Improved racket threader

A stringing machine and improved technology, applied in the field of improved racket stringing machines, can solve the problems of inaccurate stringing, laboriousness, and inaccurate pounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

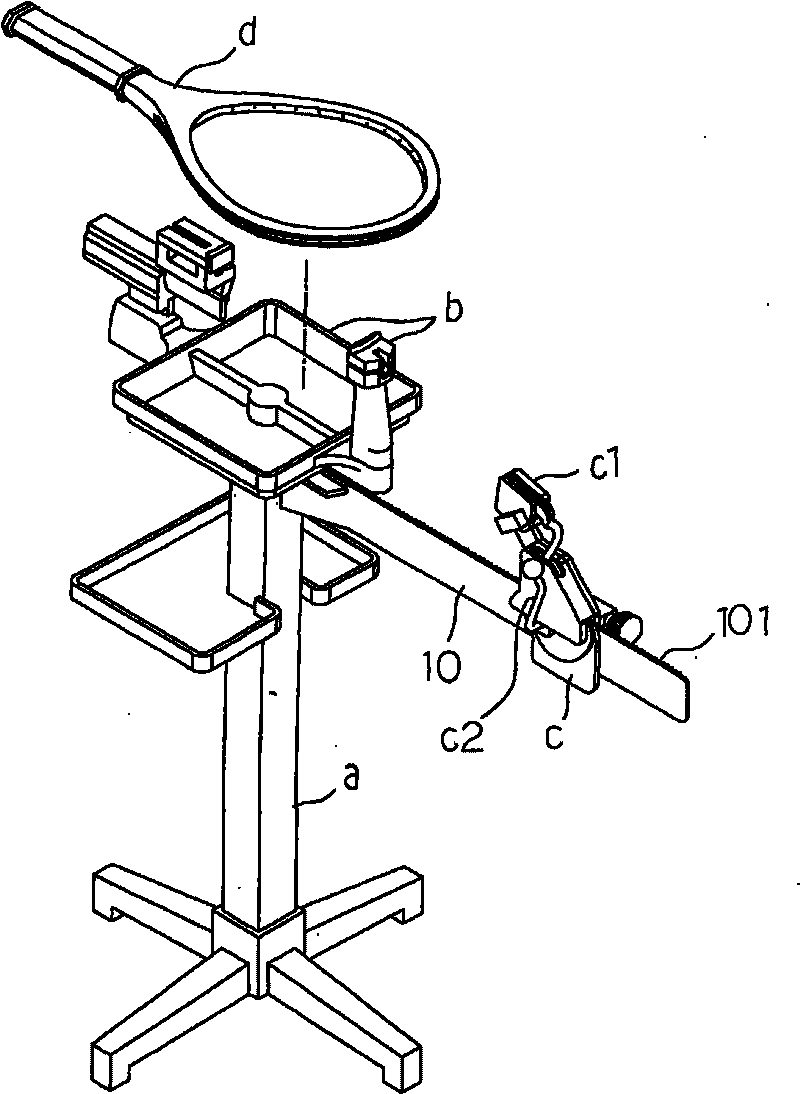

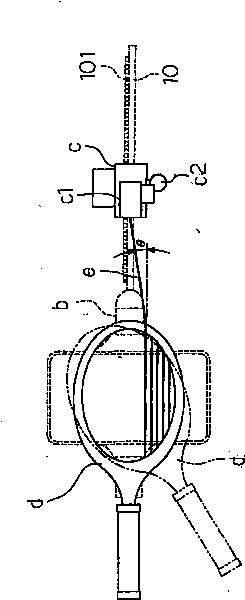

[0040] Please refer to image 3 As shown, in the improved racket stringing machine of the present invention, its improved structure includes a horizontal position adjusting device and a braking device of the stringing machine. The horizontal position adjustment device includes a base rod 1, a consolidation seat 2, and the racket threading machine mainly has a base a, a holding frame b and a wire drawing head c (this is the same as the above-mentioned conventional one, and will not be repeated here. ), the wiring head c has a puller c1 and a puller rod c2; where:

[0041] The base bar 1 is horizontal and used to combine with the wire-drawing head c. The base bar 1 is combined with a rack 11, so that the wire-drawing head c can be displaced according to the rack 11; and one end of the base bar 1 is fixed with a sliding seat 12. The sliding seat 12 is horizontal and fixed to the end of the base rod 1, and the cross section of the sliding seat 12 can be a U-shaped structure;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com