Supersonic deformeter

A strain gauge and ultrasonic technology, applied in the field of ultrasonic strain gauges, can solve the problems of difficulty in judging the change of sound velocity, short life of resistance strain gauges, and limited ray penetration depth, etc., and achieve easy installation, no electromagnetic interference, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

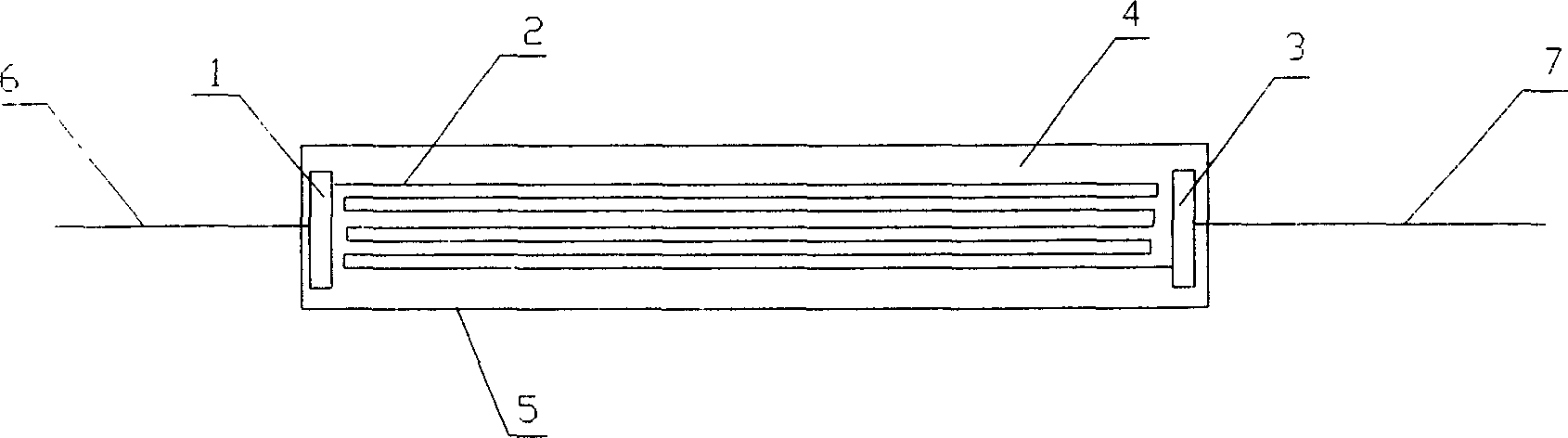

[0025] The present invention mainly consists of emitting piezoelectric sheet (piezoelectric crystal or piezoelectric ceramic), sound transmission medium (wire or air grid), receiving piezoelectric sheet (piezoelectric crystal or piezoelectric ceramic), sound insulation material (such as Foam, etc., when the sound transmission medium is made of metal wire, vacuum can also be used for sound insulation), metal casing (can be made of stainless steel or other alloy steel), power lead wires at the transmitting end, power lead wires at the receiving end, etc.

[0026] The two sides of the emitting piezoelectric sheet and the receiving piezoelectric sheet are plated with silver film as electrodes, and a lead wire is respectively connected to the electrode surface to connect with the external core wire as a power supply circuit. The transmitting piezoelectric sheet, the receiving piezoelectric sheet and the metal casing are fixed by sound-insulating materials such as foam. The sound-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com