Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Little and maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

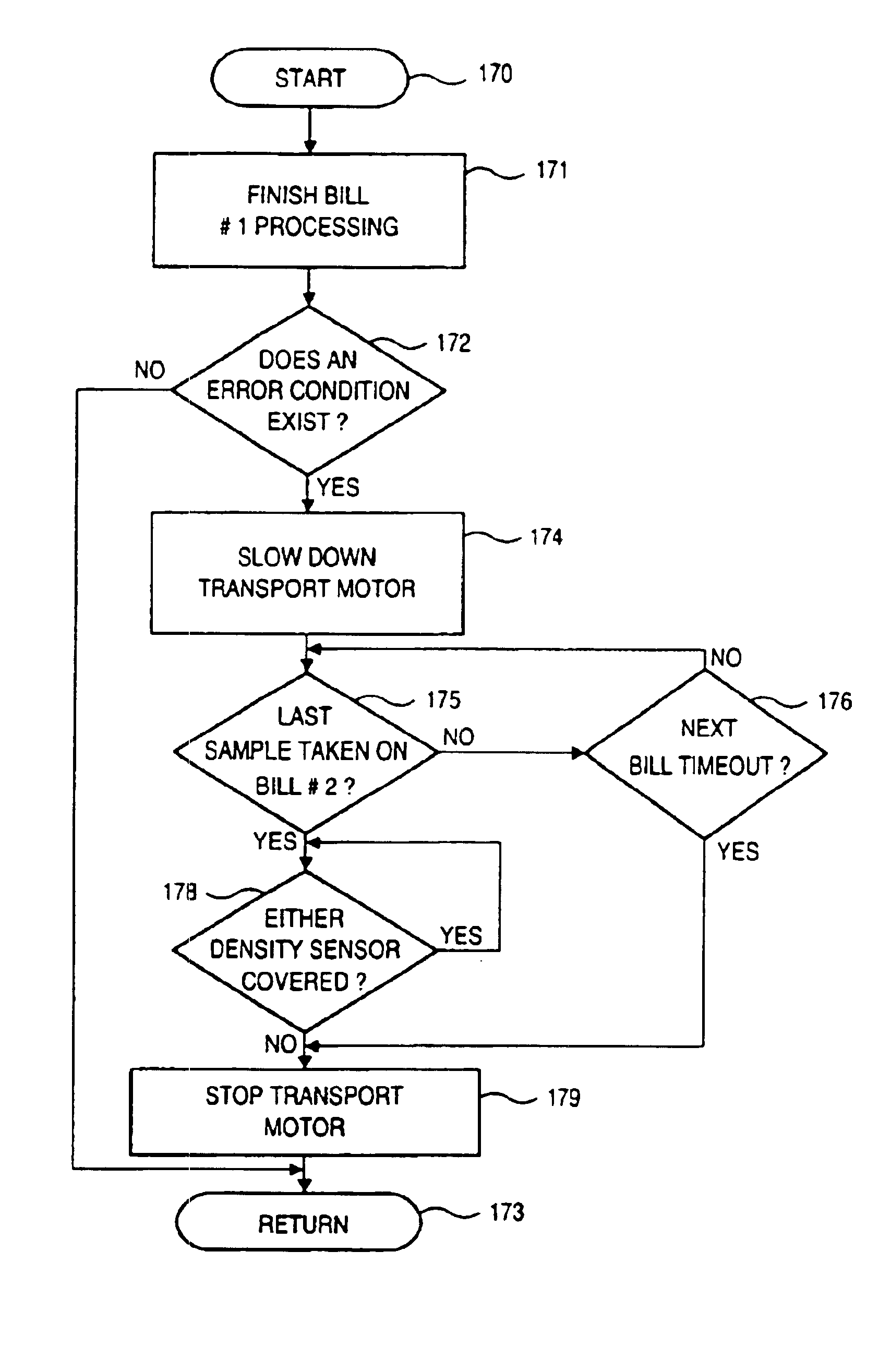

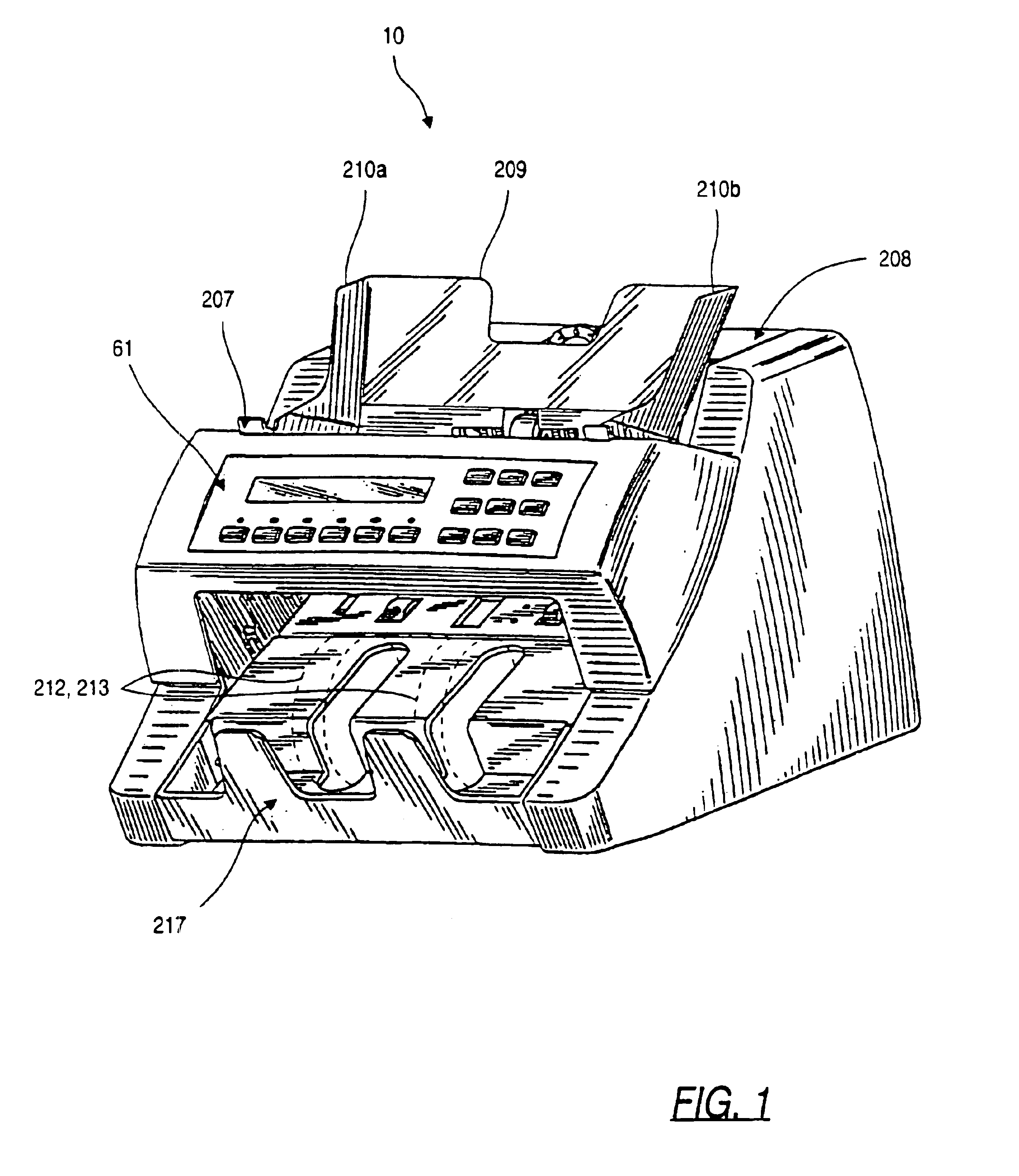

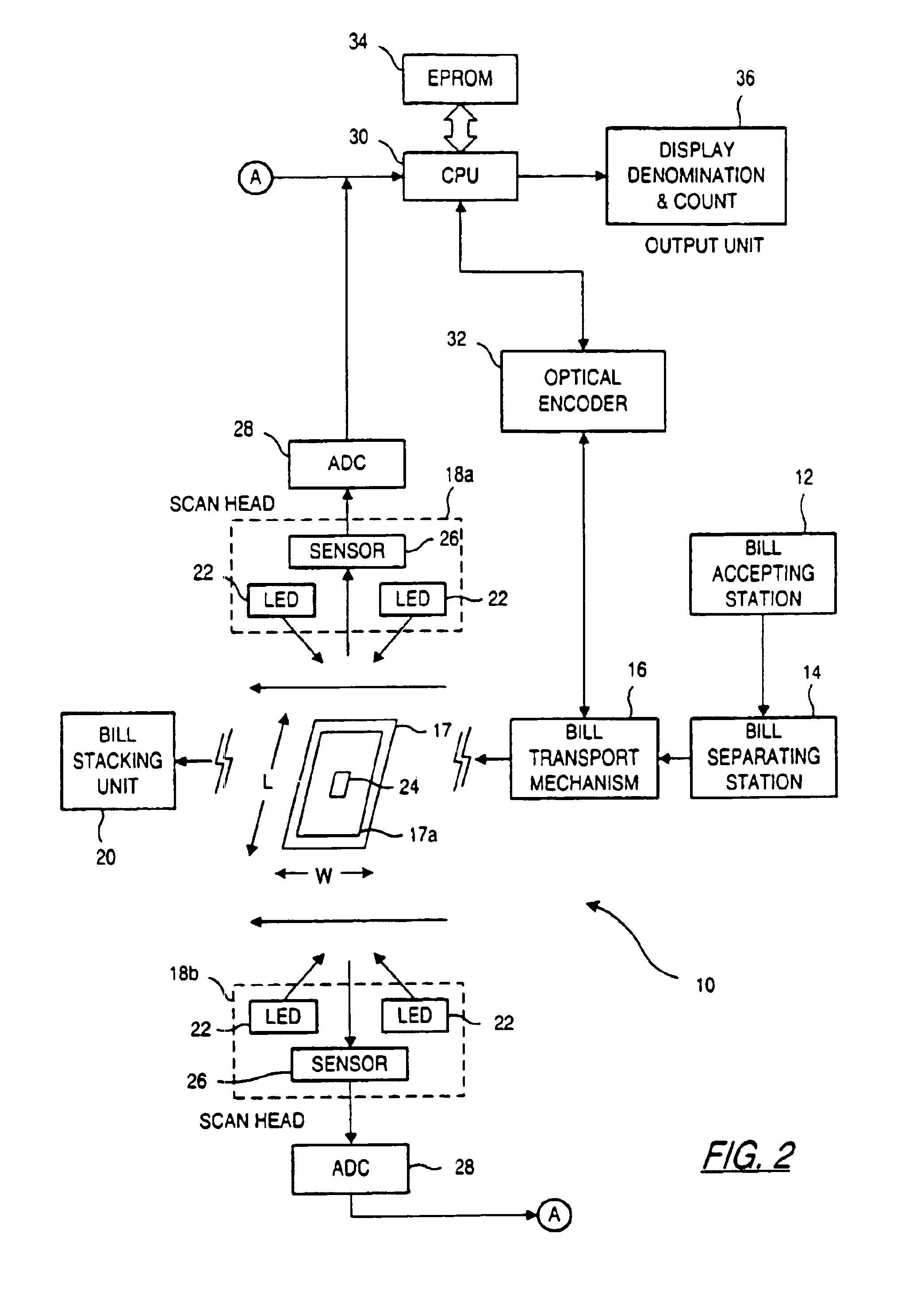

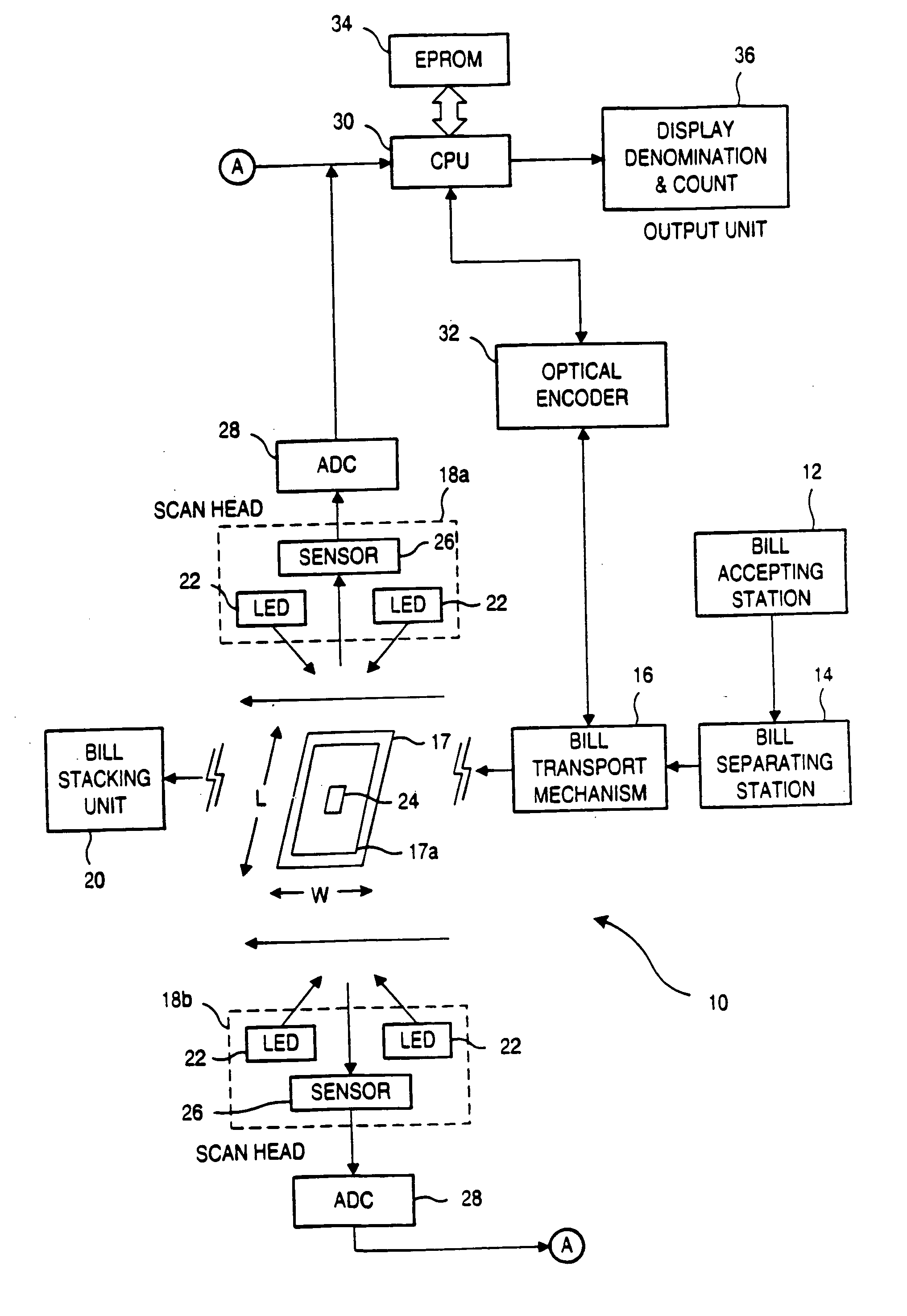

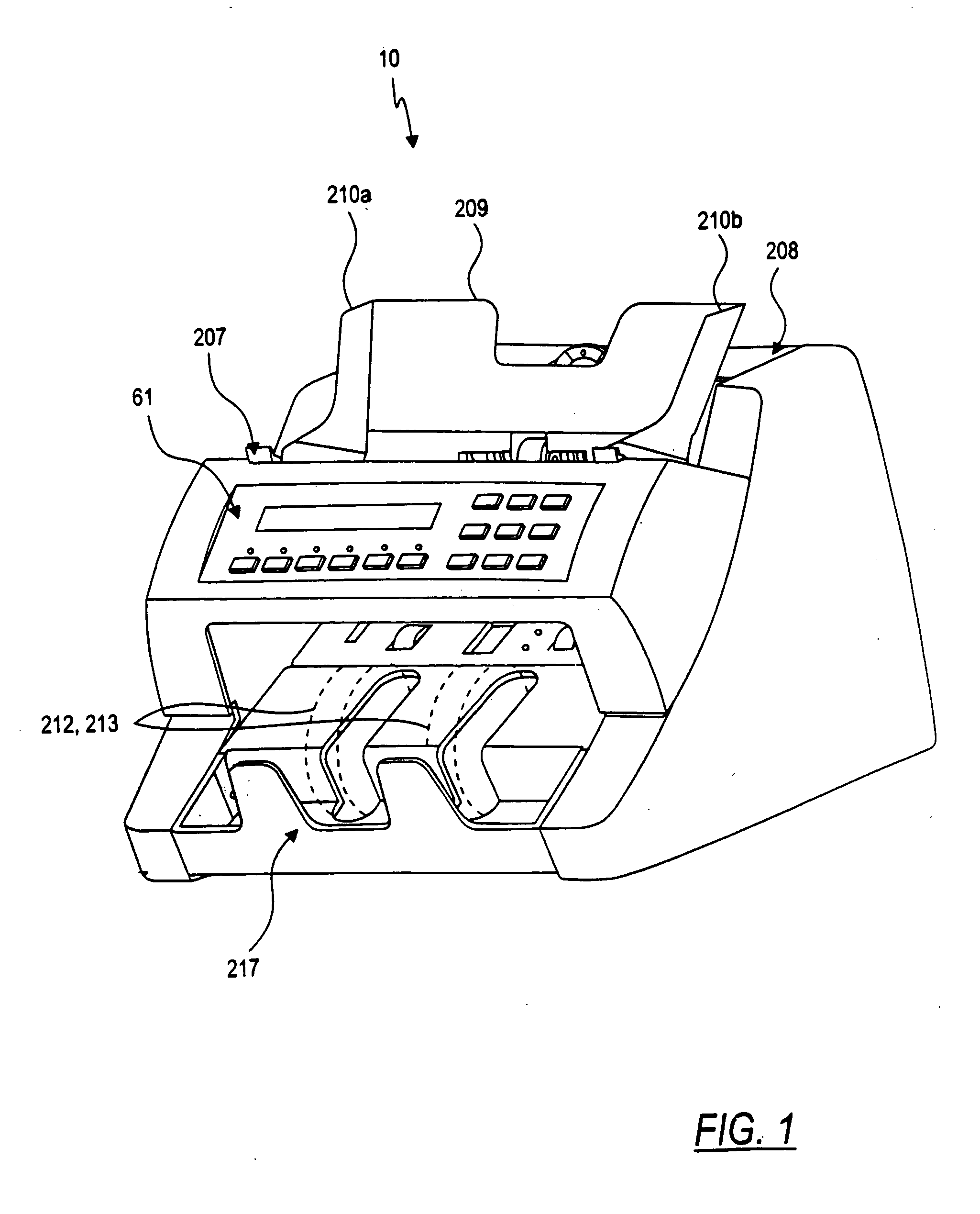

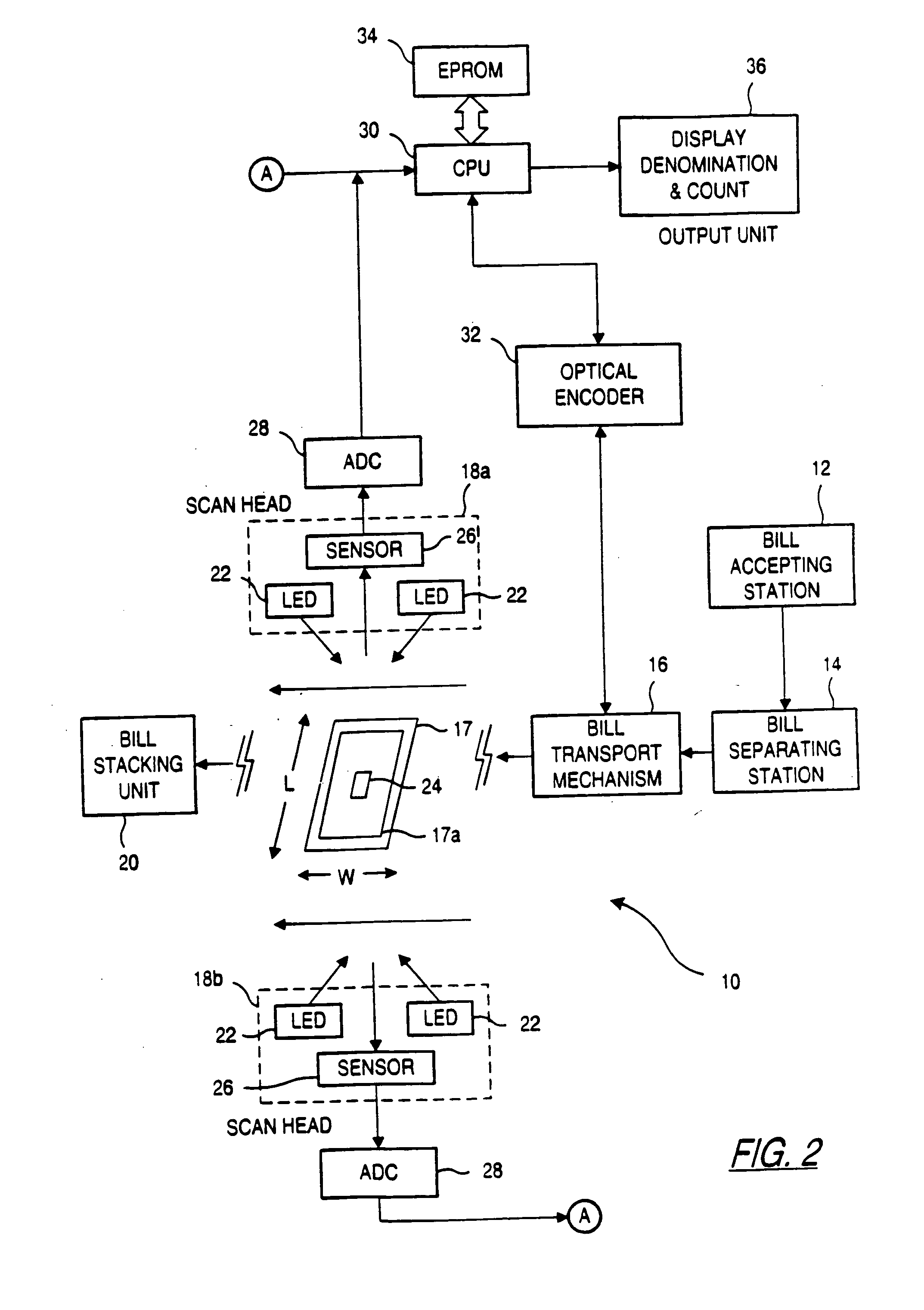

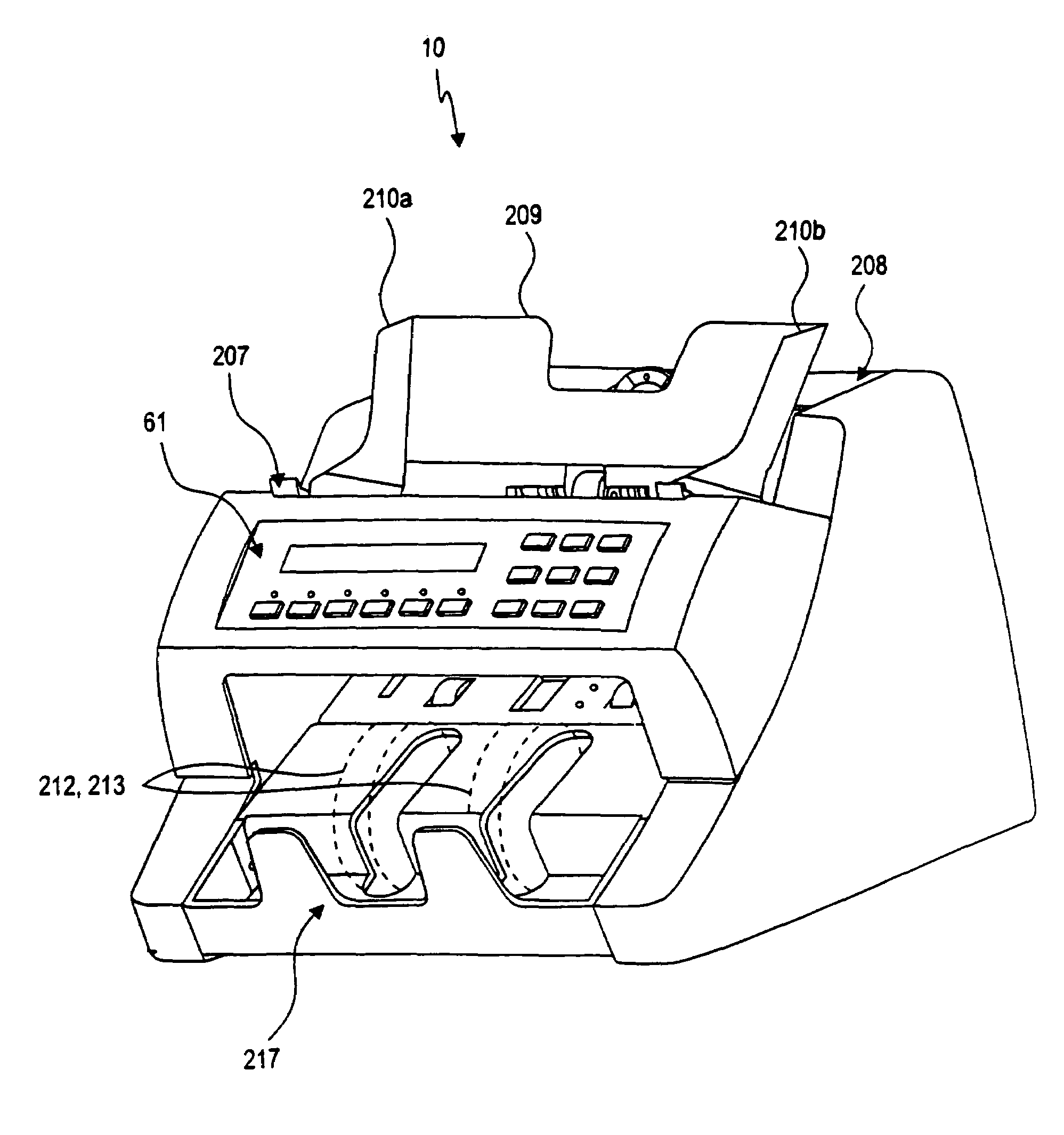

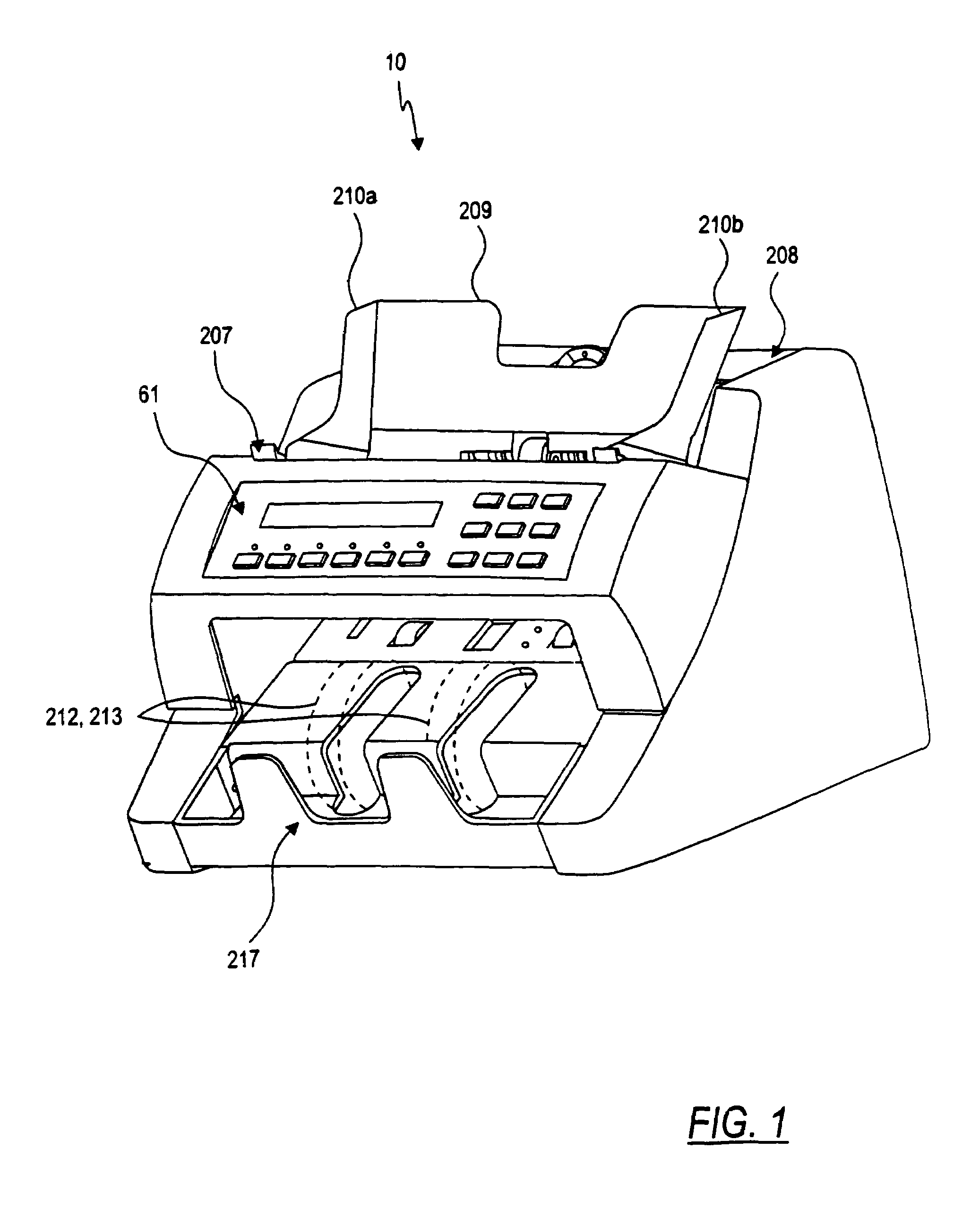

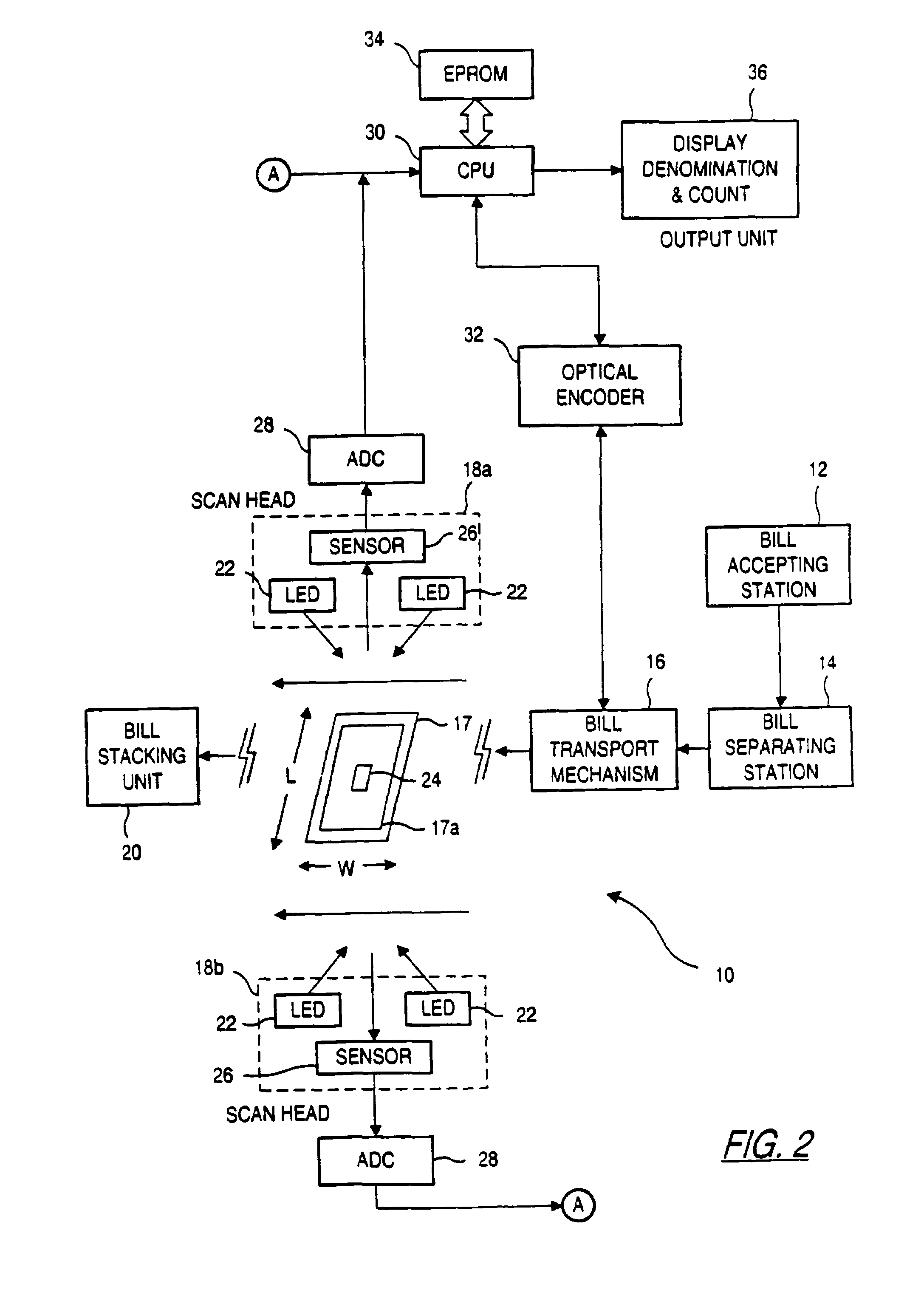

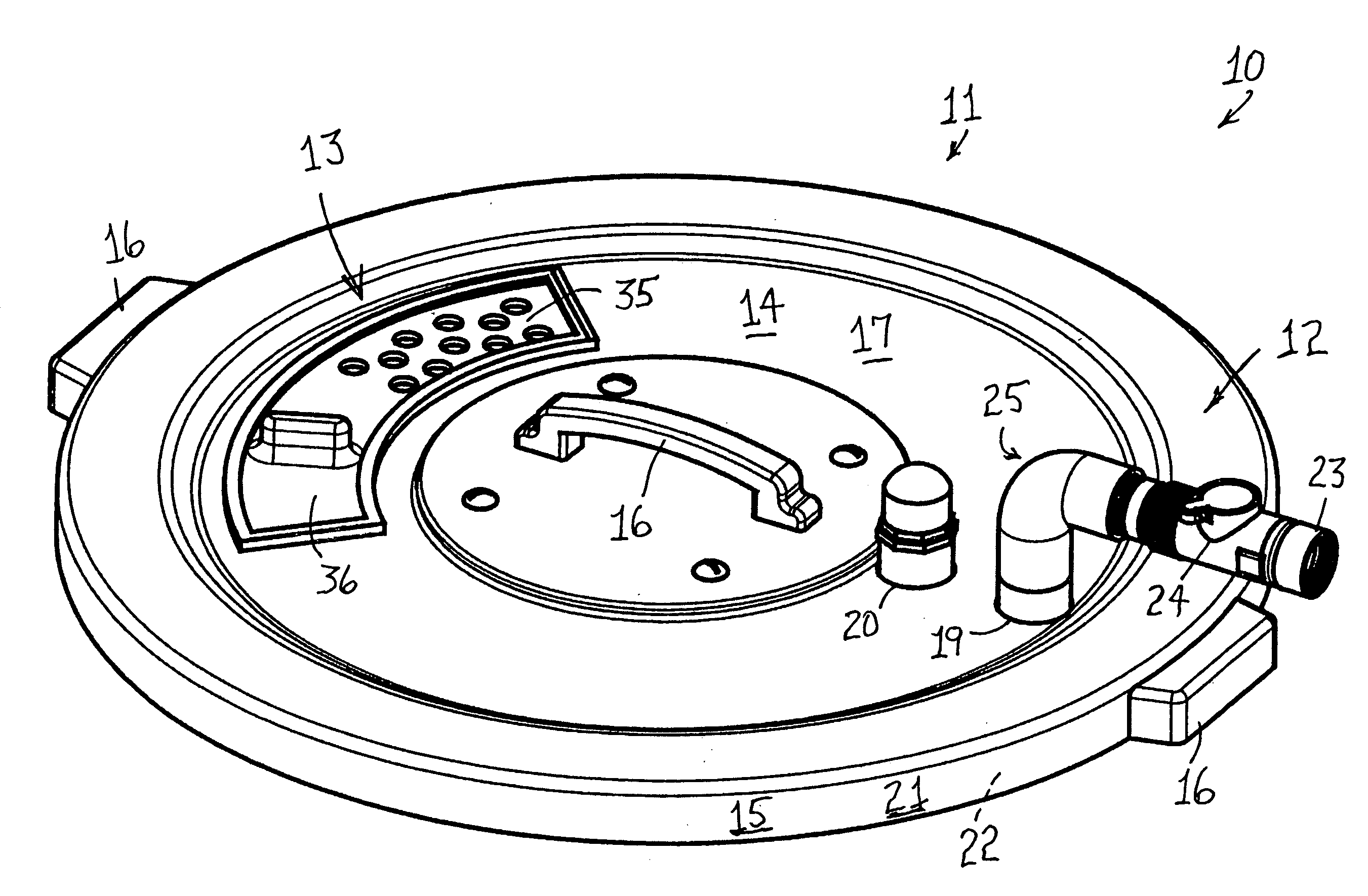

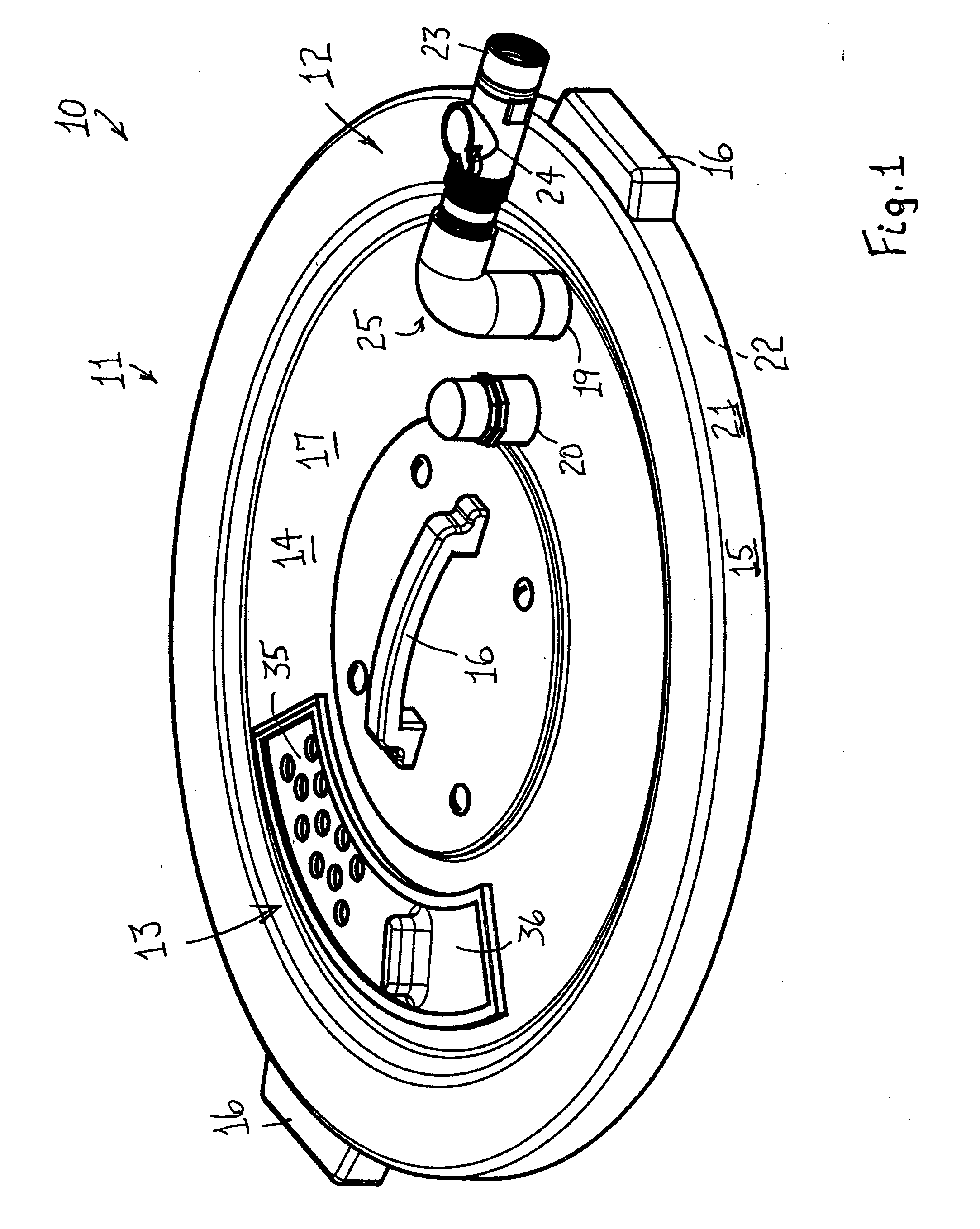

Method and apparatus for discriminating and counting documents

InactiveUS6915893B2Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringMechanical engineering

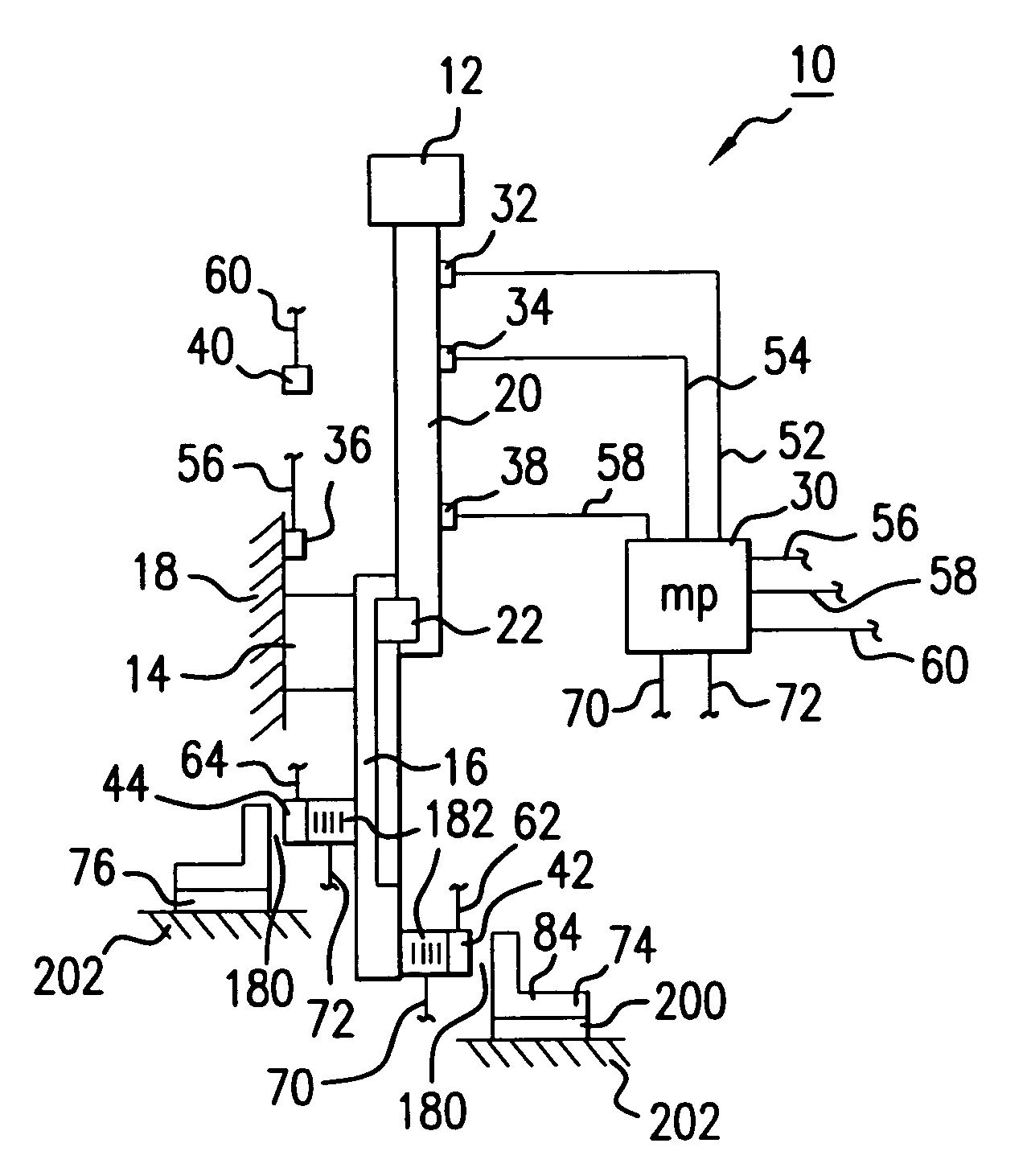

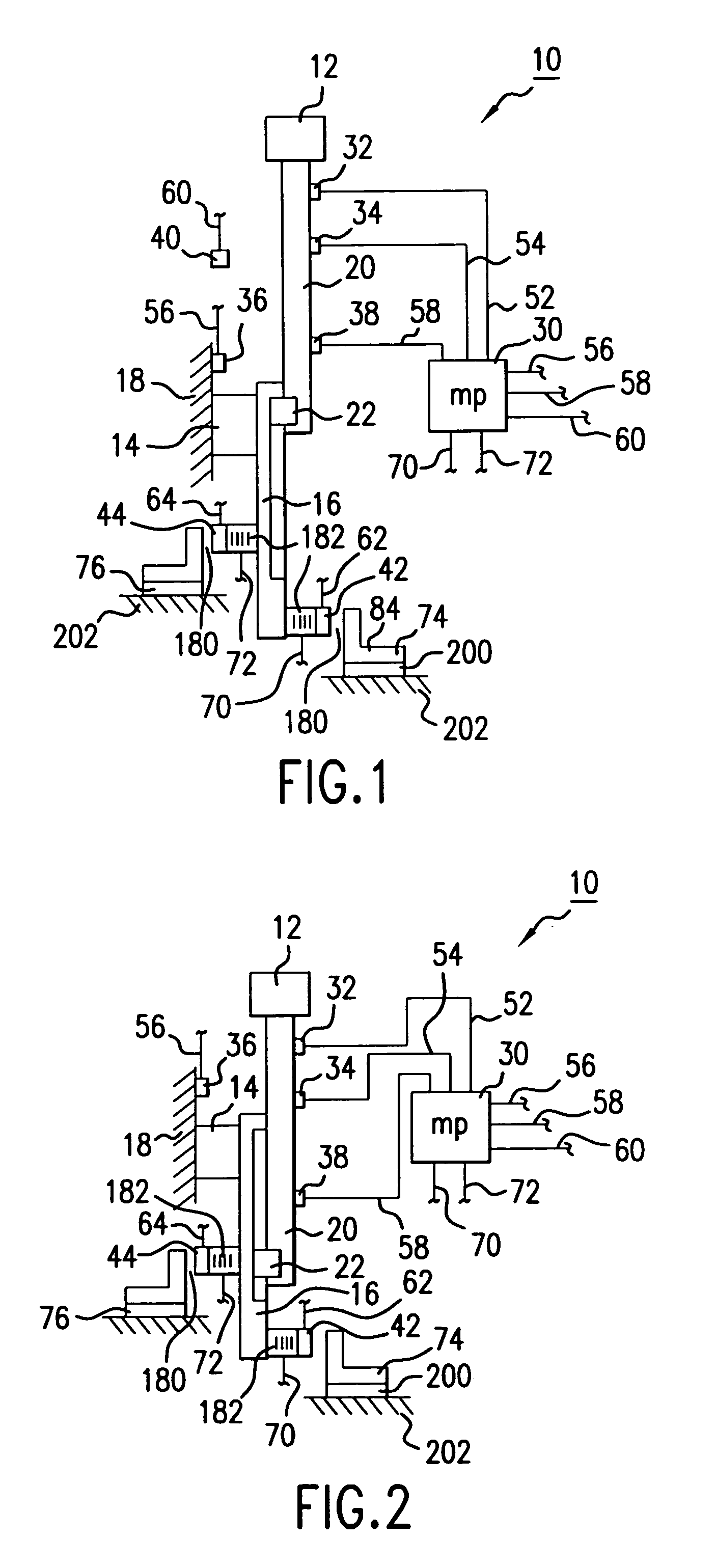

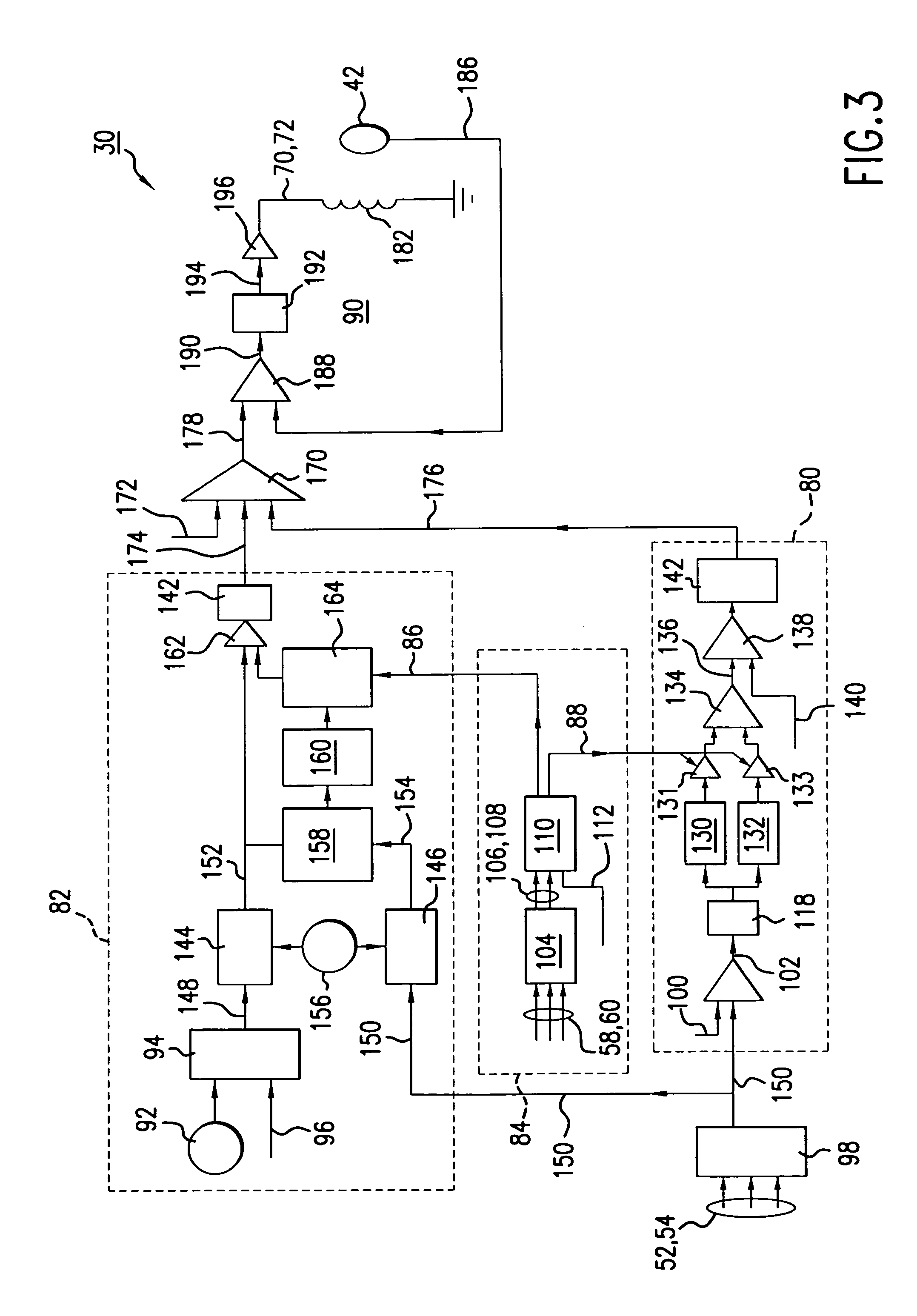

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

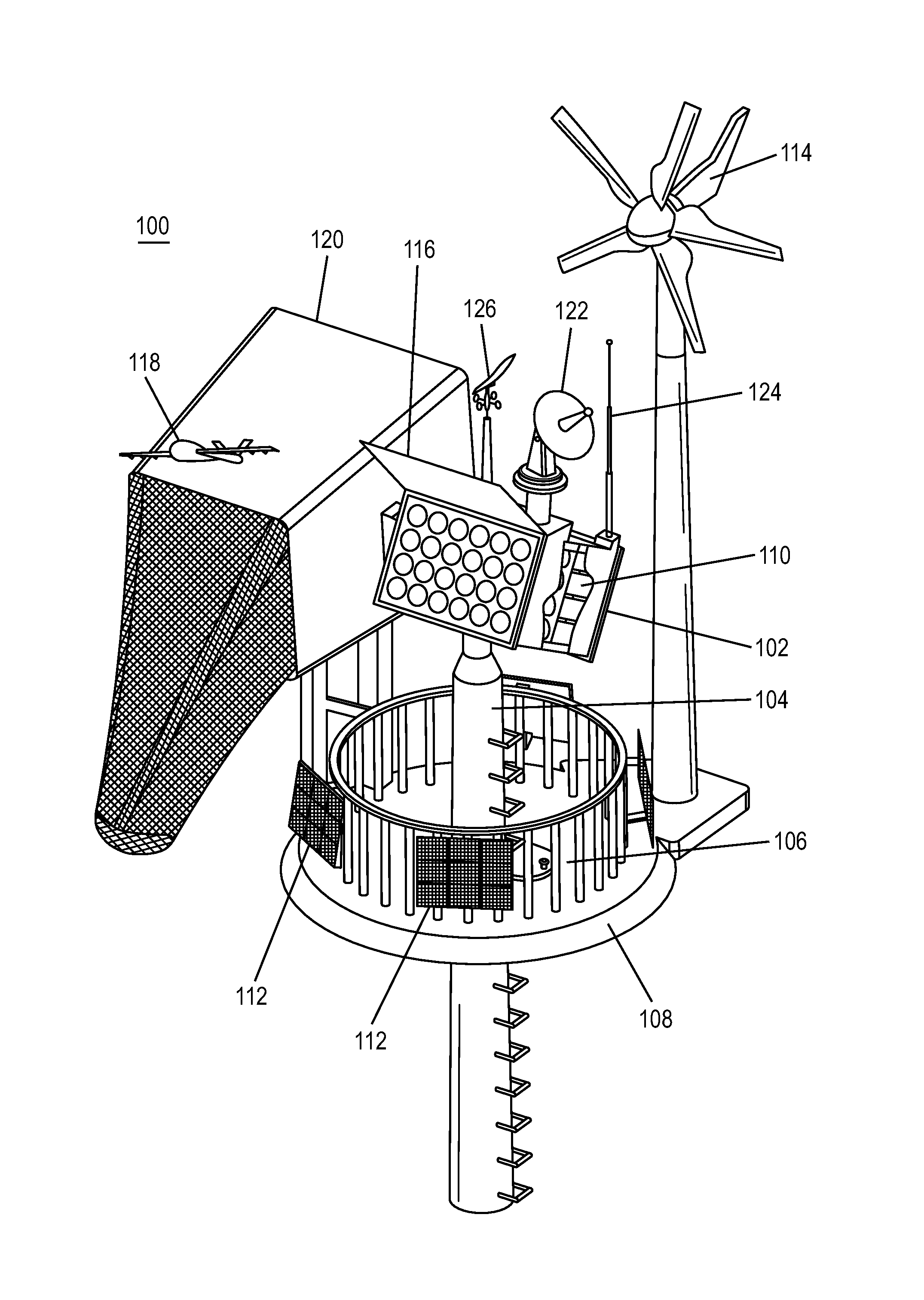

Systems and methods for deployment and operation of unmanned aerial vehicles

InactiveUS8439301B1Extended shelf lifeImprove launch reliabilityRocket launchersArresting gearLogistics managementCommand and control

An unmanned aerial vehicle (UAV) system provides for UAV deployment and remote, unattended operation with reduced logistics requirements. The system includes a launcher that can include one or more launch tubes, each launch tube configured to house a UAV in a canister and one or more gas generators operatively connected to each canister and configured to push the UAV out of the launch tube by releasing gas into the canister. A controller for activating the gas generators can sequentially, and with a predetermined time delay, expel the UAV with a desired velocity and acceleration. The system further includes a UAV recovery device, a power supply, a security subsystem, a command and control subsystem and a communications subsystem. Command, control and communications can be provided between a remote station and the UAV.

Owner:SEACORP LLC

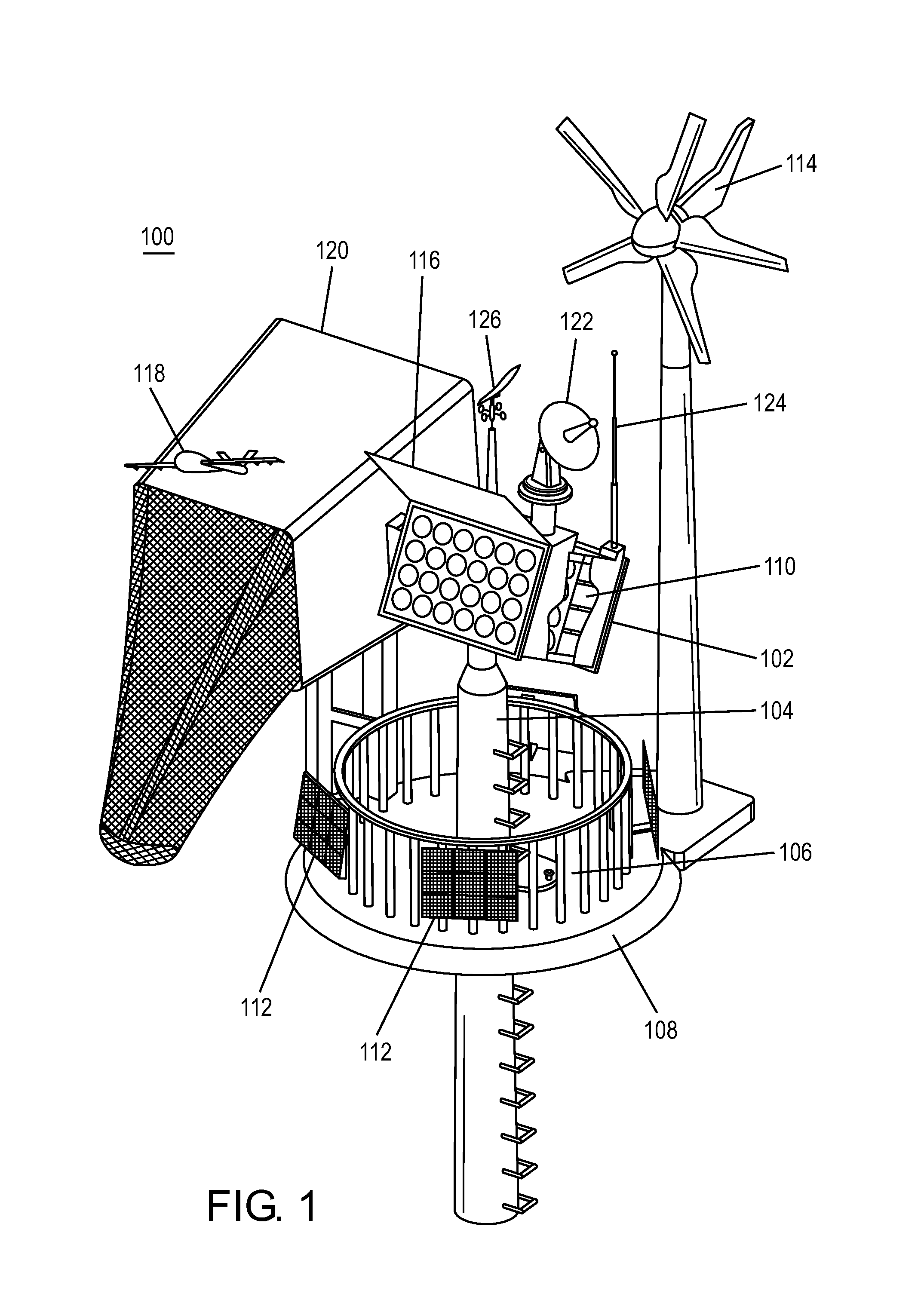

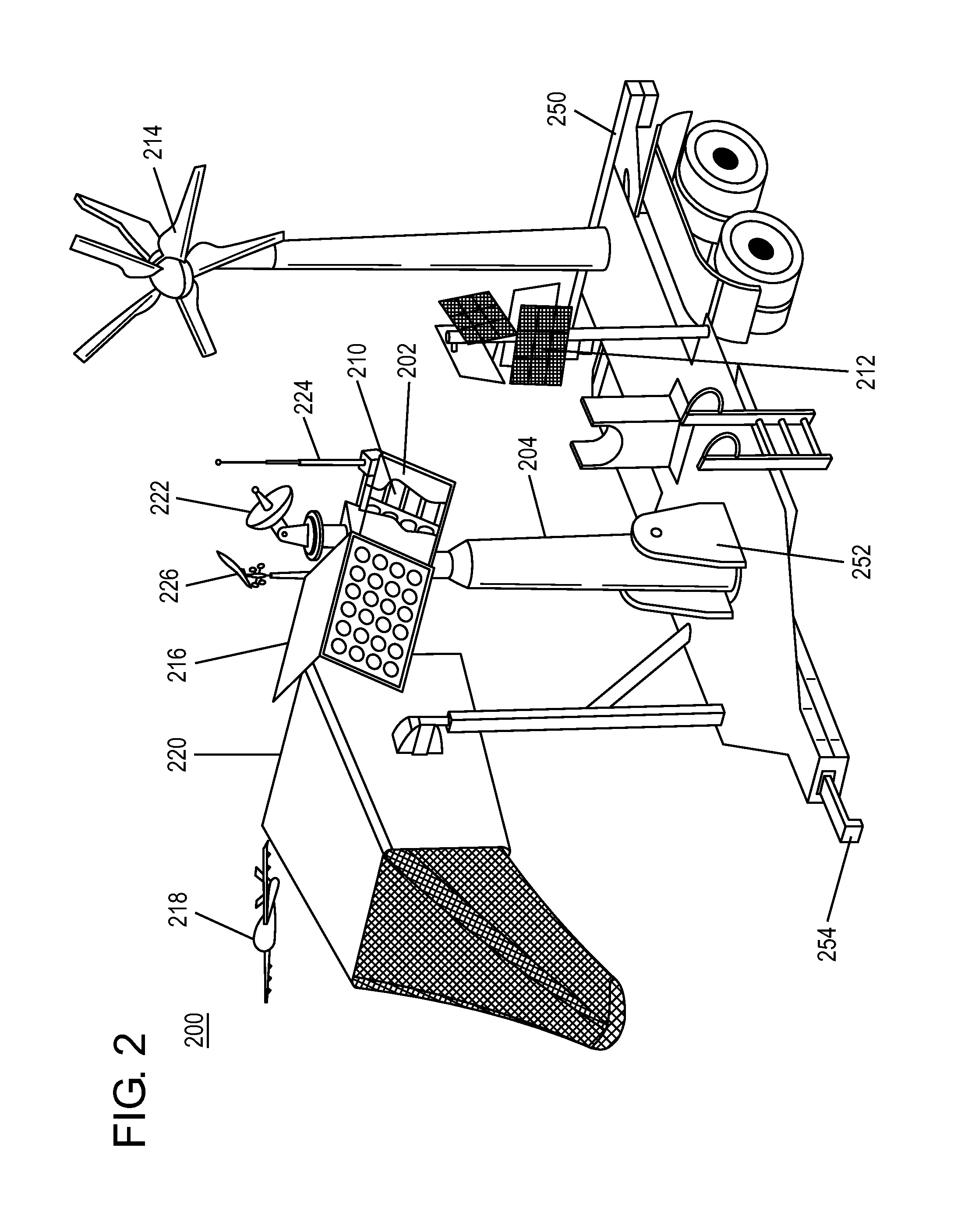

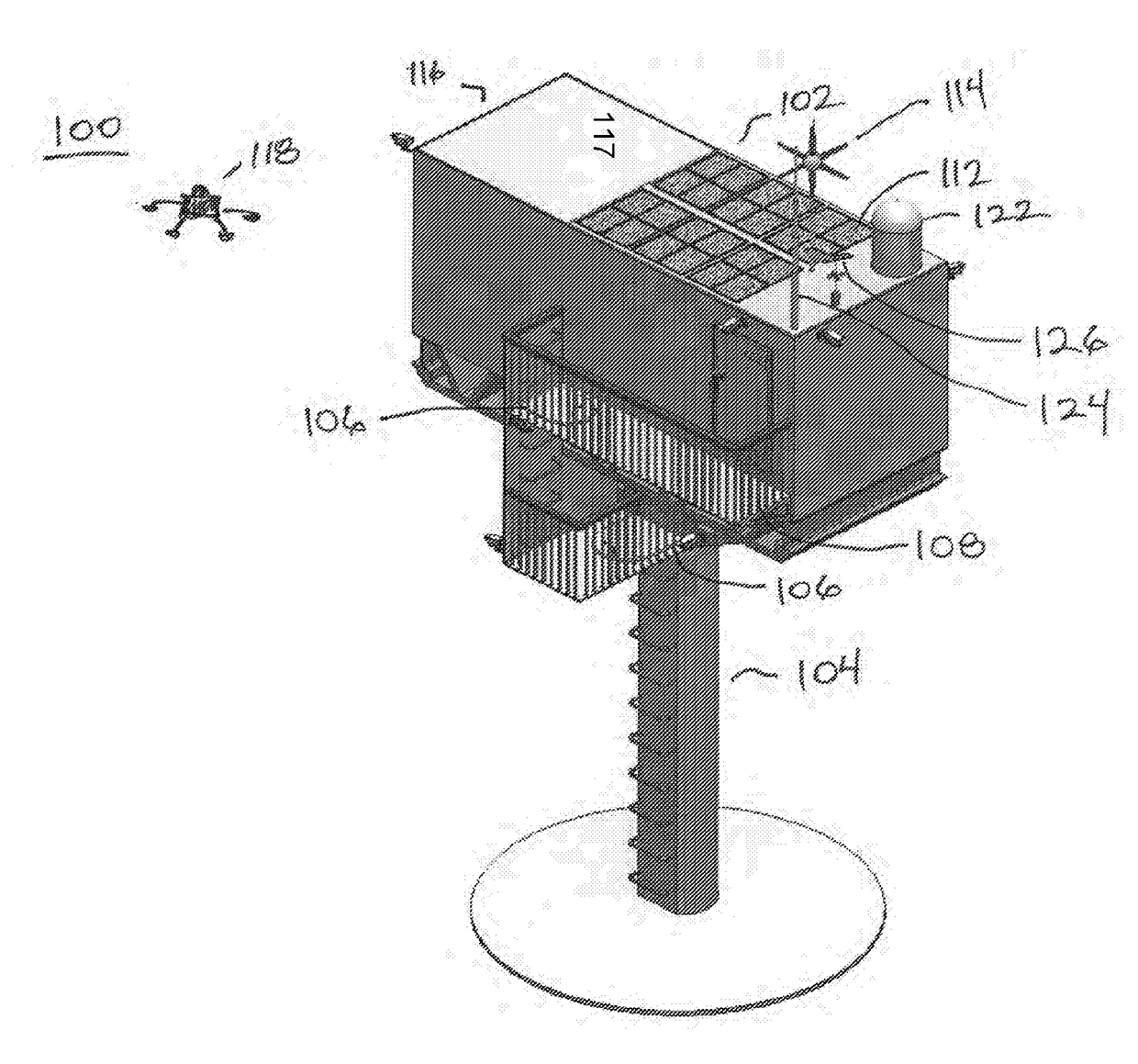

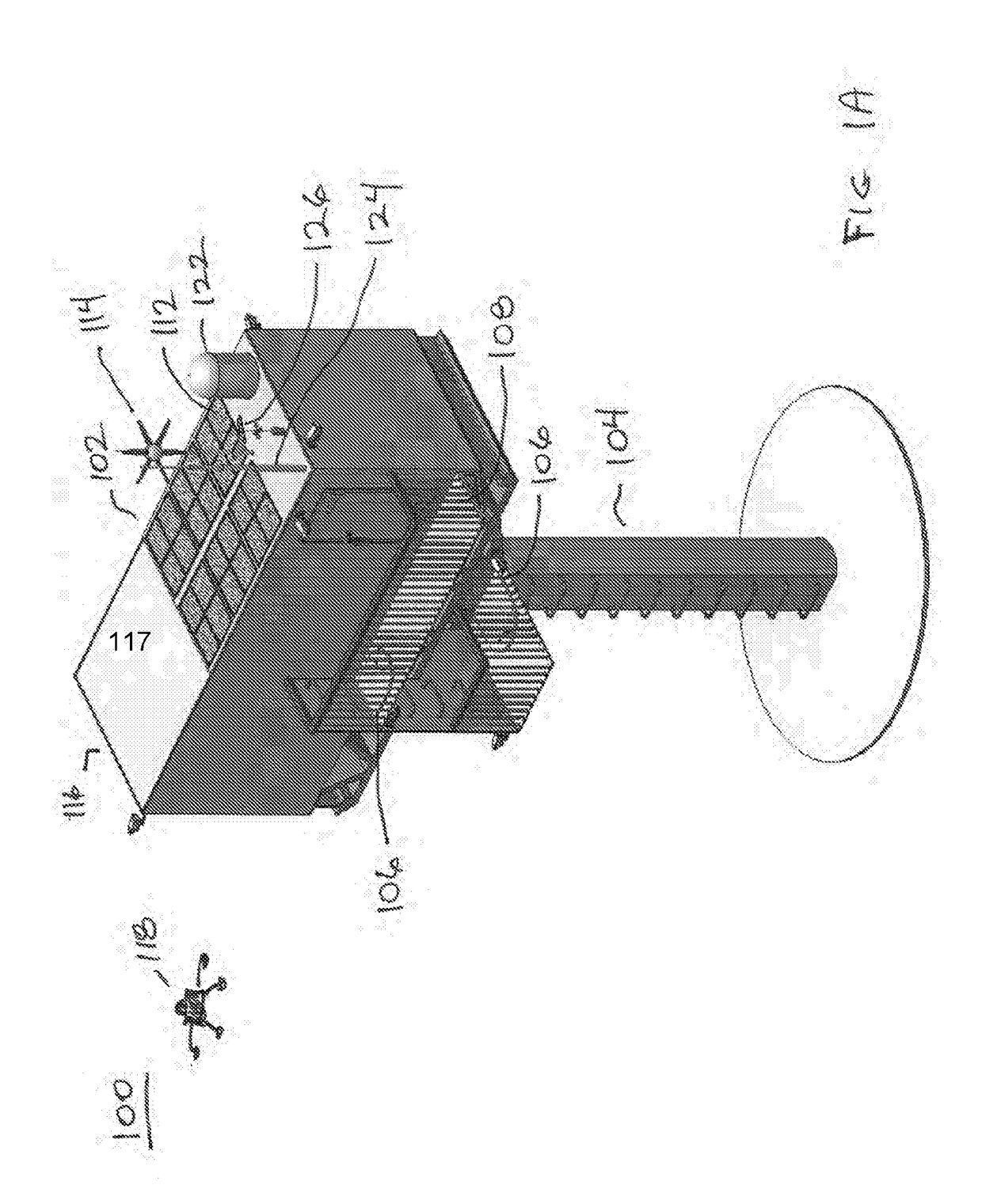

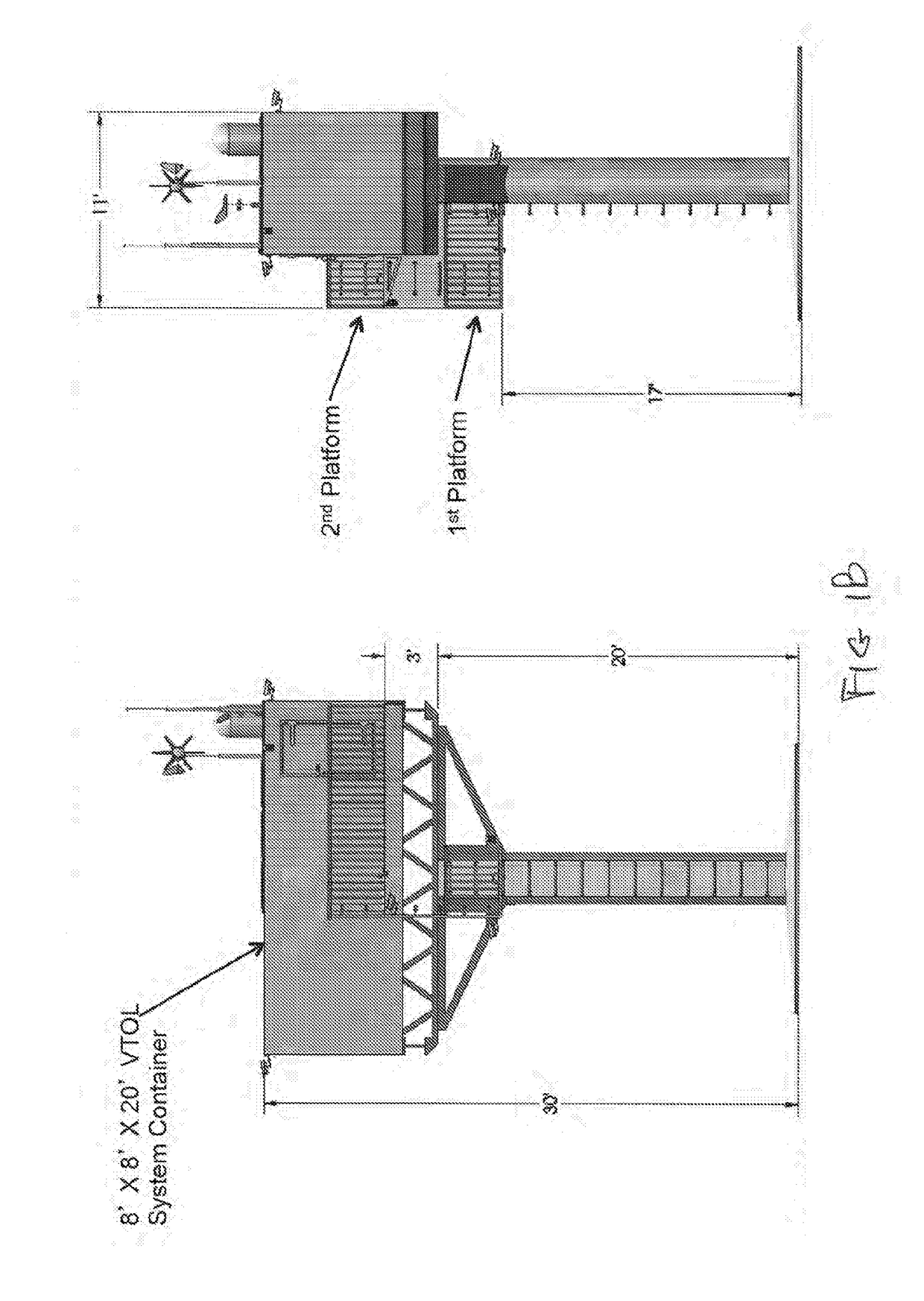

Systems and methods for deployment and operation of vertical take-off and landing (VTOL) unmanned aerial vehicles

InactiveUS20170225802A1Quickly instal and removeFacilitate recoveryBatteries circuit arrangementsCharging stationsElectricityLogistics management

An unmanned aerial vehicle (UAV) system provides for UAV deployment and remote, unattended operation with reduced logistics requirements. The system includes a launcher that can include one or more containers, or hangars, configured to house vertical take-off and landing (VTOL) UAVs. The system can further include a VTOL UAV orientation and charging module configured to mechanically position a UAV within a container and facilitate electrical mating and charging of a battery in the UAV. These operations, and others, can be performed by remote command that can initiate a series of pre-programmed steps. The UAV system can further include a power generation and storage subsystem, a security subsystem, a command and control subsystem and a communications subsystem. Command, control and communications can be provided between a remote station and the UAV.

Owner:SEACORP LLC

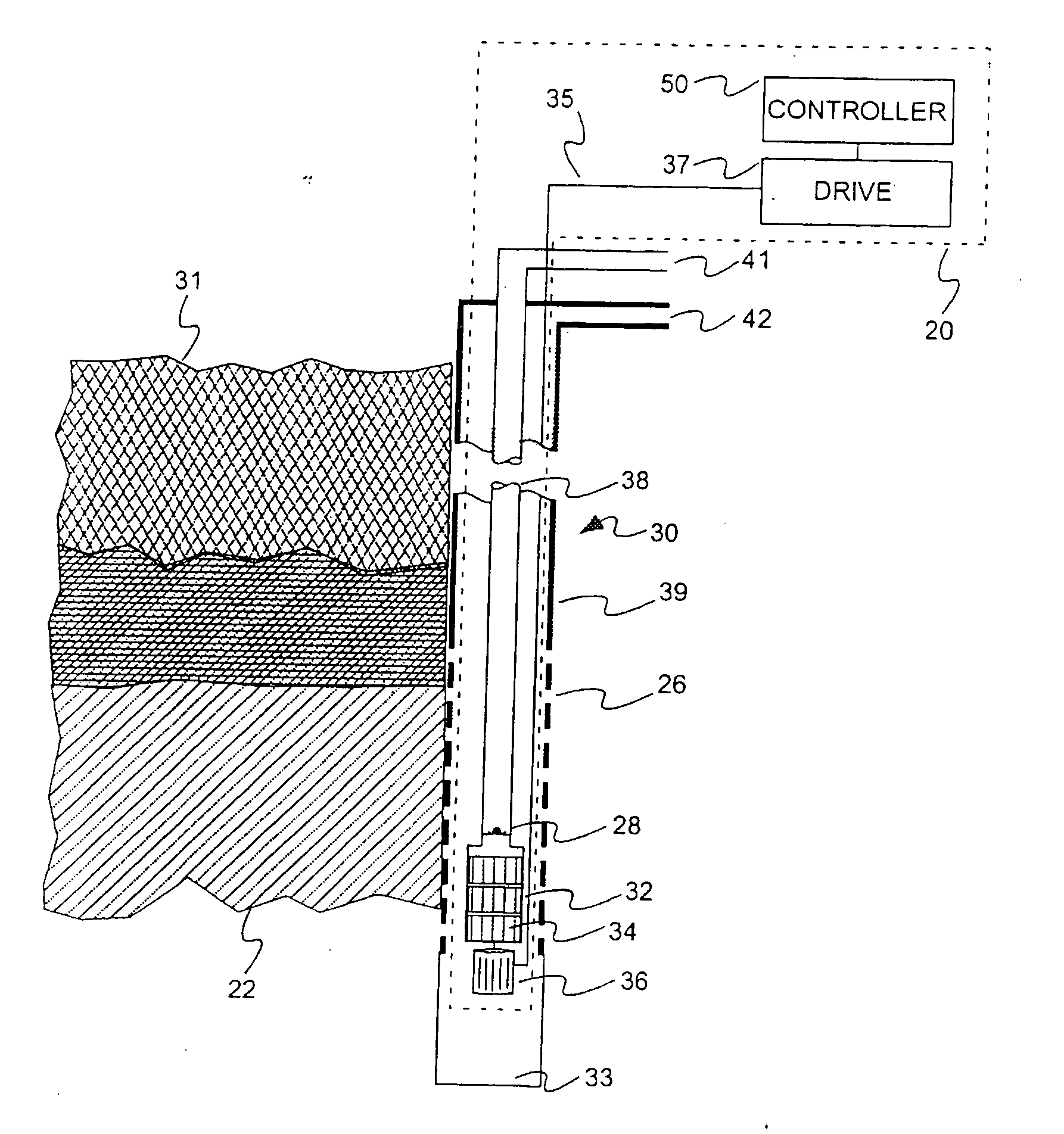

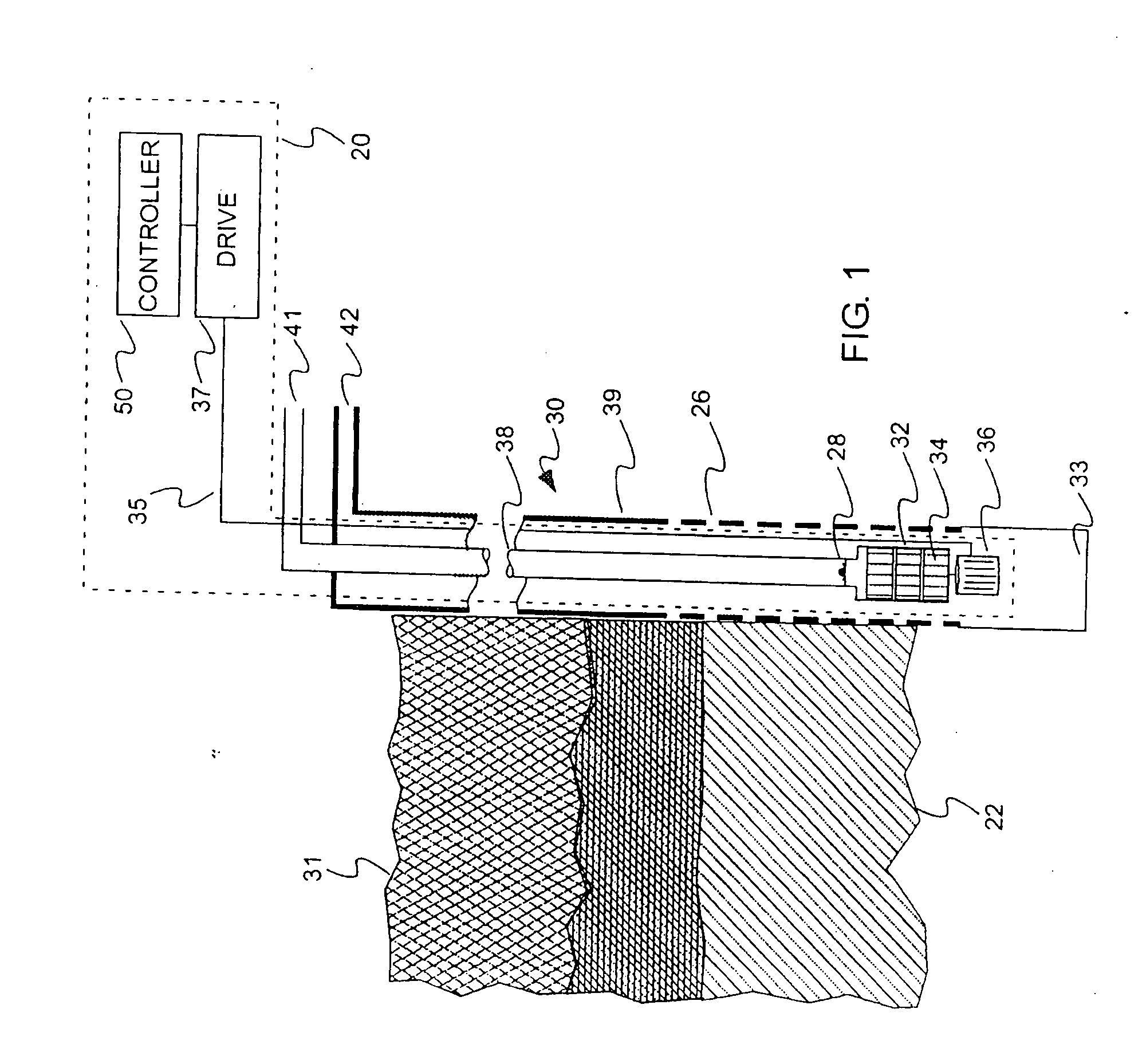

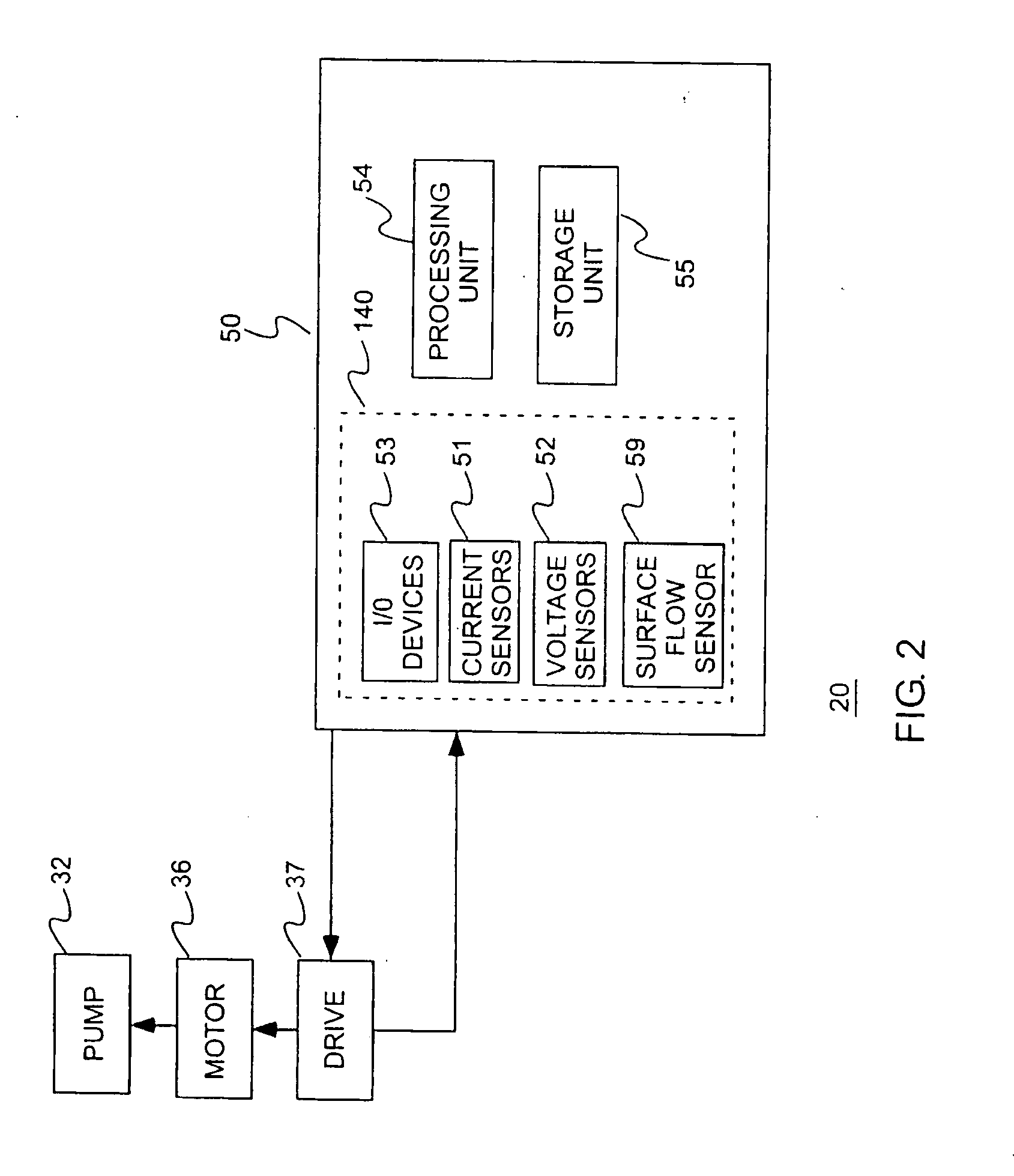

Determination And Control Of Wellbore Fluid Level, Output Flow, And Desired Pump Operating Speed, Using A Control System For A Centrifugal Pump Disposed Within The Wellbore

ActiveUS20080067116A1Enhance market appealBroad possible marketLevel controlWind motor controlEngineeringSystem parameters

A method and apparatus for determining a fluid level and / or output flow during operation of a centrifugal pump, are provided, which may be used for production of gas and / or oil from a well, and include a vector feedback model to derive values of torque and speed from signals indicative of instantaneous current and voltage drawn by the pump motor, a pump model which derives values of the fluid flow rate and the head pressure for the pump from torque and speed inputs, a pumping system model that derives, from the estimated values of the pump operating parameters, an estimated value of fluid level and other pumping system parameters. Controllers responsive to the estimated values of the pumping system parameters control the pump to maintain fluid level at the pump input, near an optimum level, or within a safe operating range and / or output flow from the pump.

Owner:UNICO LLC

Method and apparatus for discriminating and counting documents

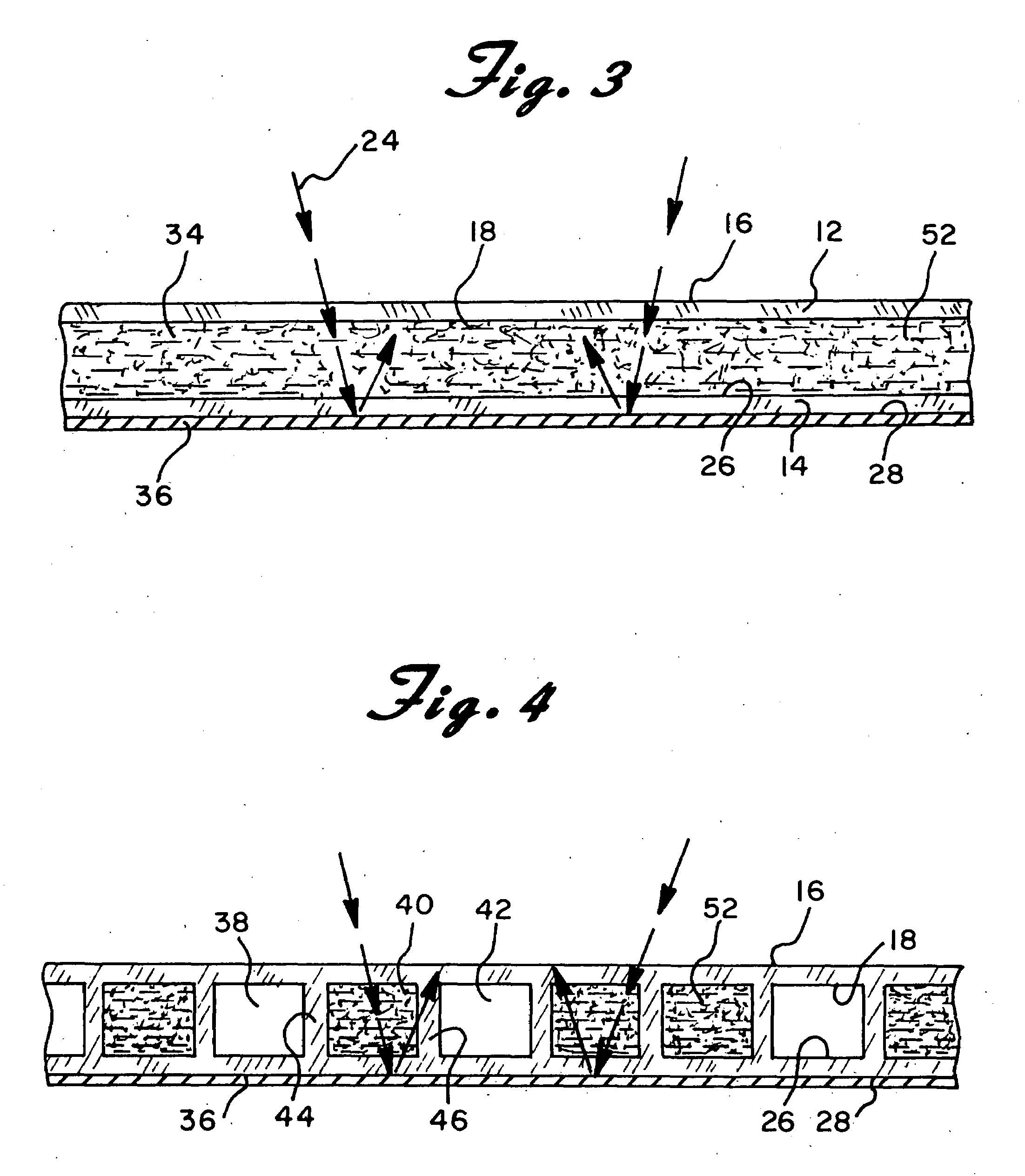

InactiveUS20050213803A1Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringPaper document

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

Method and apparatus for discriminating and counting documents

InactiveUS7817842B2Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringDocumentation

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

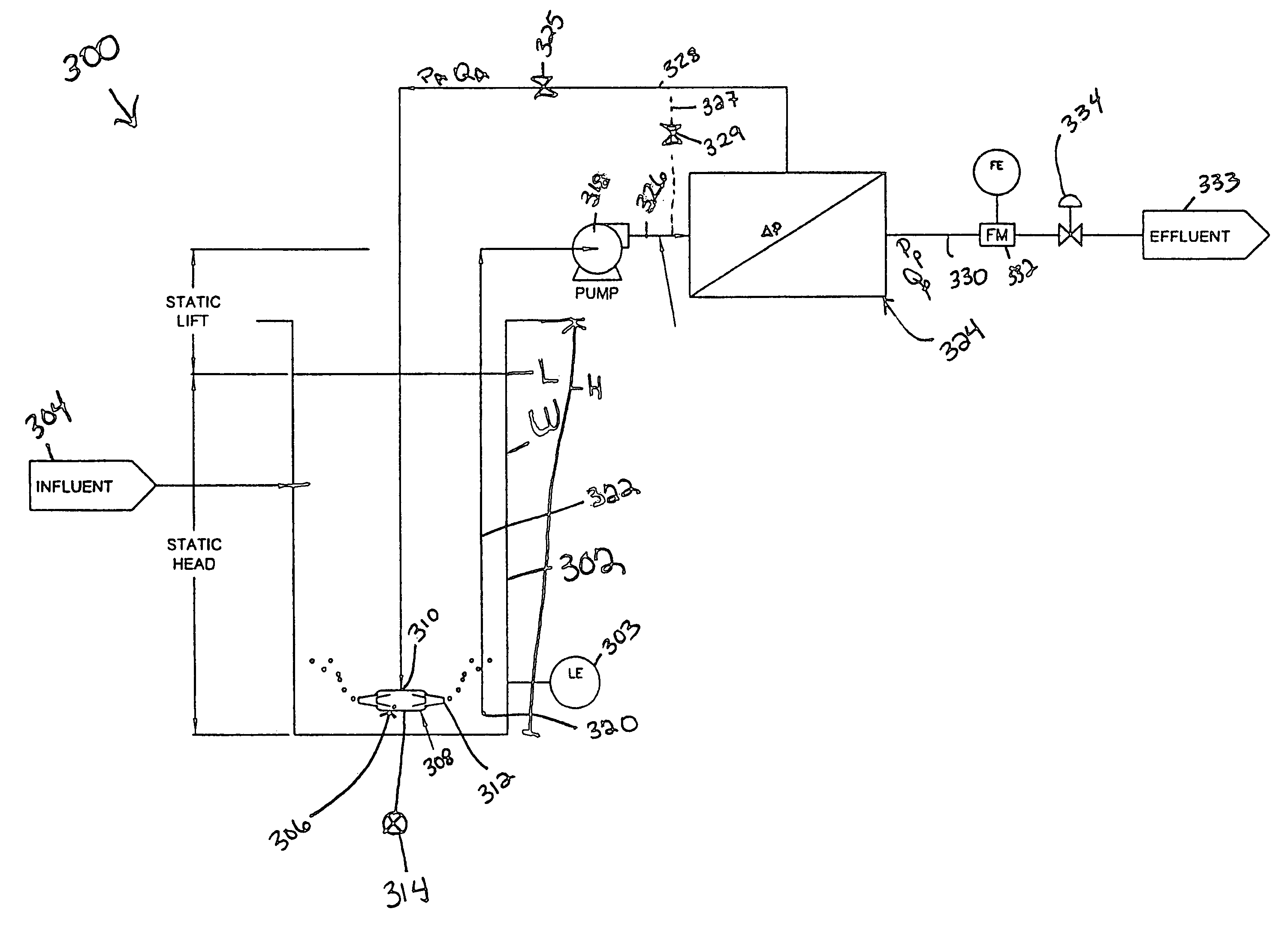

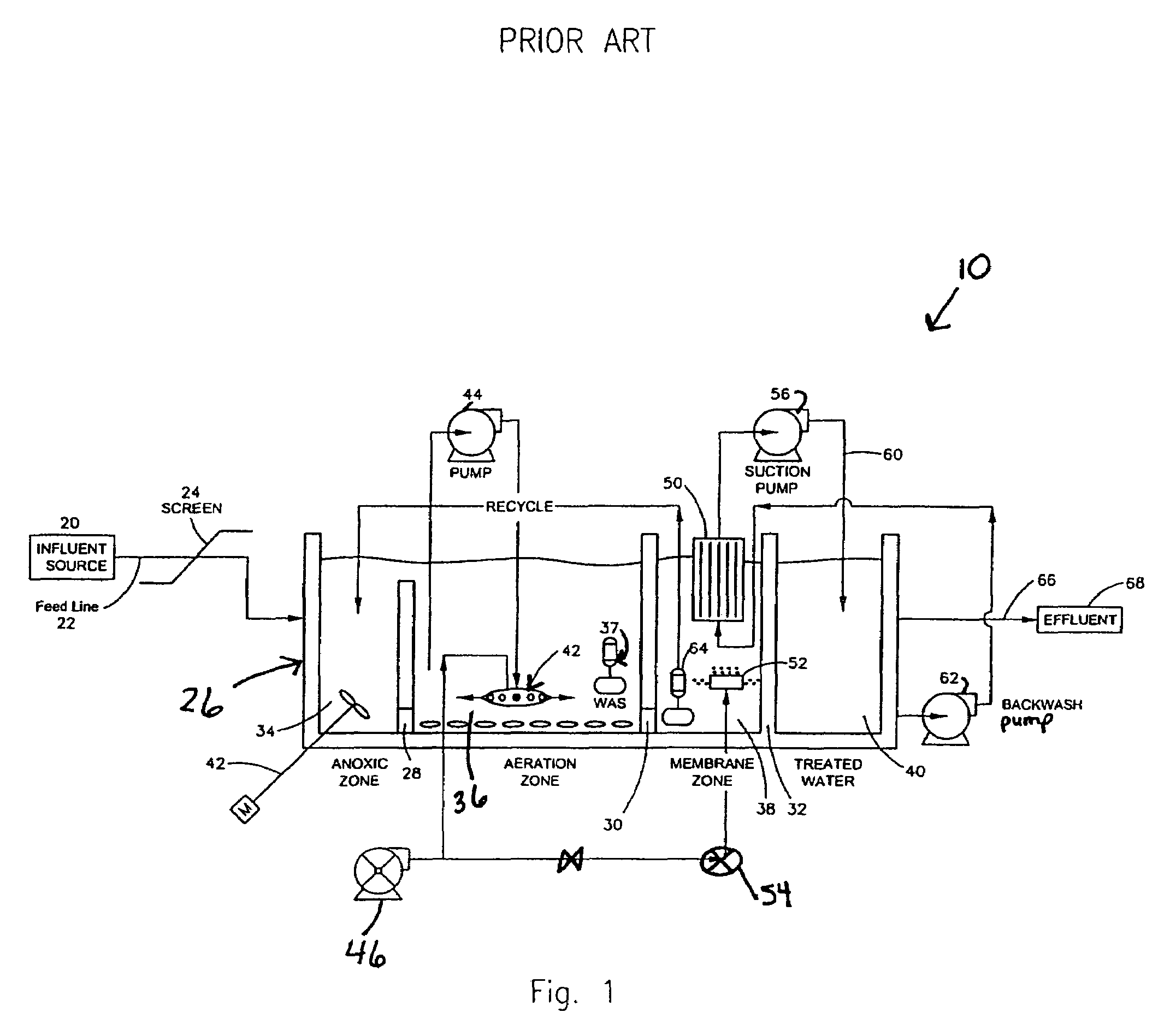

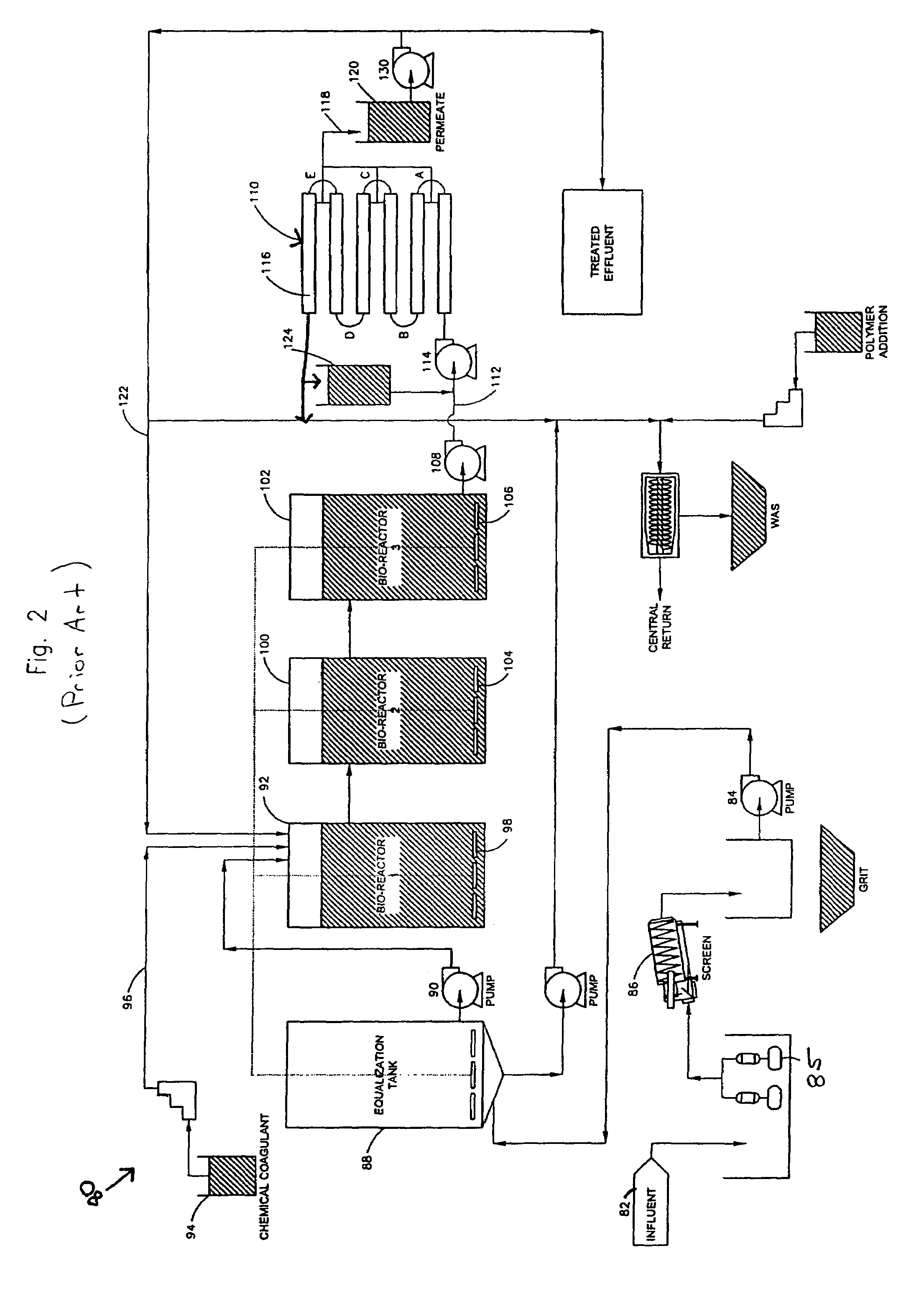

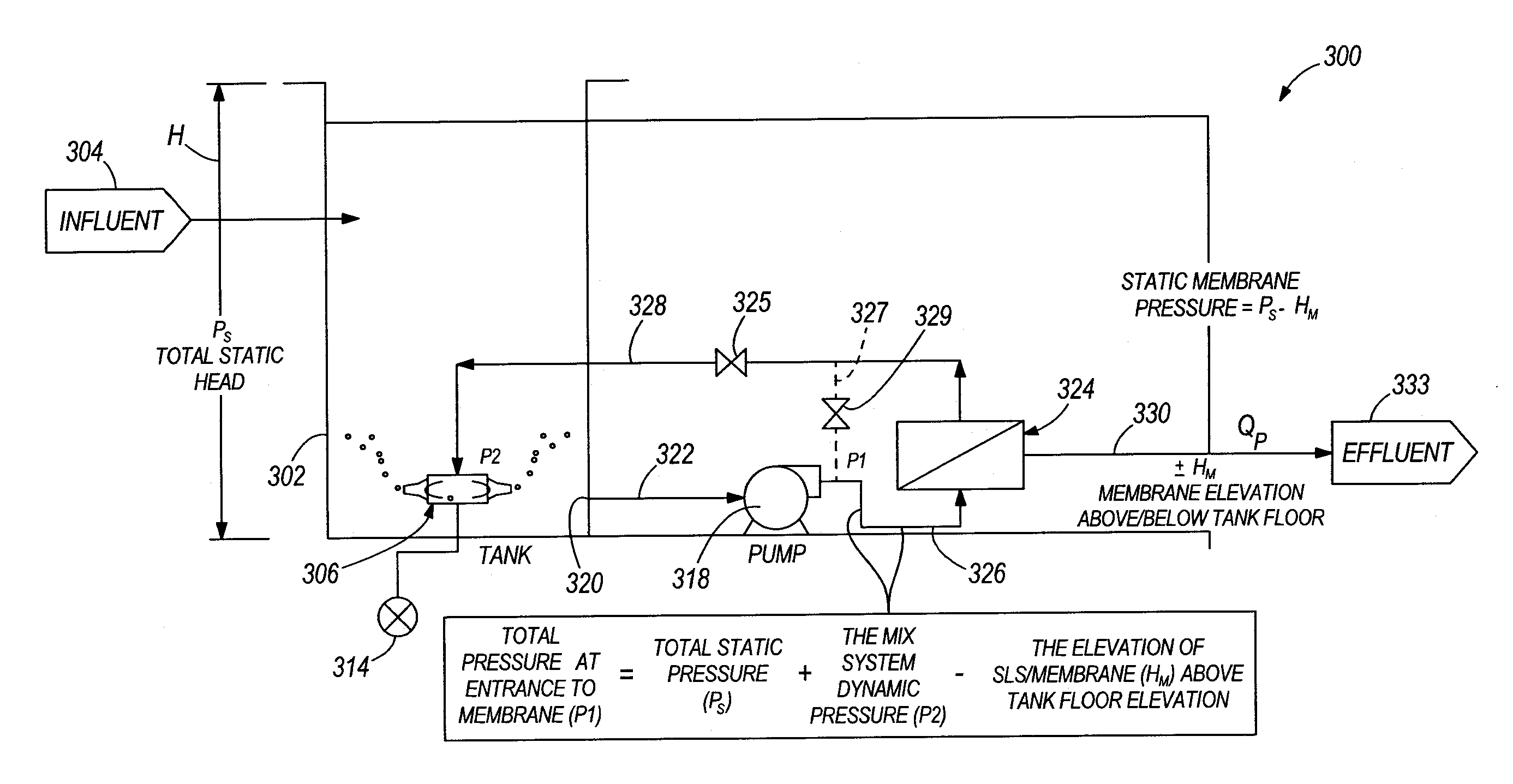

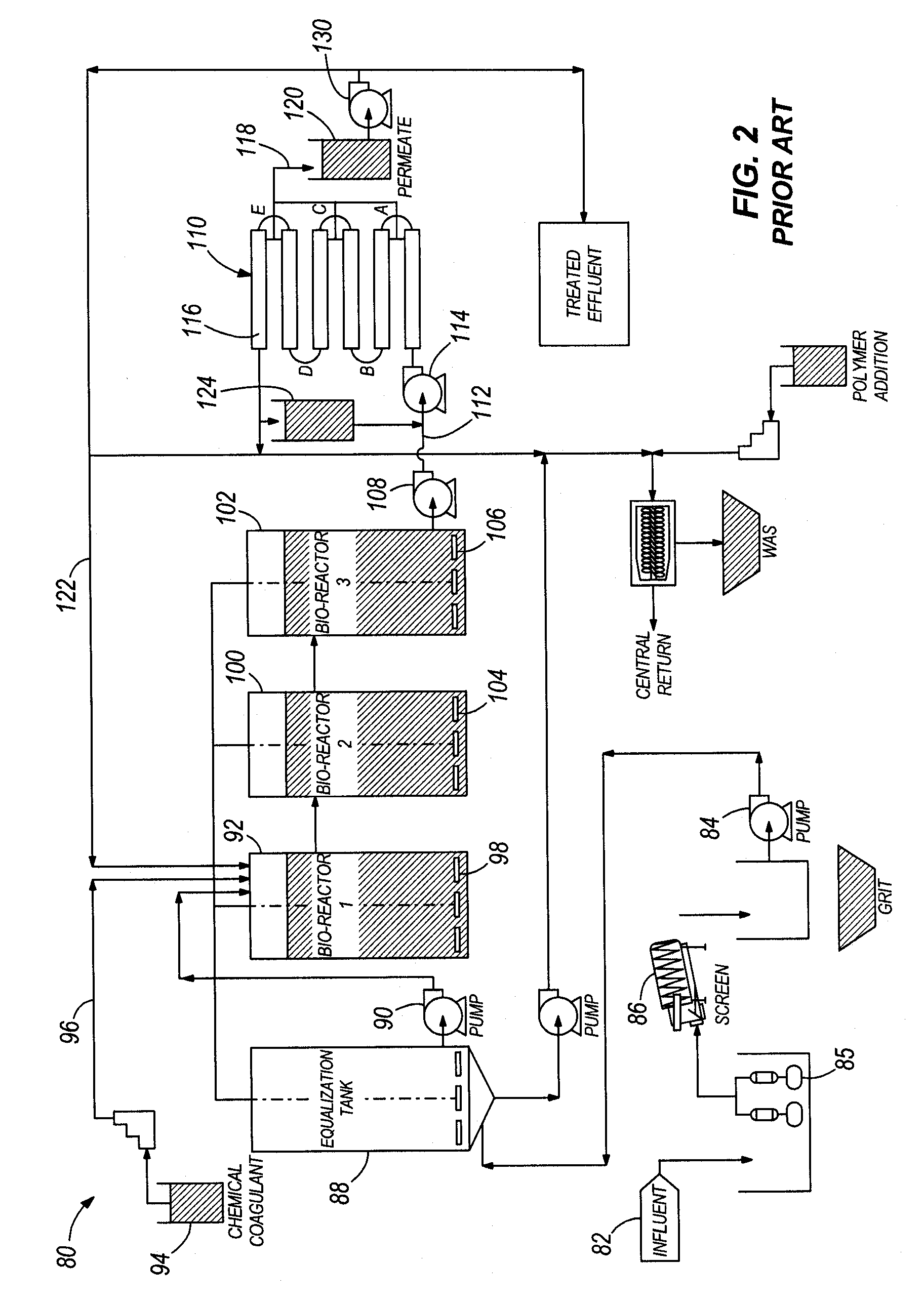

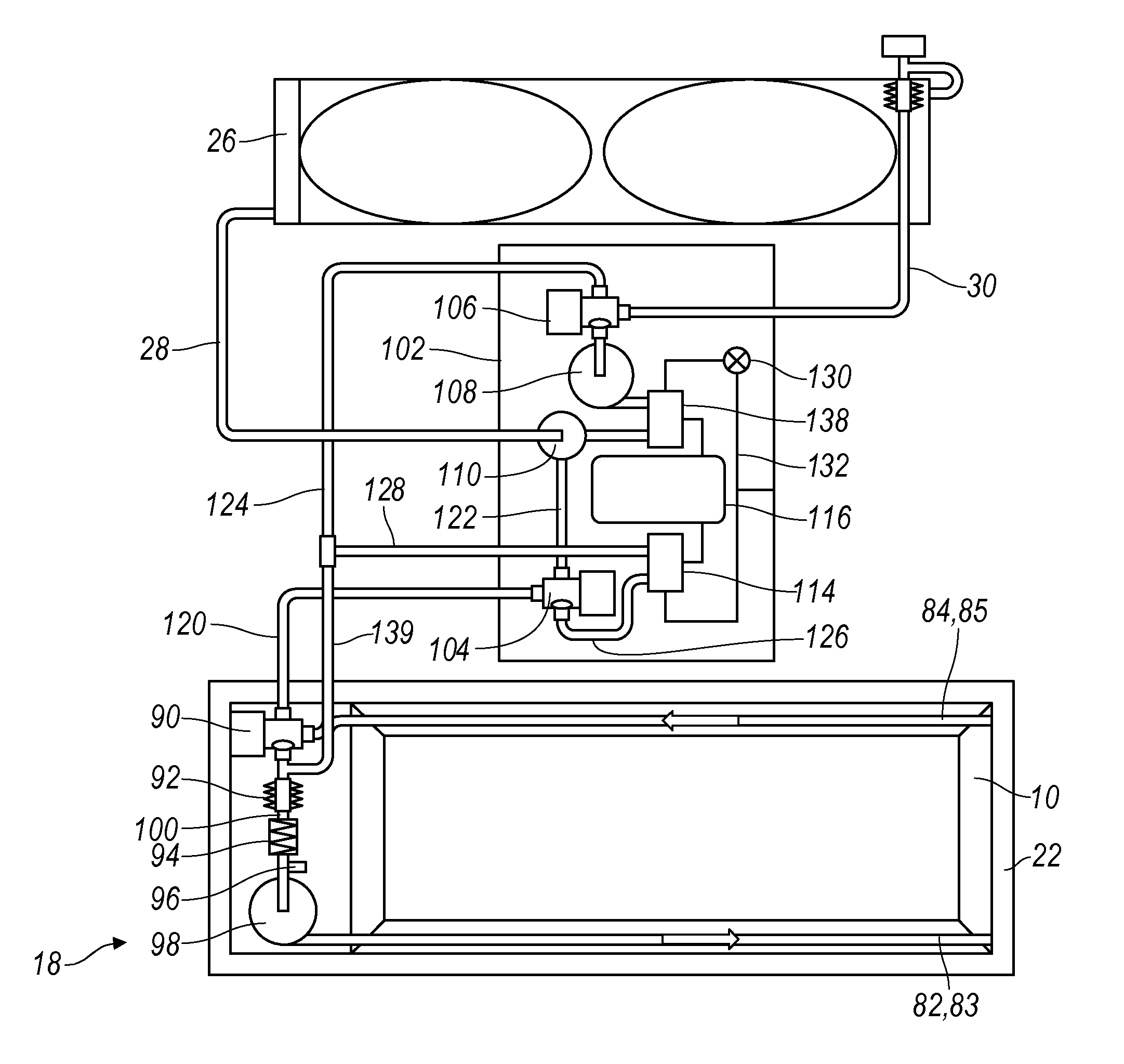

Hydraulically integrated solids/liquid separation system for wastewater treatment

InactiveUS7396453B1Enhance it market appealEliminate redundancyMembranesMixing methodsClosed loopEquipment requirement

A system and method for treating wastewater includes a treatment container for receiving and treating wastewater and a mixing / aeration system disposed in the treatment container. Wastewater is pumped under pressure from the treatment container through a solids / liquid separation system, preferably comprising multiple parallel membrane bioreactors, to separate the solids and liquids in the wastewater. Liquid retentate from the solids / liquid separation system is cycled back to the treatment container via the mixing / aeration system. The closed-loop system and method for solids / liquid separation and aeration / mixing provides for reduced equipment requirements and energy usage during operation.

Owner:PROCORP ENTERPRISES

Solid product dissolver and method of use thereof

InactiveUS20050244315A1Easy to transportEasy to assembleWater treatment parameter controlDissolving using flow mixingIndustrial waterWater treatment

The present invention provides a device for producing a water treatment solution from a solid chemical block for distribution into a water system selected from the group comprising an institutional water system and an industrial water system. The device includes a housing to contain the solid chemical block. A fluid, preferably water at ambient temperature, is introduced into the housing to dissolve the block and form a liquid solution that may then be dispensed into either an institutional water system or an industrial water system. A method of dispensing the liquid solution with the device is also provided.

Owner:ECOLAB USA INC

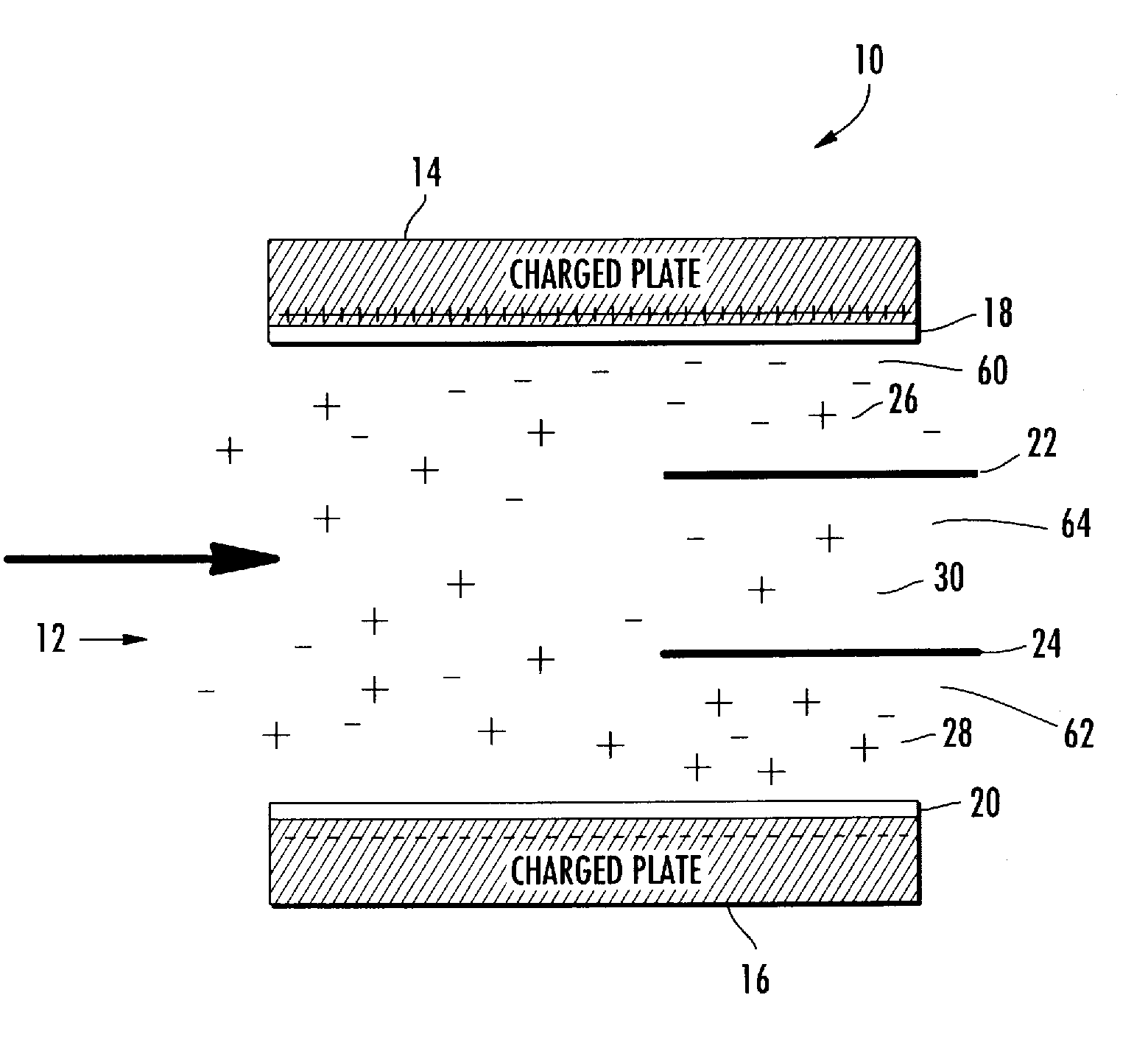

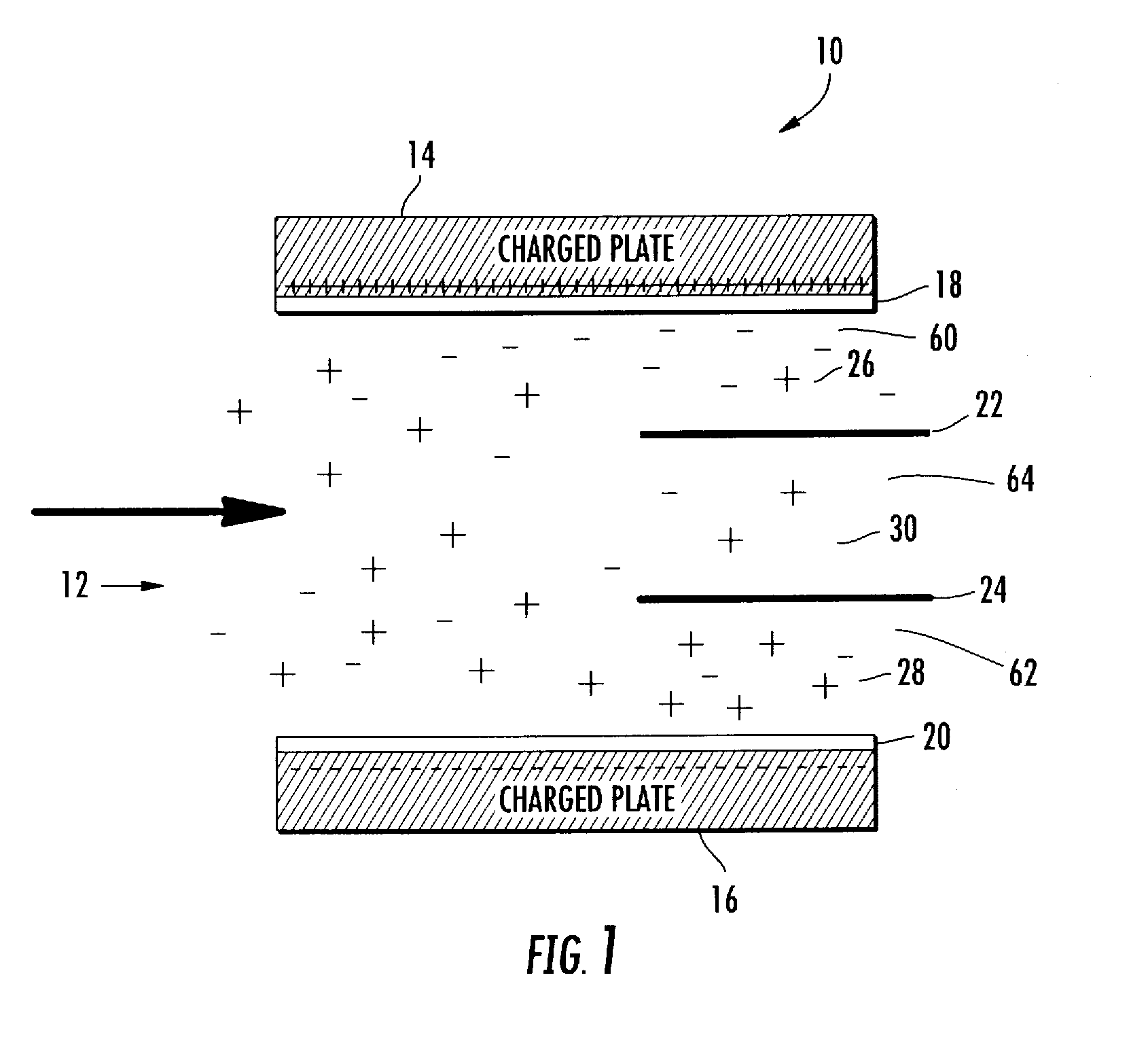

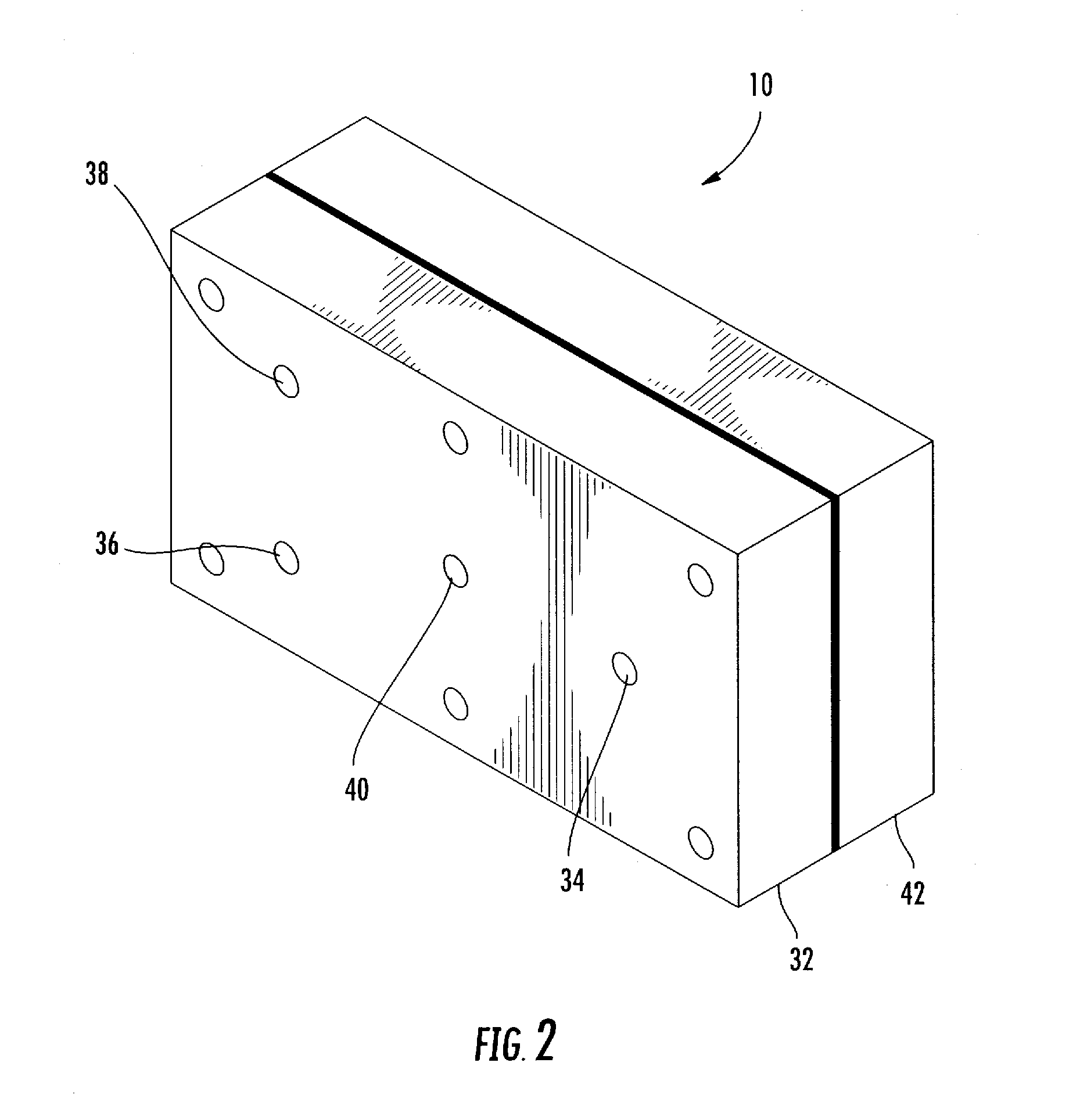

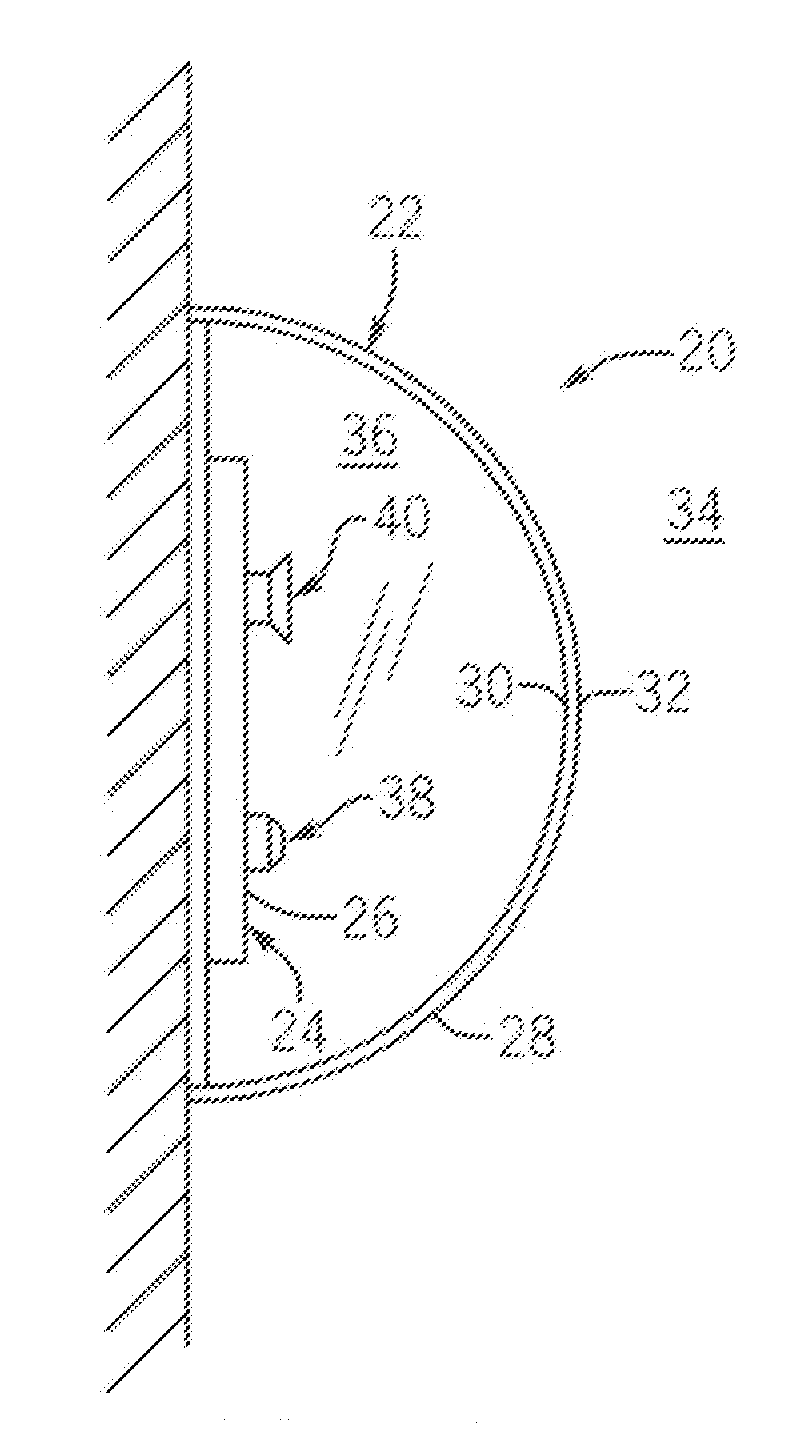

Microscale capacitive deionization apparatus

ActiveUS20080023333A1Little chanceFlexibility in production sizeElectrolysis componentsElectrostatic separatorsCapacitanceCapacitive deionization

The present device is a microchannel separator that uses a separation driving force created by an electric field. An ionic fluid flows through the microchannels and is subjected to an electric field by two spaced apart parallel electrodes possessing an electric charge. The ions in the ionic fluid are attracted towards the charged electrodes and thus are concentrated in the region of flow near the charged electrodes and depleted from the central region of flow between the charged electrodes. The charged electrodes are insulated from the ionic fluid by an impermeable barrier which prevents arcing and adherence of the ions to the charged electrodes. After a sufficient length of passage of the ionic fluid through a main channel two blocking plates separate the flow into a central and two outer output channels. The central channel draws a portion of the ionic fluid from the central region of the main channel that has fewer ions than the ionic fluid in the regions near the charged electrodes. The concentrated ionic fluid in the outer channels is discharged separately from the central channel.

Owner:VECENERGY AEGIR

Hydraulically integrated solids/liquid separation system and method for wastewater treatment

InactiveUS20090014387A1Eliminate redundancyLess energySemi-permeable membranesMembranesAeration systemClosed loop

Owner:PROCORP ENTERPRISES

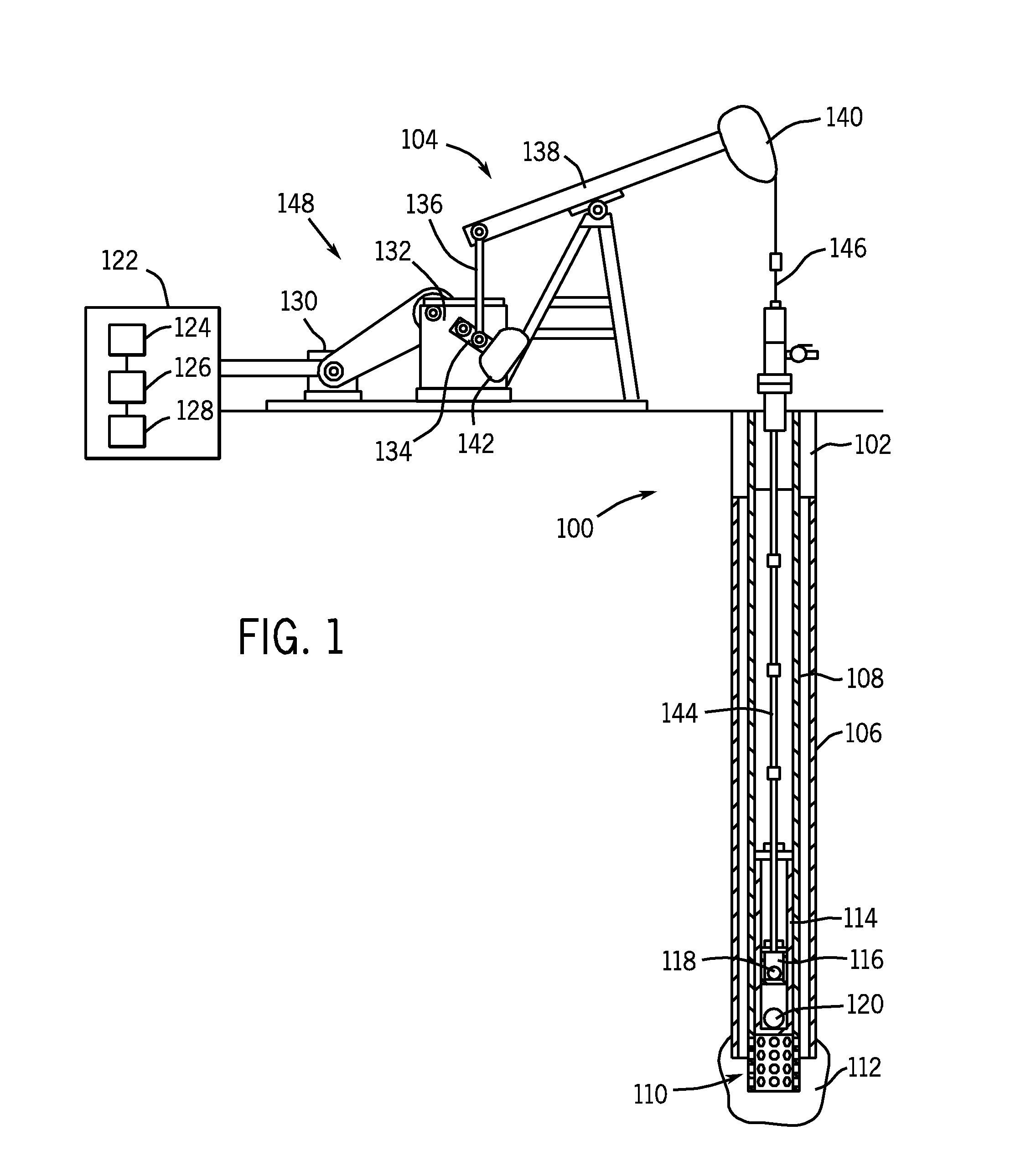

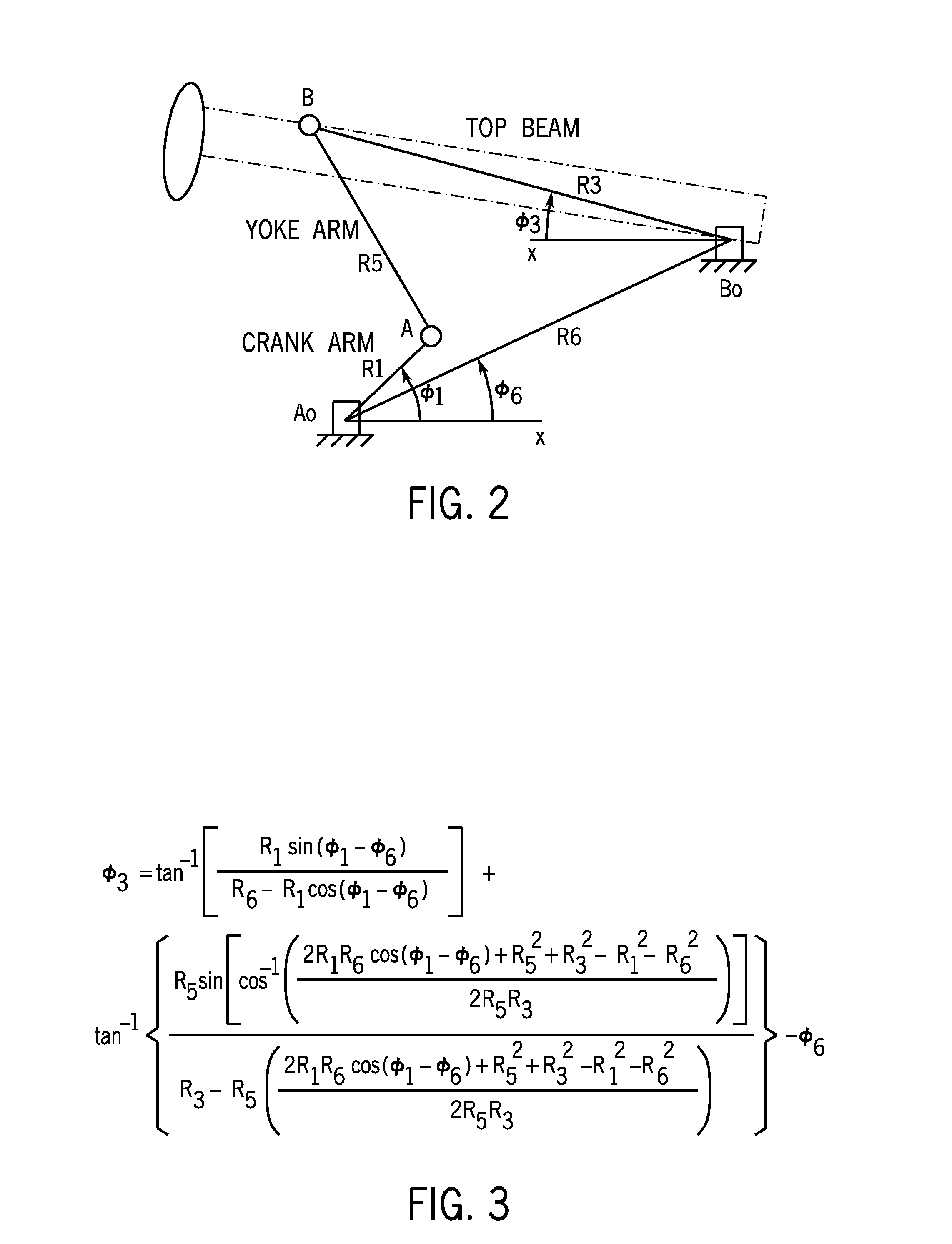

Apparatus and Method of Referencing a Sucker Rod Pump

ActiveUS20140129037A1Control performanceDurable and long lastingConstructionsFlexible member pumpsEngineeringArm position

There is provided a method and system to determine the position of a sucker rod pumping system without a position sensing device during production pumping. A pump control system of the sucker rod pumping system includes a controller coupled to a database, with the controller configured to access an rxless torque value in the database. With the stored rxless torque value representative of toggle points of the crank arm during an initial calibration pumping cycle, the controller further is configured to continuously sample the rxless torque value of the system and determine the crank arm position in relation to the sample rxless torque value. The controller adjusts the pumping system for optimal operations, without a crank arm position sensor during production pumping by identifying a toggle point and setting the crank arm position estimate equal to the value corresponding to the crank position at the identified toggle point.

Owner:UNICO LLC

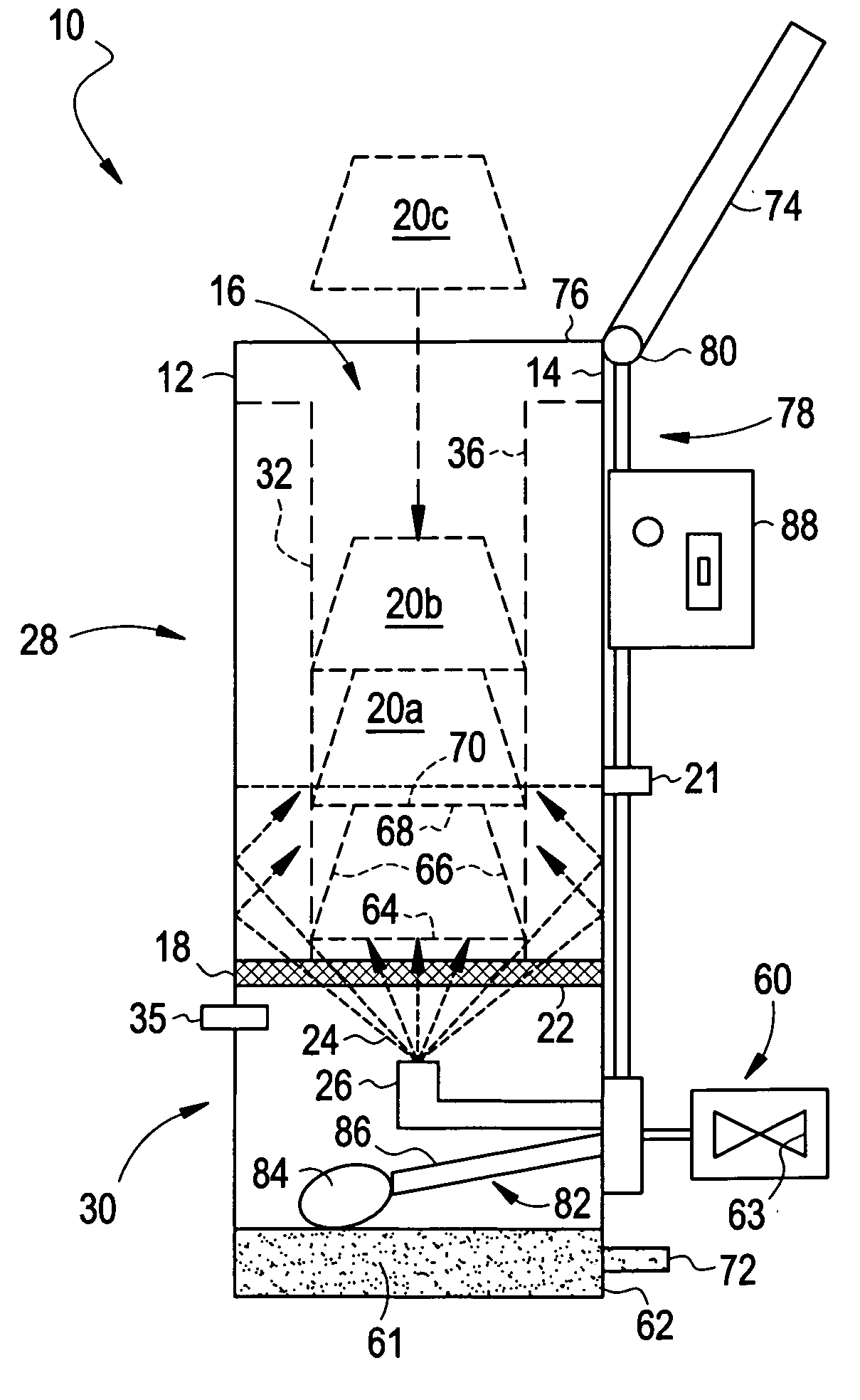

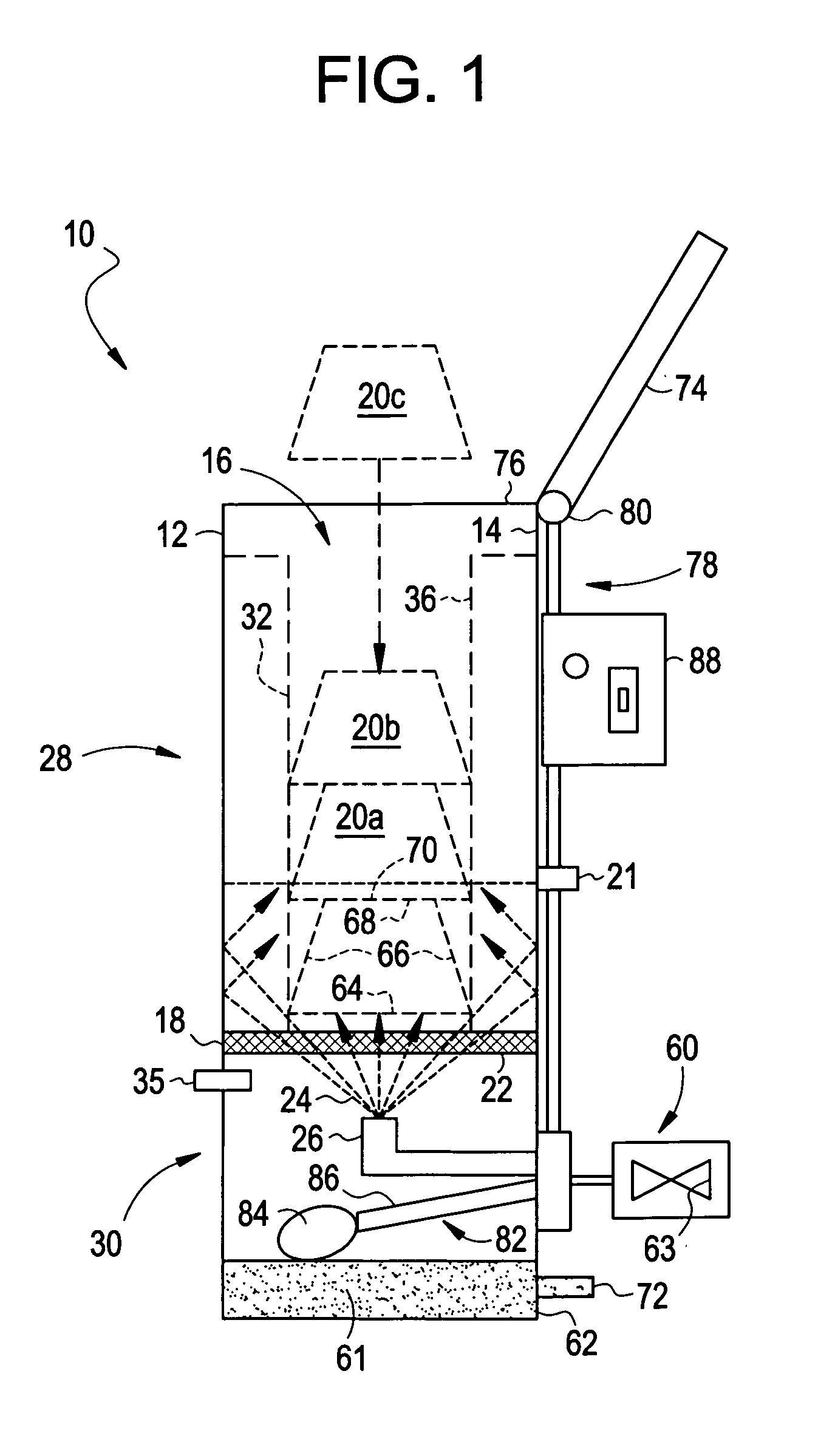

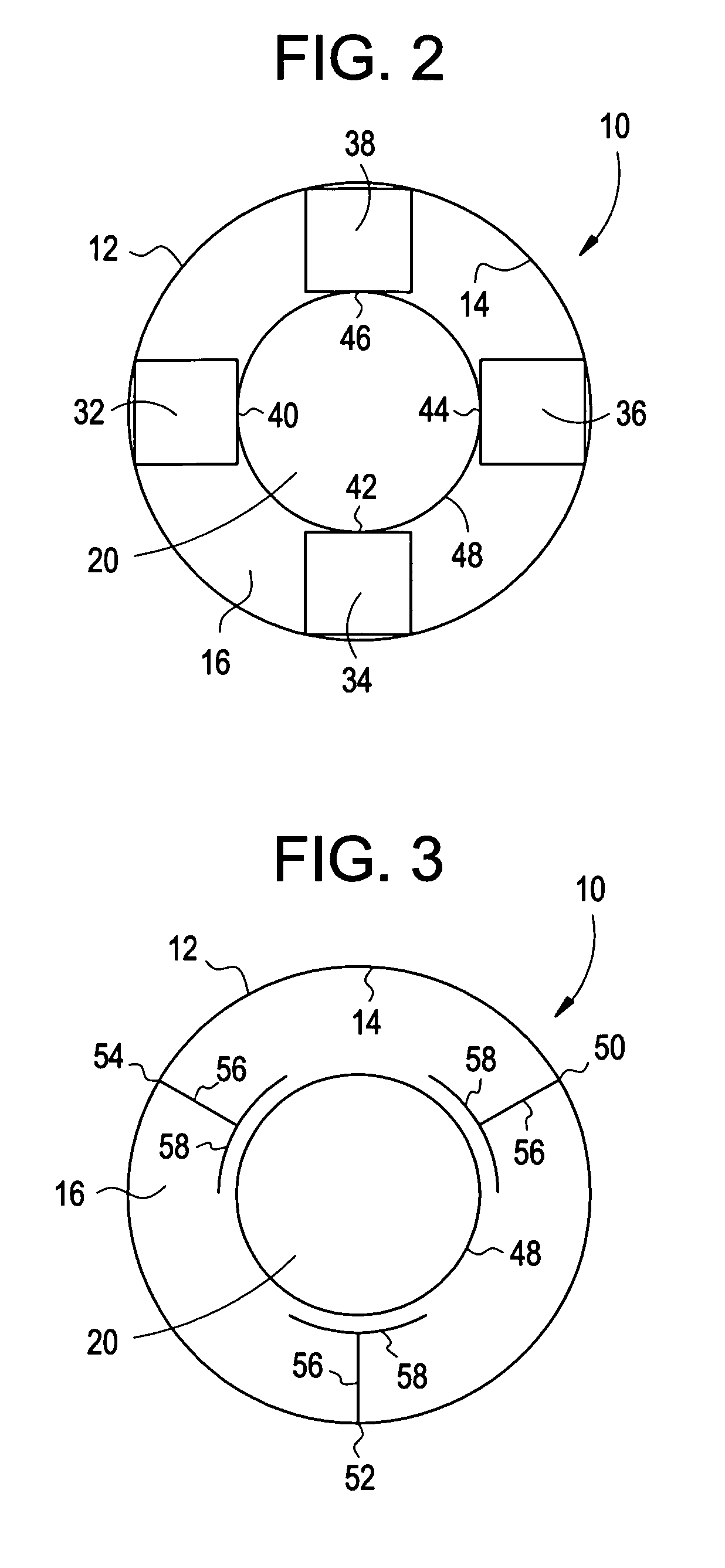

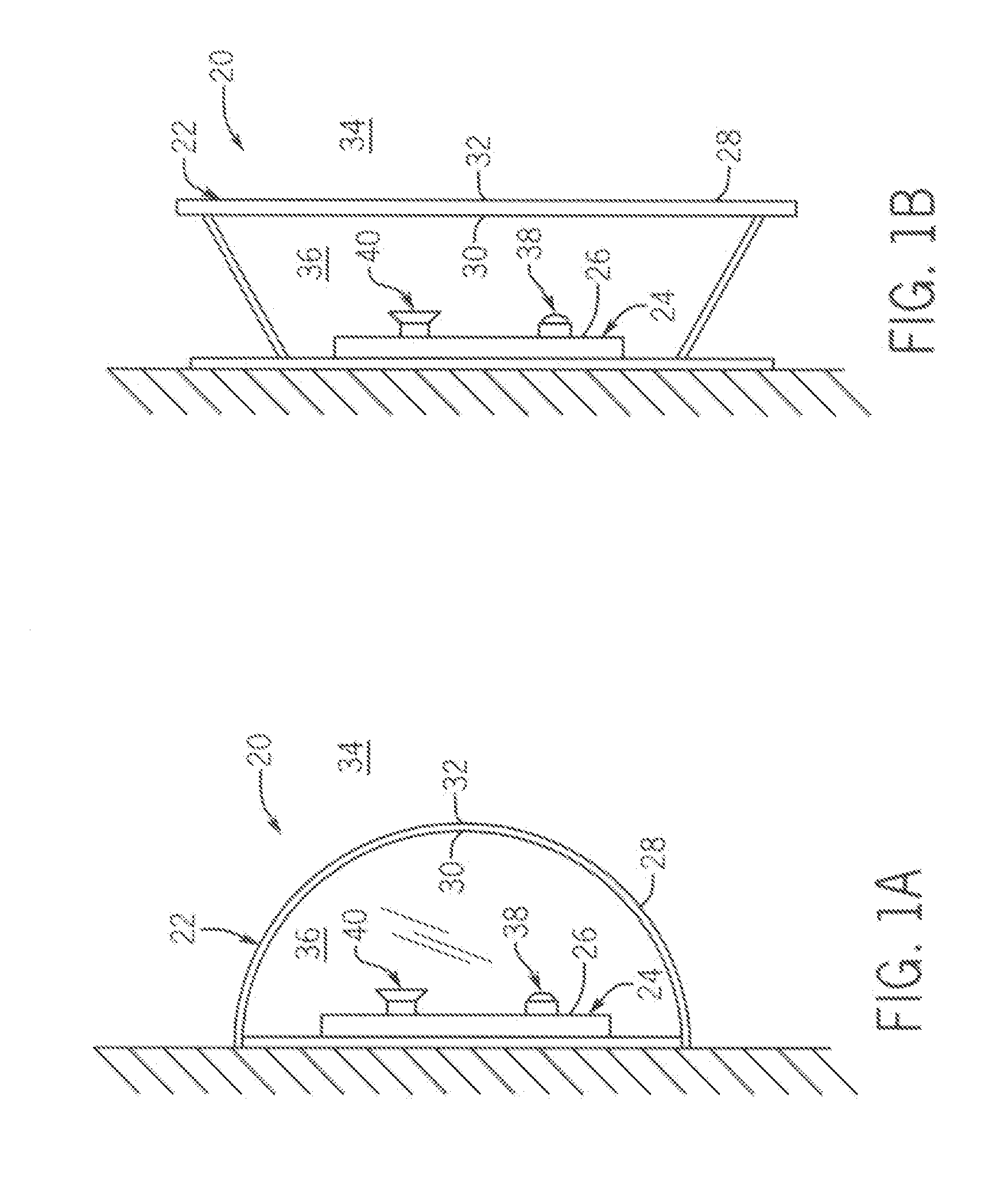

Luminous Flux Depreciation Notification System for Light Fixtures Incorporating Light Emitting Diode Sources

InactiveUS20110299068A1Broad possible marketDurable and long lastingPhotometry using reference valueElectrical apparatusInterior spaceMonitoring system

A LED light fixture and a luminous flux monitoring system for a light fixture. The light fixture includes a housing defining an interior space including an interior surface and a transmissive panel. A light source is coupled to the interior surface. The system includes a light sensor coupled to the interior surface and aligned to receive light from the transmissive panel, light source, and / or interior surface. The light sensor is configured to measure luminous flux in the interior space. A controller is coupled to the light source and the light sensor. The controller is configured to determine if a light sensor measurement of luminous flux in the interior space is more or less than a reference value of the luminous flux. If the measurement of luminous flux is less than the reference value, the controller is configured to activate an end-of-life indicator. The reference value equals (total flux−internal ambient flux)×depreciation factor.

Owner:OLDENBURG GROUP

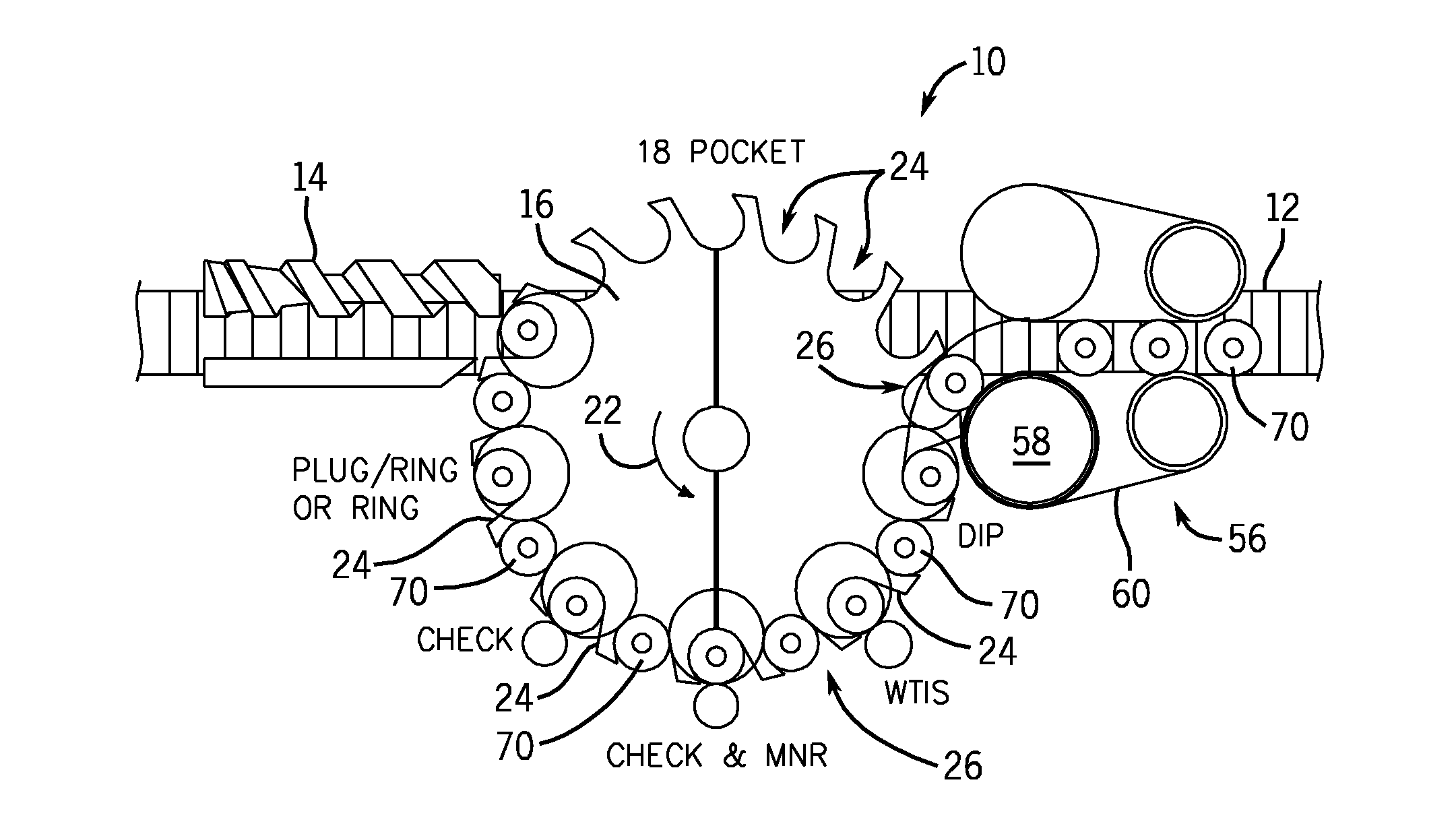

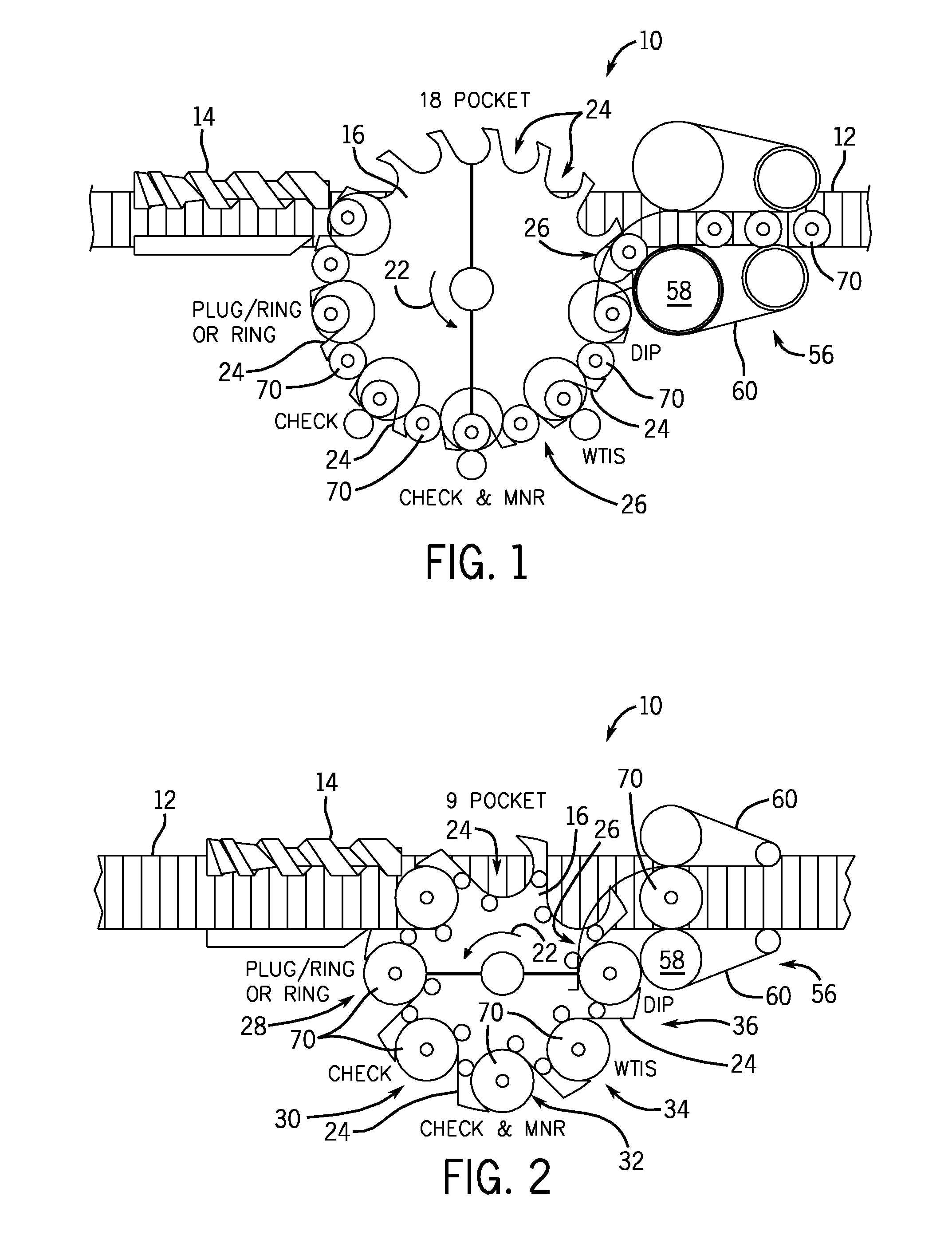

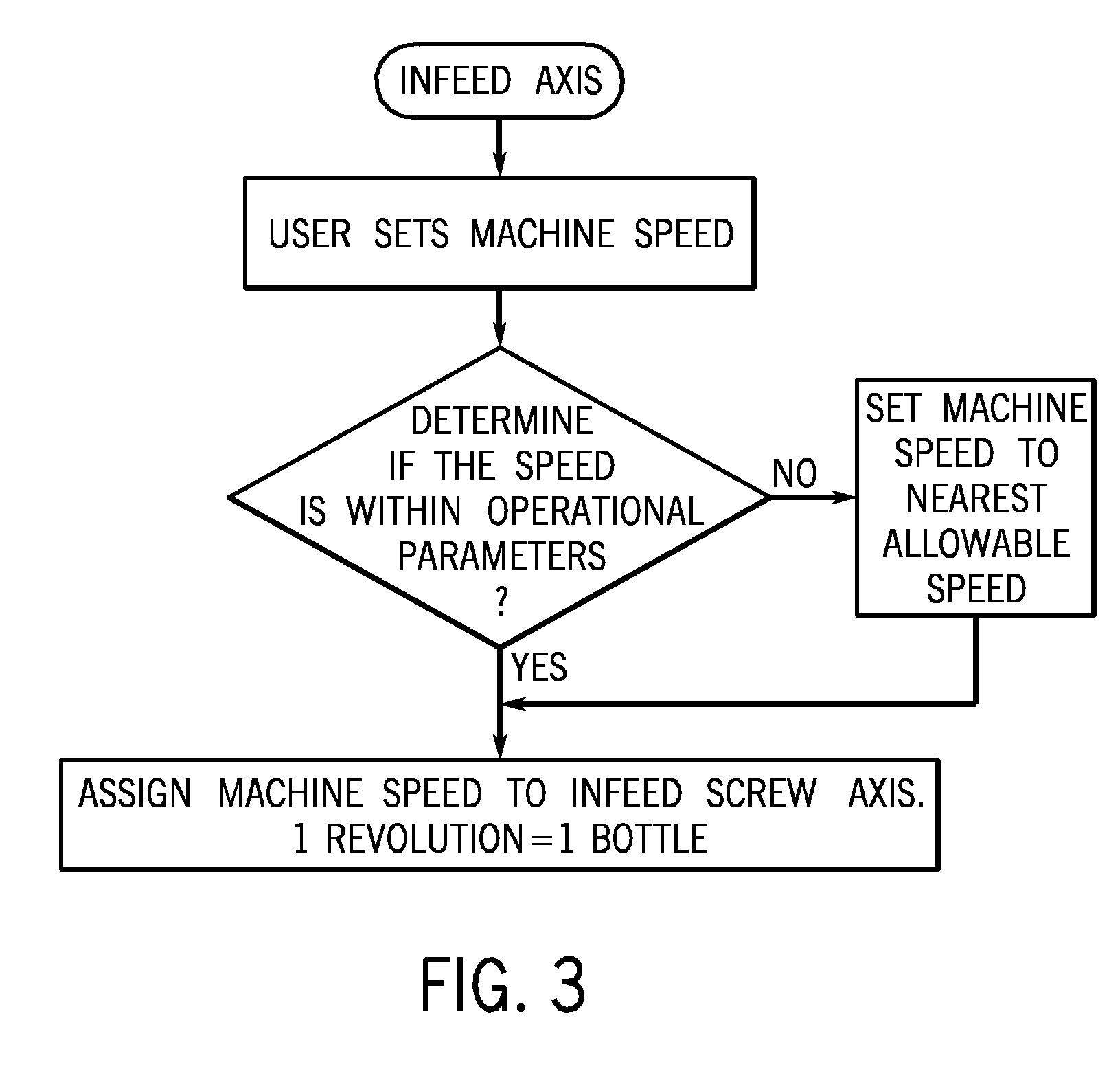

Star Wheel Conveyor Outfeed Mechanism and Method

InactiveUS20120175224A1Broad possible marketDurable and long lastingPackagingConveyor partsEngineeringMechanical engineering

Owner:EMHART GLASS SA

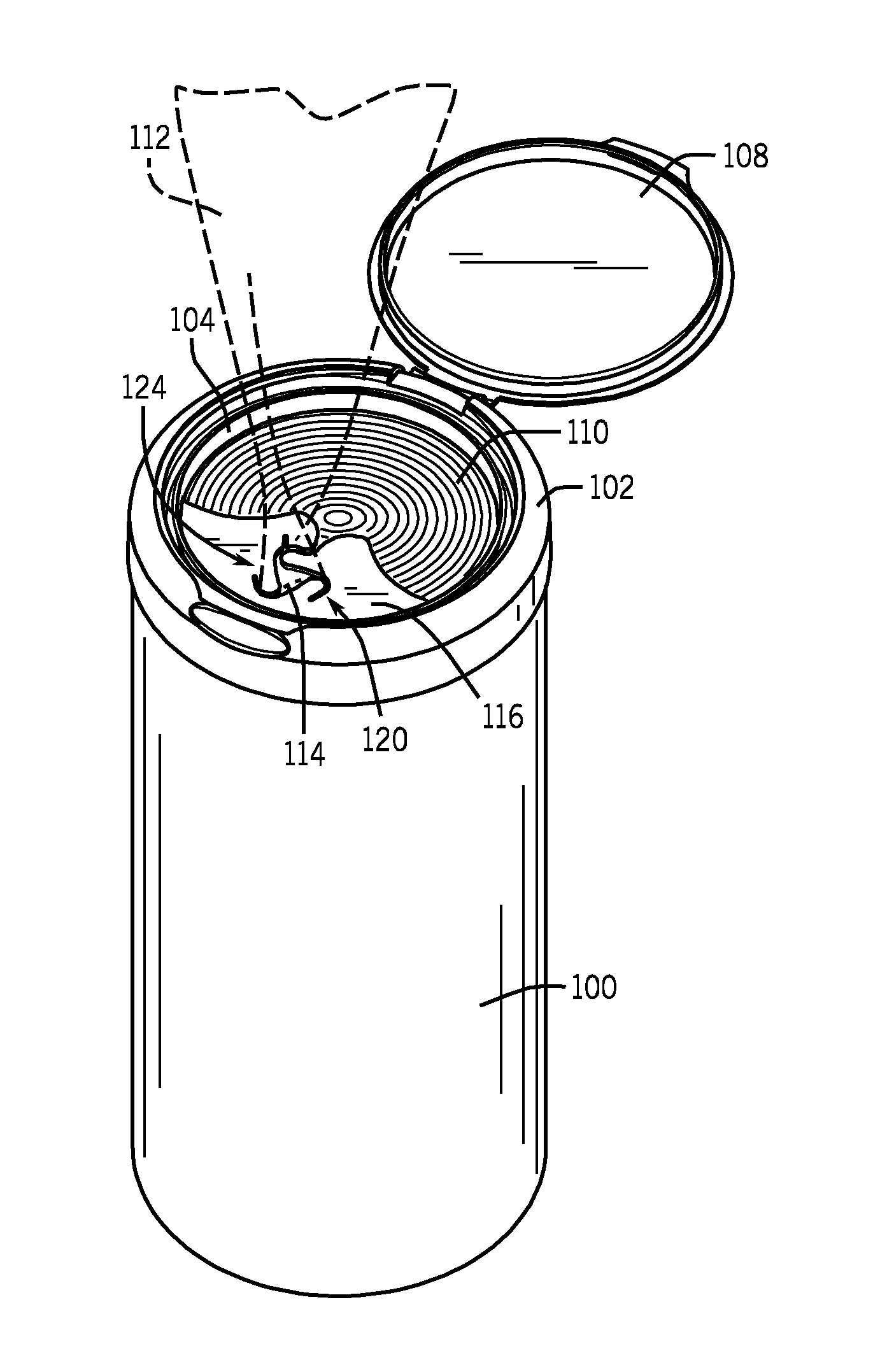

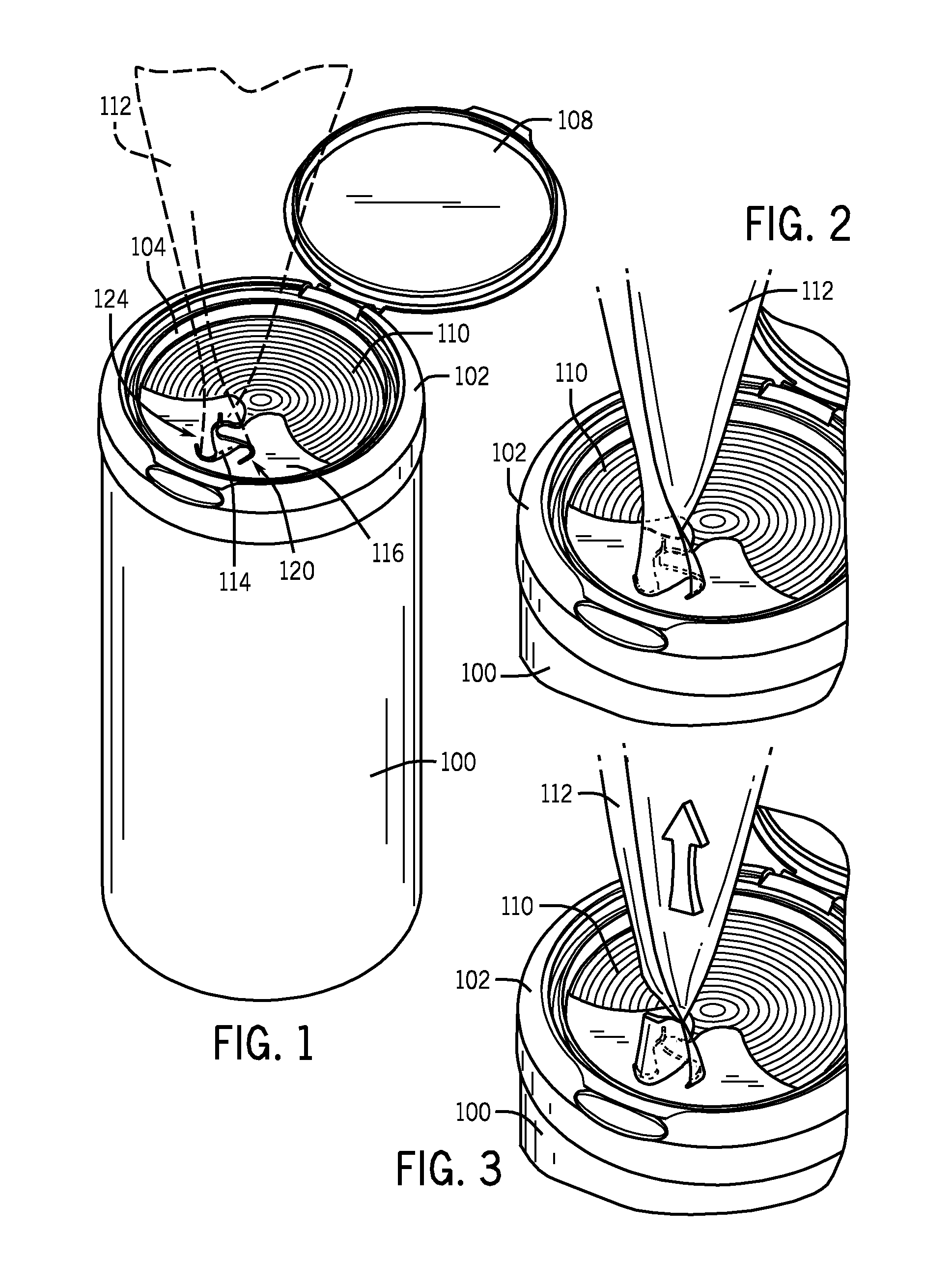

Dispensing aperture for wipes

InactiveUS20140291343A1Sufficient pliabilityDurable and long lastingDispensing apparatusDomestic applicationsPliabilityTowelettes

There is provided a method of use and a canister closure member configured to selectively enclose a canister containing a continuous web of we towelettes defining individual wet towelettes by a plurality of perforations so that the web of towelettes can be separated into individual sheets. The canister closure member includes a dispensing structure and a single wipe dispenser structure defined in the dispensing structure. The single wipe dispenser includes three fingers defined in the dispensing structure. The fingers define a dispensing orifice with the three fingers configured to prevent more than one individual sheet of towellete to exit the canister. Each finger has a characteristic of flexibility, of sufficient pliability, to allow the towelettes to move through the dispensing orifice and a characteristic of strength sufficient to restrain the towelettes until a single towelette separates from the continuous web at the perforations.

Owner:ROCKLINE INDUSTRIES INC

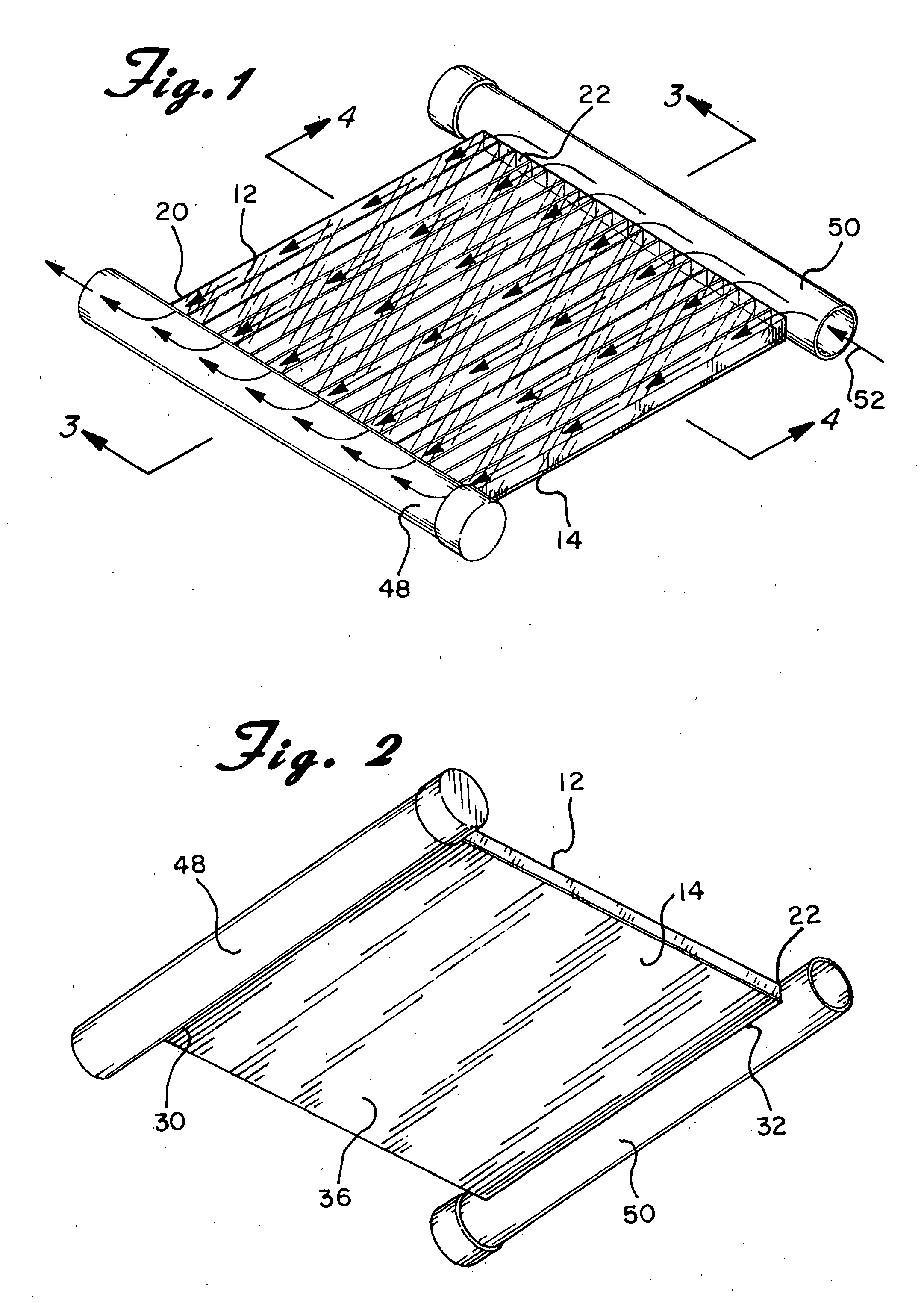

Solar panel

InactiveUS20090095282A1Produced inexpensively and efficientlyEasy to mass produceSolar heating energySolar heat devicesEngineeringGuide tube

A solar panel that utilizes the sun's rays to heat a liquid to be used for providing heat or hot water includes front and rear parallel but spaced apart clear plastic panels. Each panel has a front surface, a back surface and left and right side edges. The front panel is intended to face the sun and is substantially transparent so that the sun's rays can pass therethrough. The rear panel has a reflective coating thereon wherein rays from the sun that pass through the front panel and through the space between the panels is reflective back toward the space. Located within the space between the panels are a plurality of conduits formed by a plurality of internal walls that extend between the front and rear panels and between the left and right side edges. Within the conduits is a darkened oily liquid that is heated by the incoming rays of the sun and by the rays reflected by the rear panel. In a preferred embodiment, the front and rear panels and the internal walls are extruded as a single unit.

Owner:HELIOS PRODS

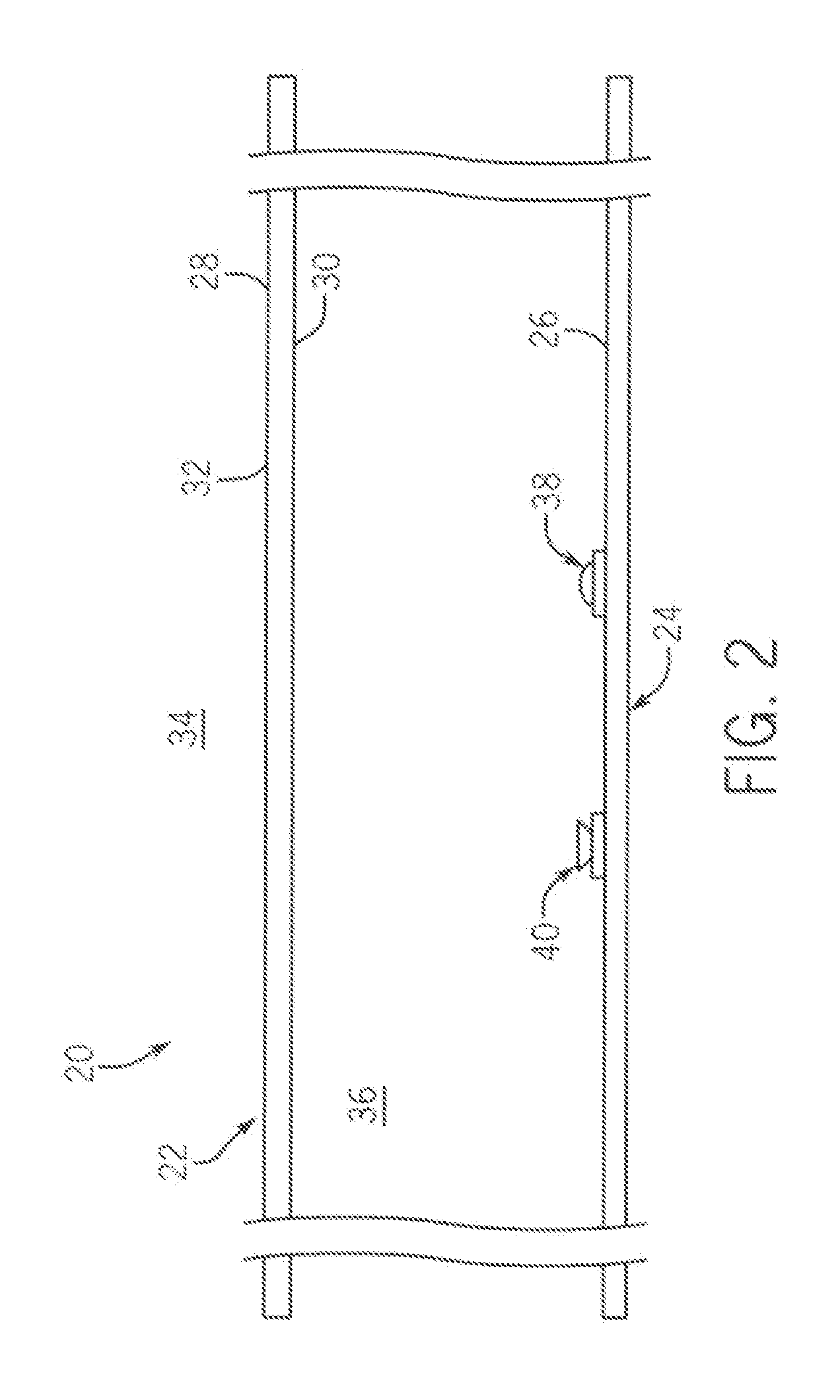

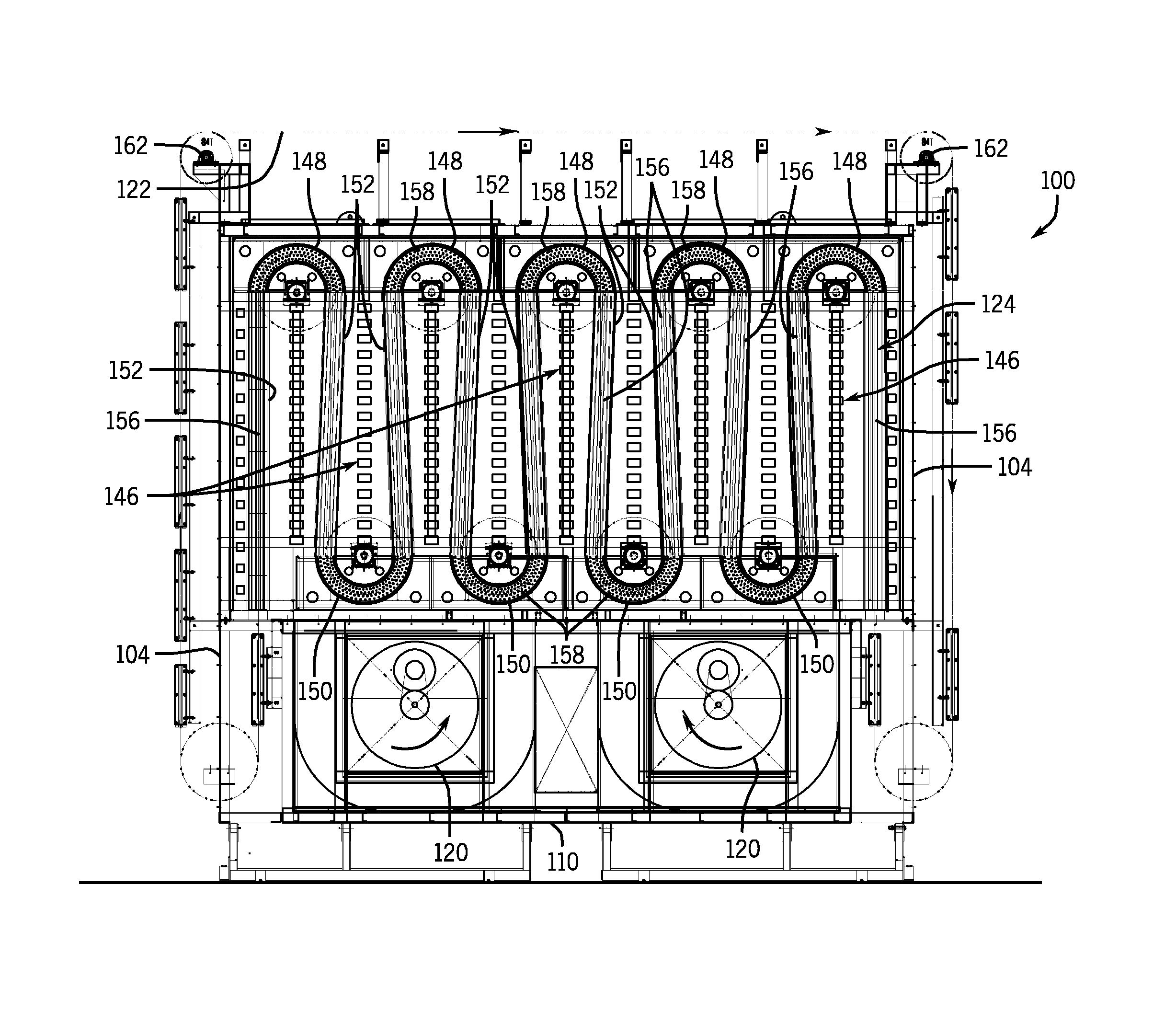

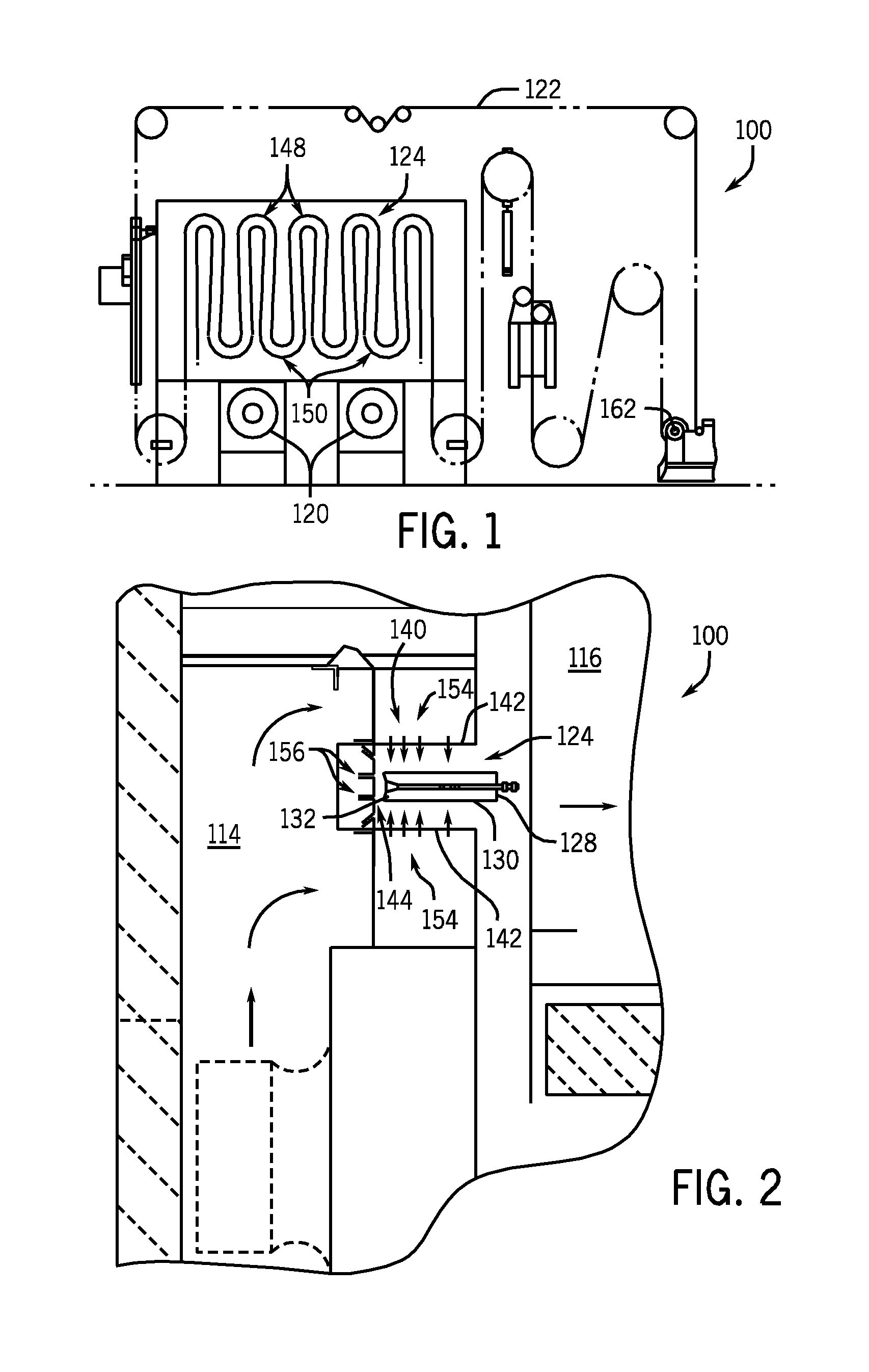

Pin Oven with a Continuous U-Shaped Duct

ActiveUS20140259731A1Increase temperatureEven airflowAgriculture tools and machinesDrying solid materials with heatInterior spaceEngineering

An oven configured for drying a container. The oven includes a housing defining an interior space including a supply chamber and a return chamber. A conveyor is configured for movement within a portion of the interior space of the housing defined by a plurality of semi-circular shaped duct sections connected at each end of the semi-circular shaped duct sections to a straight duct section. Each duct section includes two side walls coupled to a back wall defining a continuous U-shaped duct path through which the conveyor moves. The oven is further configured to provide a temperature difference between any two points within the interior space of the oven housing controlled to plus or minus two degrees Fahrenheit, by a uniform air flow throughout the oven. The uniform air flow is facilitated by the sizing and spacing of various circular orifices and slotted orifices in the continuous duct path.

Owner:INT THERMAL SYST

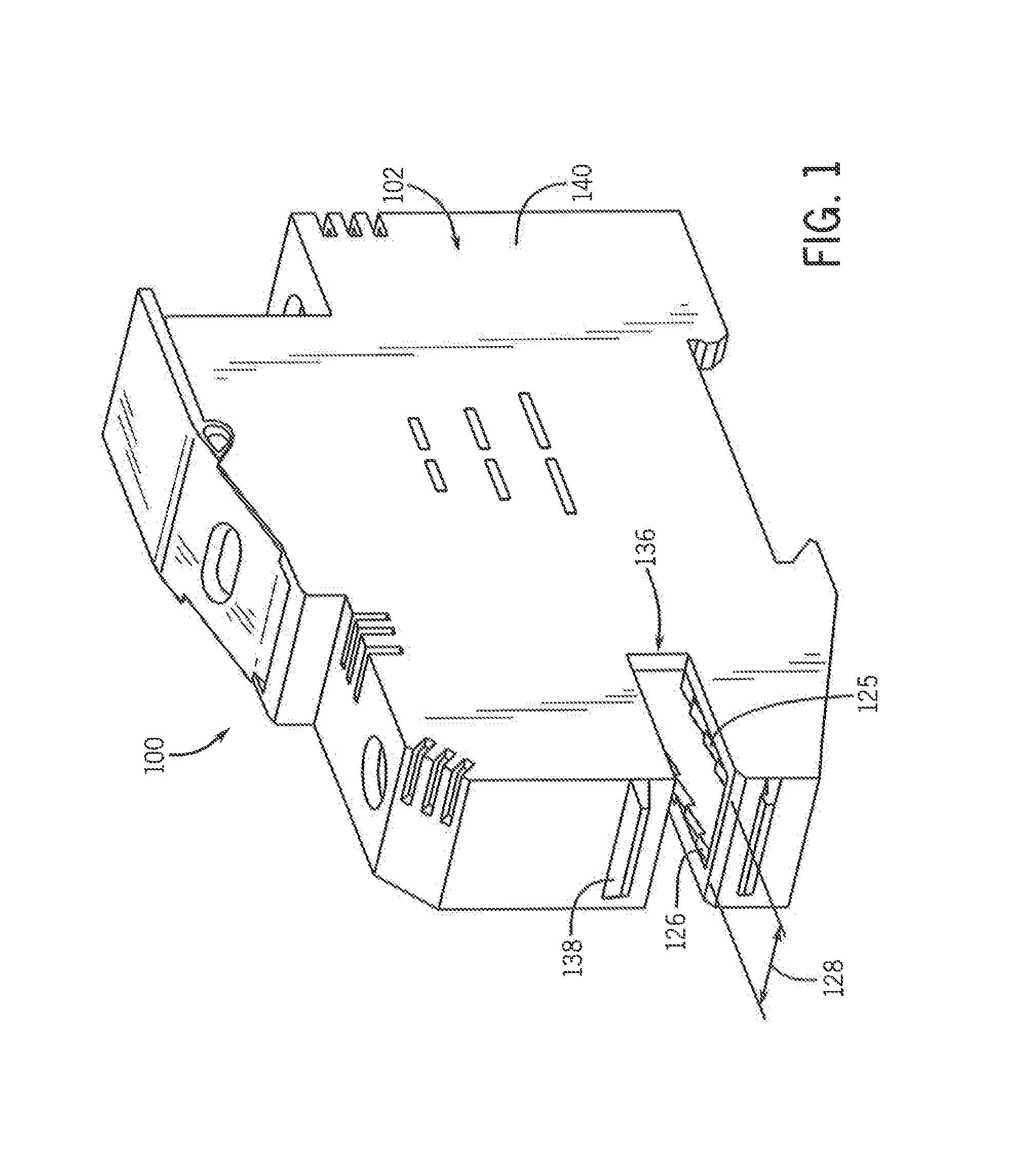

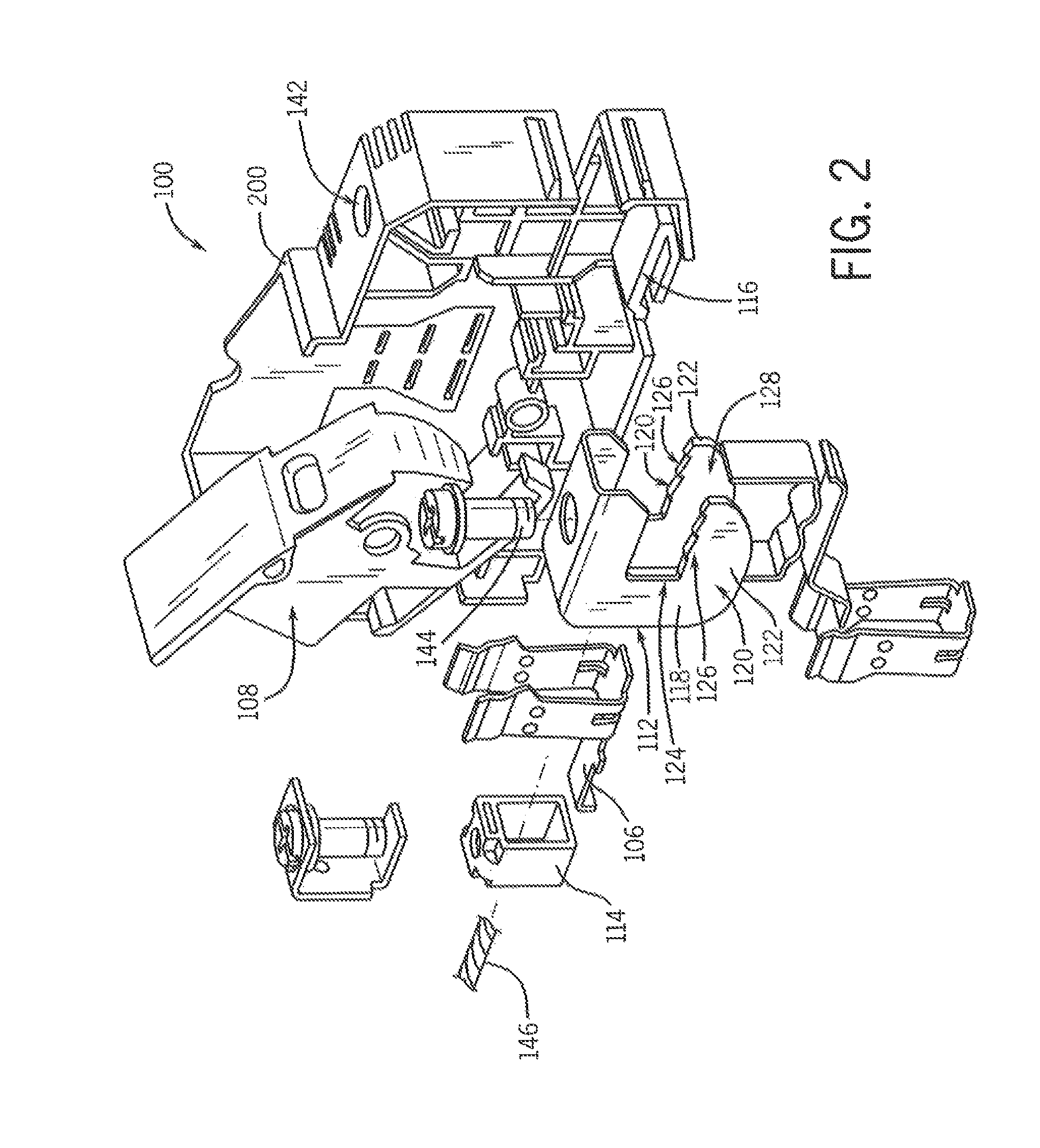

Enclosed bus bar fuse holder

ActiveUS9136083B2Durable and long lastingLittle and maintenanceElectrically conductive connectionsCoupling protective earth/shielding arrangementsElectrical conductorEngineering

There is provided a bus bar fuse holder configured to receive a fuse link and couple each end of the fuse link to a line conductor and a load conductor within the holder. The bus bar holder includes a housing that defines a space in the housing proximate one of a line terminal and load terminal. A clamp unit is configured to receive a portion of a bus bar with the lineup clamp unit disposed in the space defined in the housing. The space configured in the housing also encloses a substantial portion of the bus bar within the housing in a space defined between U-shaped members of the clamp unit.

Owner:REGAL BELOIT AMERICA INC A SUBSIDIARY OF REGAL BELOIT

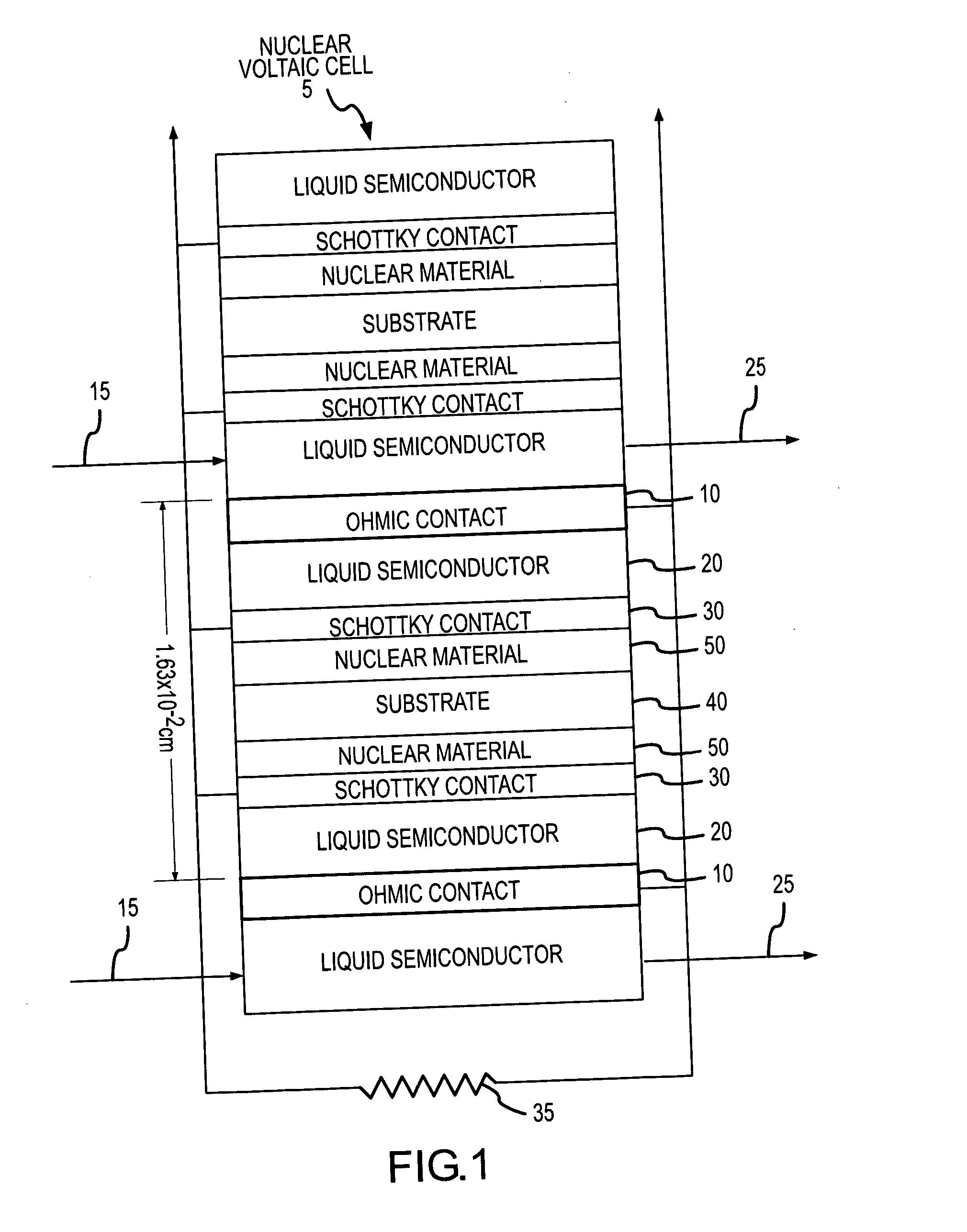

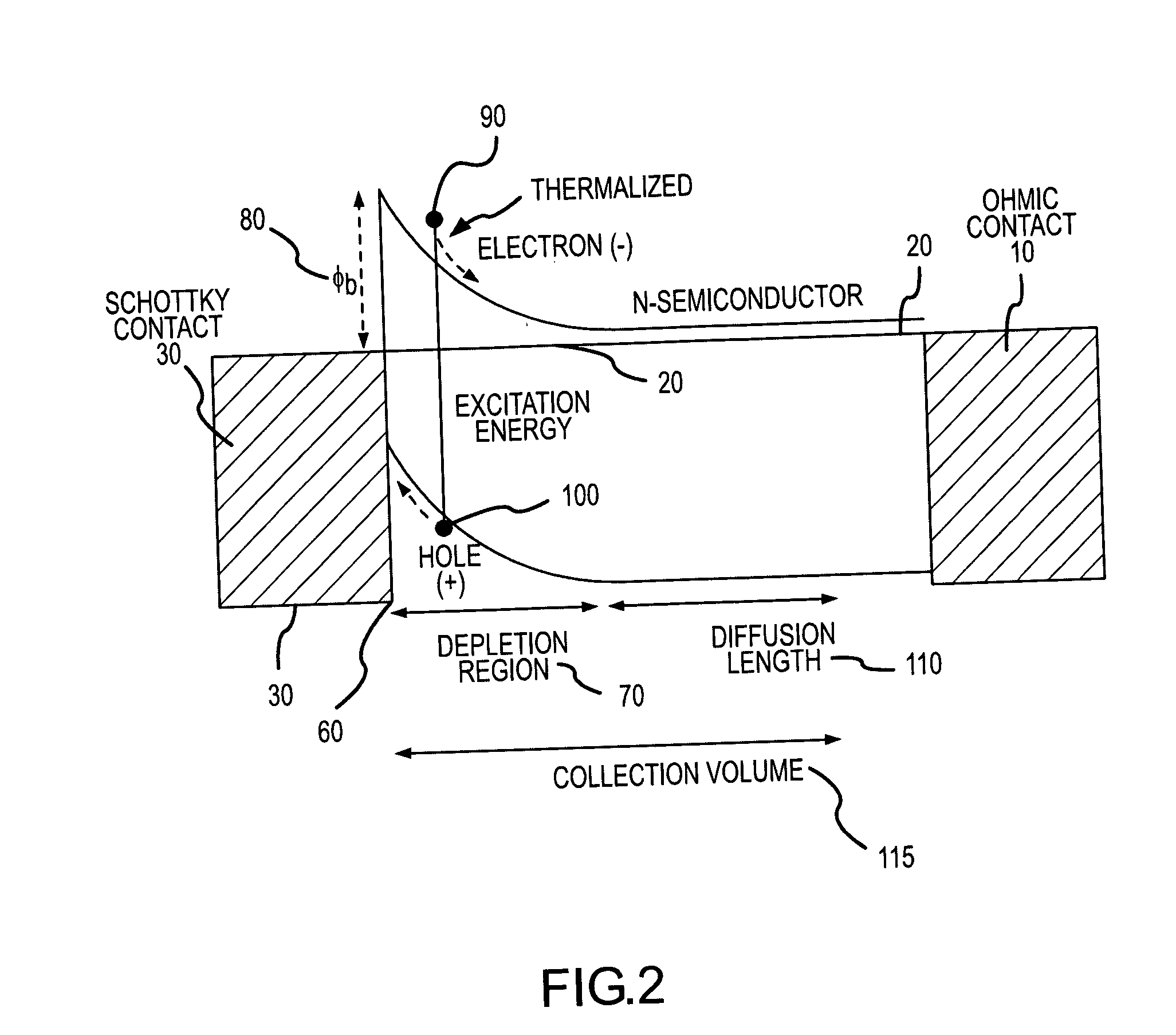

Nuclear voltaic cell

InactiveUS20060251204A1Small sizeGenerating large amountElectrical apparatusReaction to electrical energyElectric forceElectricity

The invention describes a product and a method for generating electrical power directly from nuclear power. More particularly, the invention describes the use of a liquid semiconductor as a means for efficiently converting nuclear energy, either nuclear fission and / or radiation energy, directly into electrical energy. Direct conversion of nuclear energy to electrical energy is achieved by placing nuclear material in close proximity to a liquid semiconductor. Nuclear energy emitted from the nuclear material, in the form of fission fragments or radiation, enters the liquid semiconductor and creates electron-hole pairs. By using an appropriate electrical circuit an electrical load is applied and electrical energy generated as a result of the creation of the electron-hole pairs.

Owner:TSANG FRANCIS YU HEI +5

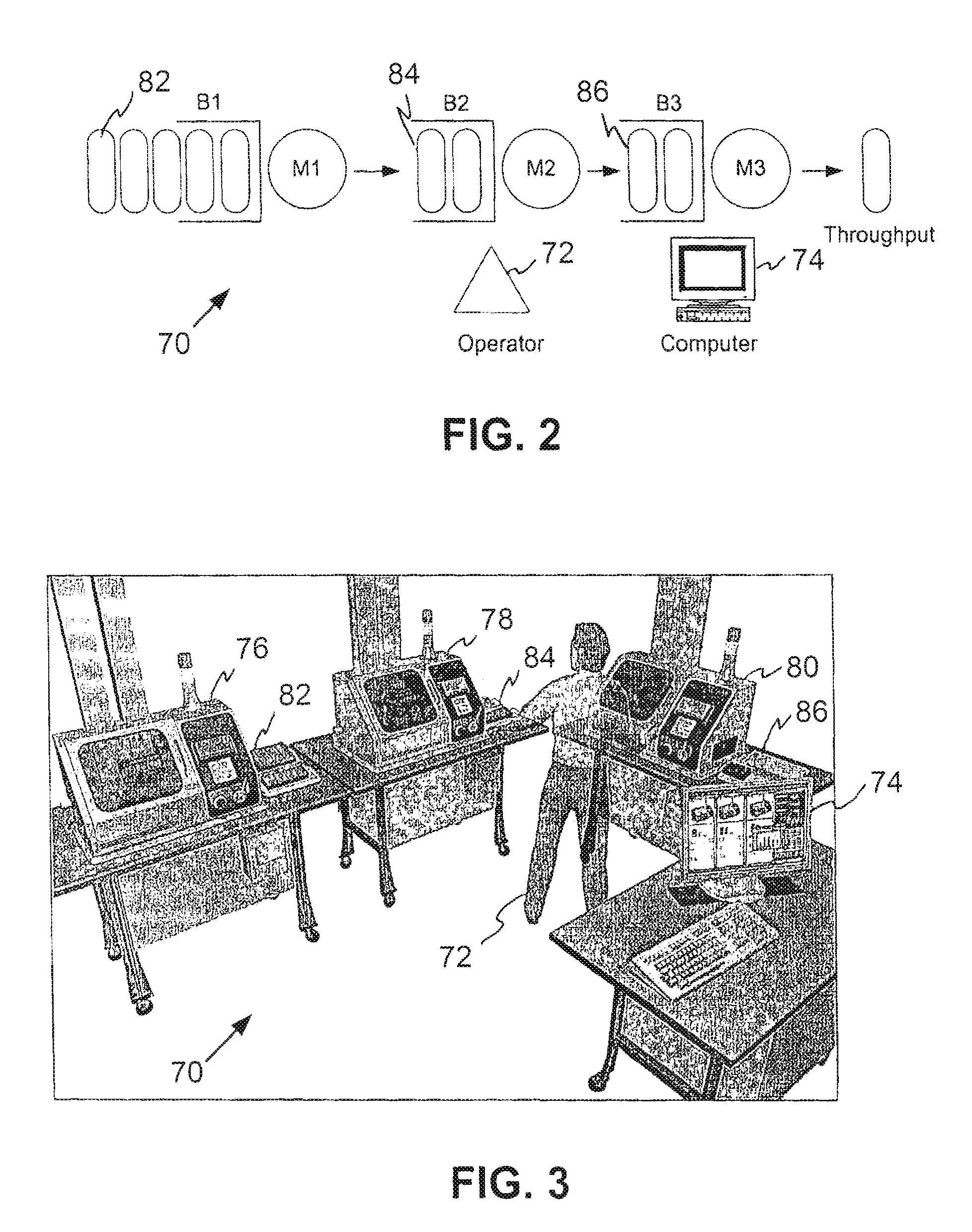

Systems and methods for a real time machine simulator to explore the effects of rules used in a modular manufacturing or assembly system

InactiveUS7949501B1Easy to exploreMaximize throughputProgramme controlTotal factory controlHypothesisModularity

A simulation device for simulating and exploring the effects of different policies used on a machine in a manufacturing system. The simulation device representing the machine includes controls to allow the participation of an operator in simulation modeling. The operator initiates the simulation process by, for example, loading a block into the simulator according to a hypothesis policy. During the simulation, a computer records all the changes in the system and those changes are transmitted to the computer. When the simulation stops, the total number of items completed by the system represents the throughput of the system during the simulation time. The operator can view the results of the simulation and change the policies and repeat the simulation using the same system structure or parameters.

Owner:NORTHWESTERN UNIV

Trash can cleaning lid

A trash can lid has incorporated in it an apparatus for coupling to and receiving water from a hose and conveying the water to a spray-head mechanism, wherein the water is pressurized and from whence the pressurized water is directed against the angled blades of rotary water-deflector, such that a rotary spray of pressurized water is directed against the interior walls of the trash can, thereby flushing wastes from the walls to the bottom of the trash can.

Owner:VETTER DOUGLAS J +1

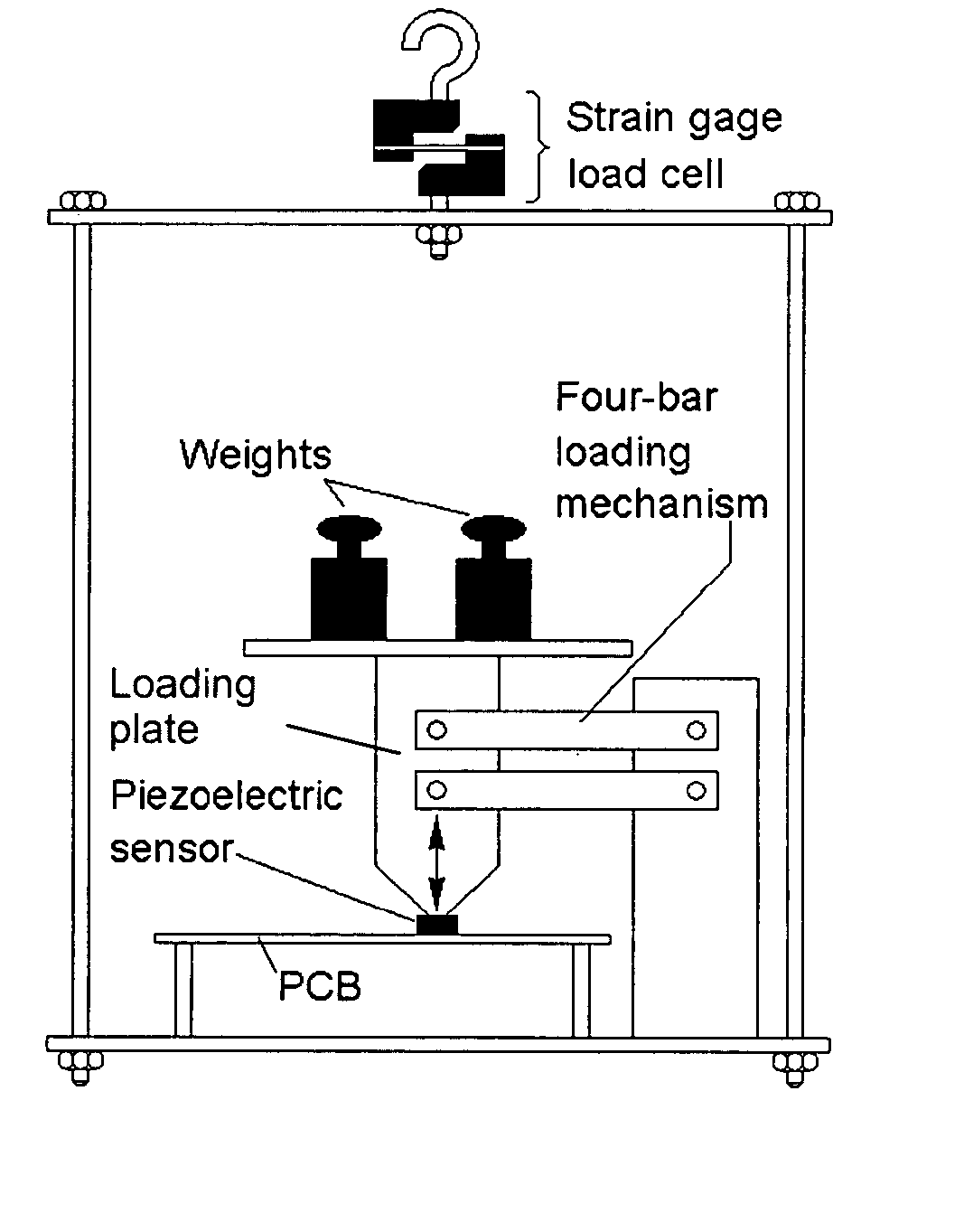

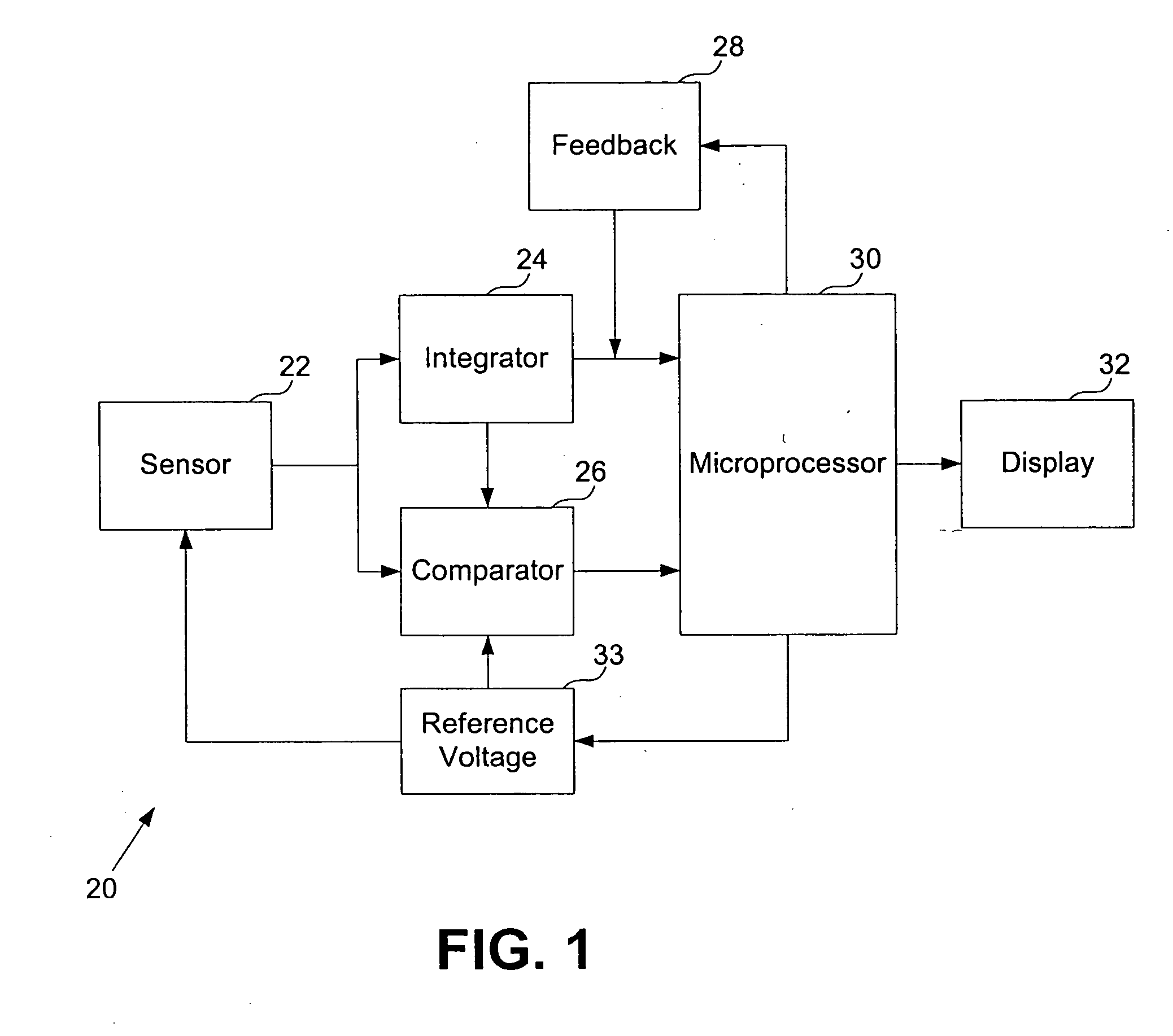

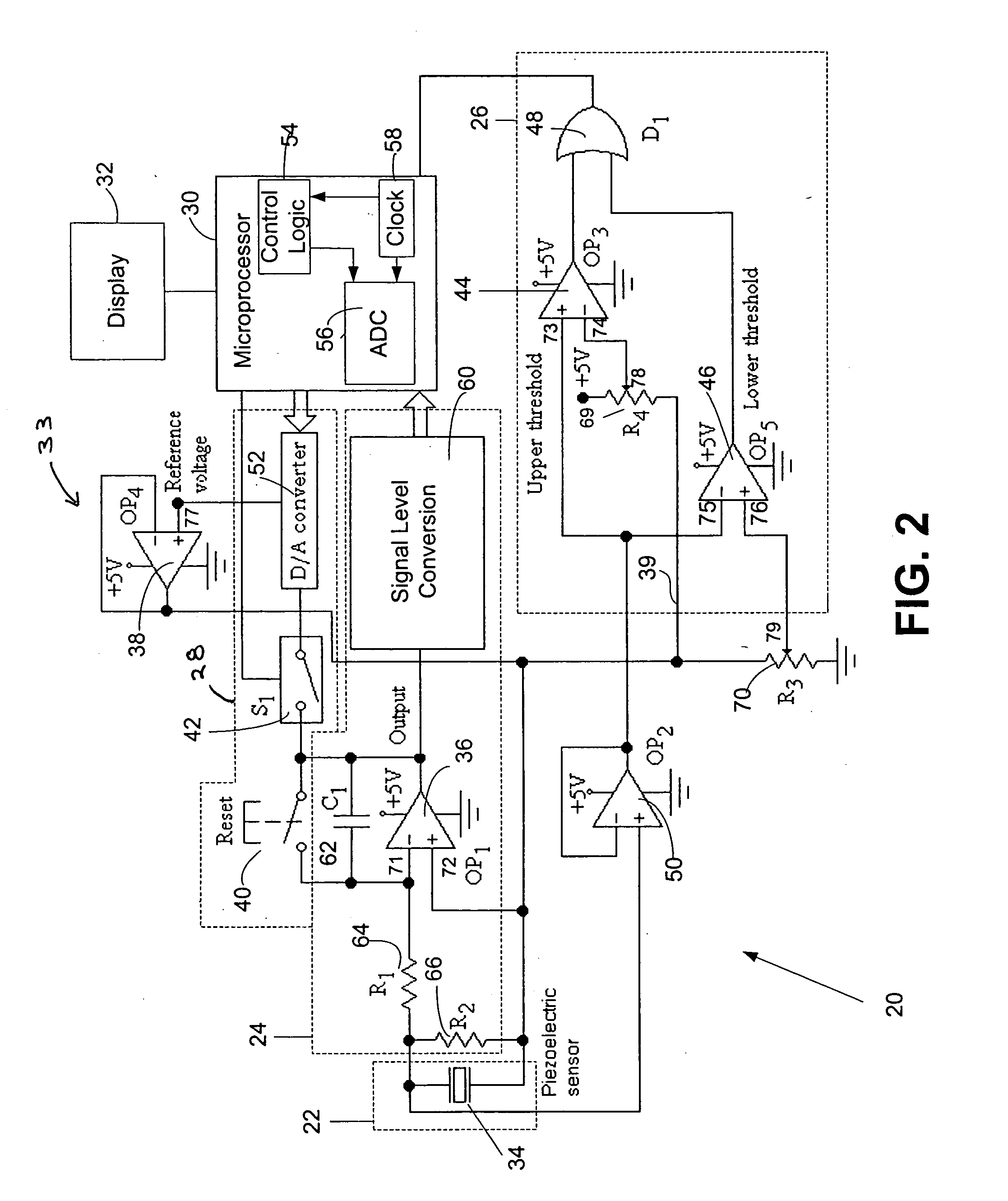

System and method for load sensing using piezoelectric effect

InactiveUS20050011277A1Reduce costly machine down-timeImprove enterprise-wide decision makingWeighing apparatus using elastically-deformable membersElectrical apparatusElectricityLoad sensing

System and method for measuring static load by using a piezoelectric load sensor with a feedback technique to compensate for the signal loss due to charge leakage, and therefore ensures measurement accuracy. The system is integrated with other structure, objects and devices to measure static loads applied to a mechanical shaft, in an on-line, in-process, quasi real-time fashion. The system can be used to measure static load and thus oversee an entire machine system or a manufacturing process.

Owner:UNIV OF MASSACHUSETTS

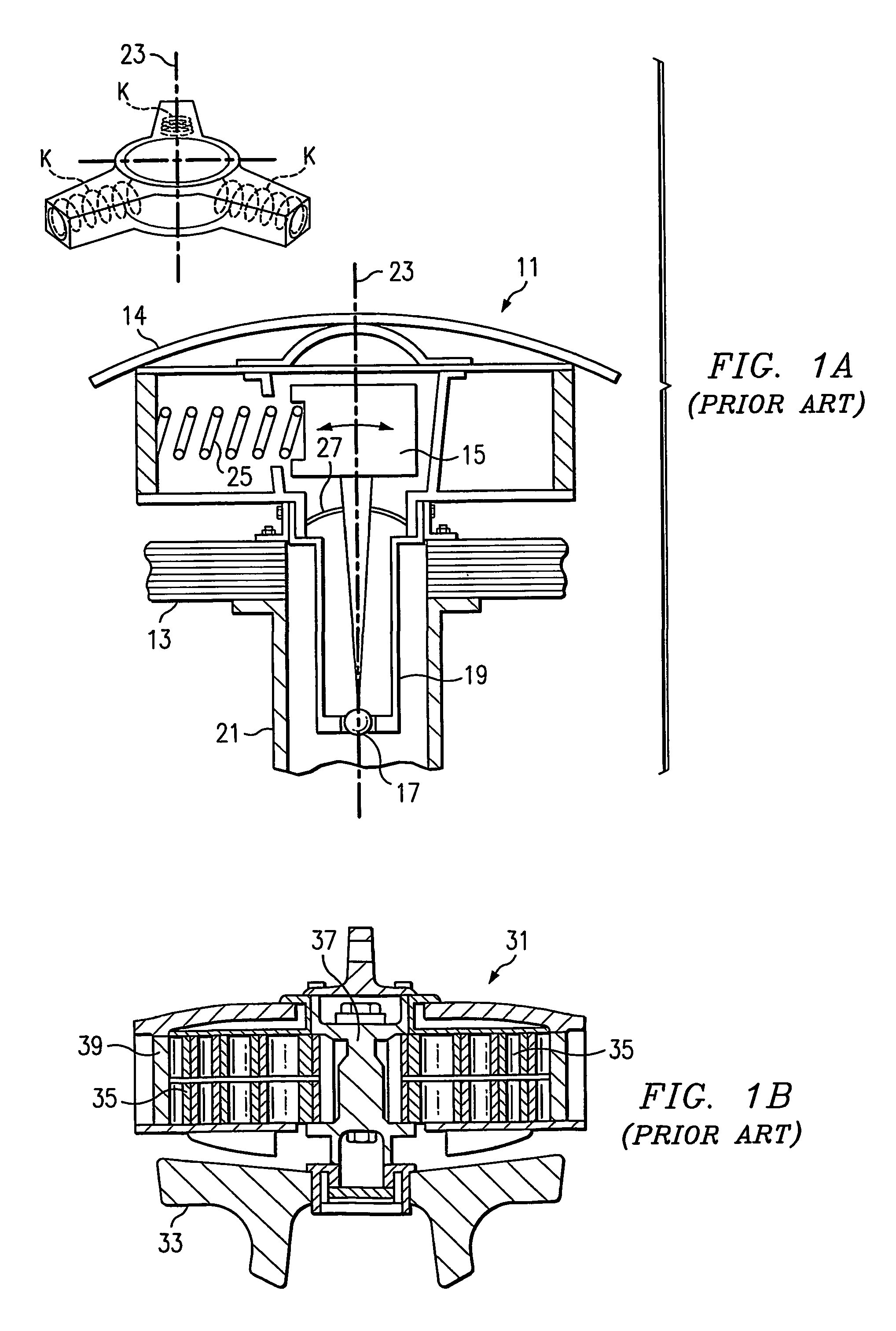

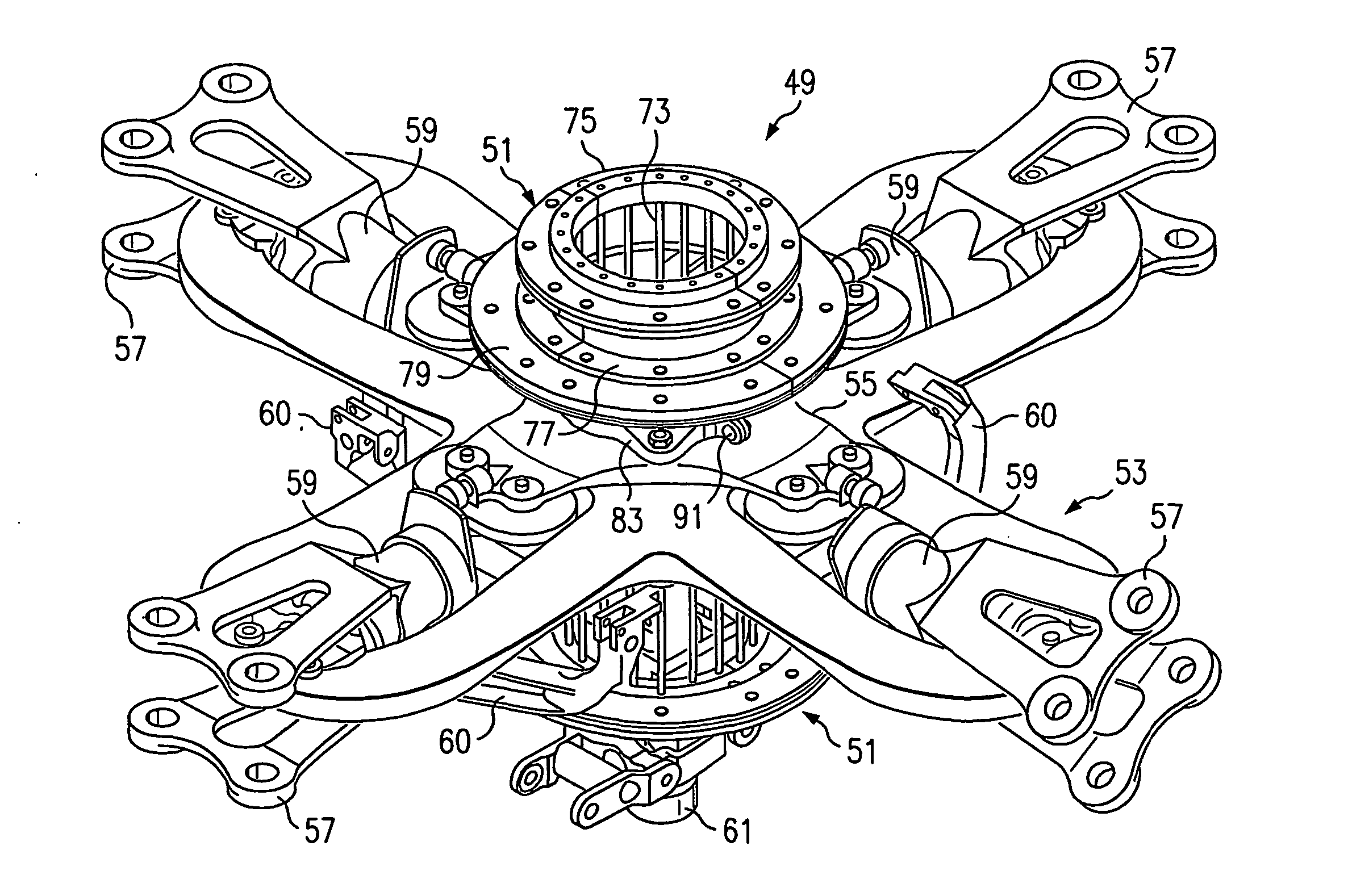

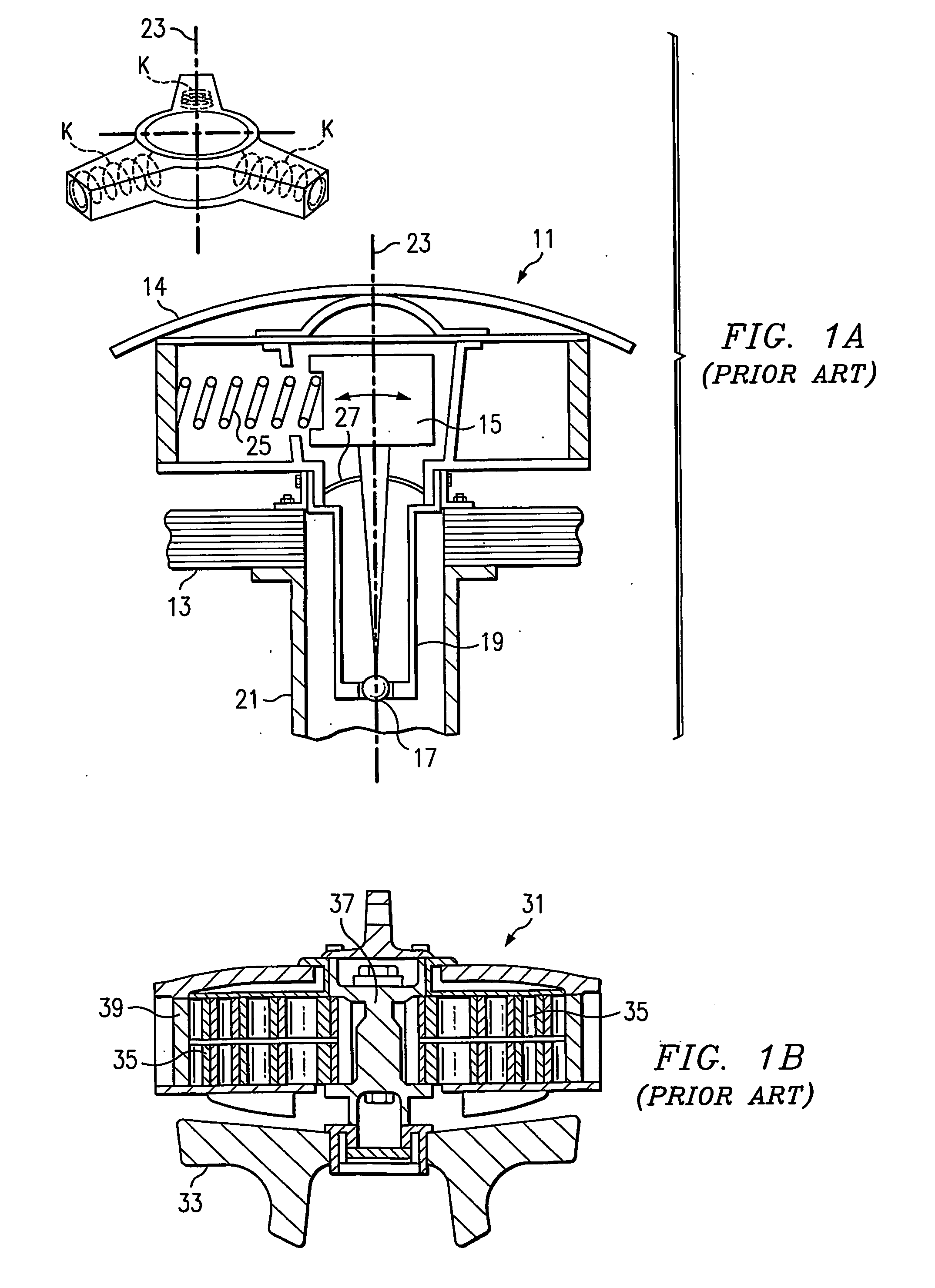

Rotor system vibration absorber

InactiveUS7153094B2Vibration minimizationLittle and maintenanceOther chemical processesPump componentsSpring forceEngineering

A rotor system vibration absorber for use with a helicopter of other rotorcraft is disclosed in which spring forces are provided by a plurality of elongated rods arranged in a selected pattern. The rods are coupled at one end to a fixed base that is coupled to a rotor hub, and at the other end to a tuning weight.

Owner:BELL HELICOPTER TEXTRON INC

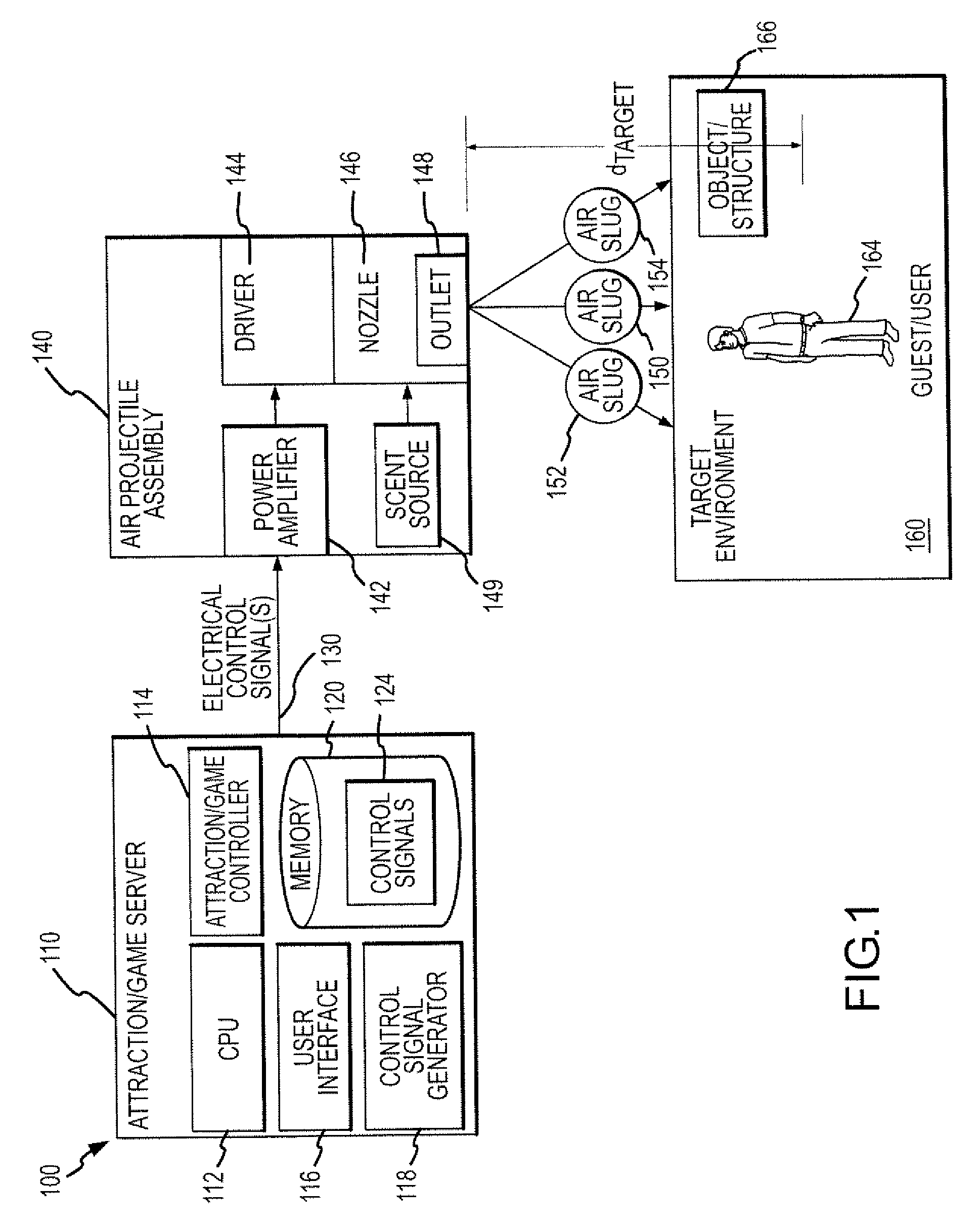

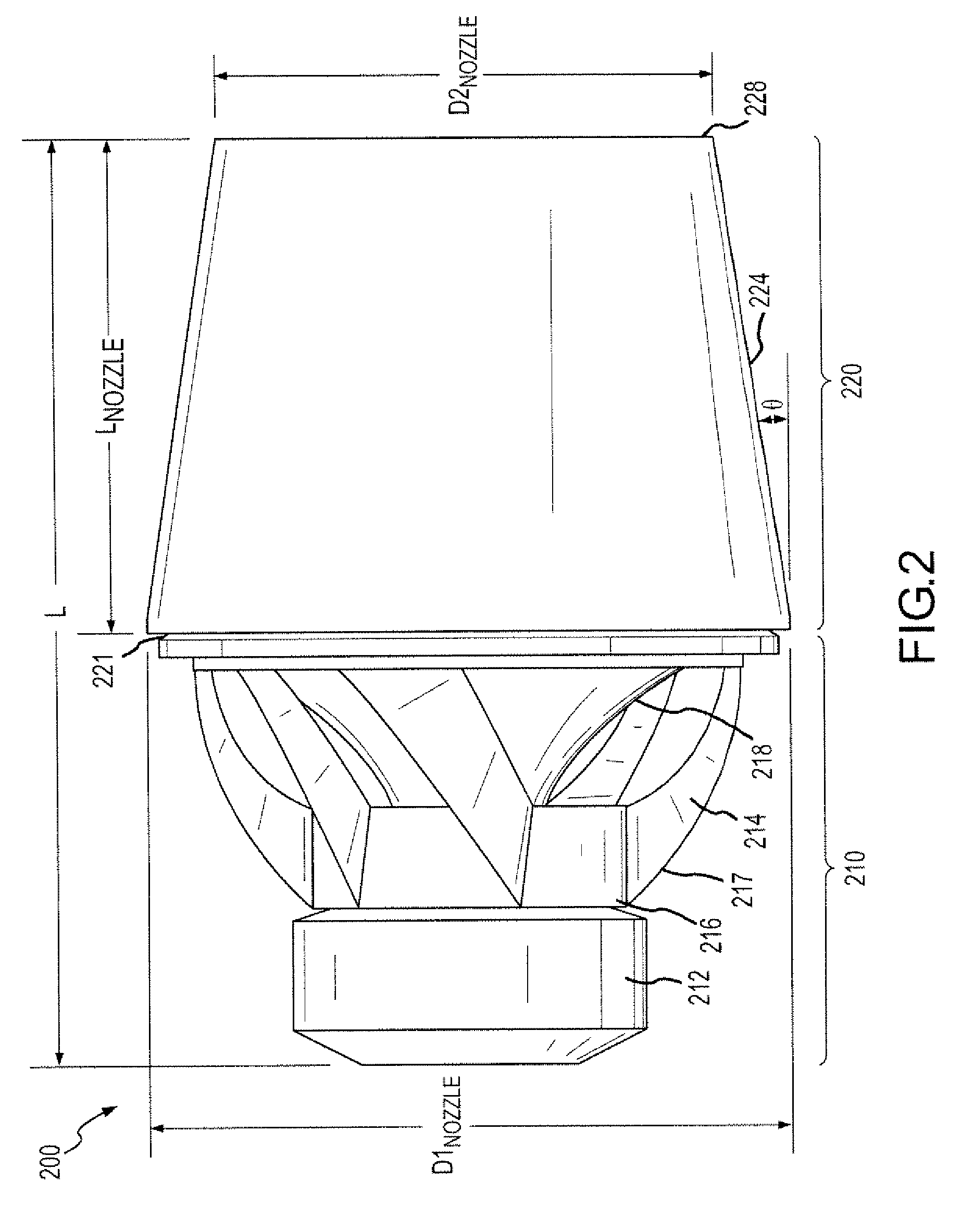

Device for producing high speed air projectiles or pulses

InactiveUS20080121220A1Rapid responseImproved power handlingCompressed gas gunsElectricityDriver/operator

An assembly for producing air projectiles. The assembly includes a driver with an attached converging nozzle. The driver includes a flexible diaphragm and is responsive to an electrical control signal to displace the flexible diaphragm from a first position to a second position. In one embodiment, the driver is an audio speaker driver such as a woofer and the diaphragm is a speaker cone or diaphragm. The nozzle has an inner bore or chamber that converges from a first size at a first end proximate to the driver to a second, smaller size at a second distal end. The second end of the nozzle may include a planar muzzle extending perpendicular to a central axis of the bore and including an outlet smaller than the diaphragm diameter. The driver has a rapid response to control signals such as less than about 20 milliseconds to produce a projectile at the muzzle.

Owner:DISNEY ENTERPRISES INC

Electromagnetic active vibration control system and electromagnetic actuator

InactiveUS6974006B2Accurate and robust and efficientEasy constructionPortable framesMechanical oscillations controlControl systemFeedback control

A multi-sensor, multi-actuator control system for controlling vibration in a mechanical structure. The system employs feedforward and feedback control strategies in tandem. Outputs from adaptive feedforward and modal feedback control loops are added to each other. The control system may be dynamically adapted to the changing physical characteristics of the controlled structure. For example, the plant transfer function estimates for the feedforward unit and the gain for the feedback unit may be calculated as functions of sensed physical parameters (location, mass, etc.), and the plant transfer function estimates may be dynamically modified to reflect time-varying feedback control gains. If desired, the control system may be used to cancel low frequency vibrations (<20 Hz) in industrial processes. The actuators may be formed of electromagnets, fixed armatures and interposed flux sensors. In a preferred embodiment of the invention, the robust actuators are sealed so as to be impervious to fluids and dust.

Owner:VSSL COMML

Needleless injection device and method of injecting

InactiveUS20080044526A1Enhance market appealBroad possible marketJet injection syringesInjection based meat processingFood additiveNeedle Free Injection

A needleless injection device and method for injecting a food subject is disclosed in which one or more types of liquid food additive are individually and / or simultaneously delivered to a food subject within a sealed injection chamber or compartment. The needleless injection device and method of the present invention utilizes rapid, high pressure injection bursts to completely and uniformly inject the food subject, allowing different food subjects or different food additives to be sequentially injected in an efficient and instant manner. The needleless injection device and method for injecting minimizes contamination by totally enclosing the injection process within a sealed chamber, and by eliminating the need for the injection nozzles to contact, or be placed immediately adjacent to the food subject.

Owner:HANSEN CONLY L +1

Rotor system vibration absorber

InactiveUS20060222505A1Vibration minimizationLittle and maintenancePump componentsOther chemical processesSpring forceEngineering

A rotor system vibration absorber for use with a helicopter of other rotocraft is disclosed in which spring forces are provided by a plurality of elongated rods (73) arranged in a selected pattern. The rods are coupled at one end to a fixed base (79) that is coupled to a rotor hub (55), and at the other end to a tuning weight (81).

Owner:BELL HELICOPTER TEXTRON INC

Mobile compression and tension bridge and shelter structure

InactiveUS7546654B2Low costRaise the ratioPortable bridgeBuilding constructionsEngineeringMechanical engineering

Owner:CARMEL MORDEHAY

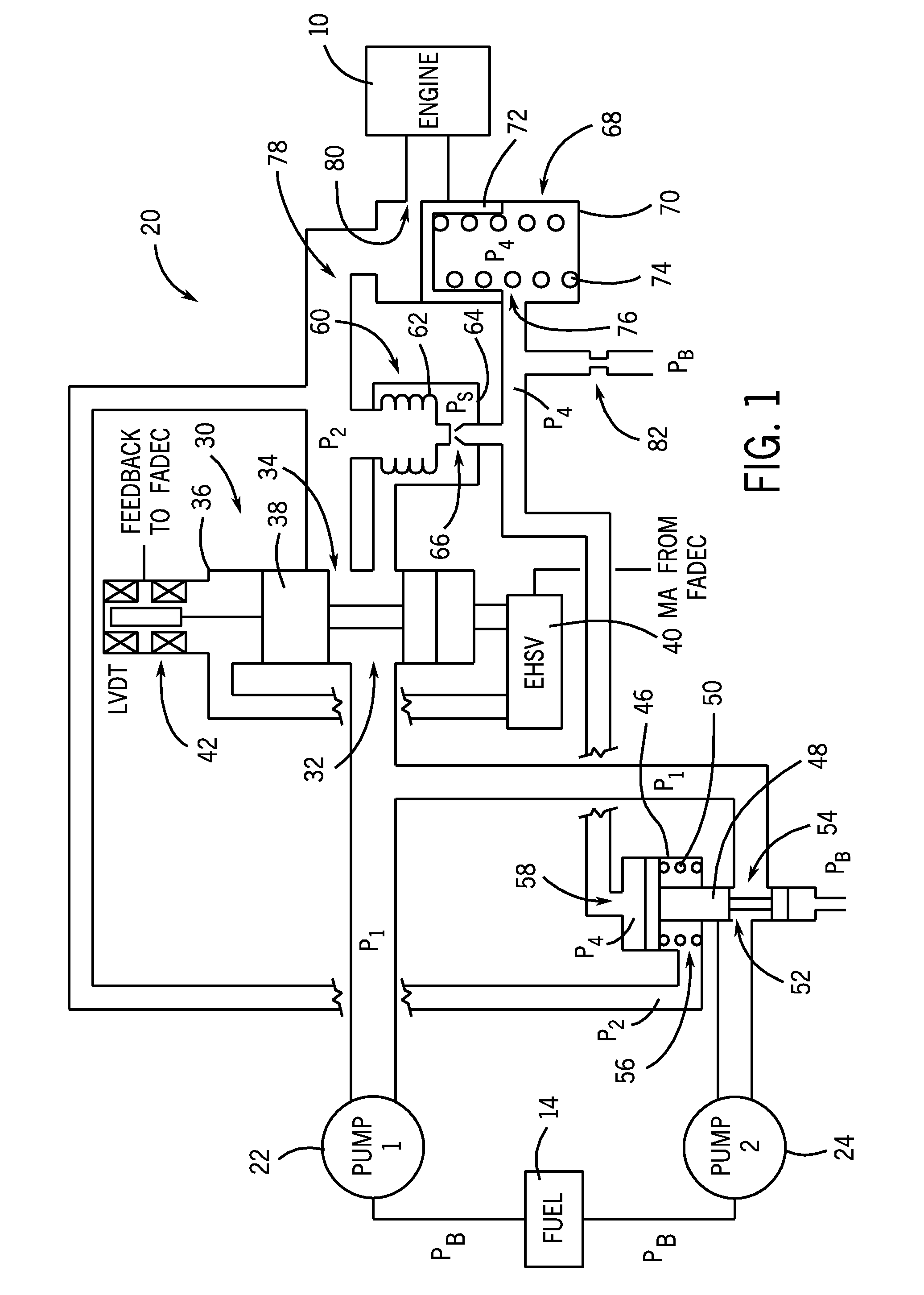

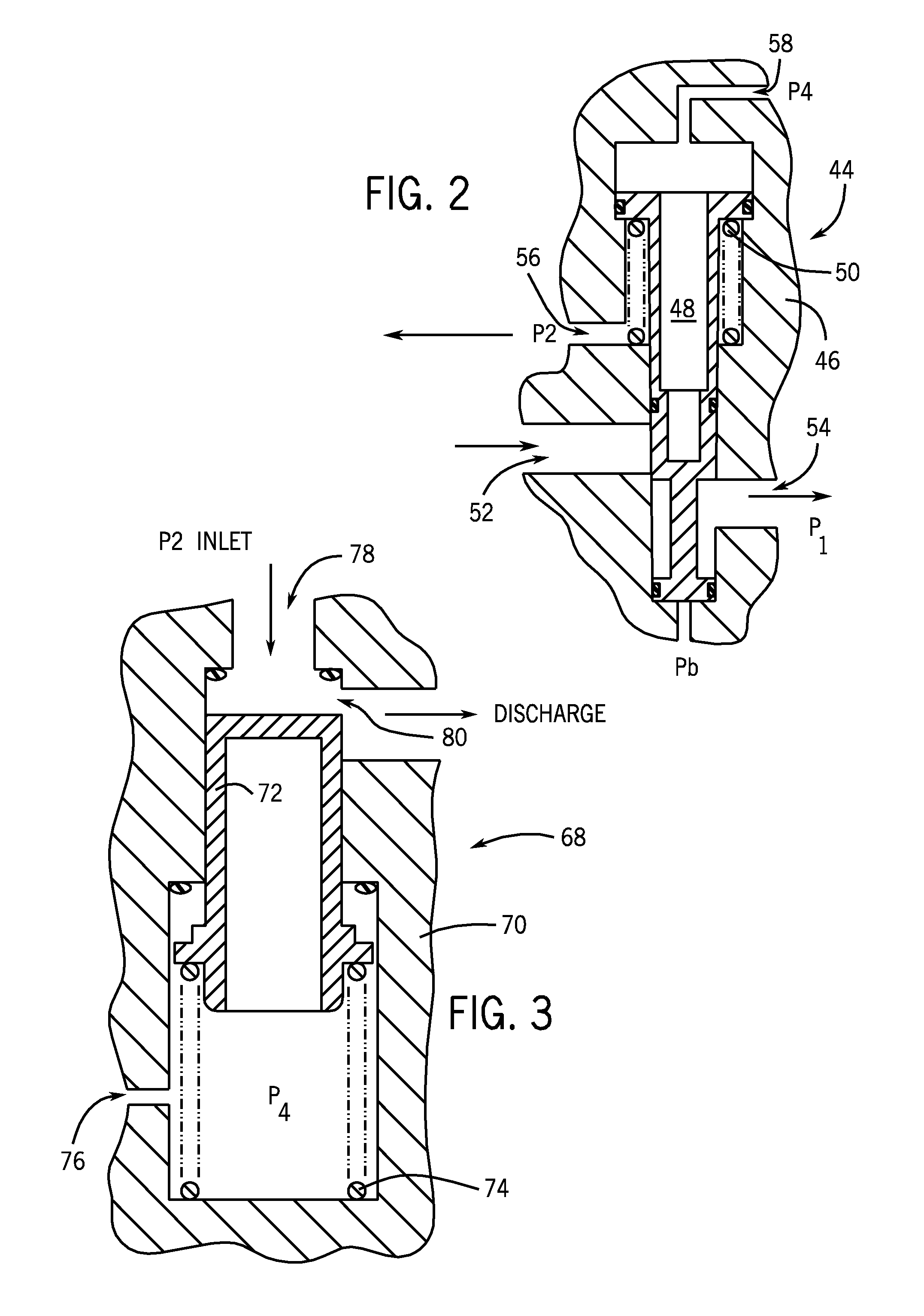

System for metering a fuel supply

ActiveUS7966994B2Broad possible marketDurable and long lastingEngine fuctionsTurbine/propulsion fuel deliveryFuel supplyMotor fuel

A system for metering fuel to an engine. The system includes a fuel metering valve having a throttled inlet and a throttled outlet. The system also provides regulation of redundant pump supplies of fuel to the engine. The throttling of the inlet to the fuel metering valve is provided by a valve that also functions to selectively couple a second fuel pump to the fuel metering valve.

Owner:WOODWARD GOVERNOR CO

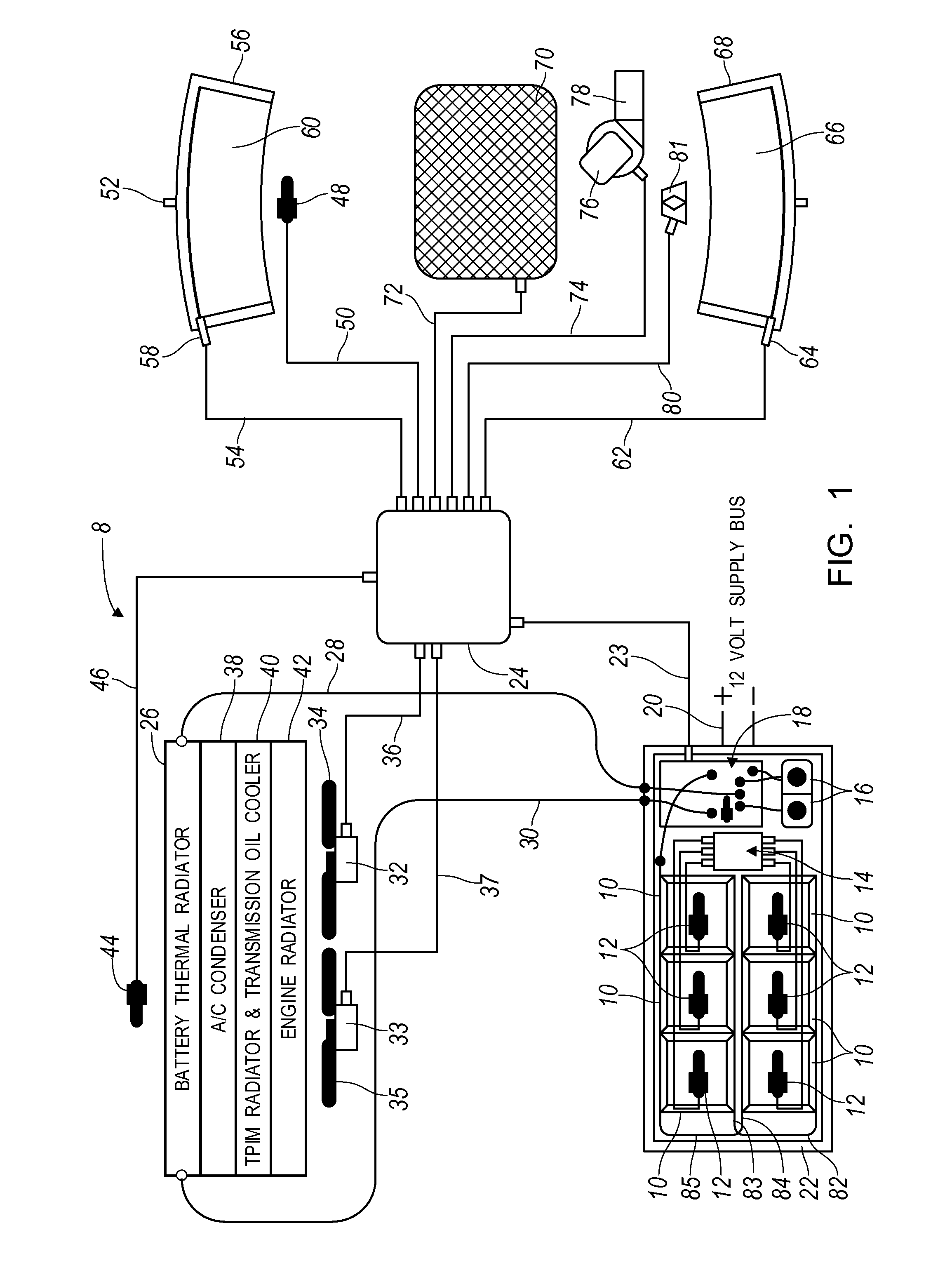

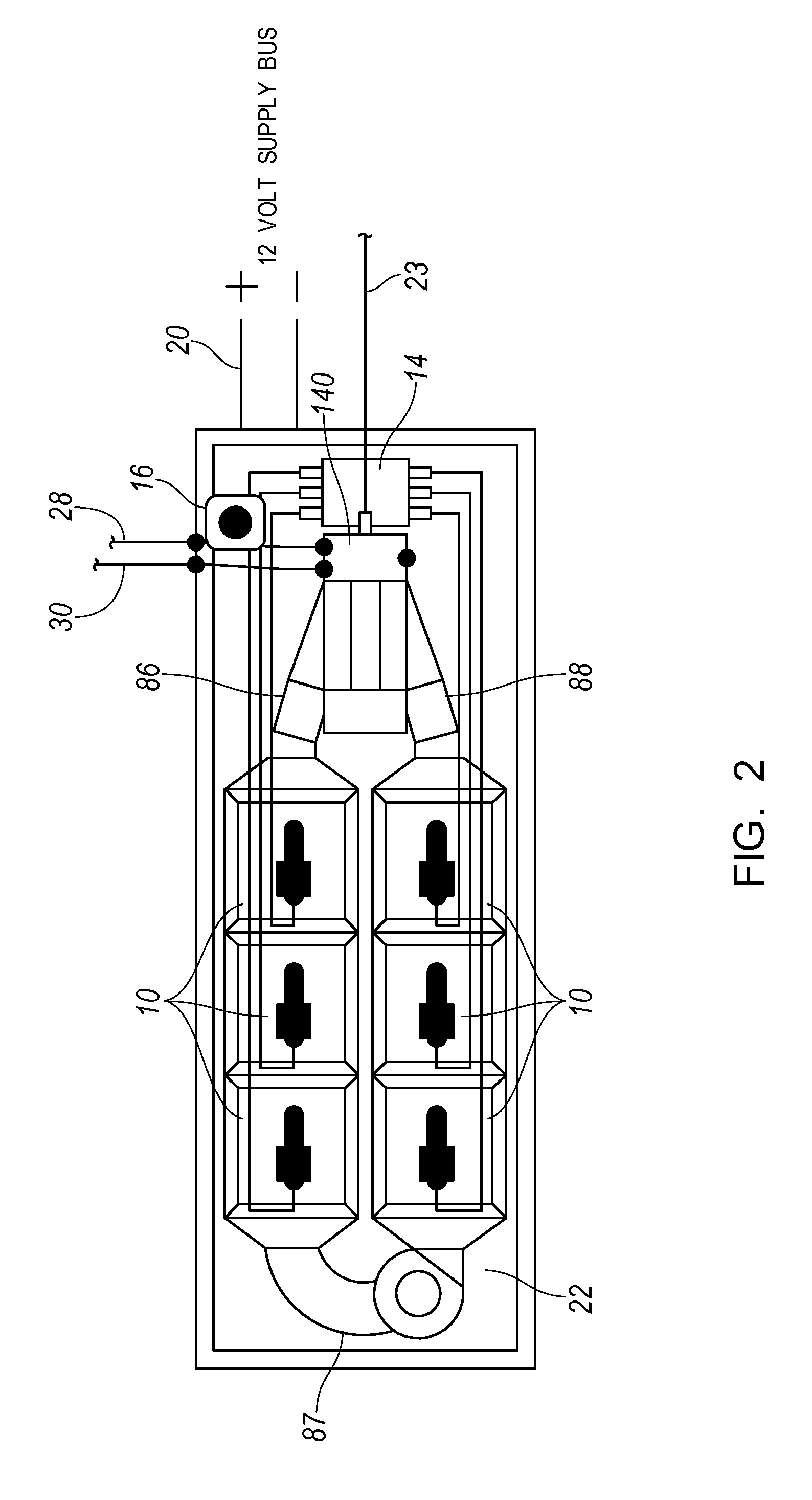

Temperature control of a vehicle battery

ActiveUS8679659B2Increased durabilityMinimum consumptionCell temperature controlSecondary cells charging/dischargingTemperature controlCoolant flow

The method for thermal management of a battery can include vehicle systems to control the thermal input to the battery and a dedicated battery thermal management system. The battery thermal management system includes transferring battery heat to coolant flowing in a circuit, if ambient air temperature is greater than the battery temperature, using an evaporator / chiller to transfer heat from the coolant to a refrigerant, using a condenser to transfer heat from the refrigerant to the coolant, and using a radiator to transfer heat from the coolant to ambient air; and if coolant can be maintained in the reference temperature range without using a heat source or refrigerant, using a radiator to transfer heat from the coolant to the ambient air.

Owner:GM GLOBAL TECH OPERATIONS LLC

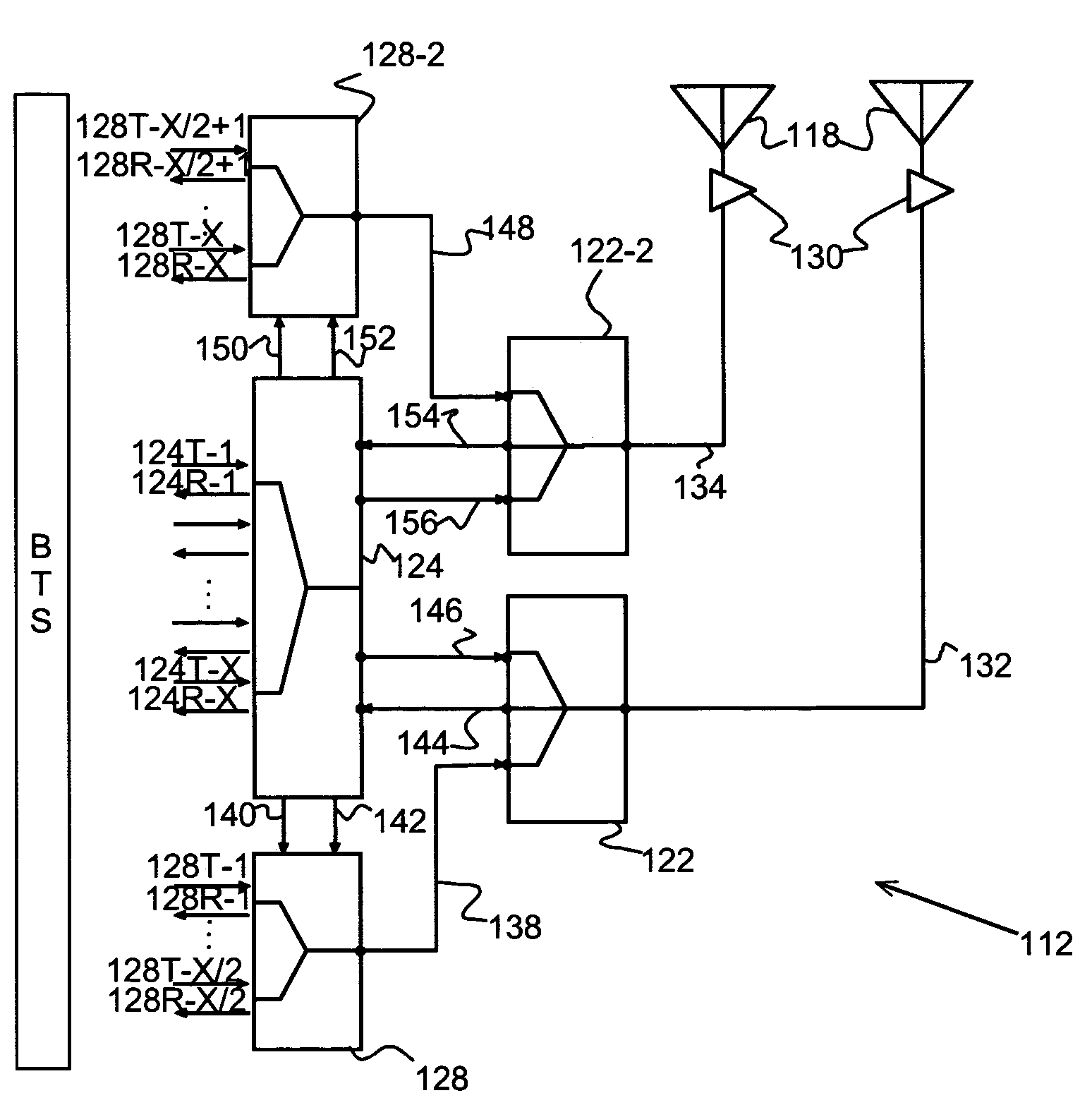

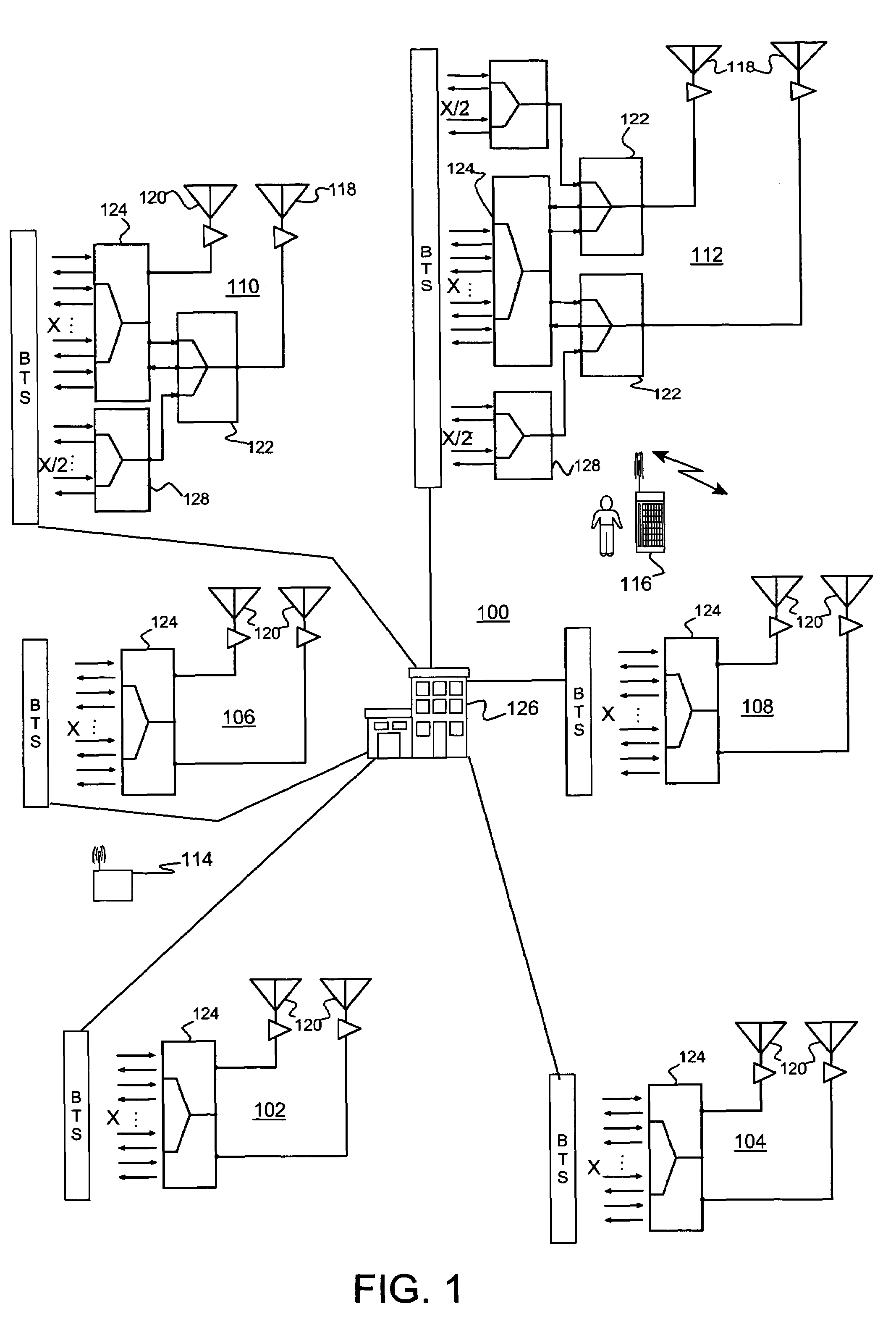

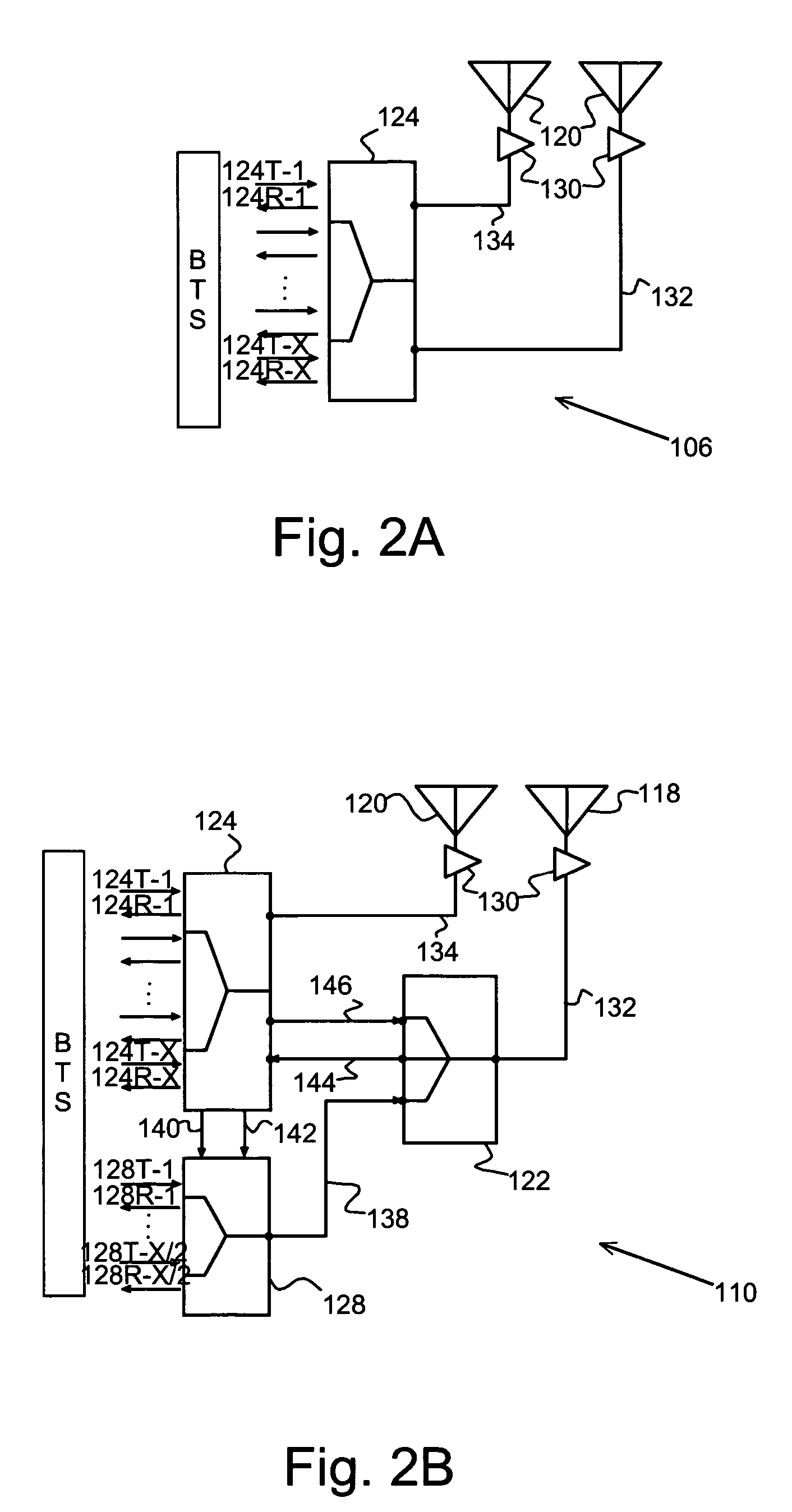

Mobile communications network with expanded carrier capacity and method of expanding base station carrier capacity

ActiveUS7376446B2Increase capacityMinimal insertion lossSubstation equipmentTransmissionCommunications systemSignal on

A base station for a mobile communications system, a mobile communications system including the base station and a method of increasing base station capacity. Each base station antenna is coupled to a transmission line that may be connected to a triplexer. The triplexer separates uplink signals from a duplex signal on the transmission line. The uplink and downlink signals are both in two sub-bands that are separated by a third sub-band. The triplexer passes the uplink signal to a duplexer / combiner that forwards the uplink signal to a combiner. The duplexer / combiner and combiner each pass downlink signals in one of the sub-bands to the triplexer, which combines the passes to the duplex signal.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com