Motor stator

A motor stator and stator technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve problems such as bad phenomena and easy slack, and achieve high safety and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

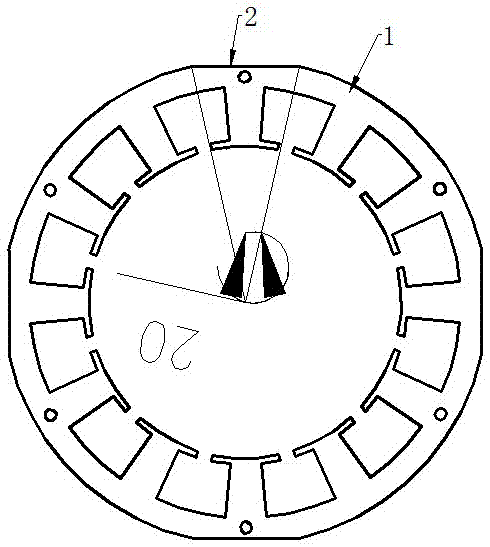

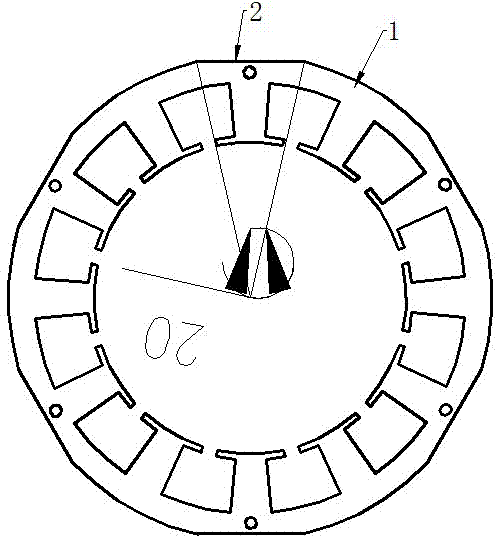

[0013] as attached figure 1 As shown, a motor stator includes a stator body 1, the cross-sectional profile of the stator body 1 is a circular structure, and 4 to 6 cut surfaces 2 are uniformly distributed around the outer edge of the stator body 1.

[0014] The length of the cut surface 2 is equal to the length of the stator body 1 .

[0015] The width of each cut plane 2 is equal, and the included angle of the arc corresponding to each cut plane 2 is not more than 30 degrees.

[0016] The included angle of the arc corresponding to each cut plane 2 is 20 degrees.

[0017] The number of the cut surfaces 2 is four.

[0018] The specific method of the present invention is: cut off a part of the outer contour of the stator on the basis of the original stator to form 4 to 6 effective planes, and add 4 planes to cooperate when the stator and the aluminum barrel are tightly matched. There will be no looseness in the case, making it safer and more durable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com