Mechanical fixing gasket

A mechanical fixation and gasket technology, which is applied in roofing, building construction, construction, etc., can solve the problems of waterproof mechanical fixation system risk, acid and alkali erosion, and weak overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following implementation, the applicant shows a state of use of the fixing gasket of the present invention with reference to the accompanying drawings. This is just an illustration, and those skilled in the art can understand that the use of mechanical fixing gaskets may be slightly different in different application environments. For example, the side plate at the end of the sleeve does not need to be fixed with nails when used on an insulation board. The adjustment of the use mode caused by these changes in the use environment is easily understood by those skilled in the art, and still belongs to the protection scope of the present invention.

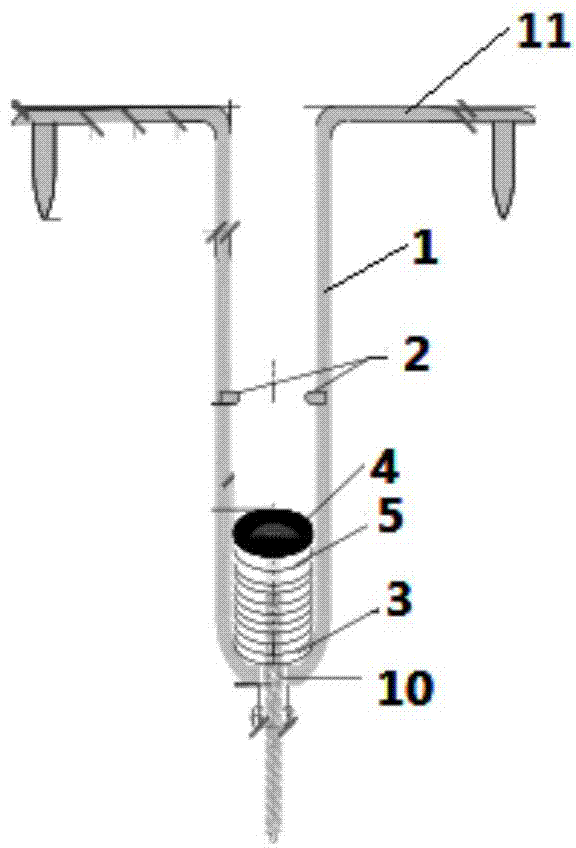

[0020] refer to figure 1 , the mechanical fixing gasket of the present invention, the main structure includes a sleeve 1, a stop card 2, a fixing spring 3, and a fixing washer 4, wherein the head of the sleeve 1 has an opening 10 for the nail body of the metal screw 5 to pass through, but The metal screw 5 does not esca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com