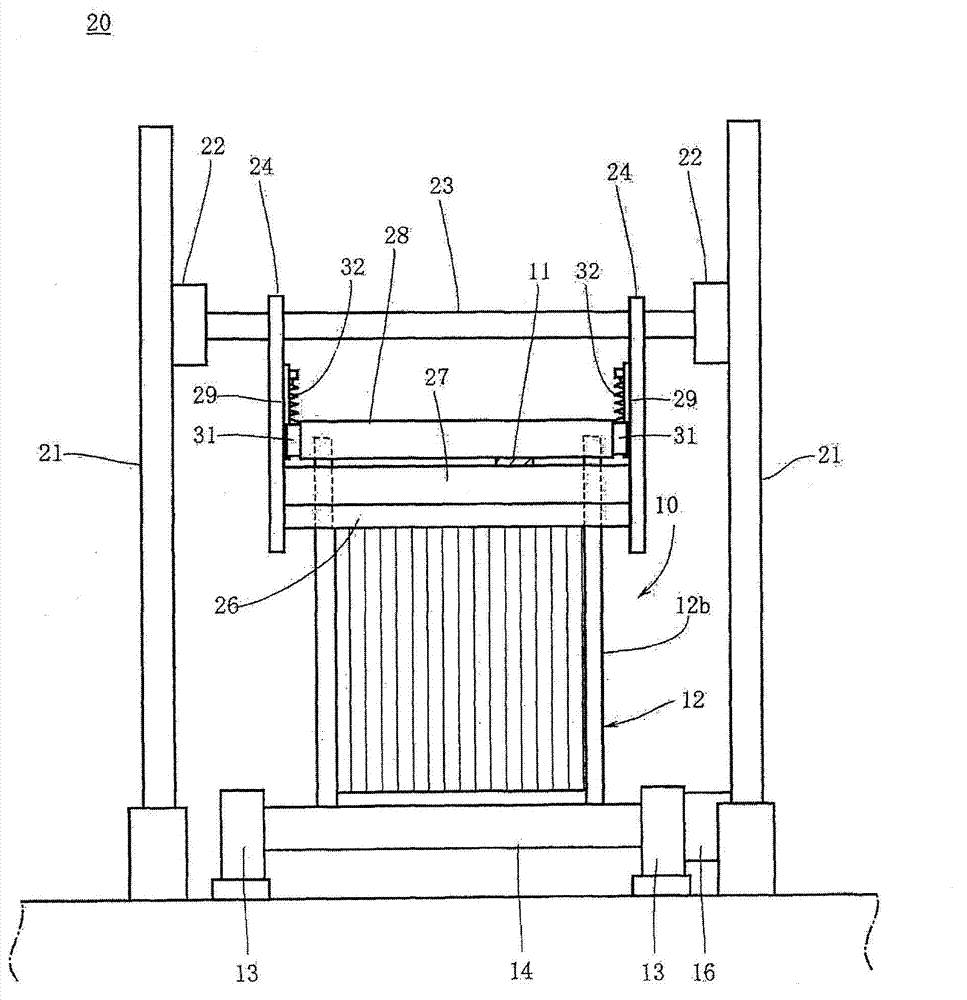

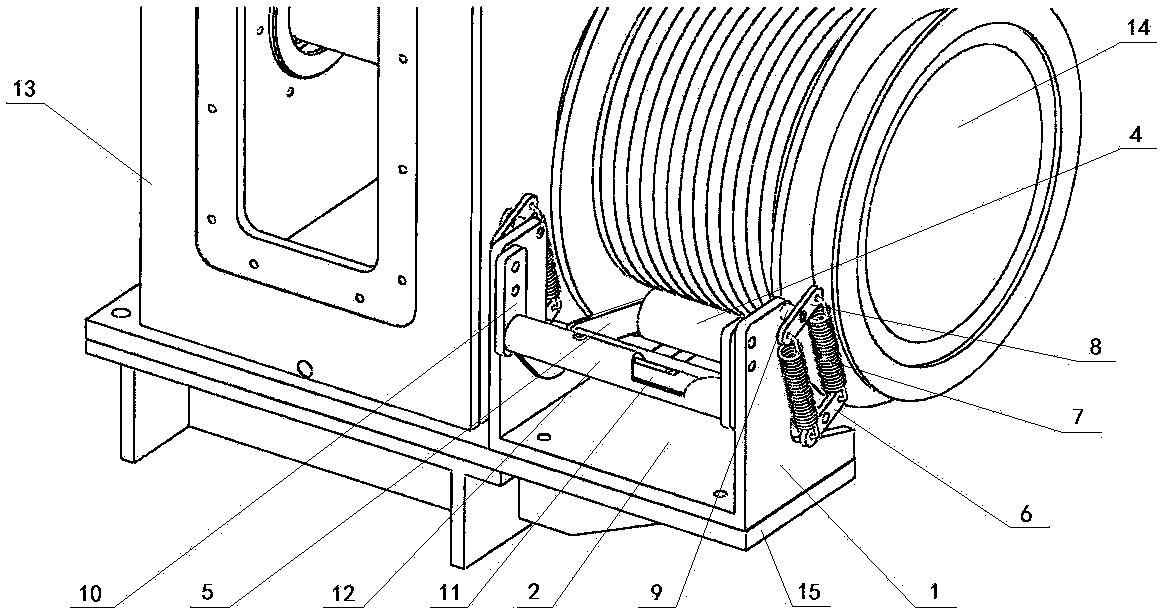

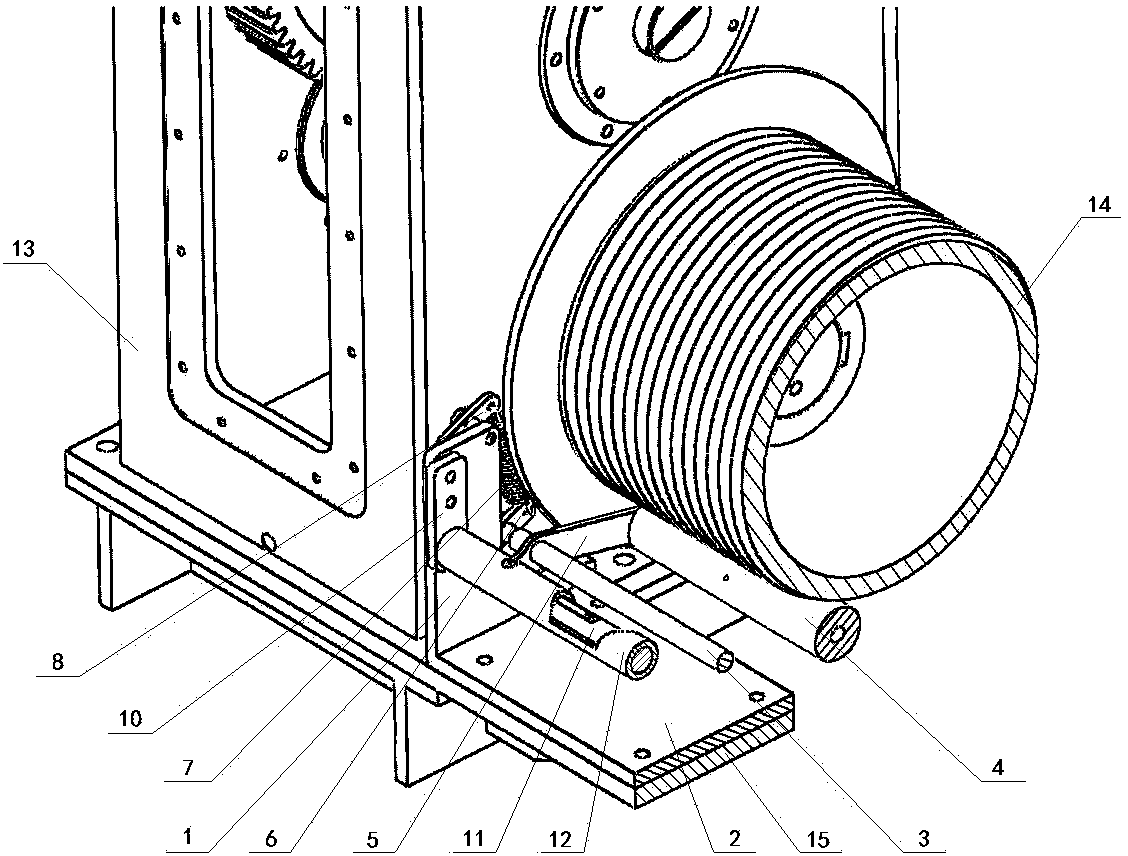

Slack preventing device for wire rod wound around spool, and slack preventing method therefore

ActiveCN103193106AAvoid slackNo slackFilament handlingInductances/transformers/magnets manufactureEngineeringMechanical engineering

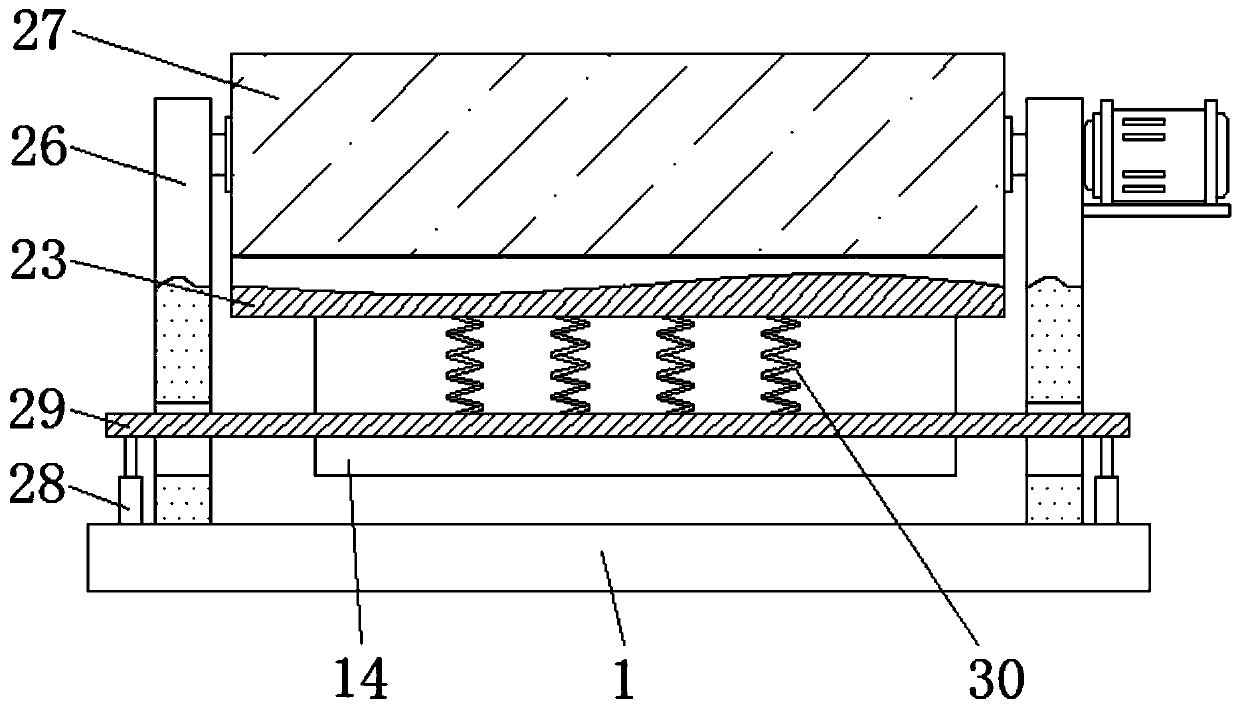

The invention prevents a slack of a wire rod in a spool by preventing the wire rod fed by rotation of the spool from returning to the spool. A wire rod slack preventing device (20) is installed parallel to a wire rod feeding machine (10) feeding a wire rod (11) by rotating a spool (12), around which the wire rod (11) is wound, and has a reverse rotation roller (26) having a rotating axis which is parallel to a rotating axis of the spool and rotating in a reverse direction to a rotating direction of the spool while being in contact with the spool, a forward rotation roller (27) having a rotating axis which is parallel to the rotating axis of the reverse rotation roller (26) and rotating in the same direction as the spool while being in contact with the reverse rotation roller (26), and a pinching roller (28) having a rotating axis which is parallel to the rotating axis of the forward rotation roller (27) and pinching the wire rod, which is fed out of the spool, together with the forward rotation roller (27). Further, a wire rod slack preventing method draws the wire rod which is fed out due to the rotation of the spool, while pinching the wire rod by the forward rotation roller (27), which rotates with the rotation of the spool, together with the pinching roller (28).

Owner:NITTOKU ENG CO LTD

Electrothermal organic electrode slurry for heater

ActiveCN101938859AMeet miniaturizationMeet thinnessHeating element materialsEpoxyLow temperature curing

The invention relates to an electrothermal organic electrode slurry for a heater. The slurry comprises the following main components in percentage by weight: 5-30% of epoxy modified high polymer, 2-6% of flame-retardant temperature-resistant high polymer, 3-6% of latent curing agent, 1-2% of latent curing promoter, 5-10% of silicon modified high polymer, 50-70% of superfine metal powder conductive filler, 1-3% of antioxidant assistant, 0-5% of base metal alloy powder conductive filler and a small amount of functional auxiliary phase. The invention solves the problem that the ordinary slurry is difficult to realize thin type, light type or special type, has the characteristics of low-temperature curing and high-temperature use, ensures direct printing or spraying and satisfies the technical development requirements of small type, thin type, light type (shape and application) and special type of the electric heater.

Owner:西安宏星电子浆料科技股份有限公司

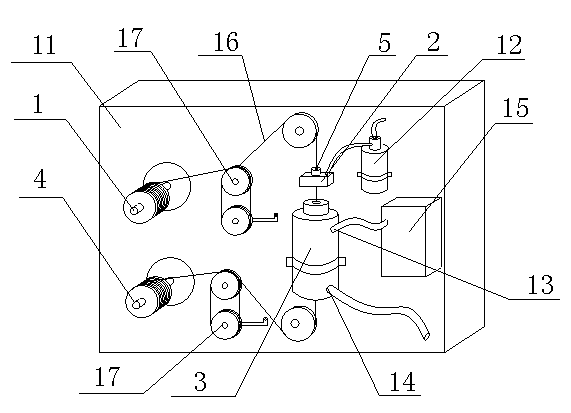

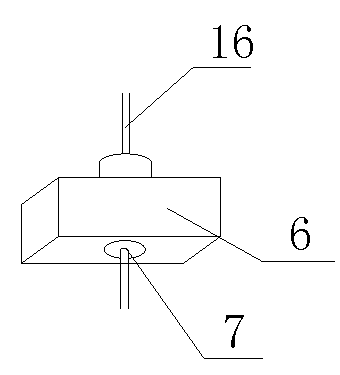

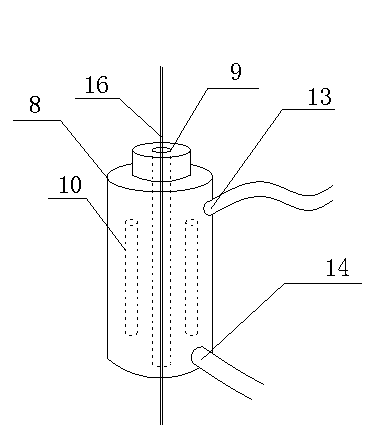

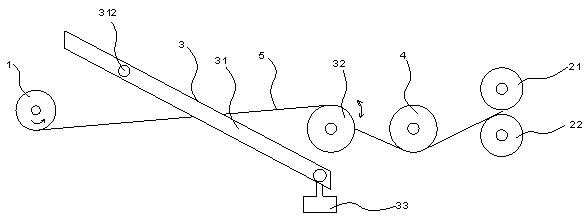

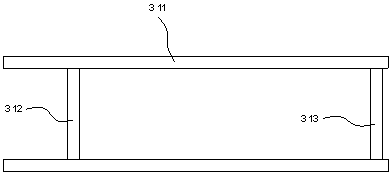

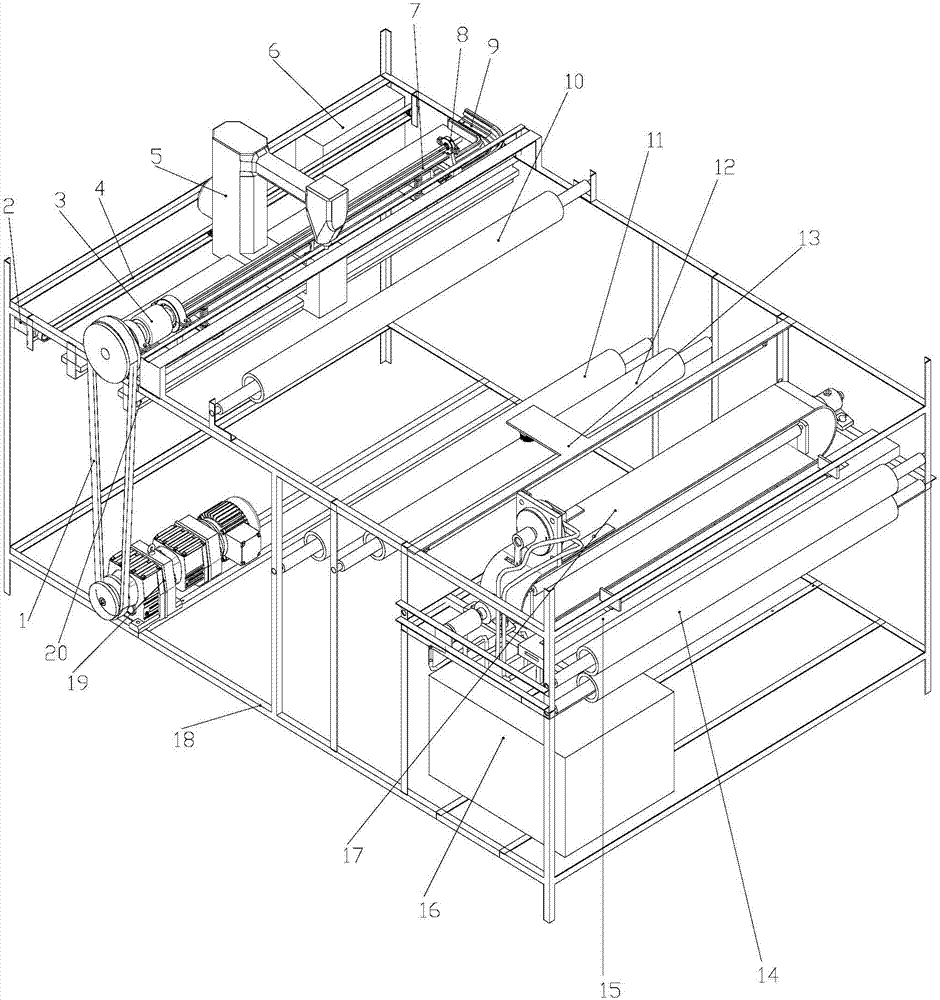

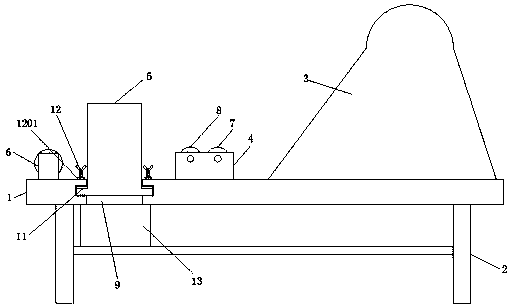

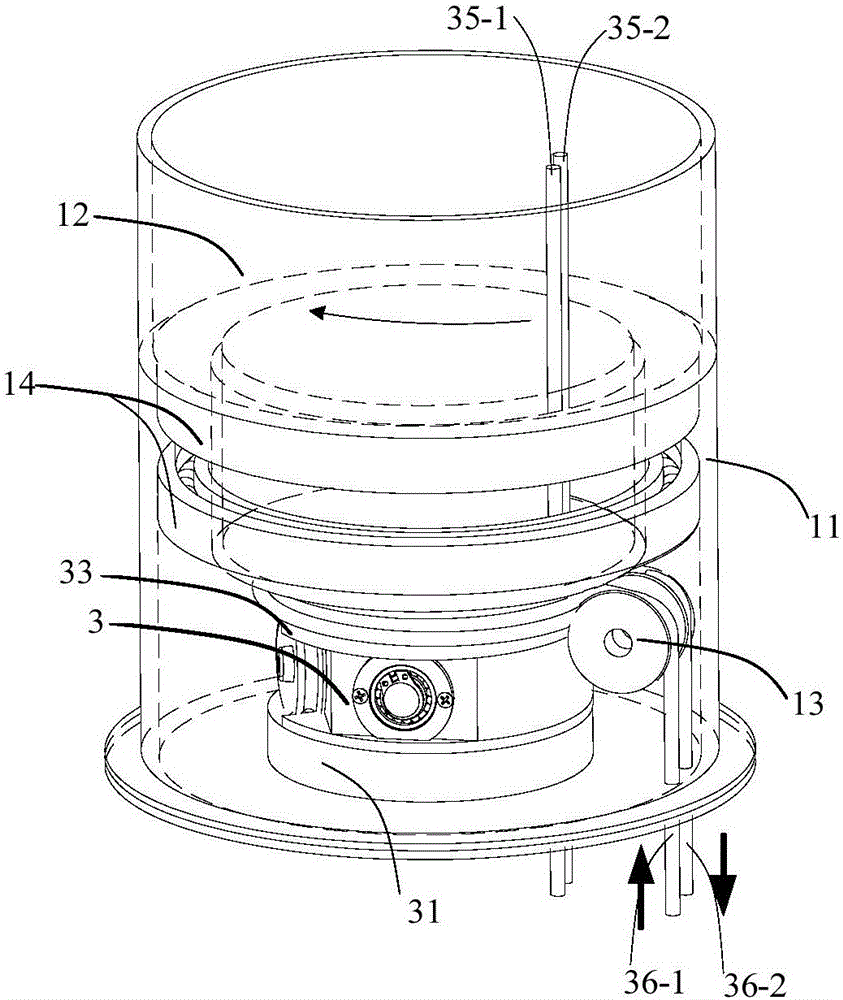

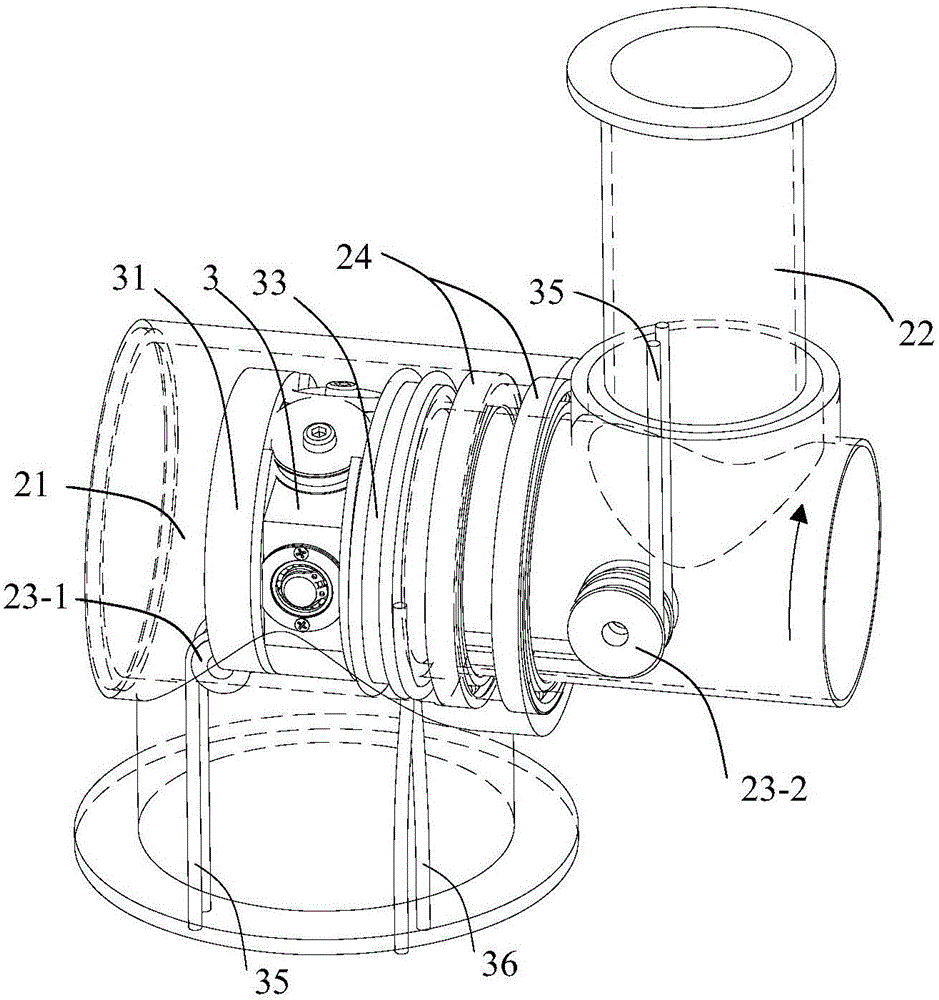

Uniform coloring machine of fibers

The invention discloses a uniform coloring machine of fibers. The machine comprises a base (11), and a pay-off reel (1), a coloring device (2), a curing furnace (3), a take-up reel (4) and a pigment pot (12) which are installed on the base (11), the pay-off reel (1), the coloring device (2), the curing furnace (3) and the take-up reel (4) are annularly assigned, a tension regulator (17) is arranged between the pay-off reel (1) and the coloring device (2), a tension regulator (17) is also arranged between the curing furnace (3) and the take-up reel (4), and the pay-off reel (1) and the take-up reel (4) are respectively installed on the base (11) through a motor. The machine which allows the tension regulator to be arranged in each of a pay-off position and a take-up position has the advantages of guarantee of the tension in fiber transmission, no fiber relax phenomenon, avoiding of the non-uniform dyeing phenomenon, and improvement of the fiber dying quality.

Owner:成都亨通光通信有限公司

Preparation method for sedative and dormitive silk quilt

The invention relates to a preparation method for a sedative and dormitive silk quilt. The preparation method comprises the following steps of soaking silk floss by using sedative and dormitive treating agents for 30-55 minutes under the conditions that the temperature is 50-60 DEG C and the bath ratio is 1:8-10; spin-drying the silk floss; drying the silk floss; and making a quilt to obtain the sedative and dormitive silk quilt. Pharmacologically, the microcapsule treating agents have effects of soothing the nerves, treating insomnia, promoting blood circulation, killing ants, mosquitoes, cockroaches and mites, restraining diseases such as hypertension, allergic rhinitis and asthma and improving appetite.

Owner:DONGHUA UNIV +1

Clamping and feeding system used for synchronous transmission of flexible membranes and application thereof

ActiveCN102674056ASynchronous Feed GuaranteeGuaranteed normal feedingWebs handlingCyclic processEngineering

The invention discloses a clamping and feeding system used for the synchronous transmission of flexible membranes, and the system comprises multiple clamping and feeding devices successively arranged at intervals along the feeding direction, wherein each clamping and feeding device comprises a movable clamping and feeding assembly and a stationary clamping and feeding assembly; the flexible membranes can be alternately clamped by each movable clamping and feeding assembly and the stationary clamping and feeding assembly; when the movable clamping and feeding assembly clamps, the movable clamping and feeding assembly moves along the feeding direction; and when the stationary clamping and feeding assembly clamps, the movable clamping and feeding assembly returns the circulating process of an initial clamping position to realize a purpose of feeding and transmitting the flexible membranes. The invention discloses a method which utilizes the system to synchronously transmit the flexible membranes. In the transmission process of the flexible film, the flexible film is always clamped by the clamping and feeding assembly. Meanwhile, the flexible membranes are returned and fed intermittently by the alternate switch of clamping or loosening. In addition, the feeding and driving assembly simultaneously moves to guarantee that the flexible membranes can be simultaneously fed on a plurality of positions.

Owner:HUAZHONG UNIV OF SCI & TECH

Mixed knitting loom

InactiveCN110284246APrevent adhesionEasy to useMechanical cleaningPressure cleaningEngineeringWaste material

The invention provides a mixed knitting loom. The mixed knitting loom comprises a base, a squeezing spring, a winding frame and a hydraulic telescopic rod, wherein a mounting bracket is fixedly welded to the front and rear ends of the upper surface of the base, the left side of a flattening plate is provided with an edge cutting device, the lower end of a reset spring is connected with a fixing block, the winding frame is fixedly welded to the upper surface of the base at the left side of the mounting frame, and the hydraulic telescopic rod is located at the upper surface of the base at the outer side of the winding frame. The mixed knitting loom has the advantages that raw edge waste materials can be effectively cleaned away, which reduces the later workload of the staff; the phenomenon that a woven fabric wrinkles in the winding process can be effectively avoided, which ensures the flatness of the woven fabric and facilitates the later sale; the phenomenon that the fabric loosens in the winding process can be effectively avoided, which facilitates the later storage and transportation.

Owner:CHANGLE LIZHI IND DESIGN CO LTD

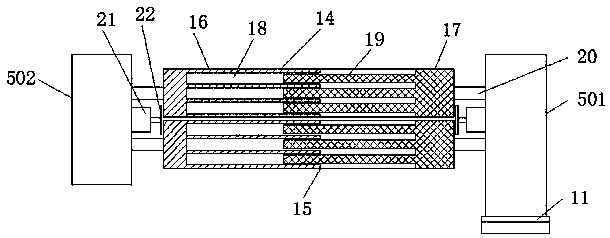

Supersonic deformeter

The invention is a kind of ultrasonic deformeter, which is mainly made up of emission piezo-electric, sound insulating material, metal shell, transmitting end power outgoing line, receiving end power outgoing line. It has merits of high accuracy, low cost, no electromagnetism interference, no loose, adjustable strain absolute magnitude, small size. It especially is suitable for long time strain measurement and the rheopectic measurement of construction structure safe monitoring, hill arpon.

Owner:WUHAN UNIV OF TECH

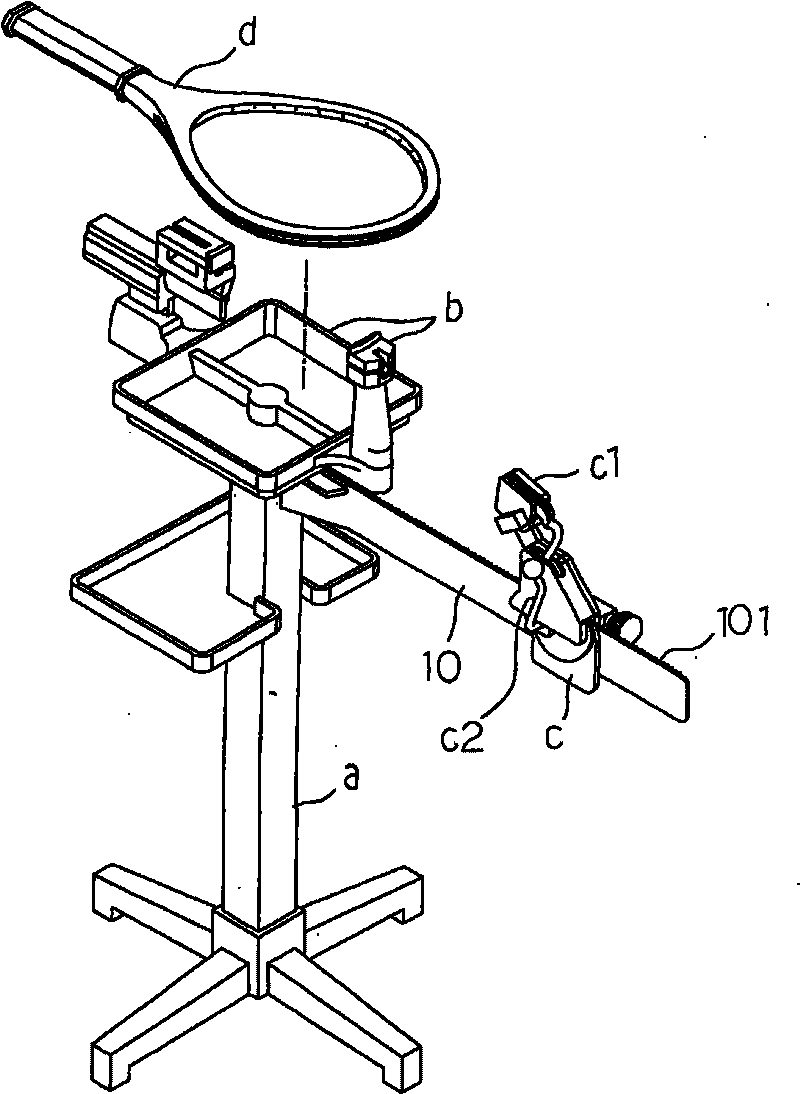

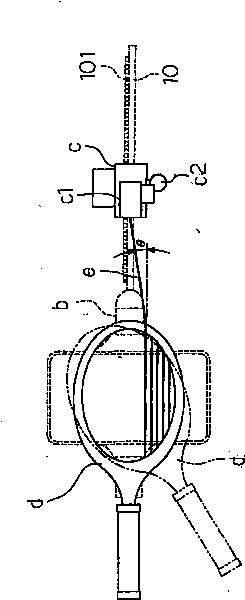

Improved racket threader

The invention discloses an improved racket threader. The improved part of the racket threader comprises a horizontal position regulation apparatus and a brake apparatus of the threader, wherein, the horizontal position regulation apparatus is fixedly connected with a base of the racket threader by utilizing a horizontal consolidated seat which is provided with a horizontal sliding rail and a basal rod capable of displacing, one end of the basal rod is pivoted on the sliding rail, a threader head arranged on the basal rod regulates the left and right horizontal positions along with the displacement of the basal rod, thus being capable of managing the threading work when the horizontal angle of a racket frame changes, the racket frame and the threader of the threader head are regulated to thread into a line, thus not wearing or damaging a basket to lead to accurate threading tension and enhancing quality and service life of threads. The brake apparatus and a clamping device are grouped on a rotary shaft in the base below a holding frame by utilizing a disk brake, and are respectively connected with two leads to a hand control switch and a foot control switch; when operators want to suspend in midway or leave, the effect of controlling the threader to suspend rotation can be conveniently achieved by a hand operation manner or a foot operation manner.

Owner:林伯修 +1

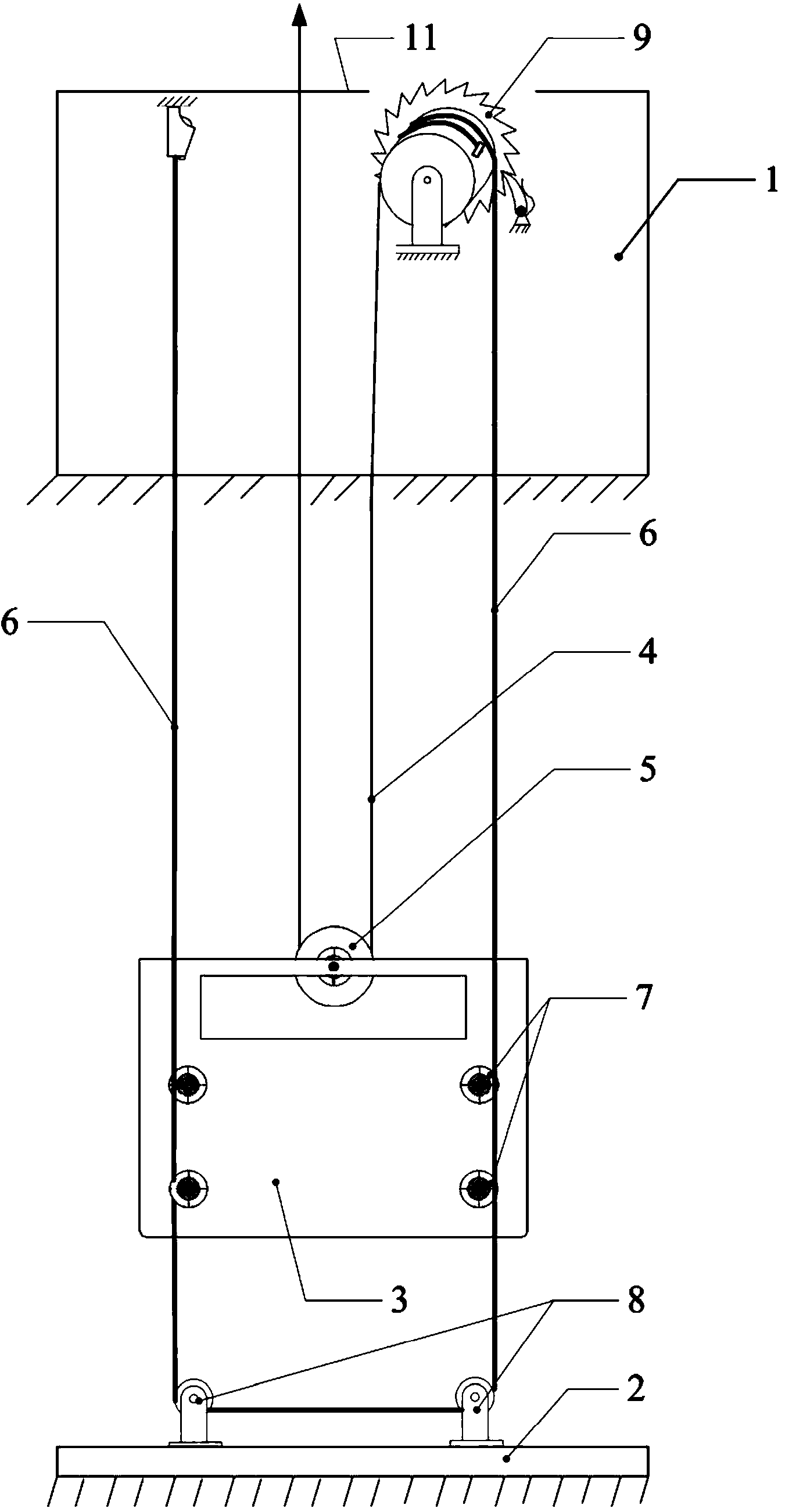

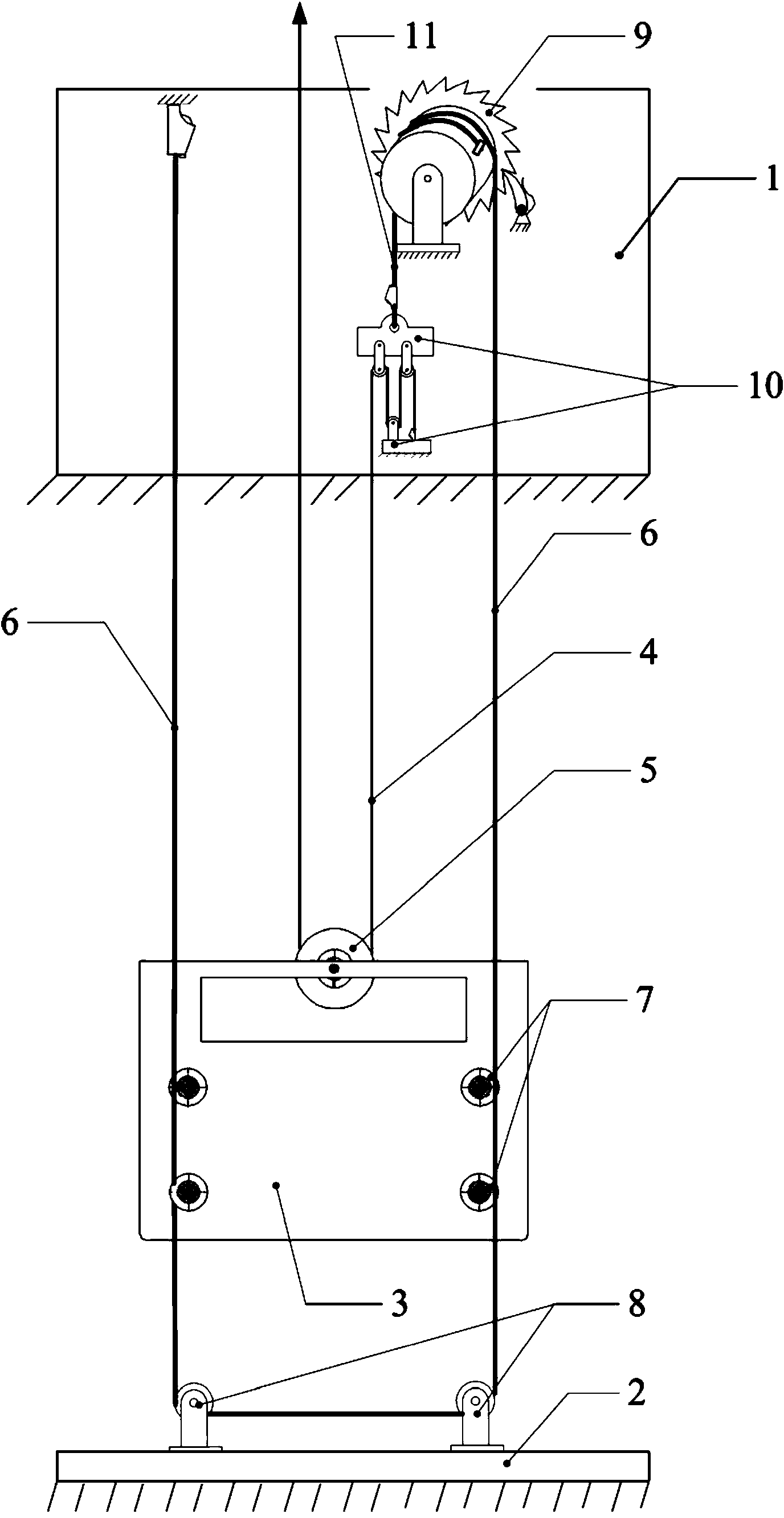

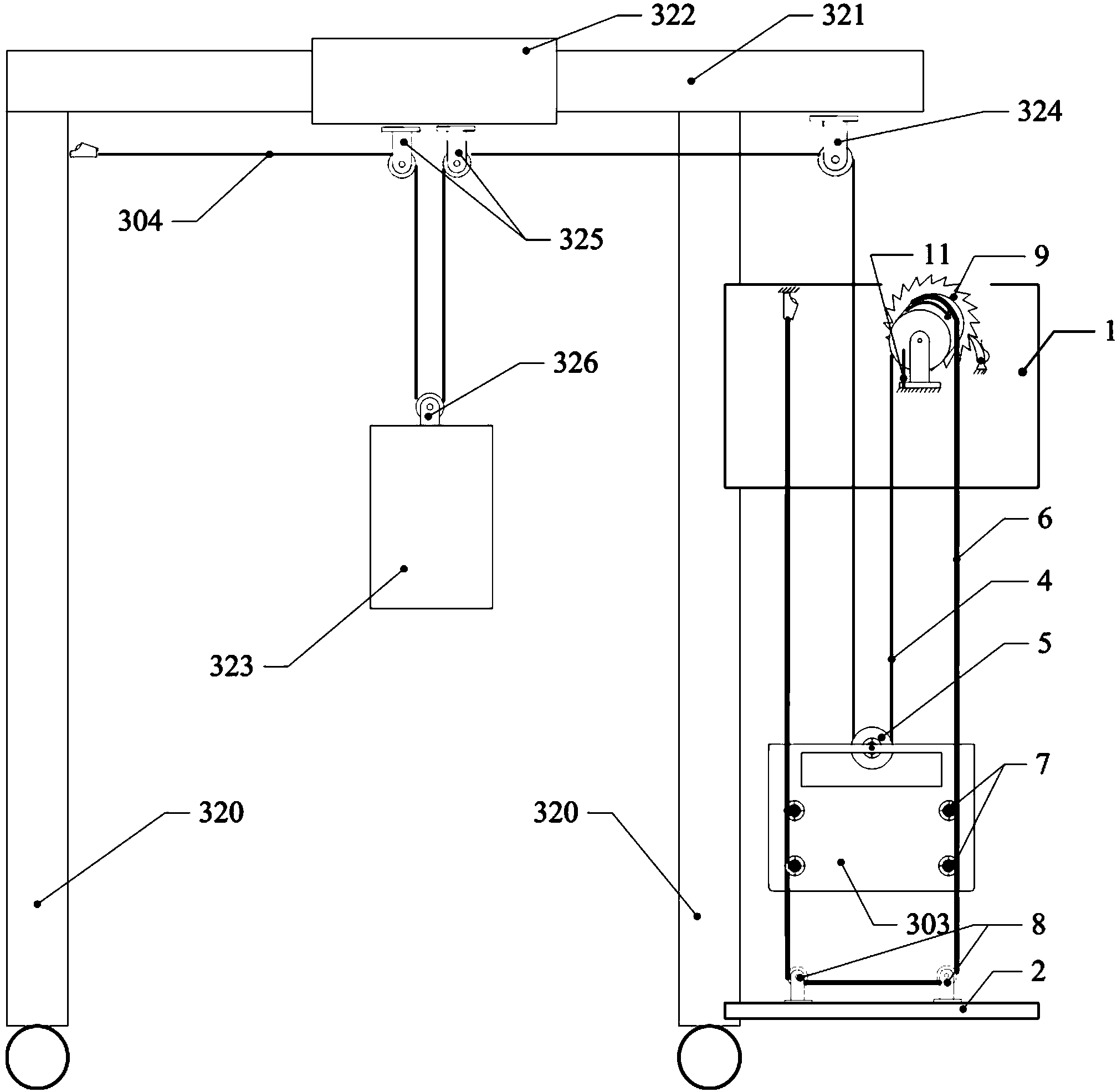

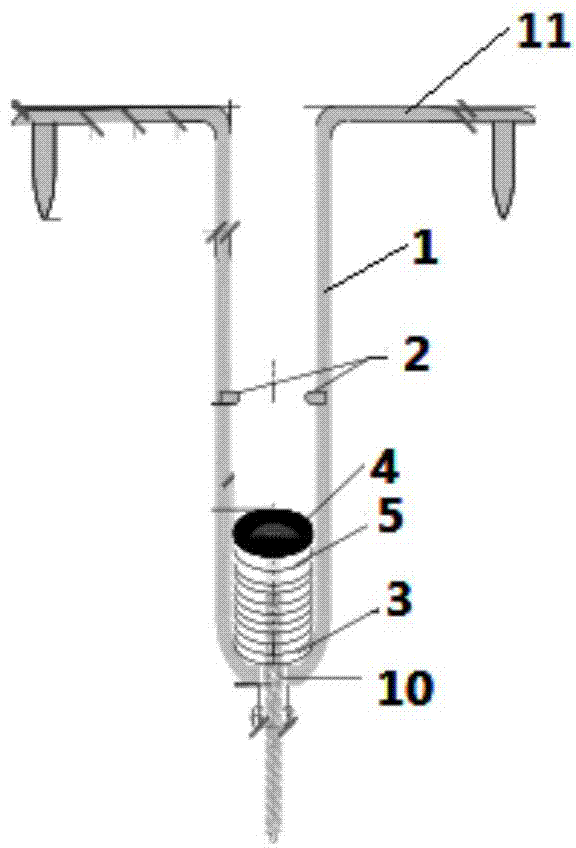

Entire flexible guide rail based on pulling force tension of lifting body and realization method thereof

InactiveCN103950808ARealize the rail function of counterweightSolve the flatnessElevatorsPull forceIndustrial engineering

The invention discloses an entire flexible guide rail based on the pulling force tension of a lifting body and a realization method thereof. The entire flexible guide rail comprises an entire guide rail steel wire rope; the entire guide rail steel wire rope forms flexible guide rails distributed in the lifting direction of the lifting body on the two sides of the lifting body through steering mechanisms; one end of the entire guide rail steel wire rope is fixed, the other end of the entire guide rail steel wire rope is pulled by the pulling force of the lifting body, and the entire guide rail steel wire rope is synchronously tensioned by the pulling force of the lifting body in the lifting process of the lifting body, so that the tensioning forces of the flexible guide rails on the two sides of the lifting body are the same. With the adoption of the technical scheme, the entire flexible guide rail can effectively solve the problem existing in an existing lifting body guide rail.

Owner:上海港研实业有限公司

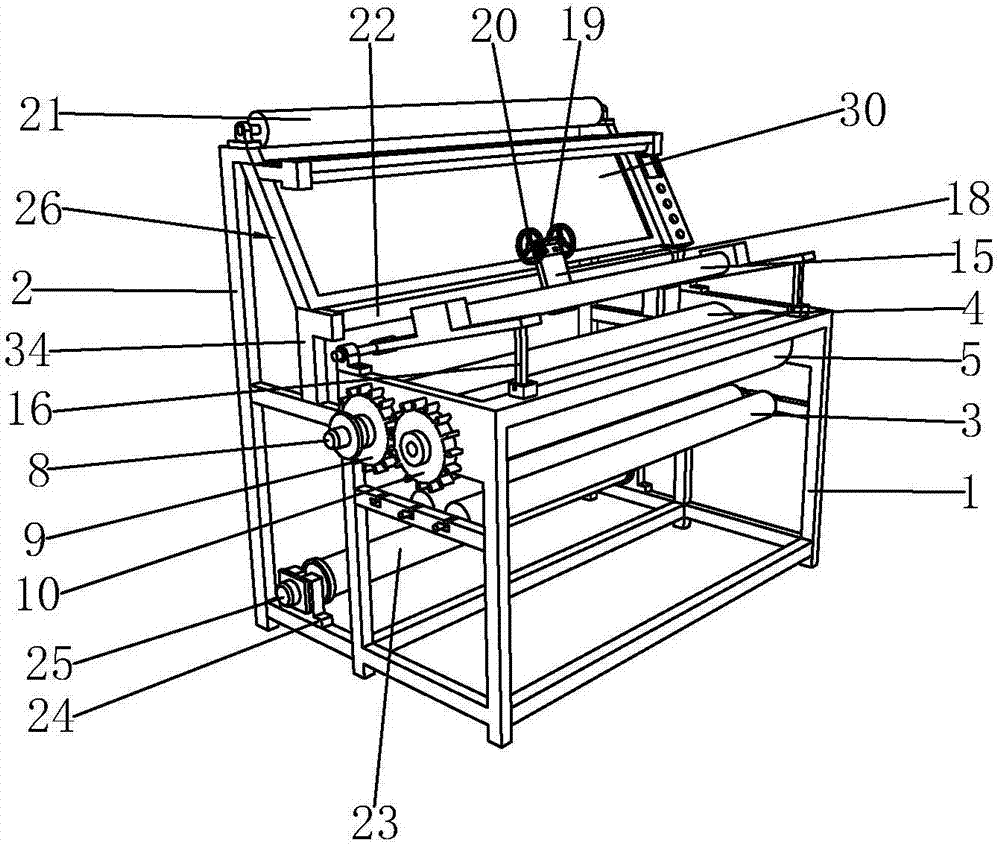

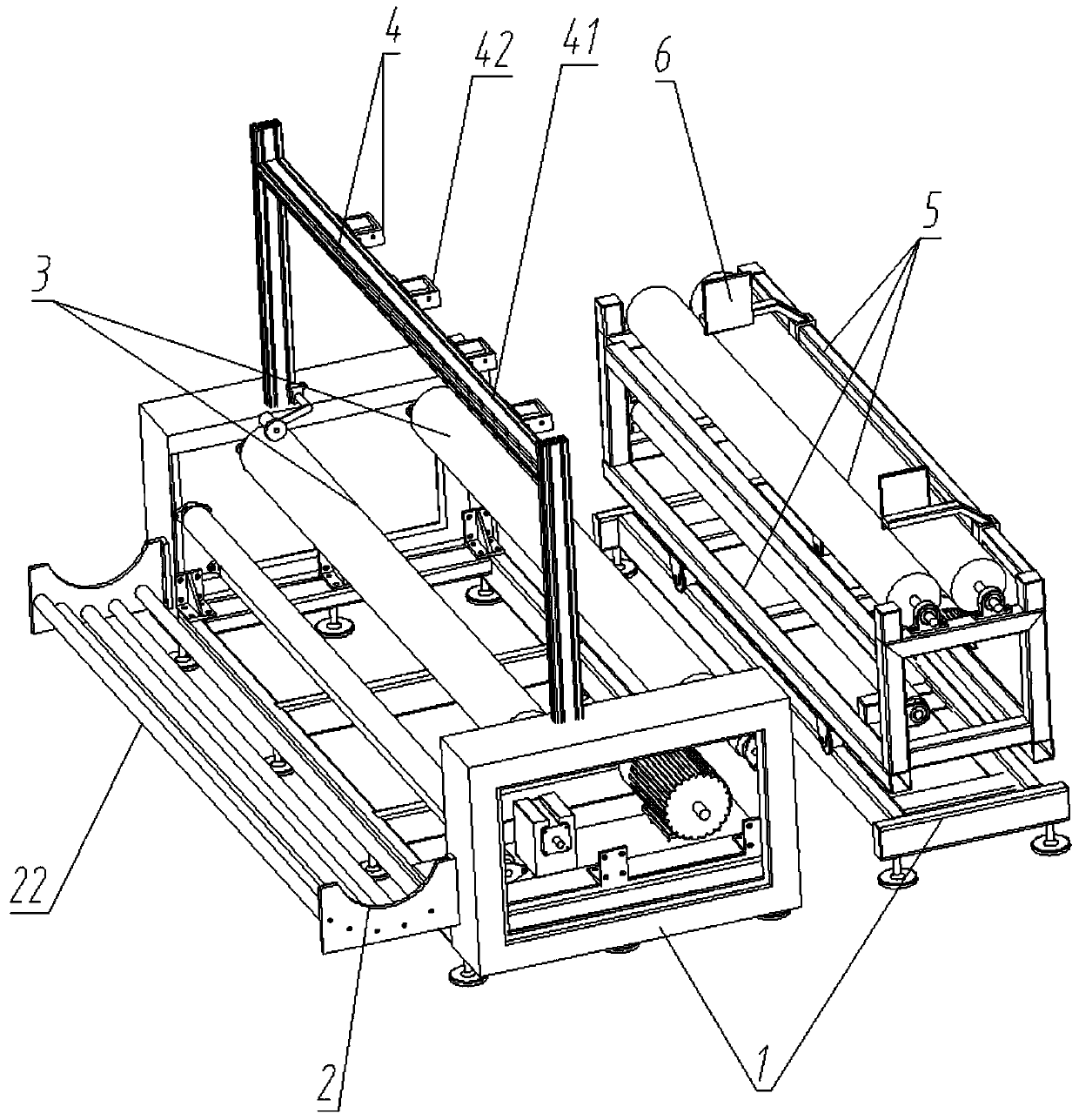

Cloth inspecting machine for textile cloth

InactiveCN106958133AImprove stabilityPracticalInspecting textilesWebs handlingPulp and paper industryTextile

The invention discloses a cloth inspecting machine for textile fabrics, which comprises a frame and a support frame. The frame is respectively provided with a cloth releasing roller, a main pressing roller and a secondary pressing roller, the main pressing roller is connected with the secondary pressing roller, and the frame The cloth guide roller and the fixed base are respectively arranged on the top of the cloth guide roller, and the swing plate is arranged on the cloth guide roller, and the tension roller is movably connected between the swing plates, and the tension roller is located above the main pressure roller and the secondary pressure roller. Connected with a support rod, the bottom of the swing plate is evenly distributed with card slots, the card slots are connected to the support rod, a mounting plate is provided on the fabric guide roller, a coder is provided on the mounting plate, and step wheels are connected to both sides of the coder , There are cloth guide rollers, cloth passing rollers and cloth receiving rollers respectively between the supporting frames. The invention is compact in structure, flexible in connection, integrates cloth inspection, cloth rolling, and code counting, has wide applicability, strong practicability, and convenient adjustment. By adjusting the tension of winding cloth, it can meet the requirements of different materials, and improve the cloth's efficiency. flatness and quality.

Owner:嵊州市靖洁纺织机械有限公司

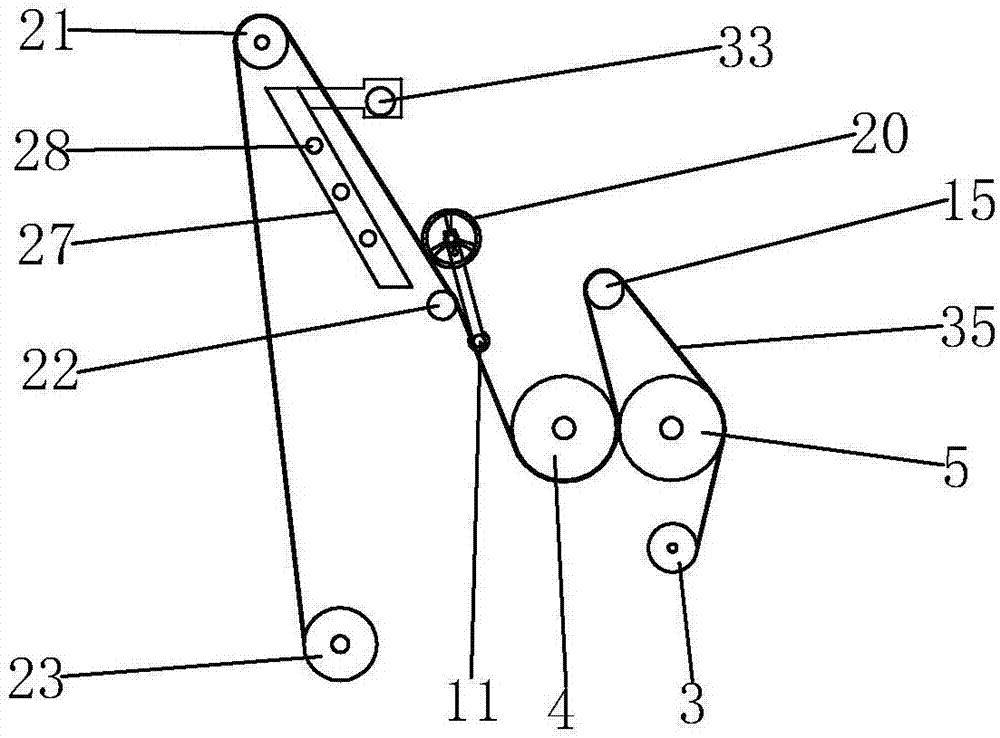

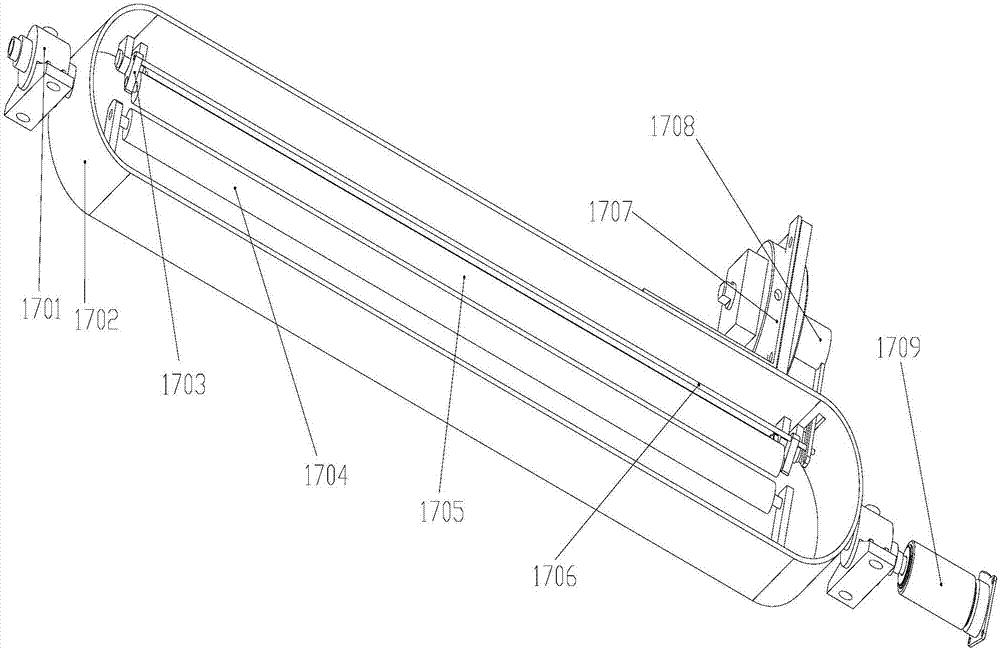

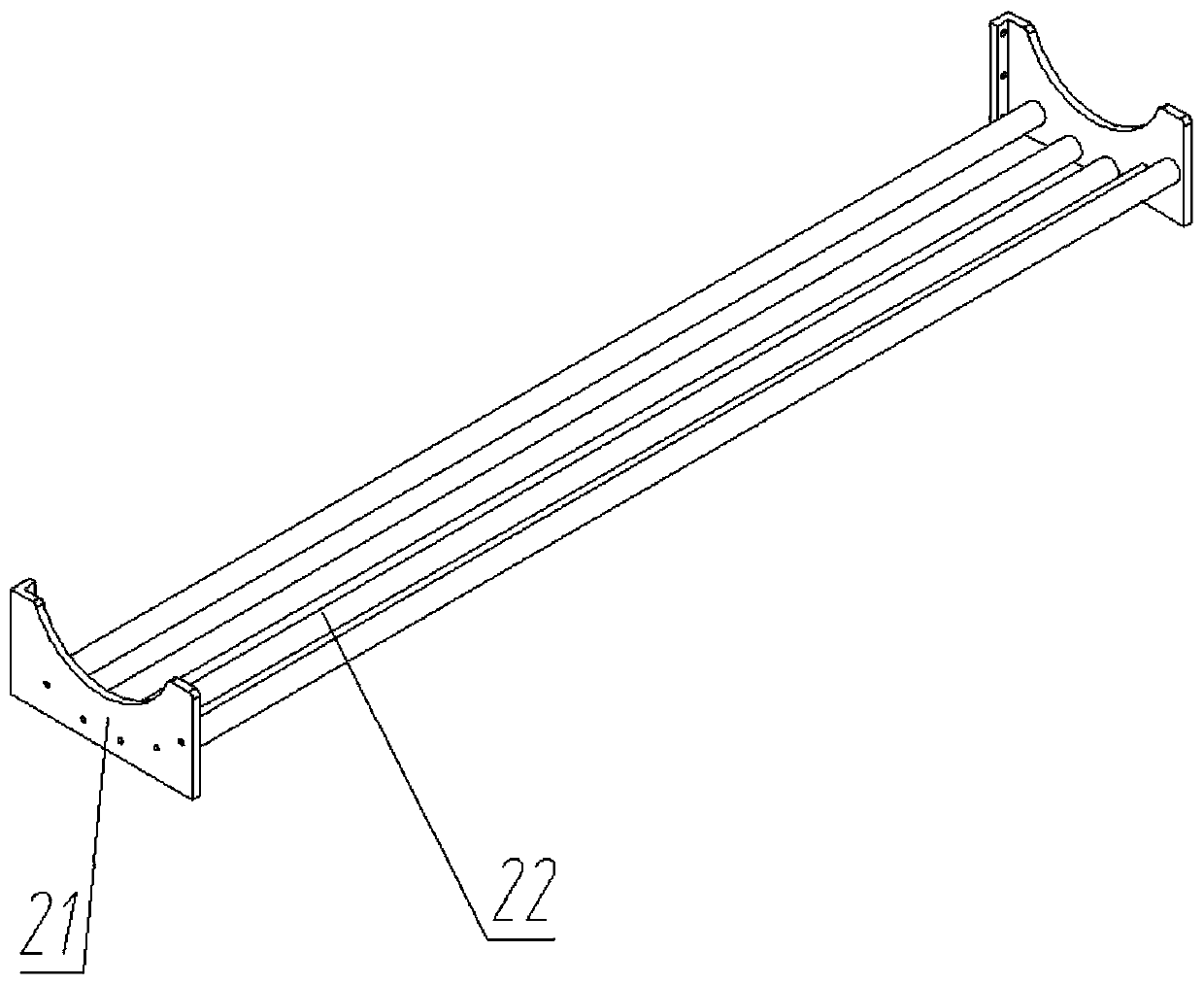

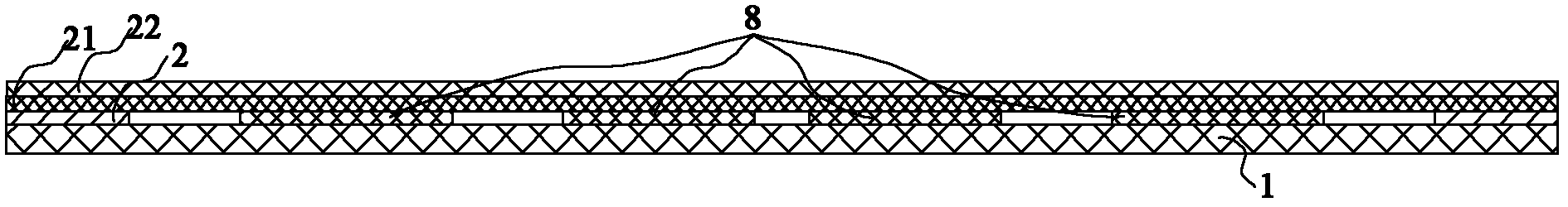

Wood veneer coiling automatic tensioning device

InactiveCN104229515ADecrease the tilt angleLittle change in tensionWebs handlingWood veneerEngineering

The invention relates to a wood veneer coiling automatic tensioning device, which provides the wood veneer coiling automatic tensioning device with the advantages that the structure is simple, and the work efficiency and the coiling reliability are improved. The wood veneer coiling automatic tensioning device comprises a coiling roller and an extruding roller group, wherein the extruding roller group is positioned in front of the coiling roller, and comprises an upper extruding roller and a lower extruding roller, a position between the upper extruding roller and the lower extruding roller is used for extruding wood veneer, the automatic tensioning device is connected between the coiling roller and the extruding roller group, and comprises a support frame, a guide roller and a balance weight block, the support frame comprises a pair of vertical plates, a tensioning roller and a rotating shaft, the tensioning roller and the rotating shaft are respectively connected between the pair of vertical plates, and are respectively positioned at the two ends of the support frame, the tensioning roller is positioned above the rotating shaft and faces the coiling roller, the guide roller is movably arranged above the rotating shaft, and the balance weight block is connected onto the rotating shaft. The wood veneer coiling automatic tensioning device has the advantages that the operation is simple and convenient, and the work is reliable.

Owner:德清县传琪装饰材料有限公司

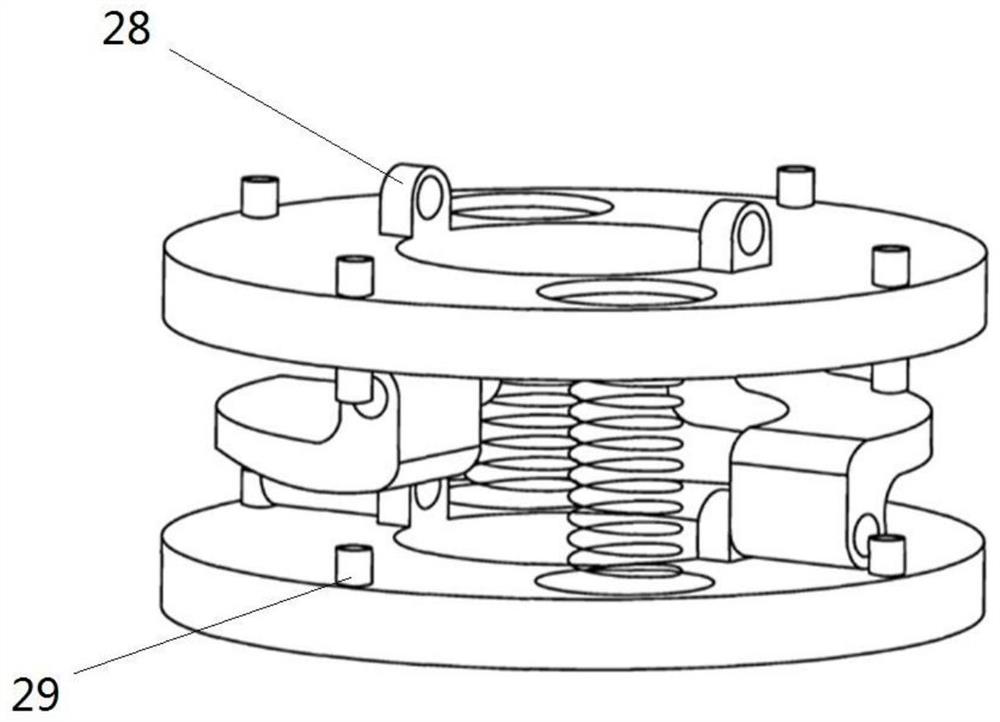

Mechanical fixing gasket

ActiveCN104763107ANo slackNo tear damageRoof covering using flexible materialsEngineeringSteel plates

The invention discloses a mechanical fixing gasket. The mechanical fixing gasket comprises a sleeve cylinder, wherein the head part of the sleeve cylinder is provided with a sleeve cylinder opening; a spring and a cushion ring are arranged at the inner part of the sleeve cylinder, and the spring and the cushion ring are orderly arranged upwards from the sleeve cylinder opening; at last, the cushion ring is blocked by a salient retaining block arranged on the inner wall of the sleeve cylinder. The mechanical fixing gasket is used for making a metal screw cross through the sleeve cylinder opening so as to fix coiled materials on a pressing type steel plate or a concrete base layer when the coiled materials are in use; and then the spring, the retaining block and the fixing cushion ring are installed so as to fix the metal screw. Through the structural improvement, the coiled material fixing gasket can prevent surface fixing force from loosening, and the coiled materials from rupture and breakage of a nail rod.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF ENG

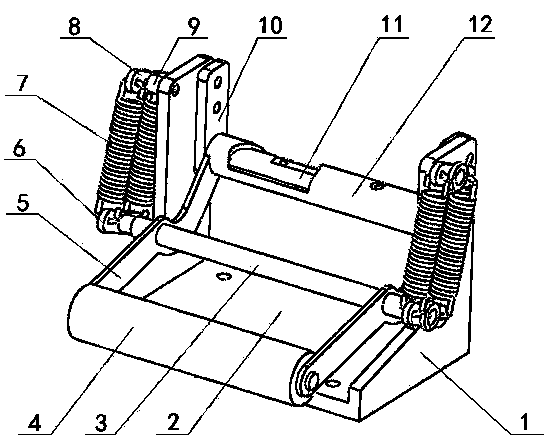

Steel wire rope locking device for winch

InactiveCN103359646AThere will be no short-distance fall phenomenonAvoid damageWinding mechanismsEngineeringWinch

The invention relates to a steel wire rope locking device for a winch. The steel wire rope locking device is characterized by comprising a support; the support comprises a rectangular baseplate; two L-shaped support plates are arranged on the two relative edges of the baseplate; vertical plate faces of the support plates are parallel and are arranged relatively, and transverse lower edges of the support plates are integrally connected with the baseplate; a rotating shaft is arranged between the vertical parts, far away from the transverse parts, of the two support plates; the two ends of the rotating shaft is movably matched with the corresponding support plates; two support arms are arranged on the baseplate, the same ends of the two support arms are respectively connected to the two ends of the rotating shaft; a middle shaft is arranged between the two support arms; a pressure roller is arranged between the outer ends of the two support arms; springs are connected between the two ends of the middle shaft and the upper parts of the corresponding support plates of the middle shaft; the two ends of a roll shaft of the pressure roller are rotatably matched with the outer ends of the corresponding support plates of the roll shaft. By adopting the device, a steel wire rope of the winch can be effectively compressed to prevent loose, thus avoiding damage to the winch or the rope due to instant falling off of a load.

Owner:WUXI HAIHE EQUIP TECH CO LTD

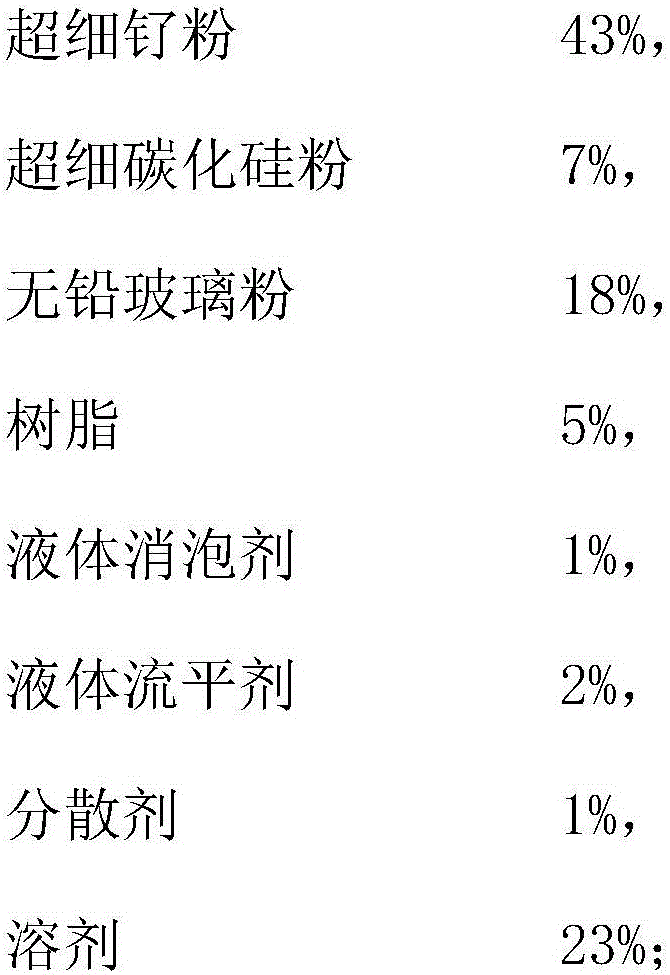

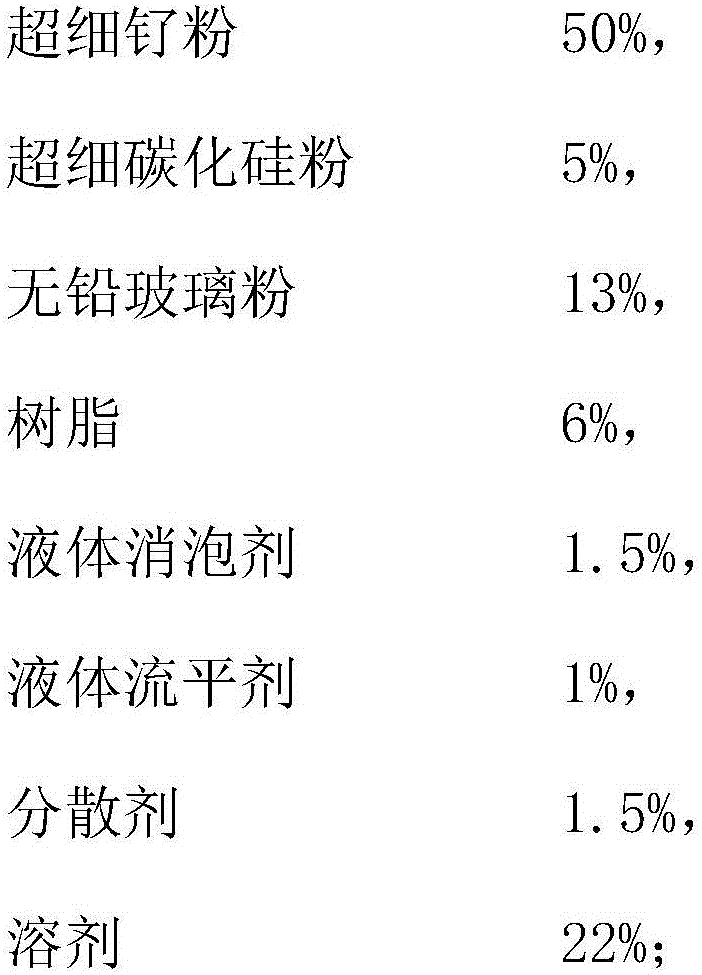

Silicon carbide-ruthenium resistance slurry and preparation method therefor

InactiveCN106211379AIncreased Design FreedomWide coefficient of power variationHeating element materialsDispersityRuthenium

The invention discloses silicon carbide-ruthenium resistance slurry. The silicon carbide-ruthenium resistance slurry comprises a functional phase and an organic carrier, wherein the functional phase comprises ultrafine ruthenium powder, ultrafine silicon carbide powder and lead-free glass powder; the organic carrier comprises resin, a solvent and additives; the resin is ethylcellulose; the solvent is one or mixture of two of butyl carbitol, terpilenol and a DBE solvent; and the additives comprise a liquid defoaming agent, a liquid flatting agent and a lubricating dispersing agent. The invention also discloses a preparation method for the silicon carbide-ruthenium resistance slurry. The silicon carbide-ruthenium resistance slurry is high in dispersity and cosolvency, high in adhesive force with a base material, excellent in temperature resistance, safe to use, and low in preparation cost.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

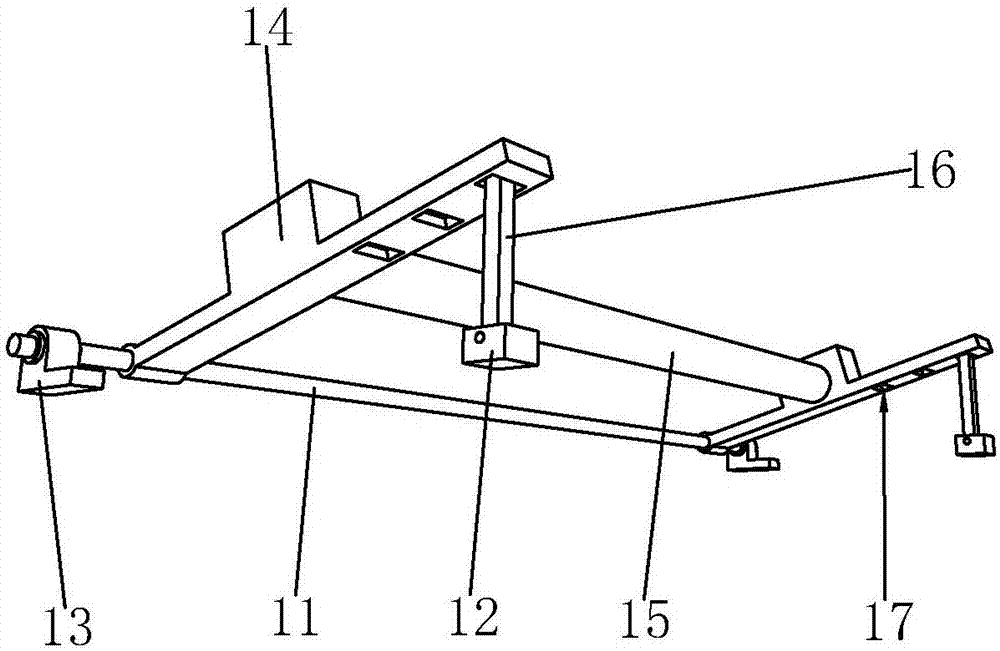

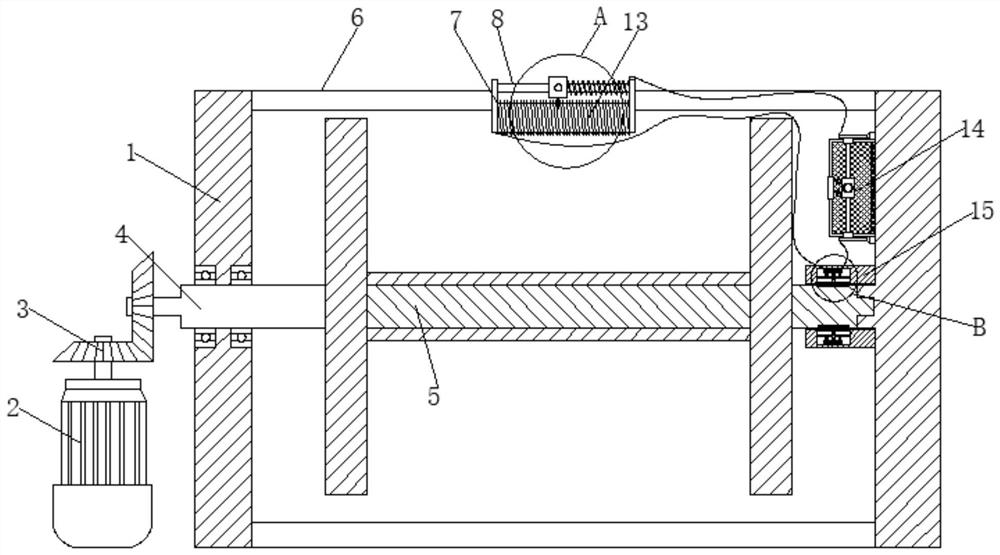

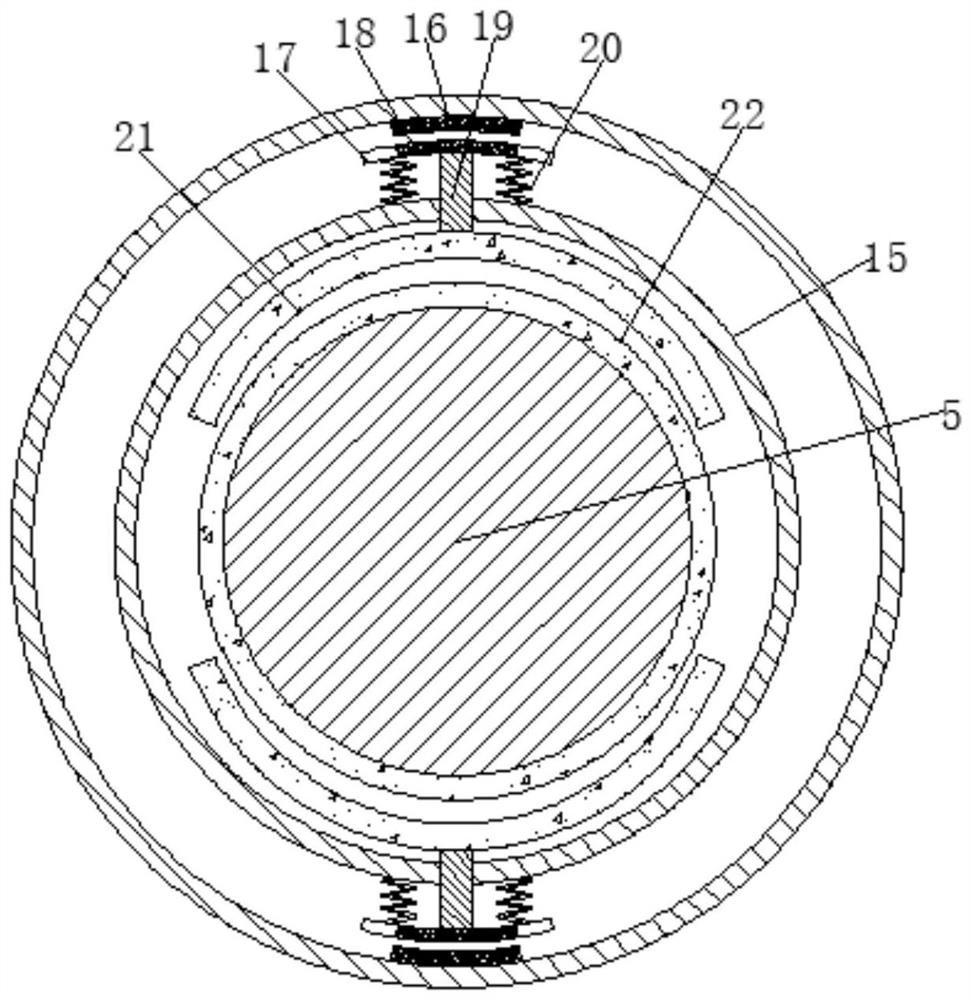

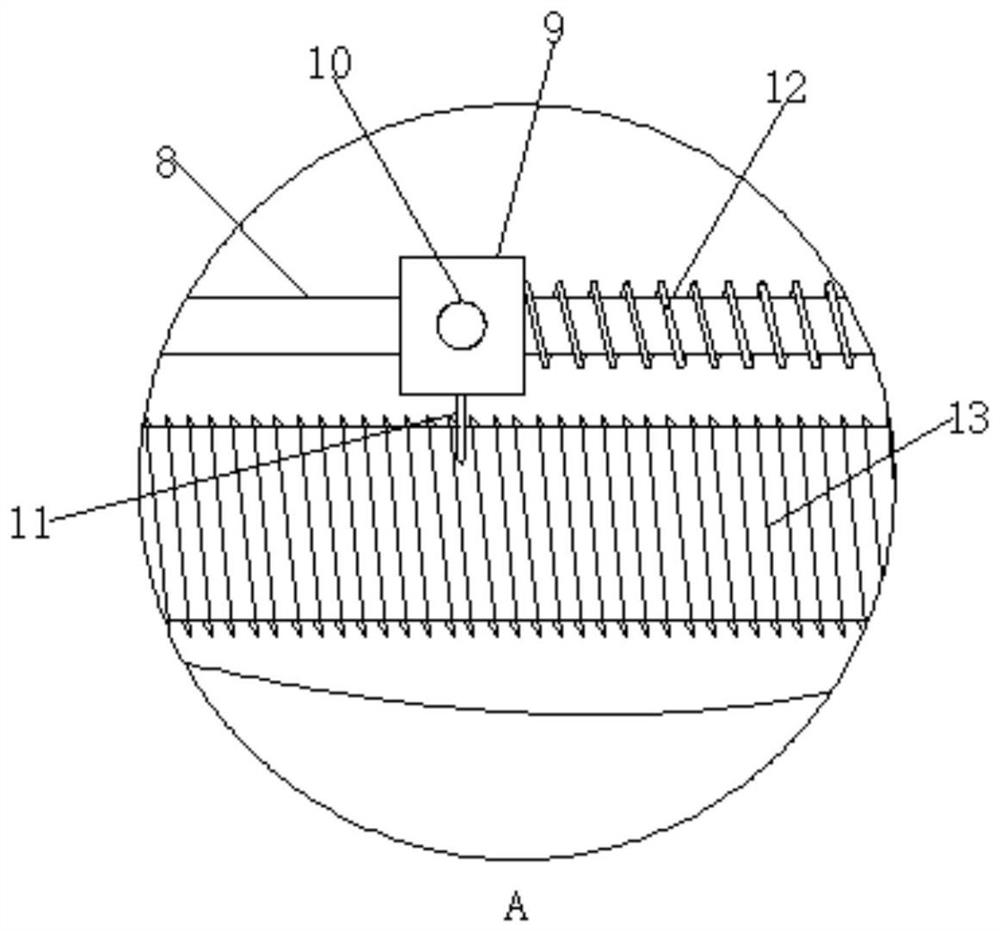

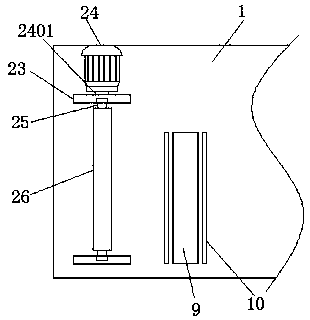

Auxiliary mechanism for wire winding tension adjustment

InactiveCN111703973AReduce tensionQuality is not affectedFilament handlingElectrical resistance and conductanceStructural engineering

The invention relates to the technical field of a wire, and discloses an auxiliary mechanism for wire winding tension adjustment. The auxiliary mechanism comprises a supporting rod, a driving machineis arranged on the side face of the supporting rod, and a bevel gear set is arranged on the surface of the driving machine. A rotation shaft is arranged in the bevel gear set, and a winding coil is arranged on the surface of the rotation shaft. A connecting rod is arranged on the surface of the supporting rod, and a guide block is arranged on the surface of the connecting rod. A sliding rod is arranged in the guide block, and a sliding block is arranged on the surface of the sliding rod. By the match usage of the sliding block and an auxiliary spring, the match usage of a sliding needle and aresistance coil, the match usage of an electromagnet and a magnetic block and the match usage of a brake pad and an abrasive disc, the auxiliary mechanism for wire winding tension adjustment can automatically adjust the winding speed of the winding coil and reduce the tension of the wire when the wire has too much tension, so that the winding coil cannot affect the quality of the wire during winding, and the wire winding quality and effect are improved.

Owner:广西南宁导思电子科技有限公司

End fixing method for motor stator winding

InactiveCN101359857AImprove operational safetyImprove reliabilityWindingsManufacturing dynamo-electric machinesFiberFree cooling

Disclosed is a fixation method for a motor stator winding overhang, which affixes a reel of double sided tape to an external circumference of the motor winding overhang; a reel of fiber felt is affixed to the double sided tape; a non-woven fiber tape is wound round the fiber felt; a TCP tape is wound round the non-woven fiber tape; the TCP tape is heated and naturally cooled, then naturally shrinks and fixes the fiber felt and the non-woven fiber tape wrapped in the TCP tape on the motor winding overhang to realize motor stator winding overhang fixing. The method adopts the simple technical proposal, has the fixed bundling of the motor stator winding overhang and good structure stability, can effectively improve the safety of motor operation, be applied to industrial production, and act as the fixation method for a small diameter motor stator winding overhang.

Owner:MIN OF RAILWAY TRANSPORT BUREAU +1

Construction method of urban stone tunnel cantilever tunneling

InactiveCN107725057AAvoid damageAvoid the large impact of blastingUnderground chambersTunnel liningEngineeringCantilever

The invention belongs to the technical field of underground excavation of a tunnel, and particularly relates to a construction method of urban stone tunnel cantilever tunneling. A rock layer is splitwhen it is hard, and exactly positioned by an excavation line; through the swaying in all rounds of a cutting mechanism at the front end of a tunneling machine and rotary rock breaking of a cutting head, the overexcavation is effectively controlled, and time for sealing an initial liner is reduced; moreover, the safety of a work face is greatly improved, and influence of vibration on surrounding buildings is weakened.

Owner:JINAN URBAN CONSTR GRP

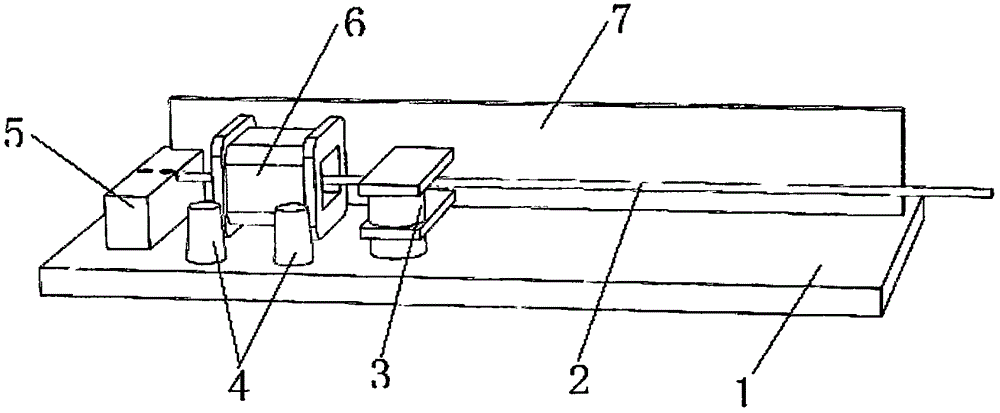

Young's modulus meter and measurement method thereof

InactiveCN105890993AAccurate measurementEasy to operateMaterial strength using tensile/compressive forcesElectricityResonance

The invention discloses a Young's modulus meter and a measurement method thereof. The Young's modulus meter comprises a frame, a fixing port, a coil, an 'F'-shaped permanent magnet, a ruler and a signal generator. One end of the frame is provided with the fixing port, the 'F'-shaped permanent magnet is vertically fixed to the frame, and the signal generator is connected with the coil through binding posts electrically. The coil is arranged between the fixing port and the permanent magnet, the fixing port, the coil and the permanent magnet are positioned on a same straight line, the ruler is transversely fixed to the frame and linearly parallel to the straight line, and an extension direction of an inner hole of the coil is parallel to the ruler. The Young's modulus meter not only has advantages of a suspension wire coupled resonance method but also can be used for measurement of Young's modulus of both a cylindrical steel wire and a rectangular-section steel sheet, looseness is avoided, and accuracy of measured Young's modulus of materials is achieved.

Owner:WEST ANHUI UNIV

Working method of robot system

ActiveCN111941404ANo slackNumber of degrees of freedomProgramme-controlled manipulatorControl engineeringProcess engineering

The invention discloses a working method of a robot system. The robot system comprises a workbench, bottom wheels, a machine body, a driving module, a control module, a hydraulic module, a communication module and a snakelike arm module, wherein the workbench is arranged above the machine body, six bottom wheels are arranged below the machine body, directions of the six bottom wheels are adjustable, and the driving module drives the bottom wheels to move through a transmission mechanism. The working method comprises a working in-place method, a jetting and spraying method and an adjusting feedback method.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Banner rolling-up machine and working method

ActiveCN108002092AAchieve lateral movementEasy to control from a distanceOther printing apparatusArticle deliveryProduction rateEngineering

The invention relates to a banner rolling-up machine and a working method, and belongs to the technical field of printing equipment. The banner rolling-up machine comprises a supporting frame, the supporting frame is provided with a variable-section banner rolling-up device and an edge hemming device; when the variable-section banner rolling-up device collects banners, a wound roll of the variable-section banner rolling-up device can be enlarged, so that the banners are not slid under action of a pressing device, after collecting is completed, the sectional area is reduced, and the banners which are rolled into a cylinder shape can be easily taken down; the edge hemming device conducts hemming treatment on edges of the two ends of the banners, so that the banners have the cylinder-shaped edges, and hanging is convenient; and the supporting frame is further provided with a central controller which is used for reducing the size of whole equipment and improving the integration and automation degree so that the whole equipment can be easily controlled and operated. According to the banner rolling-up machine and the working method, subsequent processing and collecting and automatic edgehemming of the printed banners can be achieved, collecting, winding and easily unloading of the banners can be achieved, the cost is greatly saved, and the productivity of the banners is increased.

Owner:SHANDONG UNIV OF SCI & TECH

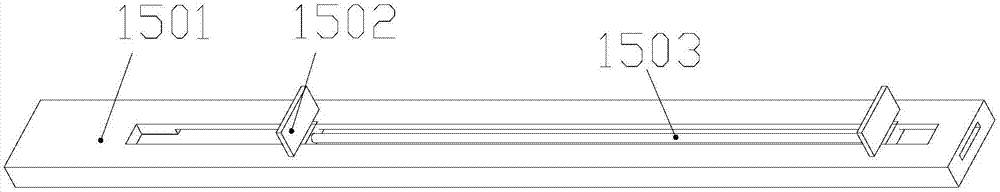

Intelligent cloth inspecting machine

PendingCN110144719ABar rotationSmooth rotationInspecting textilesEngineeringUltimate tensile strength

The invention discloses an intelligent cloth inspecting machine which comprises a rack as well as a unwinding device, a cloth tensioning device, a cloth image collecting unit, a correcting device anda controller disposed on the rack, wherein the unwinding device comprises two supporting plates which are disposed opposite to each other; the supporting plates are fixedly connected with the rack; aplurality of cross bars disposed in an arc shape are connected between the supporting plates; two ends of each cross bar are respectively and rotationally connected with the supporting plates. By adopting the intelligent cloth inspecting machine, the accuracy of the cloth inspection can be improved, the occurrence of the wrong inspection and the missed inspection can be effectively prevented, thelabor intensity of an operator can be reduced, and cloth winding is uniform and consistent, and meets the requirements of the batch inspection of cloth.

Owner:苏州艾恩西精密五金有限公司

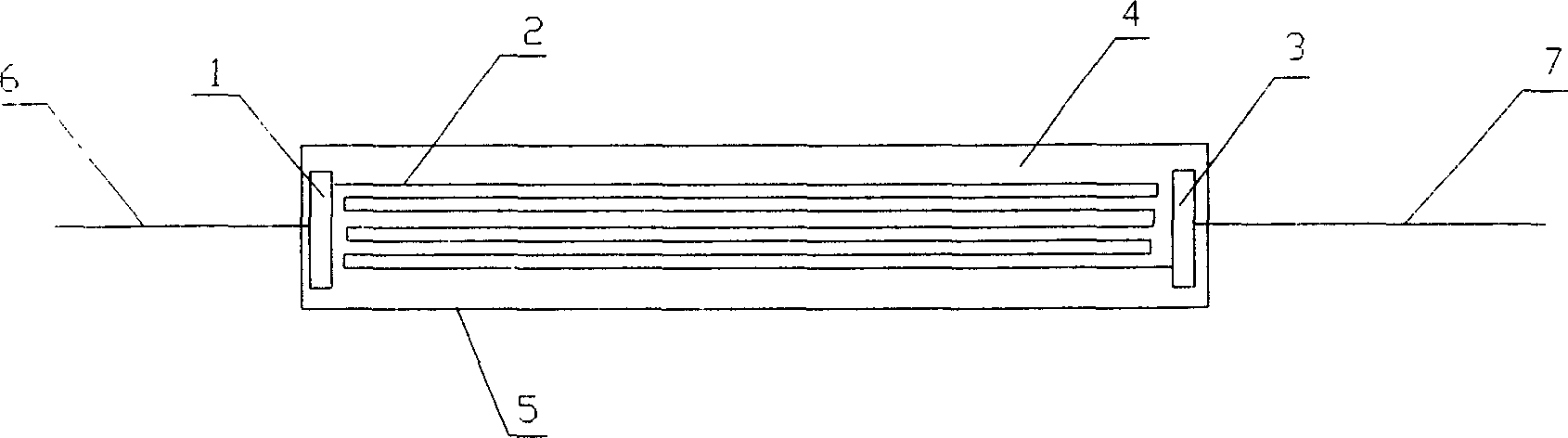

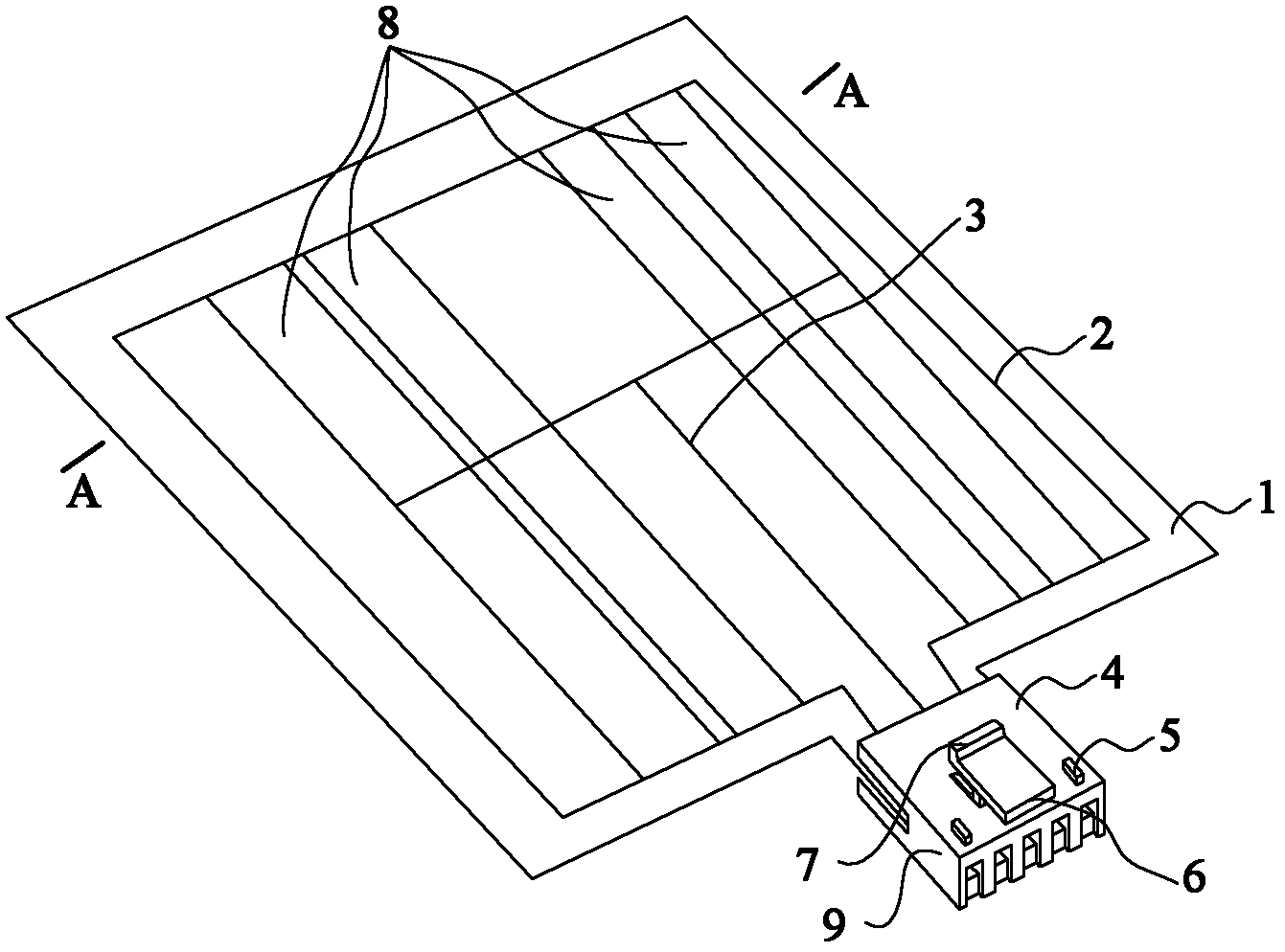

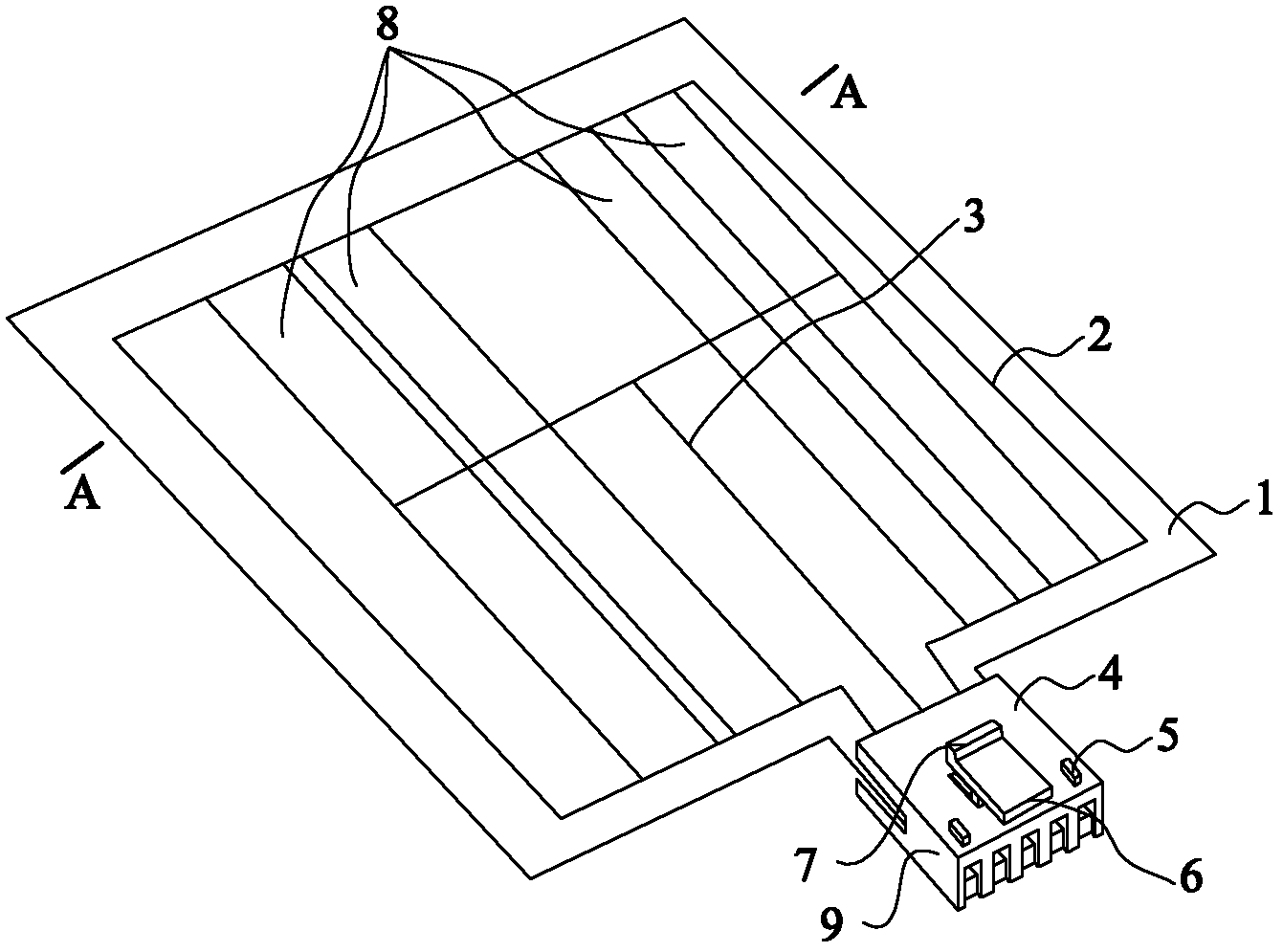

Electric heating film

InactiveCN102638906AControl thicknessIncrease freedomOhmic-resistance heatingElectricityElectrical resistance and conductance

The invention provides an electric heating film, which comprises a flexible film body and a connector. Wires are distributed on the flexible film body, heating resistive layers connected with the wires are laid on the flexible film body, and the connector is connected with the wires. According to the scheme of the electric heating film, the heating resistive layers connected with the wires are laid on the flexible film body and are formed by painting nano carbon series resistive pastes, so that the thickness of the electric heating film can be effectively controlled and thinning and special shaping of the electric heating film can be realized easily. In addition, the heating resistive layers of the electric heating film are arranged optionally, the electric heating film is simple in manufacturing process, low in cost, favorable for automatic production, high in heat efficiency and easy to control power when in use; the heating resistive layers are free of looseness, short circuit, broken circuit and the like, and accordingly safety of using is improved.

Owner:陈海龙

Special automatic-cutting-supportive weaving machinery

The invention discloses special automatic-cutting-supportive weaving machinery which comprises an operation table. The bottom of the operation table is fixedly connected with supporting legs, a weaving mechanism is arranged on one side of the top of the operation table, a pair of tightening seats are arranged on the right side of the weaving mechanism, a cutting mechanism is arranged on the rightsides of the tightening seats, a batching mechanism is arranged on the right side of the cutting mechanism, and a first winding barrel and a second winding barrel are arranged on the inner sides of the tightening seats; the cutting mechanism comprises a moving seat and a fixed seat, a sliding groove is formed in one side of the top of the operation table, and through grooves are symmetrically formed on two sides of the sliding groove. By arranging a first compacting barrel, a second compacting barrel, a motor and cutting blades, burrs of cloth woven by a loom can be cut automatically, the cloth is compressed and fixed through the first compact barrel and the second compacting barrel, and errors in cutting caused by the fact that the cloth is loose and soft are avoided; the cutting blades can be driven to cut the burrs and thread ends by starting the motor.

Owner:江苏春华纺织品有限公司

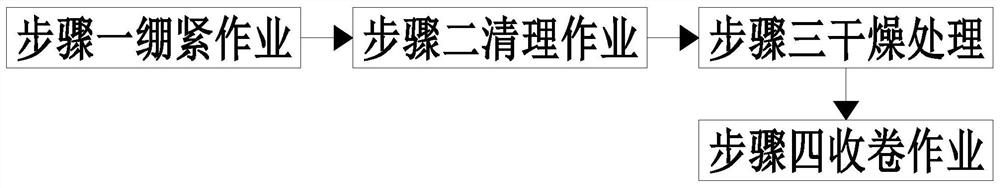

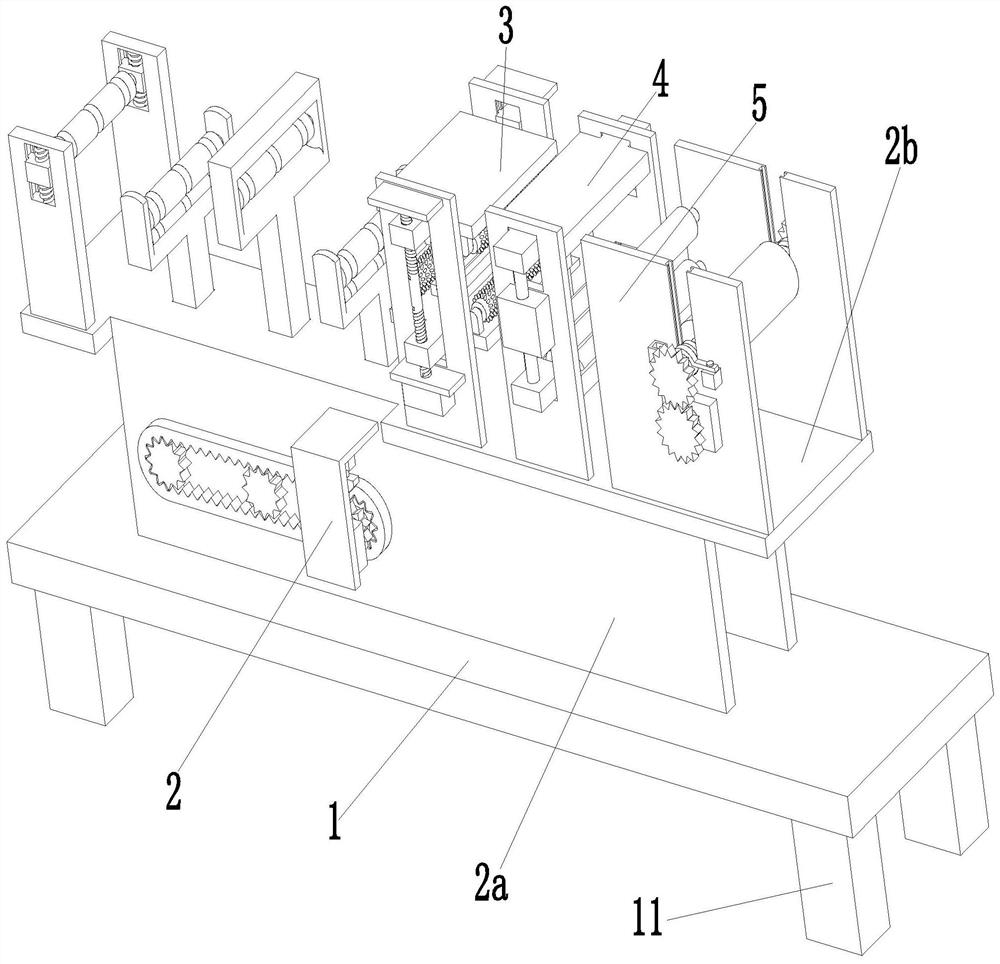

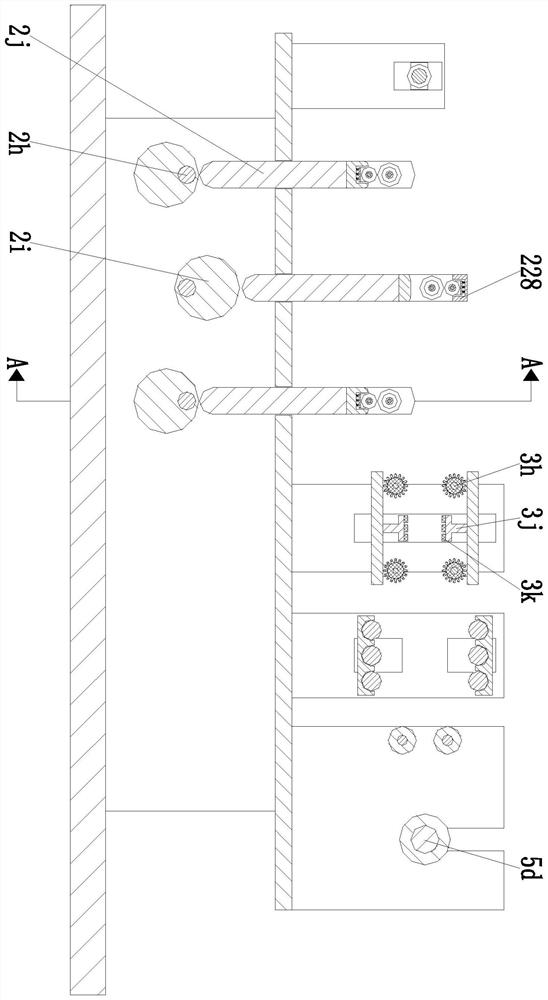

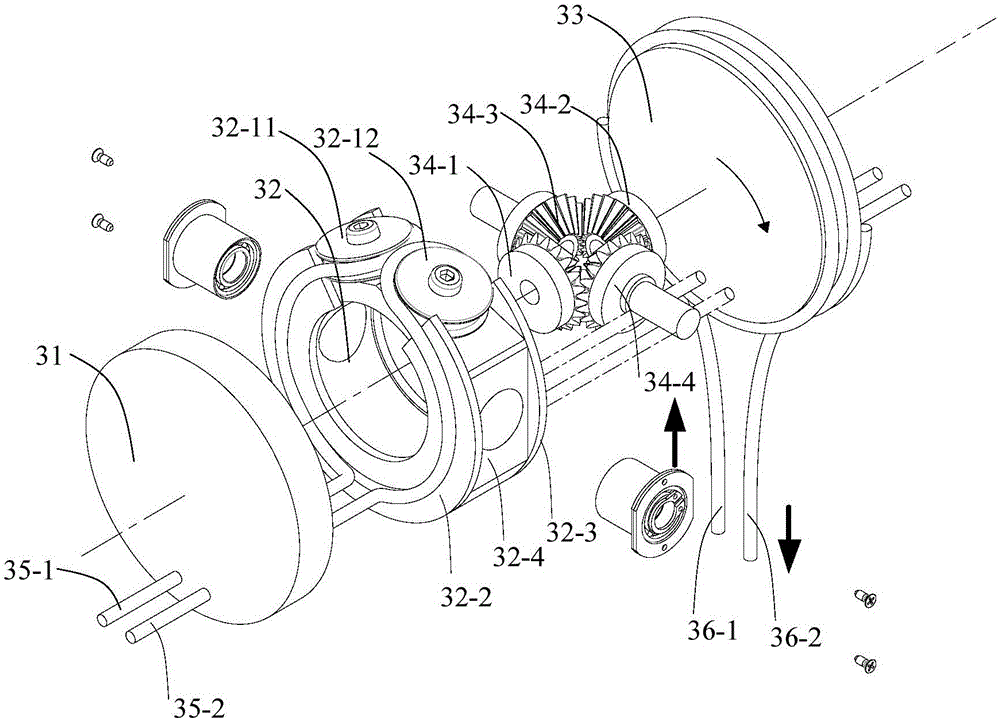

Textile yarn preparation surface clearing method

The invention relates to a textile yarn preparation surface clearing method. The method mainly comprises the following steps of straining operation, clearing operation, drying treatment, rolling operation and other multiple working procedures. Adopted yarn surface clearing equipment comprises a bottom plate, a straining device, a clearing device, a drying device and a rolling device. The method can solve the following problems existing in the existing textile yarn clearing process that a, in a traditional textile yarn clearing manner, a tool is used manually to carry out clearing operation on textile yarn, when the textile yarn is cleared manually, the effect of one-time clearing is poor, the textile yarn needs to be cleaned many times, only one piece of yarn can be cleaned each time, and the working efficiency is low; and b, existing textile yarn clearing equipment can only carry out clearing operation on a single piece of yarn, moreover, the textile yarn is usually in a loose state in the clearing process, and the clearing quality of the textile yarn is reduced.

Owner:南京白枫绿科技有限公司

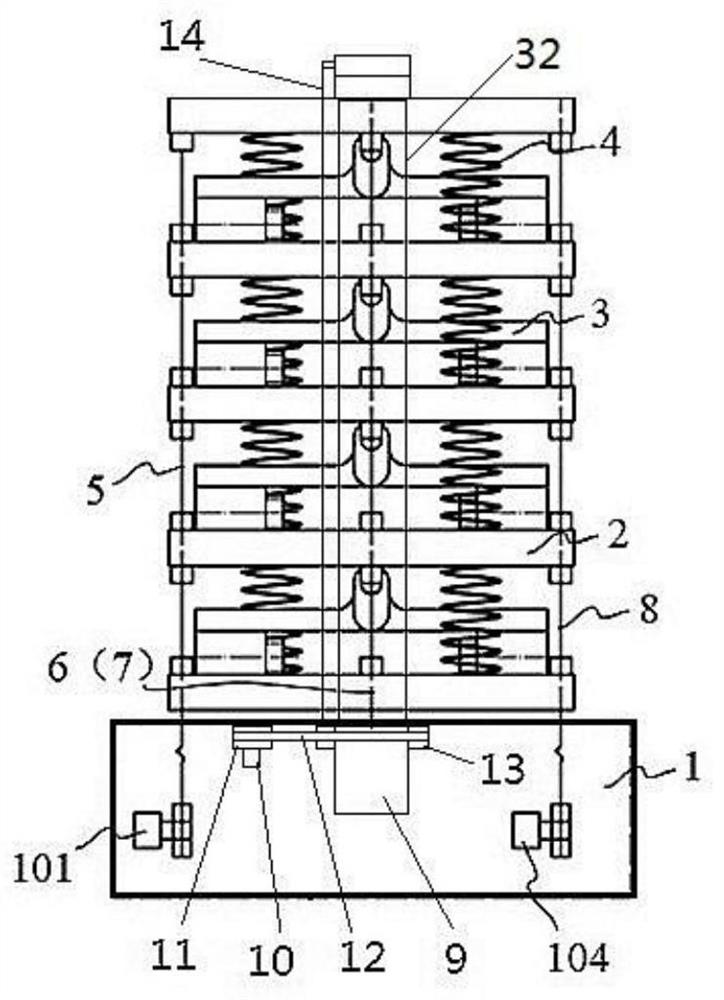

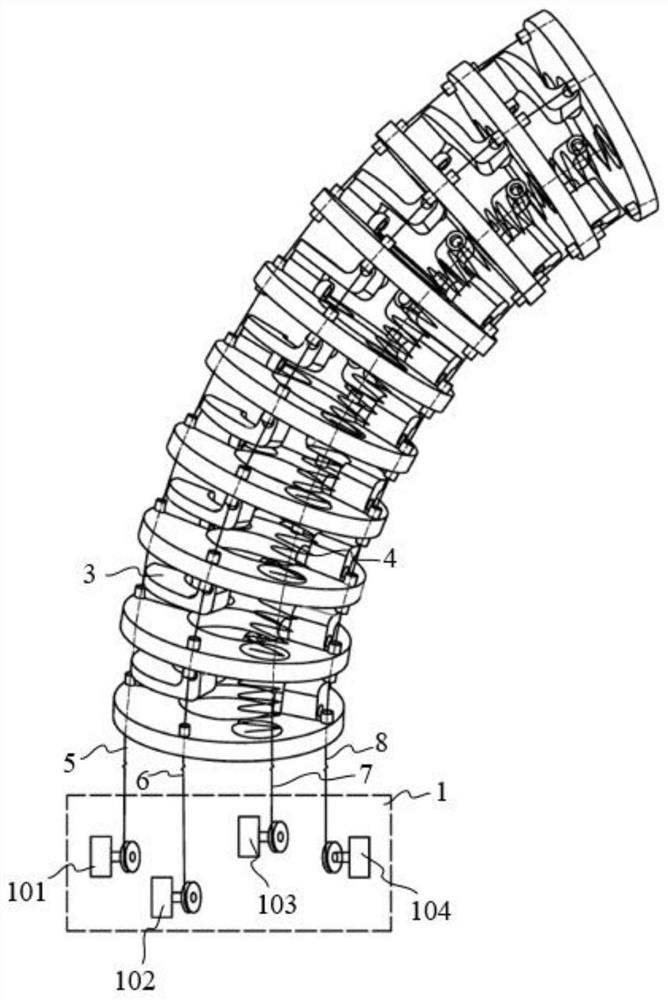

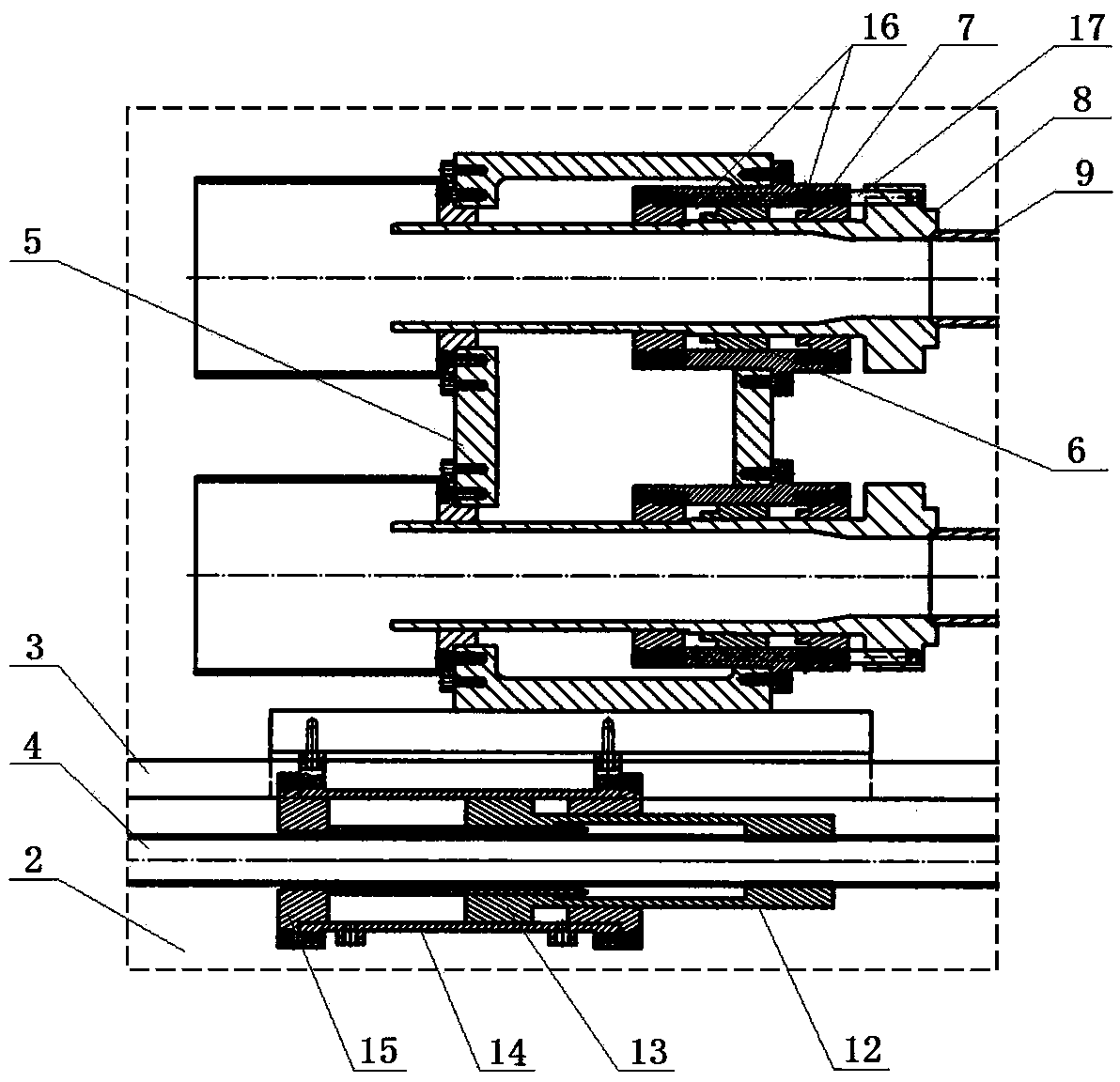

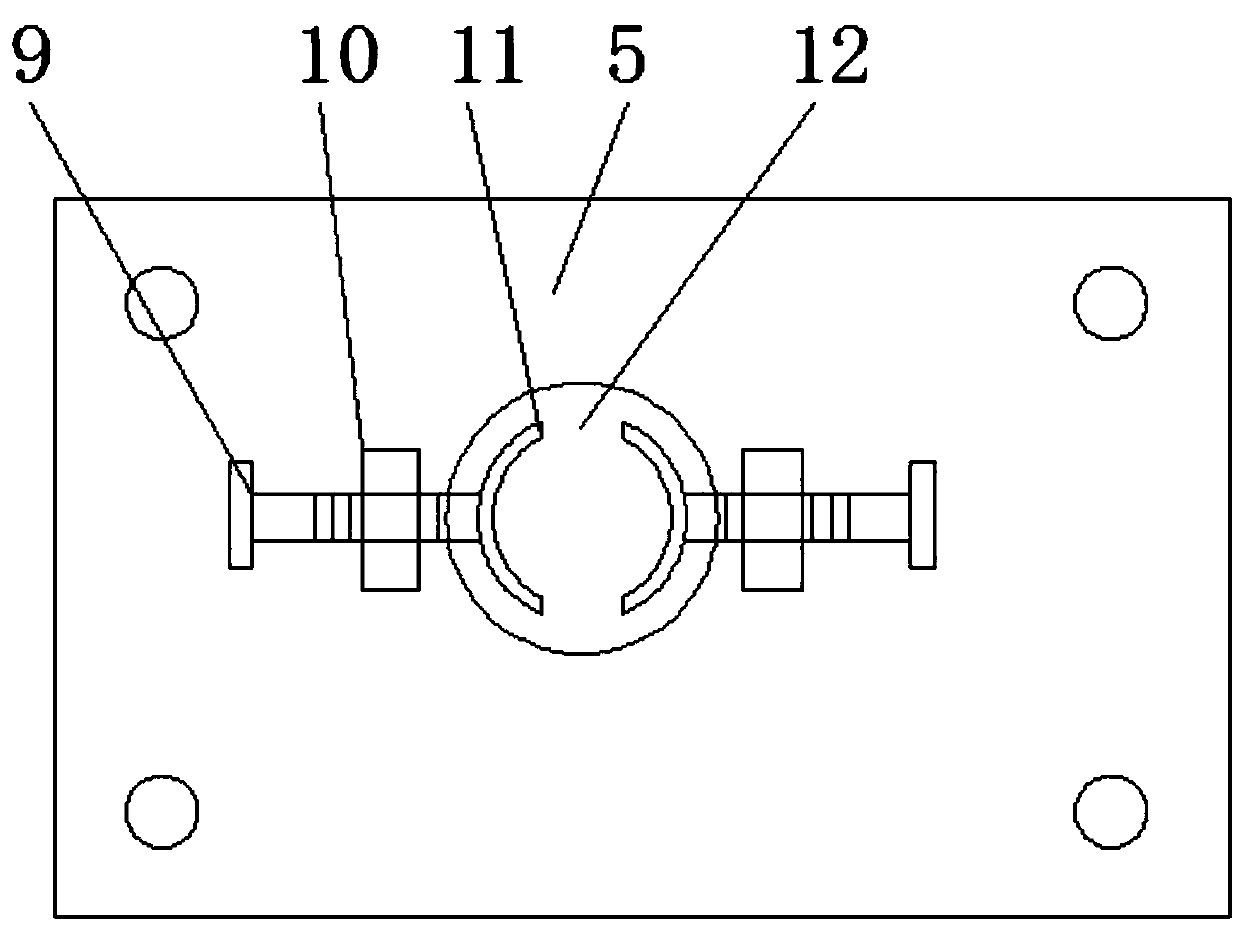

Reconfigurable rope-driven tandem decoupling mechanical arm joint and working method thereof

The invention discloses a reconfigurable rope-driven tandem decoupling mechanical arm joint and a working method thereof, and solves the kinematic coupling problem of joints of a multi-joint tandem rope-driven mechanical arm. The reconfigurable rope-driven tandem decoupling mechanical arm joint has the characteristics that based on a decoupling mechanism, modularized rope-driven joints of two different types are designed; the rotation types of the joints are changed and the number of mechanical arm joints is increased and decreased according to the requirement of a target task, so that the assembly of mechanical arms with various structures is achieved; the application manner is wide in application range, and the cost is low; a mechanical arm driving unit is positioned at a base, the rope remote driving is adopted, and the rotational inertia of the joints is reduced, so that the driving response characteristic is improved; besides, the flexibility of the ropes greatly improve the safety of interaction of the mechanical arm and the environment; and a rope-driven modularized joint is compact in structure, low in rotational inertia, quick in driving response, and good in flexibility and security interaction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

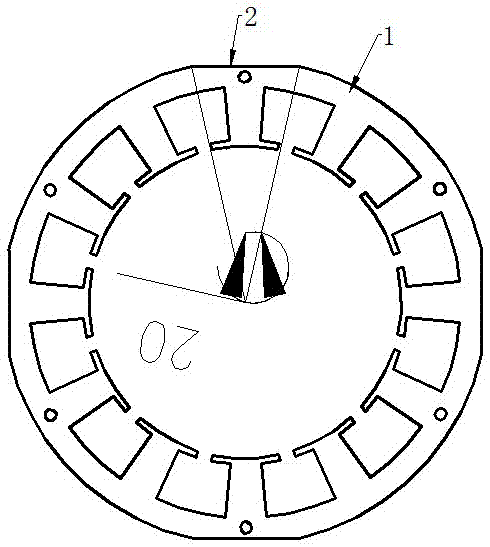

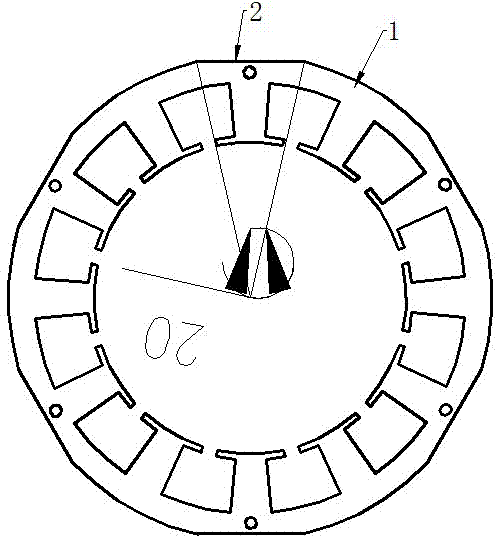

Motor stator

InactiveCN107887990AHigh safety and durabilityNo slackMagnetic circuit stationary partsManufacturing stator/rotor bodiesPhysicsRelaxation phenomenon

The invention relates to a motor stator which comprises a stator body. A cross-sectional contour of the stator body is a circular structure, and four to six sections are uniformly distributed at the circumferential direction of an outer edge of the circular structure. Compared with an ordinary stator, the motor stator has no relaxation phenomenon under a long-term condition, the safety and durability performance are better, and a part of materials is saved so as to reduce cost and improve efficiency.

Owner:XUZHOU NANPU ELECTRICAL TECH

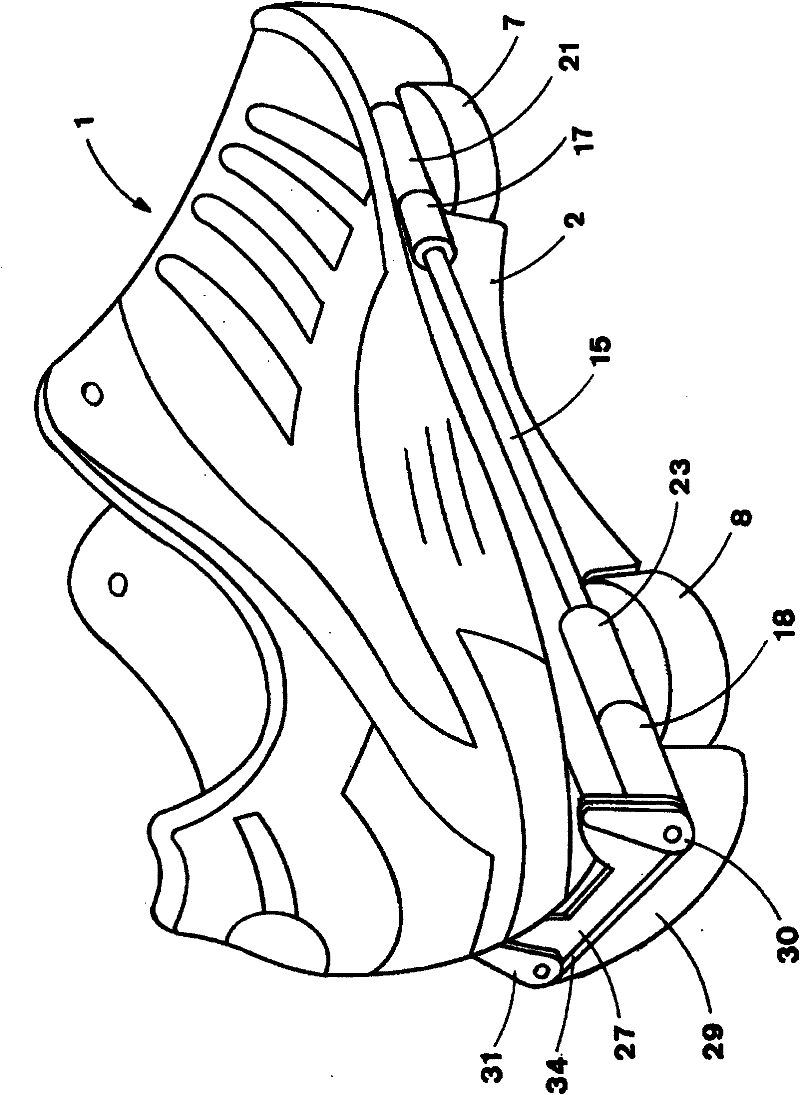

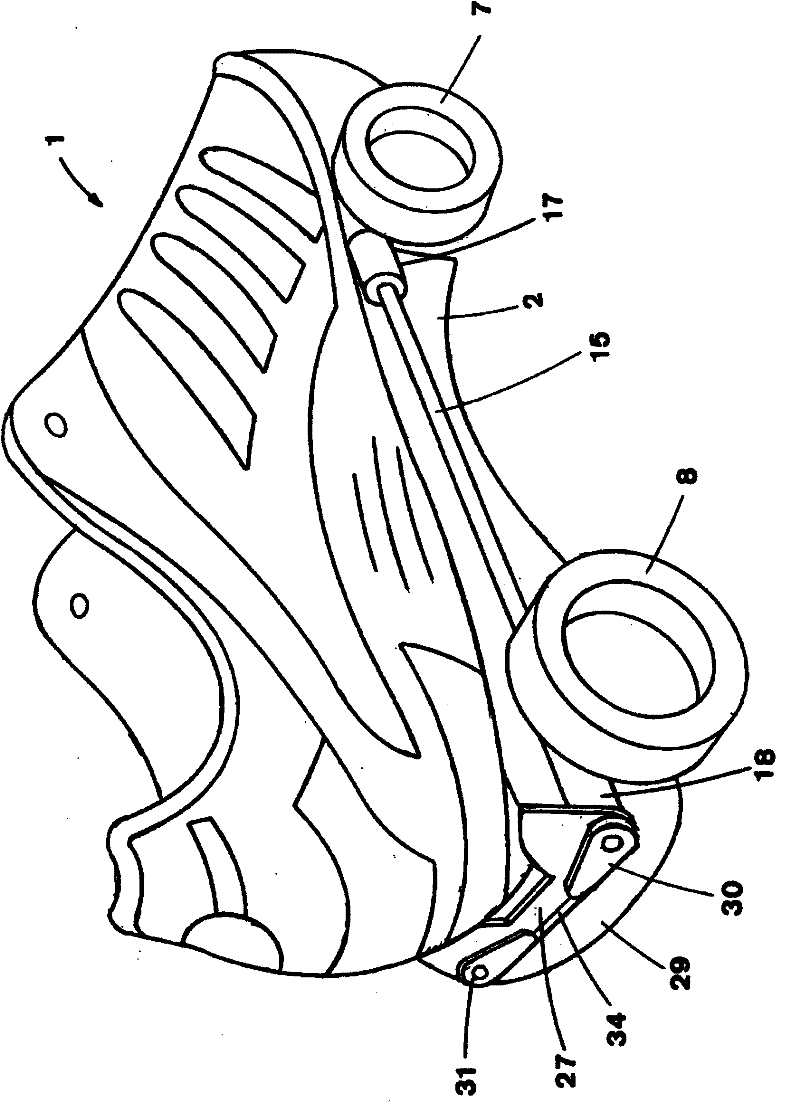

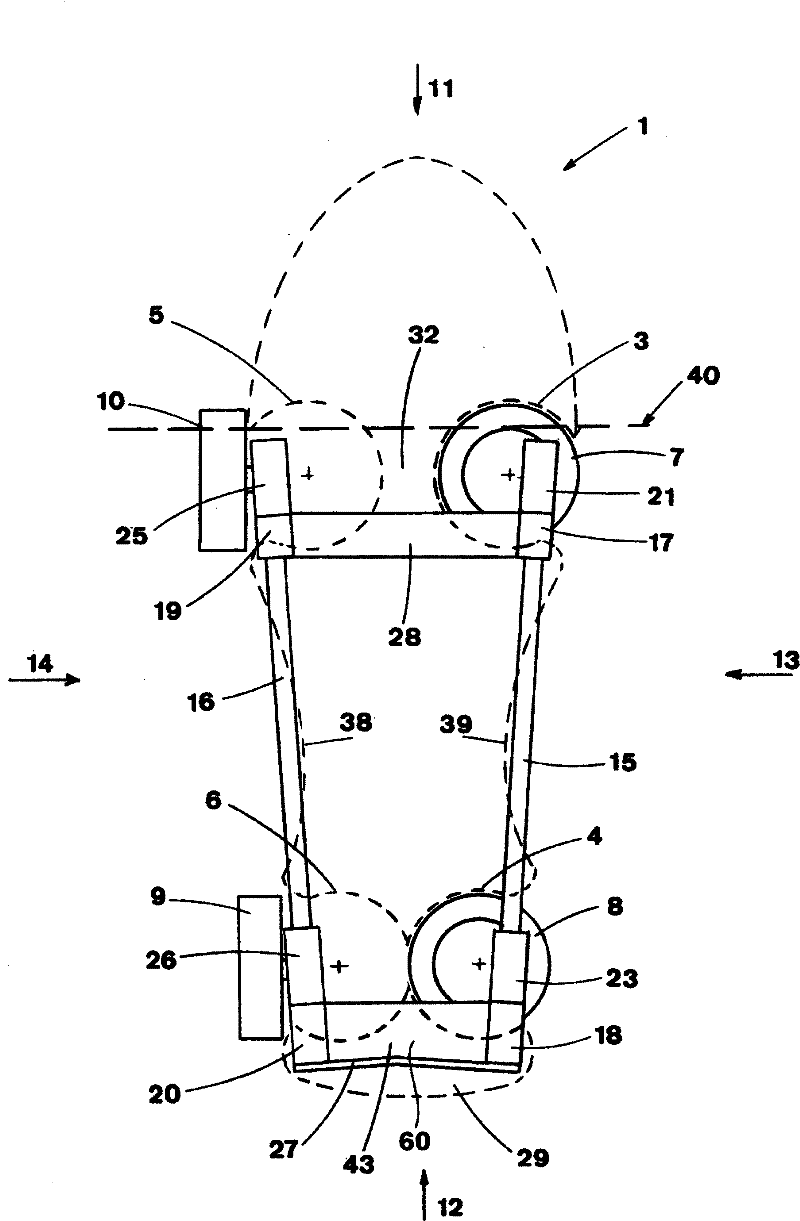

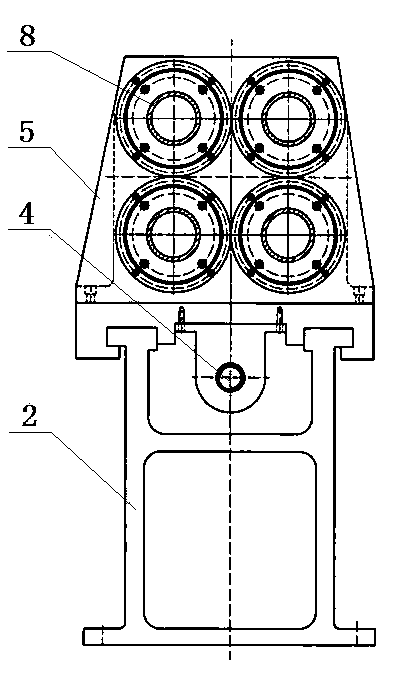

Multi-purpose shoe for walking and rolling, comprising laterally-folding wheels built into the sole

Owner:DECATHLON SA

Clamping compensation device for use in machining of plurality of workpieces

InactiveCN104227461ANo slackNo mobilityWork clamping meansOther manufacturing equipments/toolsEngineeringMachining

The invention relates to a clamping compensation device for use in machining of a plurality of workpieces. The clamping compensation device comprises a frame, wherein a sliding seat and a fixing seat are arranged in sequence along the longitudinal direction on the frame; workpiece compression sleeves are arranged on the sliding seat; the fixing seat is provided with through holes; one end, which is adjacent to the sliding seat, of each through hole is provided with a workpiece positioning sleeve; the quantities of the through holes and the workpiece compression sleeves are the same, and are not less than two; the positions of the workpiece positioning sleeves on the through holes and the workpiece compression sleeves correspond one by one. The clamping compensation device is characterized in that compensating devices are arranged between the workpiece compression sleeves and the sliding seat; the compensating devices comprise first cylinder bodies which are arranged on the workpiece compression sleeves in a sleeving manner; piston sleeves are fixed on segments of the workpiece compression sleeves positioned in the first cylinder bodies; the peripheries of the piston sleeves are in hermetic movable fit with the inner walls of the first cylinder bodies. Corresponding first cylinder body side walls at the two ends of the piston sleeves are provided with oil holes. When the device is used for clamping the plurality of workpieces, each workpiece can be clamped completely, so that the subsequent machining accuracy of the workpieces can be ensured; meanwhile, automation of equipment can be realized, and the working efficiency is increased.

Owner:无锡振华机械有限公司

Busbar connecting device for low voltage switchgear cabinet

InactiveCN109861083AAvoid damageImprove protectionBus-bar/wiring layoutsSubstation/switching arrangement casingsSet screwBusbar

The present invention discloses a busbar connecting device for a low voltage switchgear cabinet. The busbar connecting device comprises a lower housing and an upper housing, the upper surface of the lower housing is provided with a threaded groove, the front end of the upper surface of the lower housing is provided with a wire outgoing hole, the upper portion of the wire outgoing hole is sleeved with a wire outgoing protection head, the upper housing is installed at the upper portion of the lower housing through set screw nuts, a wire incoming hole is arranged at the center of the top portionof the upper housing, and the upper portion of the wire incoming hole is sleeved with a wire incoming protection head. In the invention, the wire outgoing hole and the wire incoming hole are respectively sleeved with the wire outgoing protection head and the wire incoming protection head to effectively avoid damaging of a busbar and a sub-wire due to friction so as to better protect the busbar andwire incoming, the device is provided with a fastening piece in the wire incoming through hole to allow the fastening piece to clamp the busbar through fastening screws so as to ensure that the busbar is not in a loosening state, allow the device to better protect the busbar and make the device have better market prospects.

Owner:李婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com