Device for producing high speed air projectiles or pulses

a high-speed air and projectile technology, applied in the field of air cannons, can solve problems such as air pressure, achieve the effects of increasing the volume of air that is displaced, fast response, and increasing electrical power handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

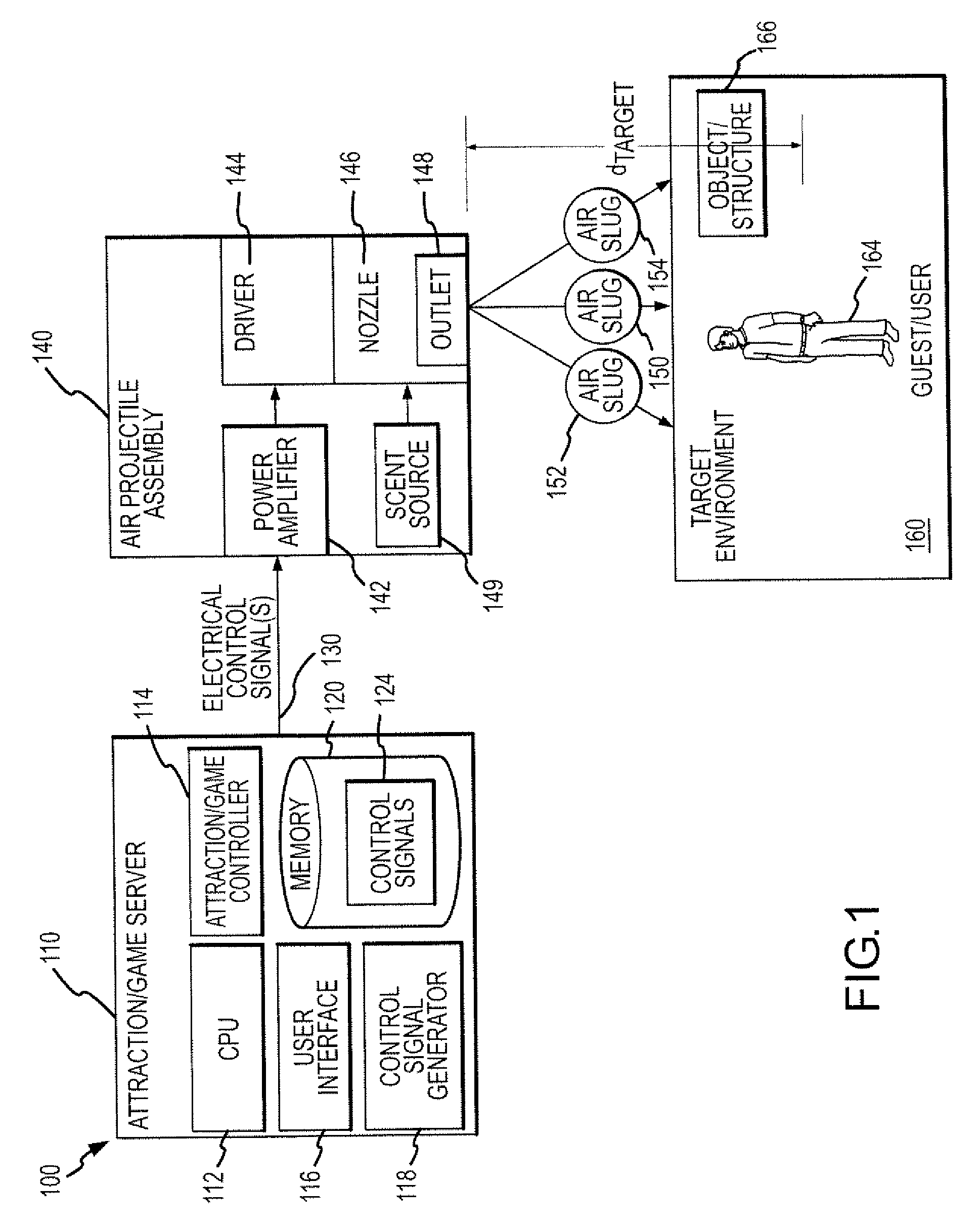

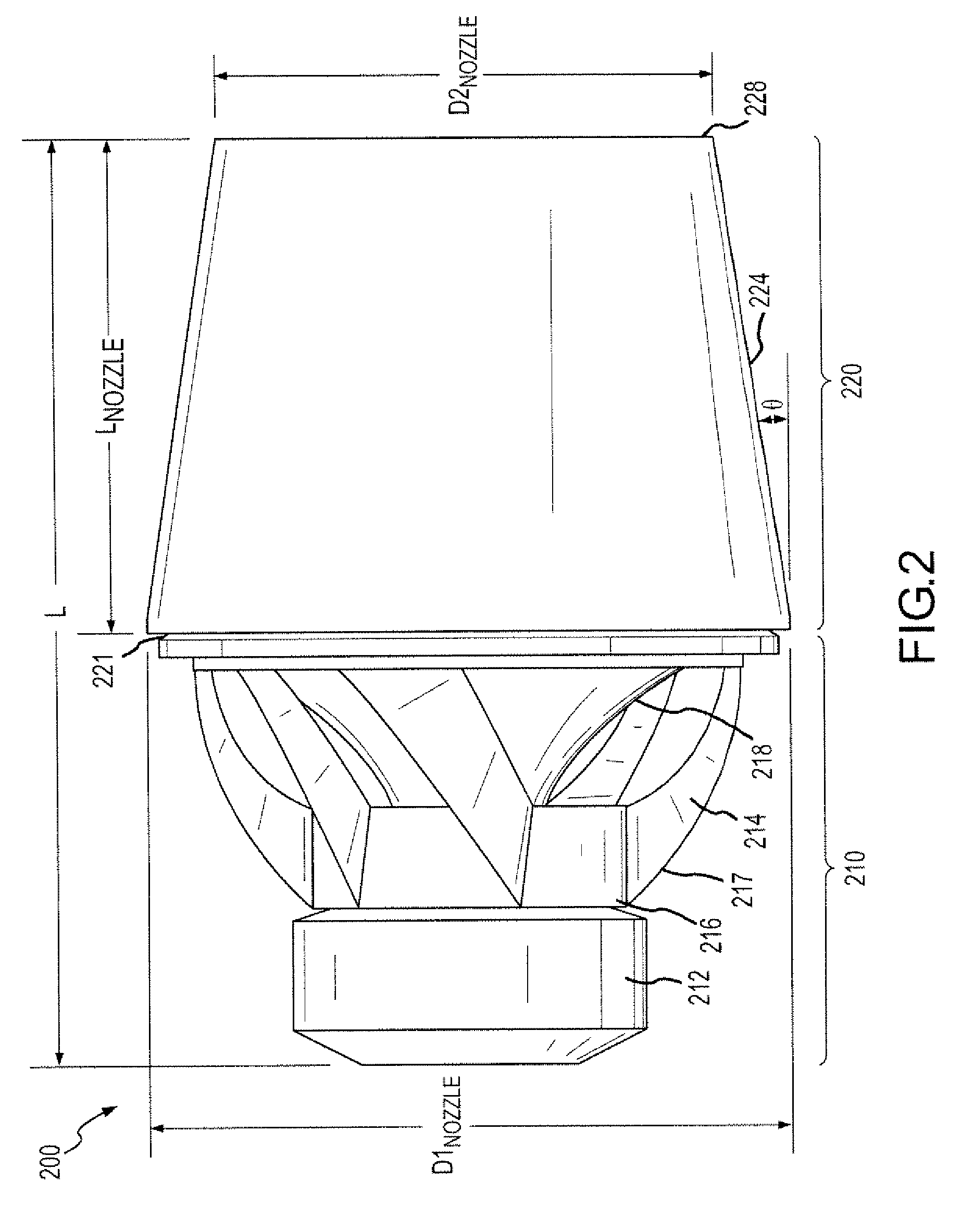

[0018]Briefly, the present invention is directed to air projectile devices that utilize a driver such as a bass audio speaker or woofer combined with a converging nozzle. The driver is triggered or controlled by a pulse such as an audio or other electrical signal that is typically amplified so as to cause a relatively large flexible membrane or cone of the driver to rapidly move or travel through its throw (e.g., at least the forward or outward portion of the driver's excursion or throw). The driver membrane or cone is provided proximate to the larger end of the nozzle and displaces a volume of air in the bore or chamber of the nozzle that is forced through the outlet in the smaller end of the nozzle toward a target. The nozzle acts to concentrate the air into a projectile or slug that is expelled at high velocity out the small diameter outlet (e.g., less than about 5 inches such as about 2 inches diameter circular hole) in the nozzle's muzzle, which may planar or, in some cases, fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com