Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "More soluble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent articles comprising supercritical fluid treated HIPE, I-HIPE foams and other foams

InactiveUS7053131B2More solubleSolve bulkyTetracycline active ingredientsBaby linensPolymer scienceInternal phase

Owner:KIMBERLY-CLARK WORLDWIDE INC

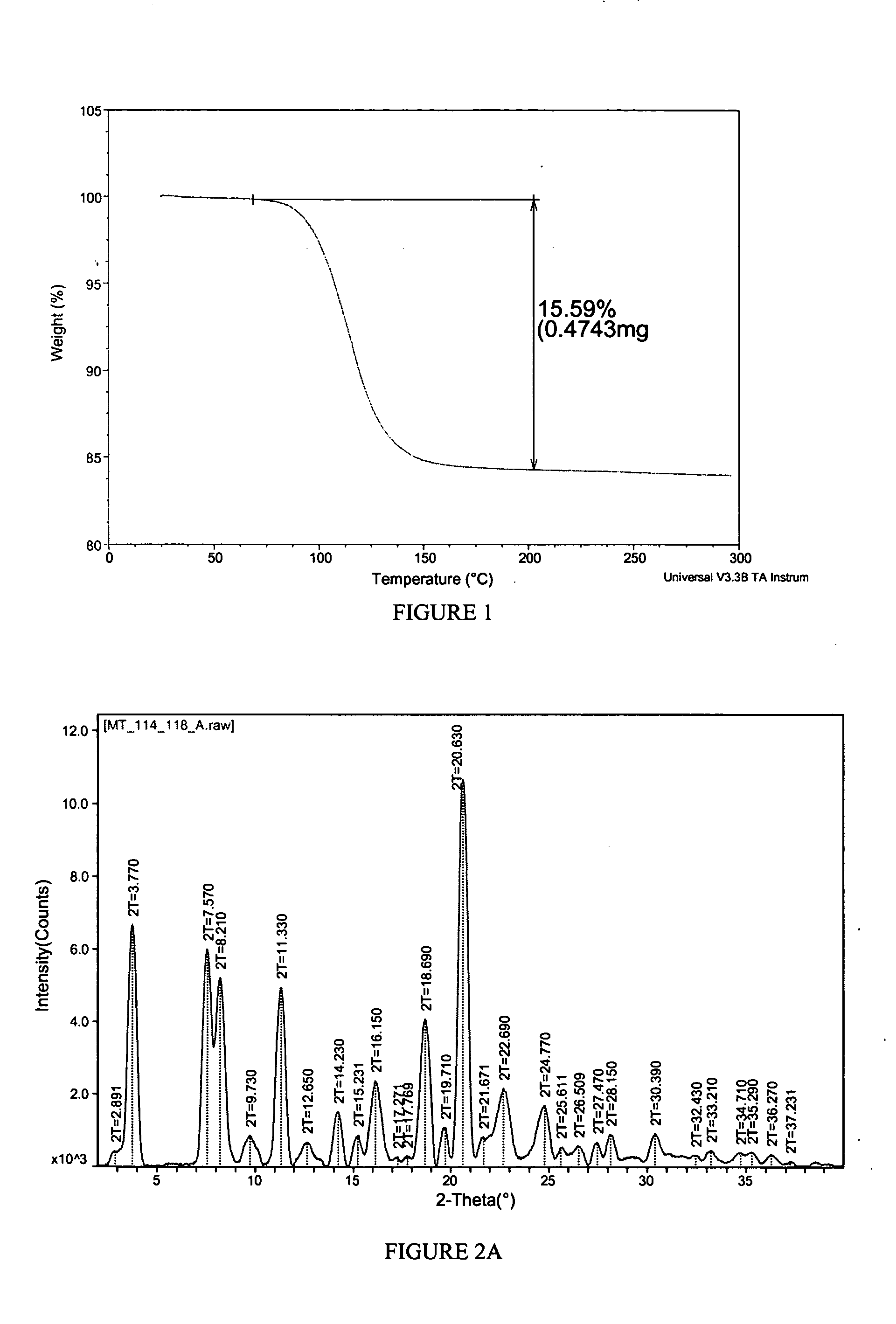

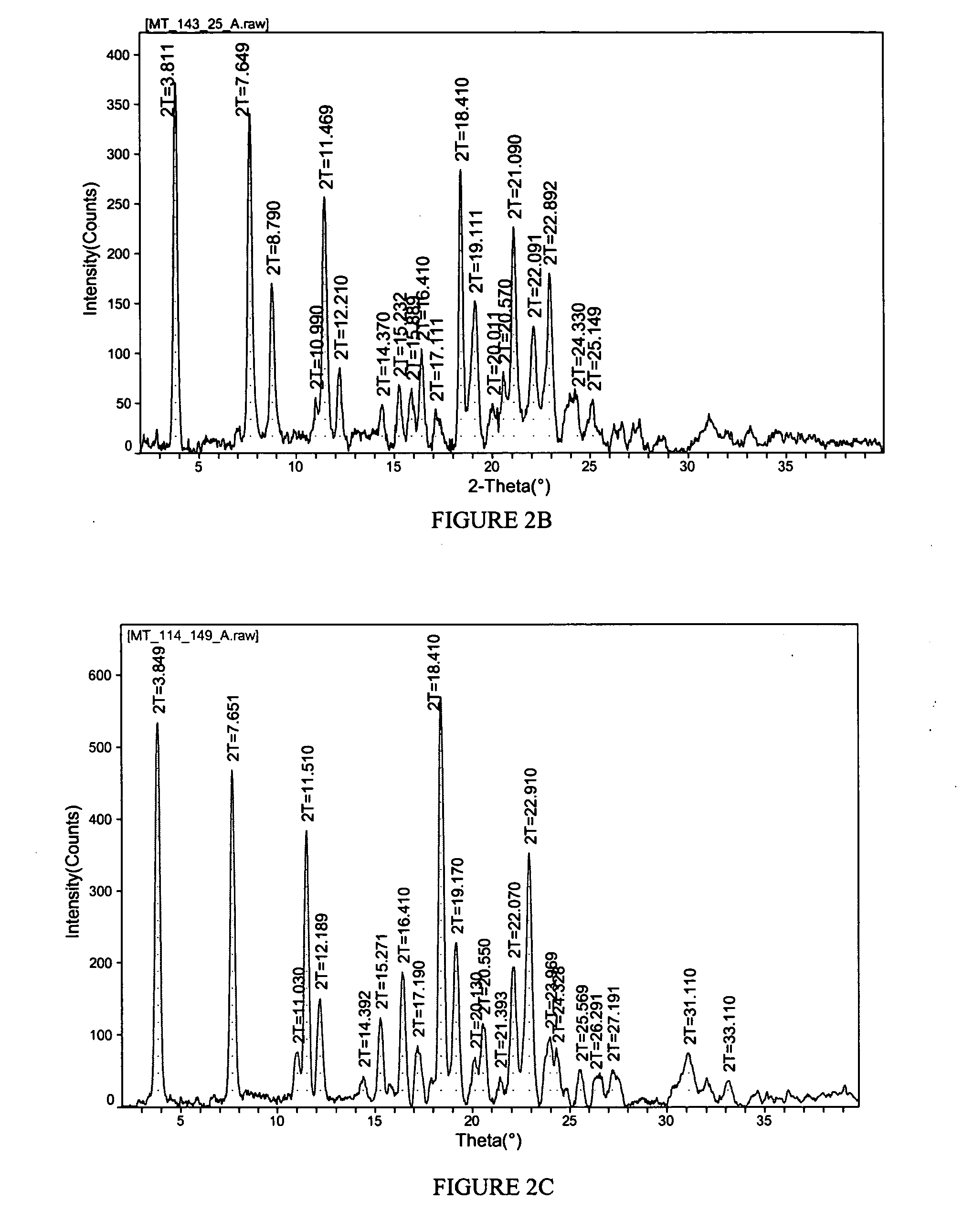

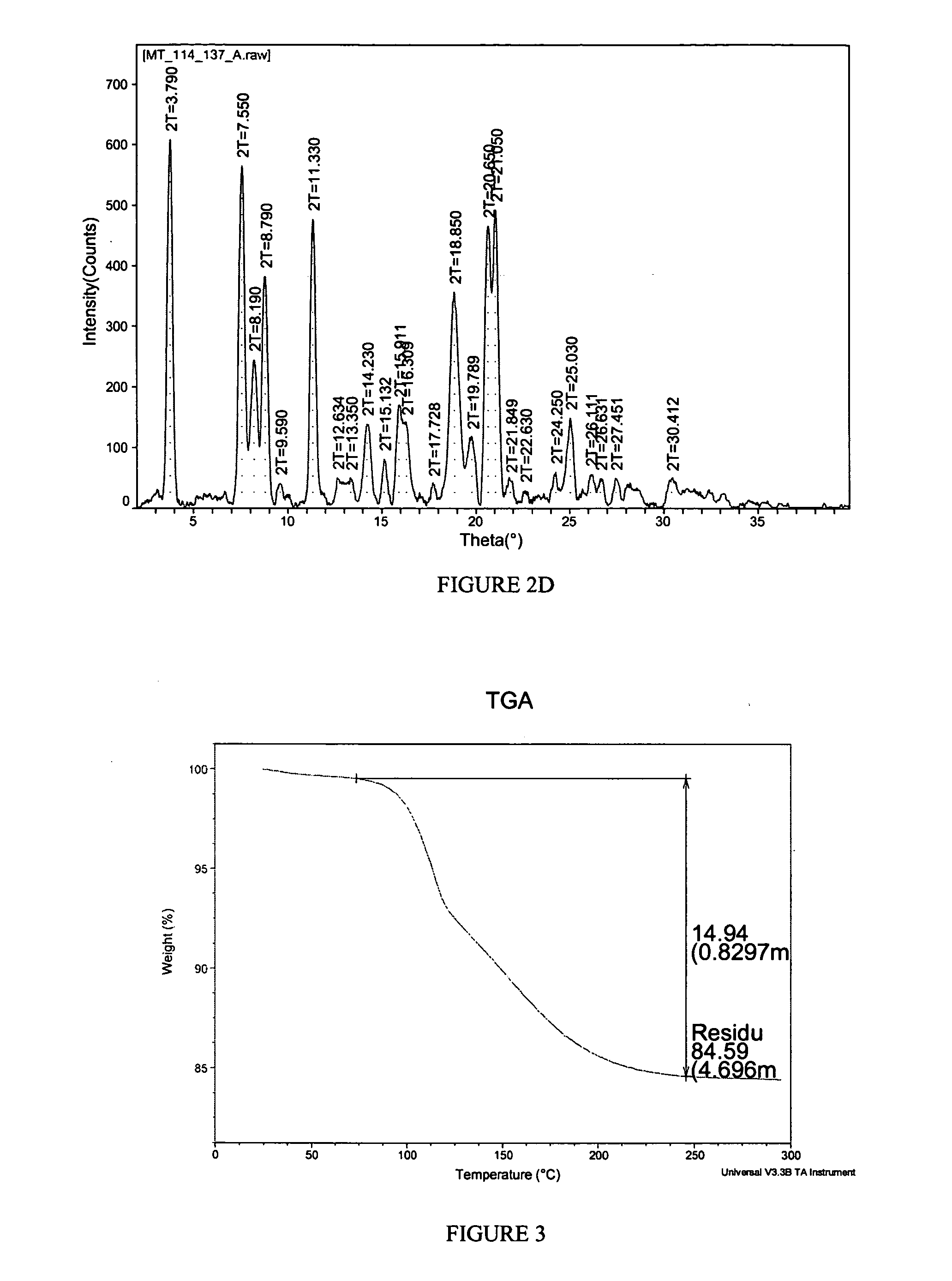

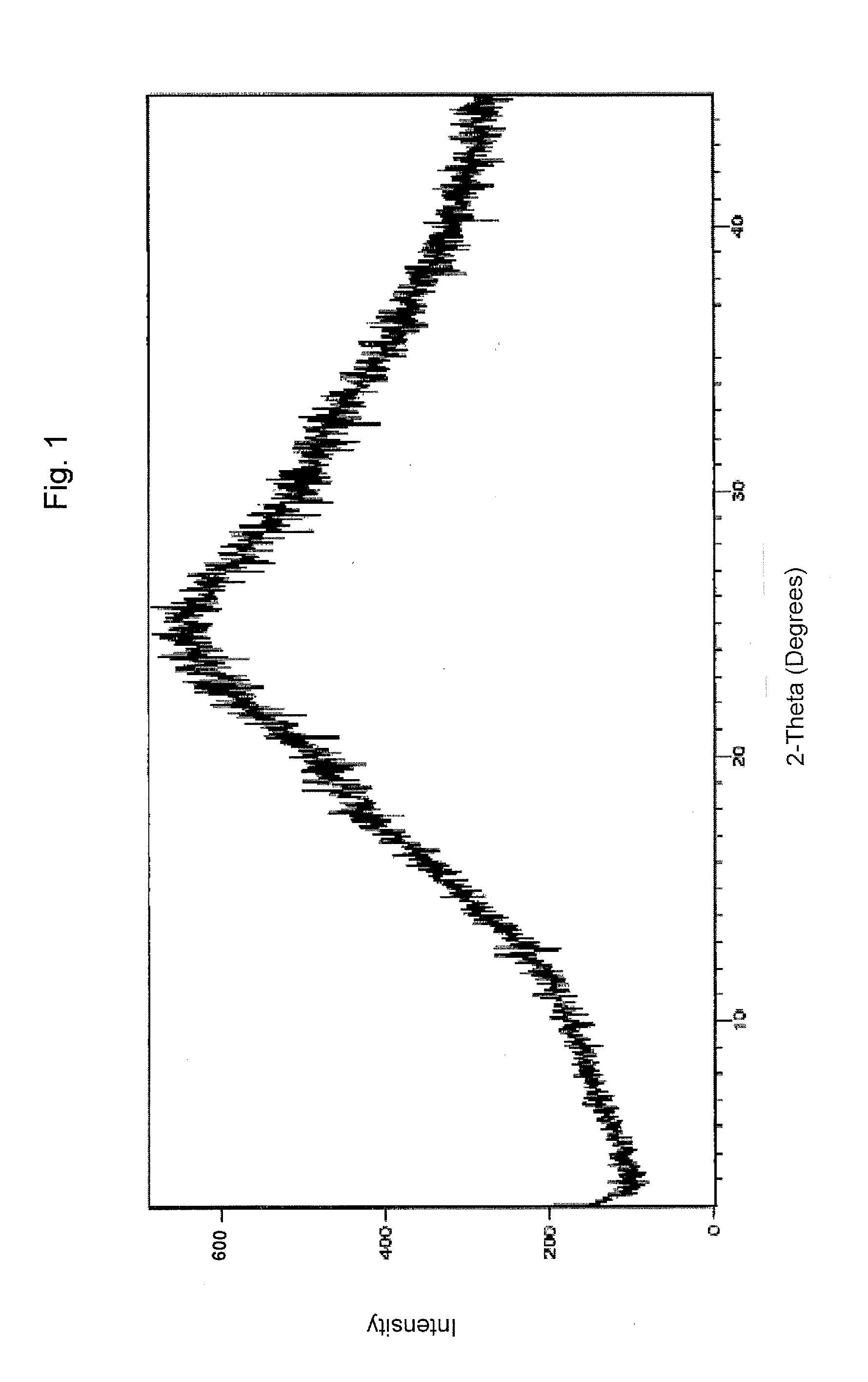

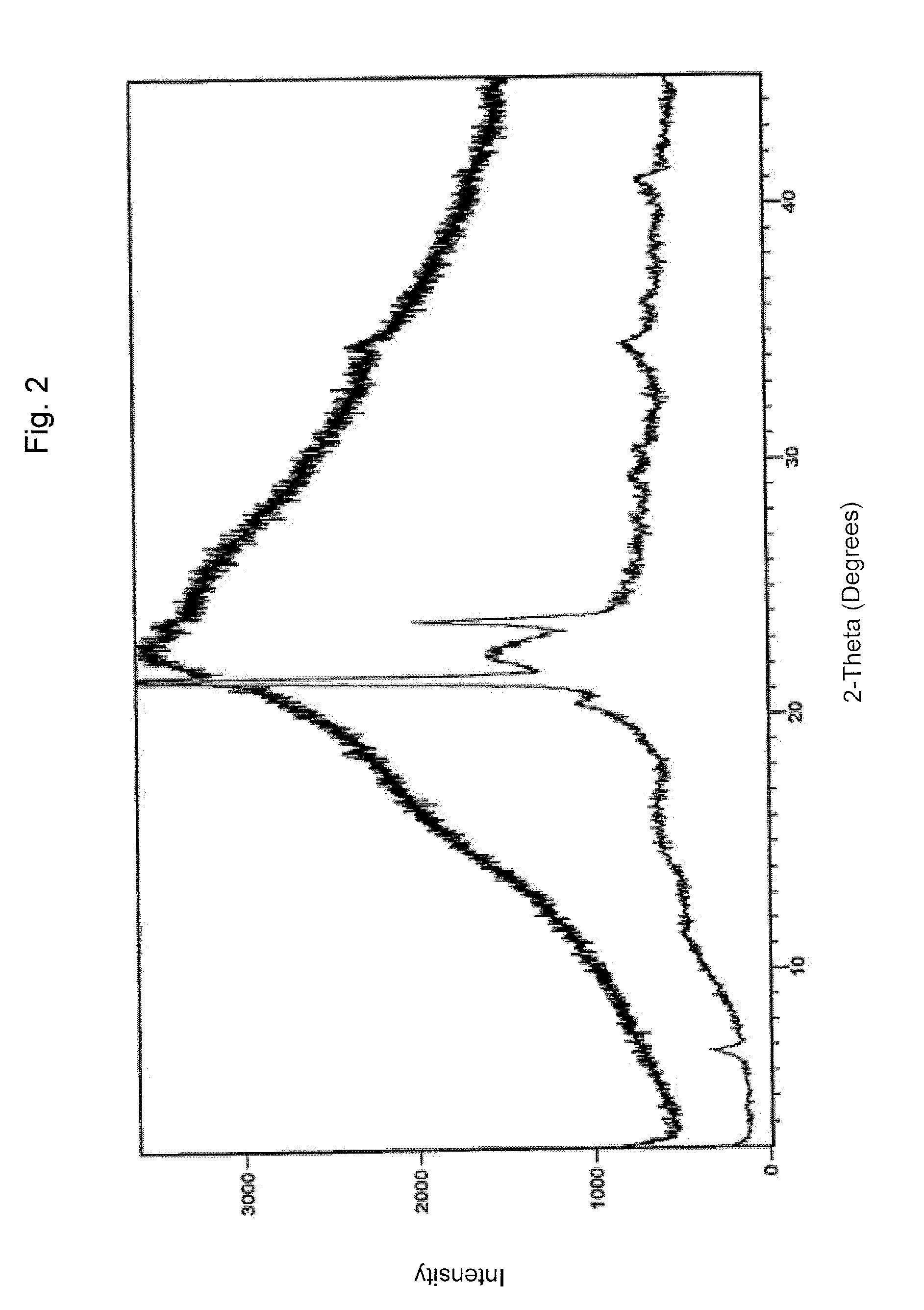

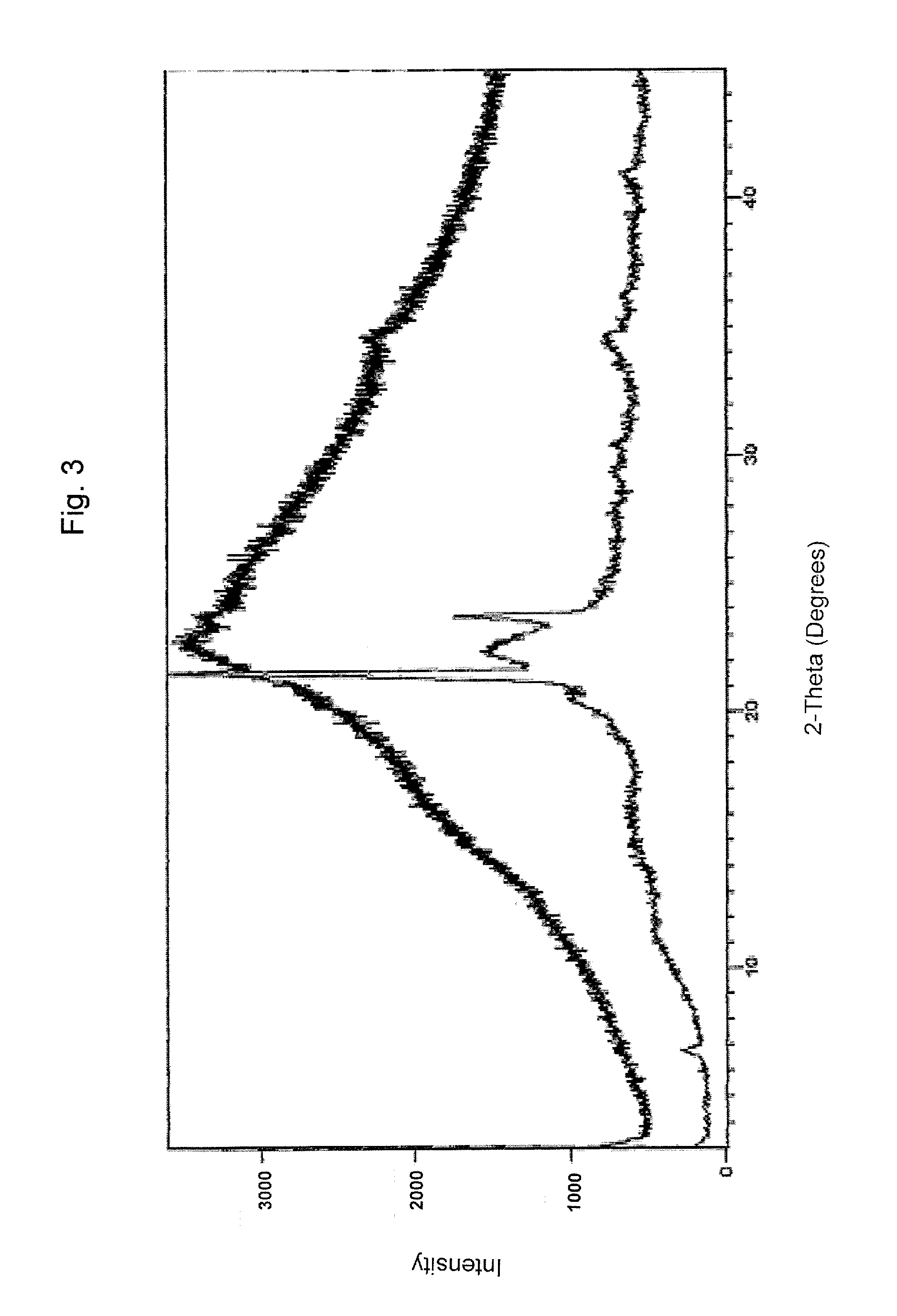

Pharmaceutical propylene glycol solvate compositions

InactiveUS20070015841A1Less hygroscopicMore solubleBiocideOrganic chemistryIsopropylene glycolChemistry

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

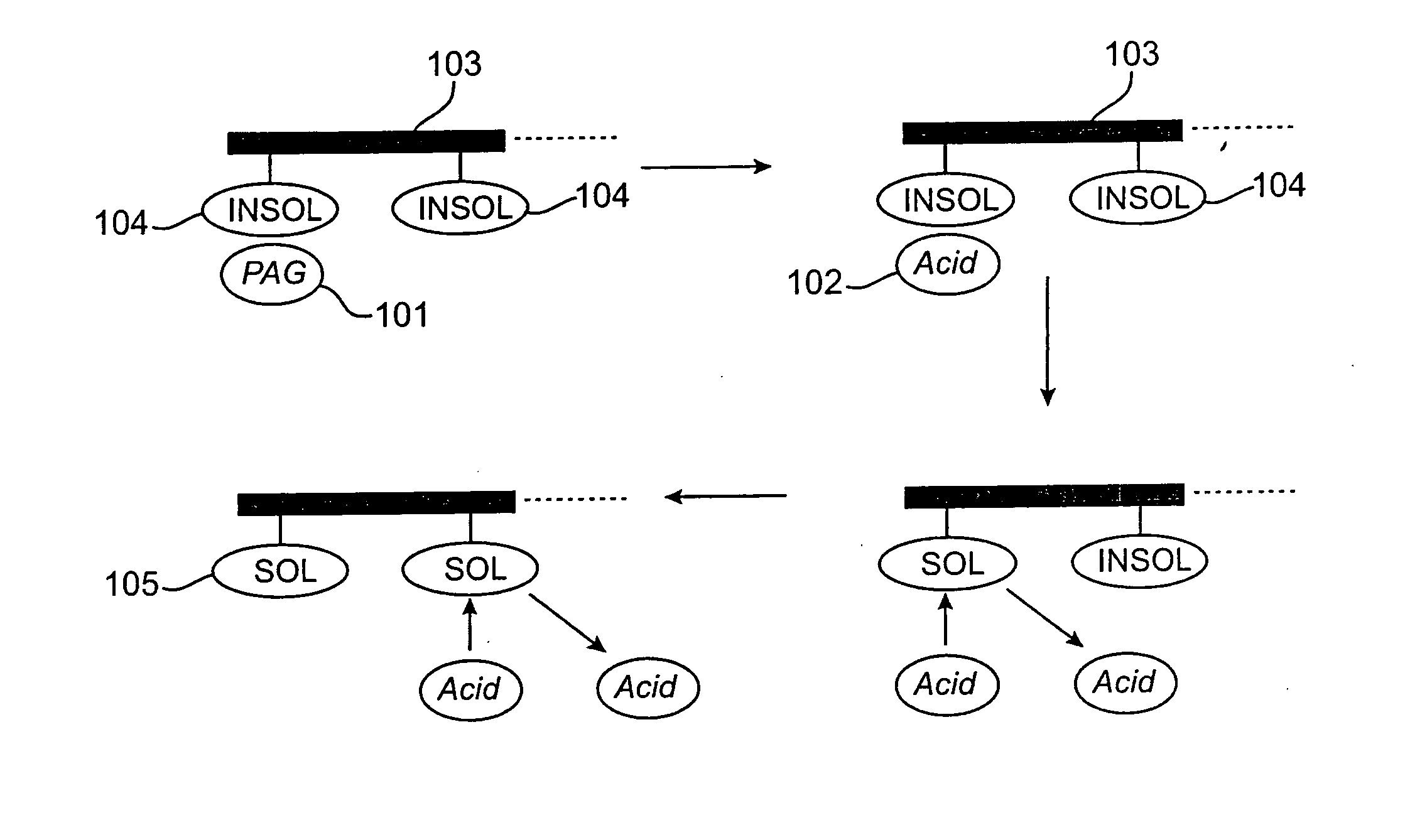

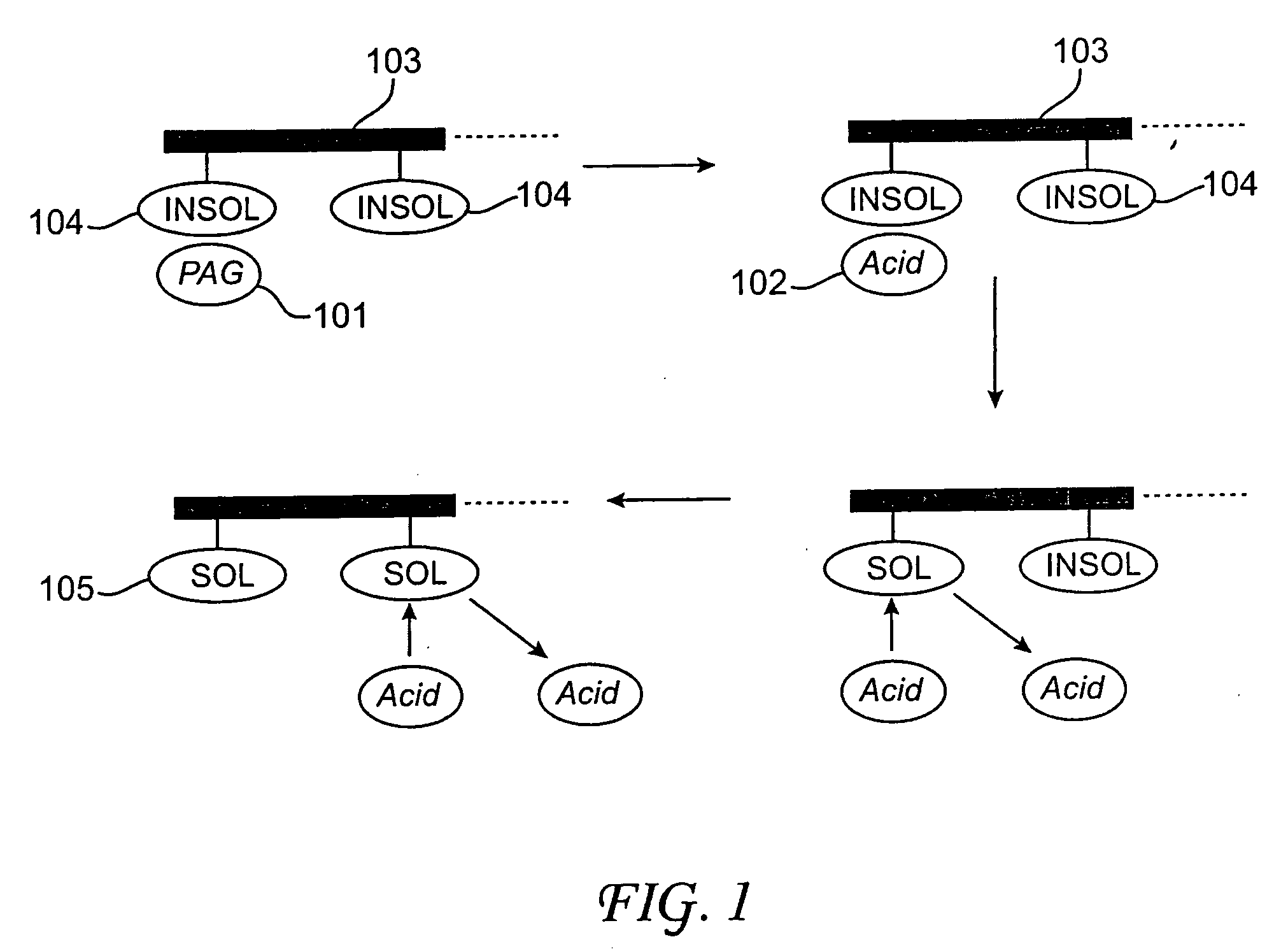

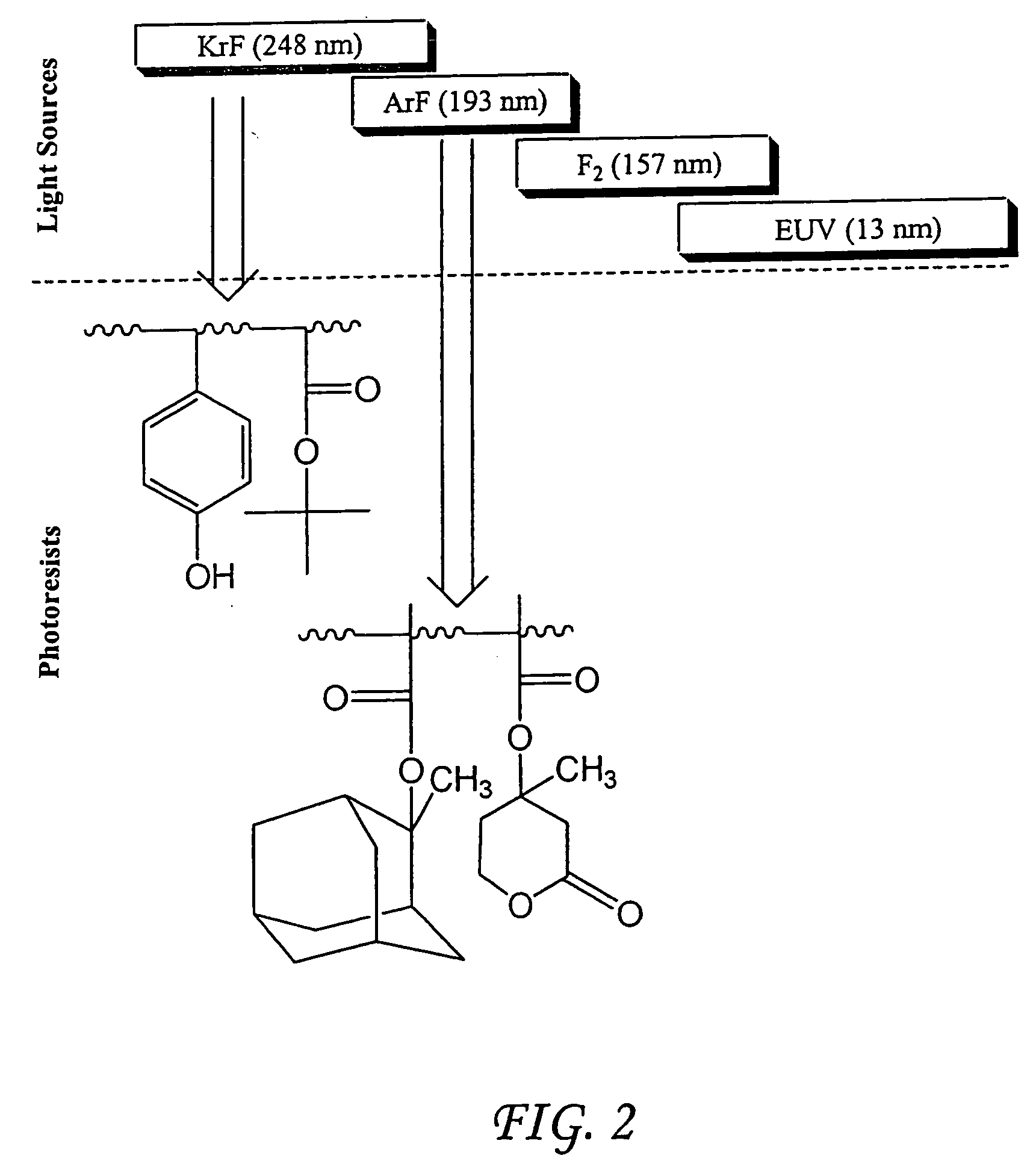

Photoresist compositions comprising diamondoid derivatives

InactiveUS20050074690A1Improve hydrophilicityMore solubleOrganic compound preparationRadiation applicationsResistDiamantane

Novel positive-working photoresist compositions are disclosed. The monomers of the base resin of the resist contain diamondoid-containing pendant groups higher than adamantane in the polymantane series; for example, diamantane, triamantane, tetramantane, pentamantane, hexamantane, etc. The diamondoid-containing pendant group may have hydrophilic-enhancing substituents such as a hydroxyl group, and may contain a lactone group. Advantages of the present compositions include enhanced resolution, sensitivity, and adhesion to the substrate.

Owner:CHEVROU USA INC

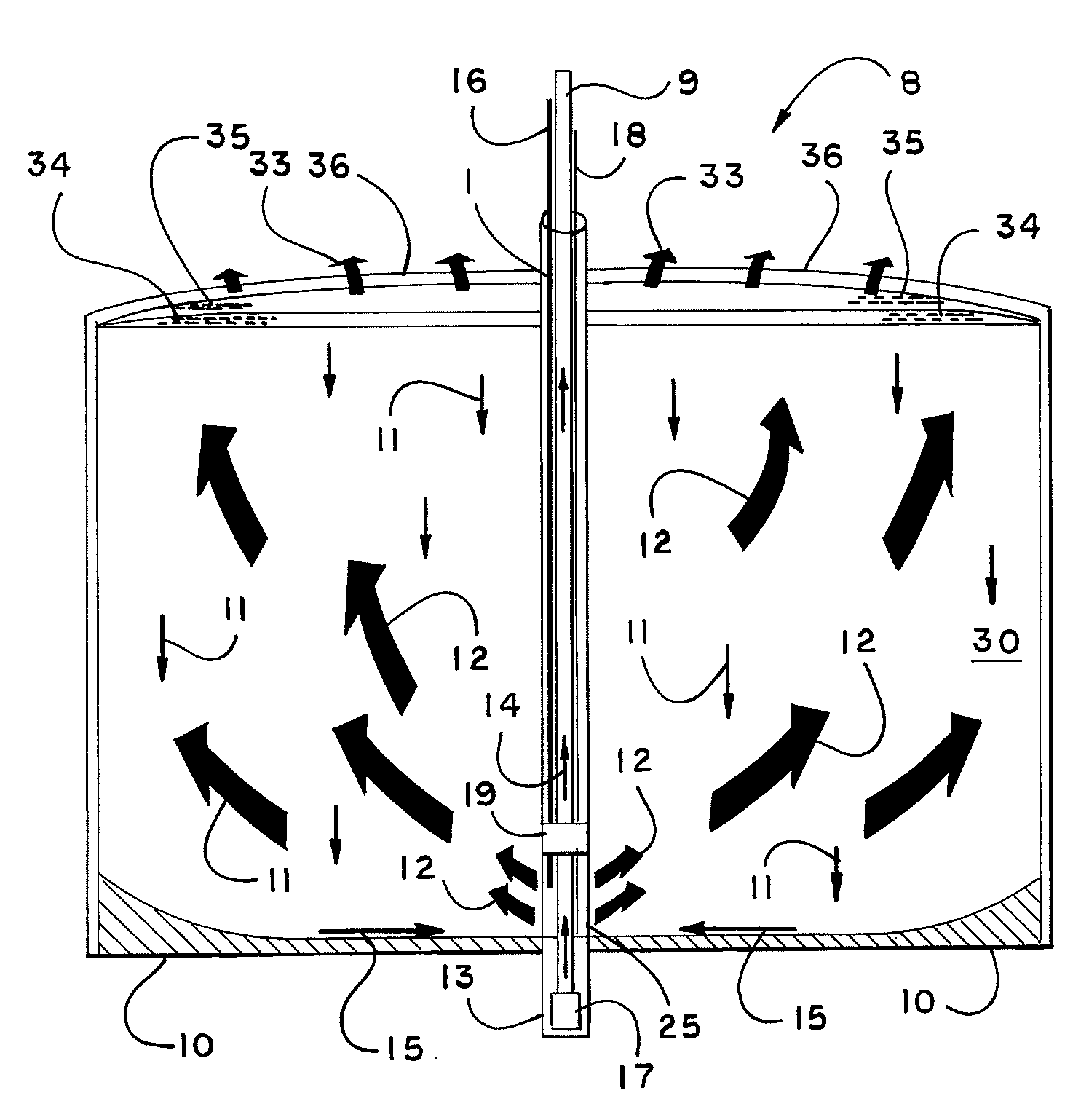

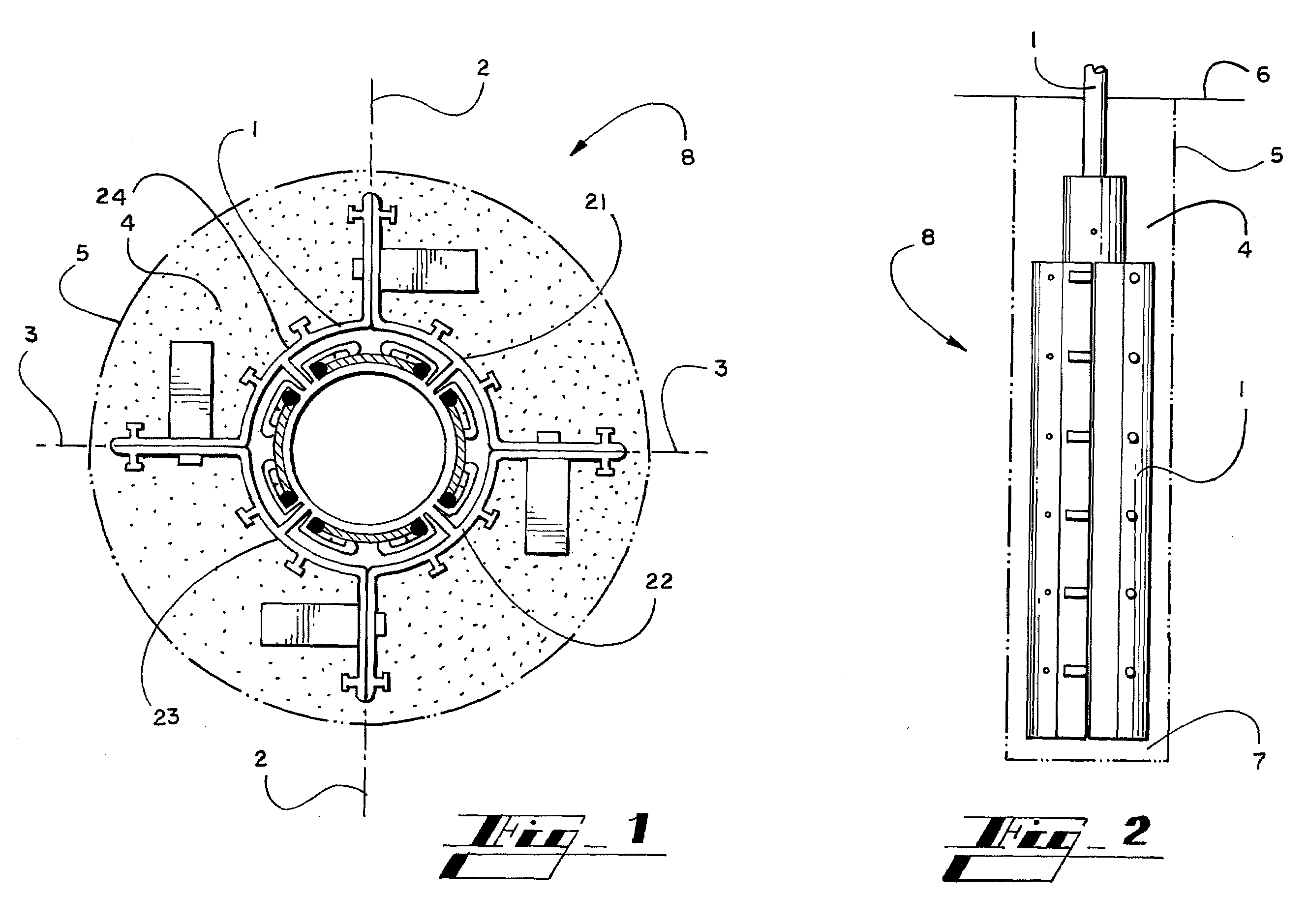

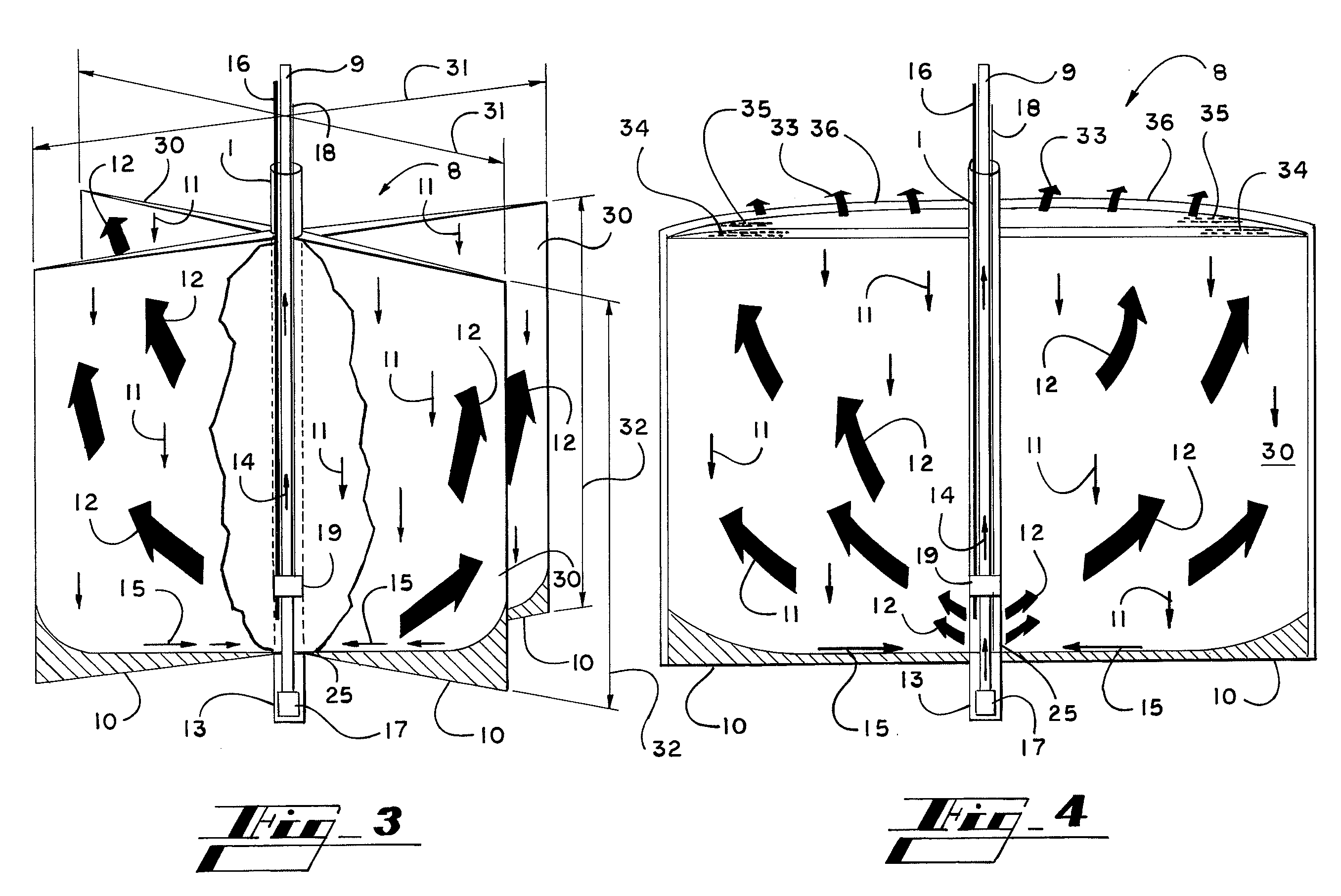

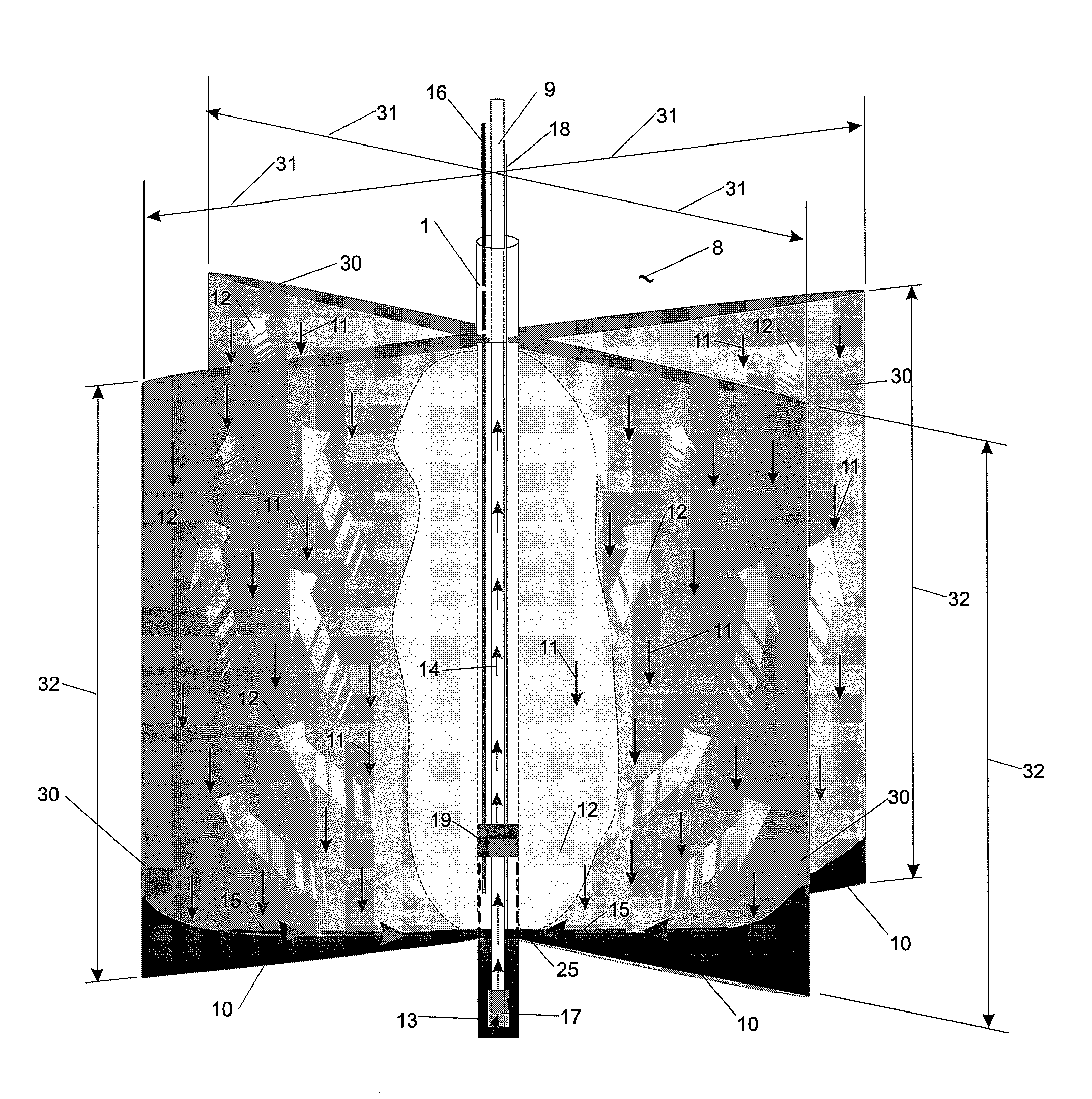

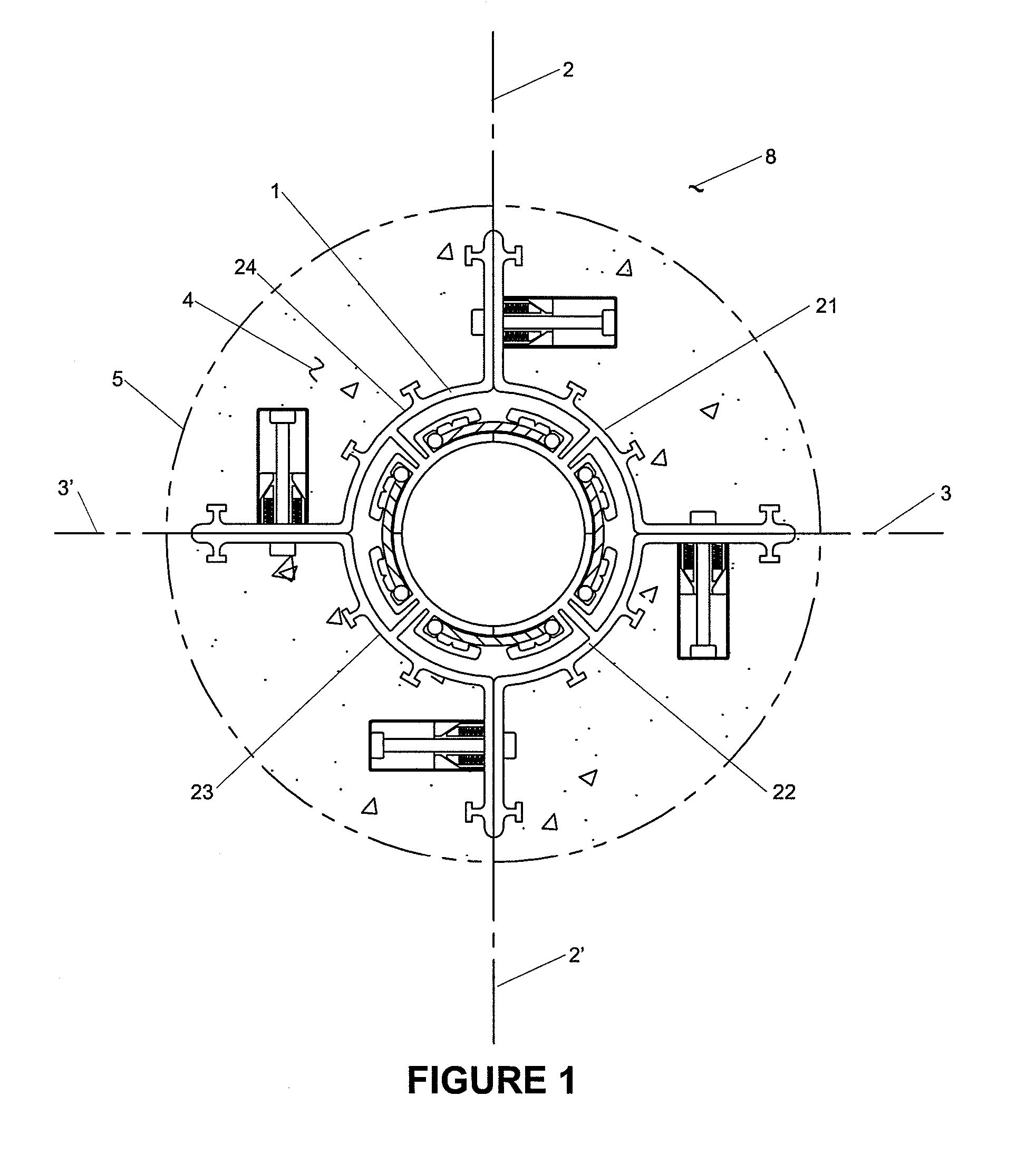

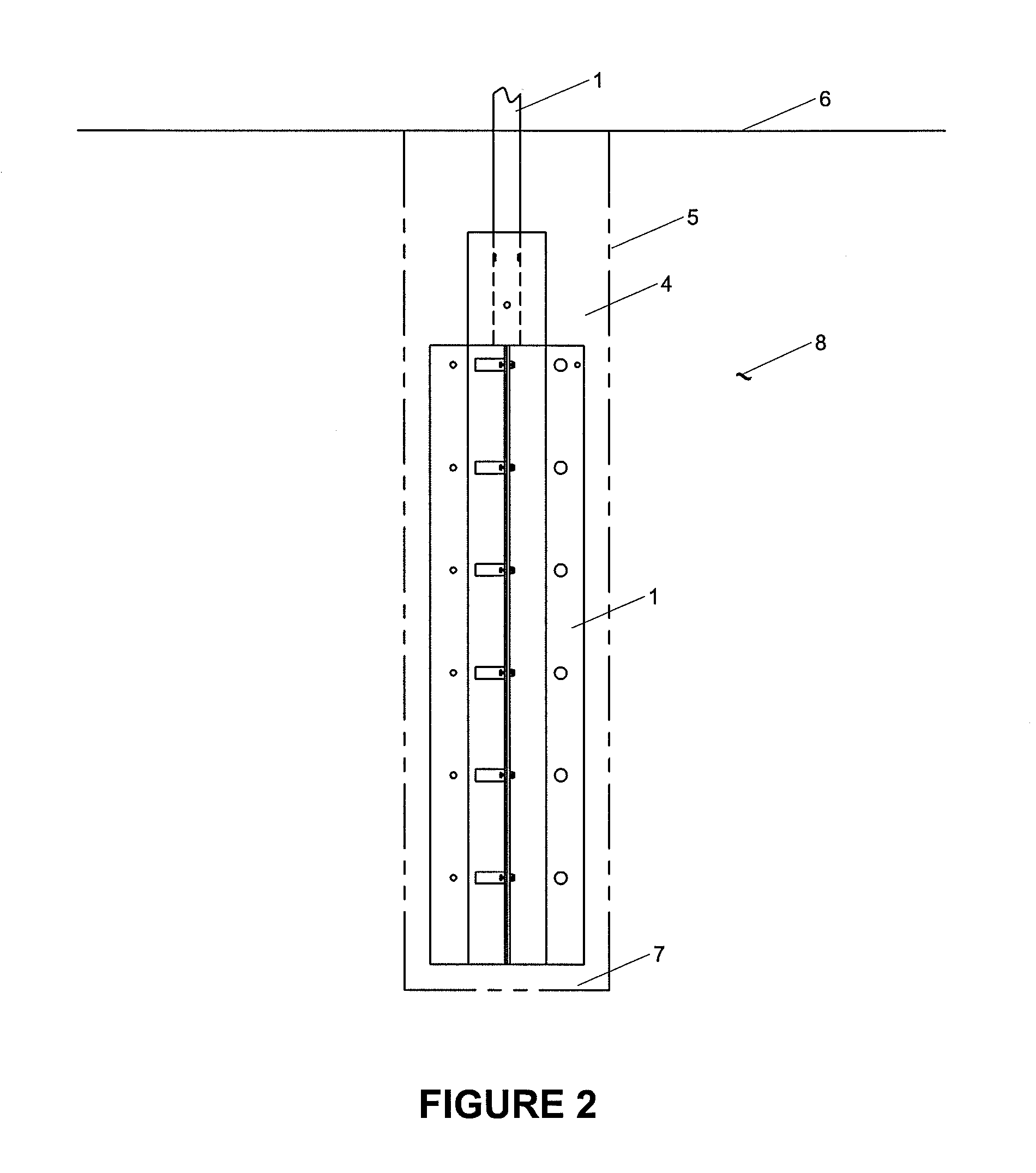

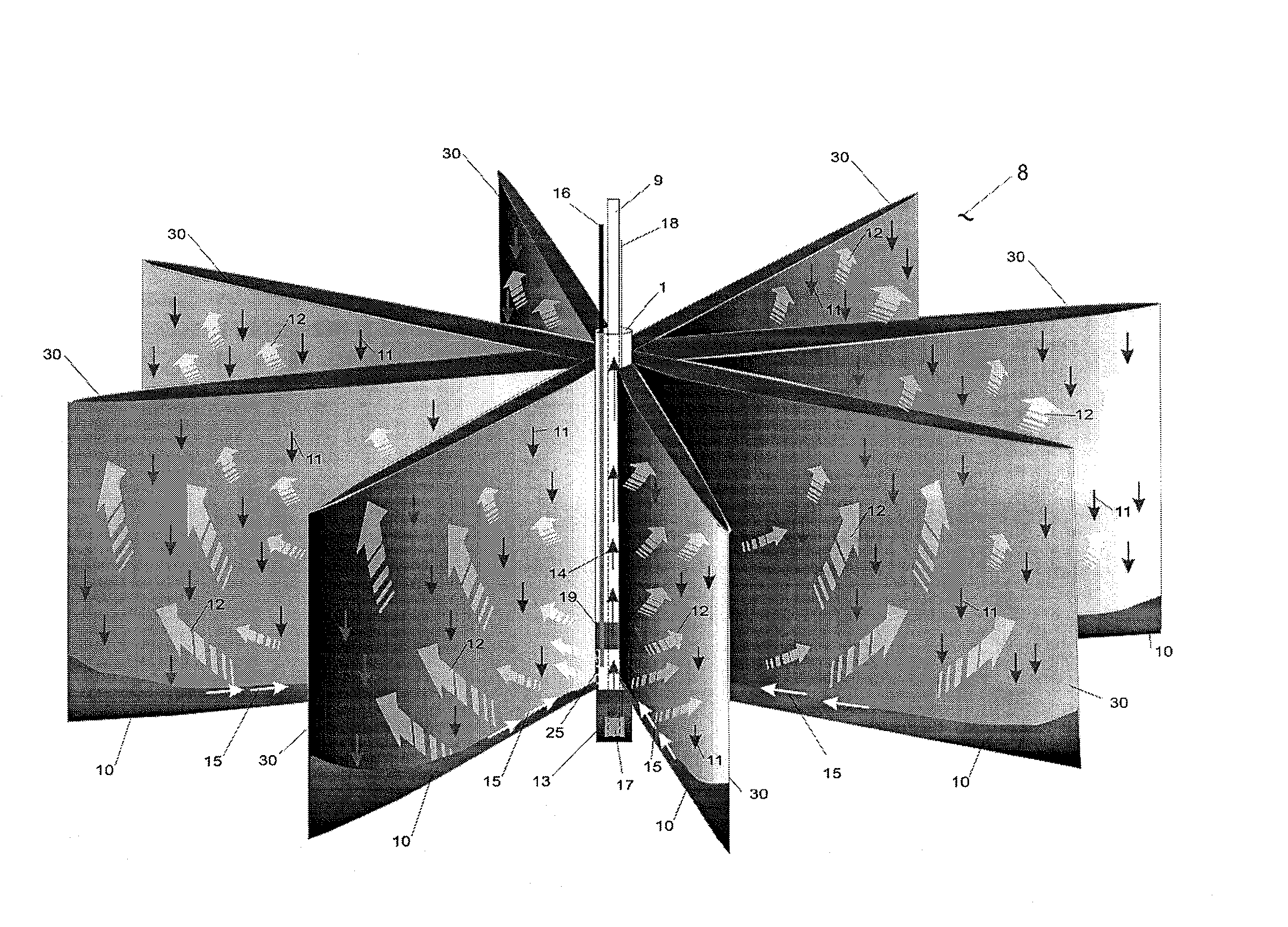

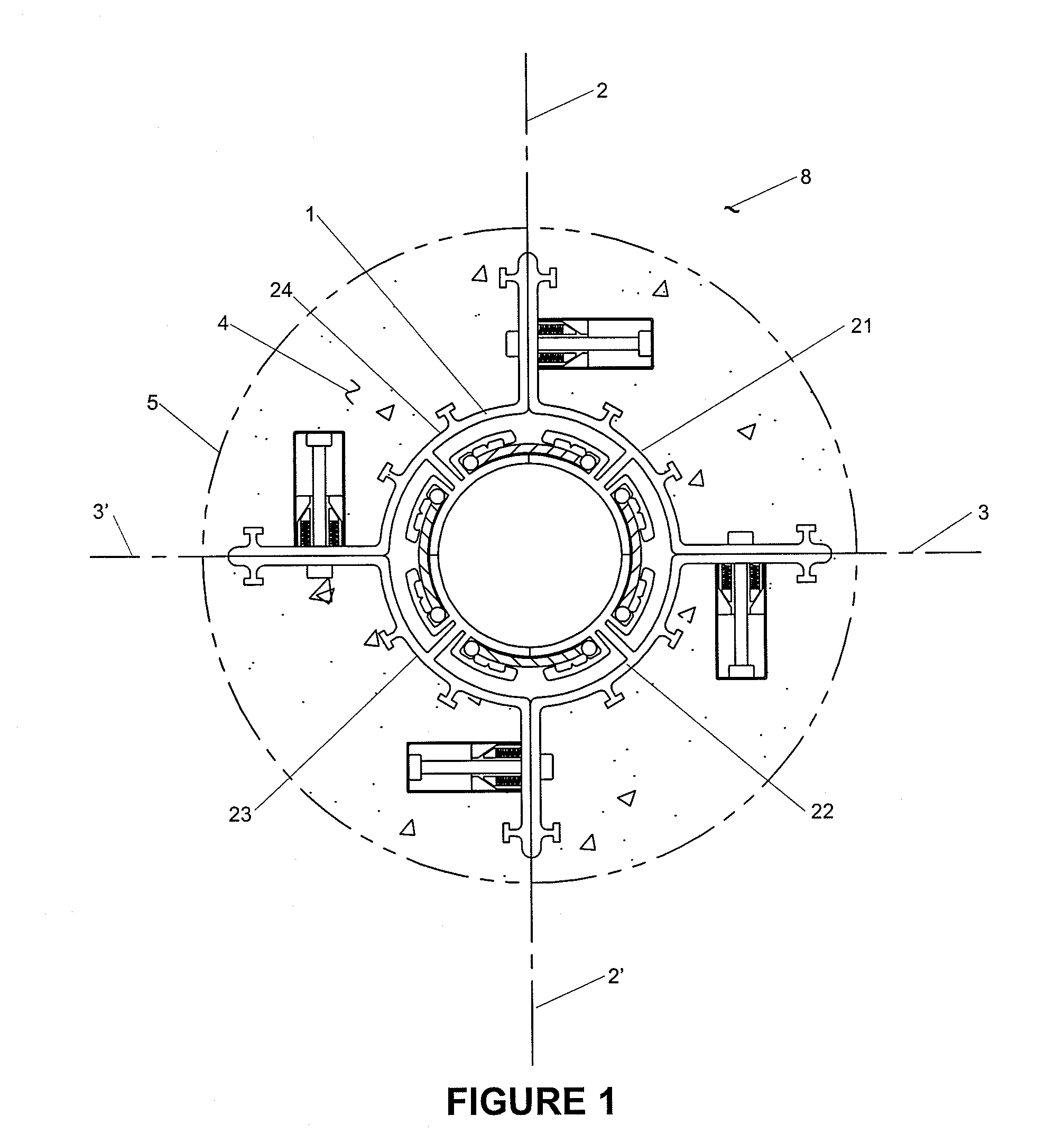

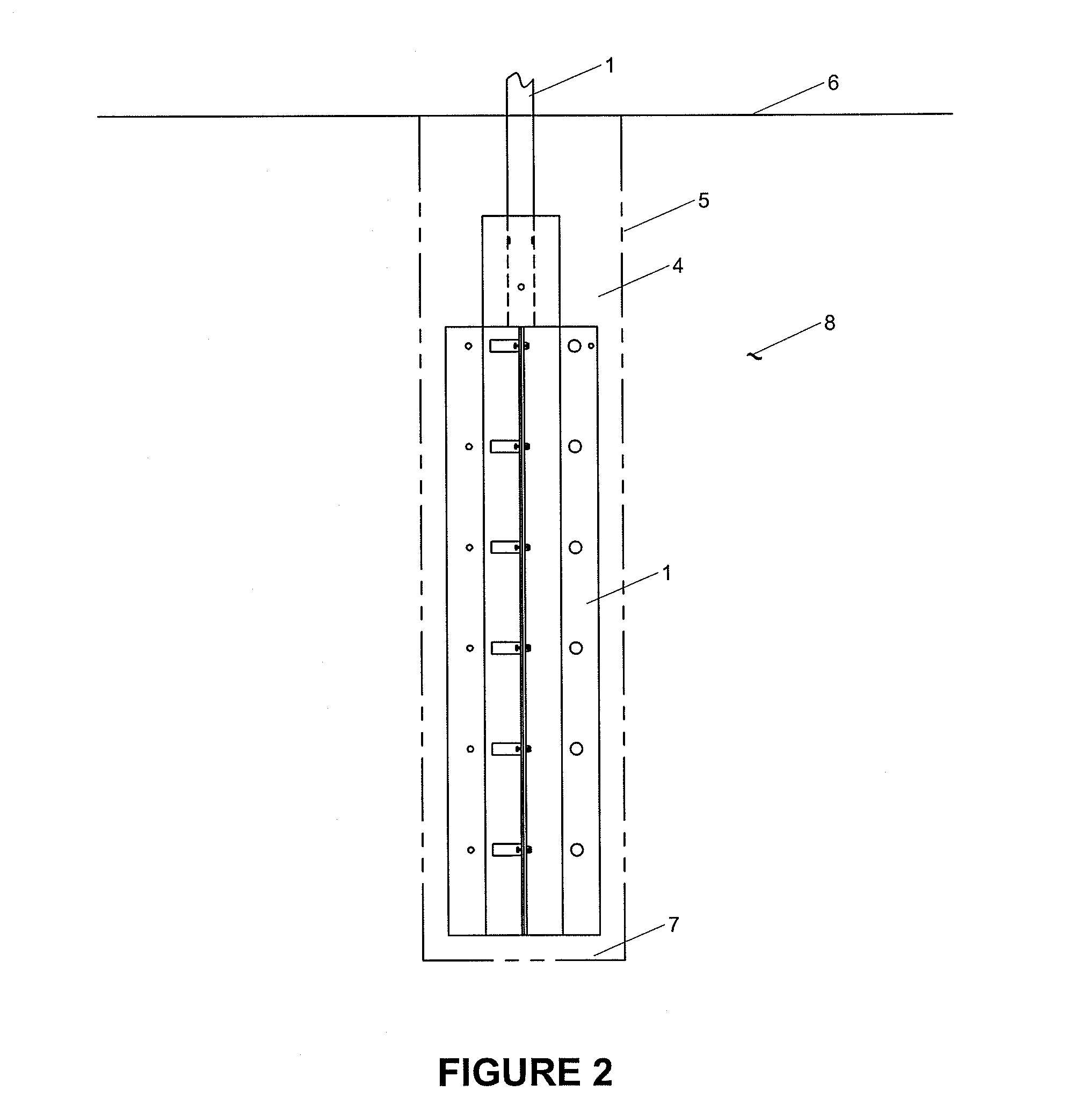

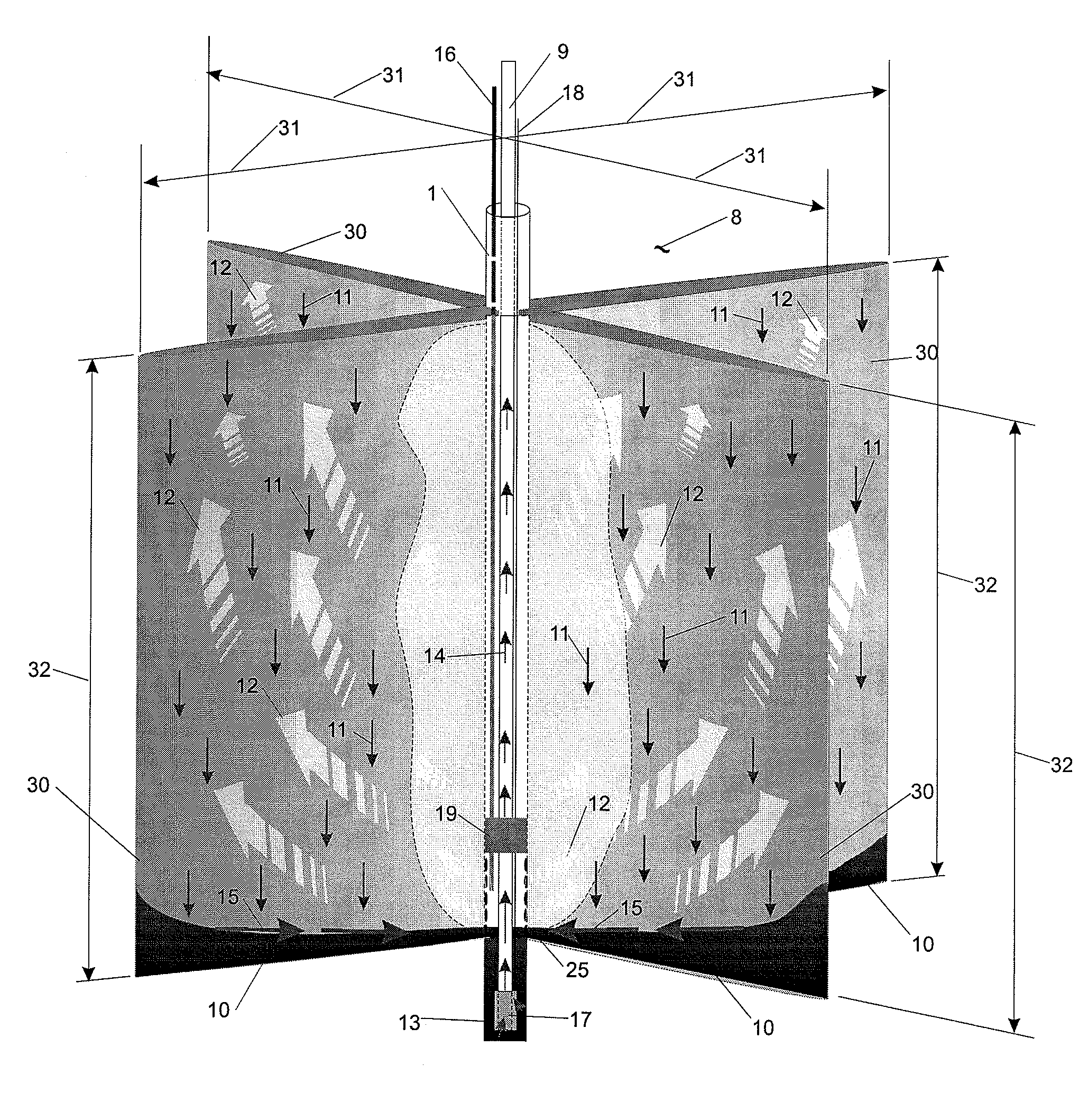

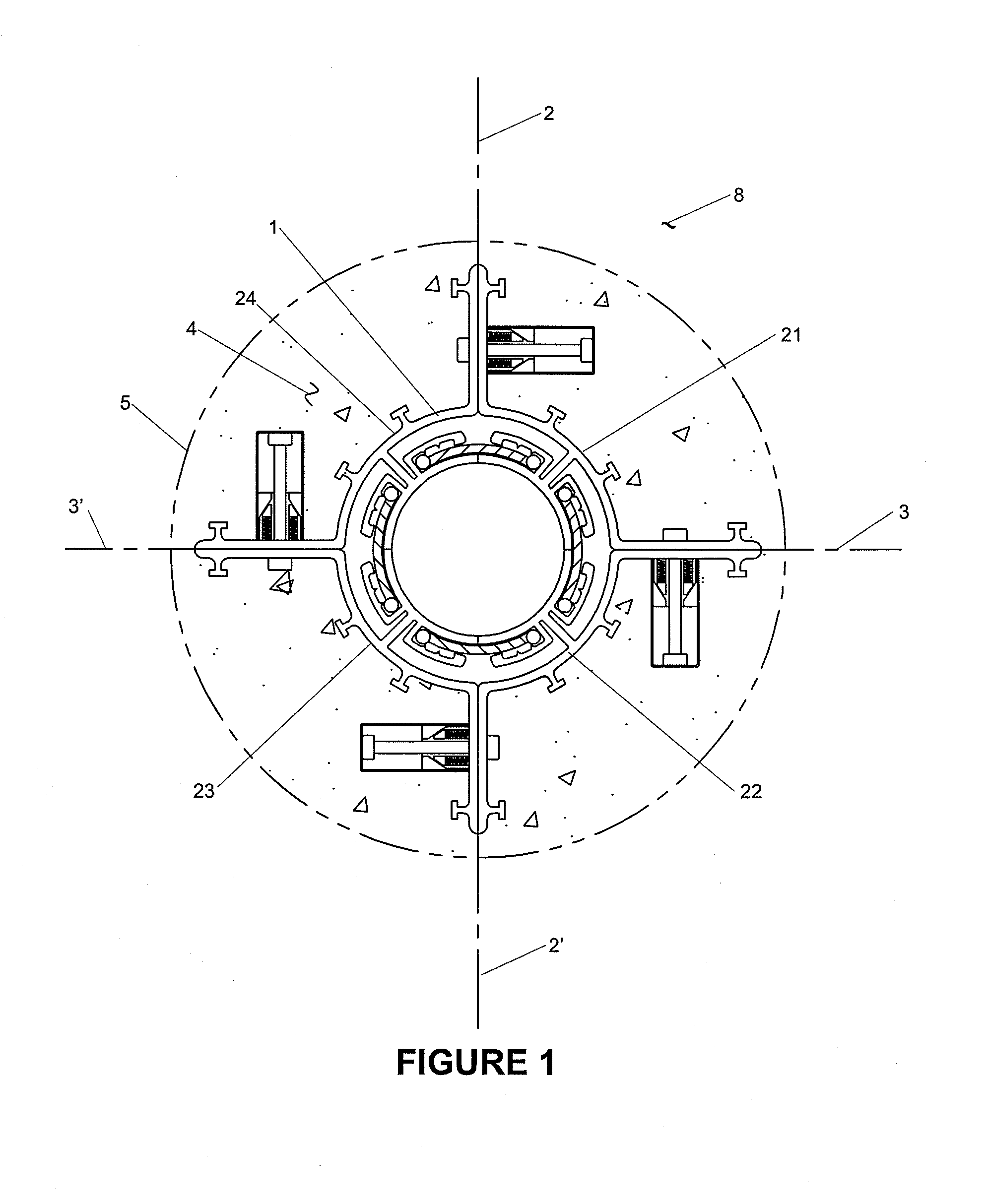

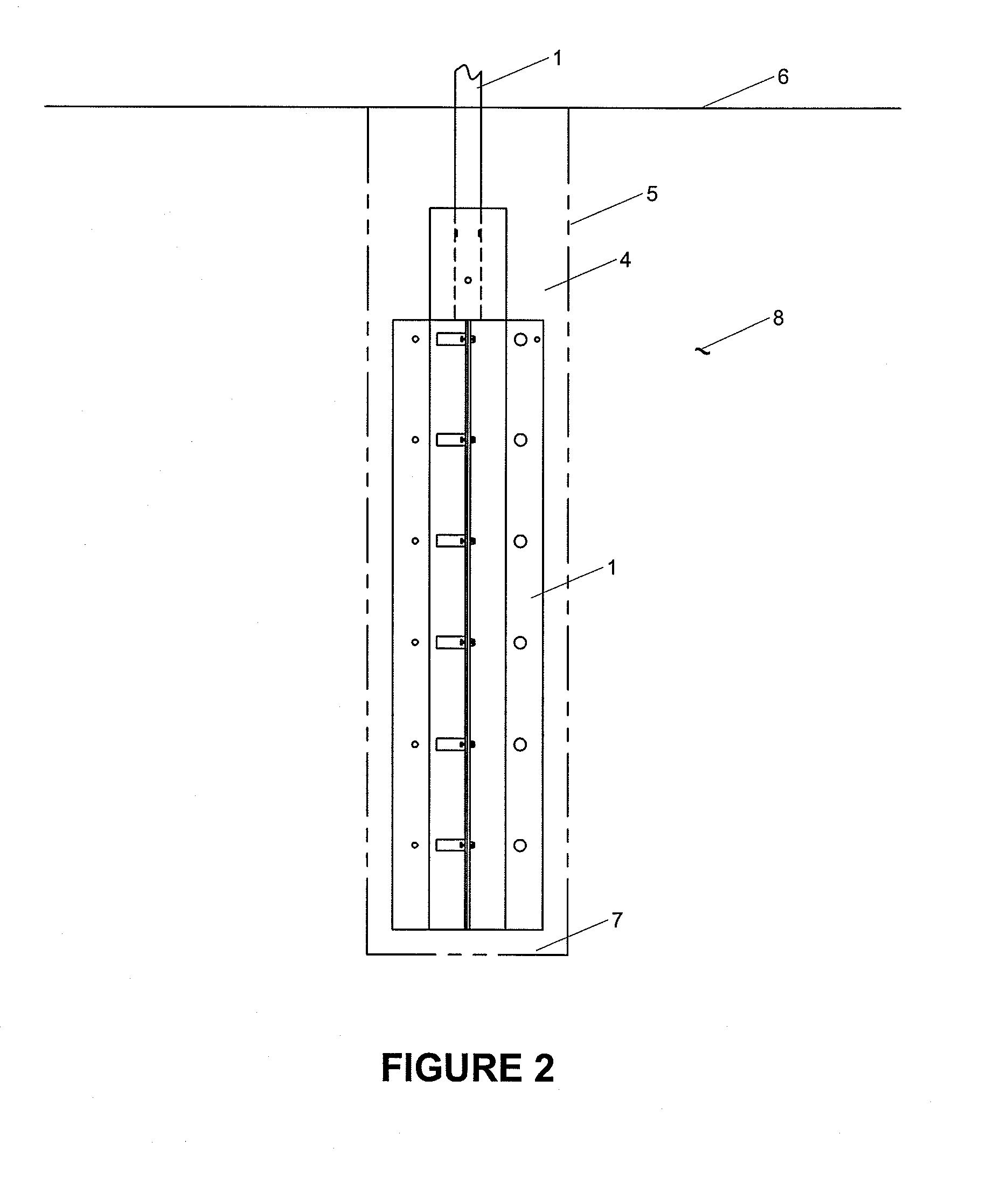

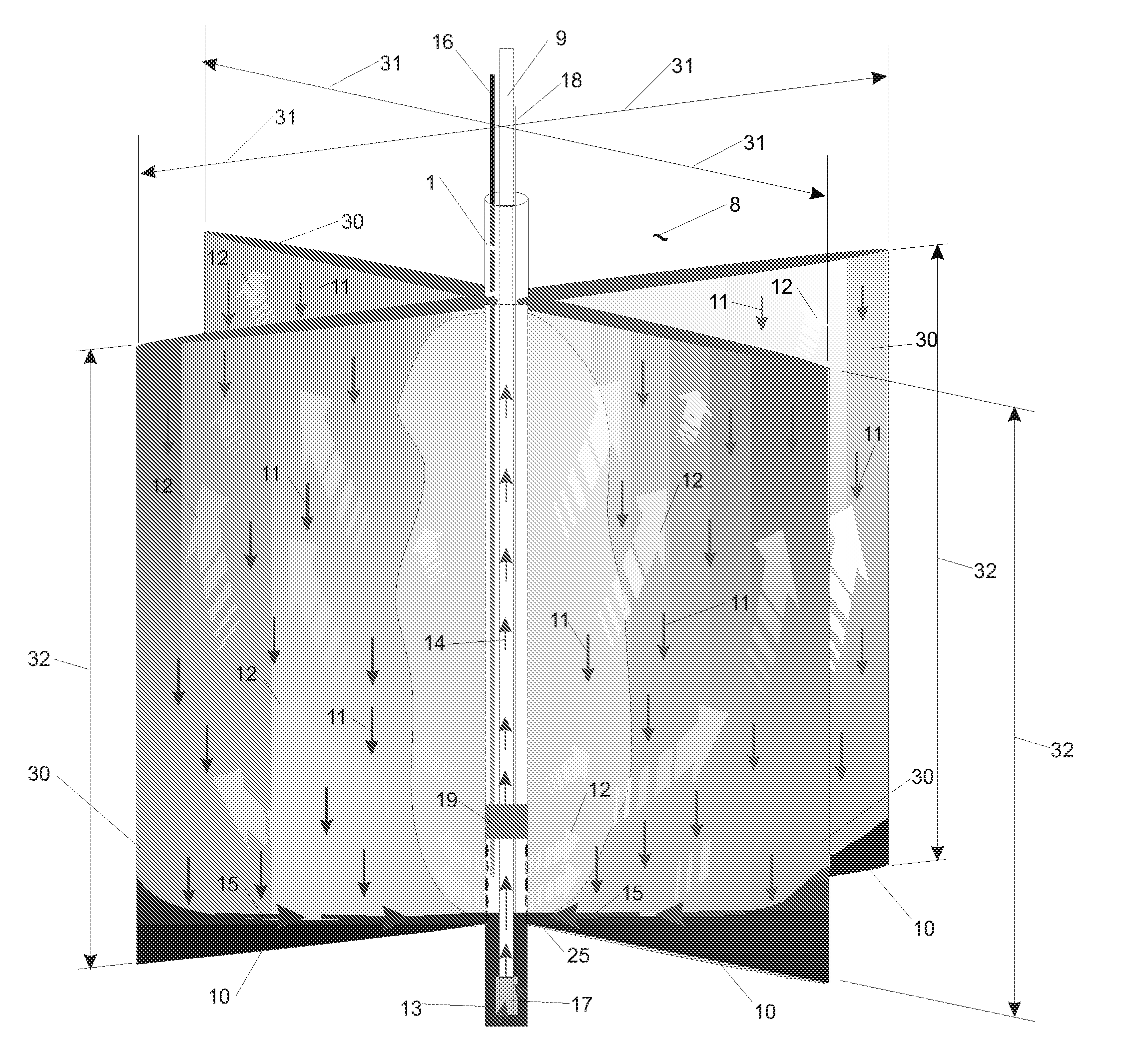

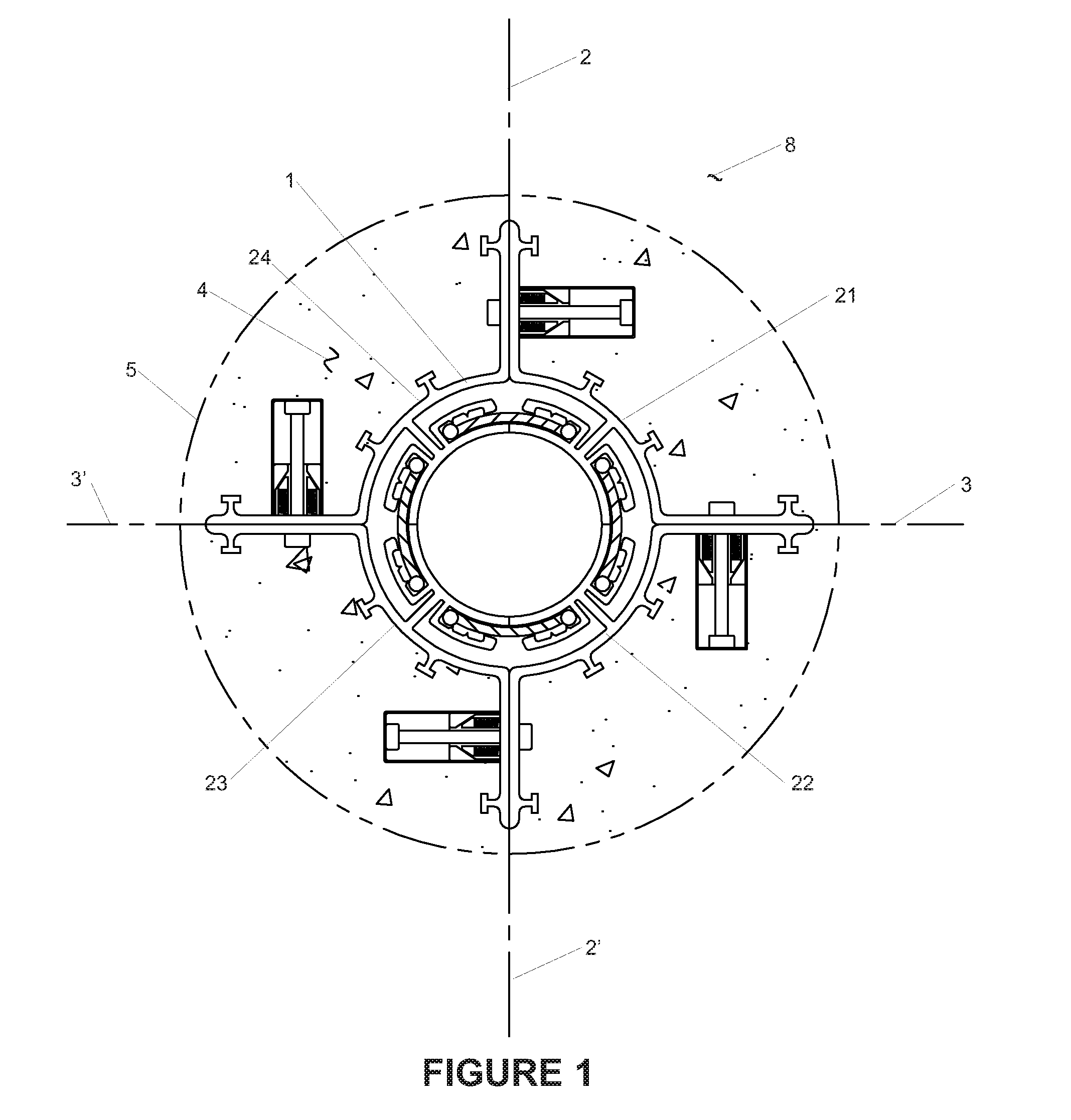

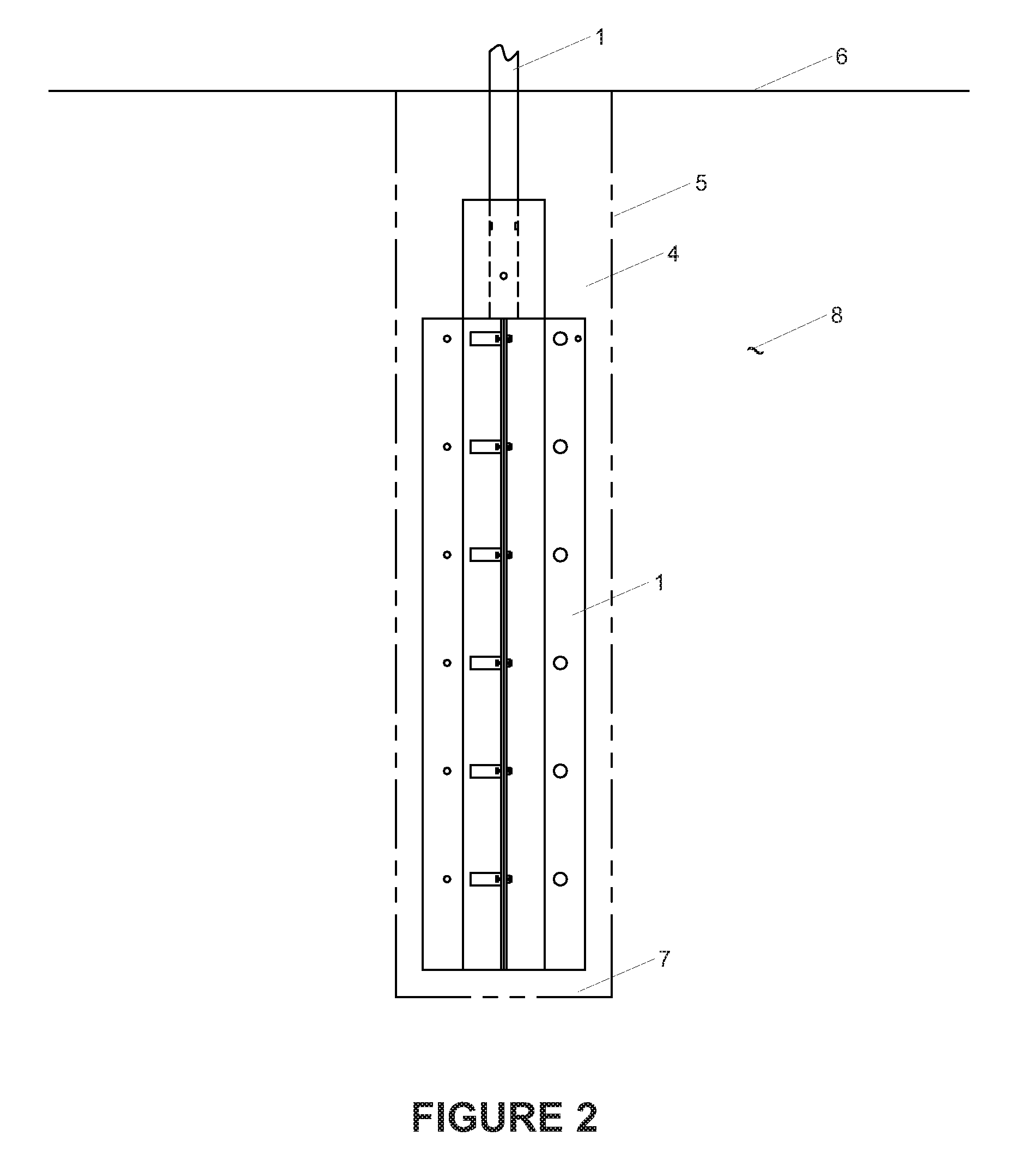

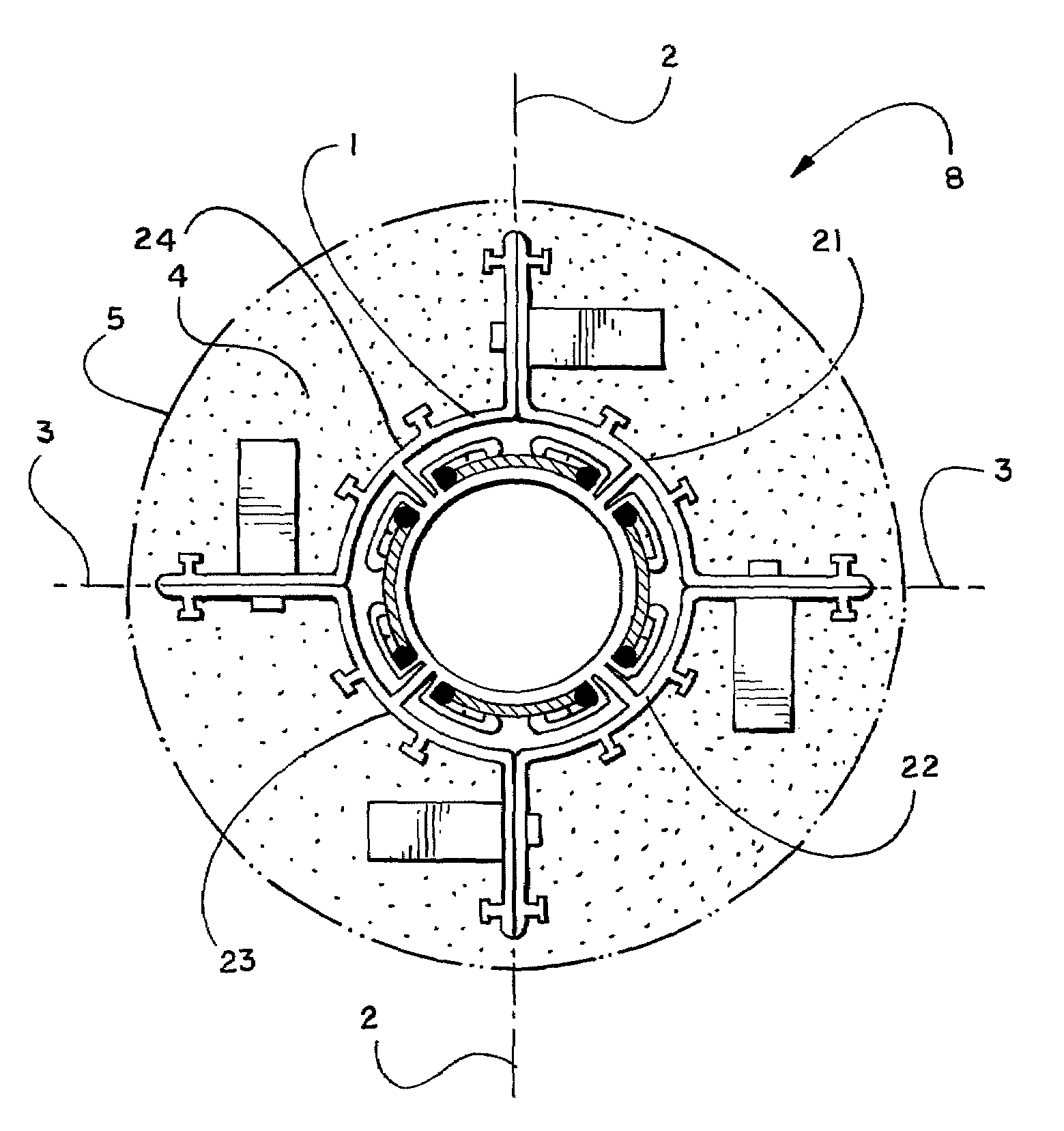

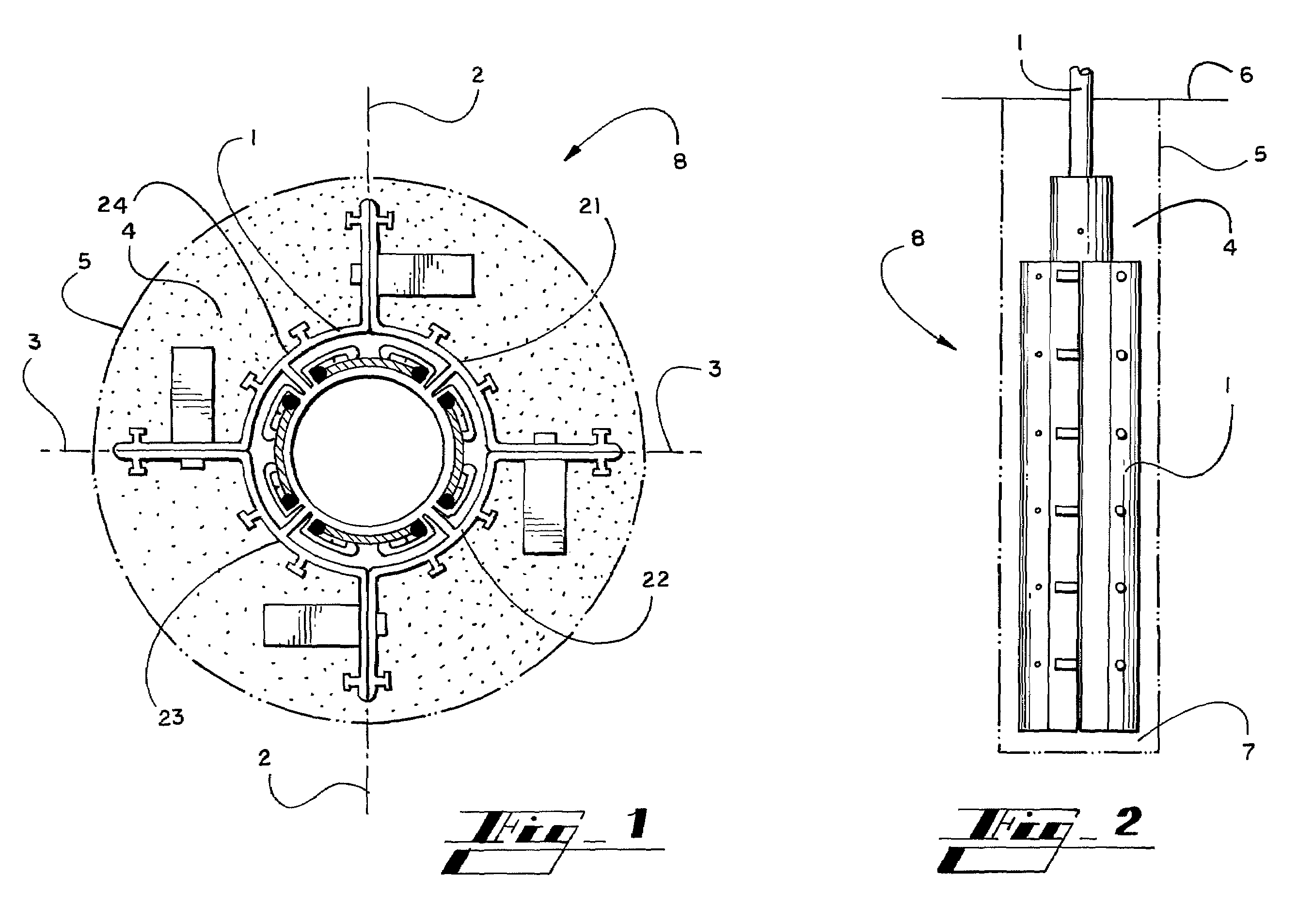

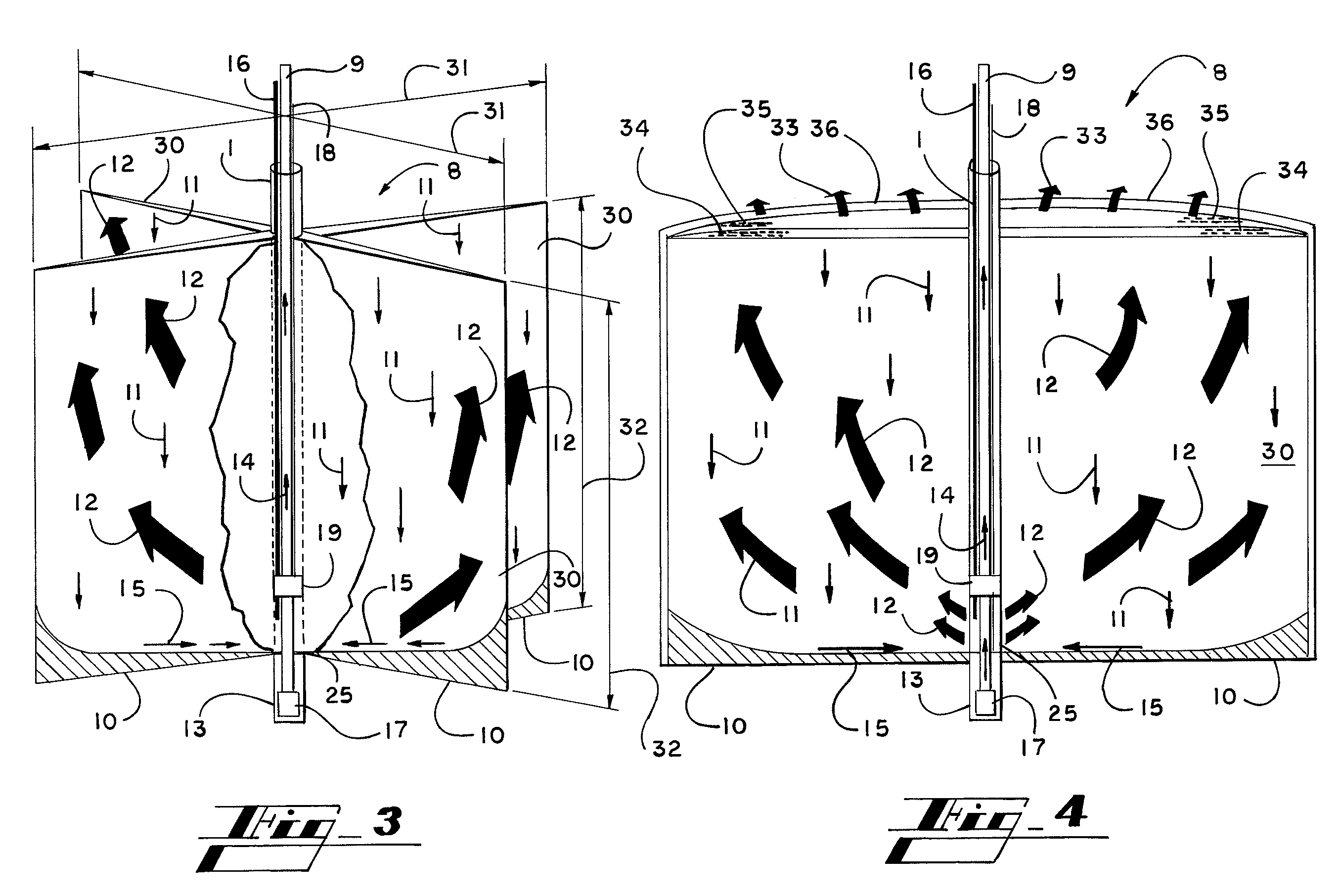

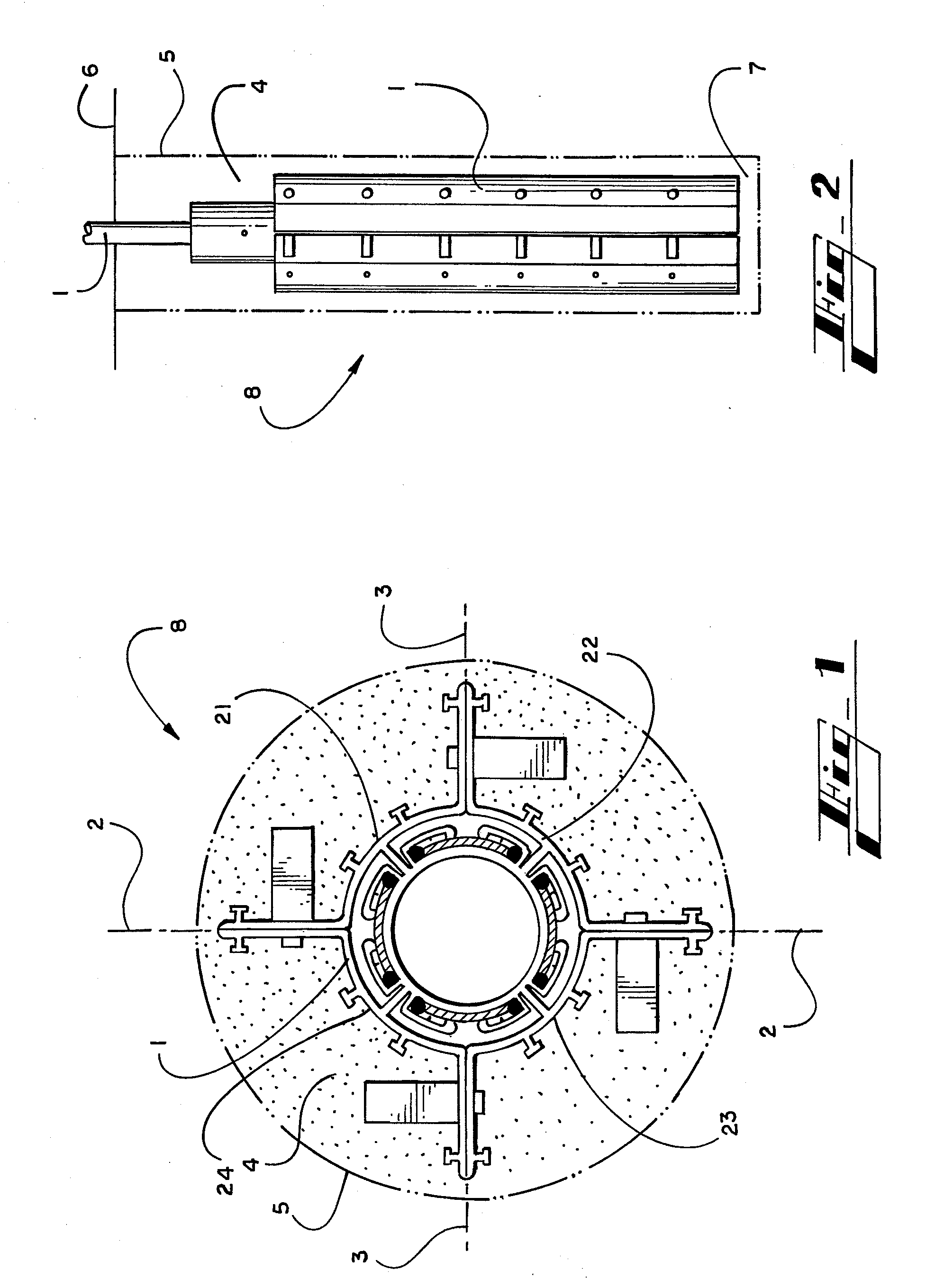

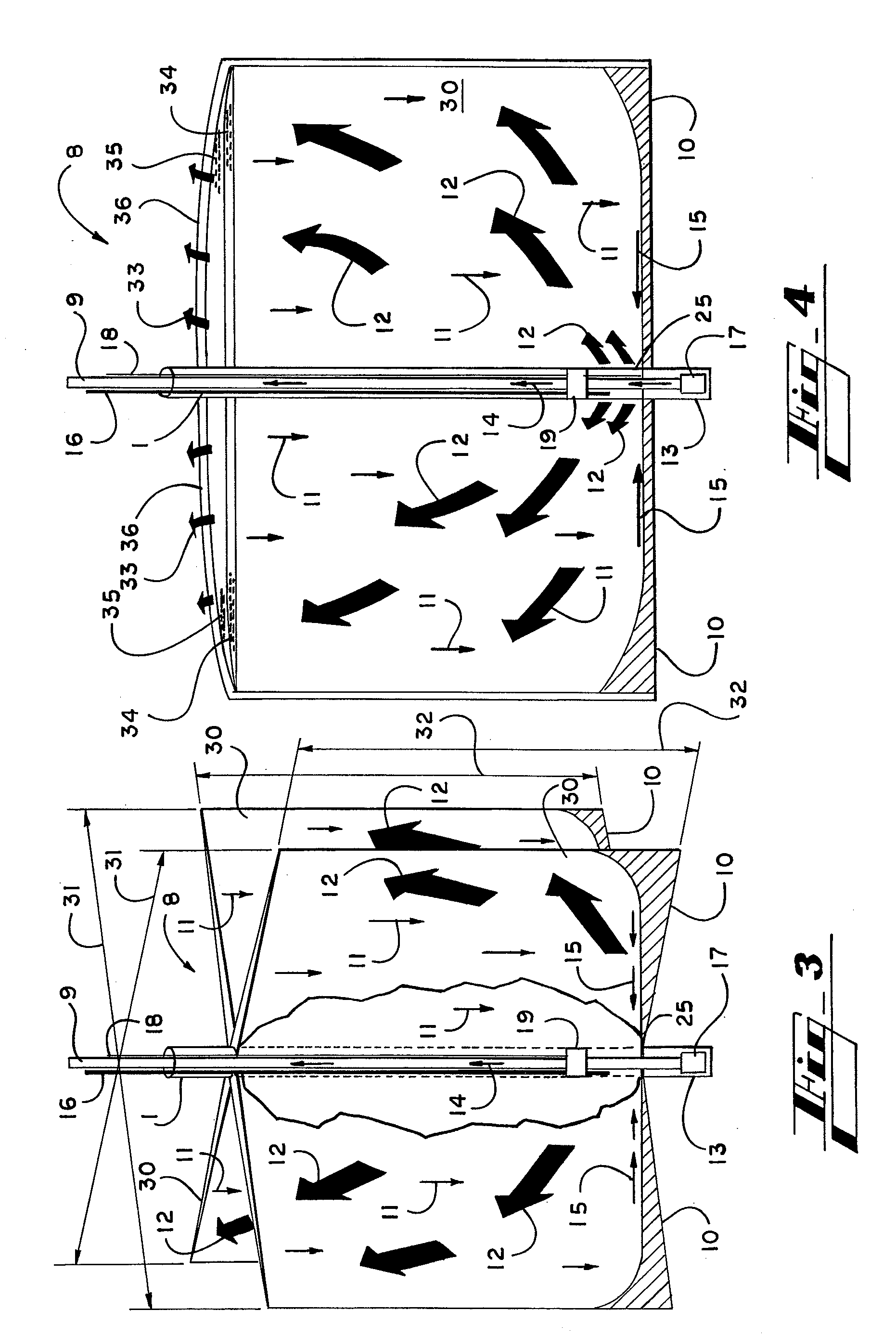

Enhanced Hydrocarbon Recovery By Steam Injection of Oil Sand Formations

InactiveUS20070199698A1Promote recoveryIncrease productionSurveyInsulationHydrocarbon solventsFuel oil

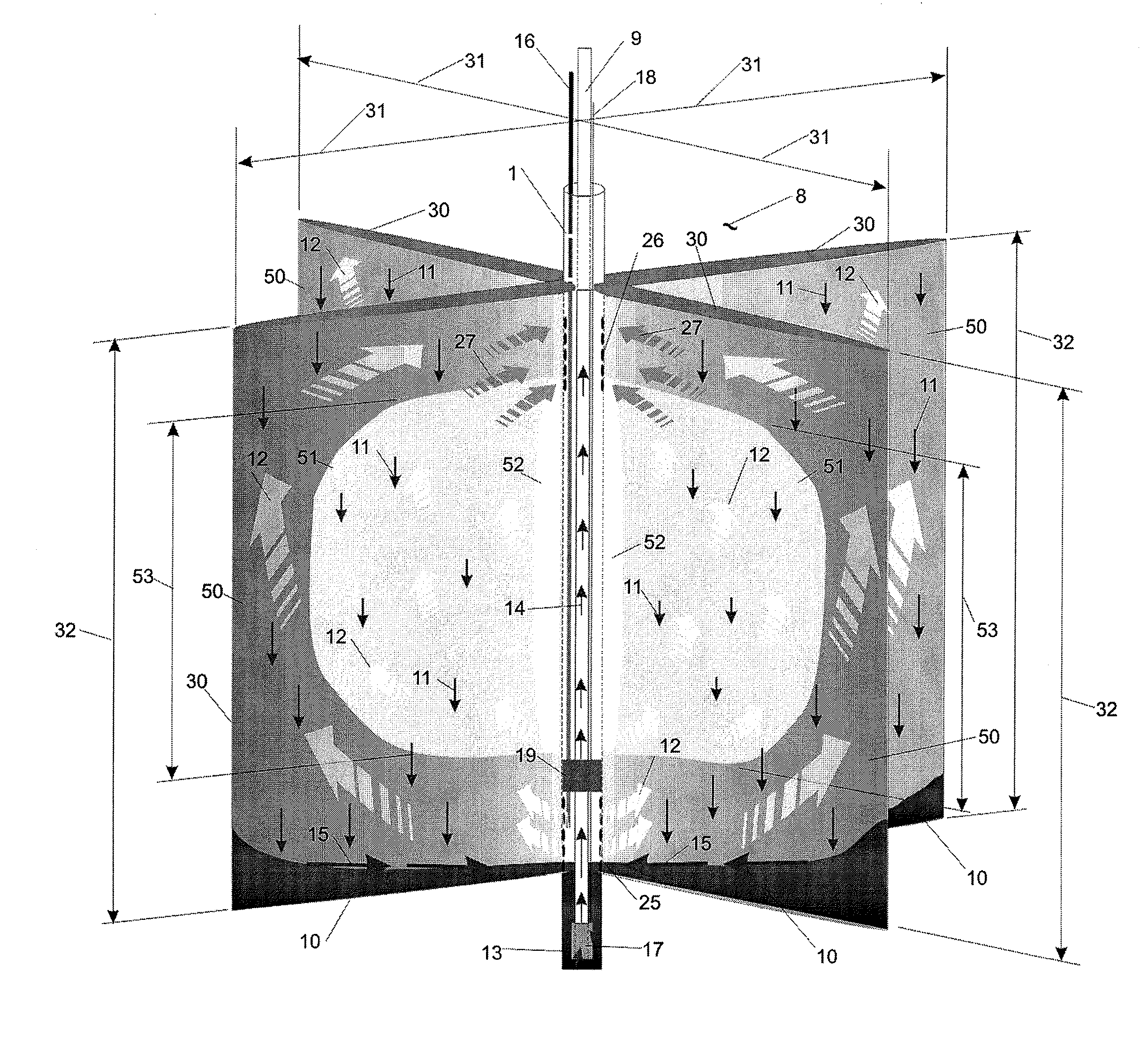

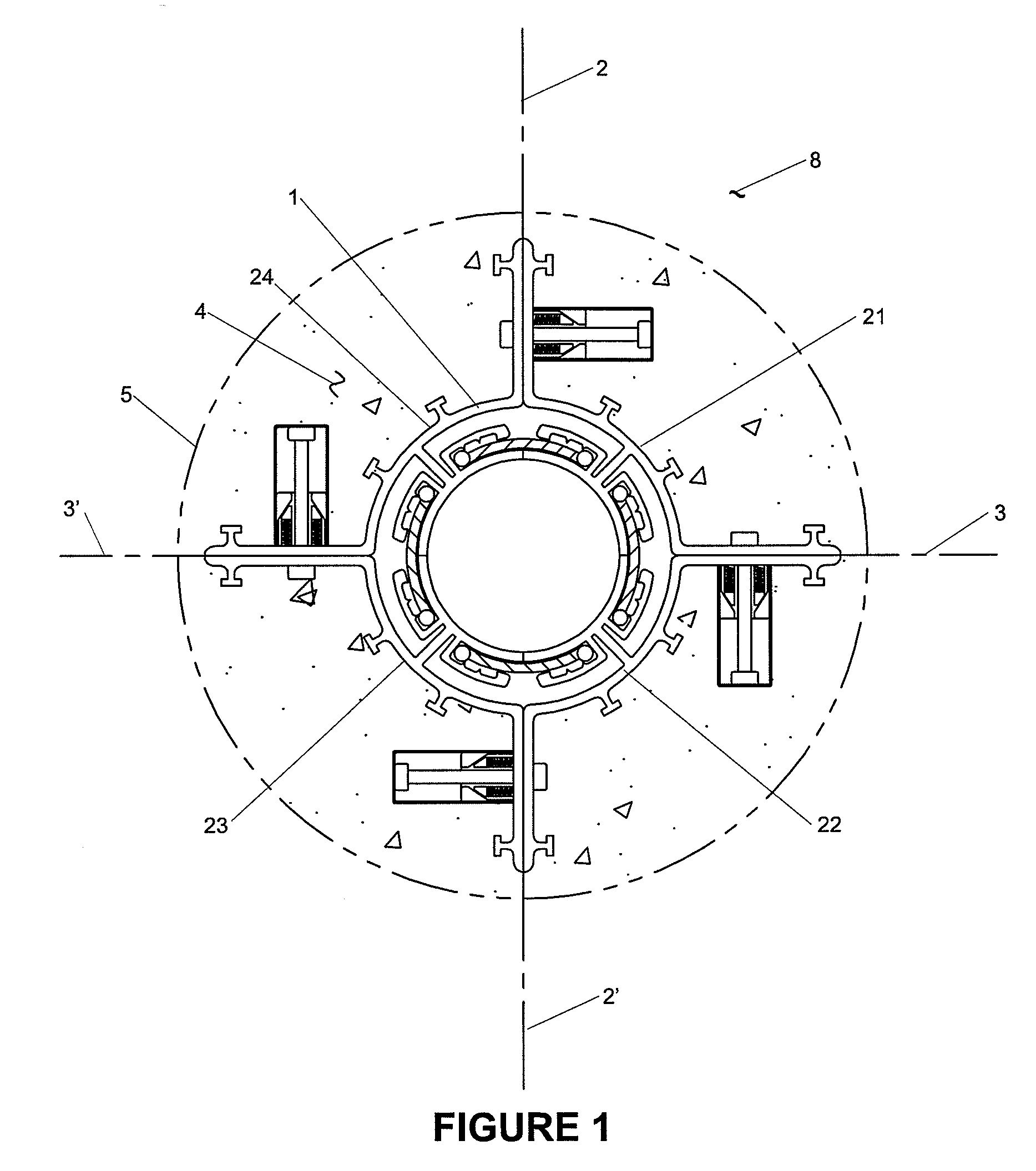

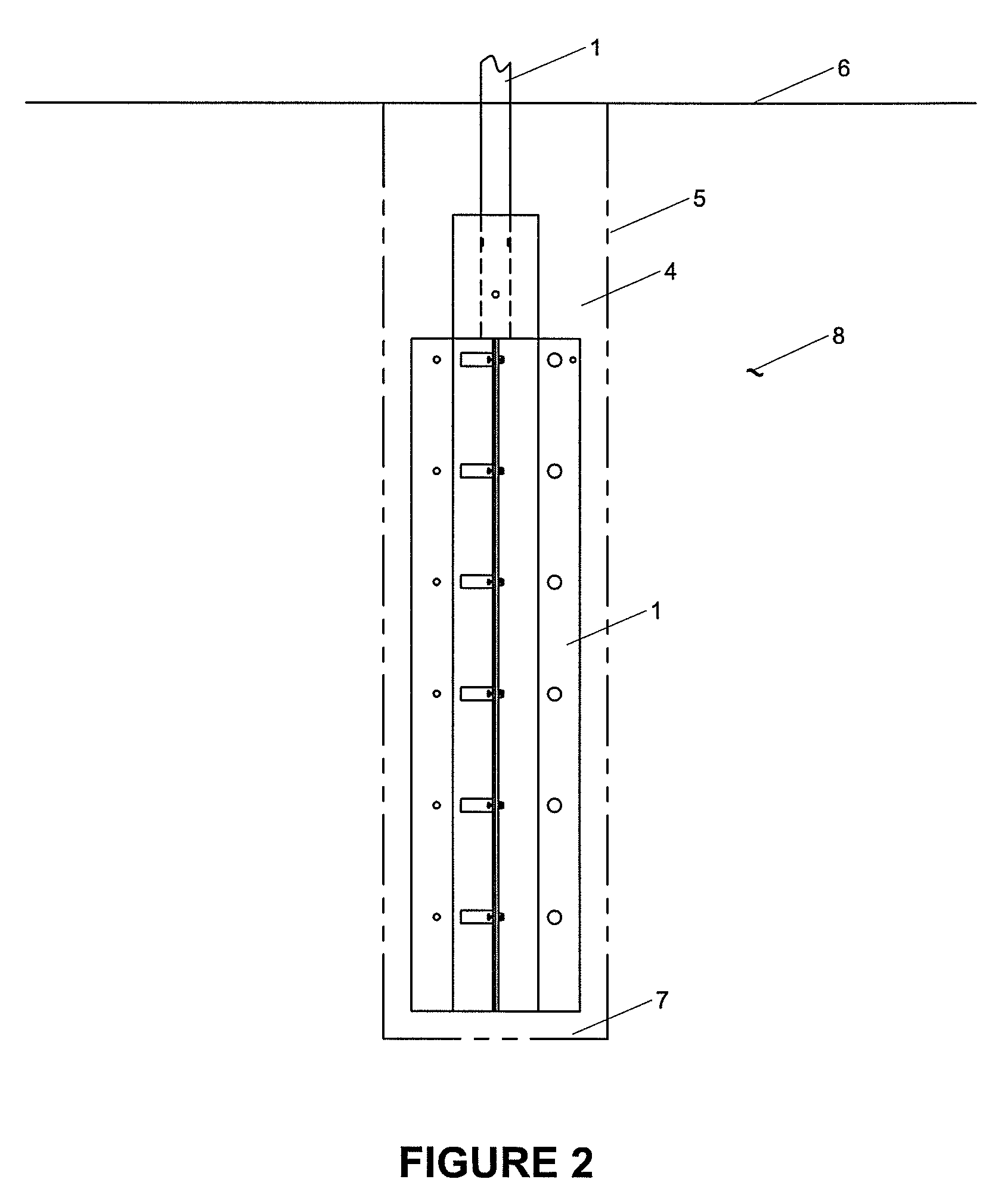

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

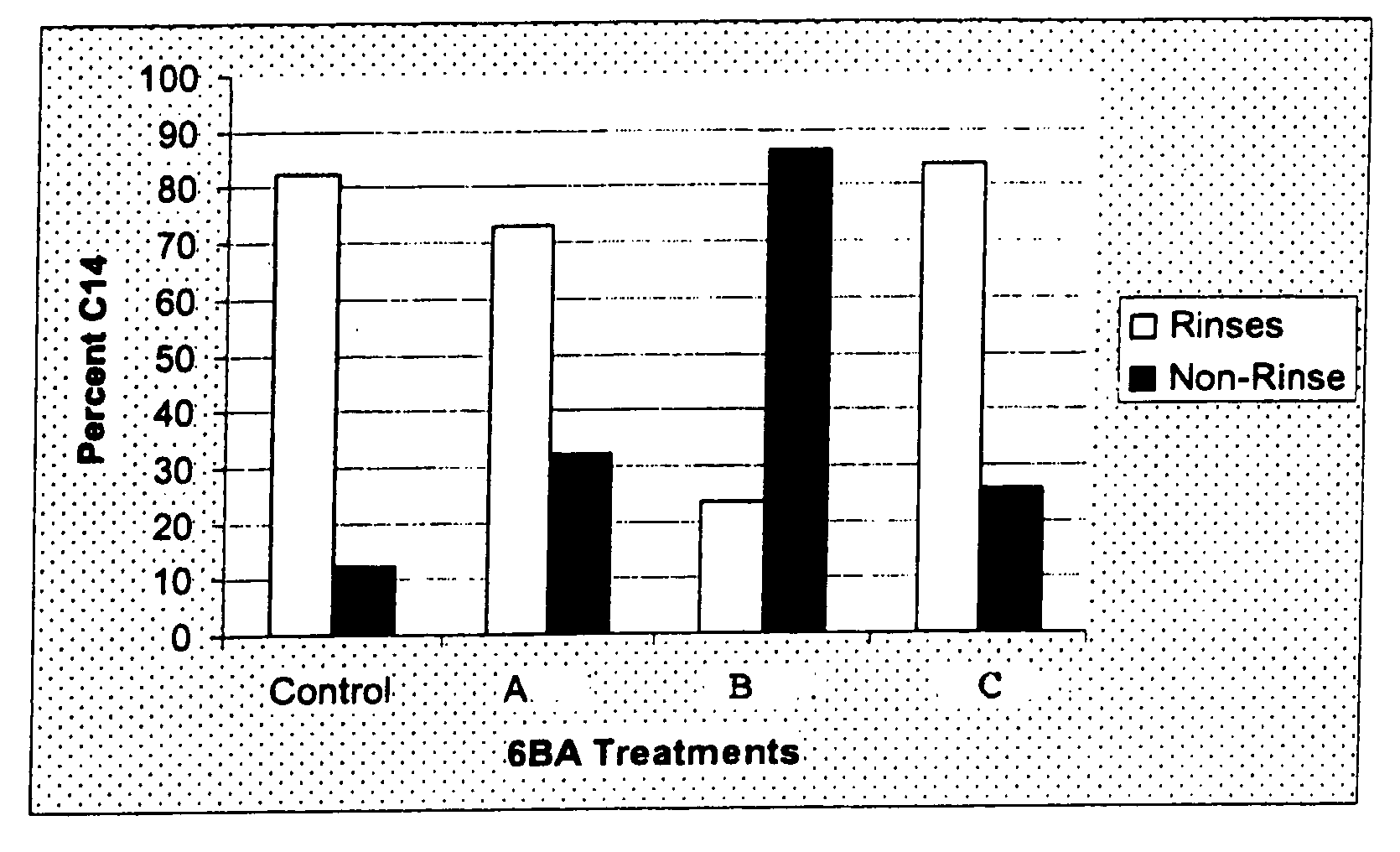

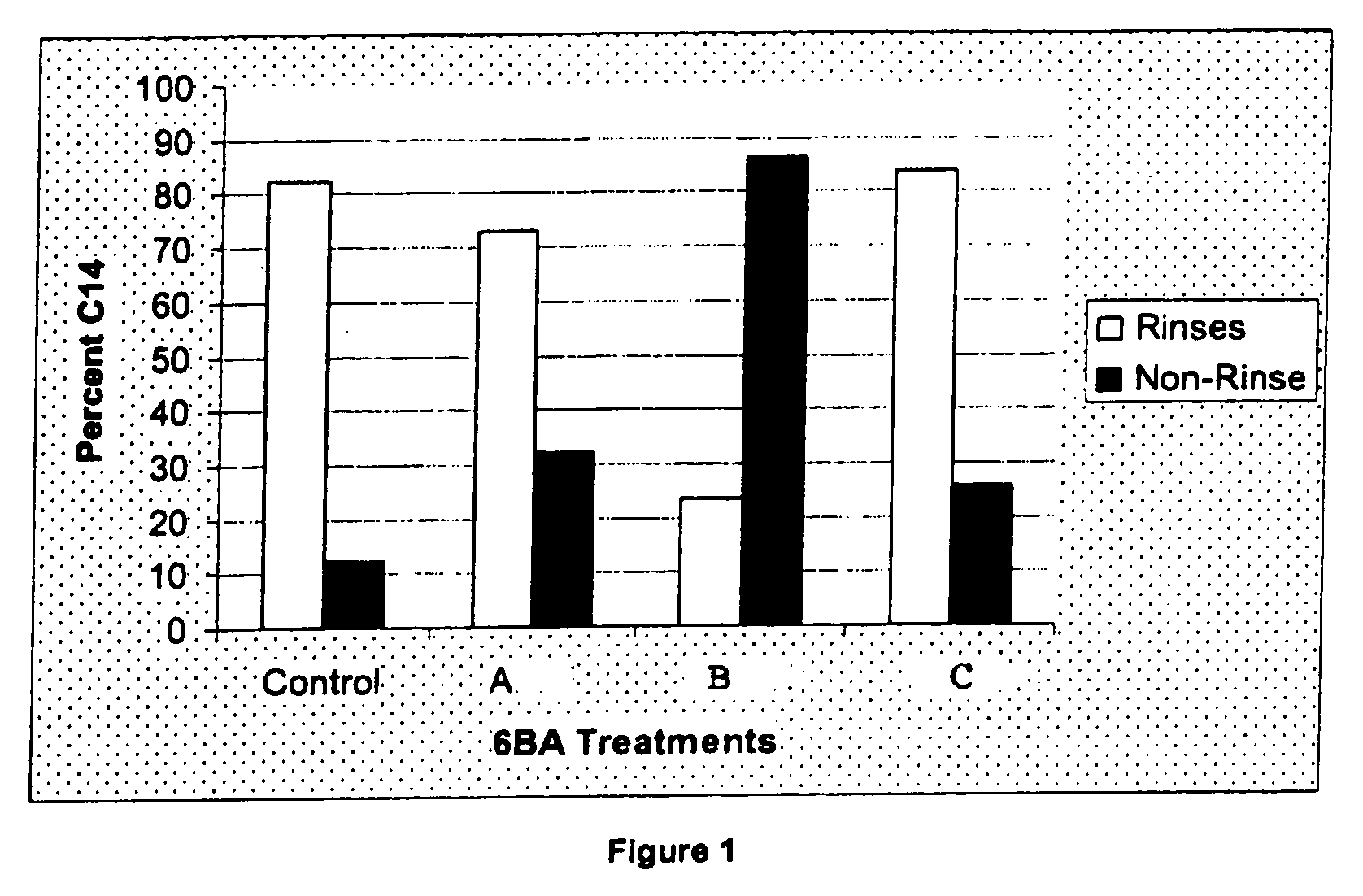

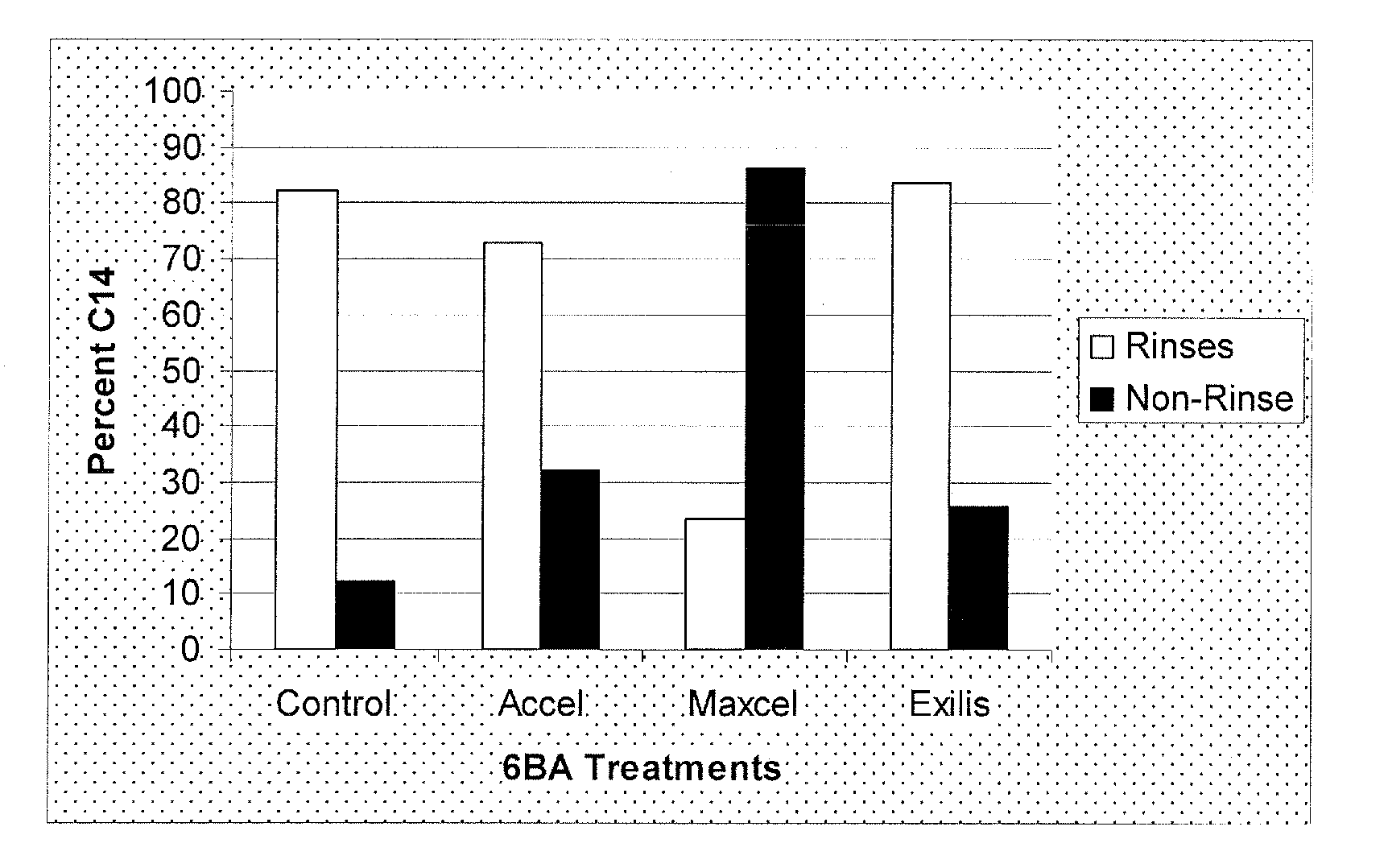

Stable and Water-Soluble Plant Growth Regulator Liquid Compositions and Methods for Use of Same

InactiveUS20080039322A1Effective amountAccurate measurementBiocidePlant growth regulatorsSolubilityAntioxidant

Soluble and stable liquid compositions containing a plant growth regulator selected from the group consisting of cytokinin and a gibberellin, an acid solubilizer such as citric acid, tartaric acid or glycolic acid and a solvent; as well as methods for making and using the composition are disclosed. The compositions improve solubility, handling, stability, safety, as well as activity improvements such as improved plant growth, yield, fruit thinning or sizing and quality. The compositions are soluble and stable by adding an ethoxylated alkyl alcohol wherein the growth regulator is 6-benzyladenine (6-BA) or forchlorfenuron (CPPU) and the ethoxylated alcohol surfactant is C12-15 alkyl alcohol in propylene glycol. The compositions may also contain a cytokinin such as 6-benzyladenine (6-BA) or forchlorfenuron (CPPU) that is increased in solubility and activity and by synergistically combined with GA3 or GA4A7 as well as in storage stability by adding an antioxidant. The compositions are formulated in a ready-to-mix formulation.

Owner:WANG YUEH +6

Enhanced hydrocarbon recovery by steam injection of oil sand formations

InactiveUS20070199697A1Promote recoveryIncrease productionSurveyInsulationHydrocarbon solventsFuel oil

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

Enhanced hydrocarbon recovery by steam injection of oil sand formations

InactiveUS20070199712A1Promote recoveryLimit upward growthInsulationFluid removalHydrocarbon solventsFuel oil

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

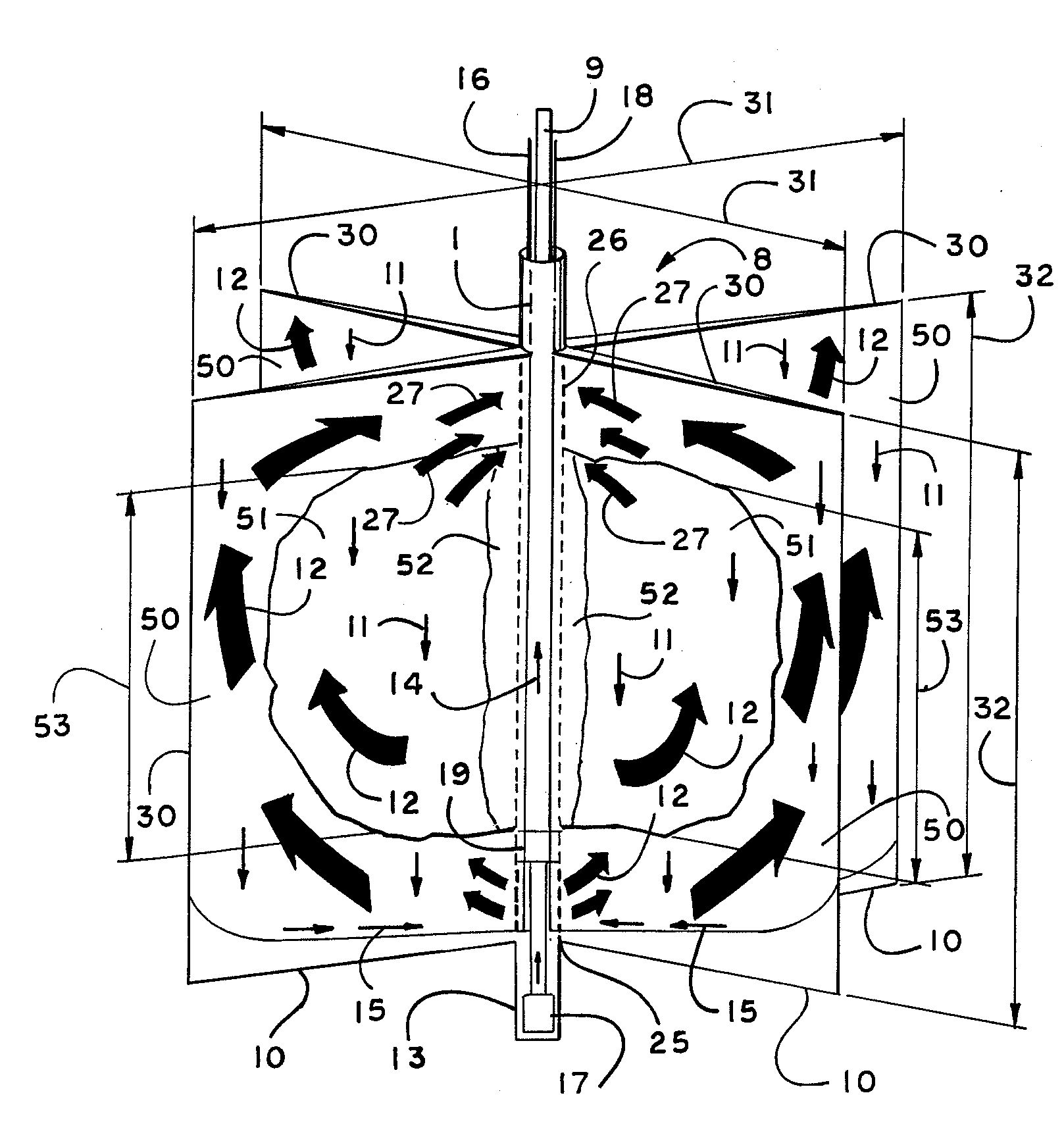

Enhanced hydrocarbon recovery by vaporizing solvents in oil sand formations

InactiveUS20070199705A1Promote recoveryLimit upward growthFluid removalHydrocarbon solventsSoil science

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injecting a hydrocarbon solvent vapor in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped vertical hydraulic fractures are constructed from the well bore into the oil sand formation. The hydrocarbon solvent vapor and a non-condensing diluent gas are injected into the well bore, fill the hydraulic fractures, and thus contact and diffuse into the in situ bitumen. The hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilizes the bitumen in a predominantly circumferentially, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The mobile oil may be deasphalted by the condensed solvent, leaving the heavy asphaltenes behind in the oil sand pore space with little loss of inherent fluid mobility in the processed oil sands. The processed product is produced with the dissolved solvent along with a tail diluent gas. The tail diluent gas is enriched with hydrocarbon solvent and re-injected into the process zone and the cycle repeated.

Owner:GEOSIERRA

Enhanced hydrocarbon recovery by vaporizing solvents in oil sand formations

InactiveUS20070199711A1Promote recoveryIncrease productionInsulationFluid removalHydrocarbon solventsSoil science

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injecting a hydrocarbon solvent vapor in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped vertical hydraulic fractures are constructed from the well bore into the oil sand formation. The hydrocarbon solvent vapor and a non-condensing diluent gas are injected into the well bore, fill the hydraulic fractures, and thus contact and diffuse into the in situ bitumen. The hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilizes the bitumen in a predominantly circumferentially, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The mobile oil may be deasphalted by the condensed solvent, leaving the heavy asphaltenes behind in the oil sand pore space with little loss of inherent fluid mobility in the processed oil sands. The processed product is produced with the dissolved solvent along with a tail diluent gas. The tail diluent gas is enriched with hydrocarbon solvent and re-injected into the process zone and the cycle repeated.

Owner:GEOSIERRA

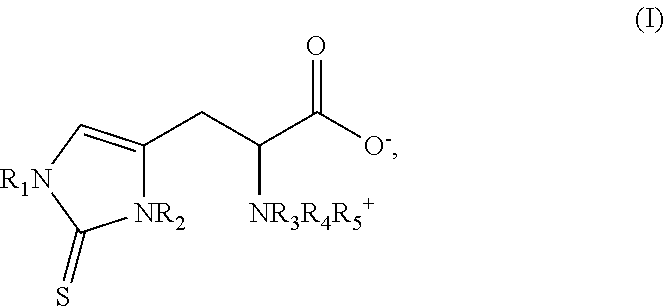

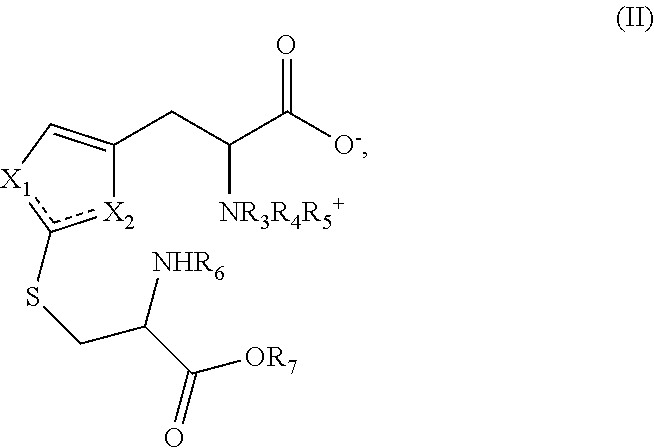

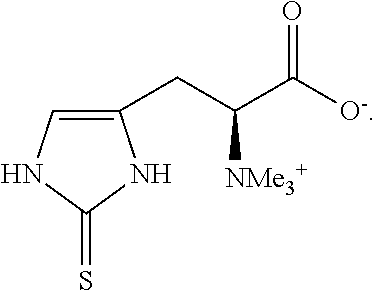

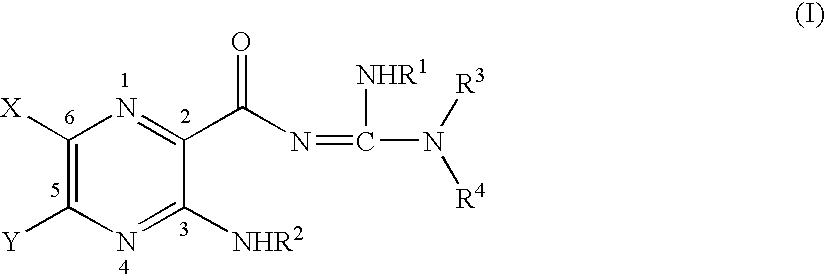

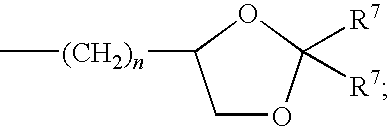

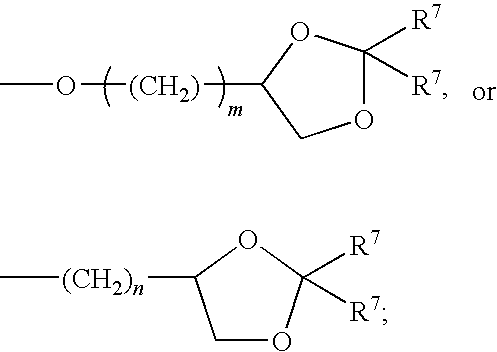

The method of synthesizing ergothioneine and analogs

ActiveUS20120136159A1More solubleHigh yieldOrganic chemistryOrganic active ingredientsThiolStereoisomerism

The present disclosure relates to a method for synthesizing ergothioneine or one of the derivatives thereof of following formula (I):or a physiologically acceptable salt, a tautomer, a stereoisomer or a mixture of stereoisomers in all proportions thereof,from a compound of betaine type of following formula (II):or a physiologically acceptable salt, a tautomer, a stereoisomer or a mixture of stereoisomers in all proportions thereof,by cleavage reaction in the presence of a thiol, at a temperature above or equal to 60° C.The present disclosure also relates to compounds of formula (II) and the method of synthesis thereof.

Owner:TETRAHEDRON SAS

Enhanced Hydrocarbon Recovery By Vaporizing Solvents in Oil Sand Formations

InactiveUS20070199699A1Improve recoveryIncrease productionSurveyInsulationHydrocarbon solventsFuel oil

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injecting a hydrocarbon solvent vapor in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped vertical hydraulic fractures are constructed from the well bore into the oil sand formation. The hydrocarbon solvent vapor and a non-condensing diluent gas are injected into the well bore, fill the hydraulic fractures, and thus contact and diffuse into the in situ bitumen. The hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilizes the bitumen in a predominantly circumferentially, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The mobile oil may be deasphalted by the condensed solvent, leaving the heavy asphaltenes behind in the oil sand pore space with little loss of inherent fluid mobility in the processed oil sands. The processed product is produced with the dissolved solvent along with a tail diluent gas. The tail diluent gas is enriched with hydrocarbon solvent and re-injected into the process zone and the cycle repeated.

Owner:GEOSIERRA

Aliphatic amide & ester pyrazinoylguanidine sodium channel blockers

InactiveUS20090227594A1More potent and/or absorbed less rapidlyLess reversibleOrganic active ingredientsSenses disorderChannel blockerTreatment use

Owner:PARION SCI DURHAM NC

Enhanced hydrocarbon recovery by steam injection of oil sand formations

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

Enhanced Hydrocarbon Recovery By Steam Injection of Oil Sand FOrmations

InactiveUS20090145606A1Promote recoveryLimit upward growthInsulationFluid removalHydrocarbon solventsFuel oil

The present invention involves a method and apparatus for enhanced recovery of petroleum fluids from the subsurface by injection of a steam and hydrocarbon vaporized solvent in contact with the oil sand formation and the heavy oil and bitumen in situ. Multiple propped hydraulic fractures are constructed from the well bore into the oil sand formation and filled with a highly permeable proppant. Steam, a hydrocarbon solvent, and a non-condensing diluent gas are injected into the well bore and the propped fractures. The injected gas flows upwards and outwards in the propped fractures contacting the oil sands and in situ bitumen on the vertical faces of the propped fractures. The steam condenses on the cool bitumen and thus heats the bitumen by conduction, while the hydrocarbon solvent vapors diffuse into the bitumen from the vertical faces of the propped fractures. The bitumen softens and flows by gravity to the well bore, exposing fresh surface of bitumen for the process to progressively soften and mobilize the bitumen in a predominantly circumferential, i.e. orthogonal to the propped fracture, diffusion direction at a nearly uniform rate into the oil sand deposit. The produced product of oil and dissolved solvent is pumped to the surface where the solvent can be recycled for further injection.

Owner:GEOSIERRA

Absorbent articles comprising supercritical fluid treated HIPE, I-HIPE foams and other foams

InactiveUS20050137274A1More solubleSolve bulkyTetracycline active ingredientsBulk chemical productionPolymer scienceInternal phase

The present invention comprises compositions and methods of making high internal phase emulsion foam (HIPE) and inverse high internal phase emulsion foam (I-HIPE) using super critical fluids. Such foams may be used in a wide variety of articles such as absorbent articles.

Owner:KO YOUNG C +1

Stable and Water-Soluble Plant Growth Regulator Liquid Compositions and Methods for Use of Same

ActiveUS20100016165A1More solubleDissolve fastPlant growth regulatorsBiocideGibberellic acidSolubility

Soluble and stable liquid compositions containing a plant growth regulator selected from the group consisting of cytokinin and a gibberellin, an acid solubilizer such as citric acid, tartaric acid or glycolic acid and a solvent; as well as methods for making and using the composition are disclosed. The compositions improve solubility, handling, stability, safety, as well as activity improvements such as improved plant growth, yield, fruit thinning or sizing and quality. The compositions are soluble and stable by adding an ethoxylated alkyl alcohol wherein the growth regulator is 6-benzyladenine (6-BA) or forchlorfenuron (CPPU) and the ethoxylated alcohol surfactant is C12-15 alkyl alcohol in propylene glycol. The compositions may also contain a cytokinin such as 6-benzyladenine (6-BA) or forchlorfenuron (CPPU) that is increased in solubility and activity and by synergistically combined with GA3 or GA4A7 as well as in storage stability by adding an antioxidant. The compositions are formulated in a ready-to-mix formulation.

Owner:VALENT BIOSCIENCES CORP

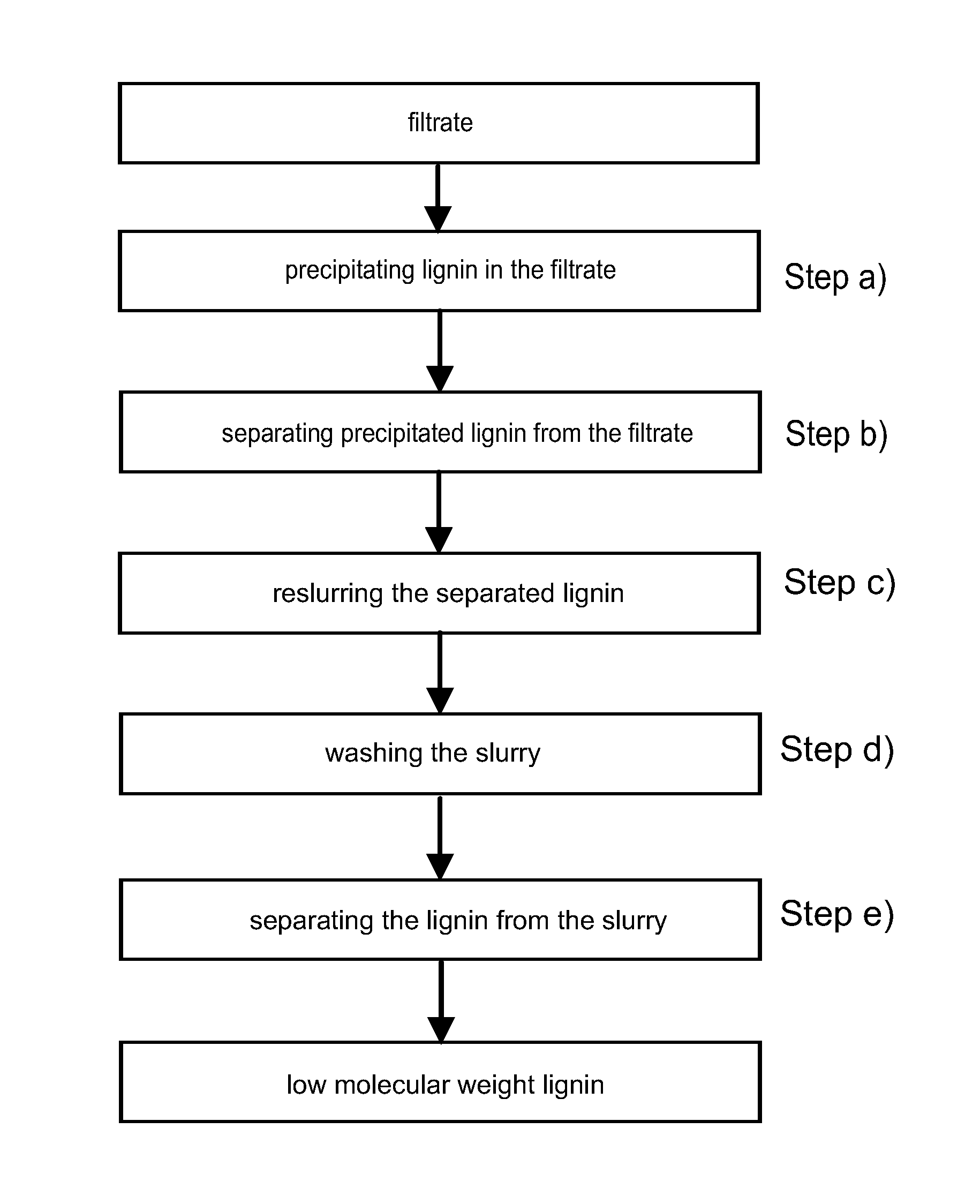

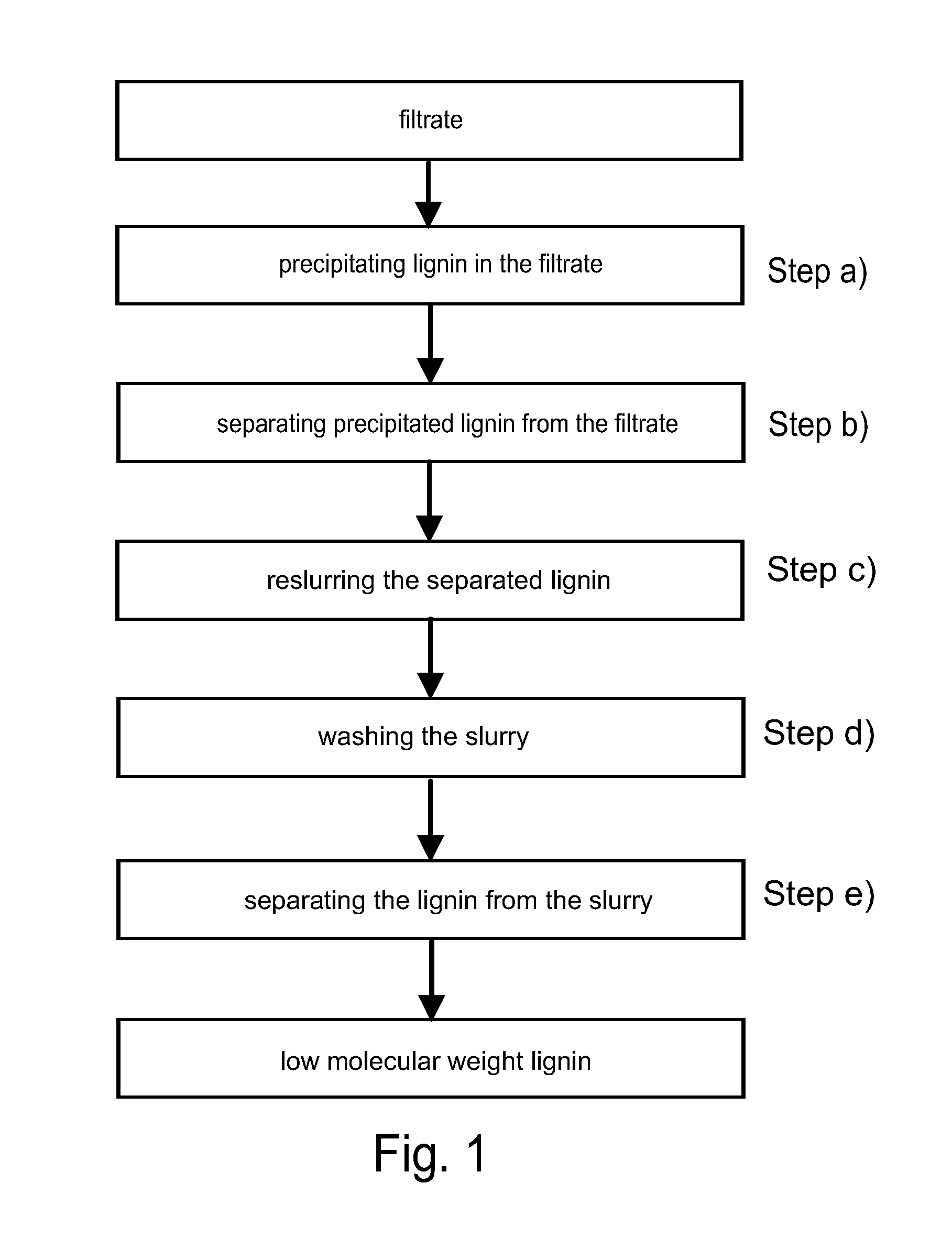

Method for recovering low molecular weight lignin from a filtrate

ActiveUS20150203522A1Reduce molecular weightMore solubleLignin derivativesPulp by-products recoveryBlack liquorFiltration

The invention relates to a method for recovering low molecular weight lignin from a filtrate, wherein the low molecular weight lignin includes lignin molecules having a molecular weight of 3000 g / mol or lower, wherein the filtrate is obtained from a process where lignin is precipitated from black liquor and the formed precipitate is separated therefrom by filtration resulting in the filtrate including low molecular weight lignin being formed, and wherein the method includes the following steps: a) adjusting the pH of the filtrate to a value of 3-4 for precipitating lignin in the filtrate; b) separating the precipitated lignin from the filtrate; c) reslurrying the separated lignin until the dry solids content of the slurry is 25-40 weight-% and adjusting the pH of the slurry to a value of 2-3; d) washing the slurry; and e) separating the lignin from the slurry.

Owner:UPM-KYMMENE OYJ

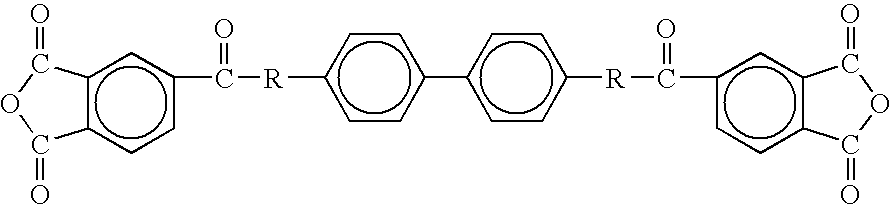

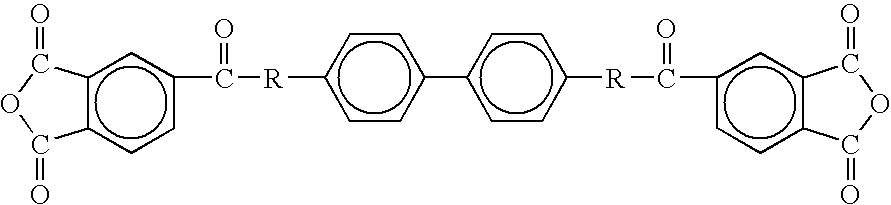

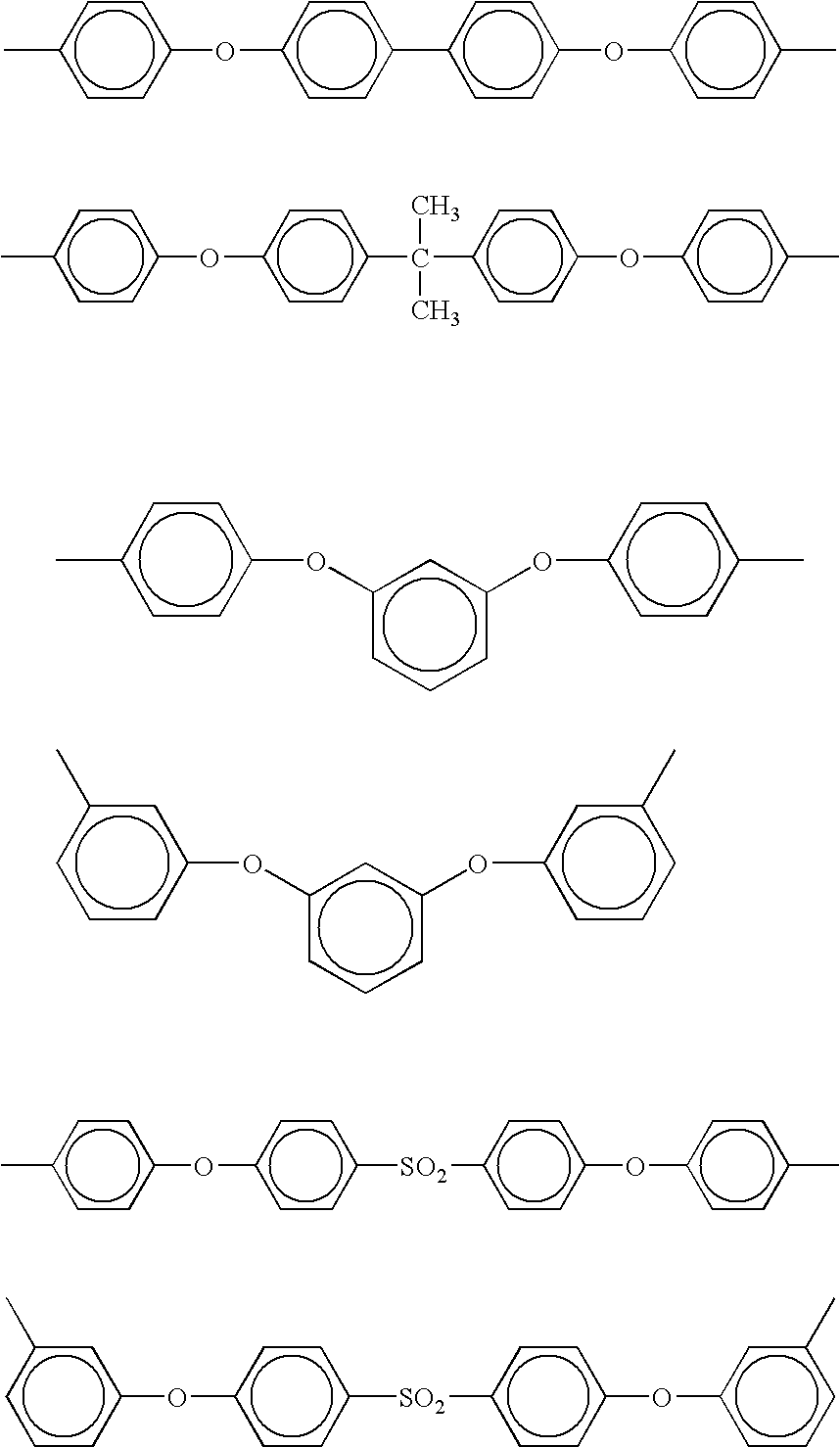

Soluble polyimide resin and method of preparing the same

InactiveUS20060287467A1High dimensional stabilityGood heat resistancePrinted circuitsChemistryOrganic solvent

The present invention provides a polyimide resin, which is prepared by epolycondensing a dianhydride monomer including at least a dianhydride represented by formula (I) wherein R is O or O(CH2)nO, n is an integer of 1 to 2 and a diamine monomer represented by formula (II) H2N—Ar—NH2 (II) wherein Ar is defined as in the text then imidizing the resulting polyamic acid resin to form a polyimide resin. Through using the dianhydride represented by formula (I) as the polymerizing unit, a biphenyl moiety and an ester moiety are introduced into the main chain of the polyimide resin, such that the resulting polyimide resin has lower moisture absorption and smaller linear thermal expansion coefficient and therefore have satisfactory heat resistance and dimensional stability, in addition, become more soluble in organic solvents.

Owner:CHANG CHUN PLASTICS

Method for surface treatment of substrate, surface-treated substrate and dental article comprising the same

InactiveUS7344771B2Reduced strengthReduced adhesion strengthDental implantsImpression capsSolubilityOptoelectronics

A method for a surface treatment of a substrate comprises providing a protective layer having a solubility parameter different from that of an adhesive by 1 or less on an bonding surface of a substrate before bonding the substrate with the adhesive.

Owner:TOMY CHOFU TOKIOTOKYO JP

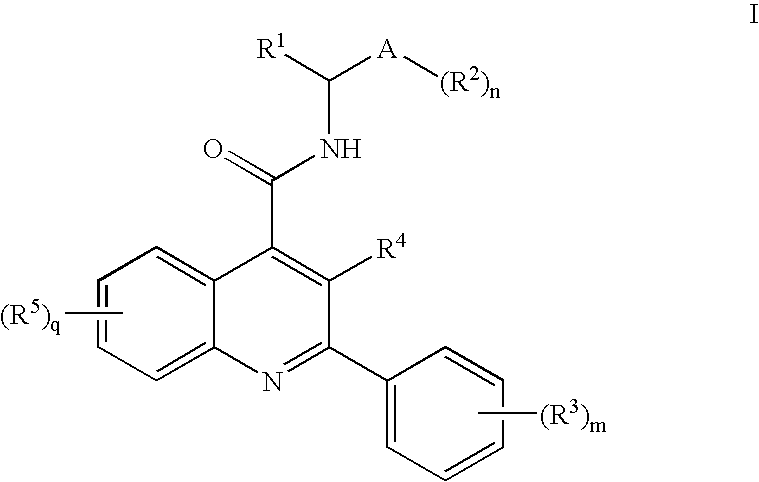

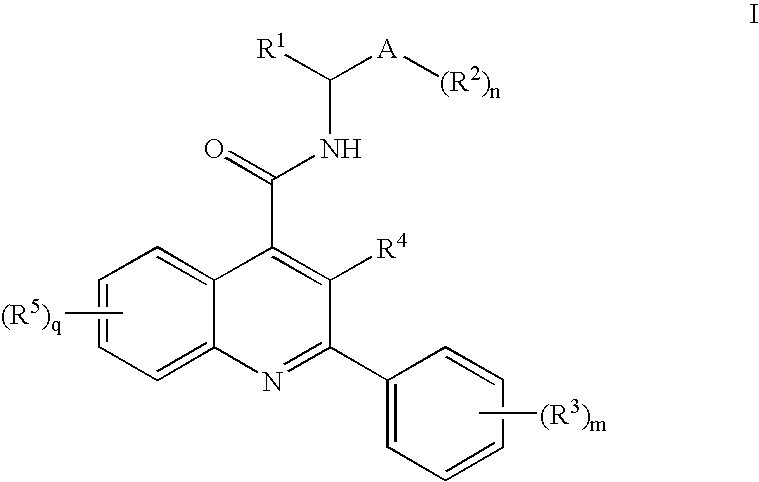

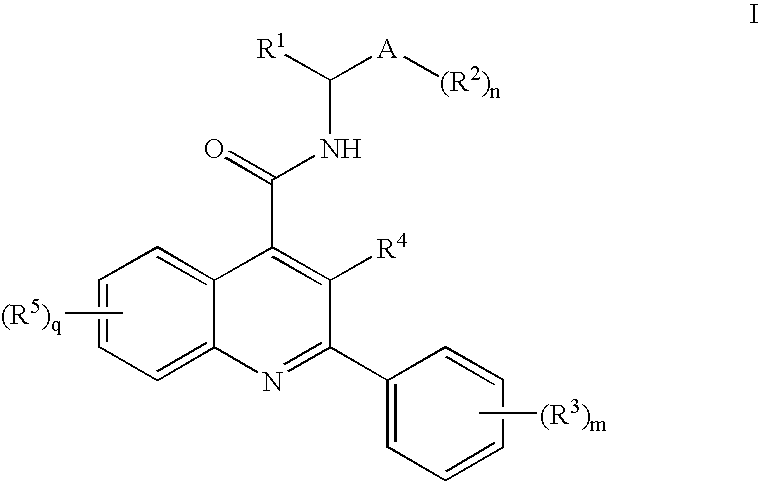

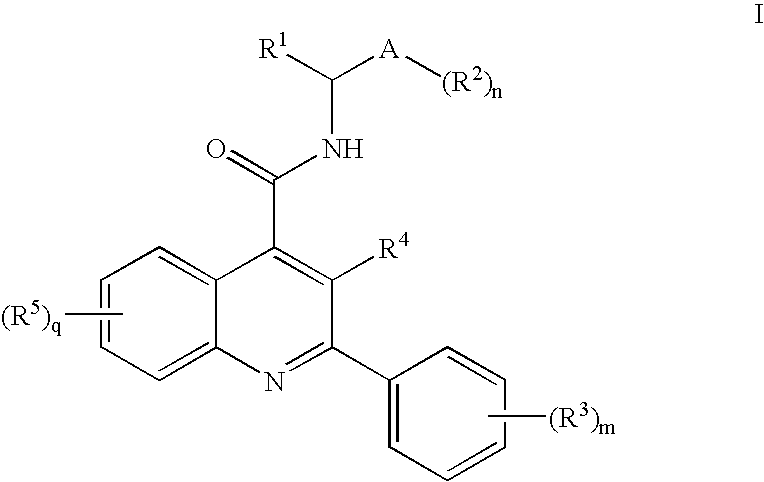

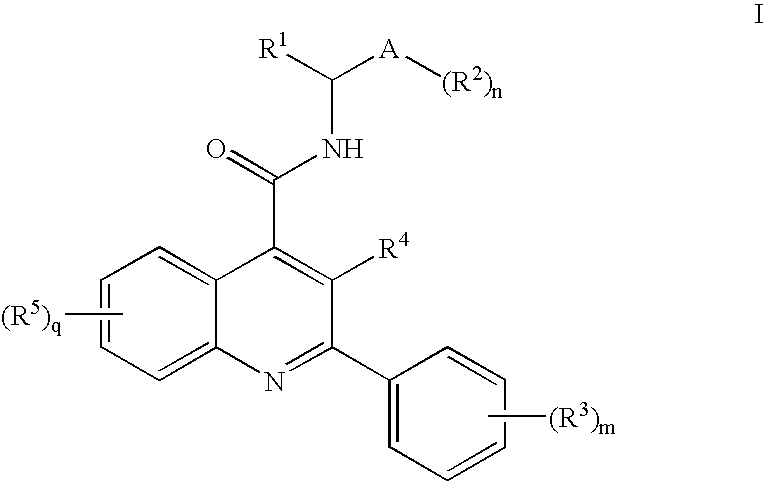

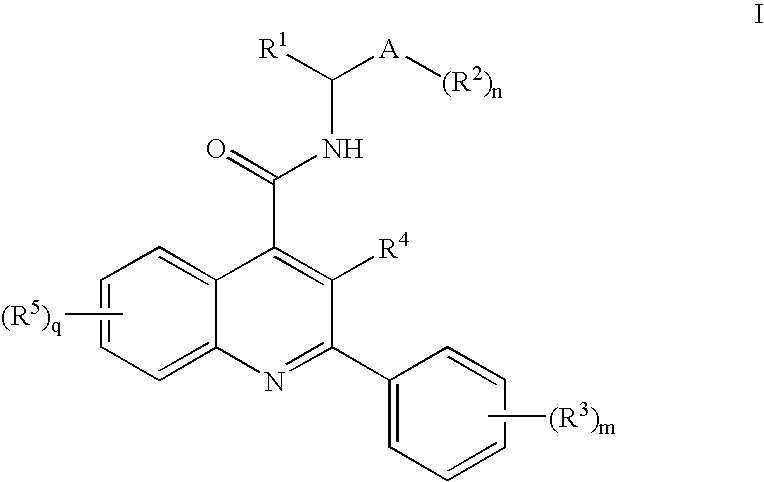

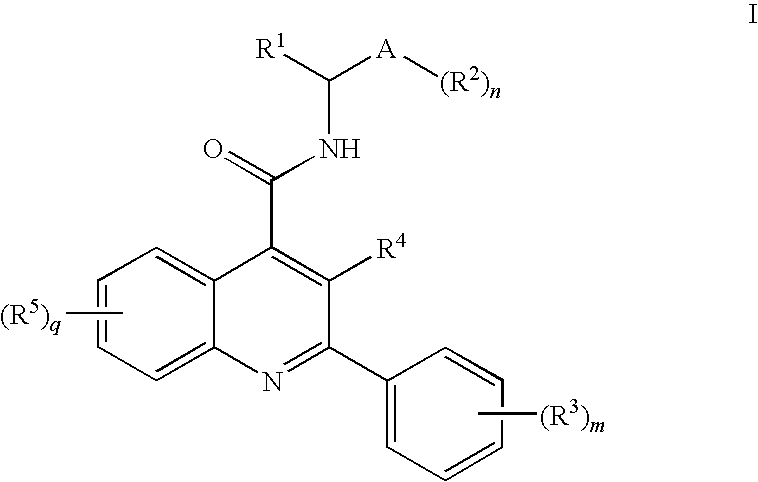

Alkylnitrile Quinolines as Nk-3 Receptor Ligands

InactiveUS20080306110A1Less side effectsToxic reductionBiocideNervous disorderQuinolineCombinatorial chemistry

Owner:ASTRAZENECA AB

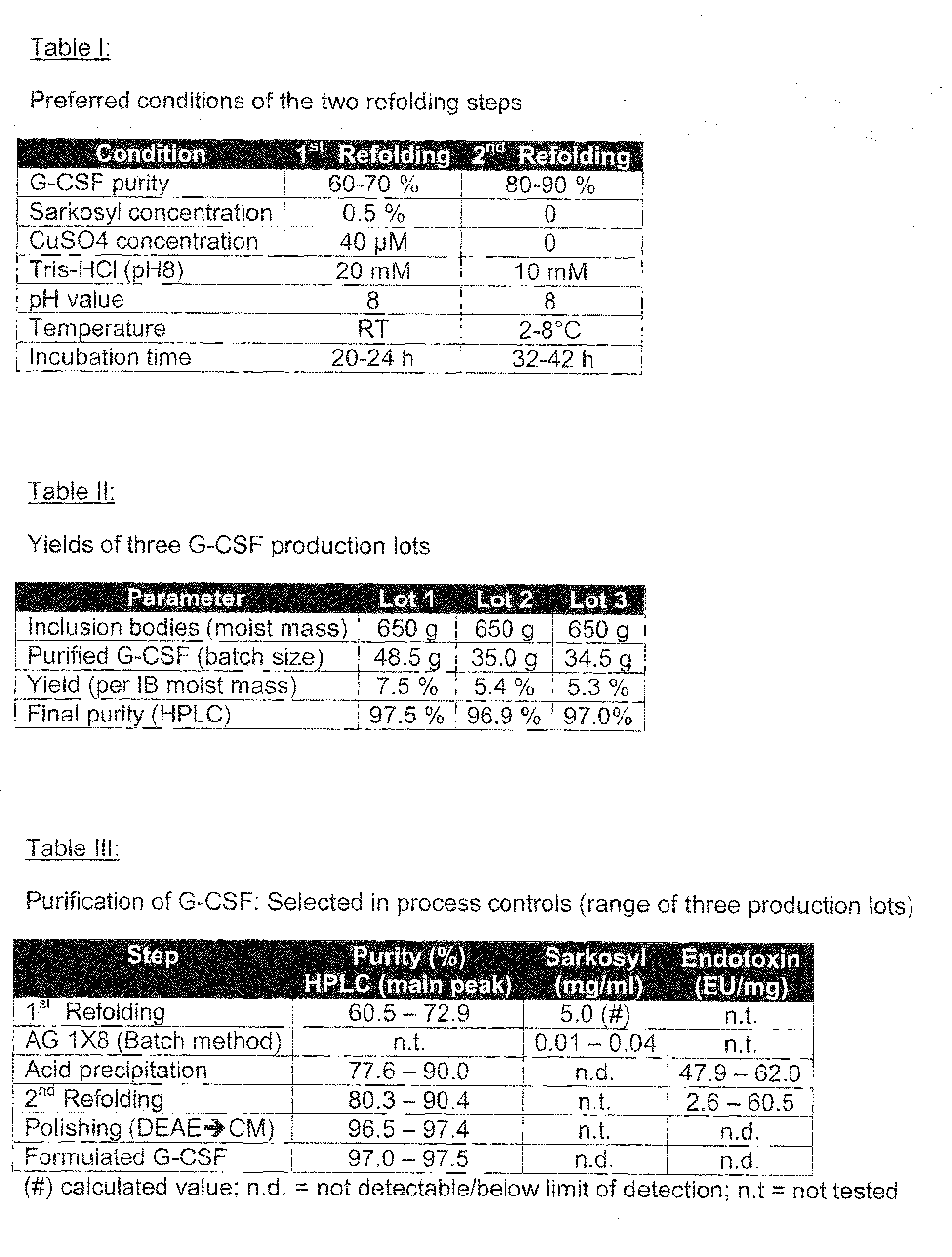

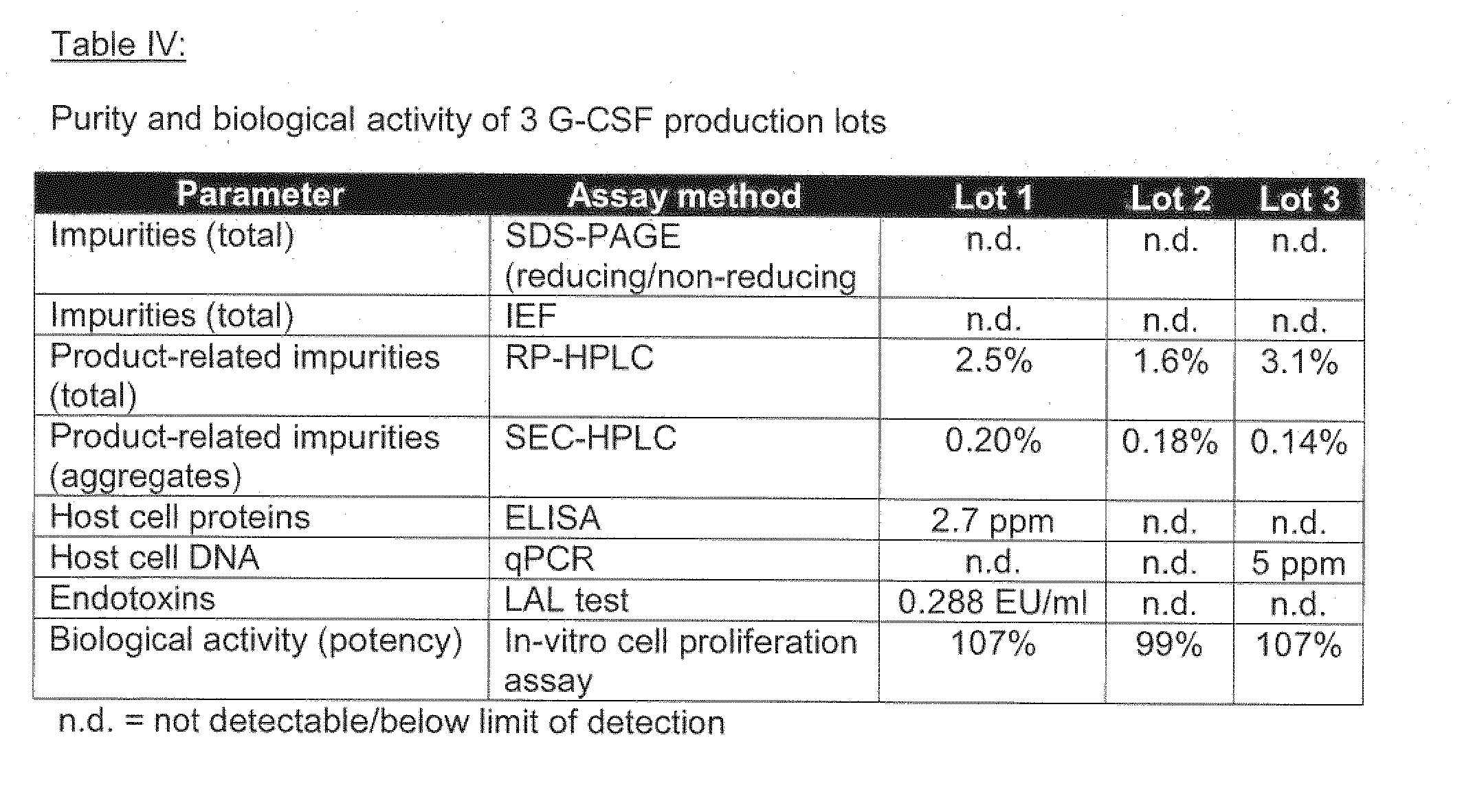

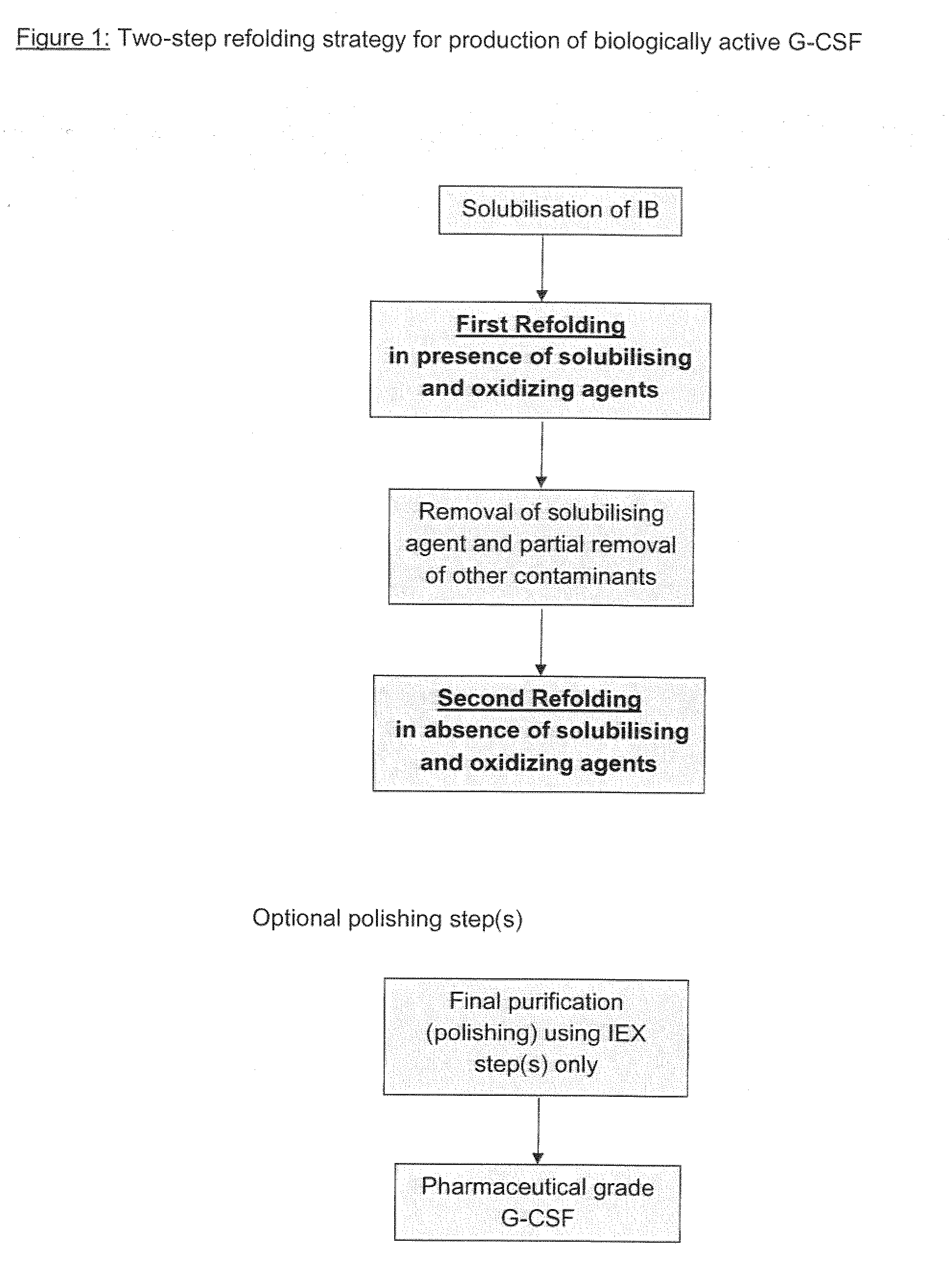

Methods for refolding g-csf from inclusion bodies

ActiveUS20150057439A1Improve yieldIncrease productionDepsipeptidesPeptide preparation methodsInclusion bodiesChemistry

New methods for the refolding of recombinant granulocyte colony stimulating factor (G-CSF) from inclusion bodies are disclosed. The methods comprise two refolding steps. In particular, the methods comprise the solubilising of G-CSF with a solubilising agent, the oxidative refolding (first refolding step) of G-CSF in the presence of the solubilising agent and an oxidizing agent, the efficient removal of the solubilising agent, and a second refolding step to complete the folding of G-CSF in the absence of the solubilising agent. Various methods are described for the efficient removal of the solubilising agent from partially refolded G-CSF.

Owner:RICHTER GEDEON NYRT

Food composition for regulating phlegm-dampness constitution and preparation method of food composition

InactiveCN105747223ARetain nutritional activityMore solubleFood ingredient functionsWheat germChinese wax

The invention provides food composition for regulating phlegm-dampness constitution and a preparation method of the food composition. The food composition comprises raw materials as follows: coix seeds, Chinese yam, white hyacinth beans, red beans, broomcorn, black soybeans, peanuts, broad beans, radish seeds, dietary fiber, lotus seeds, seabuckthorn fruits, amomum fruits, Chinese wax gourd peels, Poria cocos, wheat germs, rice and maltodextrin. The preparation method comprises steps as follows: other raw materials except maltodextrin are heated, cooked and mixed uniformly, a paste is obtained and processed by a low-temperature spray drying device, granular powder is prepared, maltodextrin is added to the granular powder, and the food composition is obtained. According to the regulating mechanisms of spleen invigorating, dampness removal, phlegm and turbidity elimination, homology of medicine and food, warming and yang activating for damp evil removal, as well as combination of phlegm-dampness removal and blood circulation promotion for simultaneous removal of turbid phlegm and blood stasis, the food composition with active functions of inhibiting bacteria, reducing blood pressure, resisting cancer, enhancing digestive tract mobility, resisting epinephrine and oxidation, regulating immunity, benefiting the bile, resisting platelet aggregation and the like is obtained.

Owner:WUHAN HUASHENG KANGYE BIOTECH CO LTD

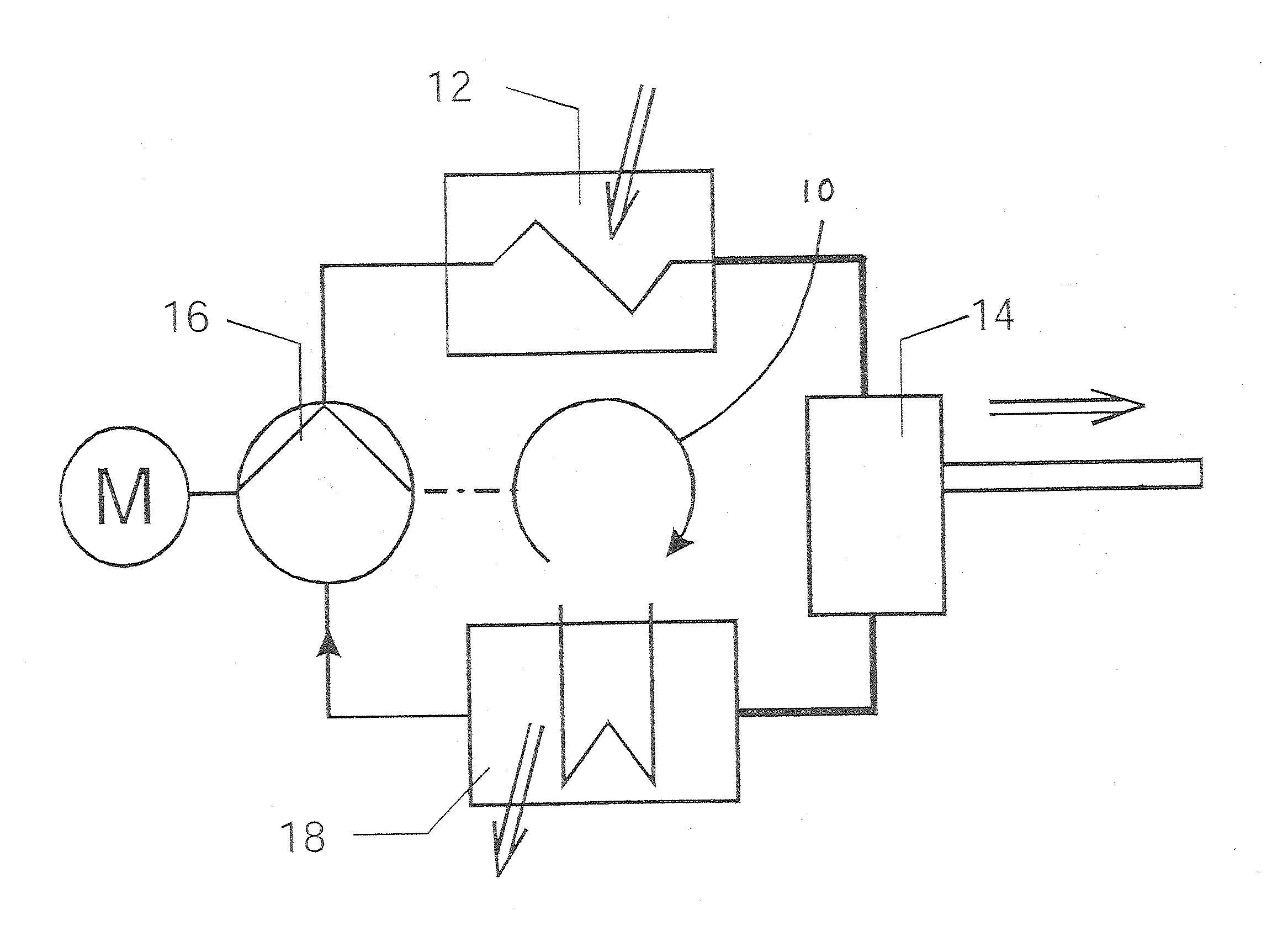

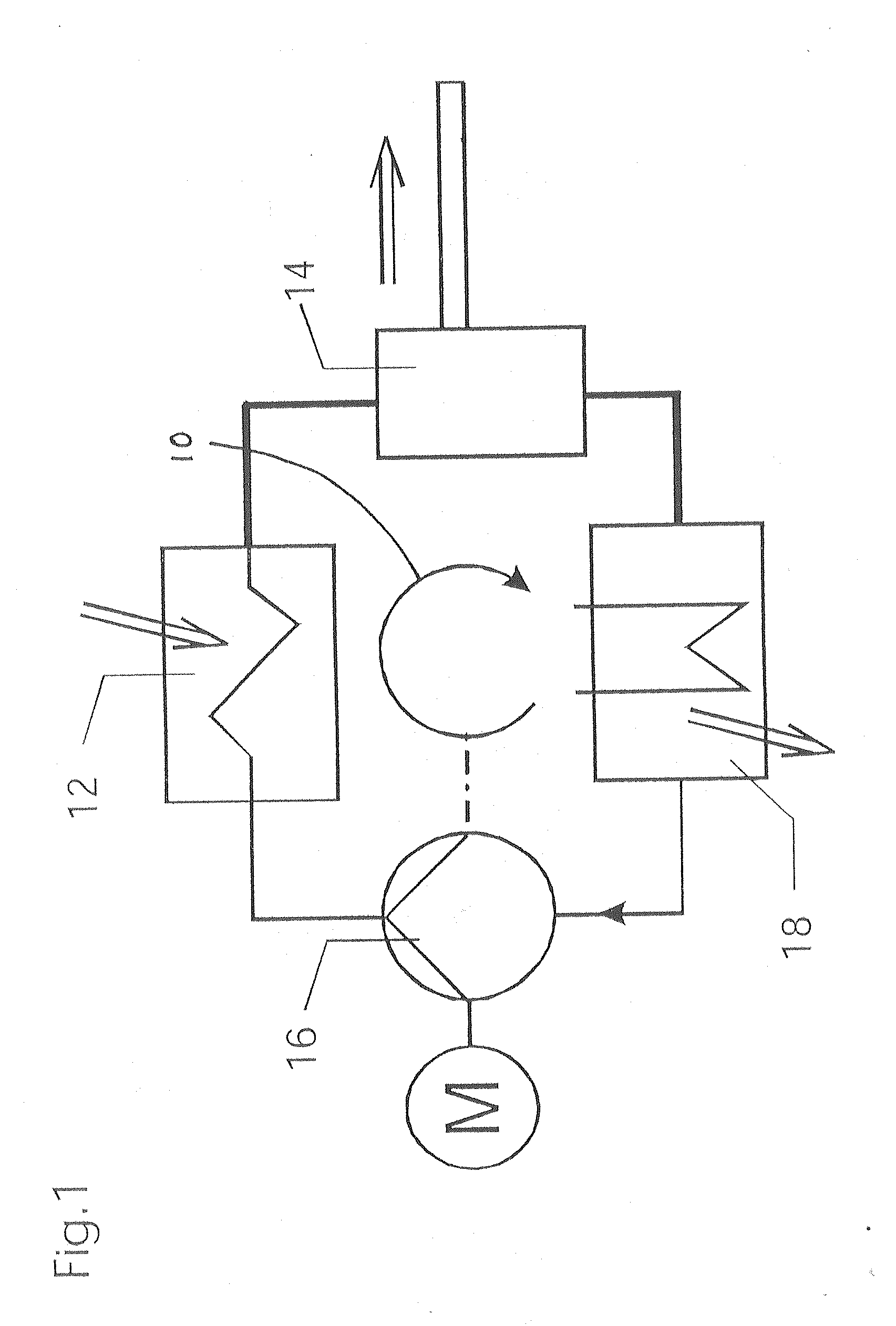

Working medium mixture for steam engines

InactiveUS20150240668A1Improve efficiencyImprove solution stabilitySteam engine plantsPower stationSteam power

The invention relates to the use of a working medium in steam power plants having a steam generator for generating working medium vapor, a pump for generating an increased pressure in the working medium vapor, an expansion machine for generating mechanical and / or electrical work by expansion of the working medium from an elevated pressure to a lower pressure level under working conditions and a condenser for condensing the working medium, wherein the working medium contains a lubricant. The invention is characterized in that the working medium contains acetone and a lubricant.

Owner:MAHLE INT GMBH

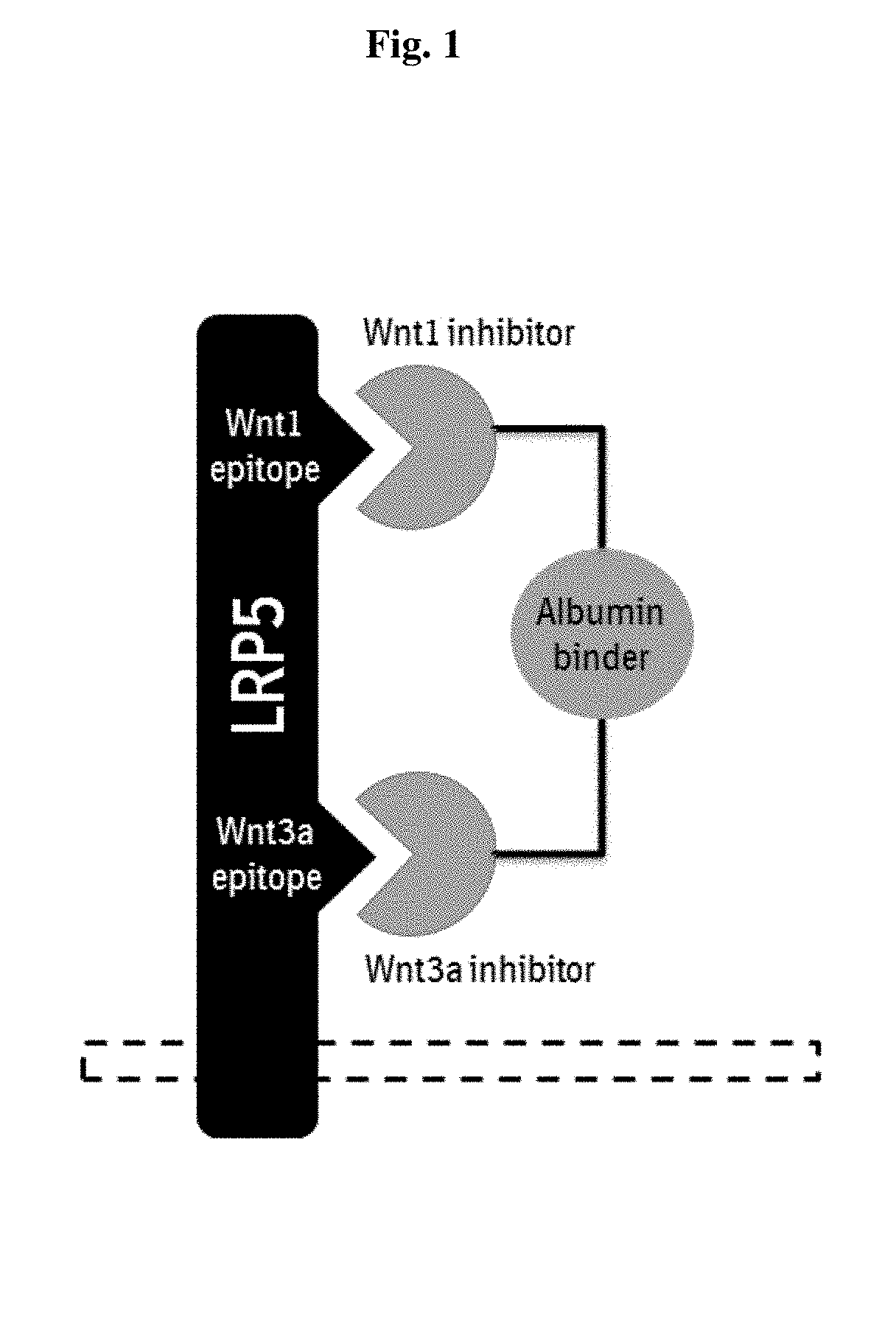

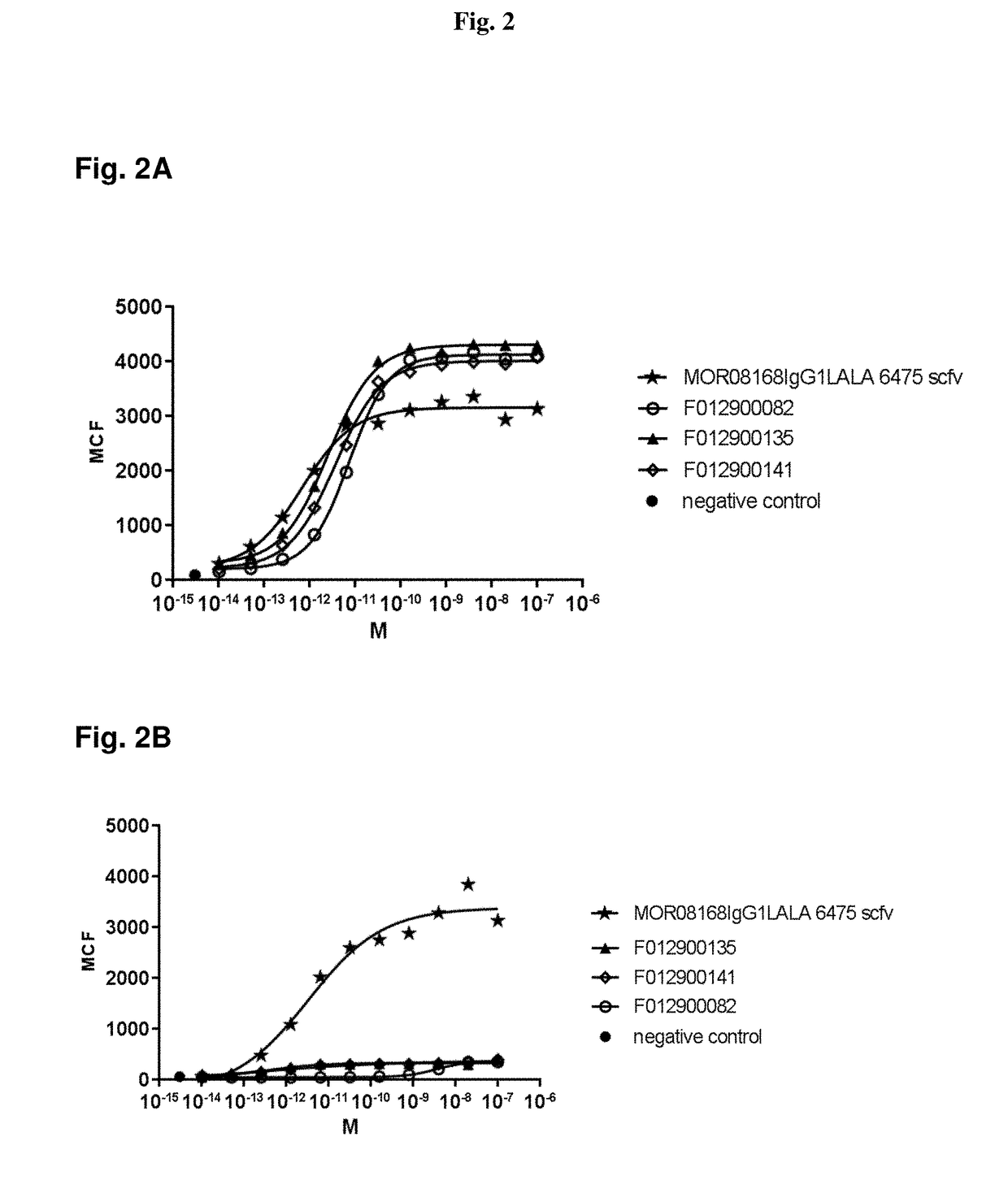

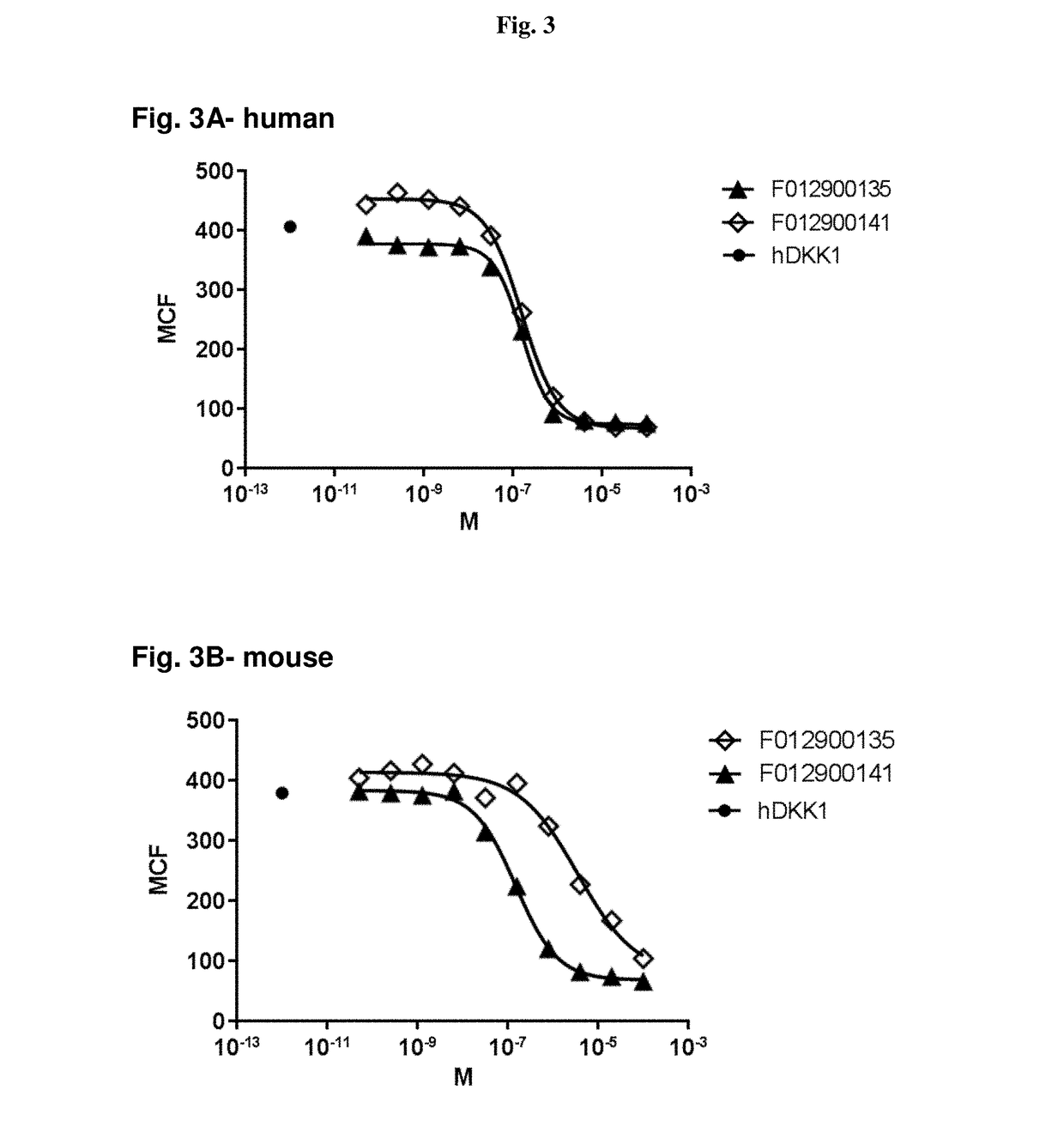

Polypeptides antagonizing wnt signaling in tumor cells

ActiveUS20180344868A1Improve propertiesLess side effectsHybrid immunoglobulinsImmunoglobulins against cell receptors/antigens/surface-determinantsDiseaseIntravenous gammaglobulin

The invention provides novel LRP5-binding polypeptides, and more specifically novel LRP5-binding immunoglobulin single variable domain constructs which can inhibit Wnt signaling pathways. The invention also relates to specific sequences of such polypeptides, methods of their production, and methods of using them, including methods of treatment of diseases such as cancer.

Owner:BOEHRINGER INGELHEIM INT GMBH

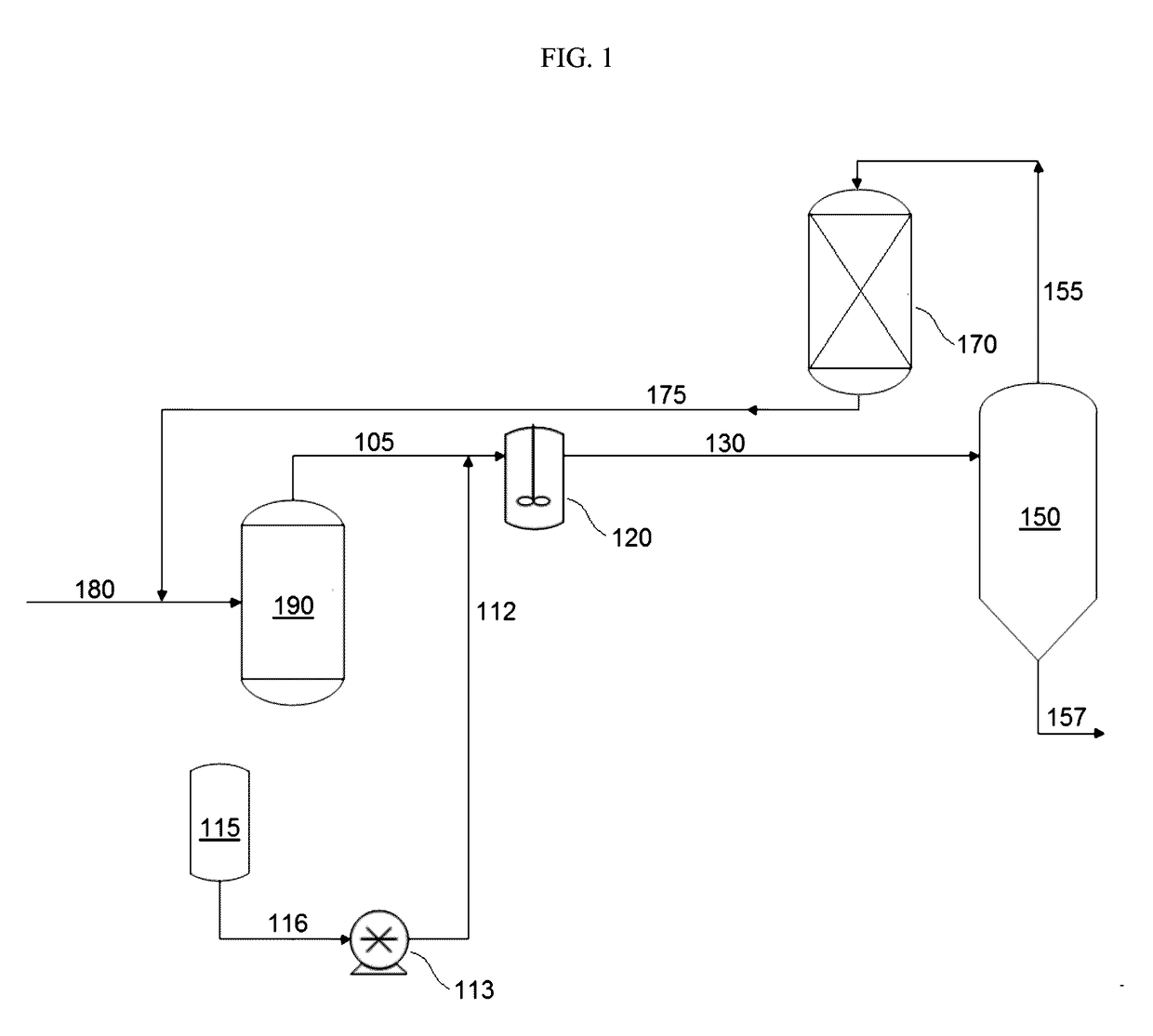

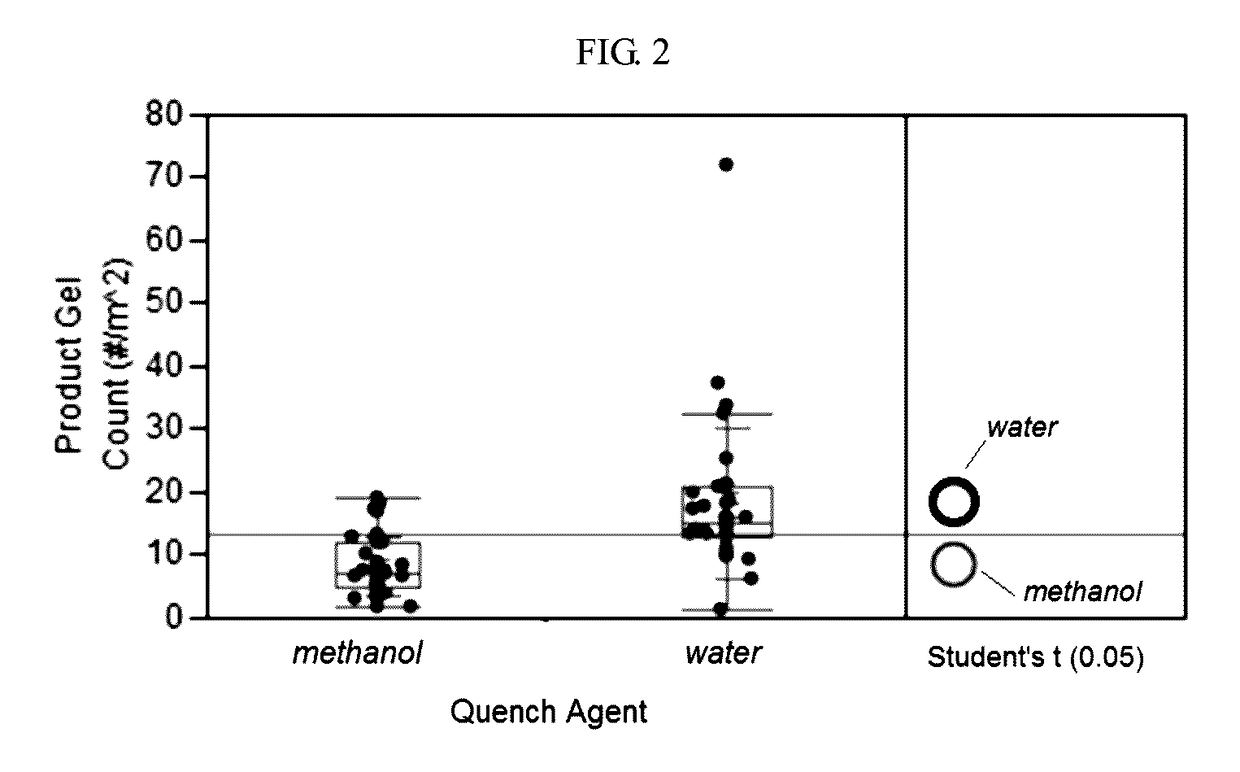

Mitigation of Catalyst Inhibition in Olefin Polymerization

This disclosure relates to a process for polymerization, and in particular to minimizing undesired polymerization reactions downstream of a polymerization reaction zone, for instance by use of a quenching agent that enables fast reaction rates with active polymerization catalyst in the polymerization effluent, so as to quench the catalyst quickly, thereby preventing uncontrolled polymerization reactions. A preferred quenching agent is methanol. Also provided are means for treating polymer recycle streams containing oxygenates, which may result from the use of such quench agents, particularly in polymerization processes including polyene (e.g., diene) monomers.

Owner:EXXONMOBIL CHEM PAT INC

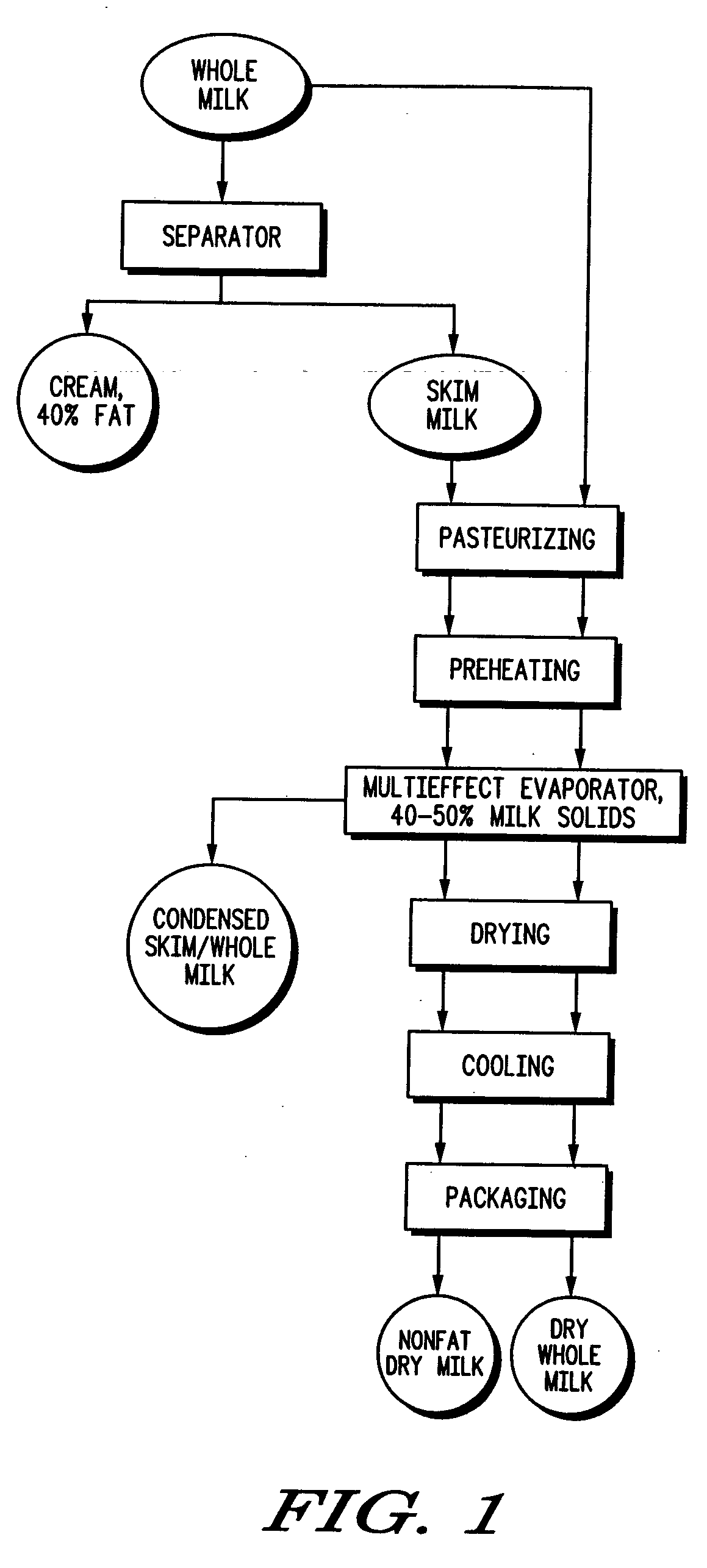

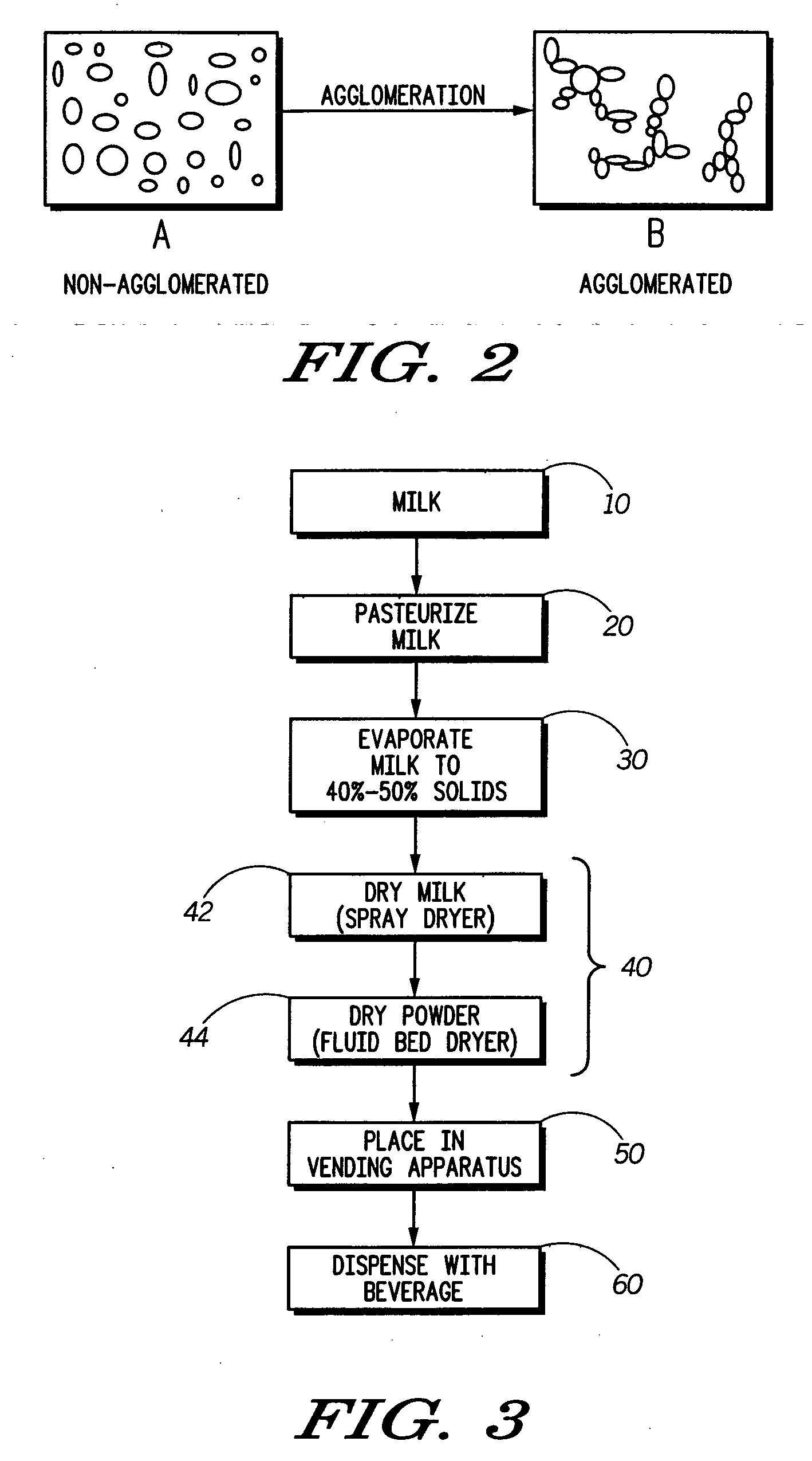

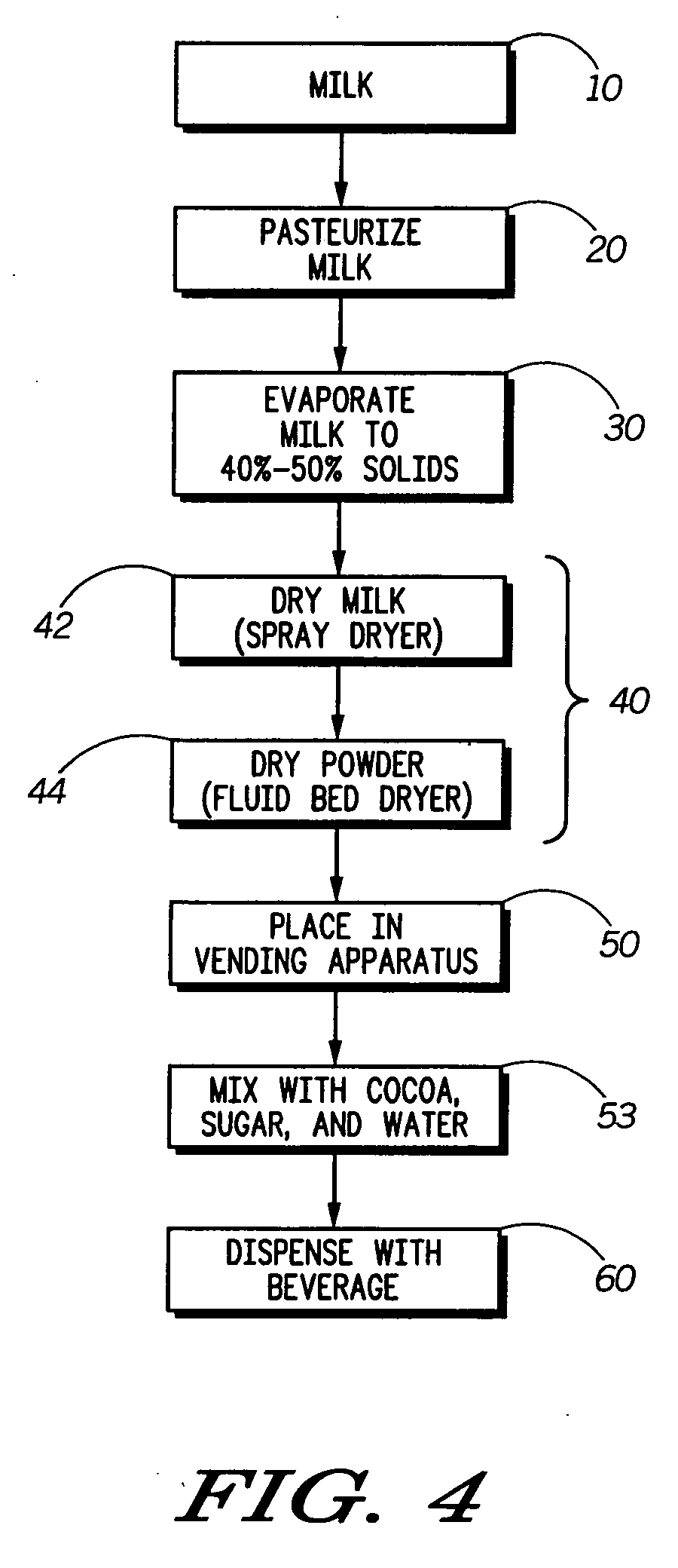

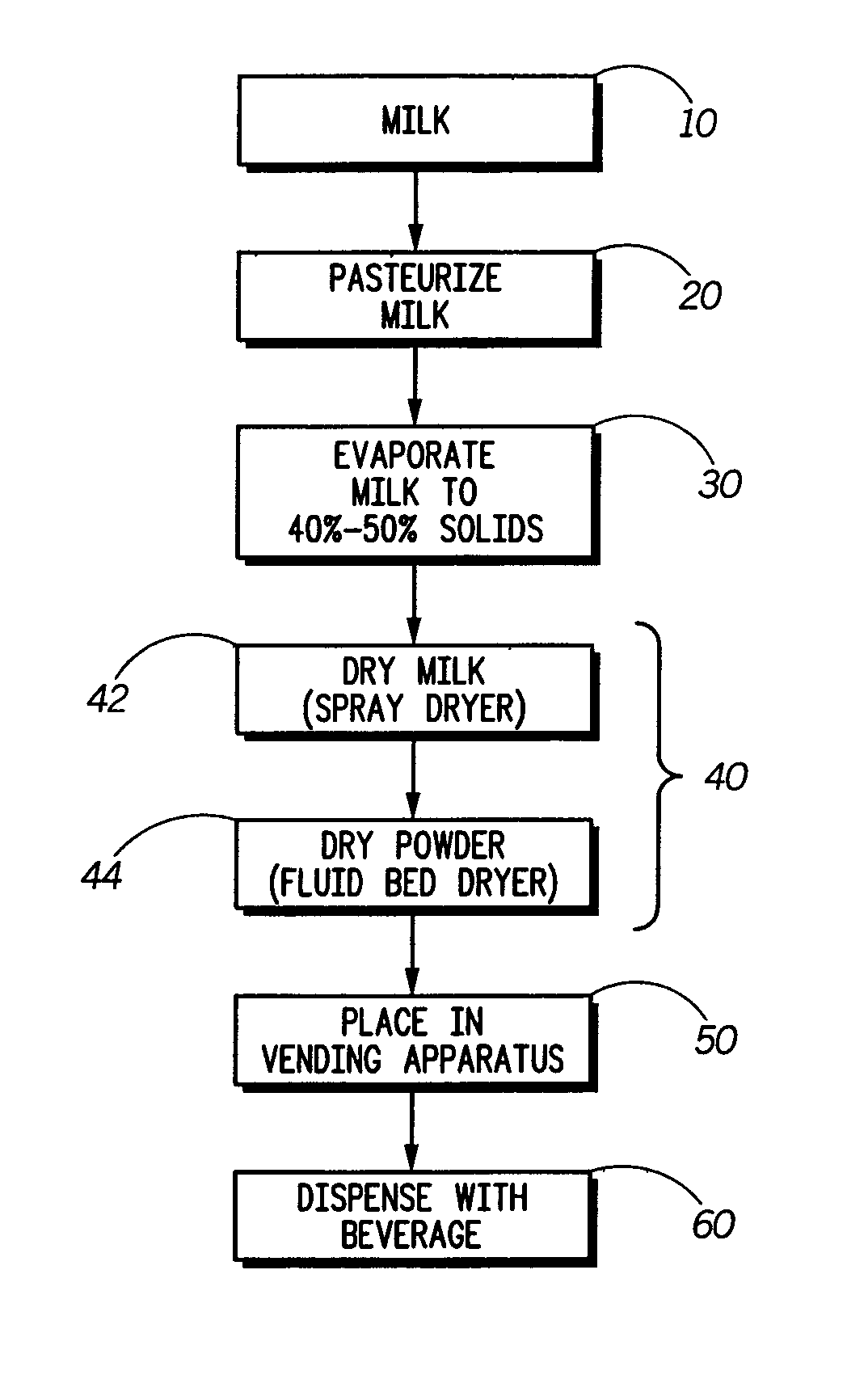

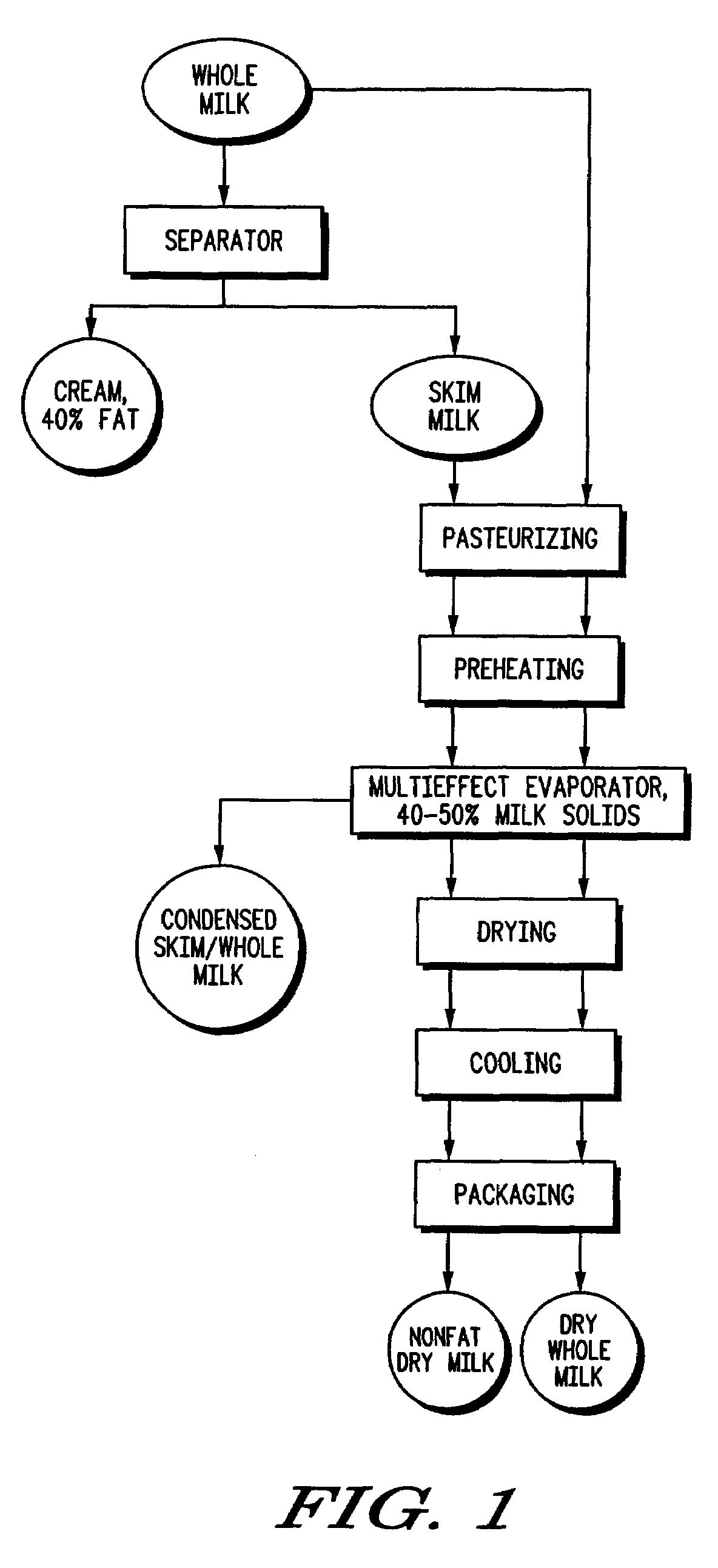

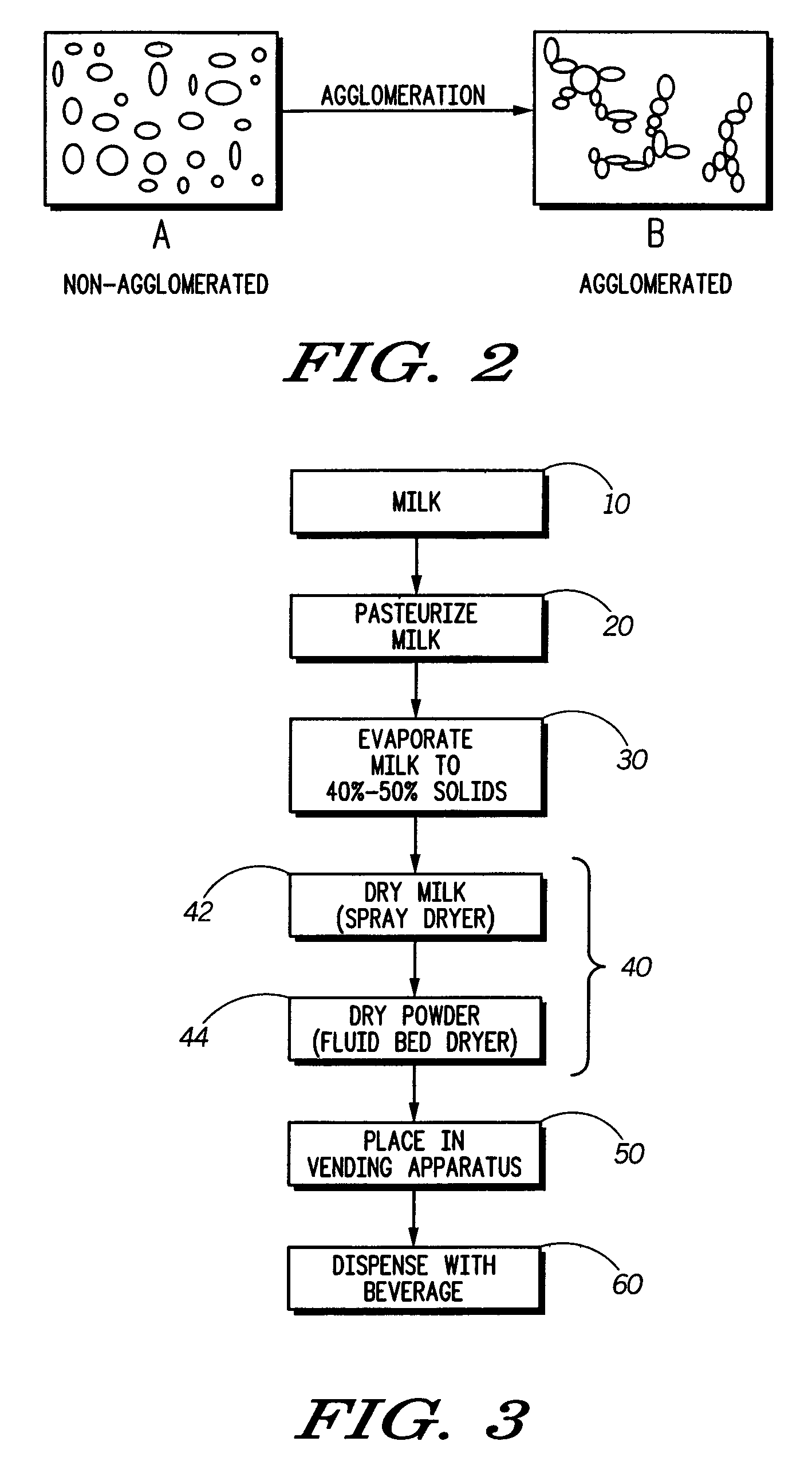

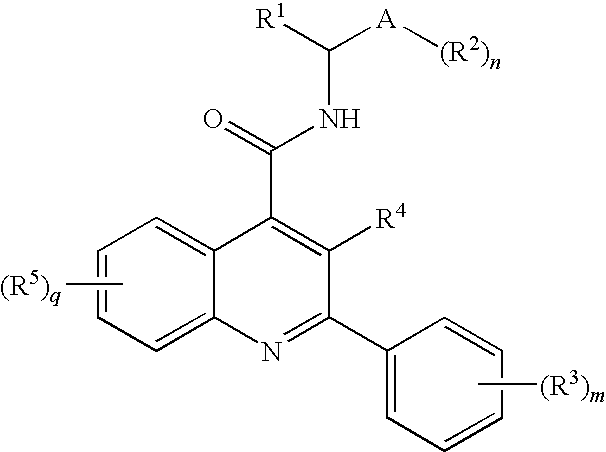

Method and apparatus for preparing a consumable beverage

InactiveUS20050287271A1Save in handling and transportation costExtend lifeMilk preparationFrozen sweetsEngineeringAdditive ingredient

A device (e.g., a vending machine) and method for preparing a consumable beverage include mixing an agglomerated natural milk powder having a scorched particle mass not greater than fifteen milligrams with hot water to produce the consumable beverage. The hot water and milk powder may be mixed prior to or during their placement of the beverage in a beverage cup, such as part of operation of a vending machine. Alternatively, the hot water and milk powder may be mixed with one or more additional ingredients, such as coffee, tea, cocoa powder, and / or sugar, to produce the beverage. Further, the hot water and milk powder may be whipped together or with an additional ingredient to produce a foaming beverage, such as cappuccino.

Owner:NATURES FIRST

N-Oxo-Heterocycle and N-Oxo-Alkyl Quinoline-4-Carboxamides as Nk-3 Receptor Ligands

InactiveUS20080234269A1Easy to adjustLess side effectsBiocideNervous disorderQuinolineCombinatorial chemistry

Owner:ASTRAZENECA AB

Method for preparing consumable vending machine beverage

InactiveUS7651718B2Prolong lifeLower the volumeMilk preparationFrozen sweetsCocoa PowdersAdditive ingredient

A device (e.g., a vending machine) and method for preparing a consumable beverage include mixing an agglomerated natural milk powder having a scorched particle mass not greater than fifteen milligrams with hot water to produce the consumable beverage. The hot water and milk powder may be mixed prior to or during their placement of the beverage in a beverage cup, such as part of operation of a vending machine. Alternatively, the hot water and milk powder may be mixed with one or more additional ingredients, such as coffee, tea, cocoa powder, and / or sugar, to produce the beverage. Further, the hot water and milk powder may be whipped together or with an additional ingredient to produce a foaming beverage, such as cappuccino.

Owner:NATURES FIRST

Amide Substituted Quinolines

InactiveUS20090054445A1Easy to adjustLess side effectsBiocideNervous disorderQuinolineCombinatorial chemistry

Owner:ASTRAZENECA AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com