Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Minimal insertion loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

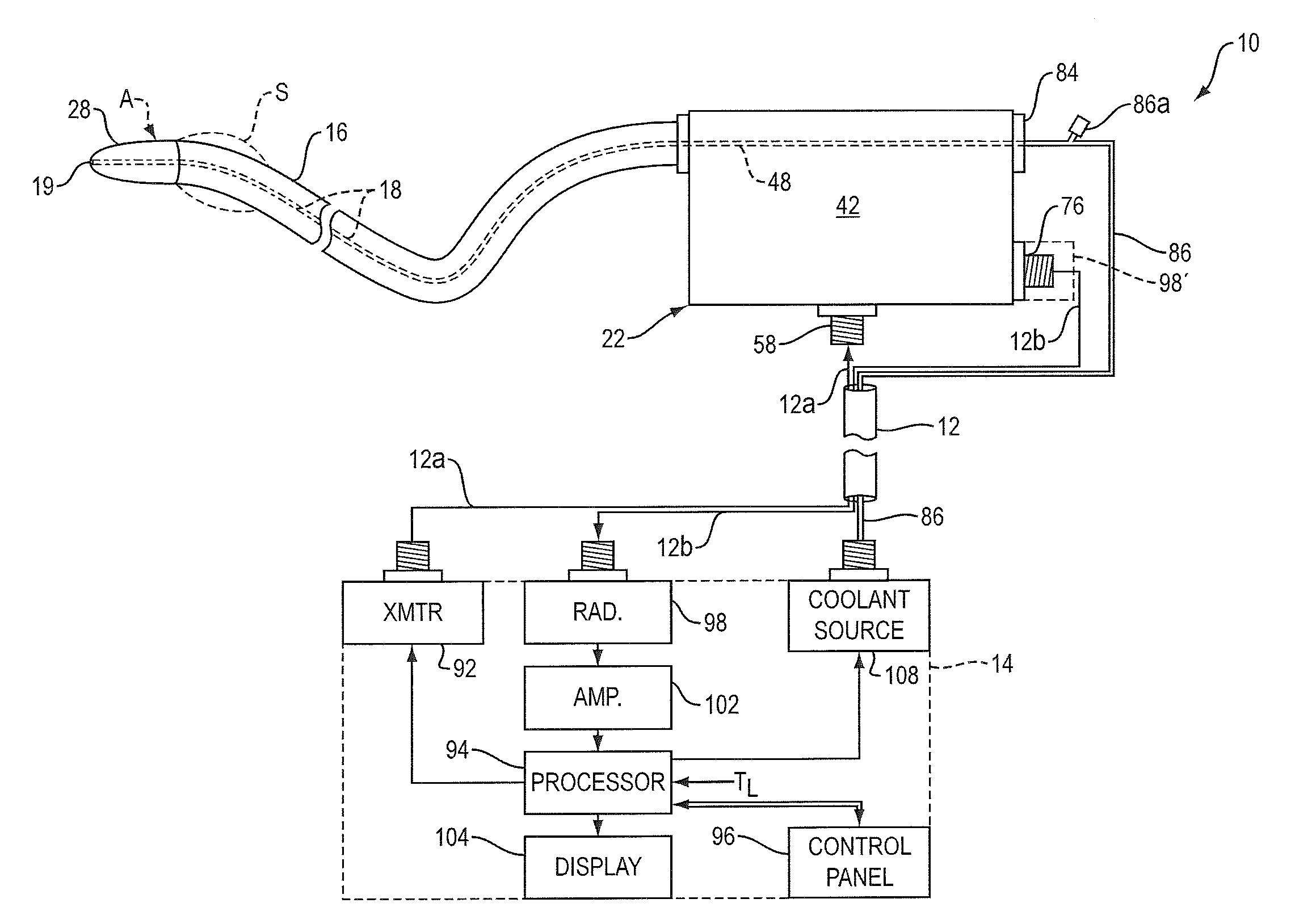

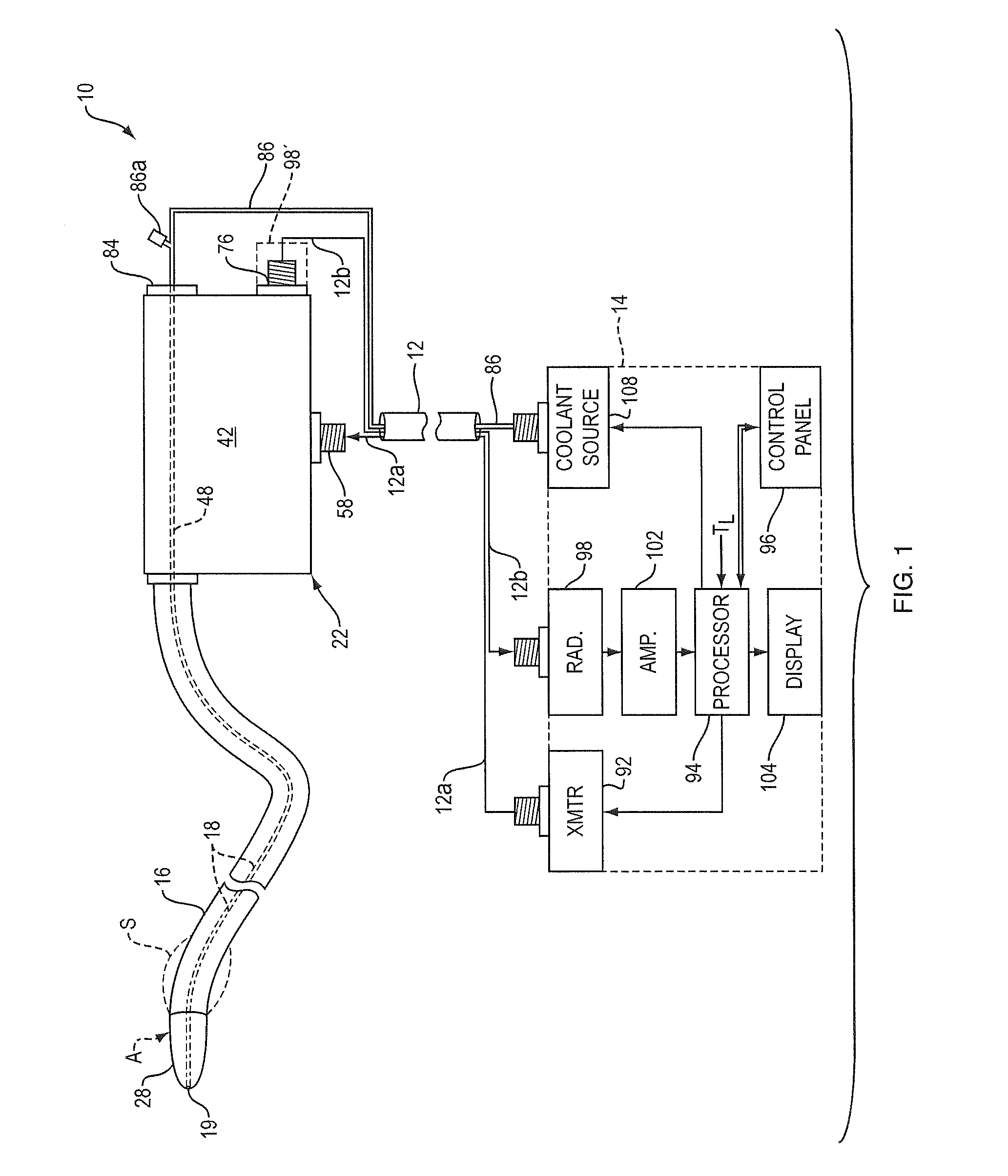

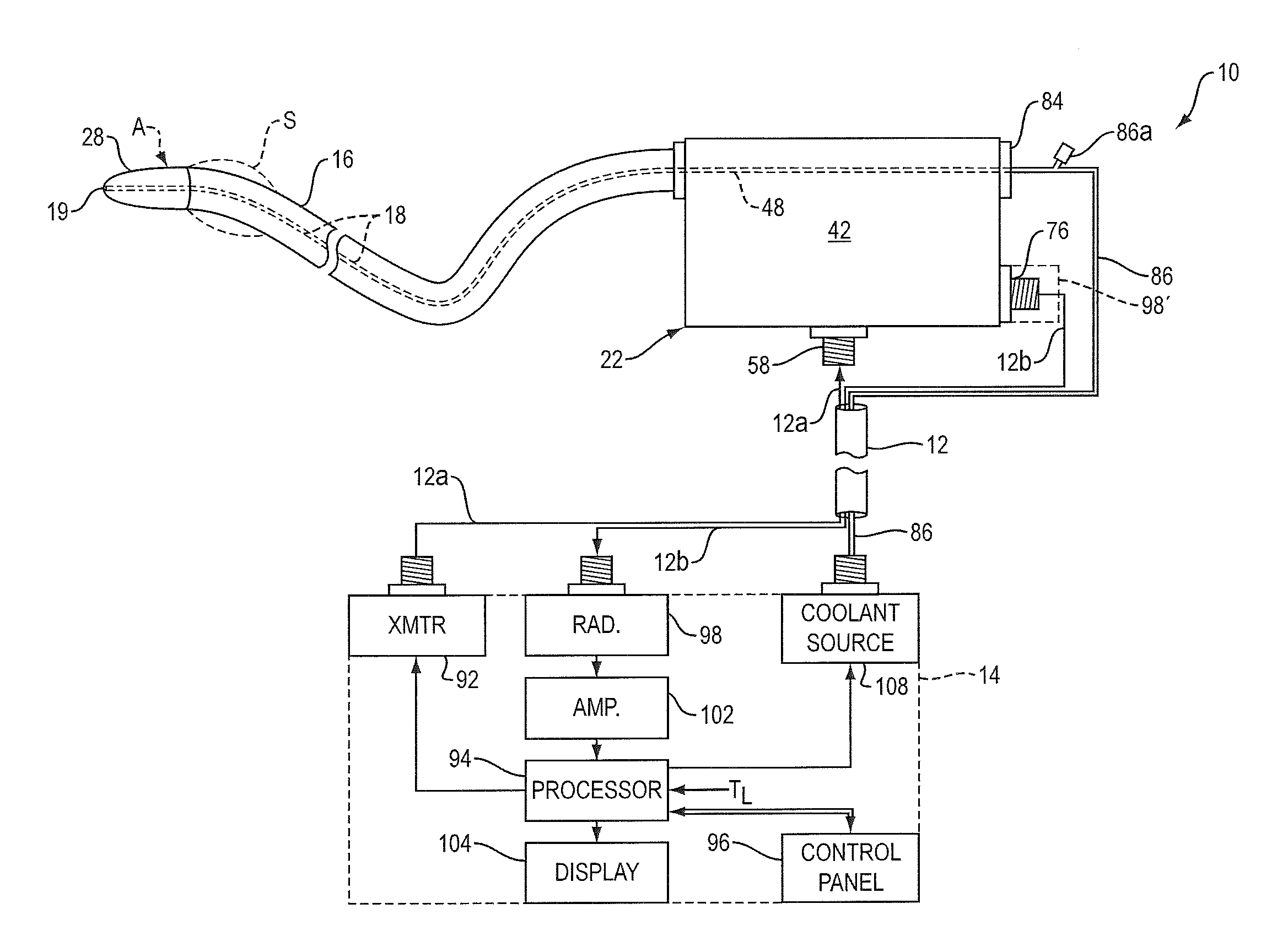

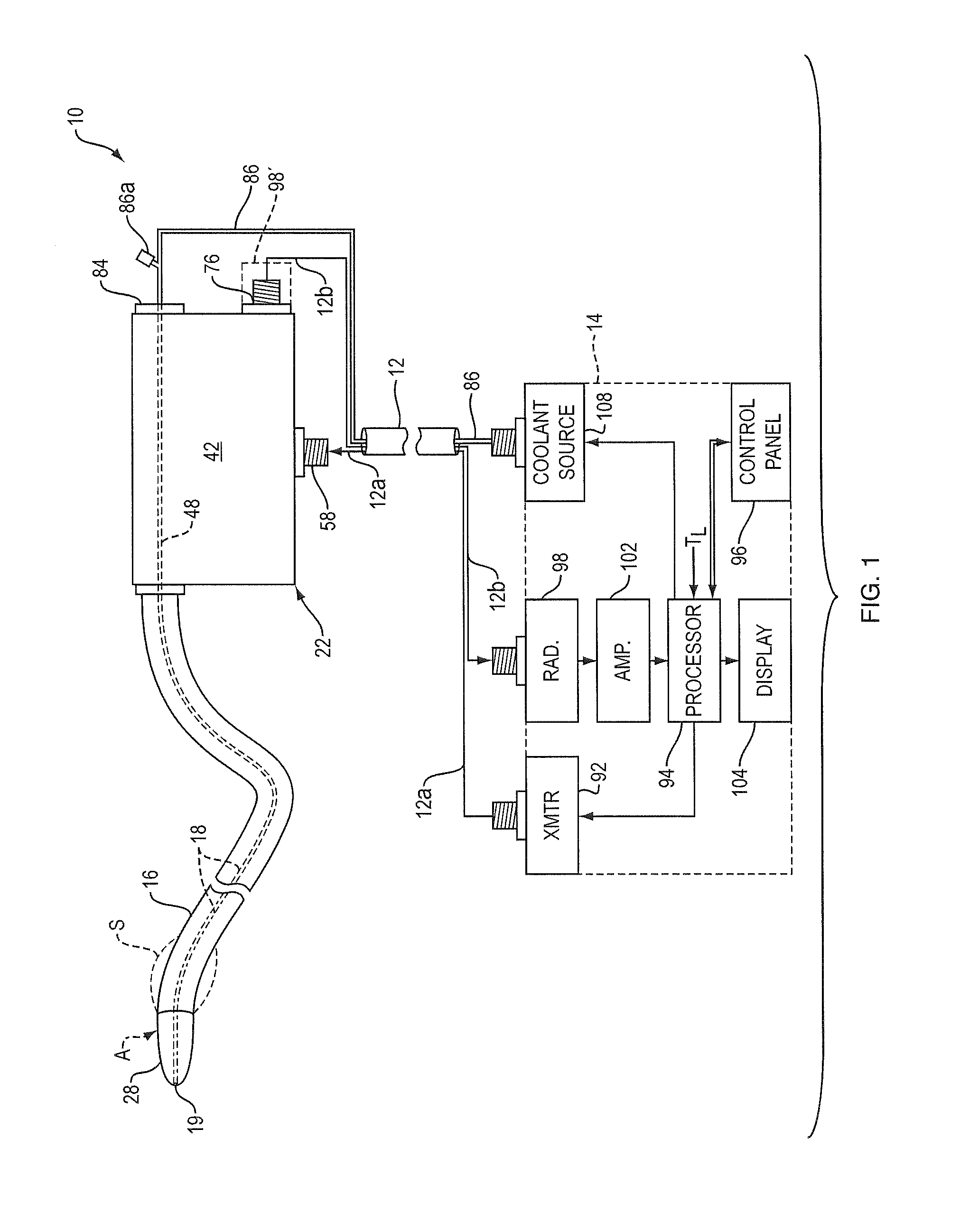

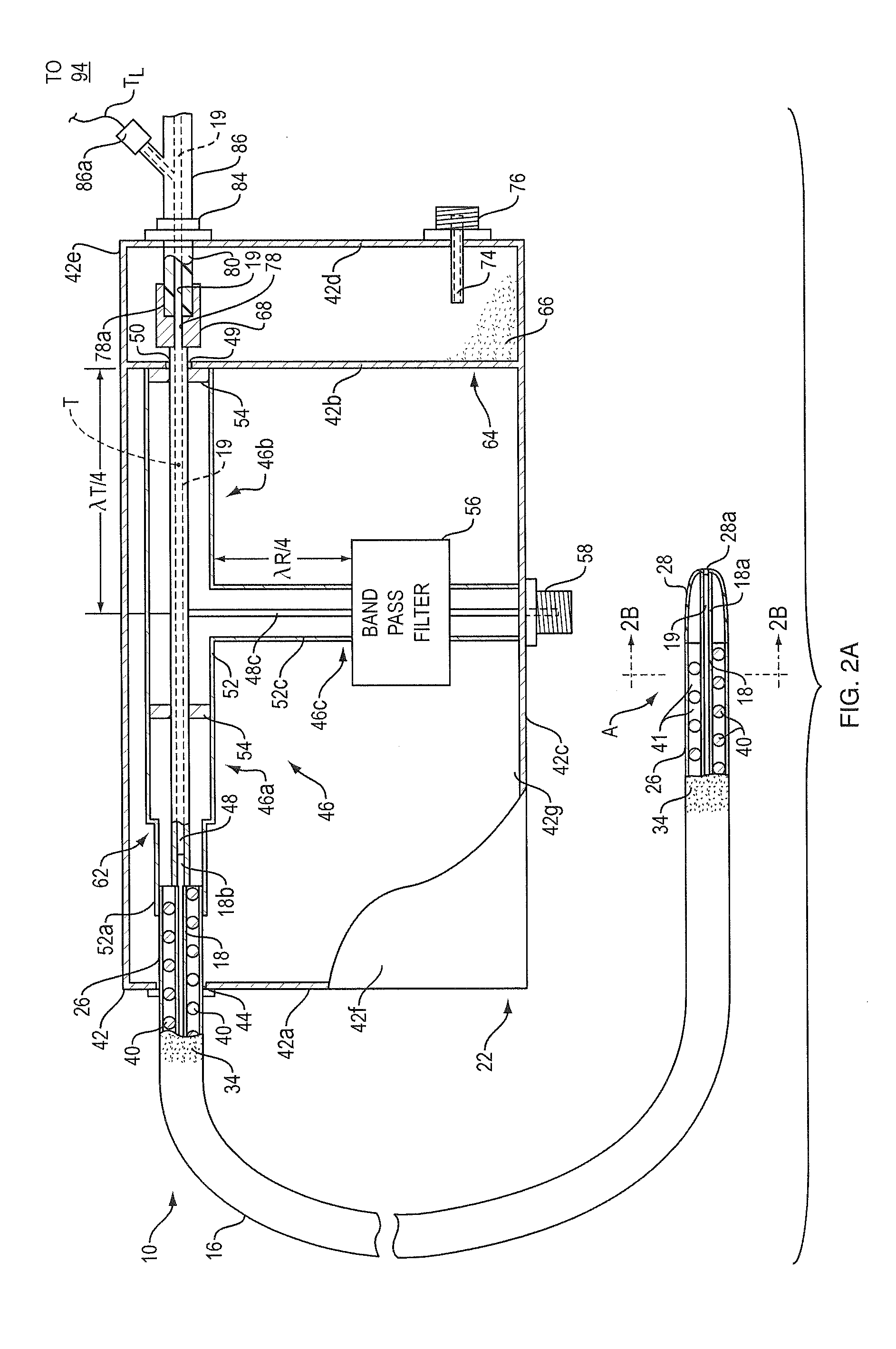

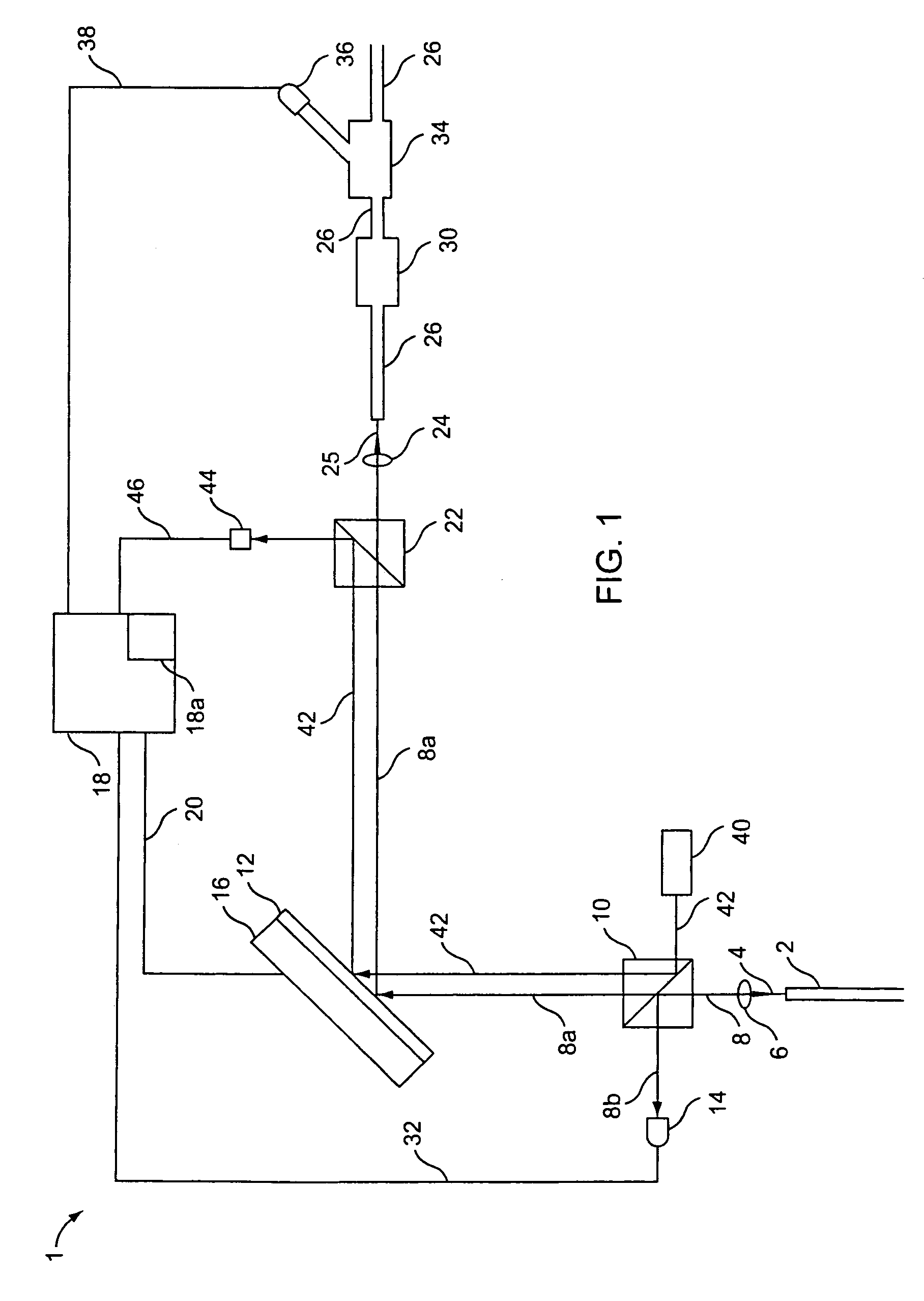

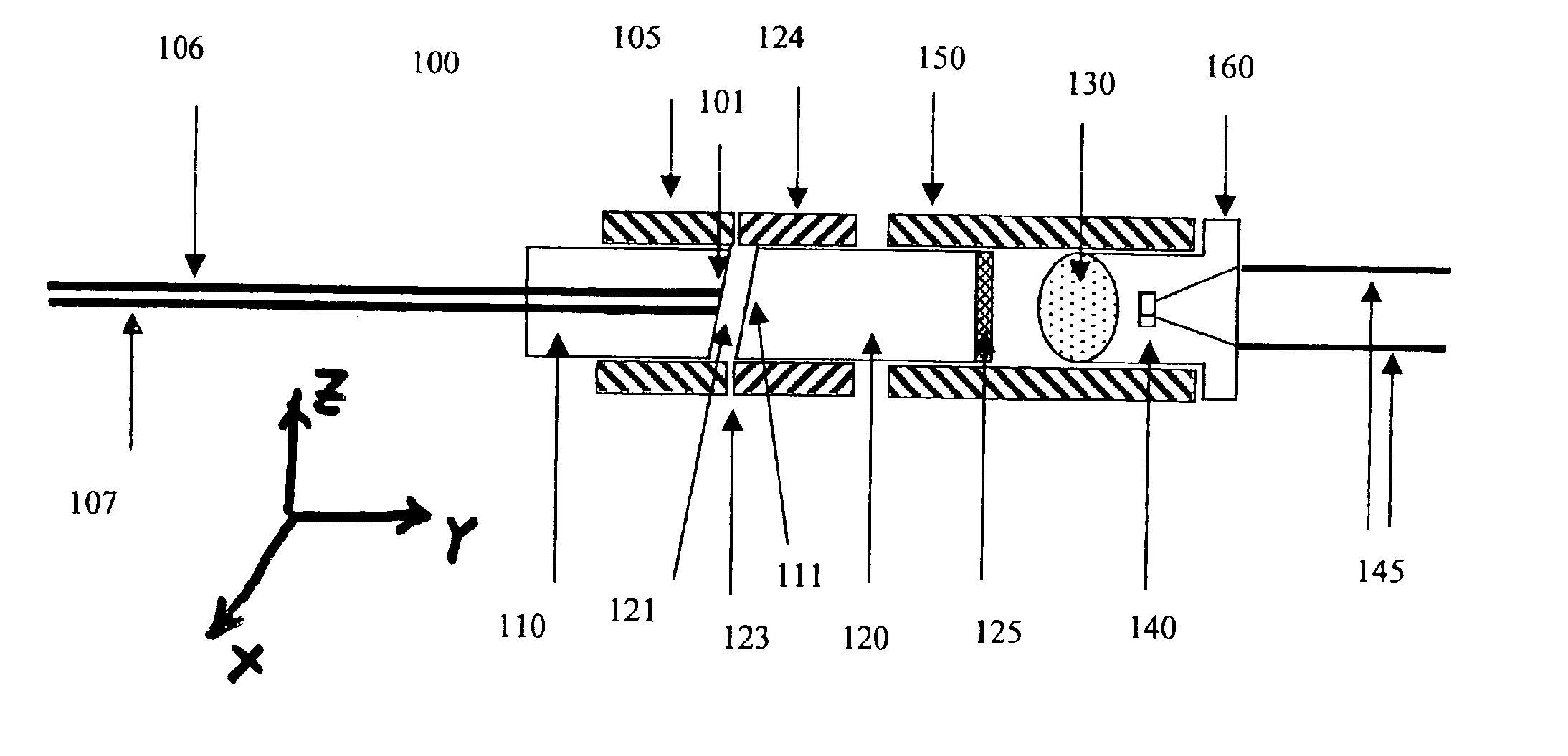

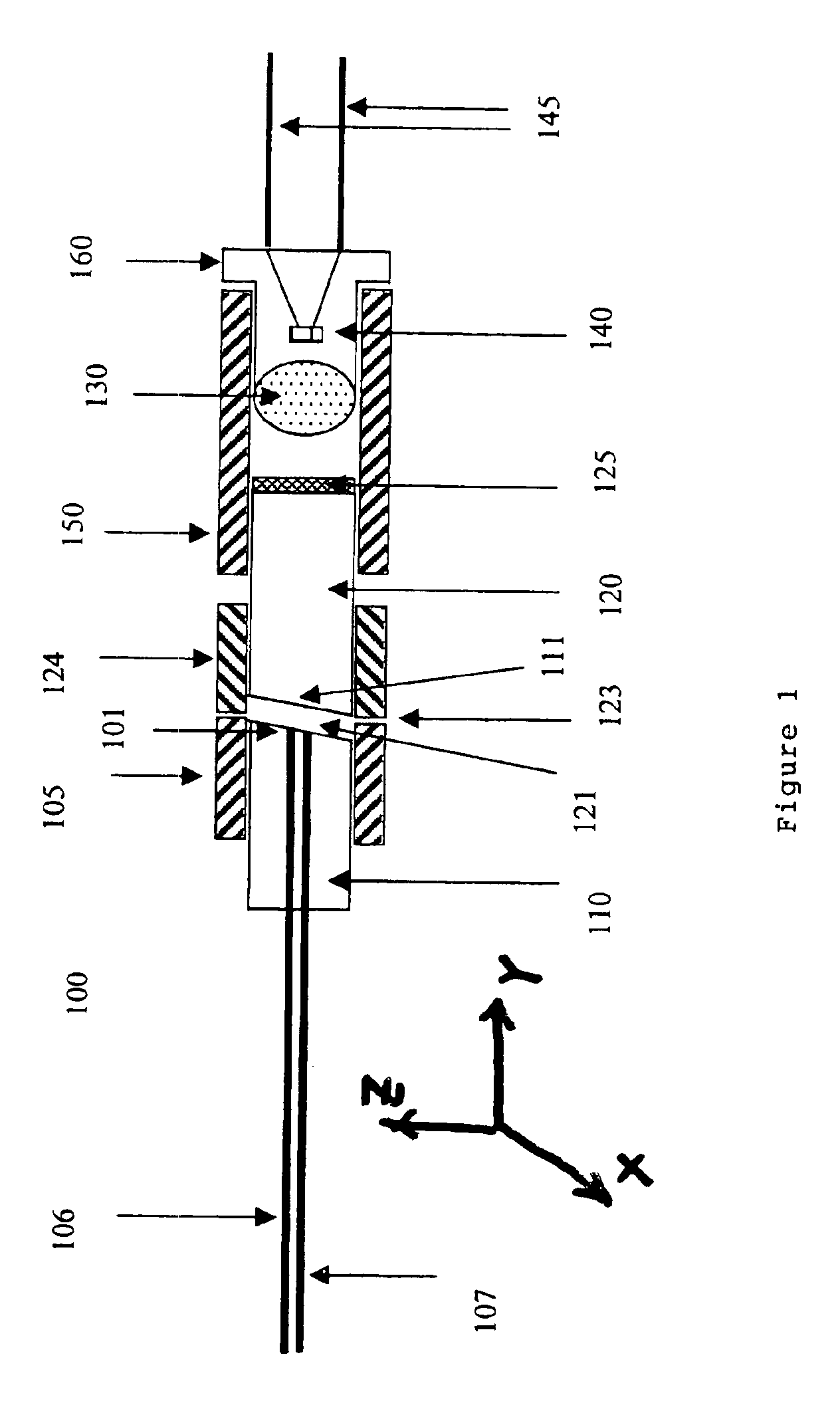

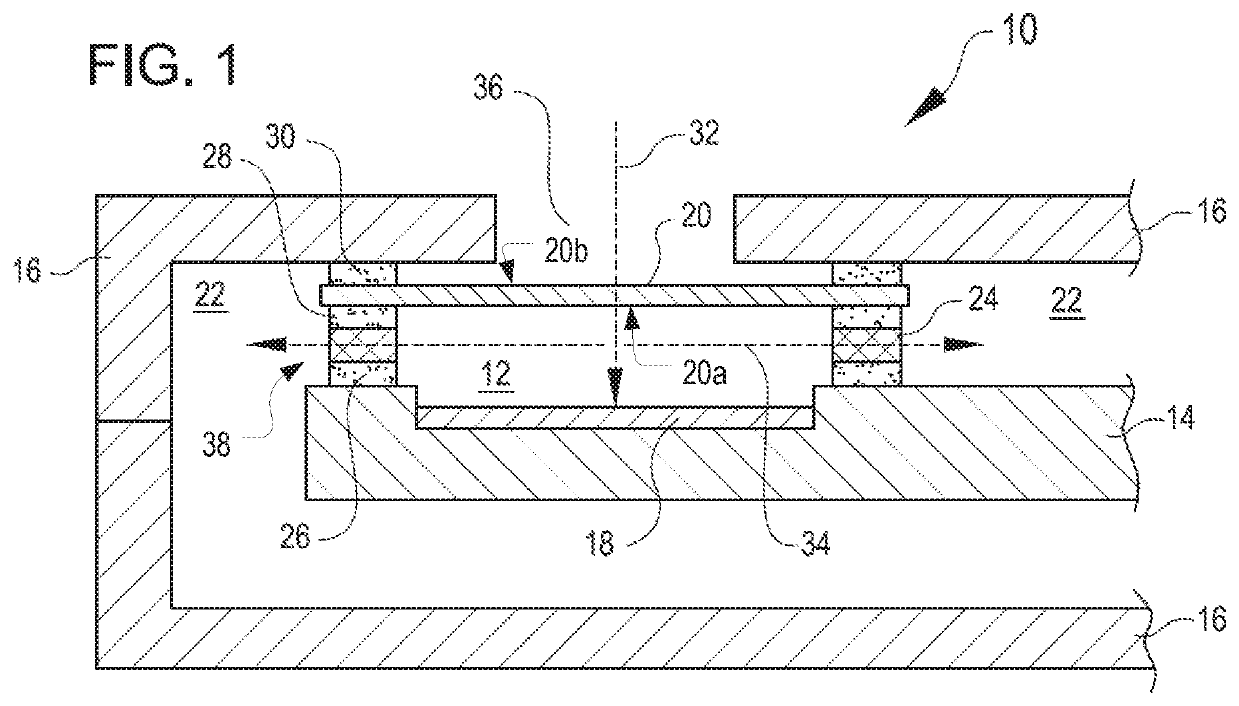

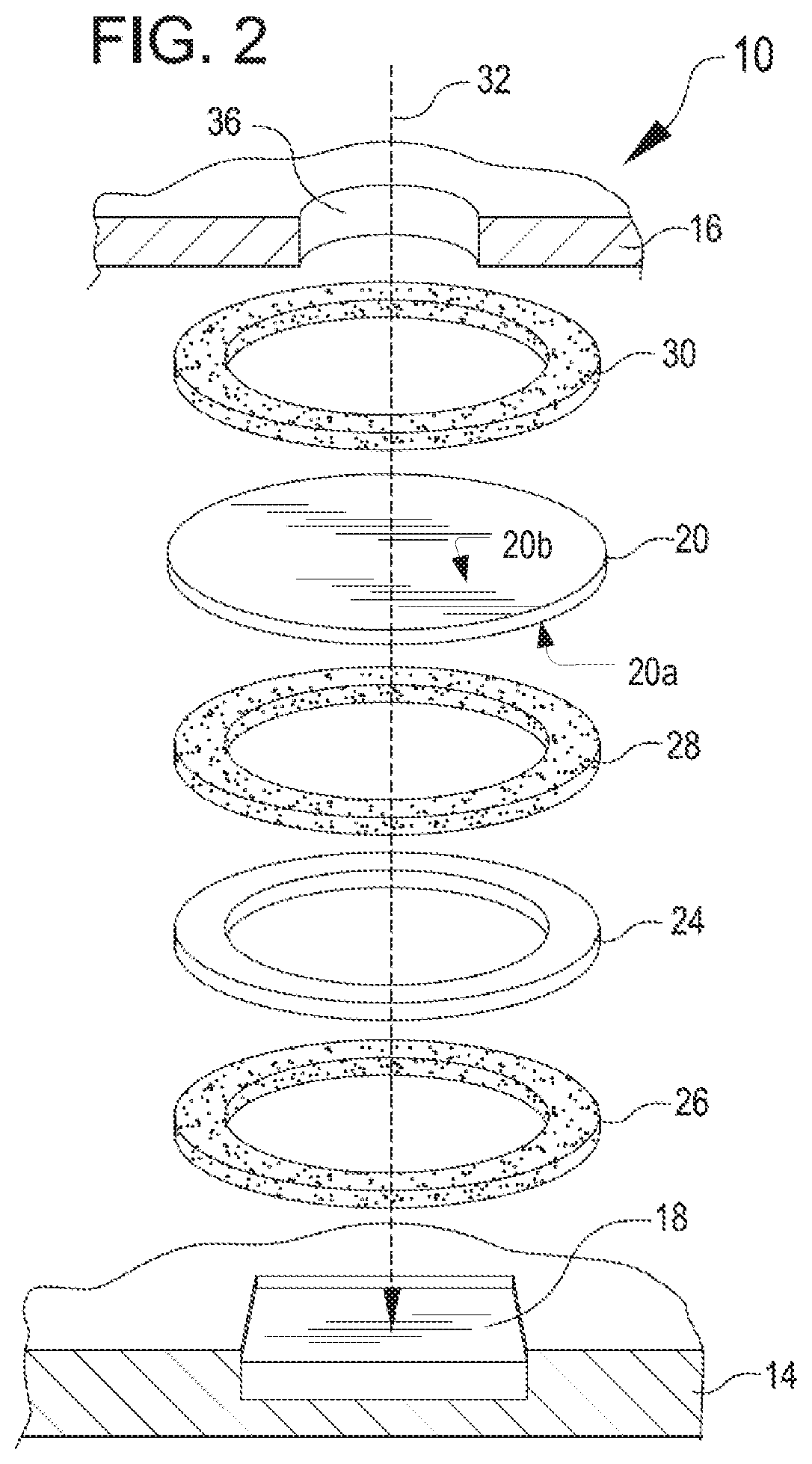

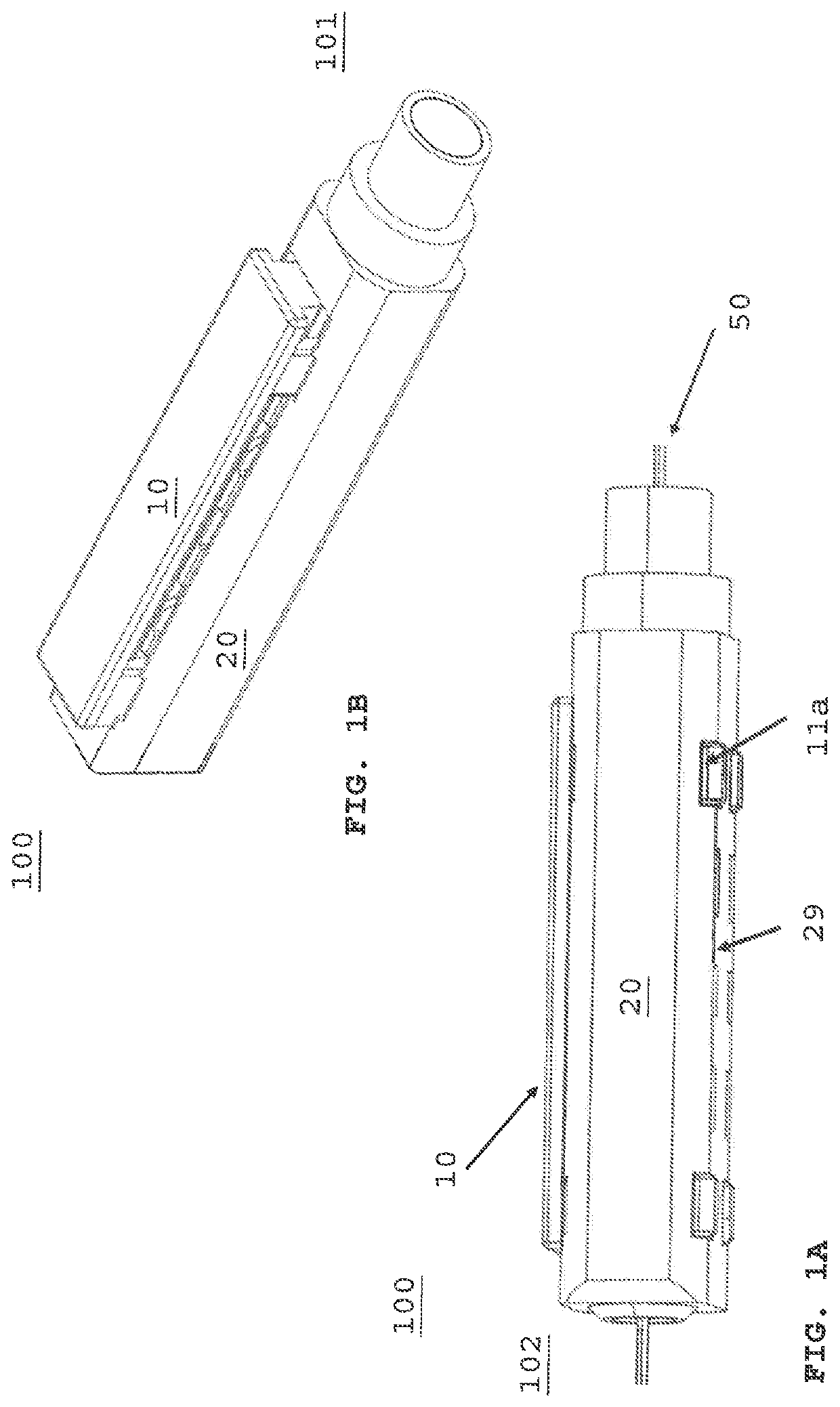

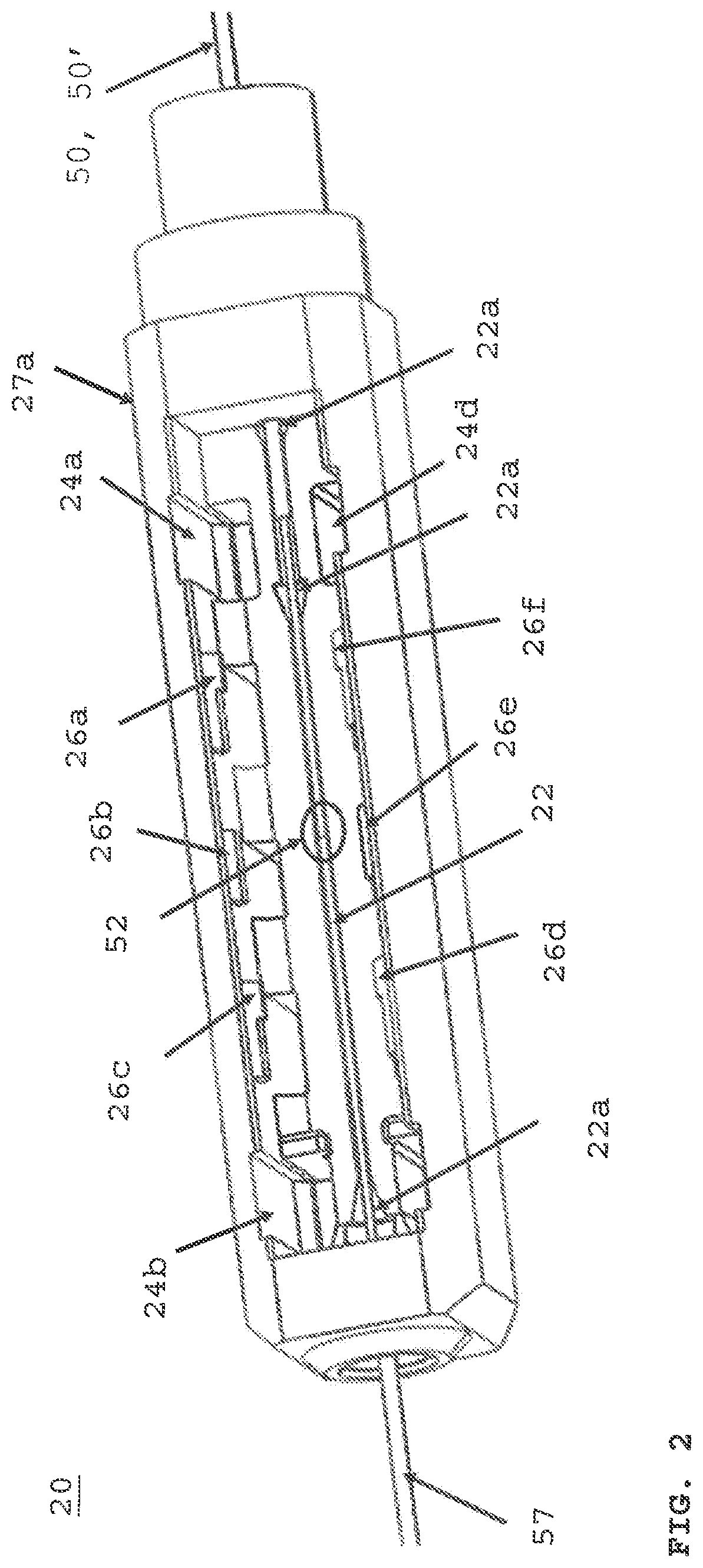

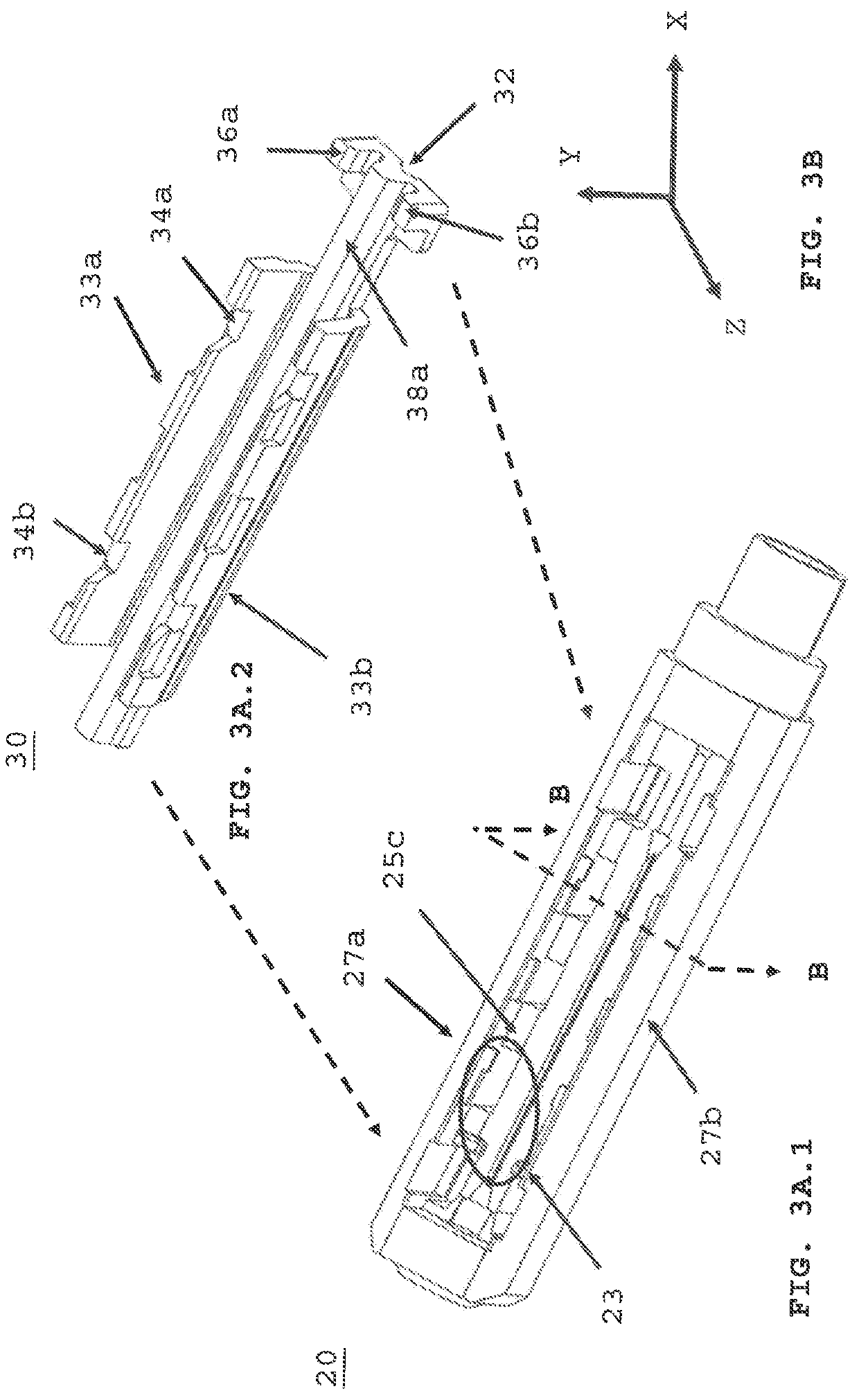

Heating/sensing catheter apparatus for minimally invasive applications

InactiveUS20130281851A1Minimize component insertion lossLower impedanceElectrotherapyCatheterElectrical conductorCoaxial cable

Catheter apparatus comprises a coaxial cable having proximal and distal ends. The cable includes a hollow center conductor, an outer conductor and an electrically insulating layer between the conductors. An antenna is at the distal end of the cable, and a diplexer is connected to the cable, the diplexer including a transmit path for connecting the antenna to a transmitter which transmits first frequency signals and a receive path for connecting the antenna to a receiver which detects second frequency signals the diplexer isolating the signals on the two paths from one another. A transmission line connects the cable to the diplexer, the transmission line having a segment with a tubular inner conductor one end of which is connected to the center conductor and a second end of which is adapted for connection to a coolant source, the center and inner conductors forming a continuous coolant pathway.

Owner:CORAL SAND BEACH LLC

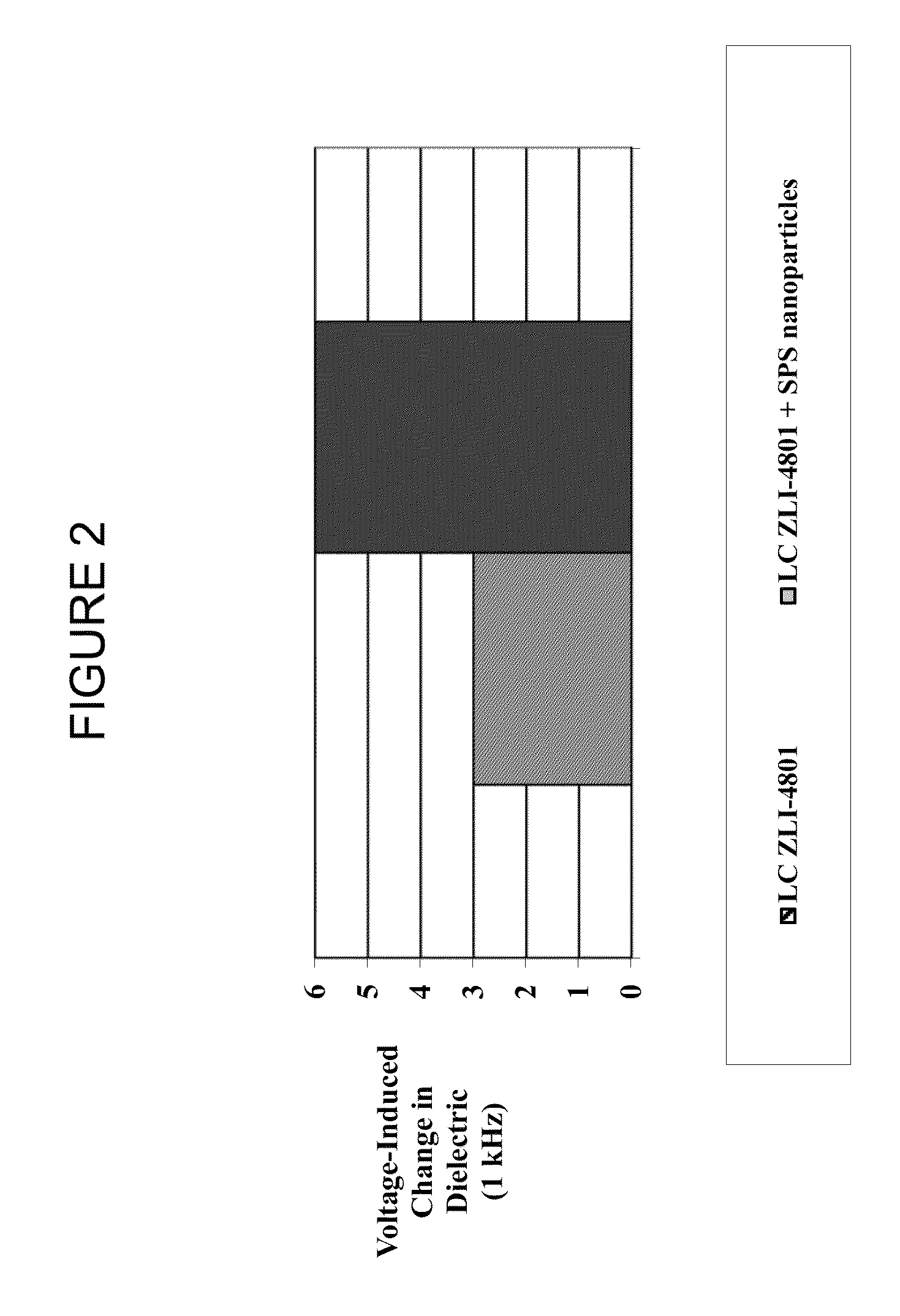

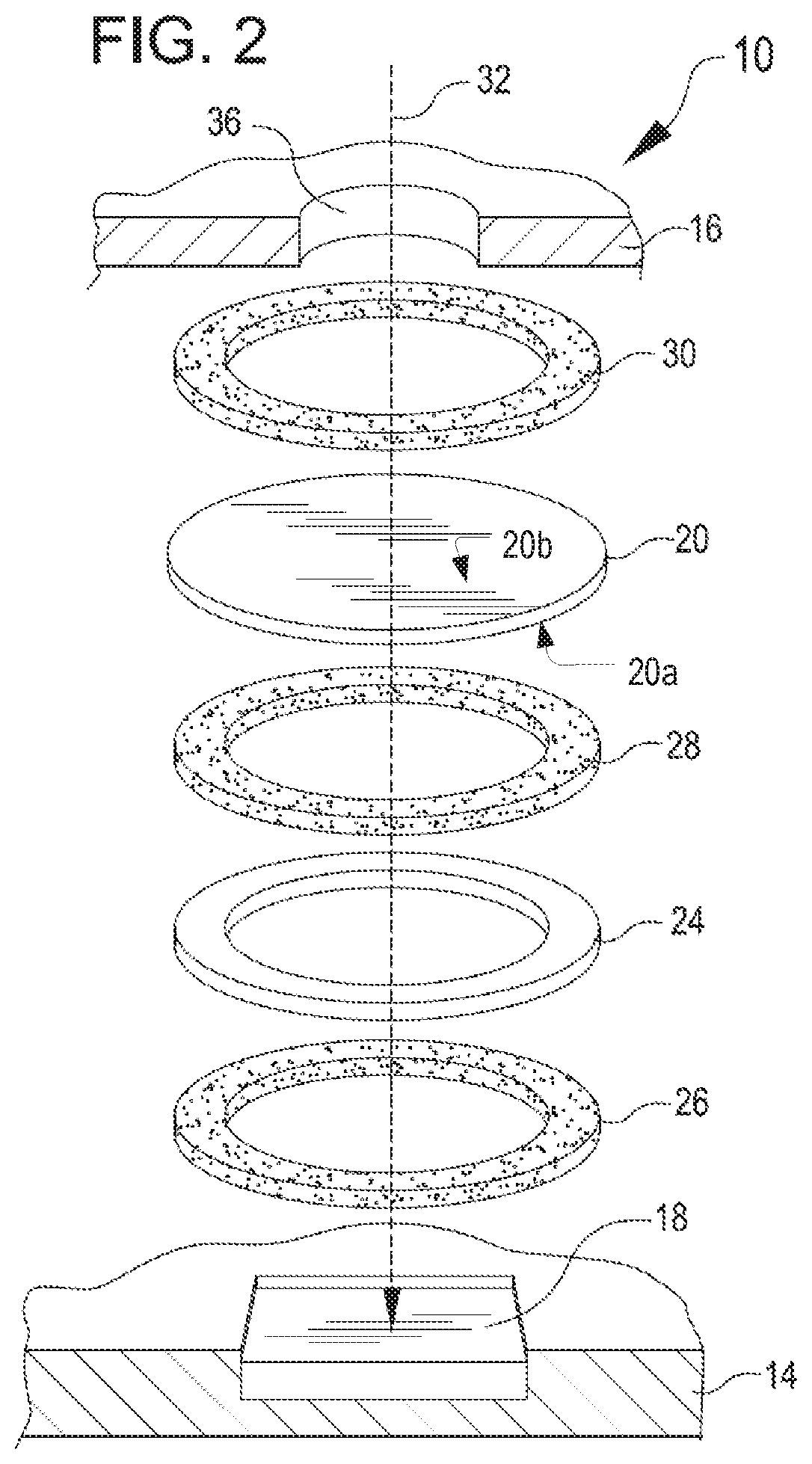

Nanoparticle-enhanced liquid crystal radio frequency phase shifter

InactiveUS20140022029A1Improve circuit performanceMinimal insertion lossNanoopticsDelay linesNanoparticleGround plane

A nanoparticle-enhanced liquid crystal phase shifter is provided including a first substrate layer, a plurality of electrodes attached to the substrate layer, a ground plane layer attached to a second substrate layer, and a liquid crystal layer between the ground plane layer and the first substrate layer, including a suspension of a liquid crystal material and highly polarizable nanoparticles having specific shape and size characteristics.

Owner:UNIV OF COLORADO THE REGENTS OF

Heating/sensing catheter appratus for minimally invasive applications

InactiveUS20140012132A1Minimally invasiveMinimal insertion lossElectrotherapyCatheterCoaxial cableElectrical conductor

Owner:CORAL SAND BEACH LLC

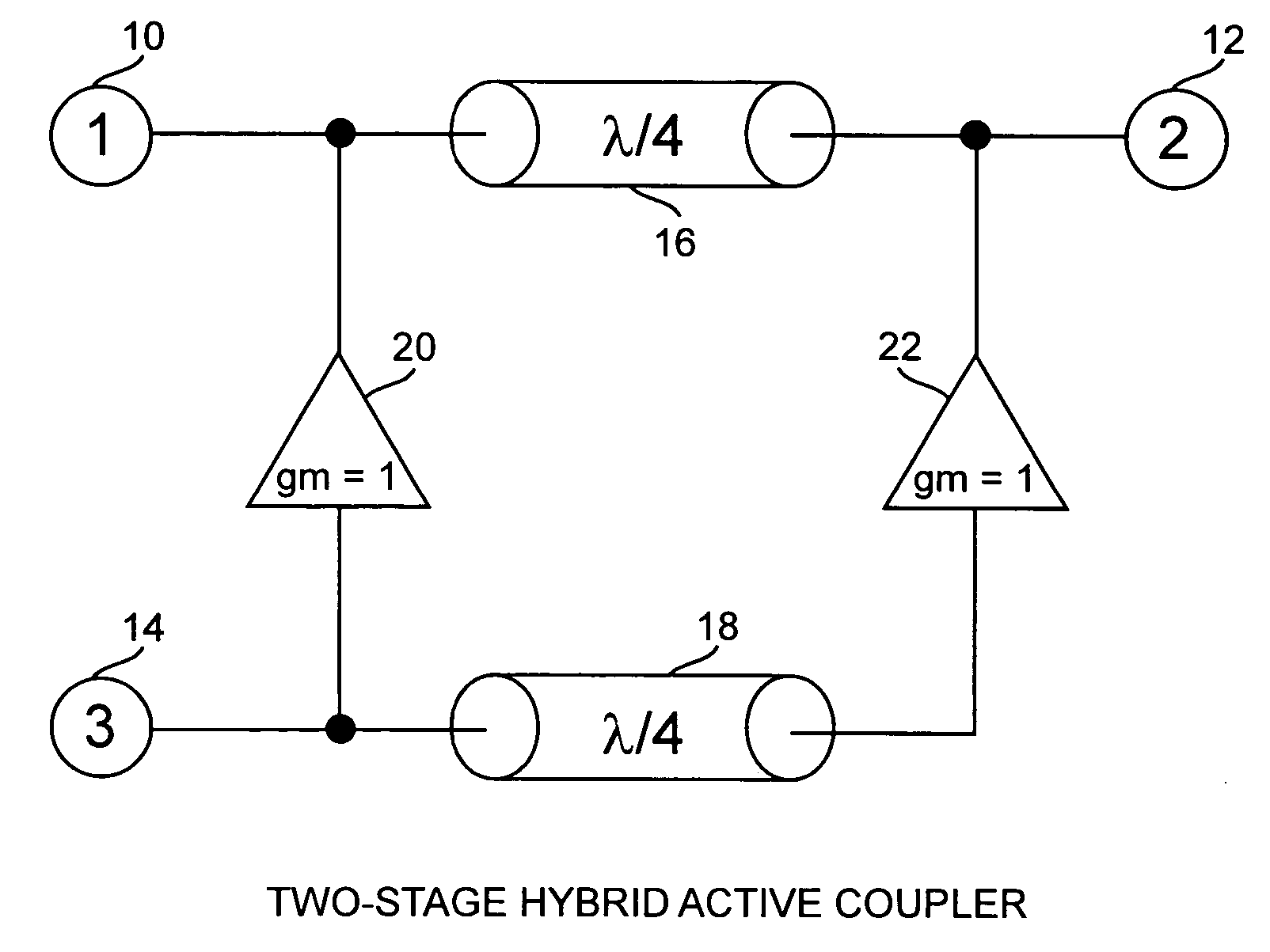

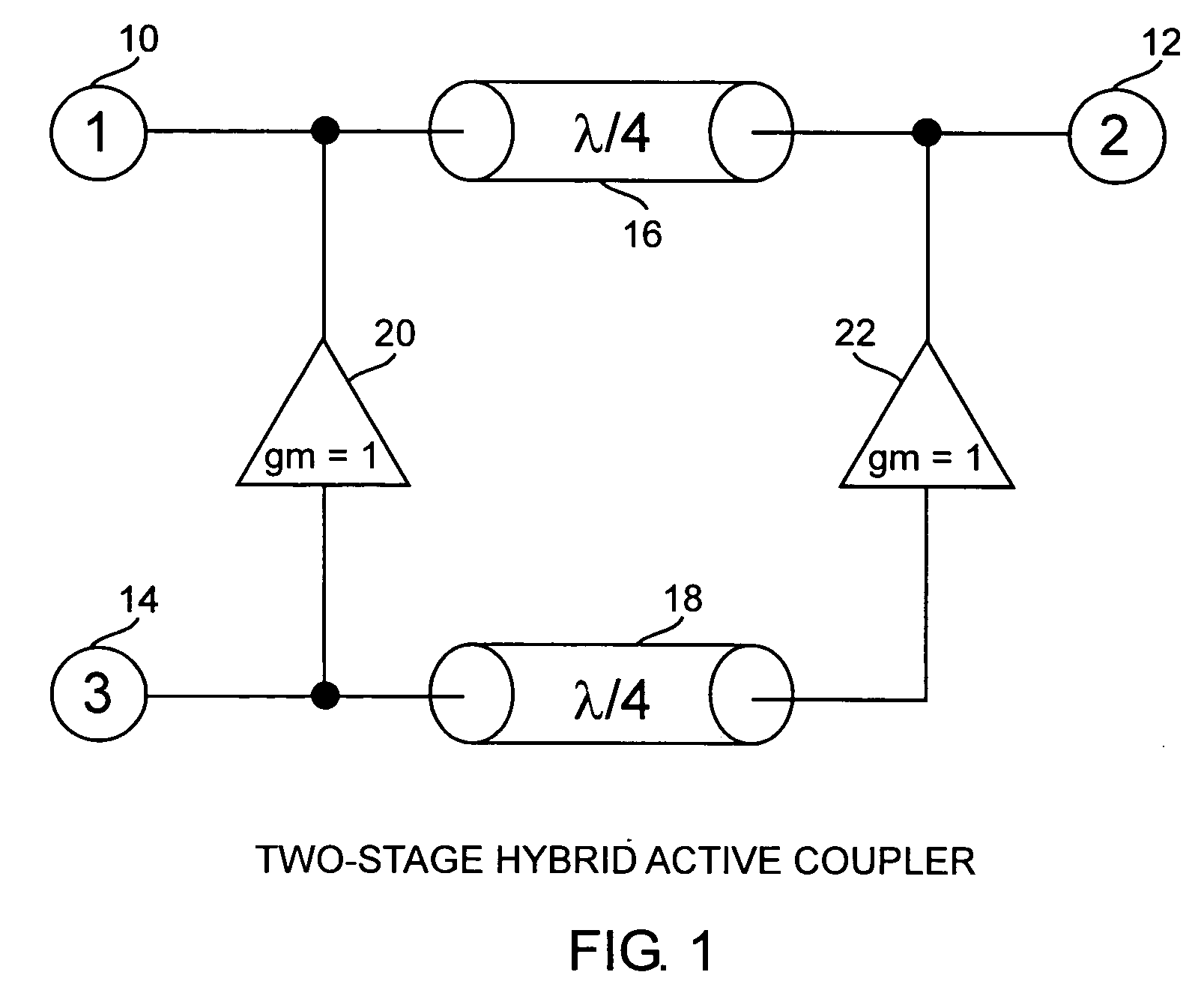

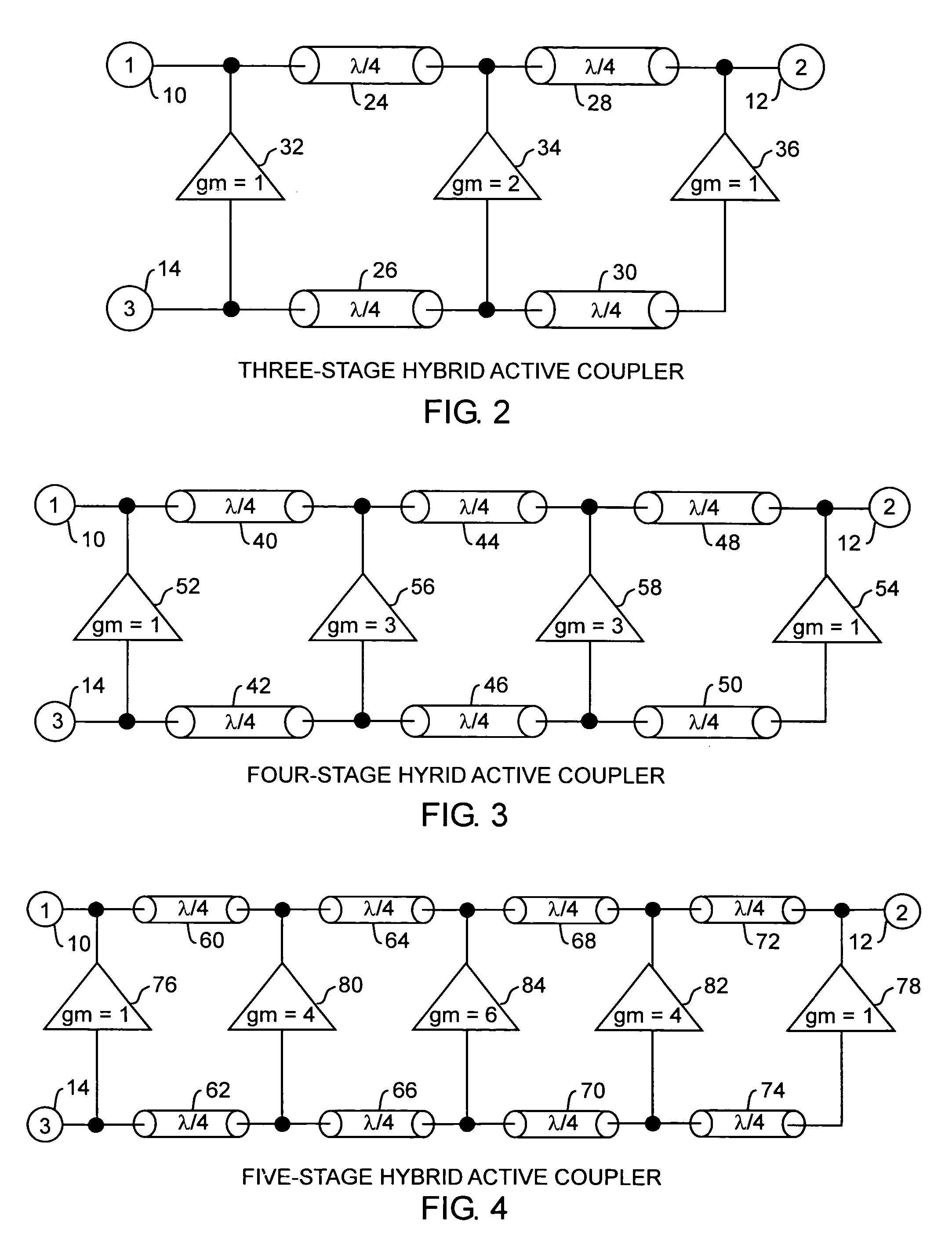

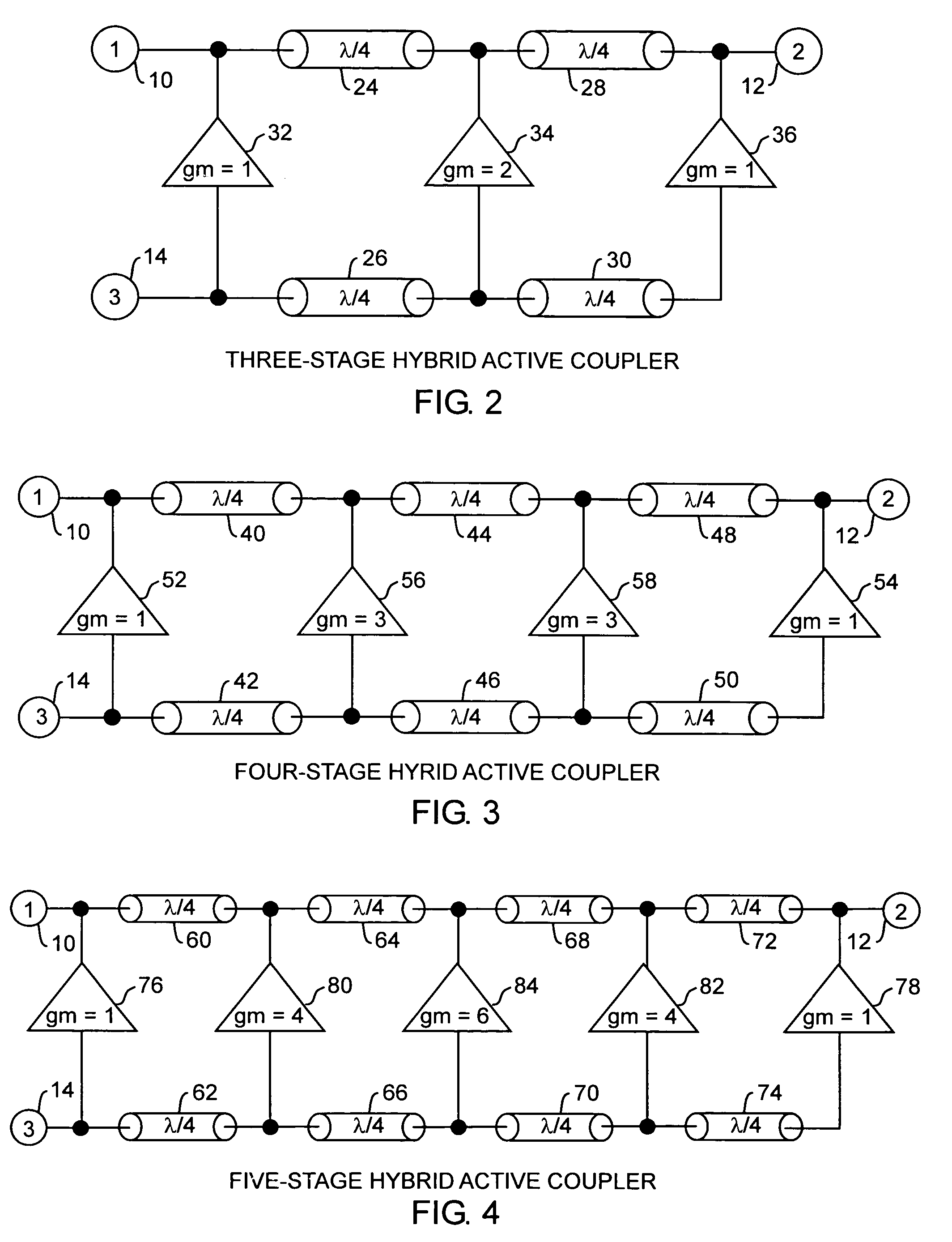

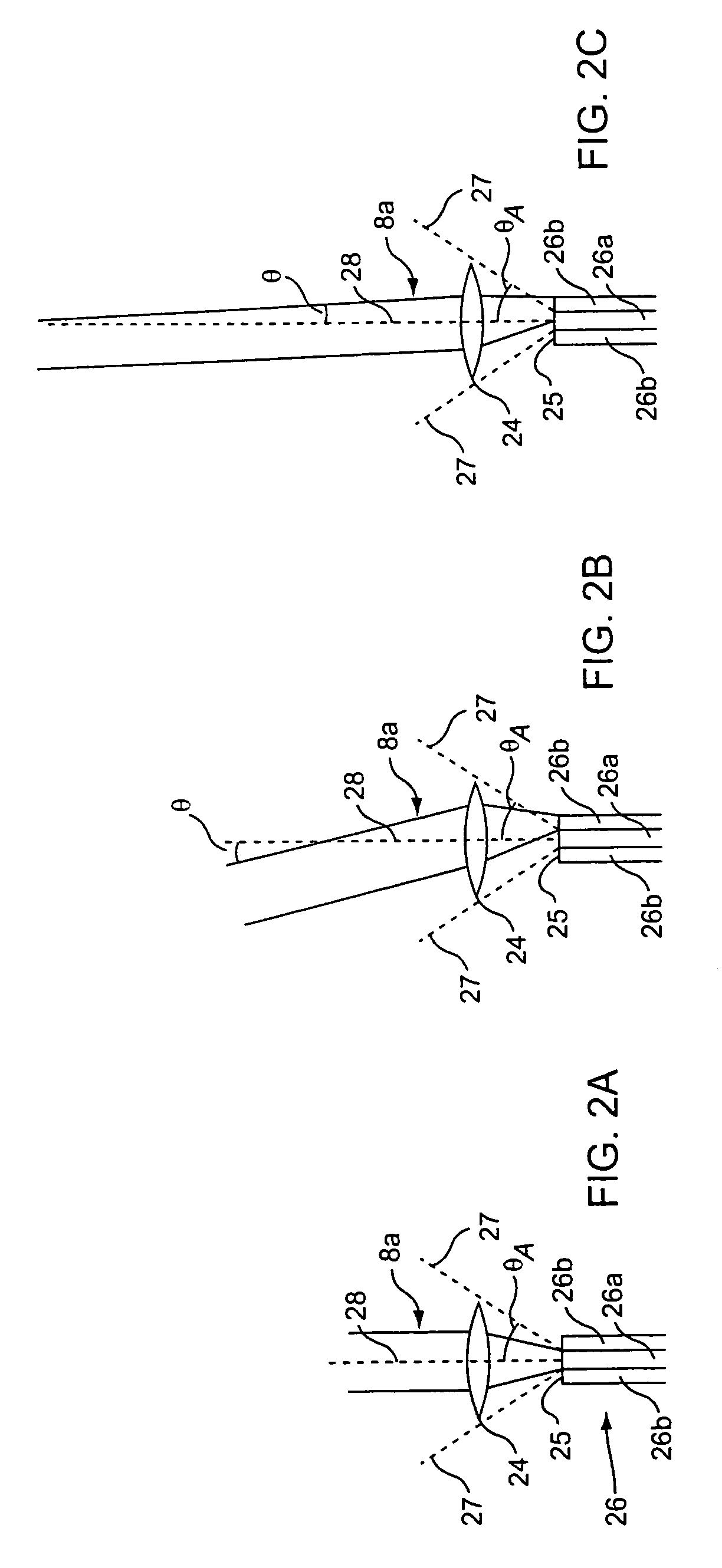

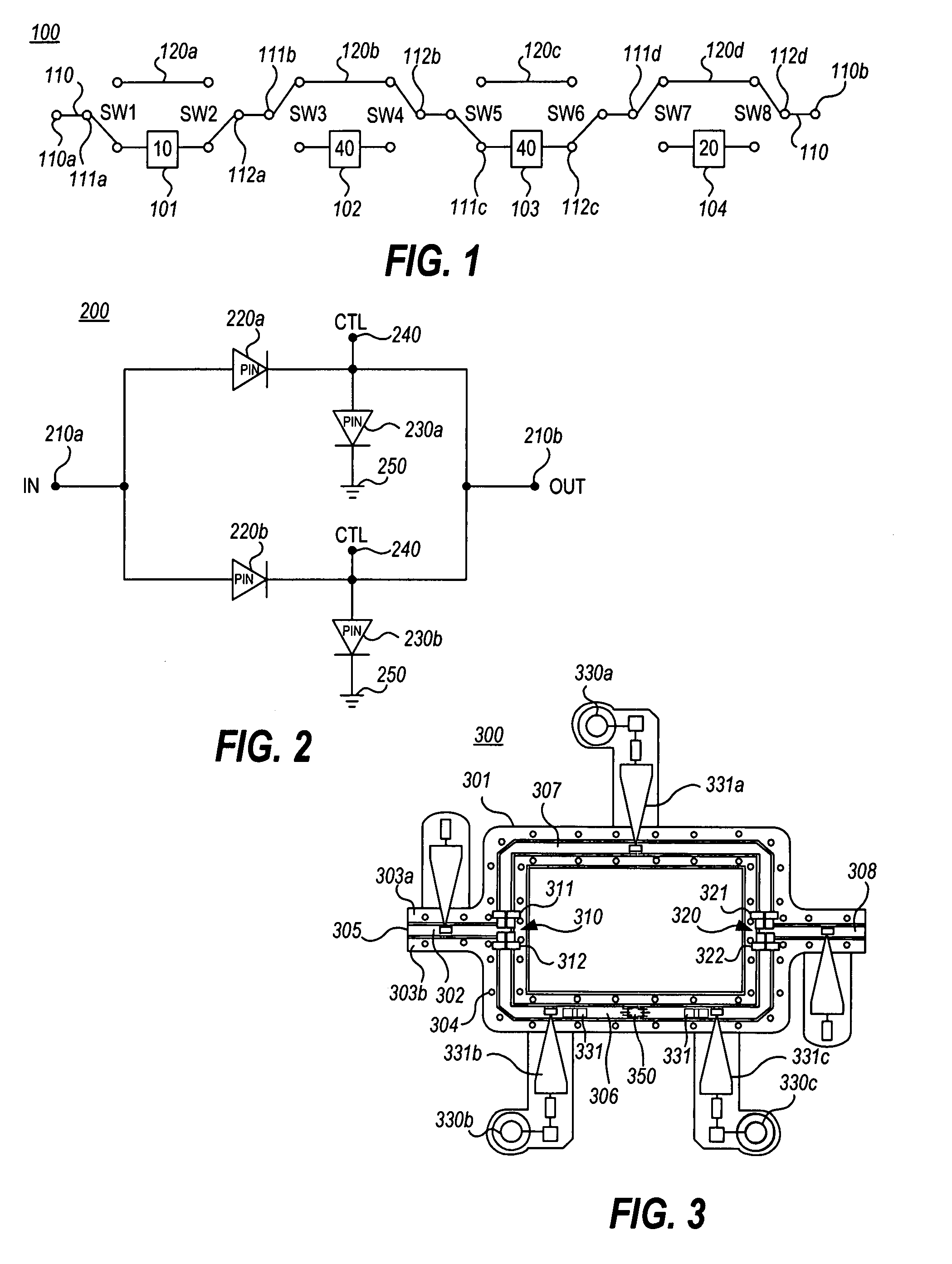

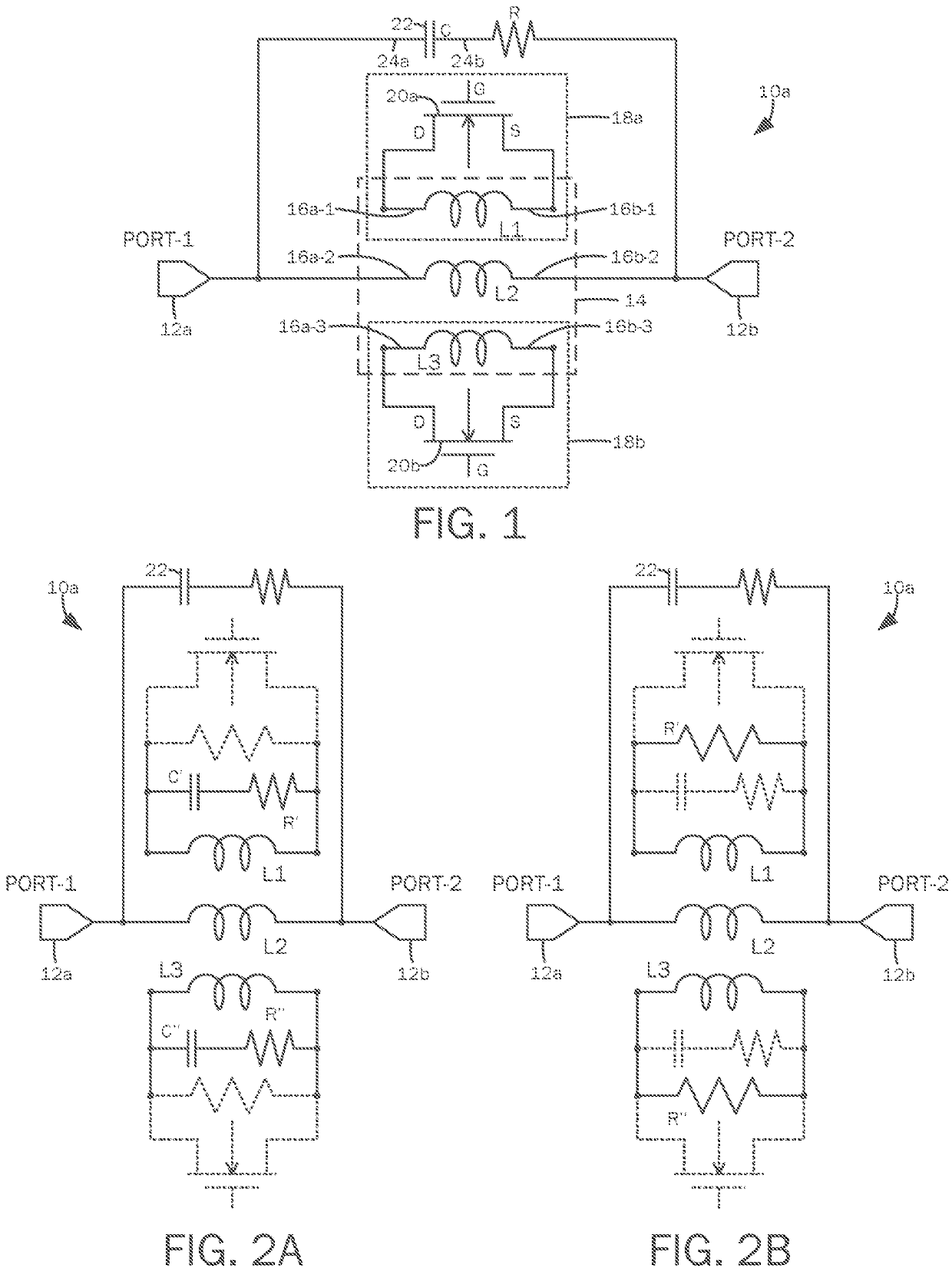

Hybrid active combiner and circulator

ActiveUS20060087376A1Reduced insertion lossMinimal insertion lossAmplifiers wit coupling networksAmplifier detailsTransceiverValue set

The hybrid active combiner and circulators serves as a coupler and is a three port network that integrates a directional coupler topology with active devices placed in the coupling paths in order to synthesize a low-loss active combiner circuit or a circulator device with minimal insertion losses. The coupler can have multiple stage amplifiers with transconductance values set according the Pascal's triangle for improved performance, and can function as a low cost and low weight transceiver well suited for various communications systems.

Owner:THE AEROSPACE CORPORATION

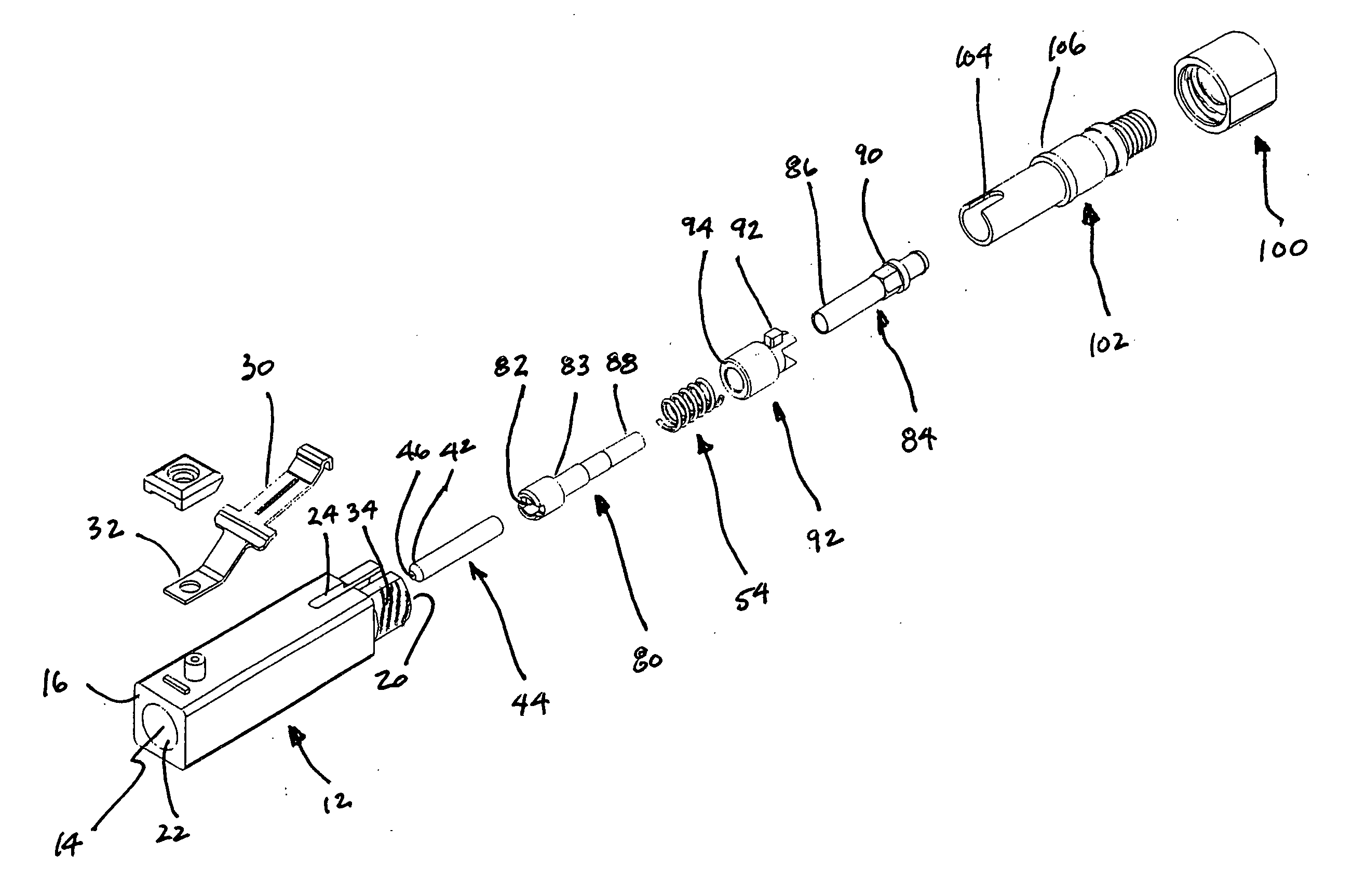

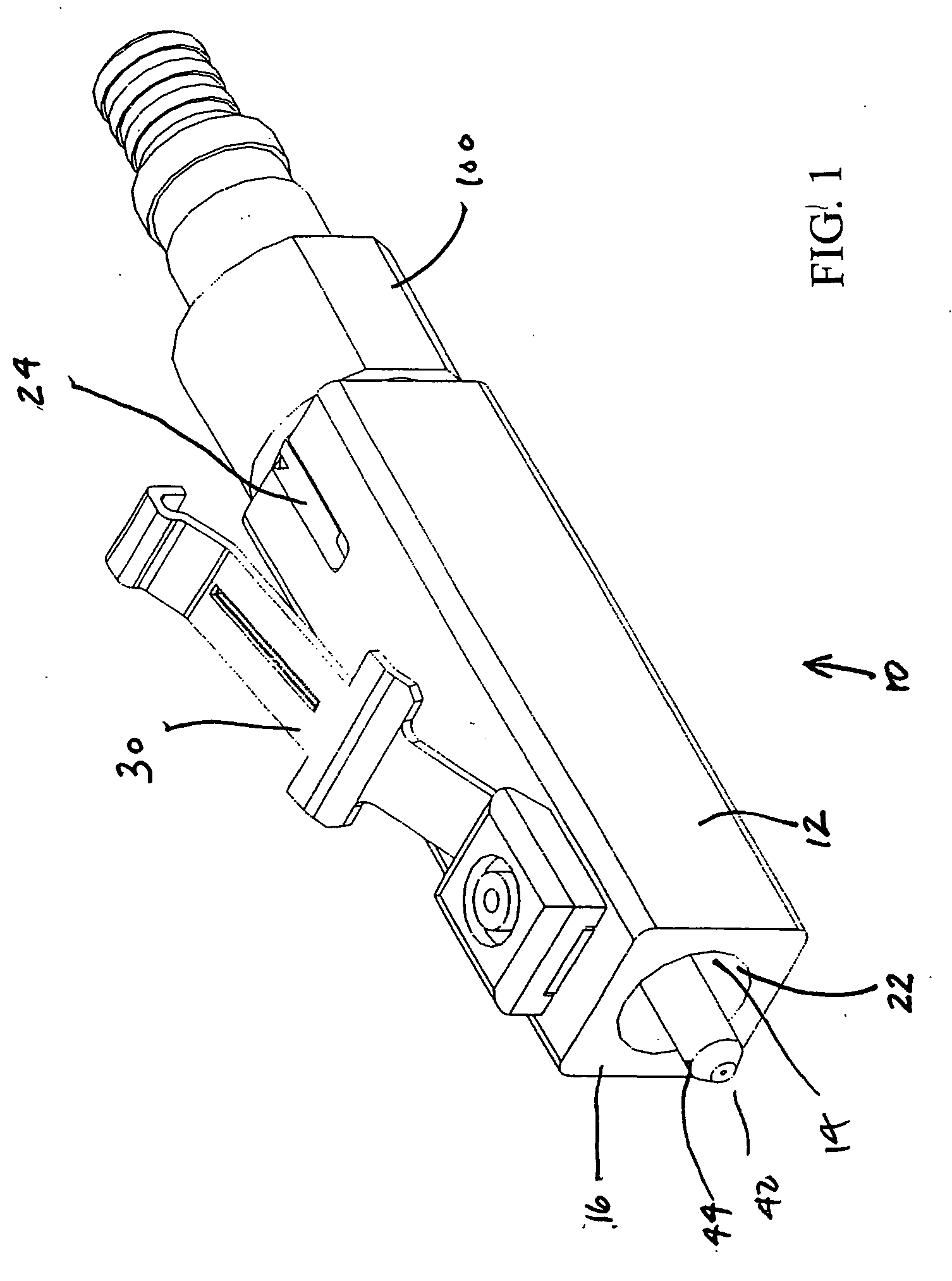

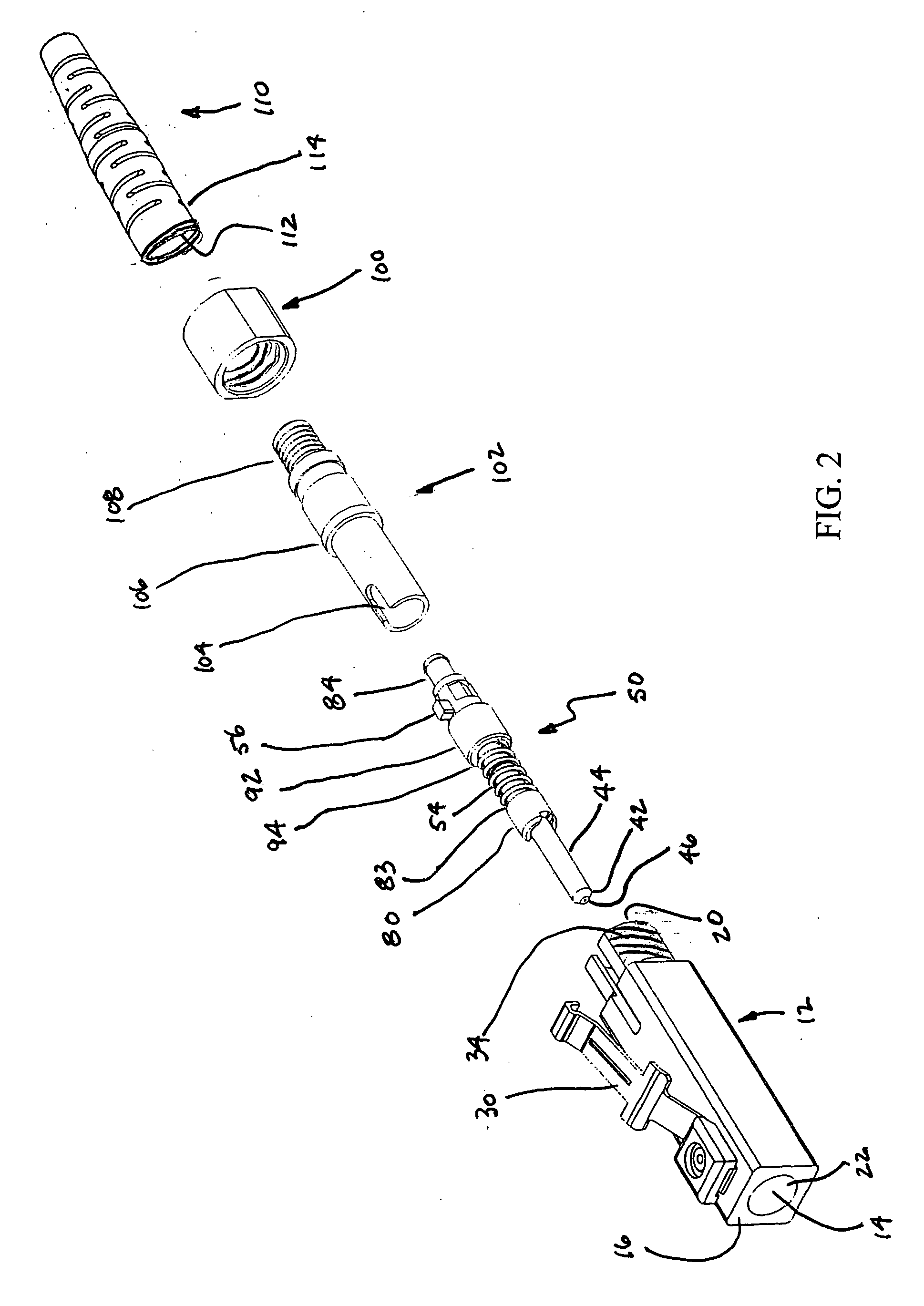

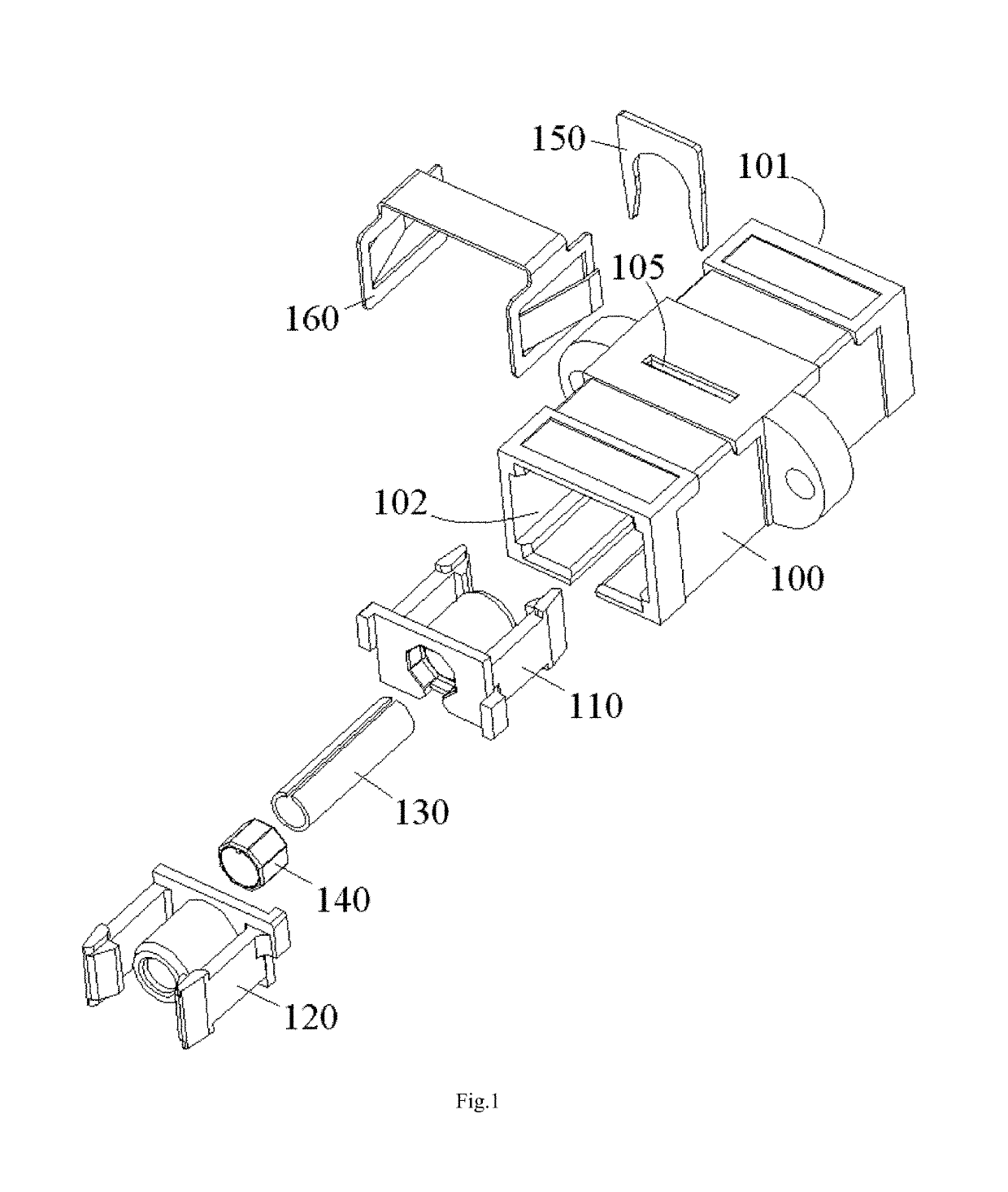

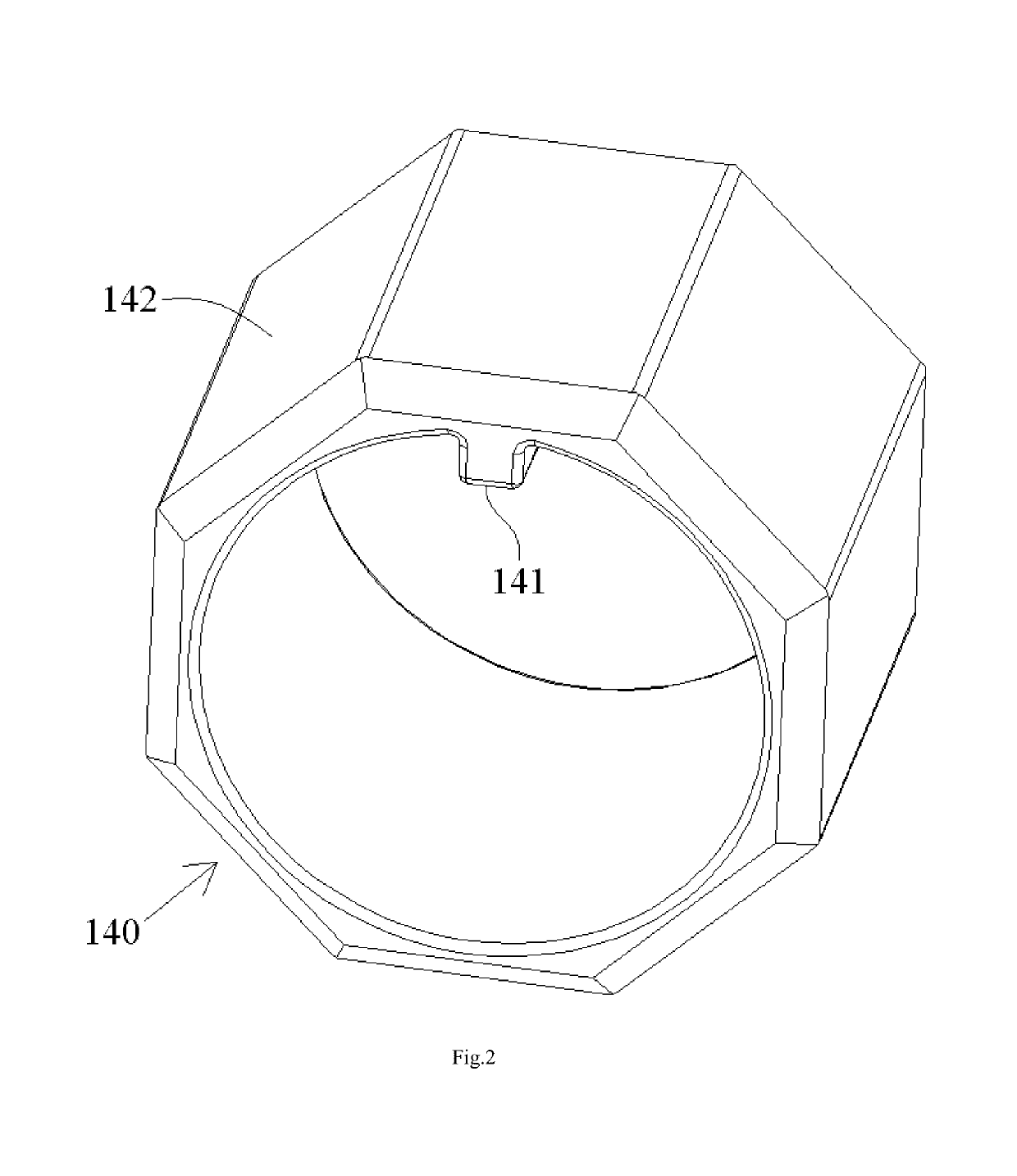

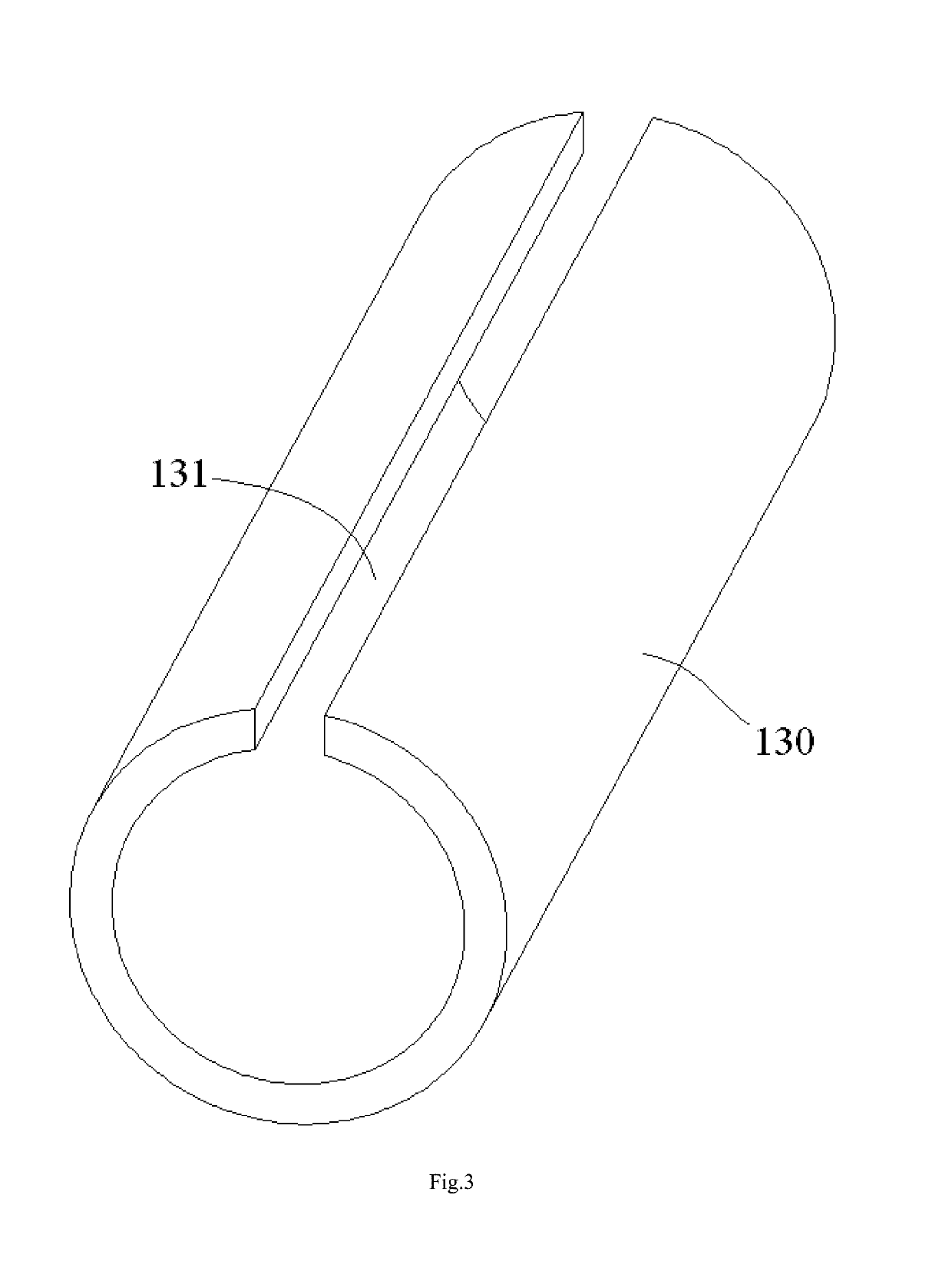

Indexed optical fiber connector

A high-performance connector for optical fibers includes a cylindrical ceramic or metallic ferrule installed in a structure. This structure is positioned in a non-plastic (metallic system) base member to form a fiber holder. This overall generally cylindrical structure includes a small passageway along its central axis for holding an optical fiber. This entire structure is mounted within the non-plastic housing that includes an opening at one end thereof from which the ceramic ferrule protrudes. A cylindrical spring that is integral to the ferrule support structure and interacts with an interior surface of the surrounding structure via a secondary piece of the cylindrical structure urges the ceramic ferrule outward from the opening in the housing. The housing includes a metallic leaf-spring latch which is located on a single surface thereof, which is manually operable and used to lock the connector to an associated receptacle. Said connector; because it is manufactured of non-plastics in its structural elements (metallics and / or ceramics) has very stable optical performance criteria over a broad range of environments (both thermal and mechanical). The high performance optical connector also introduces the ability to remove the cylindrical fiber holder to directly inspect or clean the sensitive internal components (springs, internal metallic or ceramic components). In addition, the cylindrical structure provides a mean of “tuning” it to remove the effects of fiber eccentricity. When tuned, the fiber holder retains such tuning even outside the housing allowing re-assembly of the high-performance connector without loss of “tuning”.

Owner:MOLEX INC

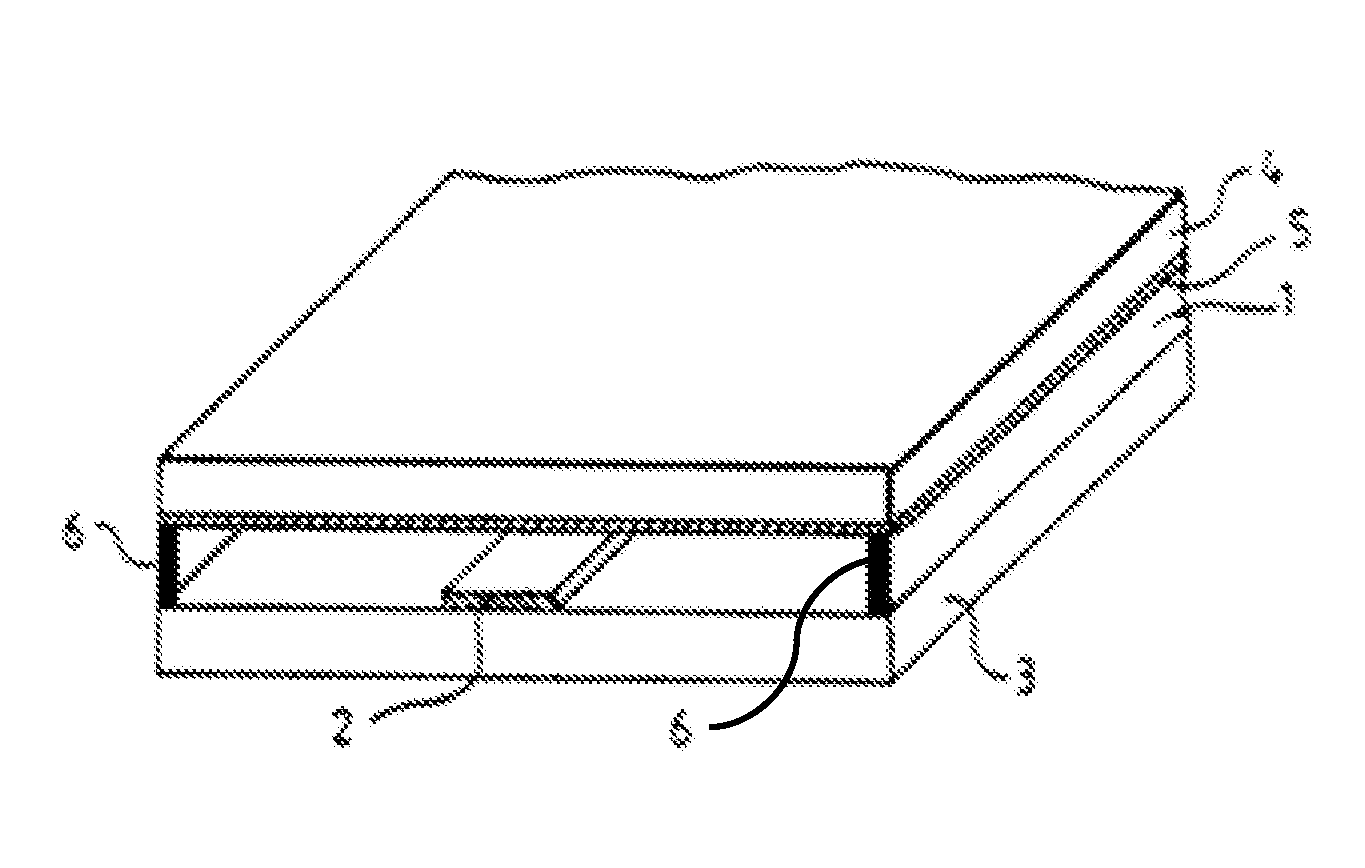

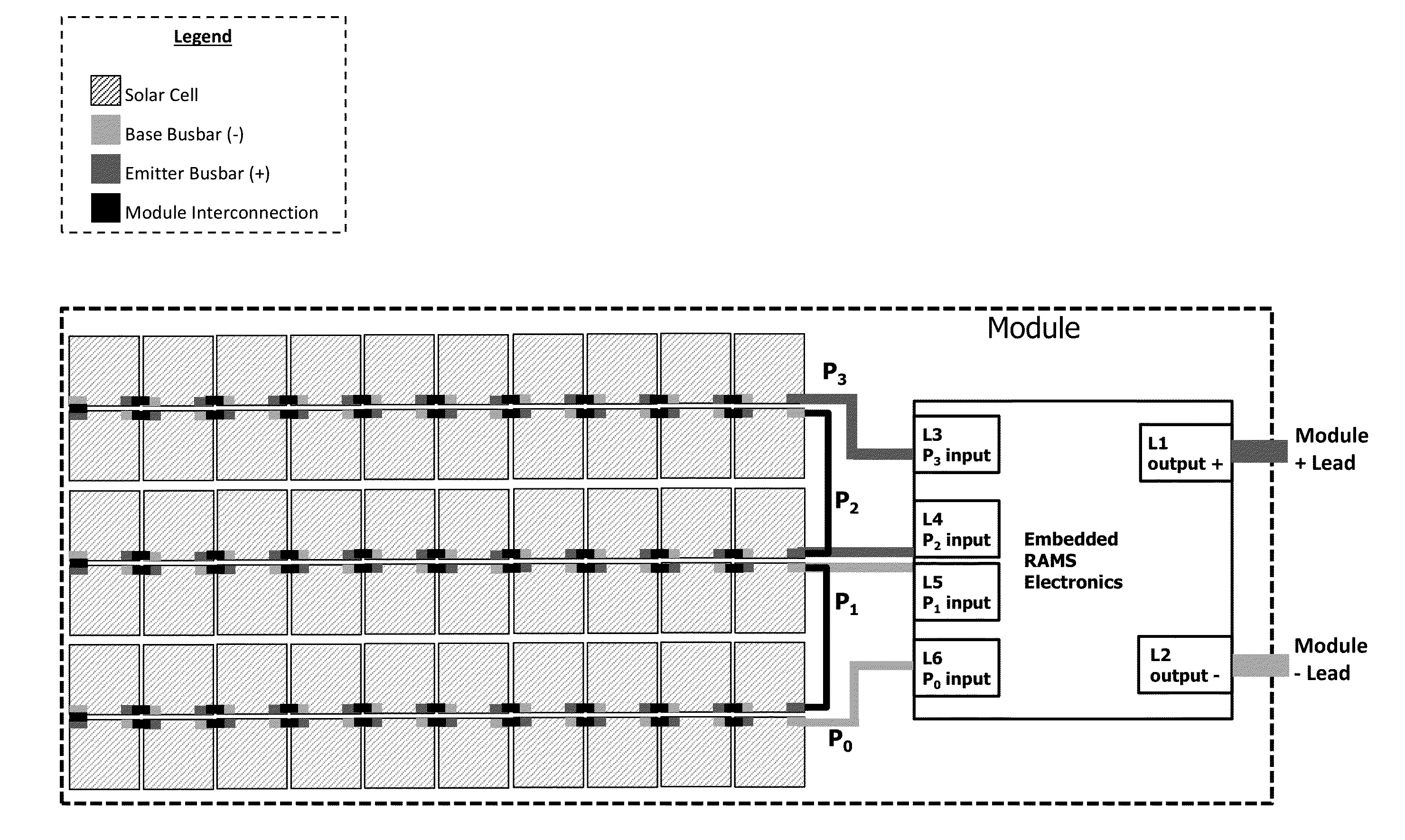

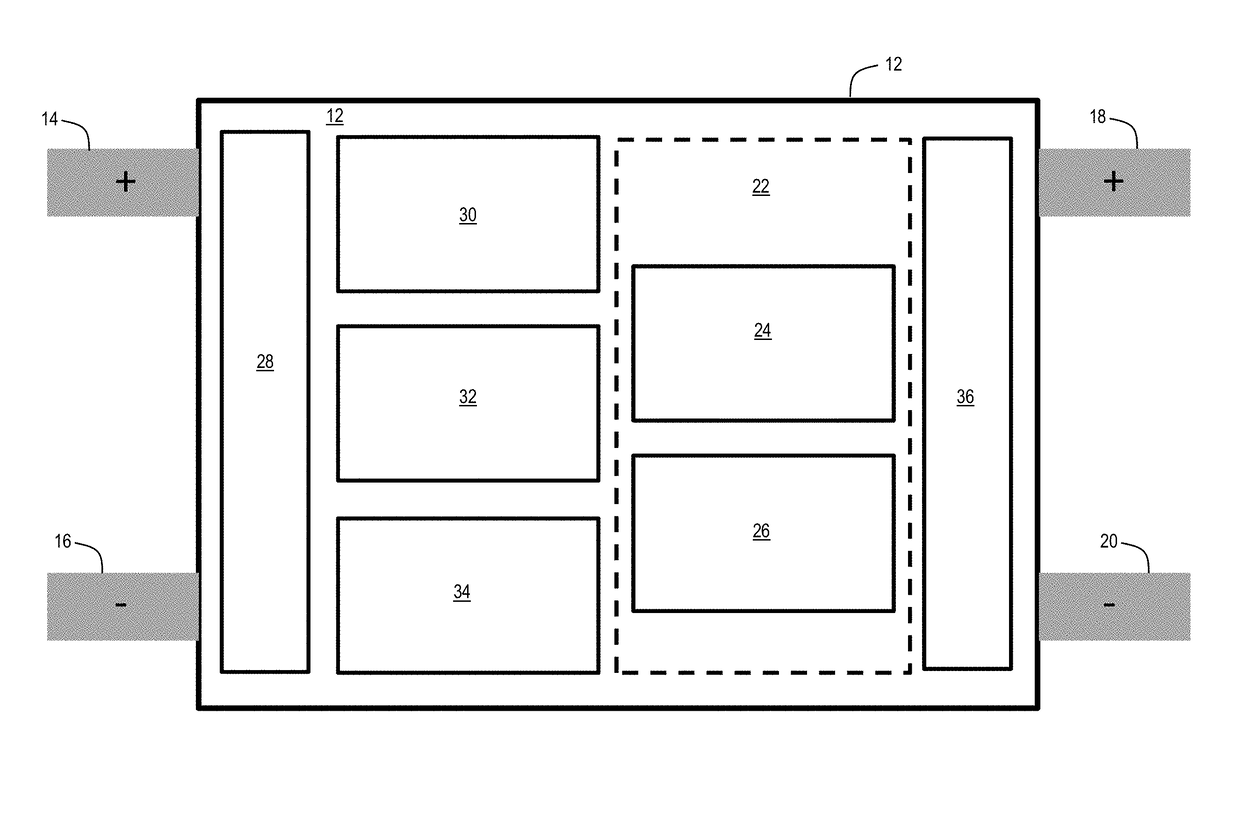

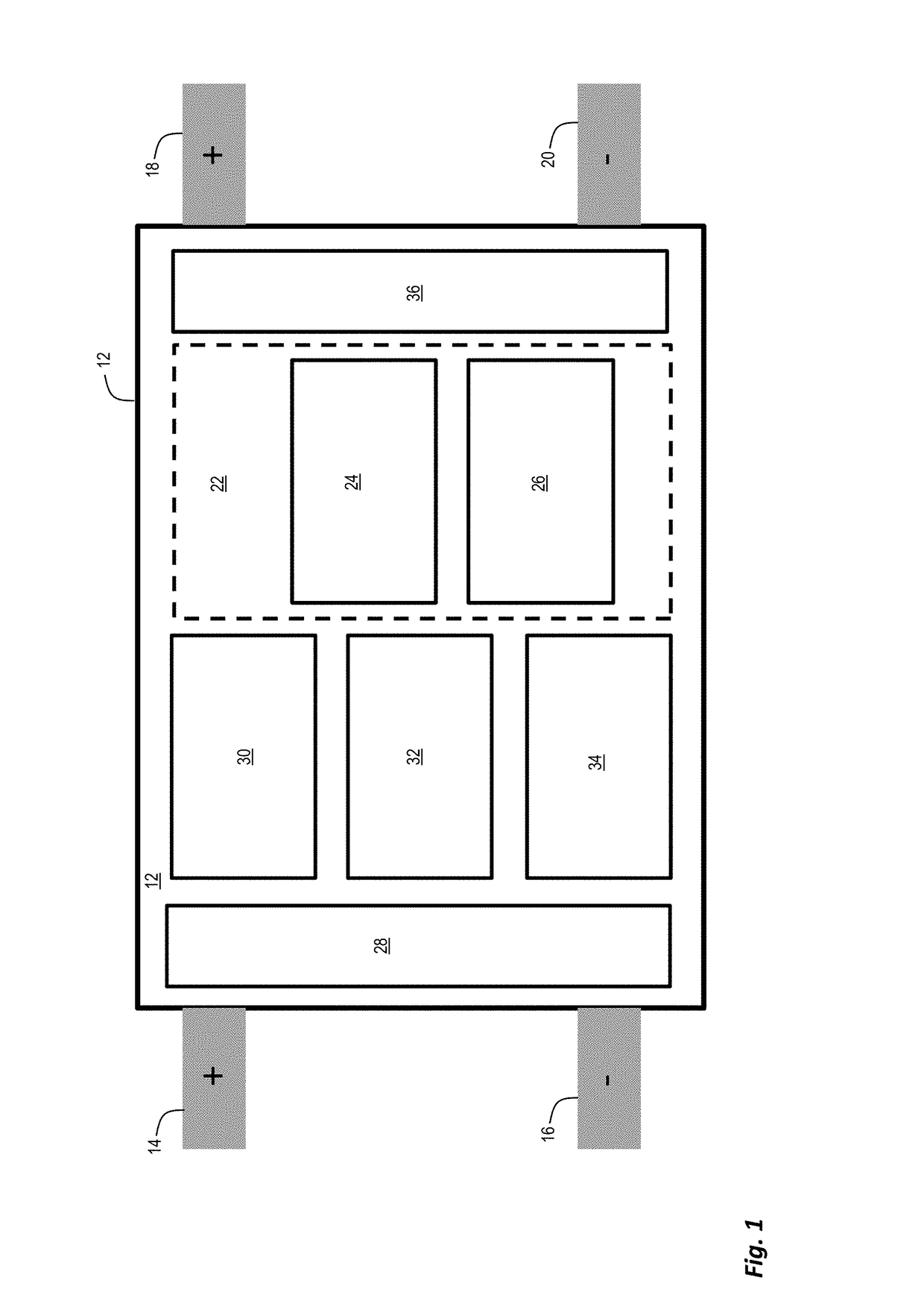

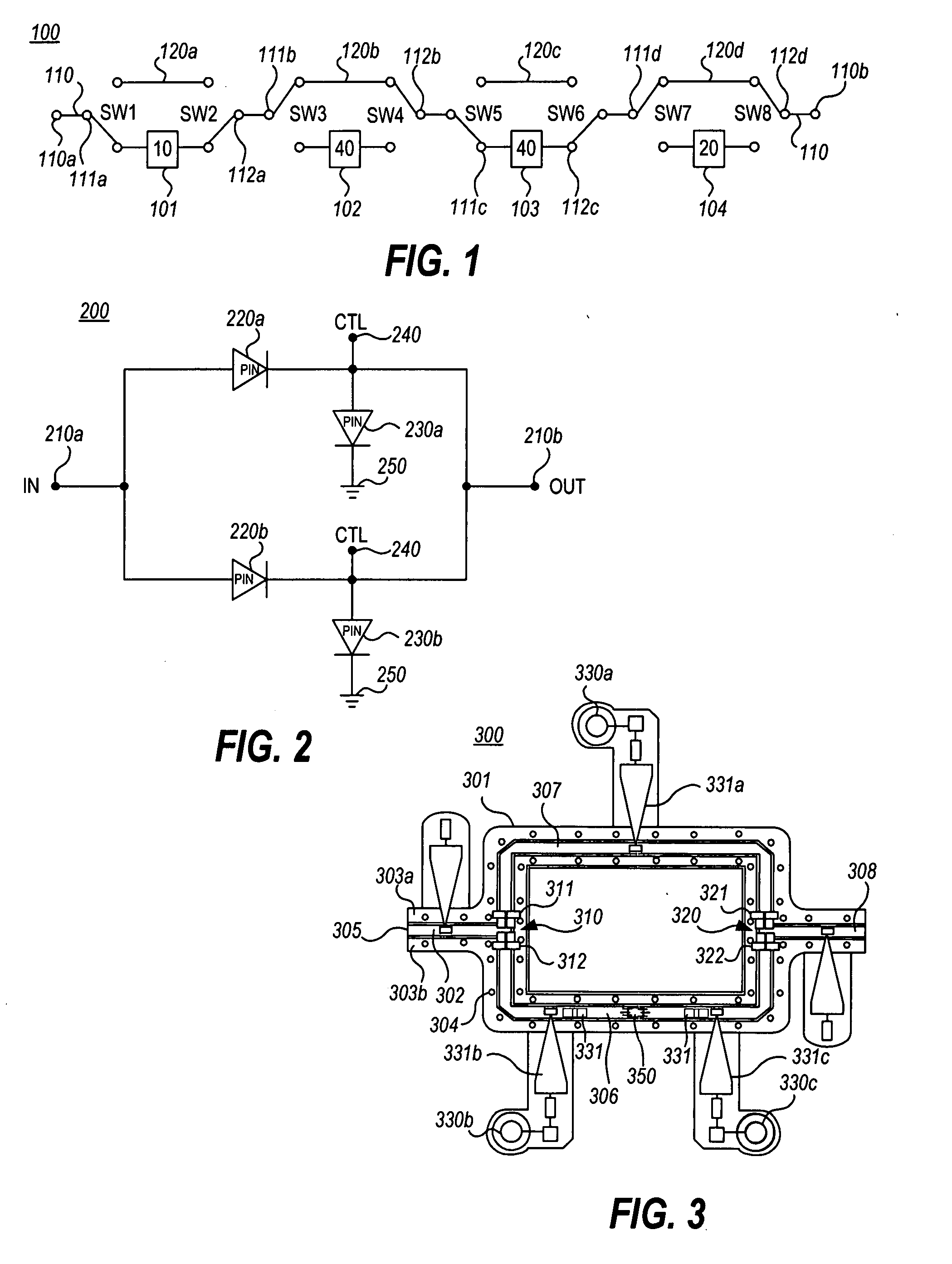

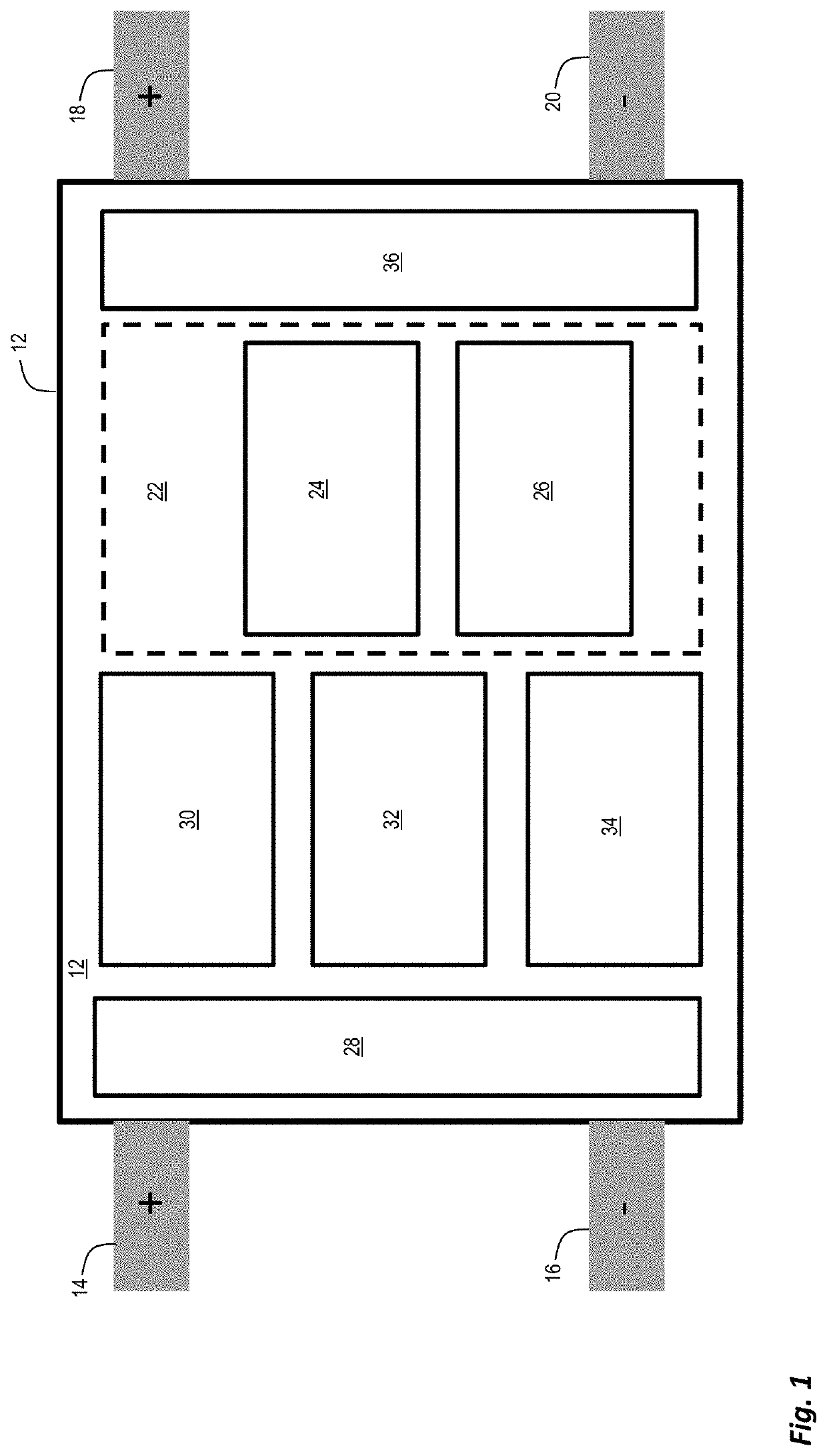

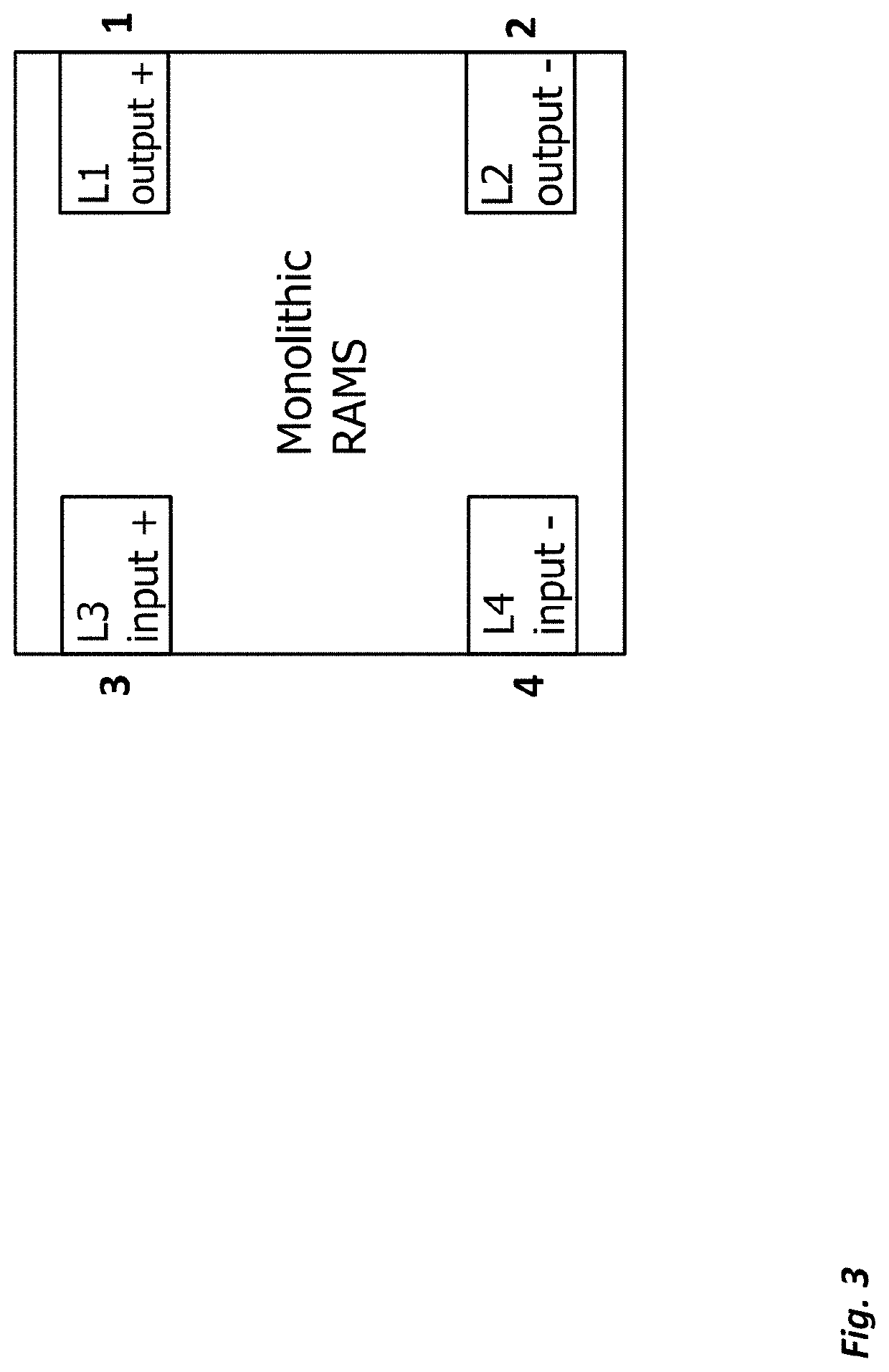

Solar photovoltaic module power control and status monitoring system utilizing laminate-embedded remote access module switch

InactiveUS20150349708A1Eliminates and reduces disadvantageImprove securityPhotovoltaic supportsPV power plantsElectricityRemote control

A solar photovoltaic module laminate for electric power generation is provided. The module comprises a plurality of solar cells embedded within the module laminate and electrically interconnected to form at least one string of electrically interconnected solar cells within said module laminate. And at least one remote-access module switch (RAMS) power electronic circuit embedded within the module laminate electrically interconnected to and powered with said at least one string of electrically interconnected solar cells and serving as a remote-controlled module power delivery gate switch.

Owner:BEAMREACH SOLAR INC +1

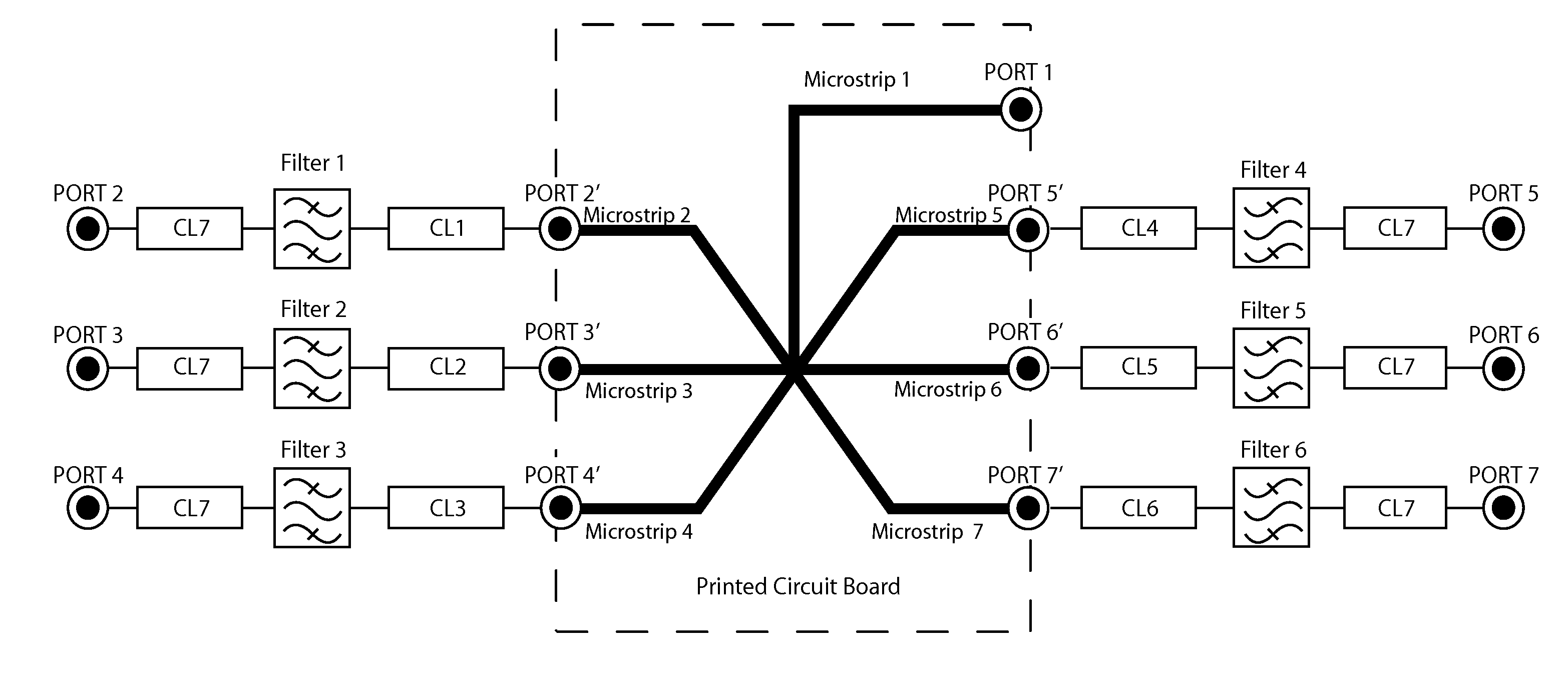

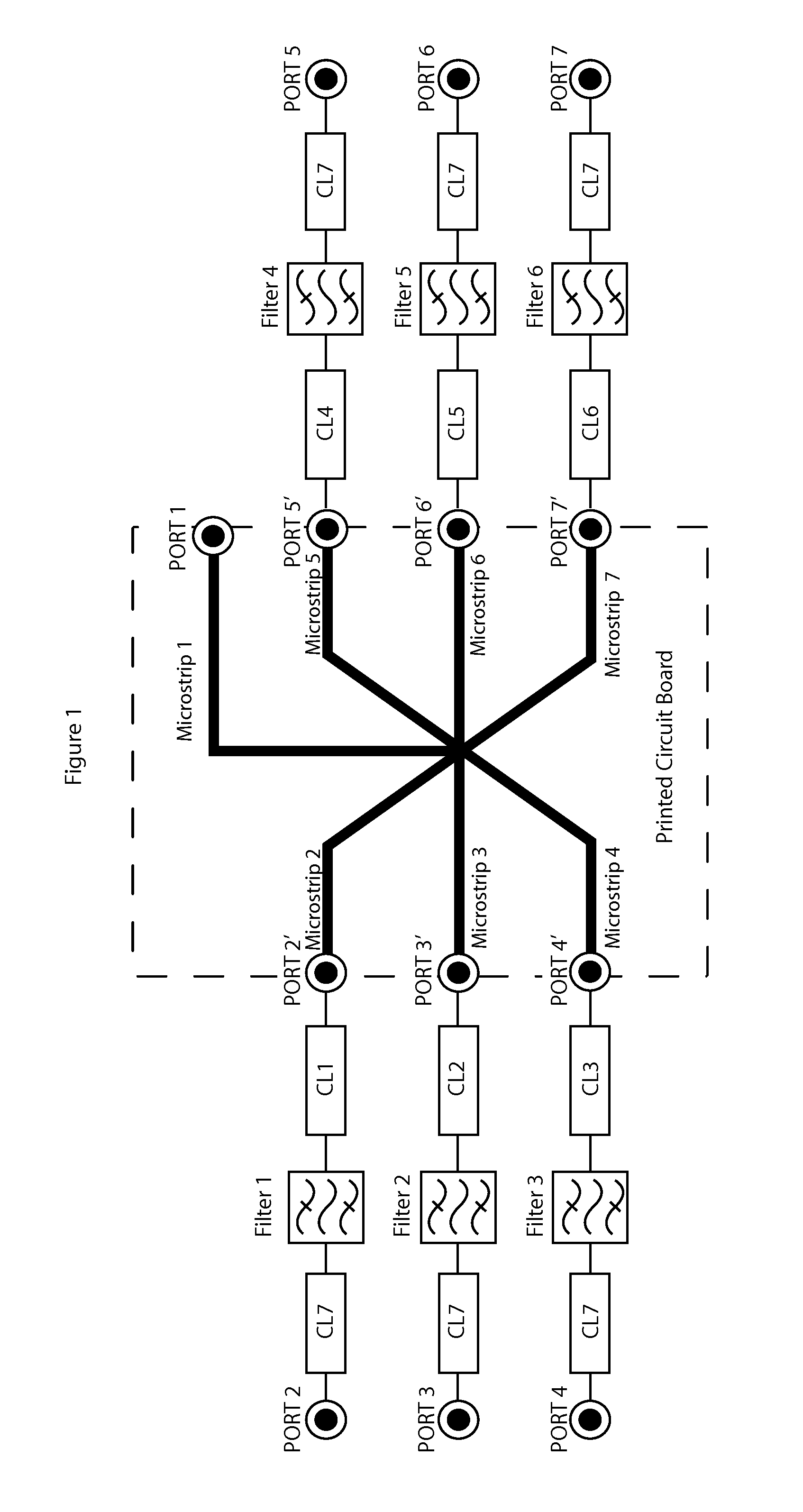

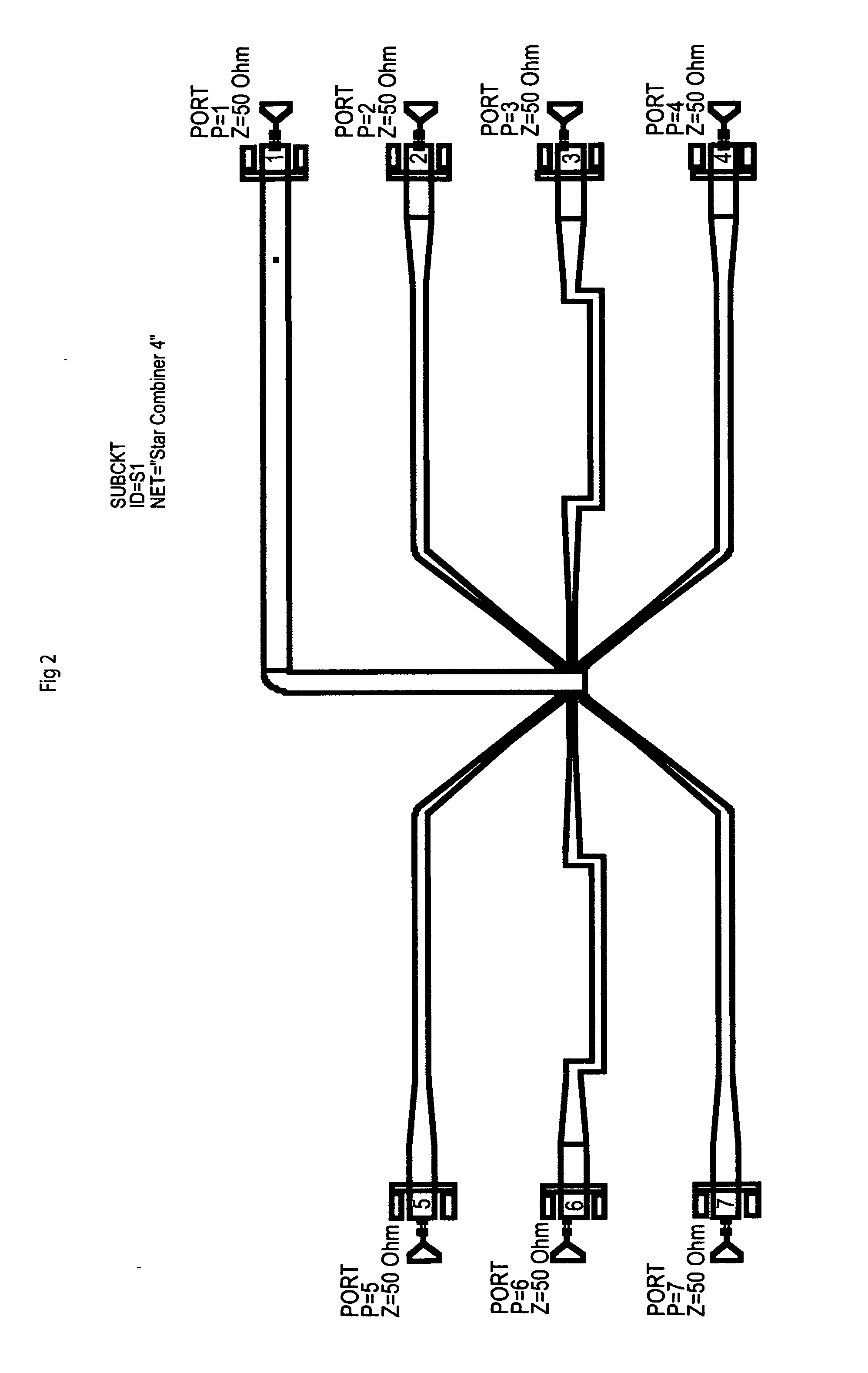

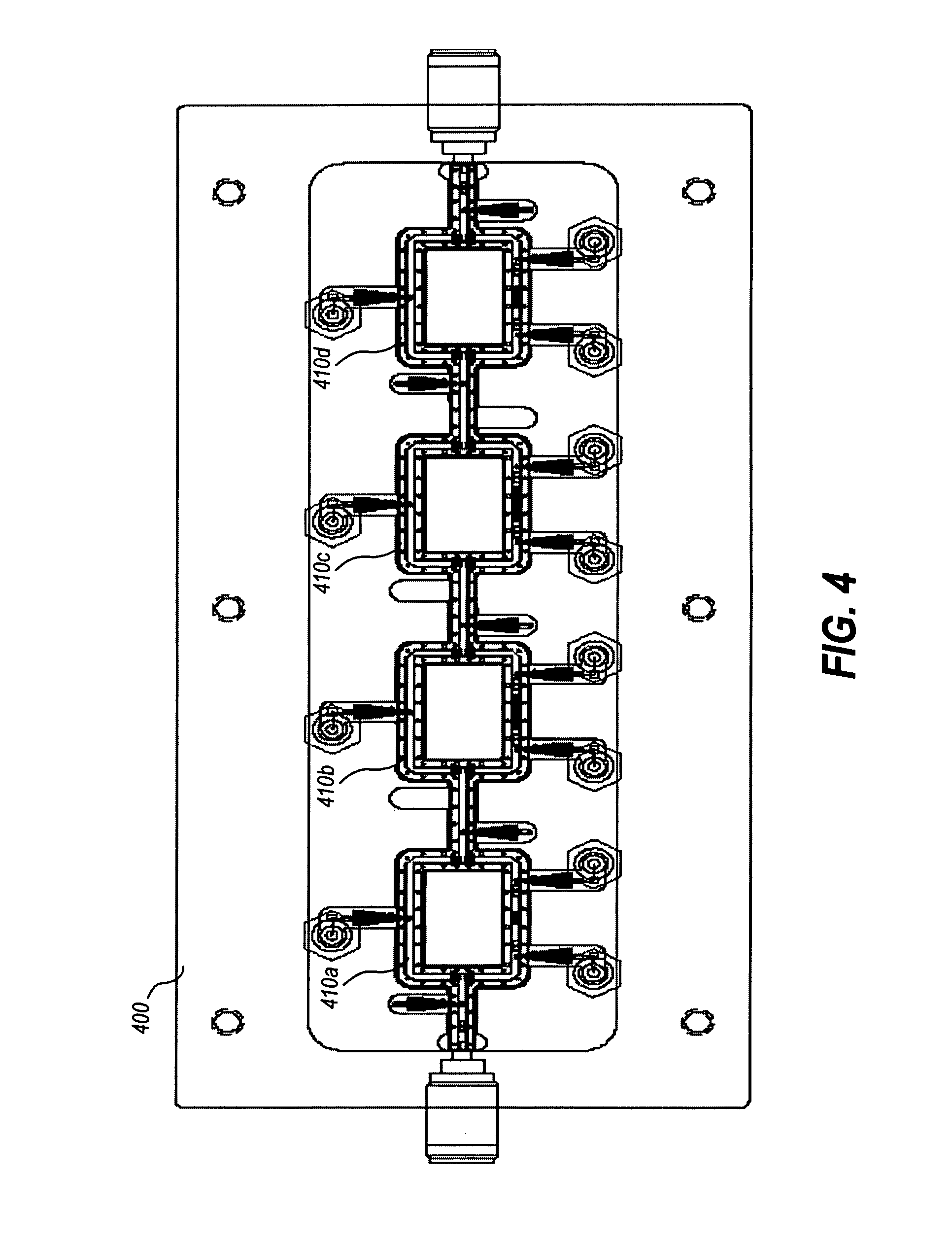

Low loss RF transceiver combiner

InactiveUS20120019336A1Minimal insertion lossInsertion loss experienced by this technique is minimalCoupling devicesCoaxial cableTransceiver

A Radio Frequency (RF) splitter / combiner technique for splitting and combining RF signals using a combination of microstrip traces and coaxial cable for an N-port network is disclosed.

Owner:VISLINK TECH INC

Hybrid active combiner and circulator

ActiveUS7129783B2Reduced insertion lossMinimal insertion lossAmplifiers wit coupling networksAmplifier detailsTransceiverValue set

The hybrid active combiner and circulators serves as a coupler and is a three port network that integrates a directional coupler topology with active devices placed in the coupling paths in order to synthesize a low-loss active combiner circuit or a circulator device with minimal insertion losses. The coupler can have multiple stage amplifiers with transconductance values set according the Pascal's triangle for improved performance, and can function as a low cost and low weight transceiver well suited for various communications systems.

Owner:THE AEROSPACE CORPORATION

Alignment sleeve assembly and fiber optic adapter

ActiveUS10302874B2Improve alignment accuracyMinimal insertion lossCoupling light guidesFiberEngineering

A fiber optic adapter, including: a mating retainer; an alignment sleeve received in the mating retainer, a ferrule of a fiber optic connector being adapted to be inserted into the alignment sleeve through an insertion port of the fiber optic adapter; and an adjustment element configured to adjust a circumferential angle of the alignment sleeve relative to the mating retainer to a predetermined circumferential angle and hold the alignment sleeve at the predetermined circumferential angle relative to the mating retainer. The adjustment element may adjust the circumferential angle of the alignment sleeve with respect to the mating retainer to the predetermined circumferential angle, for example, at which the fiber insertion loss of the coupled connectors is minimal, and hold the alignment sleeve at the predetermined circumferential angle. In this way, it may improve the alignment accuracy of the coupled connectors.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

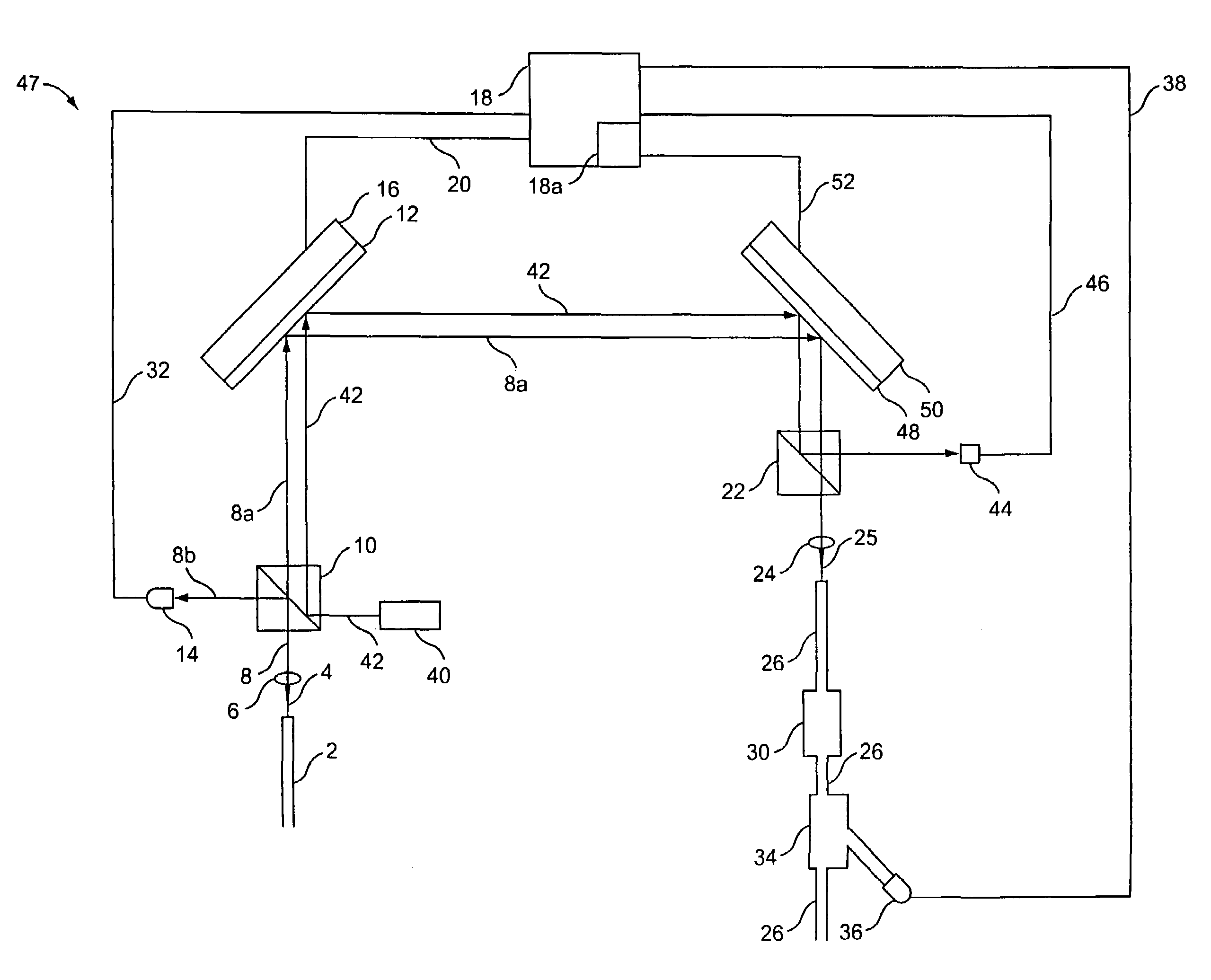

Variable optical attenuator

InactiveUS7076146B2Minimal insertion lossBetter networkCoupling light guidesOptical switchLight beam

A method of controllably attenuating a beam of light coupled into a port includes directing the beam of light against a mirror, and controlling an orientation of the mirror such that a predetermined fraction of the beam of light is coupled into the port. The predetermined fraction is less than a maximum fraction corresponding to optimal coupling of the beam of light into the port. The method may be implemented with a variable optical attenuator including a first port, a second port, a mirror located to direct light output by the first port to the second port, and a controller coupled to the mirror to align it such that the predetermined fraction of light is coupled into the second port. The method may also be implemented with an optical switch.

Owner:INTEL CORP

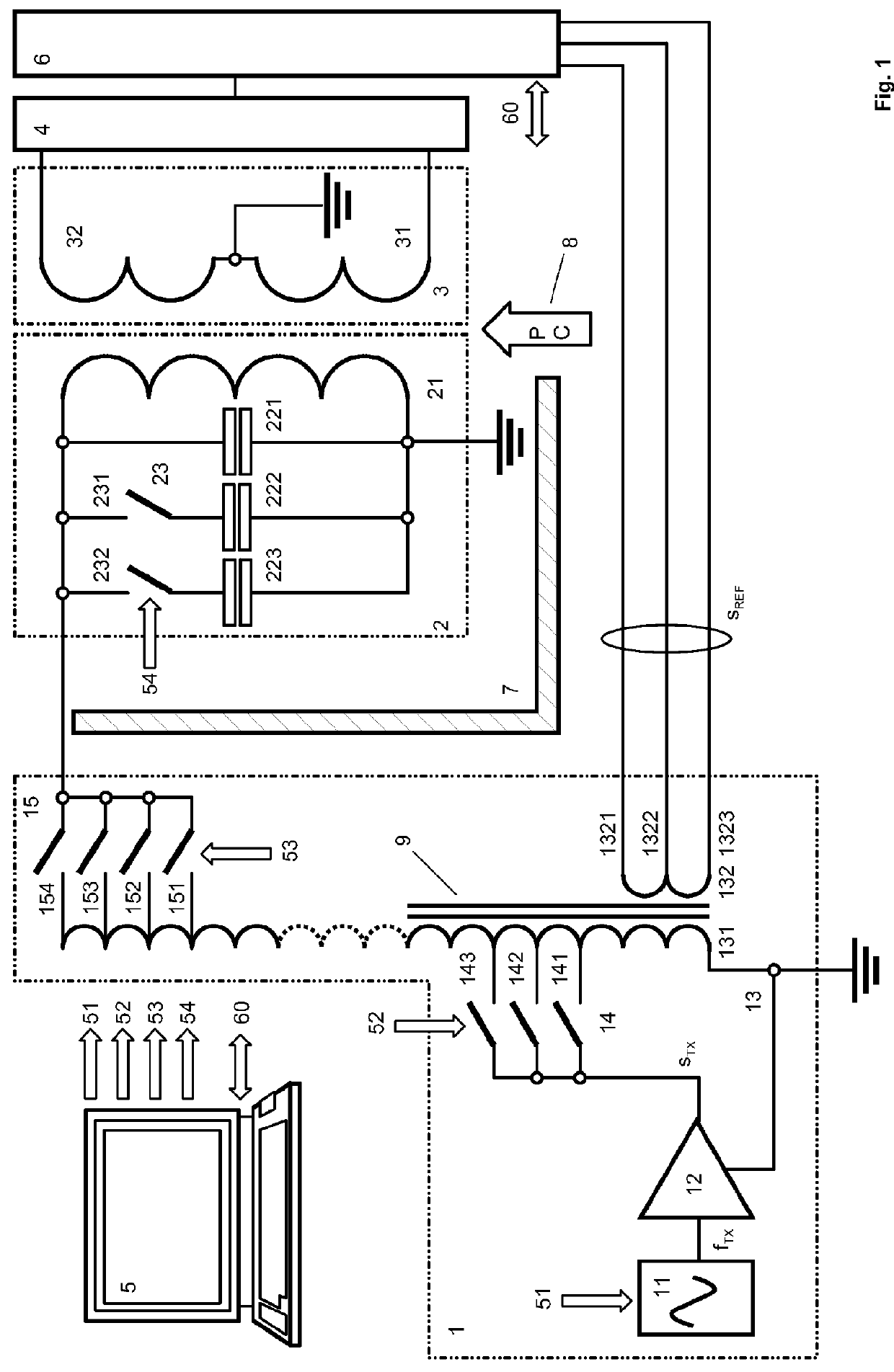

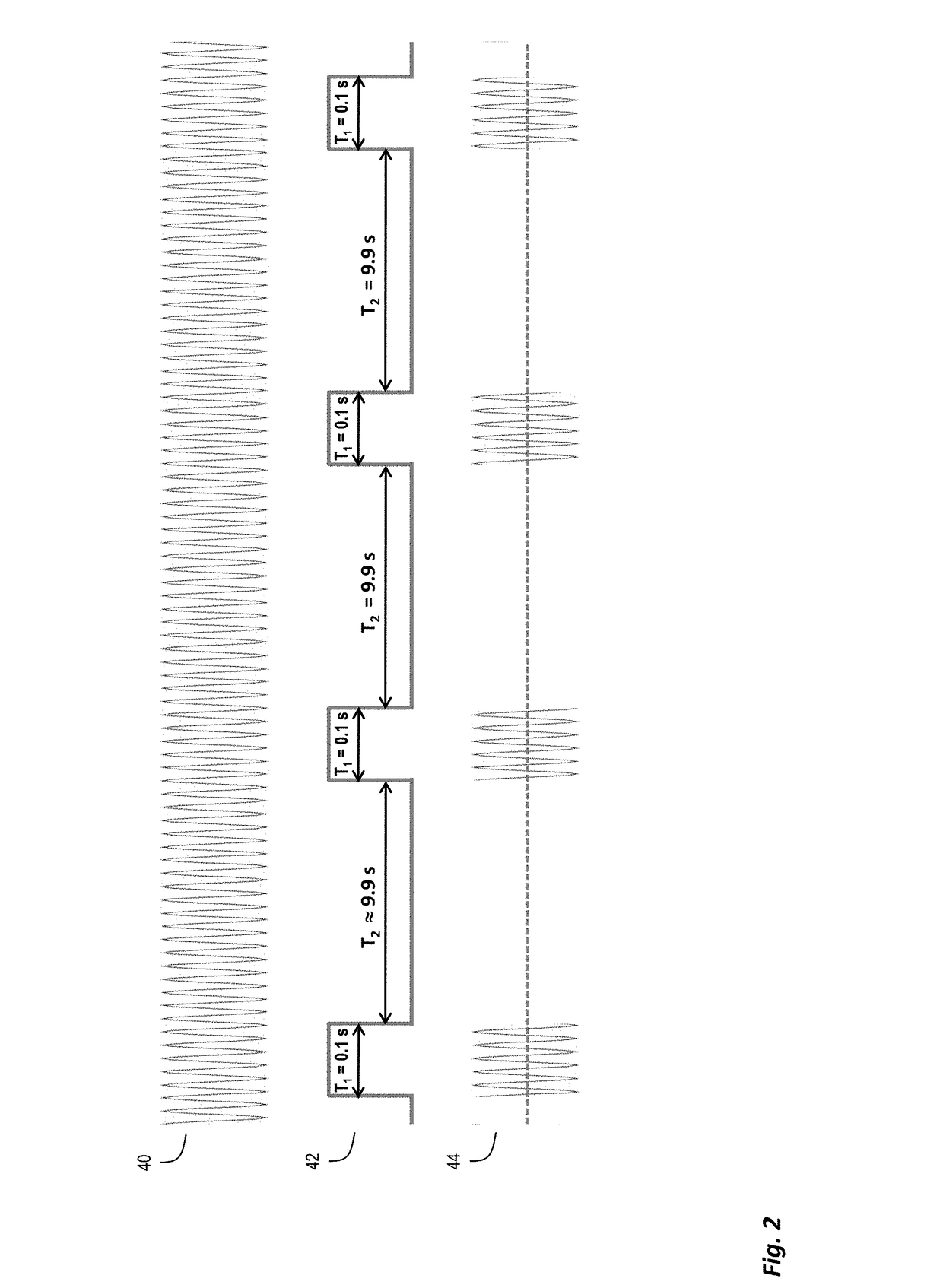

Metal detection apparatus

ActiveUS20130049745A1Minimising lossMinimal insertion lossMagnetic property measurementsElectric/magnetic detectionVIT signalsTransformer windings

A metal detection apparatus that uses one or more operating frequencies. The metal detection apparatus comprises, among other things, a transmitter unit that provides transmitter signals to a transmitter coil that is coupled to a receiver coil, which is connected to the input of a receiver unit. The transmitter unit comprises a frequency generator that provides an operating frequency to the input of an amplifier stage, whose output is connected via a transformer to the transmitter coil. The amplifier stage is connected to a first tap and the transmitter coil is connected to a second tap of the same transformer winding of the transformer. A resonant circuit is formed that is tuned to the operating frequency, and can be tuned optimally and independently of other parts of the transmitter unit.

Owner:METTLER TOLEDO SAFELINE

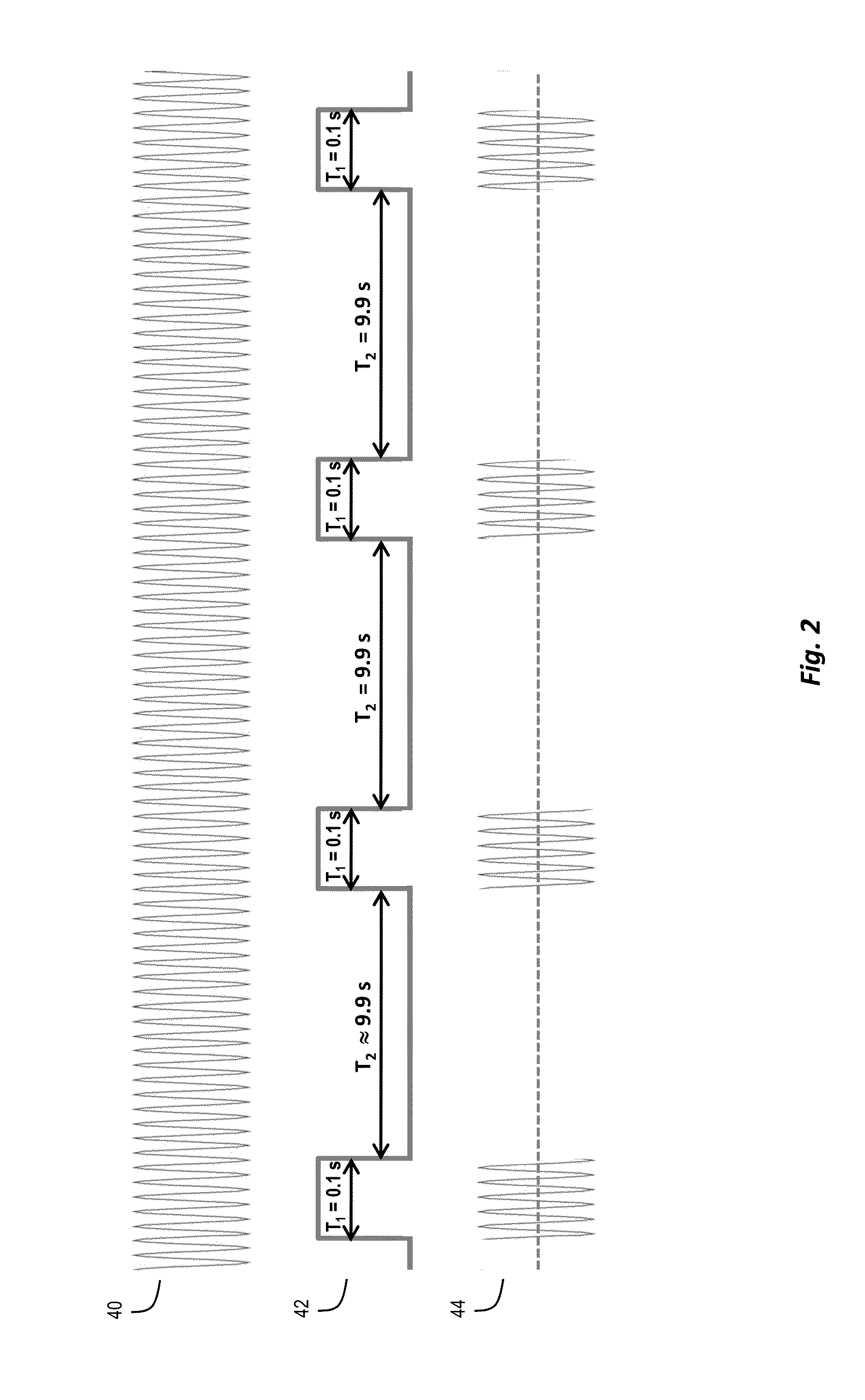

Solar photovoltaic module remote access module switch and real-time temperature monitoring

ActiveUS20170244358A1Minimal impactMinimal insertion lossProgramme controlPhotovoltaic monitoringTemperature monitoringPhotovoltaics

A solar photovoltaic module remote-access module switch and real-time temperature monitoring system is provided.

Owner:SIGMAGEN INC

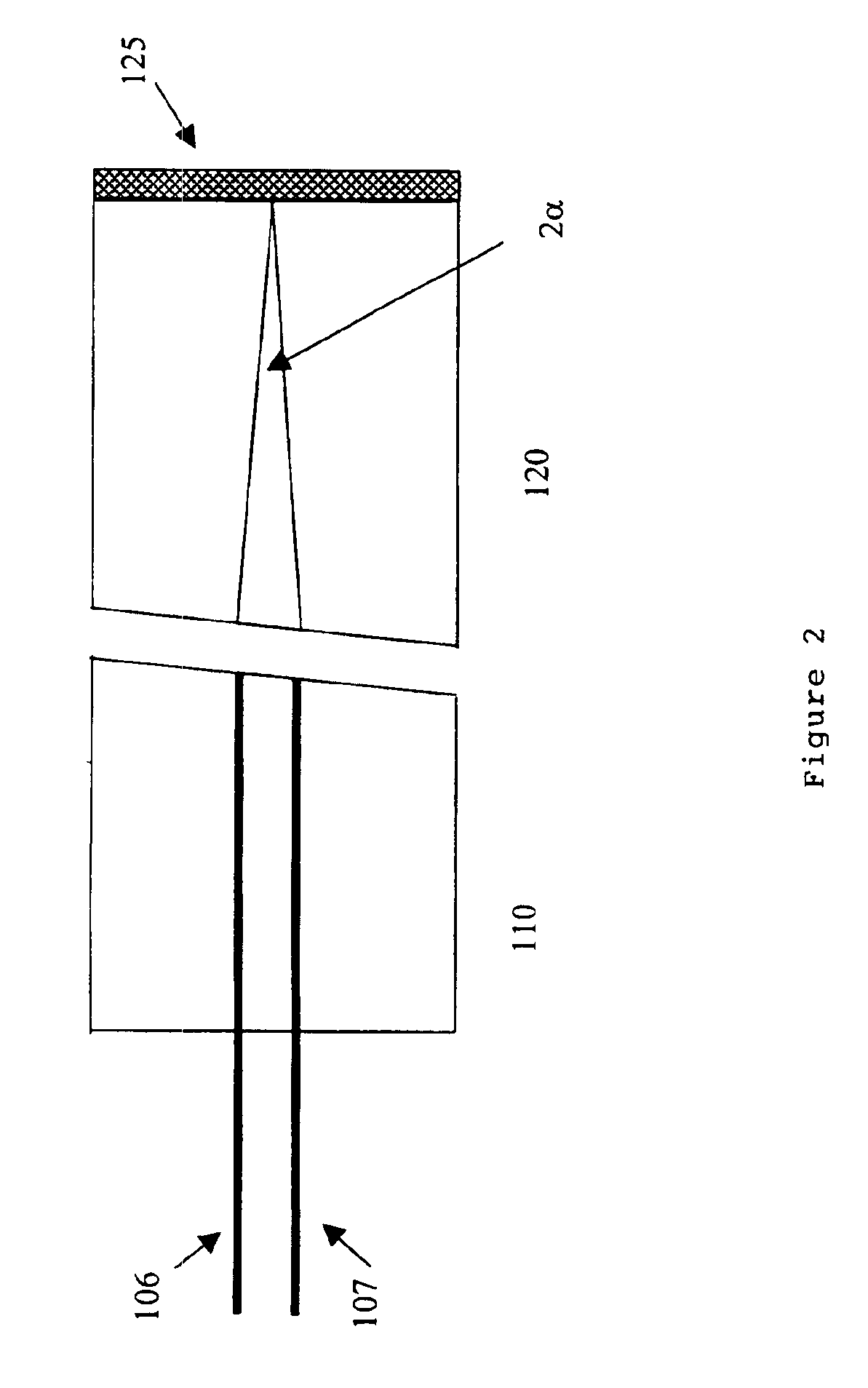

Structure and method for manufacturing compact optical power monitors of highly reliable performance

InactiveUS6895144B2Minimal insertion lossSimplified and reliable configurationMirrorsCoupling light guidesFiberOptical reflection

A new low-cost, highly reliable and compact optical power monitor is manufactured with simplified structure and improved configurations that require only lateral position adjustment for input / output beam alignment. A compact size is achieved by employing prefabricated housing containing a highly effective focus lens placed at fixed position relative to an optical sensor, e.g., a photodiode. The prefabricated housing further function as a seal housing for direct plugging into a holding tube fitting seamlessly to a GRIN lens to focus the tapped collimated beam to the photo sensor thus greatly simplify the manufacturing processes without alignment requirements. Thermal stability and reliable performance is achieved by applying multiple-layered optical reflection-transmission coating directly onto the end surface of a GRIN lens for tapping a small portion of the collimated beam onto the focus lens and the photo sensor. The insertion loss can be conveniently minimized by laterally shifting the relative position of a dual fiber ferrule and the GRIN lens without complicate angular adjustments. A power monitor with compact size, high damage threshold, low manufacture cost and high performance stability is provided for convenient implementation in new and existing optical systems.

Owner:PACTONIX

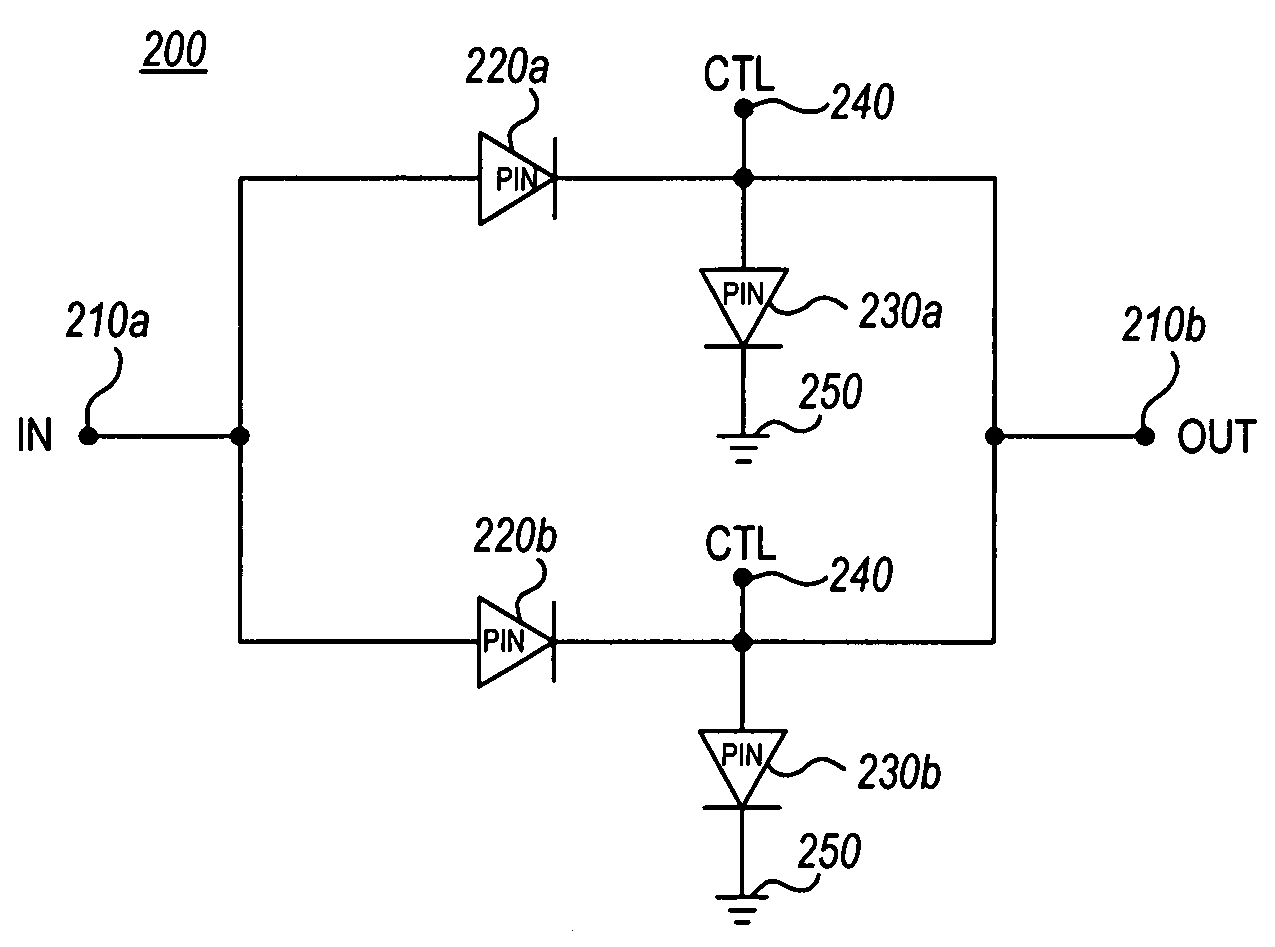

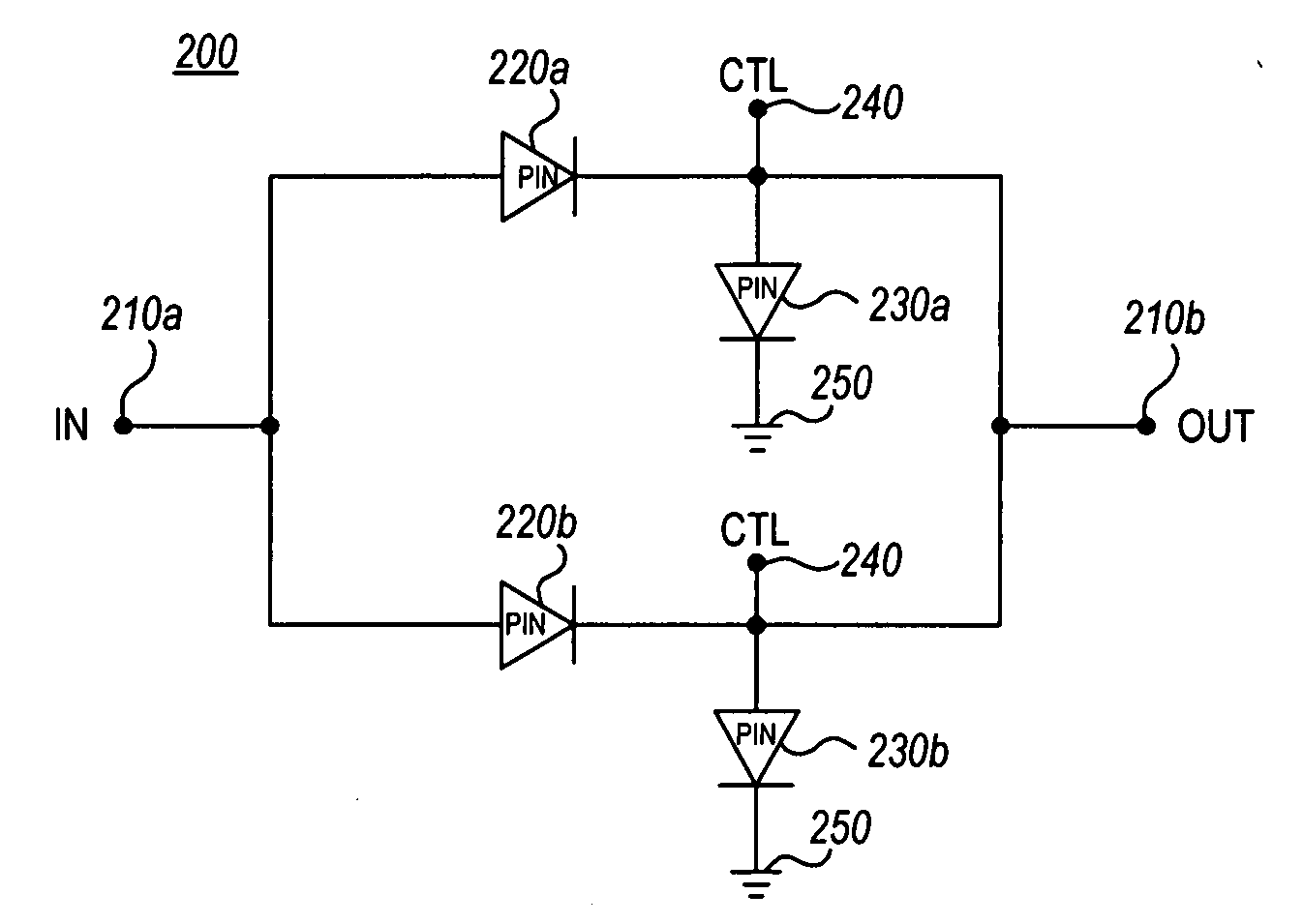

RF step attenuator

InactiveUS7639100B2Minimal insertion lossHigh Power Handling CapabilityMultiple-port networksCoupling devicesUltrasound attenuationFrequency spectrum

A broadband, high-speed RF step attenuator implemented using long-lifetime PIN diode switches is presented which provides step attenuation across a significant portion of the entire RF frequency spectrum while maintaining minimal insertion loss, return loss, and harmonics.

Owner:GIGA TRONICS

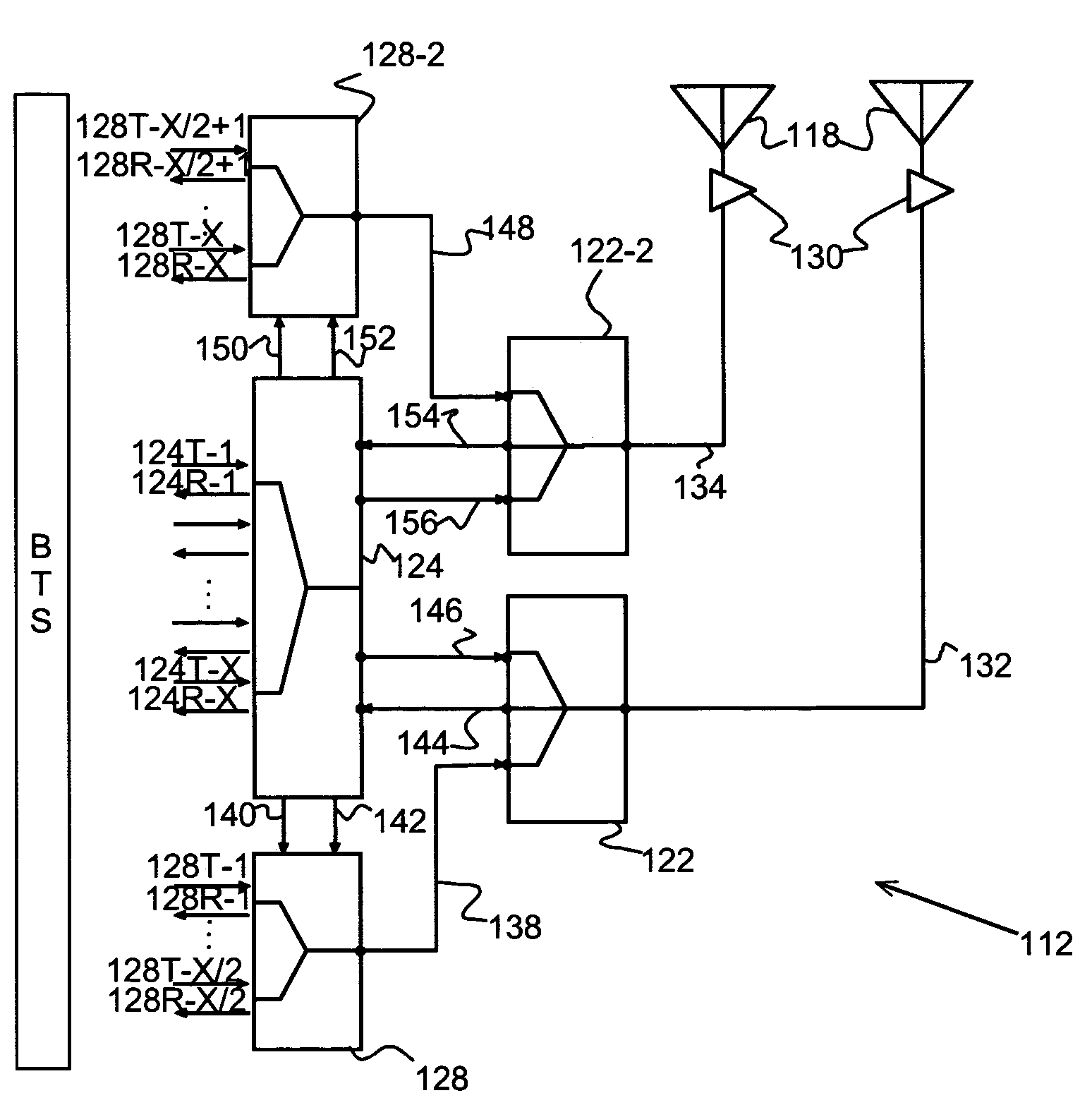

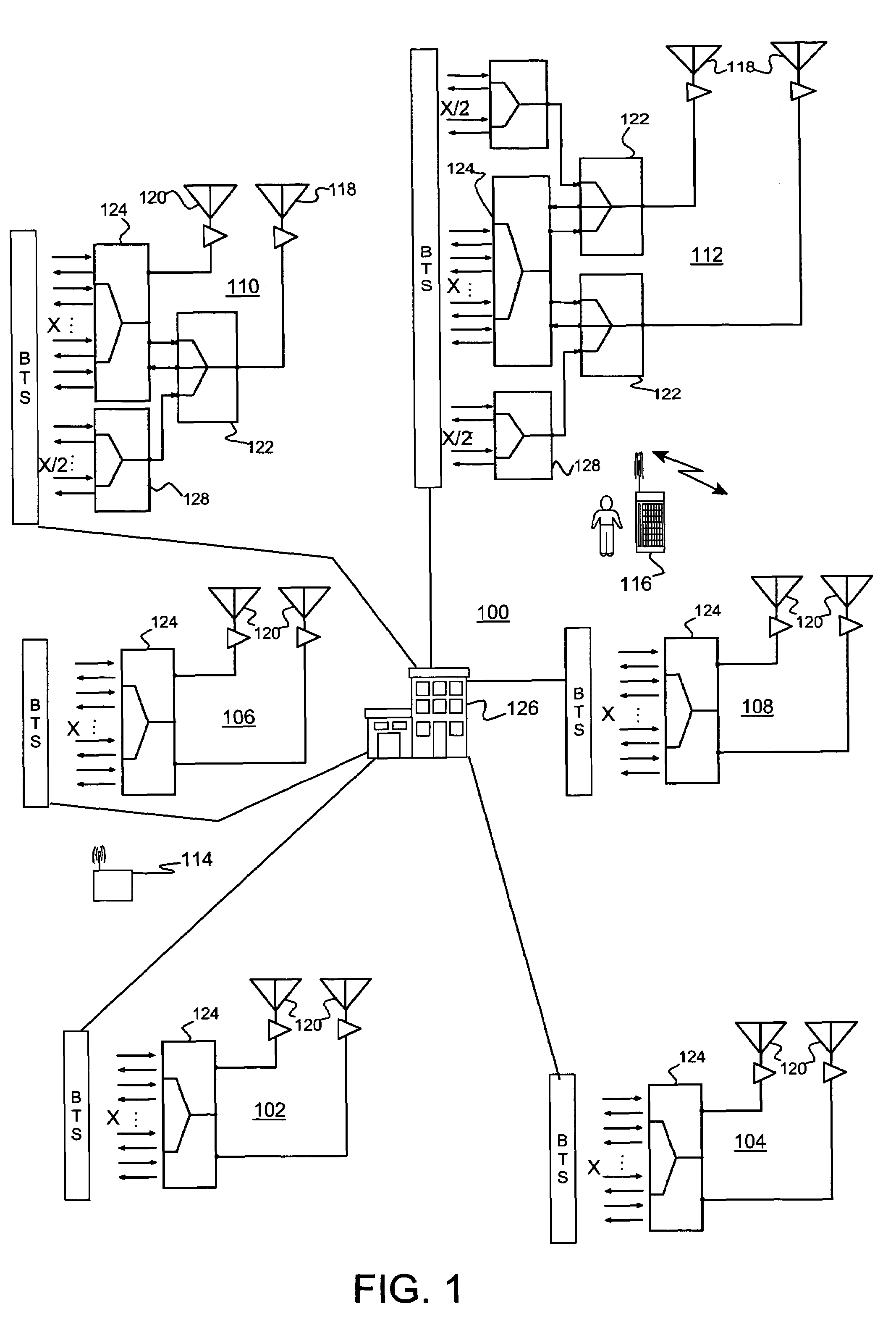

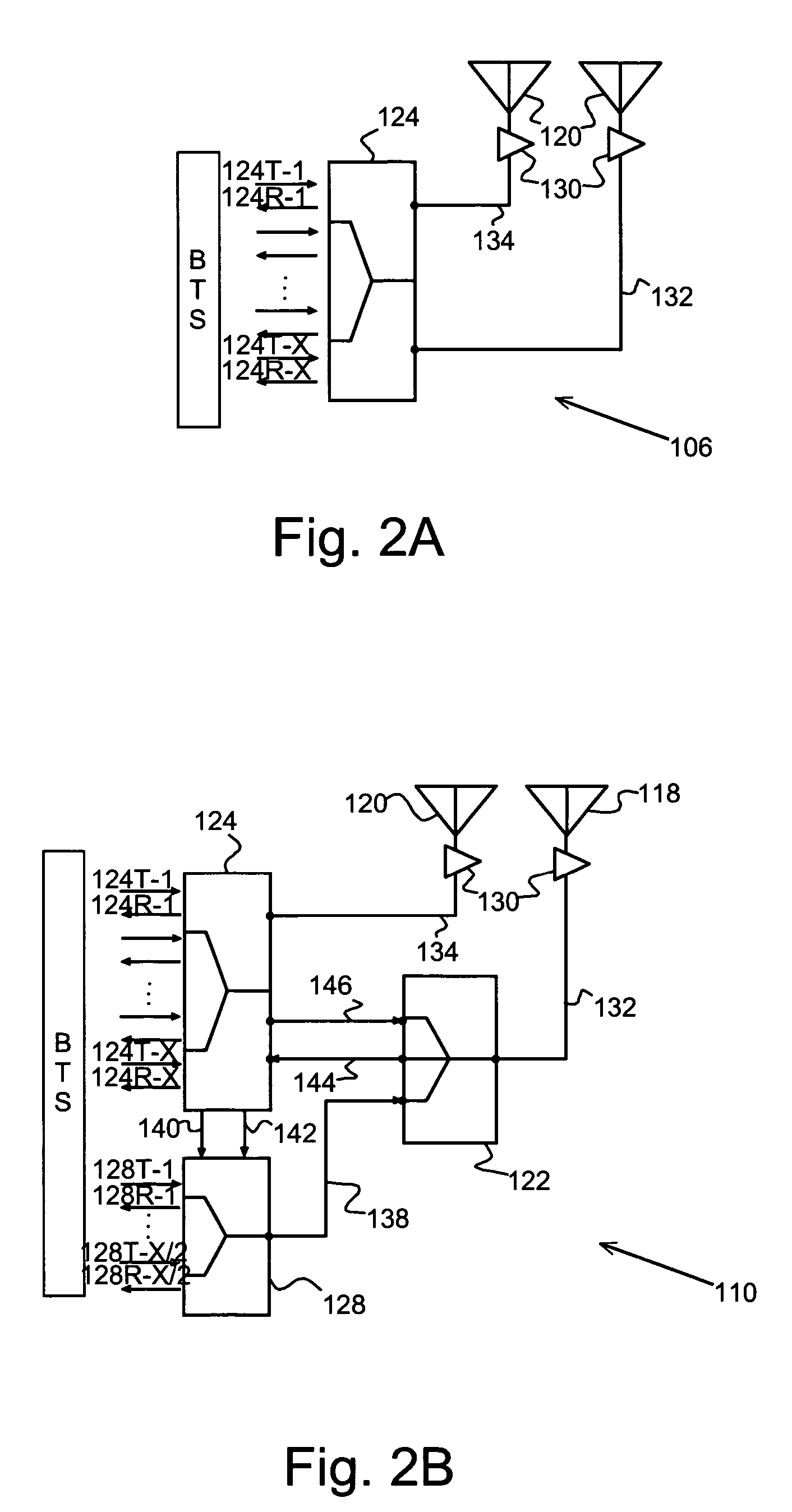

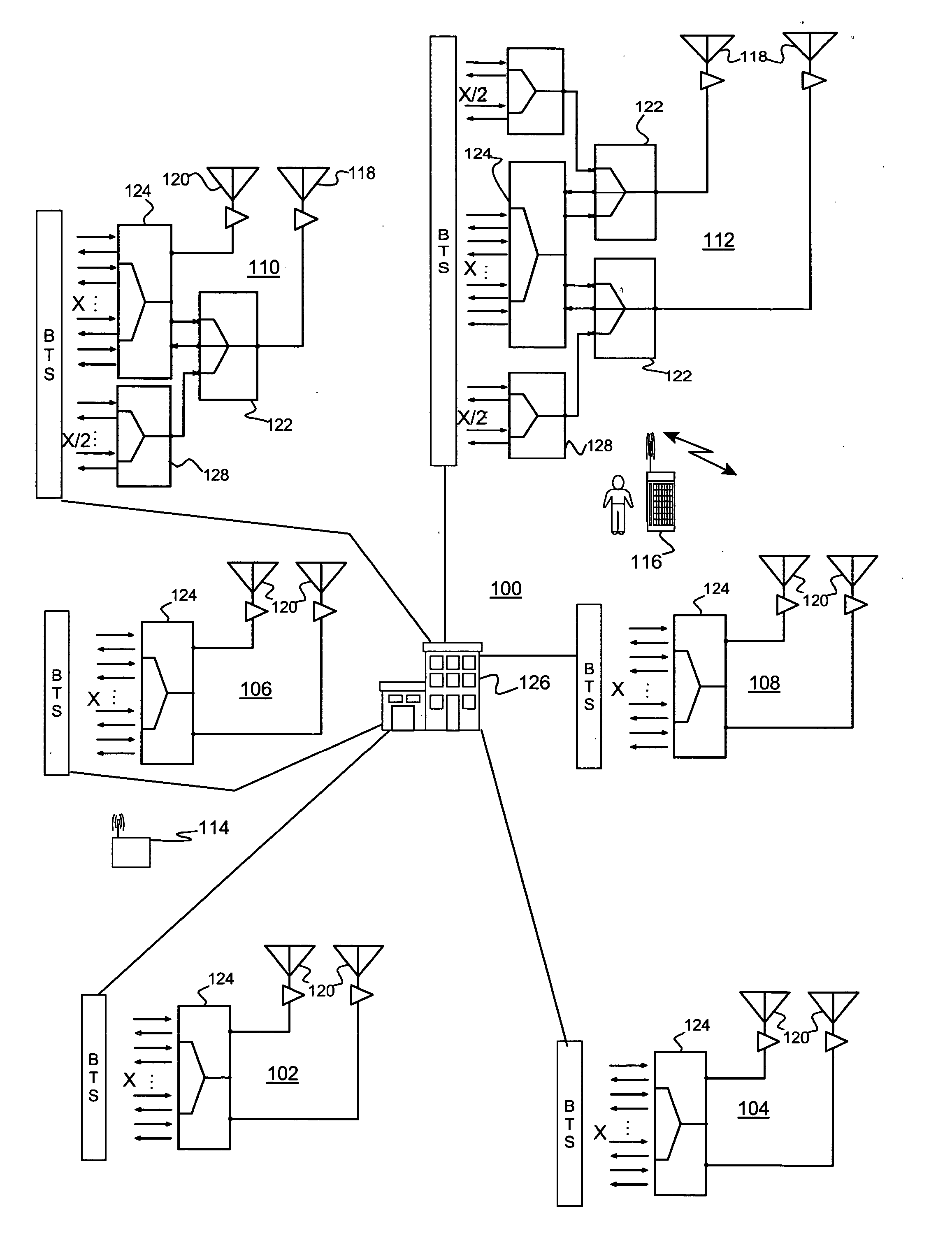

Mobile communications network with expanded carrier capacity and method of expanding base station carrier capacity

ActiveUS7376446B2Increase capacityMinimal insertion lossSubstation equipmentTransmissionCommunications systemSignal on

A base station for a mobile communications system, a mobile communications system including the base station and a method of increasing base station capacity. Each base station antenna is coupled to a transmission line that may be connected to a triplexer. The triplexer separates uplink signals from a duplex signal on the transmission line. The uplink and downlink signals are both in two sub-bands that are separated by a third sub-band. The triplexer passes the uplink signal to a duplexer / combiner that forwards the uplink signal to a combiner. The duplexer / combiner and combiner each pass downlink signals in one of the sub-bands to the triplexer, which combines the passes to the duplex signal.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Nanoparticle-enhanced liquid crystal radio frequency phase shifter

InactiveUS9059496B2Low toxicityReduce the amount of solutionNanoopticsWaveguide type devicesNanoparticleGround plane

A nanoparticle-enhanced liquid crystal phase shifter is provided including a first substrate layer, a plurality of electrodes attached to the substrate layer, a ground plane layer attached to a second substrate layer, and a liquid crystal layer between the ground plane layer and the first substrate layer, including a suspension of a liquid crystal material and highly polarizable nanoparticles having specific shape and size characteristics.

Owner:UNIV OF COLORADO THE REGENTS OF

Pressure equalizing construction for nonporous acoustic membrane

ActiveUS20200329289A1Reduce acoustic sensitivityMinimal insertion lossSemiconductor electrostatic transducersElectrostatic transducer microphonesEngineeringAcoustic membrane

A pressure equalizing assembly with a nonporous membrane traversing across an acoustic pathway defined by an opening in a housing. A breathable layer connected to the nonporous membrane may be laterally arranged to the acoustic pathway. An acoustic cavity is defined by the breathable layer and nonporous membrane. The nonporous membrane has a side facing the opening in the housing to prevent fluid or moisture from penetrating into the acoustic cavity. The breathable layer further equalizes pressure in the acoustic cavity by providing a venting layer.

Owner:WL GORE & ASSOC INC

RF step attenuator

InactiveUS20090108965A1Low insertion lossSpeed up the descentElectronic switchingDiodeUltrasound attenuationFrequency spectrum

A broadband, high-speed RF step attenuator implemented using long-lifetime PIN diode switches is presented which provides step attenuation across a significant portion of the entire RF frequency spectrum while maintaining minimal insertion loss, return loss, and harmonics.

Owner:GIGA TRONICS

Solar photovoltaic module remote access module switch and real-time temperature monitoring

ActiveUS10784815B2Minimal impactMinimal insertion lossProgramme controlPhotovoltaic monitoringTemperature monitoringEngineering physics

A photovoltaic module remote-access module switch and real-time temperature monitoring system is provided. In one embodiment, a remote-access module switch and monitoring circuit capable of communicating with a remote receiver and having a pair of output electrical leads, and a pair of input electrical leads connected to a pair of electrical power leads of a solar photovoltaic module is provided, and which further includes a series switch, a module voltage measurement circuit, a module current measurement circuit, a temperature sensor, and a communication circuit.

Owner:SIGMAGEN INC

Mobile communications network with expanded carrier capacity and method of expanding base station carrier capacity

ActiveUS20060014568A1Increasing base station capacityNegligible footprint impactSubstation equipmentTransmissionCommunications systemSignal on

A base station for a mobile communications system, a mobile communications system including the base station and a method of increasing base station capacity. Each base station antenna is coupled to a transmission line that may be connected to a triplexer. The triplexer separates uplink signals from a duplex signal on the transmission line. The uplink and downlink signals are both in two sub-bands that are separated by a third sub-band. The triplexer passes the uplink signal to a duplexer / combiner that forwards the uplink signal to a combiner. The duplexer / combiner and combiner each pass downlink signals in one of the sub-bands to the triplexer, which combines the passes to the duplex signal.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Mechanical splice assembly for splicing opposing optical fibers within a fiber optic connector and method of performing the same

InactiveUS20200264381A1Signal loss increaseAvoid vertical movementCoupling light guidesMechanical spliceOptical fiber connector

A field installable fiber optical connector formed using a mechanical splice assembly secured within an opening of a plug frame. A fiber optical cable is secured to a distal end of a rear body that is secured to a distal end of the plug frame.

Owner:SENKO ADVANCED COMPONENTS

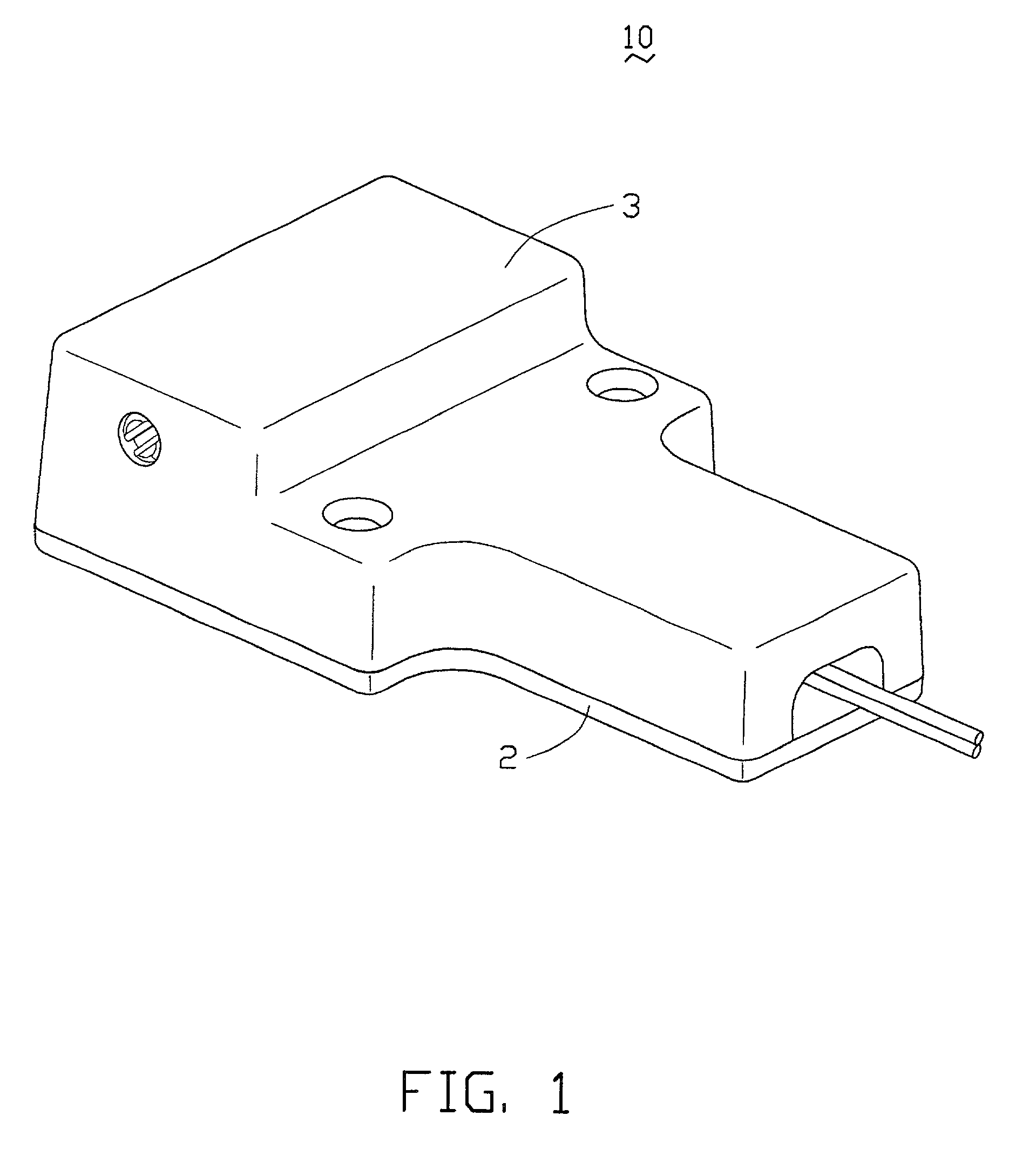

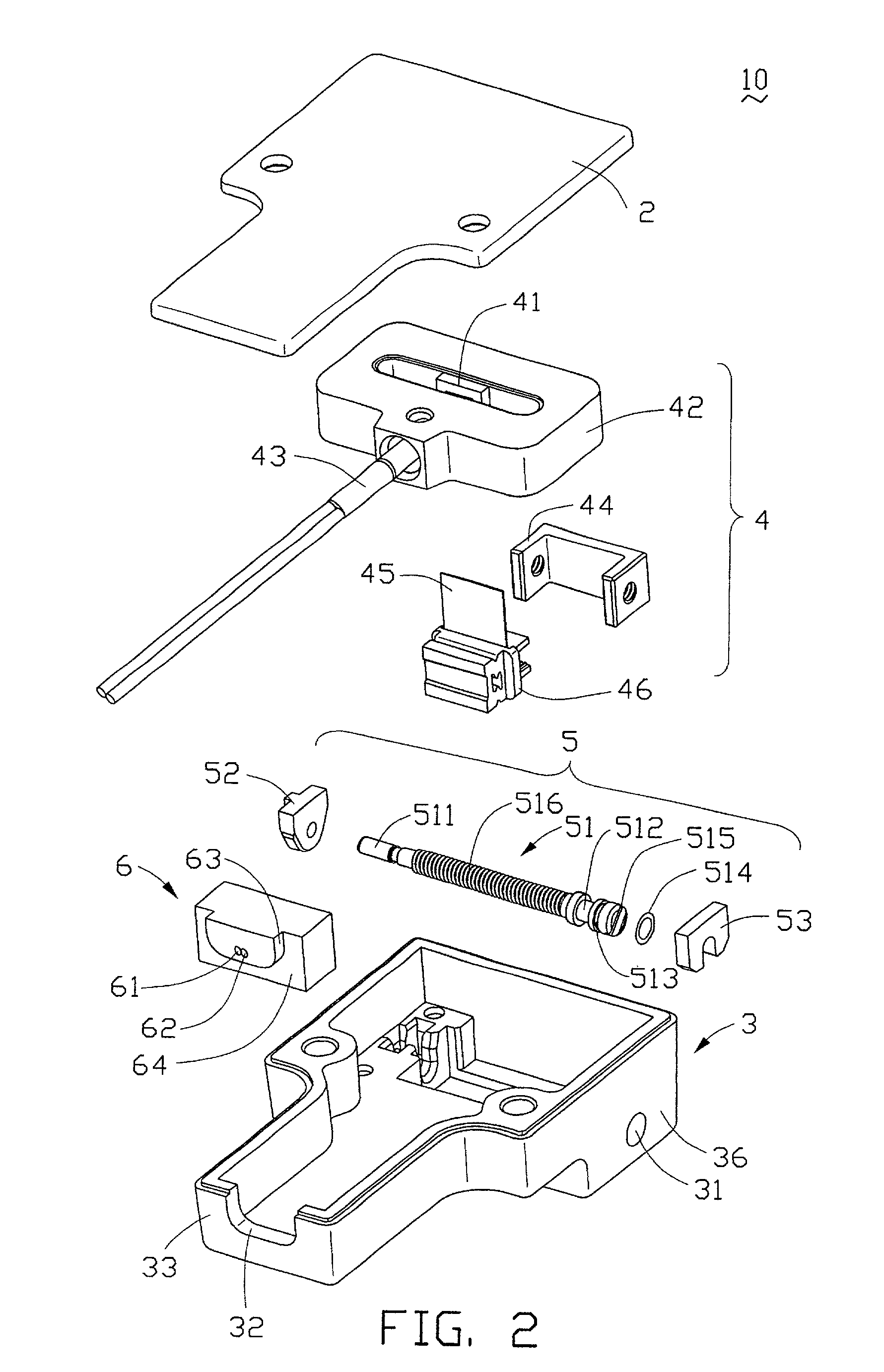

Manual variable optical attenuator having sealing gasket

InactiveUS20030045149A1Improve sealingEffectively prevents external harmful contaminationCouplings bases/casesCoupling light guidesOptical ModuleTransmittance

A manual variable optical attenuator (10) includes a base (2), a cover (3), an optical module (4), a shifting device (5), and an optical fiber retainer (6). The optical module comprises a mirror (41), a frame (42), a dual optical fiber collimator (43), a stopper (44), a graded transmittance filter (45), and a filter carrier (46). The shifting device comprises a screw pole (51), a first holder (52), and a second holder (53). The screw pole comprises a terminal portion (511) rotatably received in the first holder, a first annular groove (512) accommodating the second holder, a second annular groove (513) receiving a gasket (514), an adjusting slot (515), and a screw thread (516). T he gasket protrudes from a circumferential surface of the screw pole and seals a gap between the screw pole and a sidewall (36) of the cover. External harmful contamination cannot penetrate into the attenuator.

Owner:GOOGLE LLC

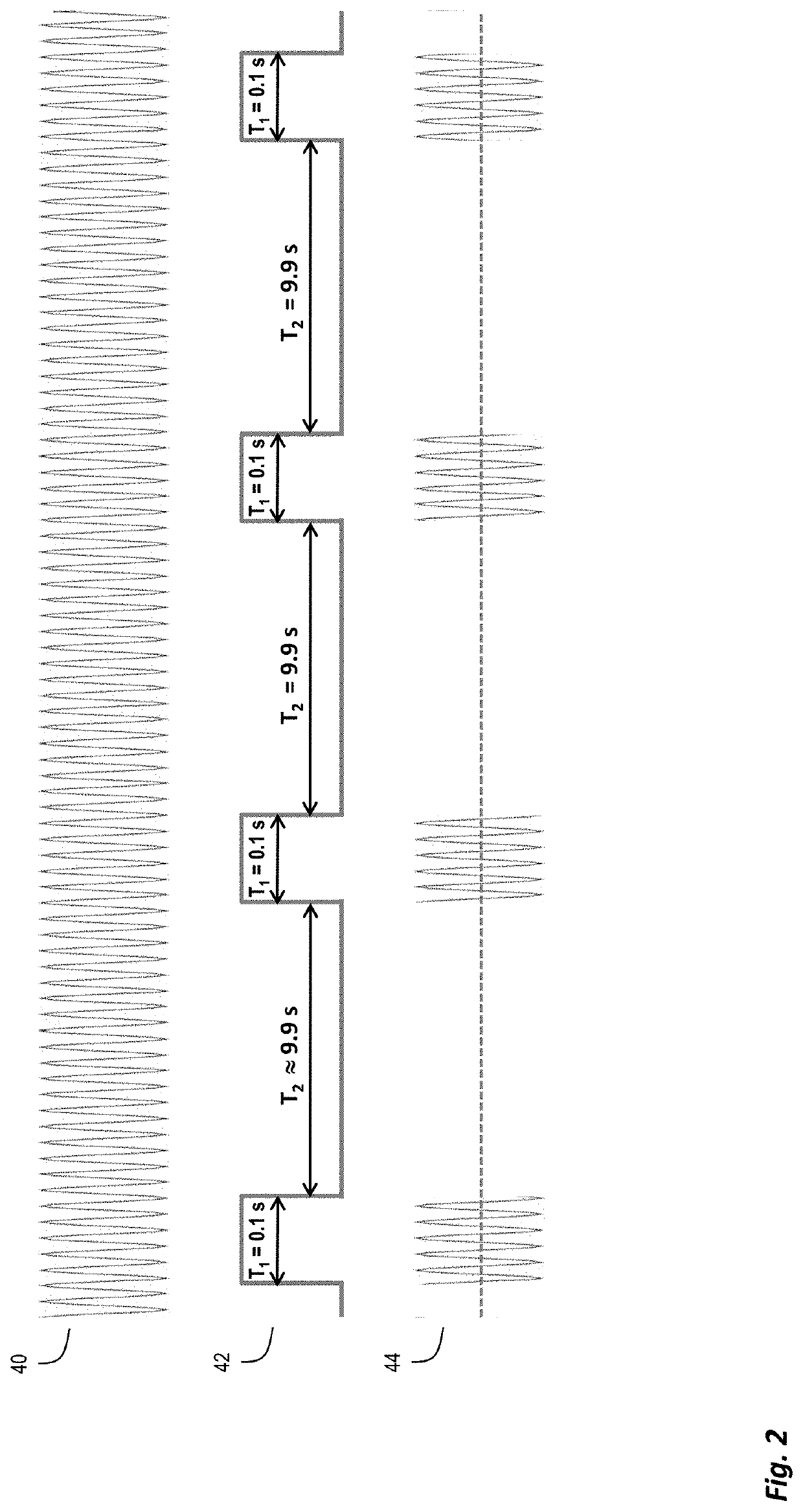

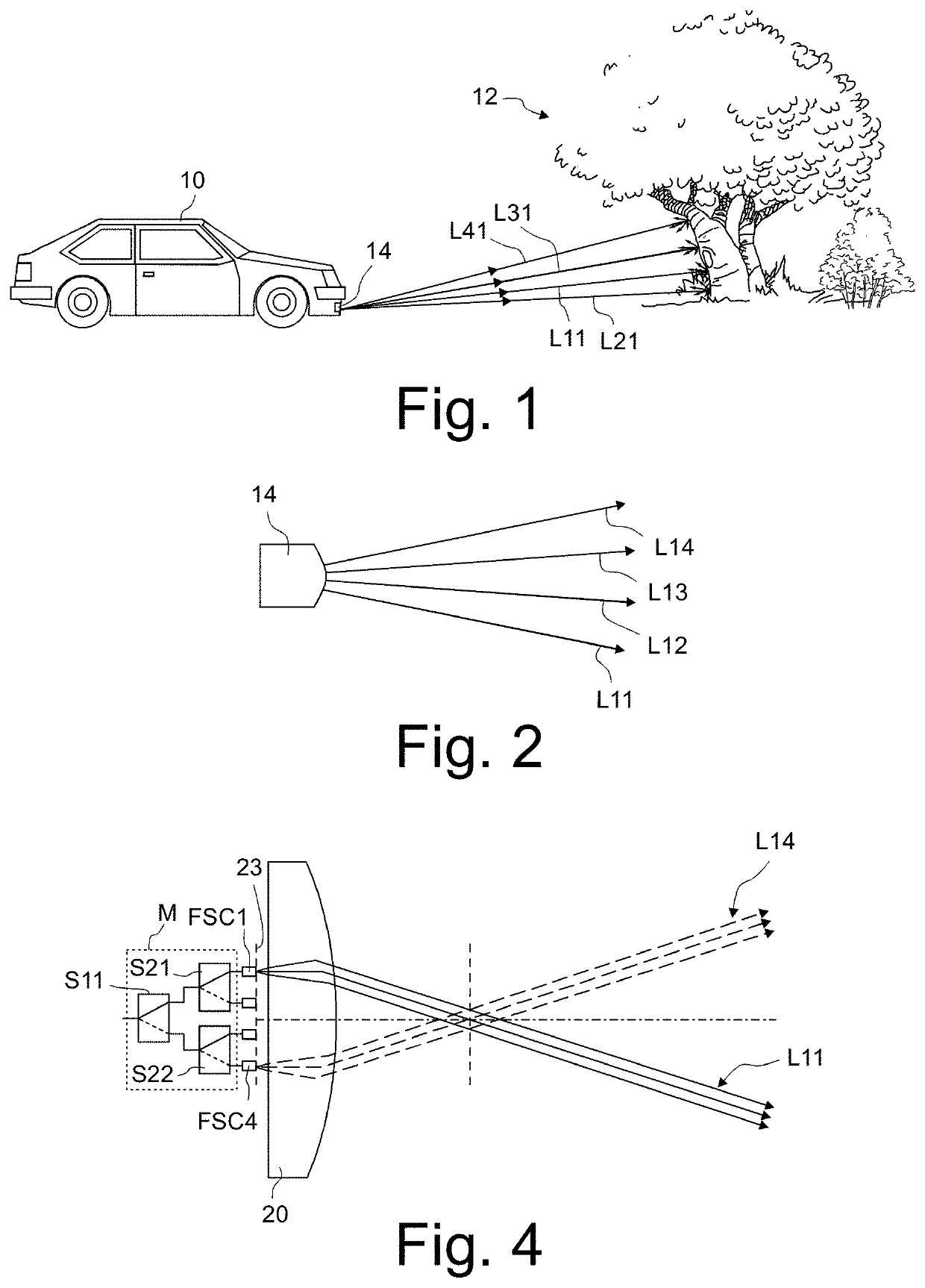

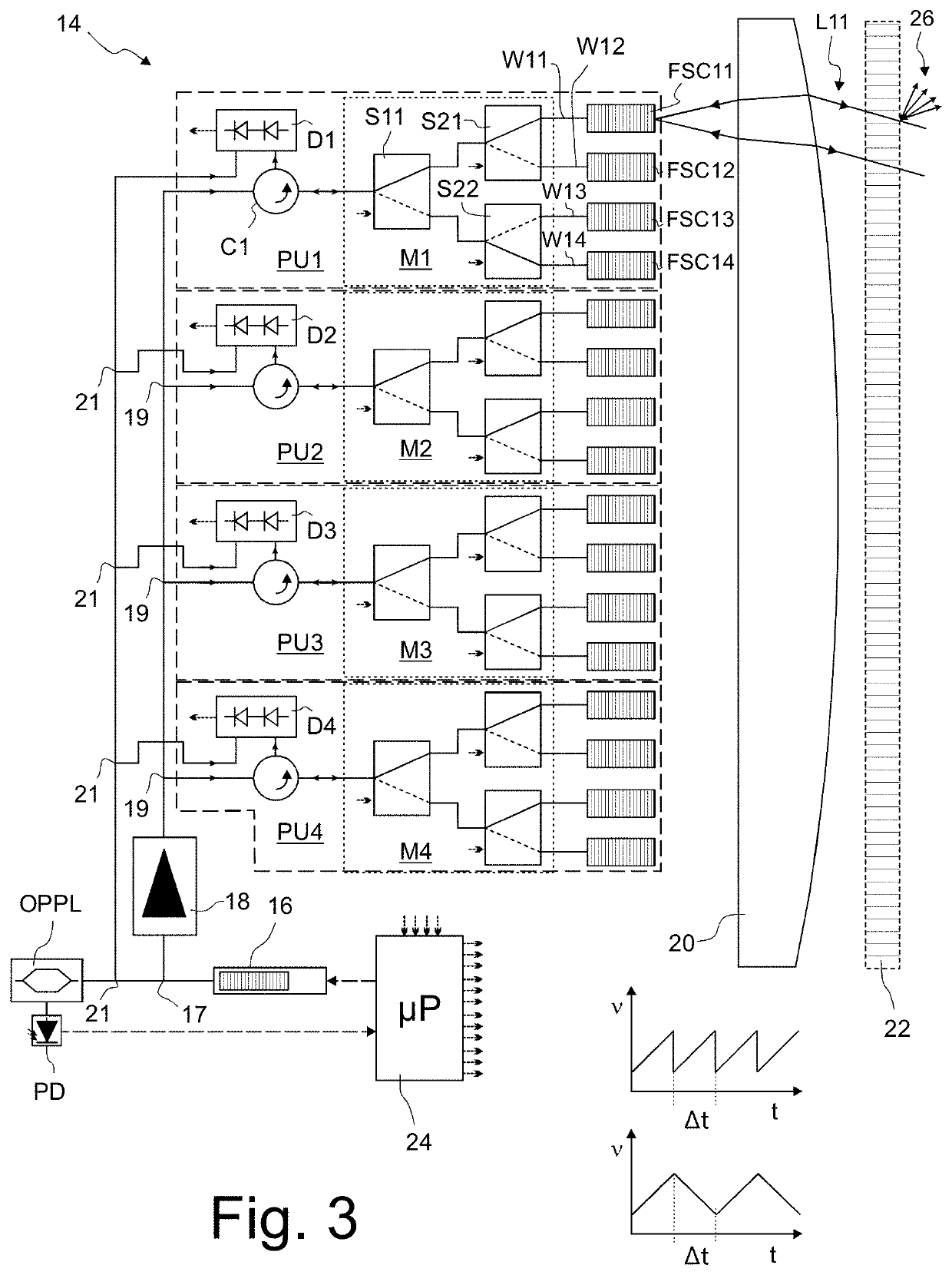

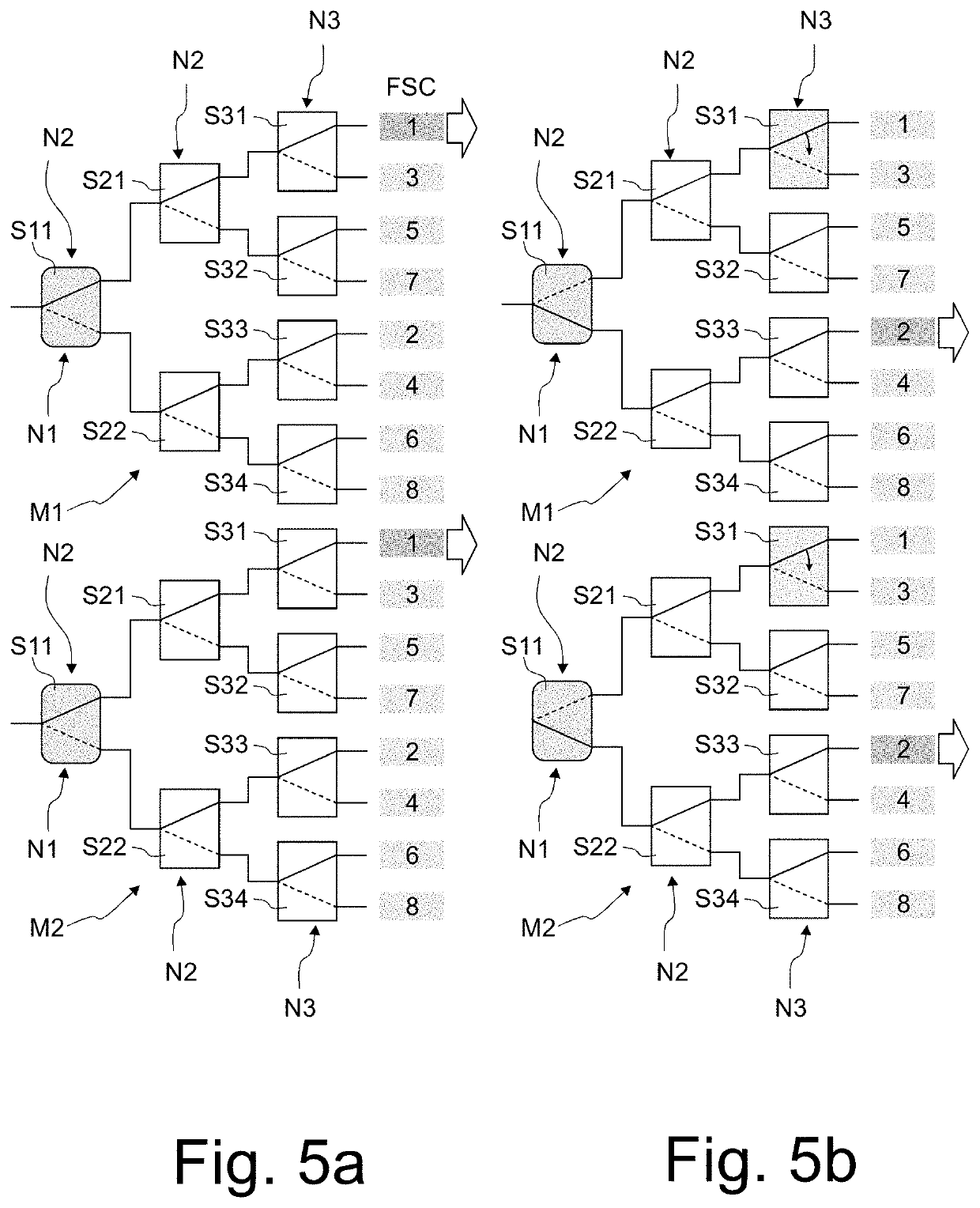

Device and method for scanning measurement of the distance to an object

ActiveUS20210364607A1High strengthShort switching timeMultiplex system selection arrangementsElectromagnetic wave reradiationOptical processingEngineering

A device for scanning measurement of a distance to an object has a light source, which generates an optical output signal having a time-varying frequency. The device includes multiple optical processing units, which are connected optically in parallel to the light source. Each processing unit has an optical distribution matrix including multiple optical switches that distribute optical output signals selectively onto different optical waveguides. Optical output signals are outcoupled into the free space via free space couplers and optical output signals reflected on the object are coupled as optical measurement signals into the waveguides. A detector detects a superposition of the optical measurement signal and the optical output signal generated by the light source. A circulator directs optical output signals supplied by the light source to the distribution matrix and optical measurement signals coming from the distribution matrix to the detector.

Owner:SCANTINEL PHOTONICS GMBH

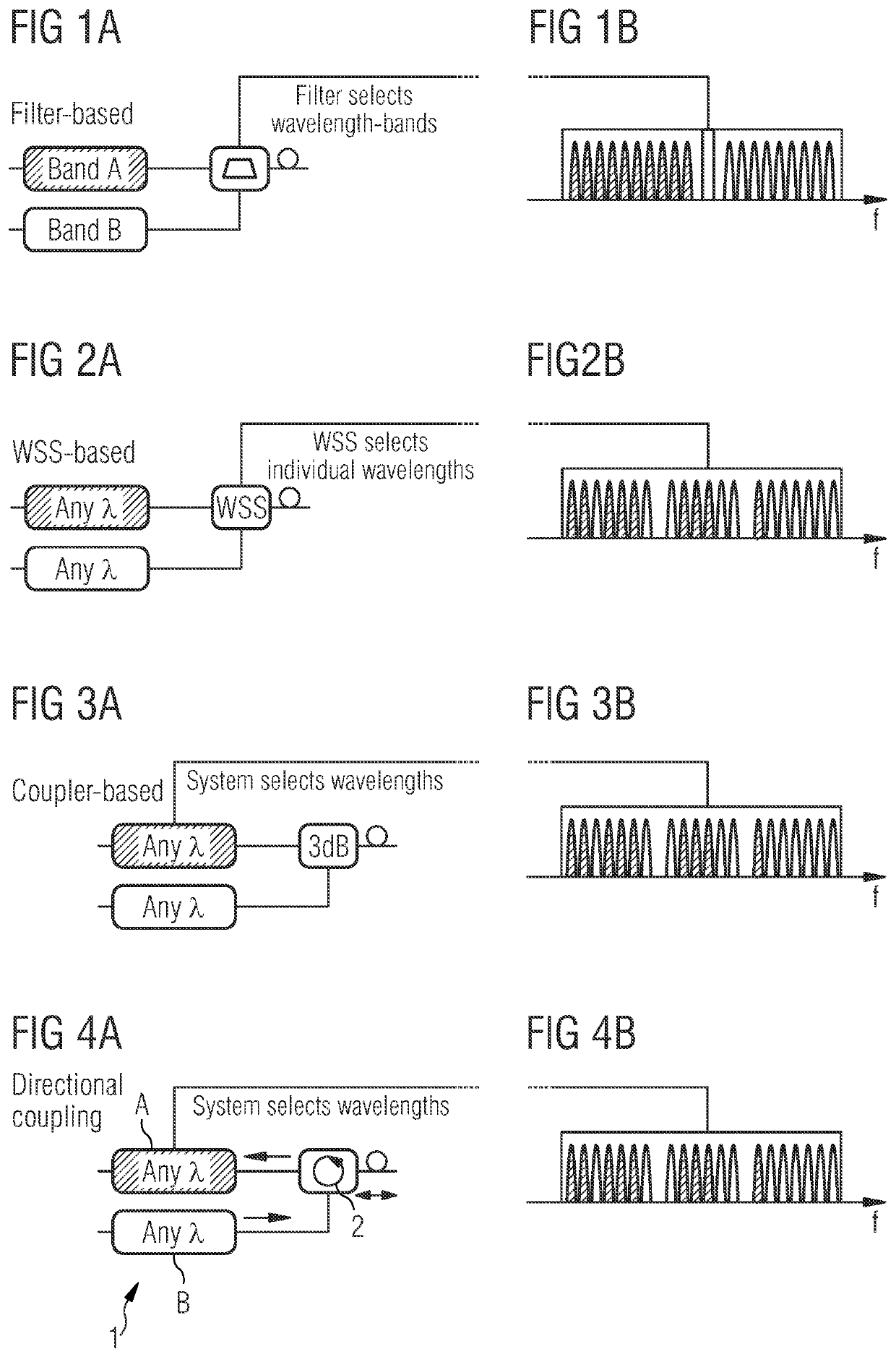

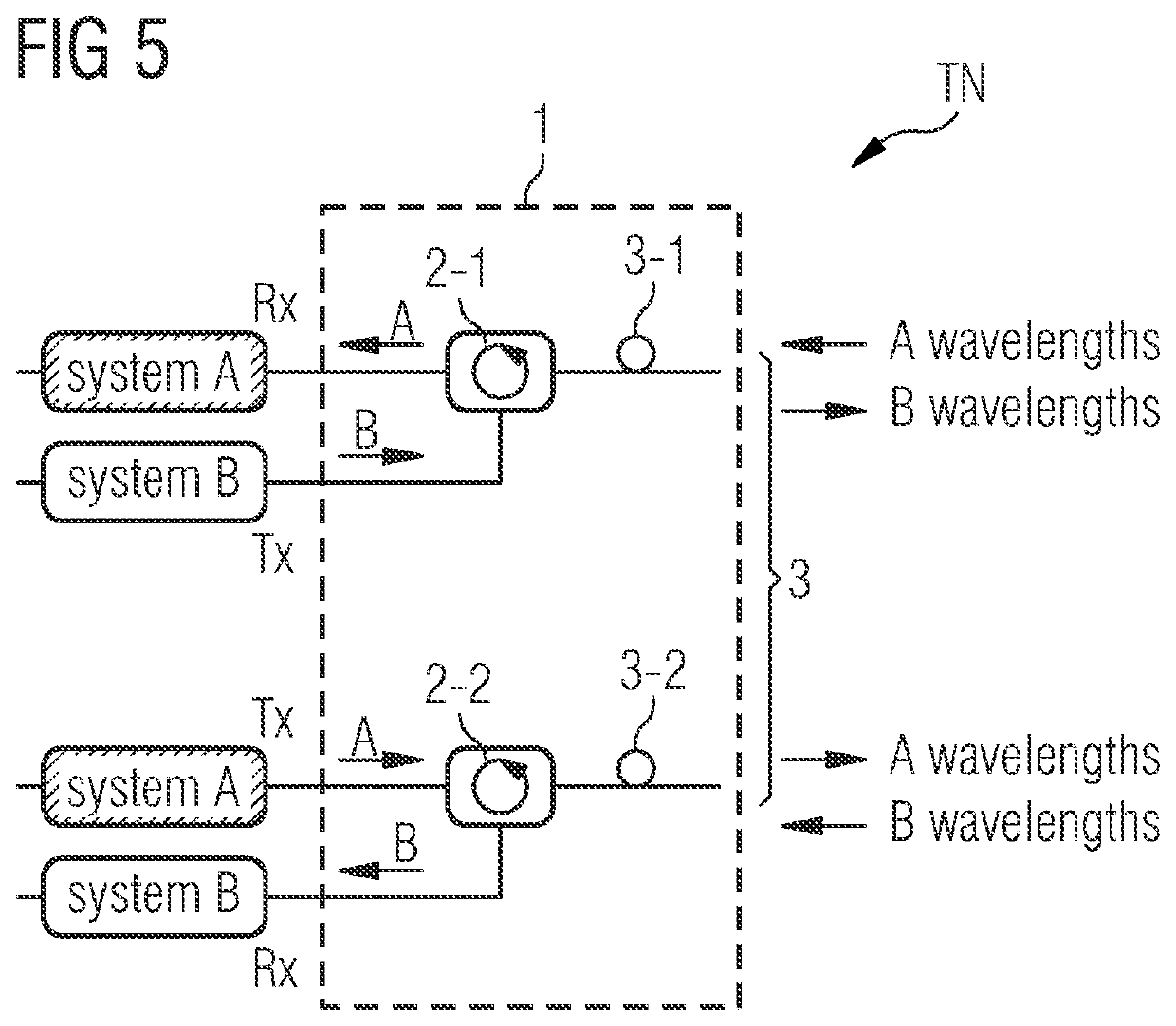

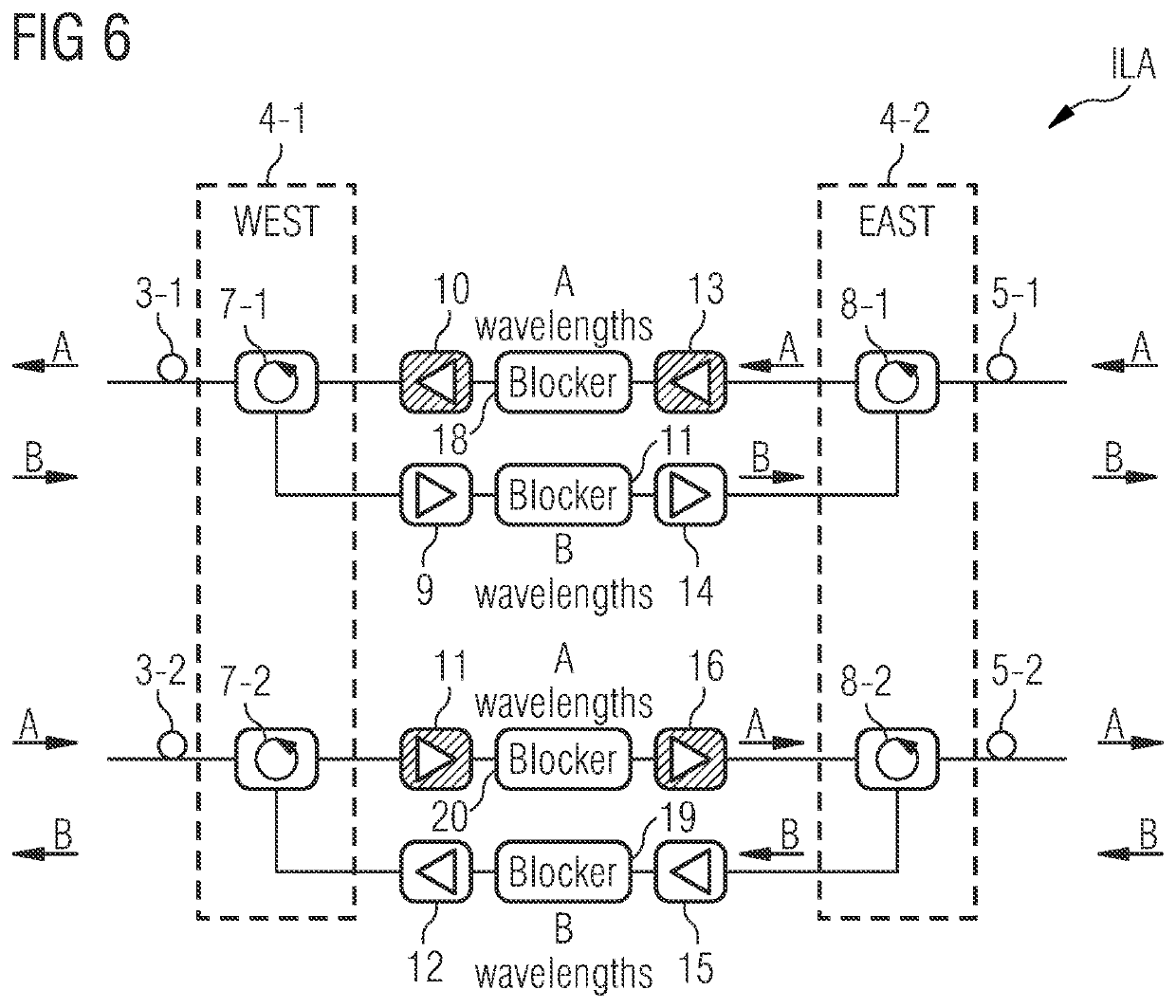

Method and apparatus for management of a spectral capacity of a wavelength division multiplexing system

ActiveUS20210409847A1Low insertion lossLow loss couplingMultiplex system selection arrangementsWavelength-division multiplex systemsSoftware engineeringOptical circulator

An apparatus for management of a spectral capacity of a wavelength division multiplexing, WDM, system includes at least one pair of transmission fibers provided for transporting optical signals. Each transmission fiber of a transmission fiber pair is connected to a first port of an optical circulator having at least two additional ports and adapted to transmit an incoming optical signal entering one of its ports via its next port. WDM subsystems configured with counter-propagating assignable wavelengths are connected to associated ports of the optical circulator of the apparatus.

Owner:ADVA OPTICAL NETWORKING SE

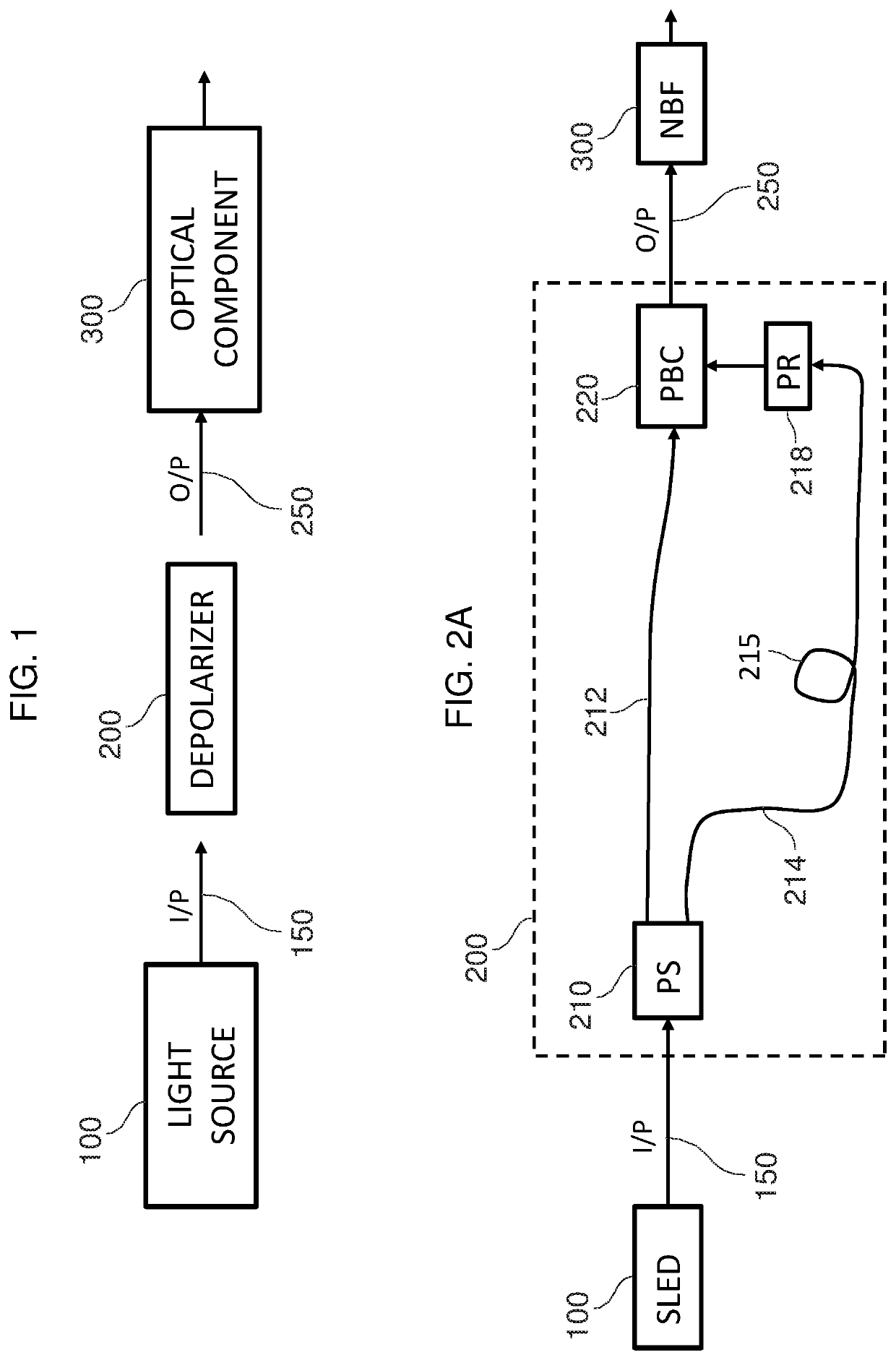

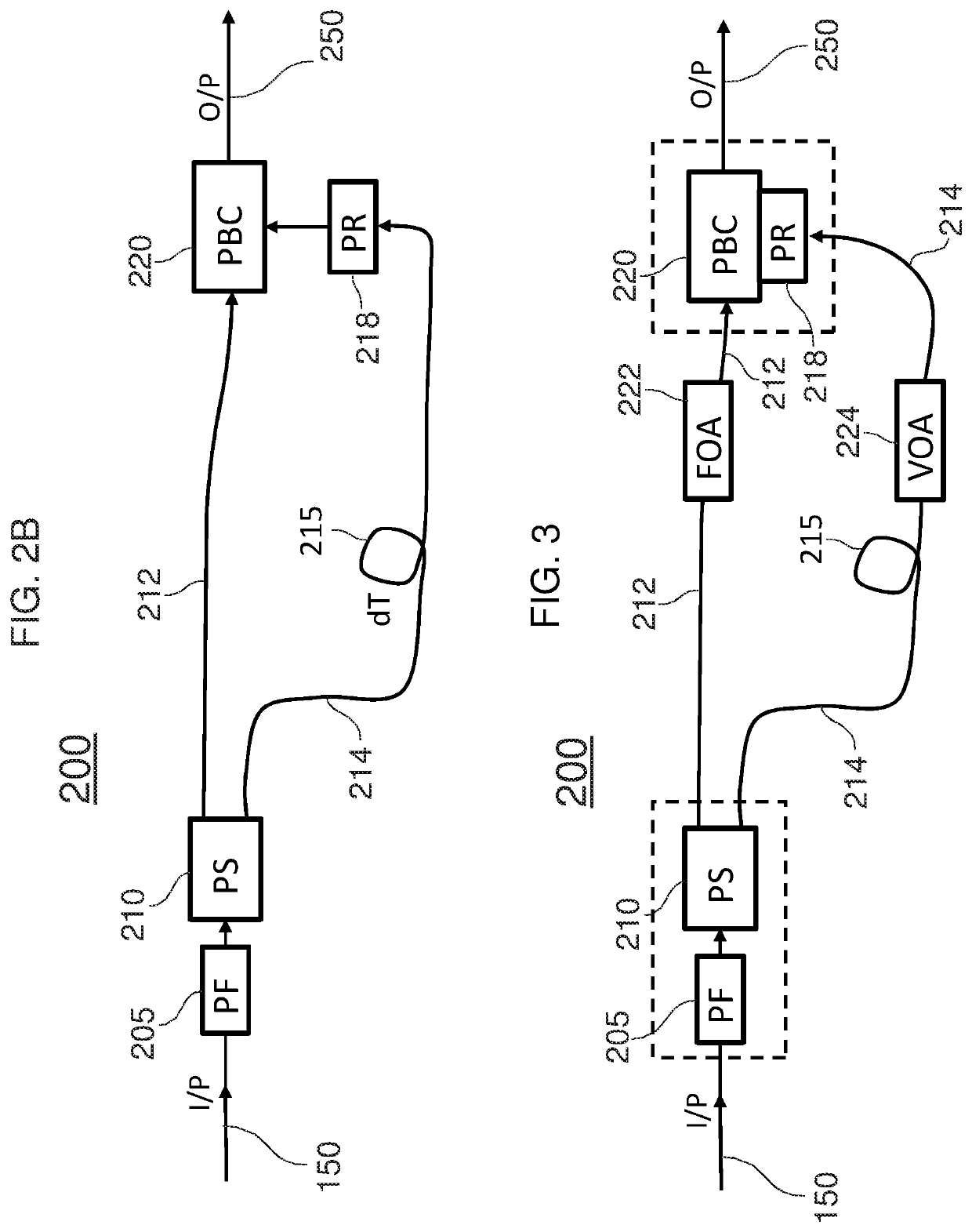

Depolarizers

ActiveUS10809460B2Low DOP performanceLow insertion lossMechanical apparatusFibre light guidesLight beamBroadband light source

A depolarizer for a broadband optical source to split the source beam by power, not by polarization state, and route the components into respective light paths. A polarization rotator arranged in one of the light paths rotates the polarization state of that beam component to make it orthogonal to that of the other. The components are then recombined by a combiner and output. A variable optical attenuator is arranged in one of the light paths, which during operation is adjusted by a controller to maintain power equalization between the light paths and hence depolarization performance. The controller receives power measurements from the light paths and from after the combiner via respective sensors. With this feedforward design reminiscent of a Mach-Zehnder interferometer the light from a light source which generates highly polarized light can be depolarized in theory with zero insertion loss and in practice with losses of about 1 dB.

Owner:EXALOS

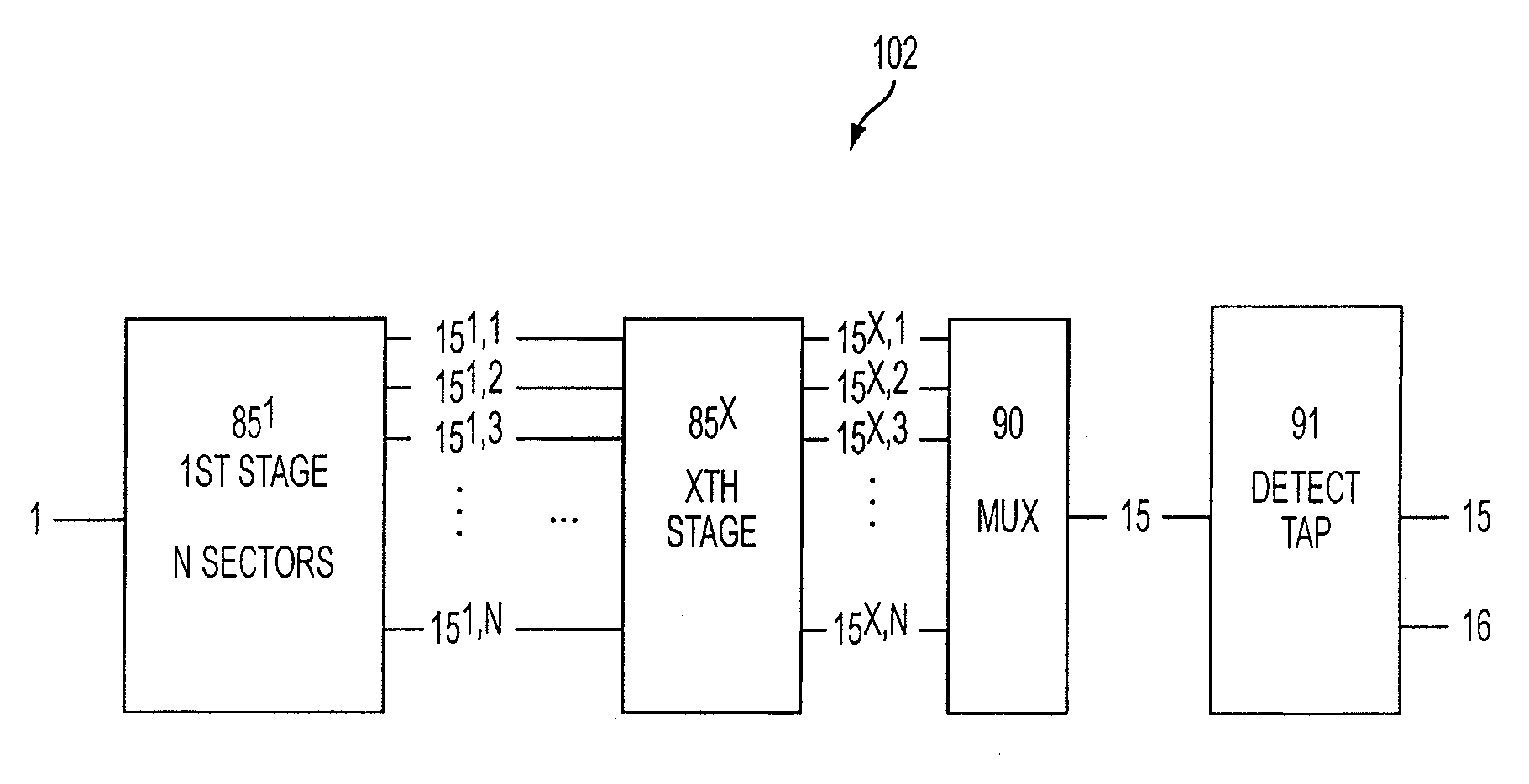

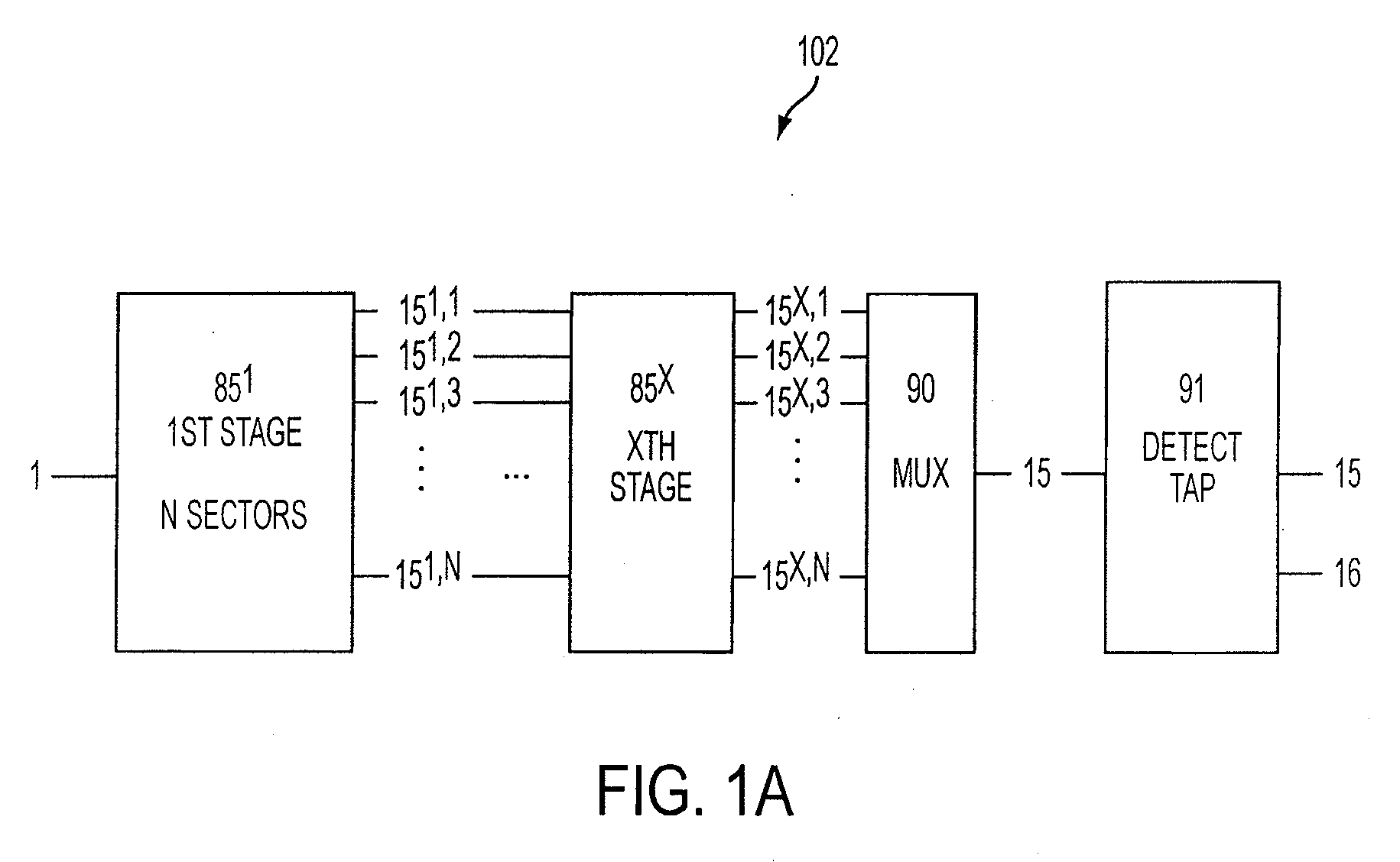

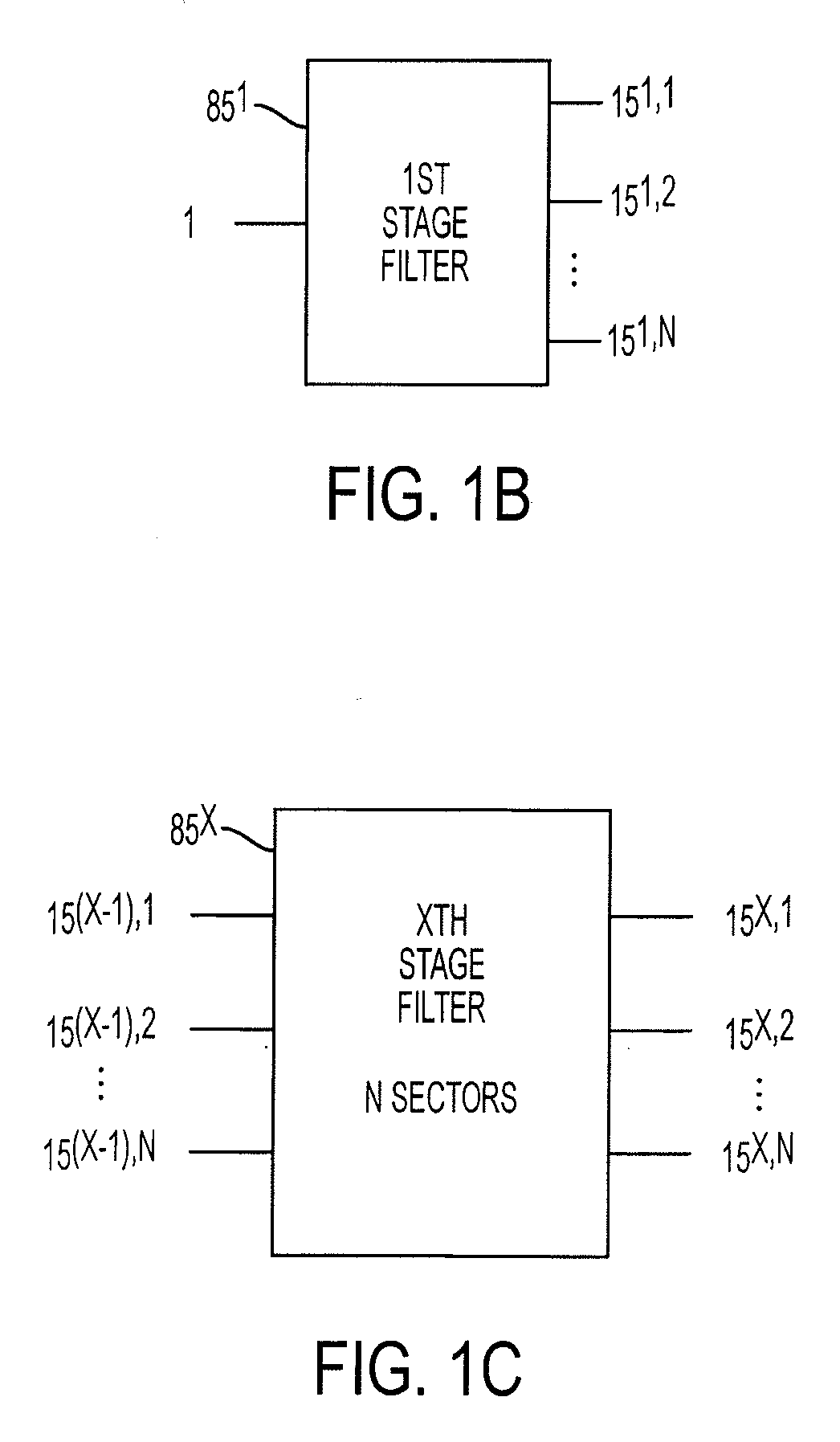

Flat top tunable filter with integrated detector

InactiveUS20090195715A1Maximum optical flatnessMinimal insertion lossOptical light guidesNon-linear opticsSingle stagePhotodetector

A free space tunable filter produces a passband output as a result of sequential processing by an array of narrowband tunable filters (NBTFs) each tuned to a slIghtly different frequency. The present invention is comprised of one or more stages having multiple interleaved sectors and comprising an array of NBTFs having a masked outer surface reflective coating. Stages cascading is used to increase the device figure of merit and single stages are partitioned into multiple sectors that process a specific interleaved region of the bandwidth. Final stage output group passband signals are combined in a multiplexer and tapped with a partially transparent photodetector.

Owner:XTELLUS USA

Pressure equalizing construction for nonporous acoustic membrane

ActiveUS10911847B2Reduce sensitivityReduce sound pressureSemiconductor electrostatic transducersElectrostatic transducer microphonesEngineeringAcoustic wave

A pressure equalizing assembly with a nonporous membrane traversing across an acoustic pathway defined by an opening in a housing. A breathable layer connected to the nonporous membrane may be laterally arranged to the acoustic pathway. An acoustic cavity is defined by the breathable layer and nonporous membrane. The nonporous membrane has a side facing the opening in the housing to prevent fluid or moisture from penetrating into the acoustic cavity. The breathable layer further equalizes pressure in the acoustic cavity by providing a venting layer.

Owner:WL GORE & ASSOC INC

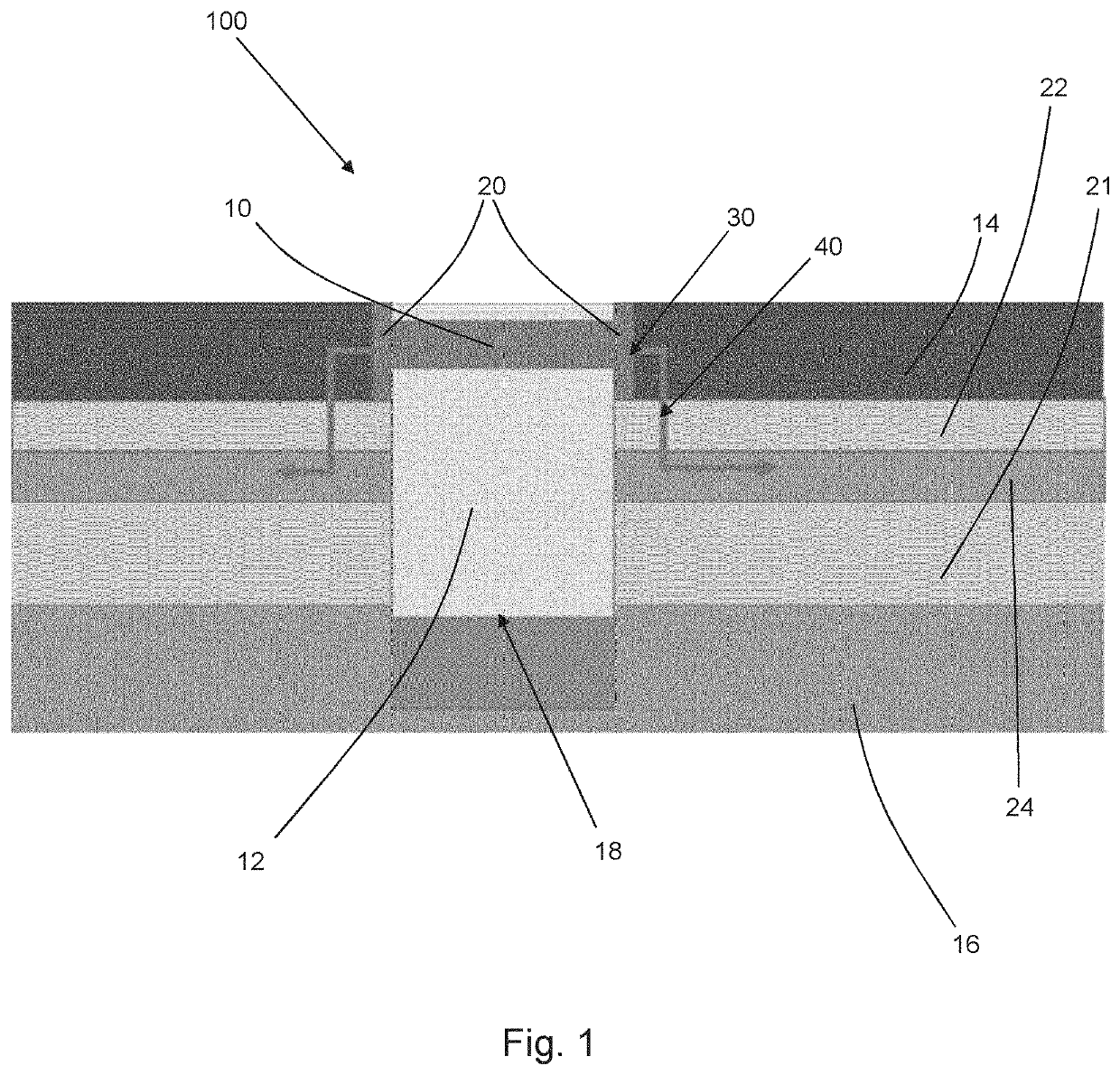

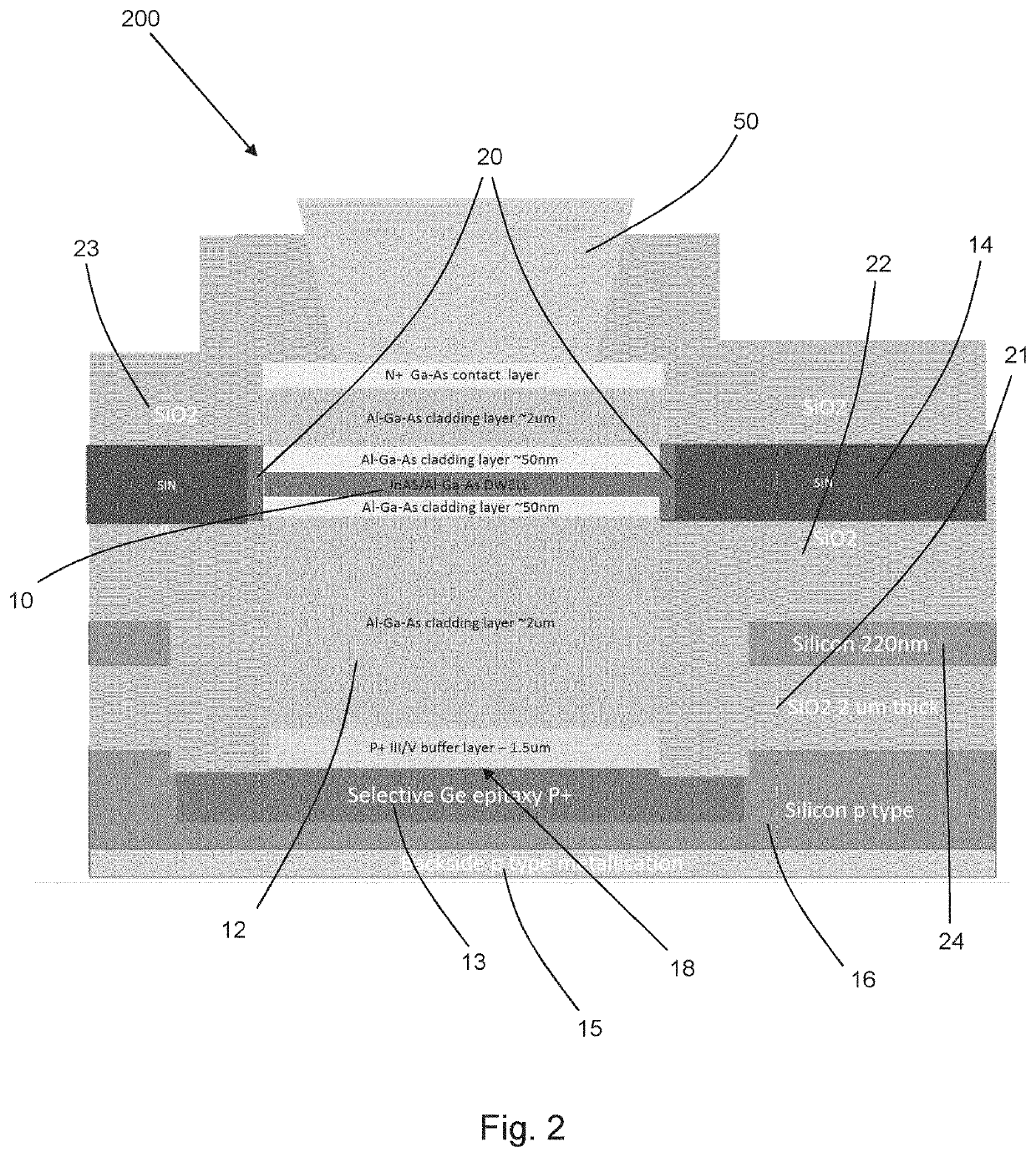

An optoelectronic semiconductor device

PendingUS20220255297A1Minimal insertion lossLow insertion lossLaser detailsLaser active region structureDeposition temperatureDevice material

A semiconductor device for use in an optoelectronic integrated circuit; the device comprising: a group four substrate, a waveguide, and a group III / V multilayer stack; wherein the group III / V multilayer stack comprises a quantum component for producing light for the waveguide; wherein the waveguide comprises a material with a deposition temperature below 550 degrees Celsius and a refractive index of any value between 1.3 and 3.8.

Owner:UNIV COLLEGE OF LONDON +1

Optical fiber connection device for a composite structure, composite structure for an aircraft, and manufacturing method thereof

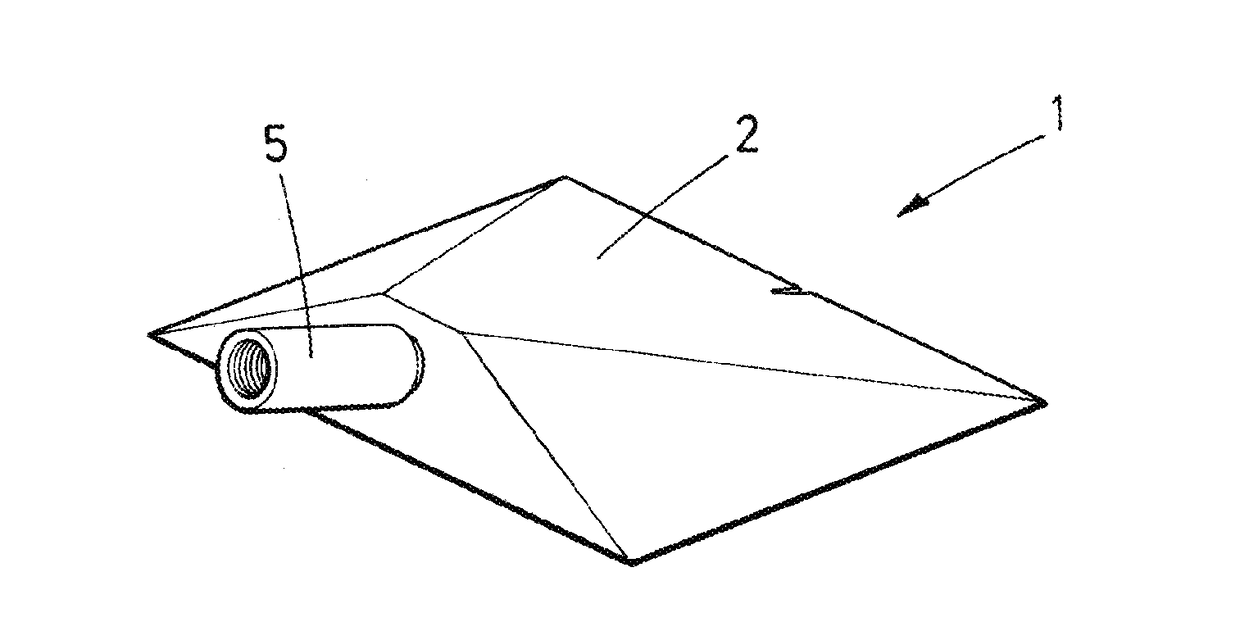

ActiveUS20180172921A1Provide informationSimple and cost-effectiveCoupling light guidesFibre mechanical structuresFiberEngineering

An optical fiber connection device comprising a prism, first and second connection elements, inner and outer ferrules and an elastic element. The prism has an inner conduit ending in a first bore configured to receive an input optical fiber, and in a second bore configured to receive the first connection element, which, in turn, is configured to receive the second connection element. This second connection element is also configured to receive an output optical fiber. The conduit comprises two sections forming a ramp to lead the input optical fiber towards the fibers connection. The first connection element has an inner box, and the second connection element has an outer protrusion to provide a unique connecting position. The inner and outer ferrules, and the elastic element are retained in the second connection element.

Owner:AIRBUS OPERATIONS SL

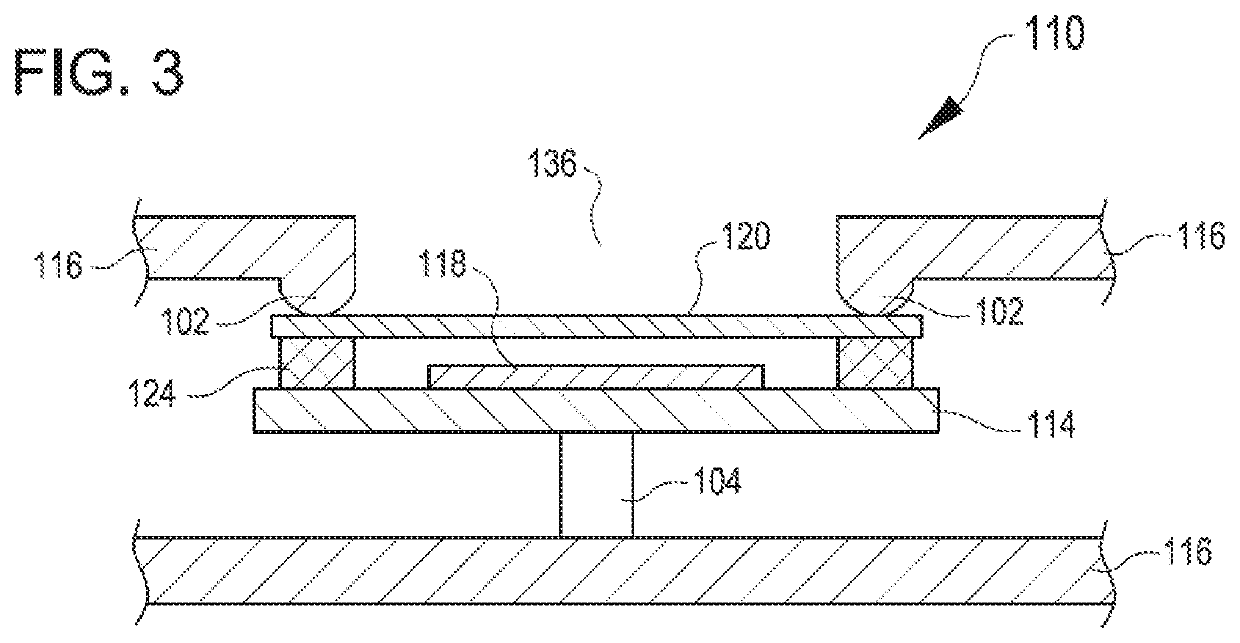

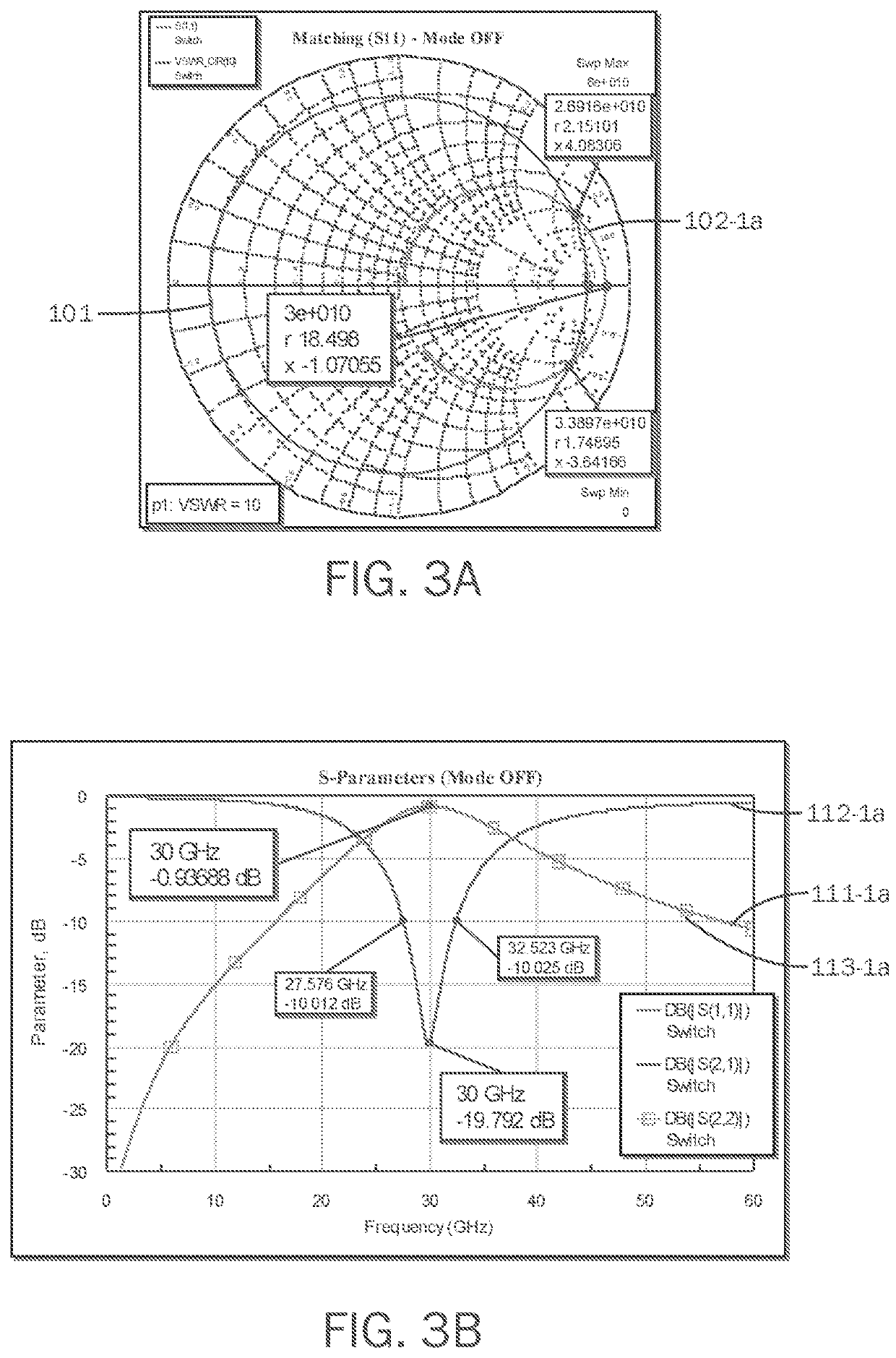

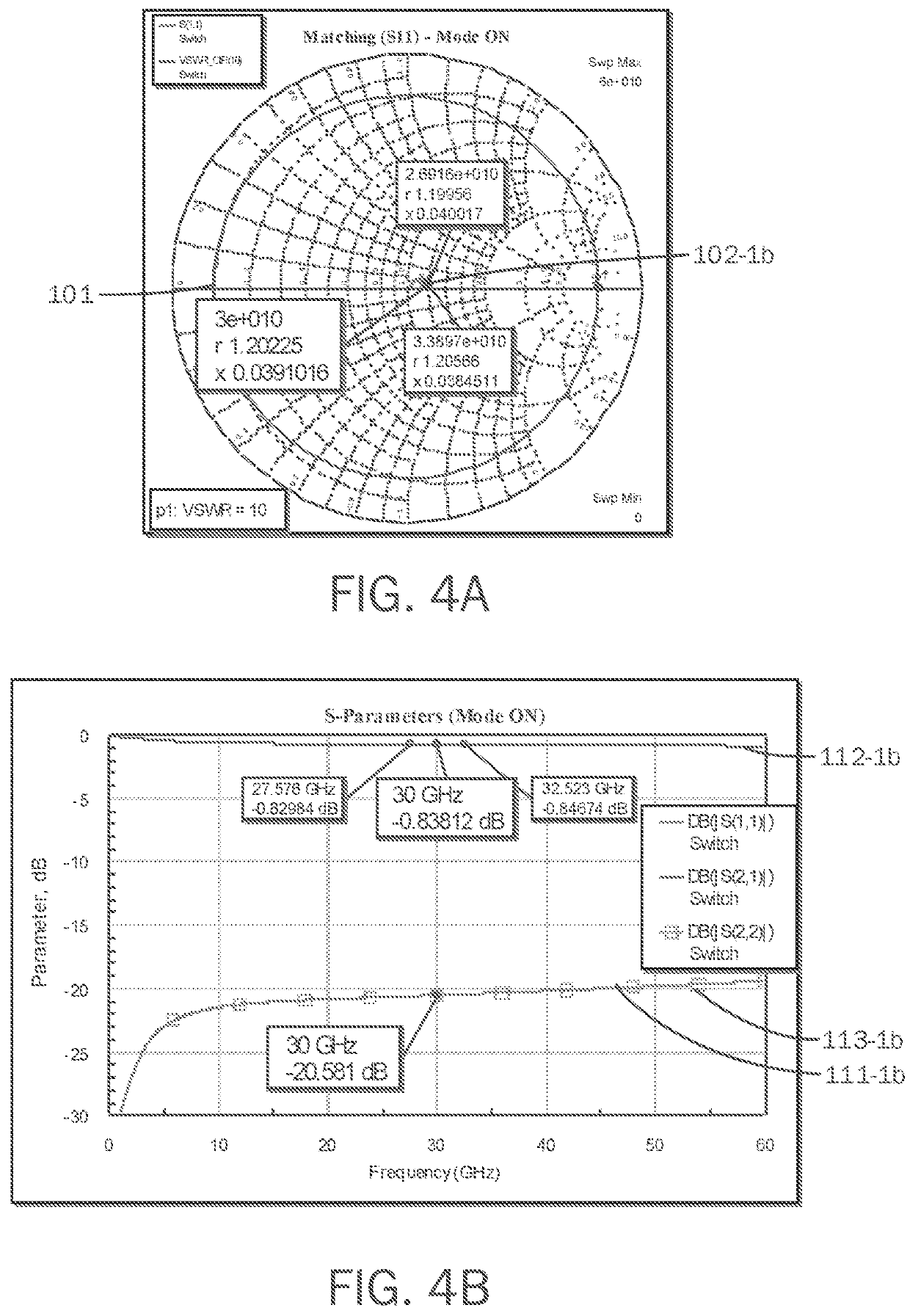

Low-loss mm-wave CMOS resonant switch

ActiveUS11437992B2Minimal insertion lossElectronic switchingTransmissionCMOSElectromagnetic coupling

A resonant switch with a first port and a second port has a capacitor connected thereto. A triple inductor network has a center inductor connected to the first port and the second port, and first and second peripheral inductors each electromagnetically coupled thereto. In a deactivated state, the center inductor and the capacitor define a parallel resonance at a predefined operating frequency range, and in an activated state, insertion loss associated with the center inductor is substantially minimized to metallic trace loss attributable thereto.

Owner:MOBIX LABS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com