Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Increased ring flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

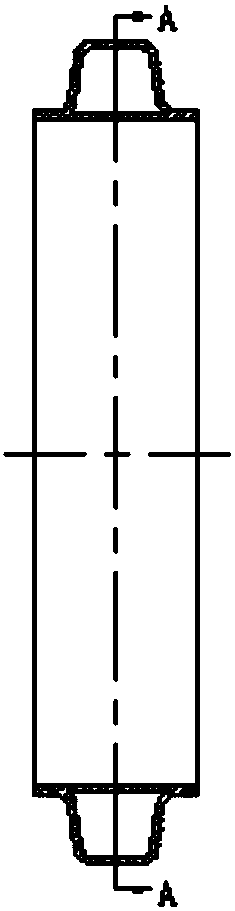

Compound double-wall corrugated pipe and preparation process thereof

InactiveCN101761710AIncreased ring stiffnessImprove toughnessFlexible pipesPolymer scienceEngineering

The invention discloses a compound double-wall corrugated pipe, which is prepared from the following components in part by weight: 100 parts of mixture of polythene and polypropylene, 3-10 parts of coupling agent, 3-10 parts of rigid particle, 2-6 parts of master batch, 2-6 parts of blue batch and 3-9 parts of defoaming agent. The preparation process comprises the following steps of: evenly mixing the components in a high-speed mixer; after evenly mixing in a cold mixer, extruding tubes by using a double-host single screw extruder; modulizing, vacuumizing and cooling the tubes to form; and fixing the length and cutting and packaging the tubes. With the blending and the modification of polypropylene and polythene and the use of the rigid particles, the compound double-wall corrugated pipe well solves the problem of strong and unyielding balance, i.e. the tubes has higher toughness while having high annular rigidity. The tubes are made of completely non-toxic raw material and have good sanitary performance as well as the characteristic of simple production process.

Owner:山东华信塑胶股份有限公司

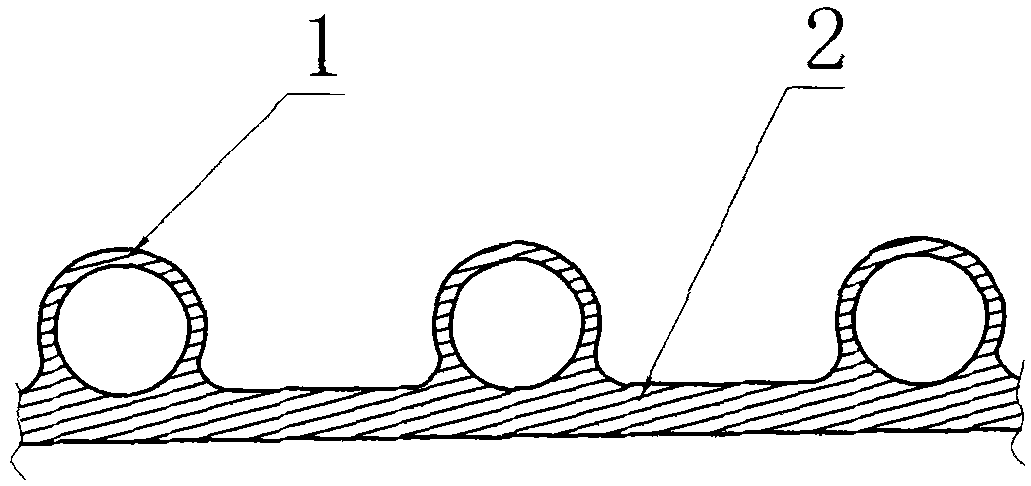

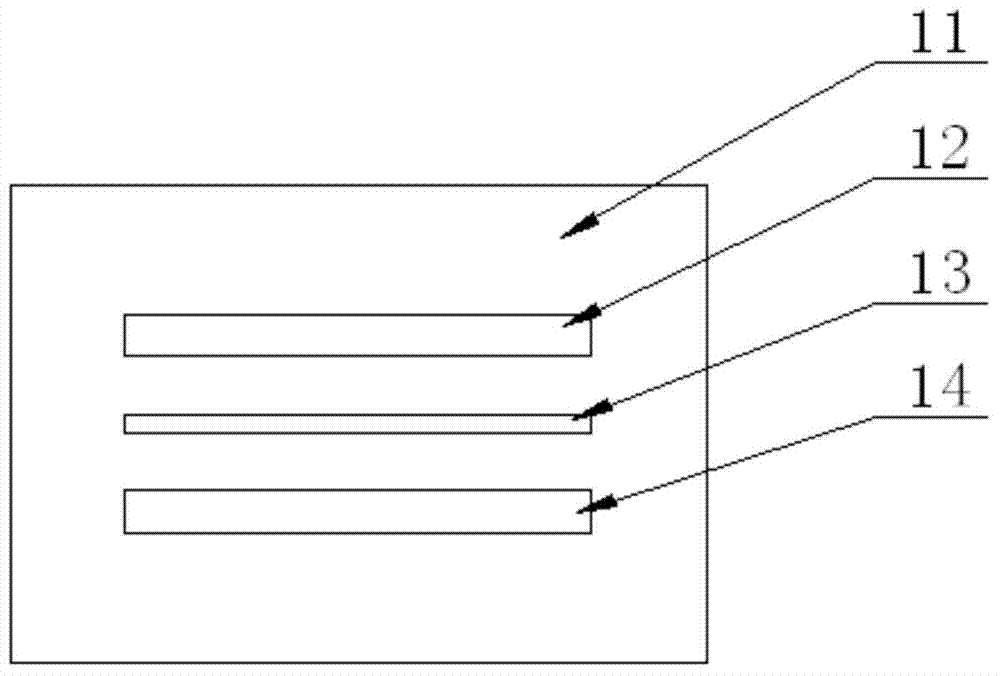

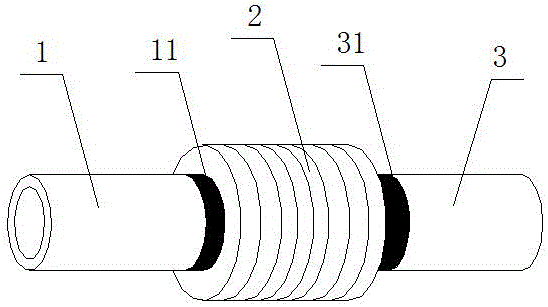

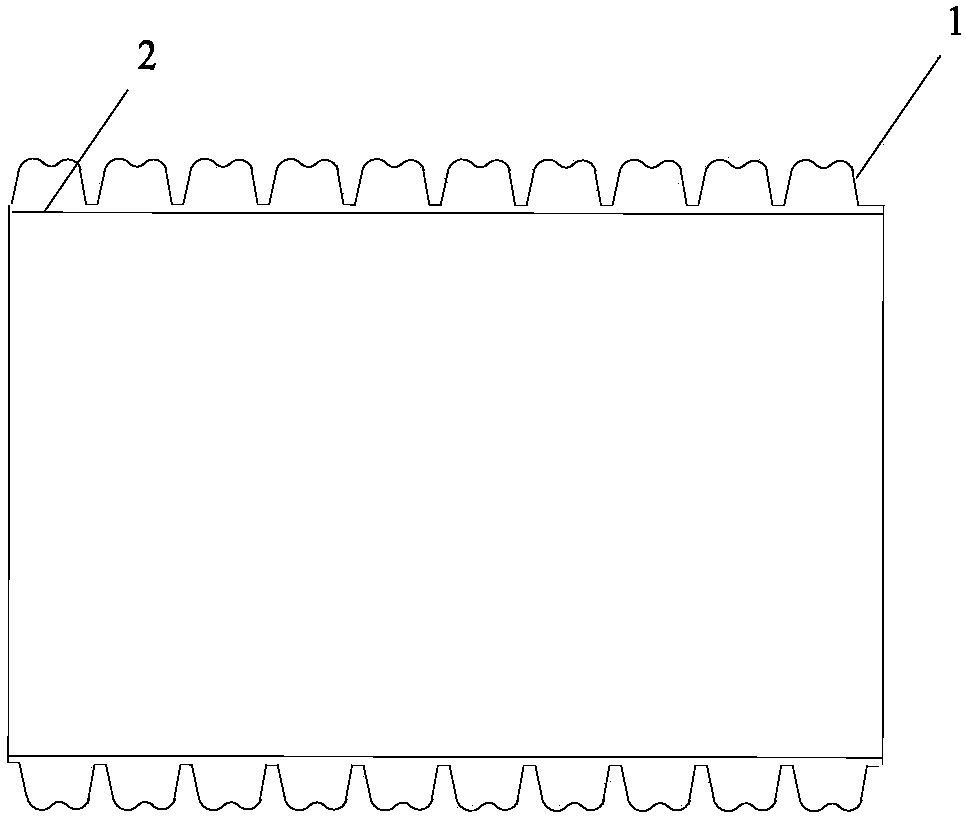

Polyethylene-wound structure wall tube and pipe without frame pipe and production method thereof

InactiveCN101852316AEnhanced centroid heightStrengthen heart distance heightRigid pipesSolid wallConductor Coil

The invention relates to a polyethylene-wound structure wall tube and pipe without a frame pipe, which is composed of an inner wall layer and an outer wall layer, wherein the inner wall layer is a continuous solid wall pipe formed by spirally winding a flaky polyethylene band, and adjacent band edges orderly being overlapped with each other; and the outer wall layer is composed of convex stiffening ribs formed by spirally winding a tubular polyethylene band on the external surface of the inner wall layer, and the tubular polyethylene band spirally presses across the overlap seam of each adjacent flaky polyethylene band edges. The production method comprises the following steps: extruding profiled bars, stretching, sizing, winding and fusing. The production method removes the original polypropylene frame pipe, can ensure the centroid distance of the stiffening rib tube, reduce the product weight by more than 20%, reduce raw material consumption, lower the product cost, greatly decrease the internal stress of the tube and pipe, reduce consumption and enhance ring stiff and ring flexibility.

Owner:韩路平 +2

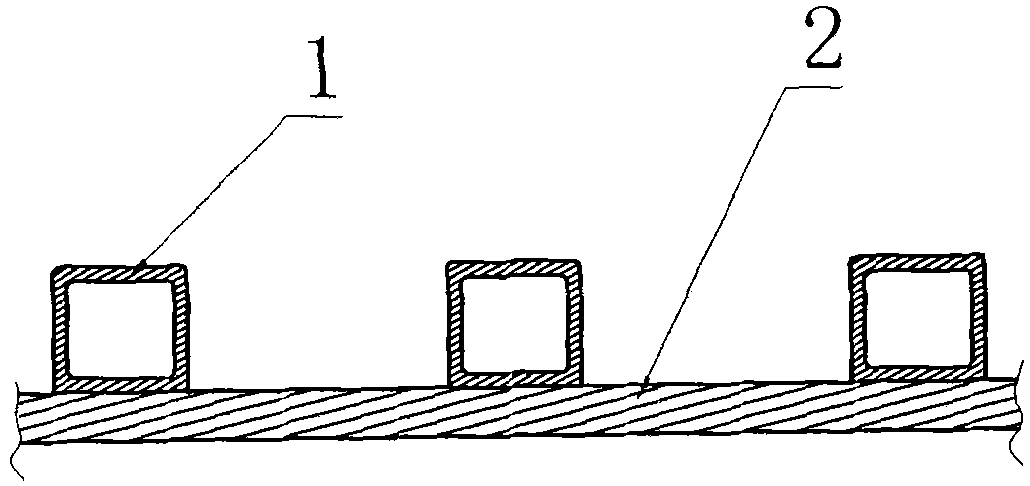

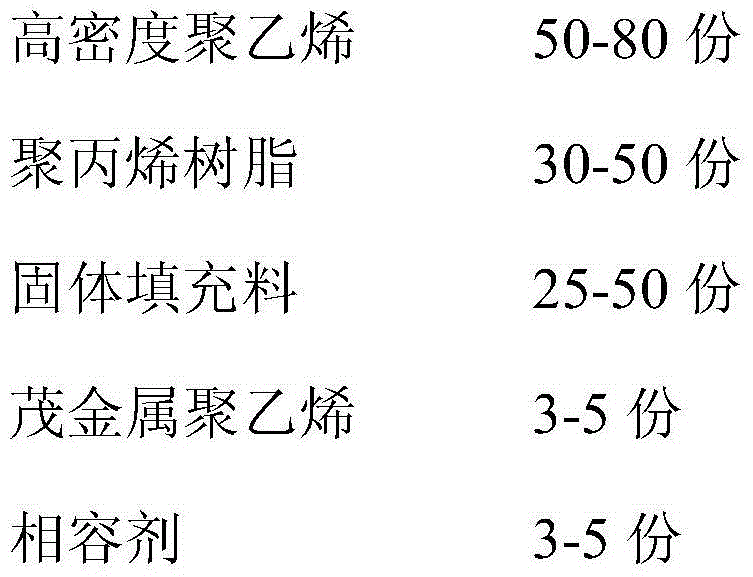

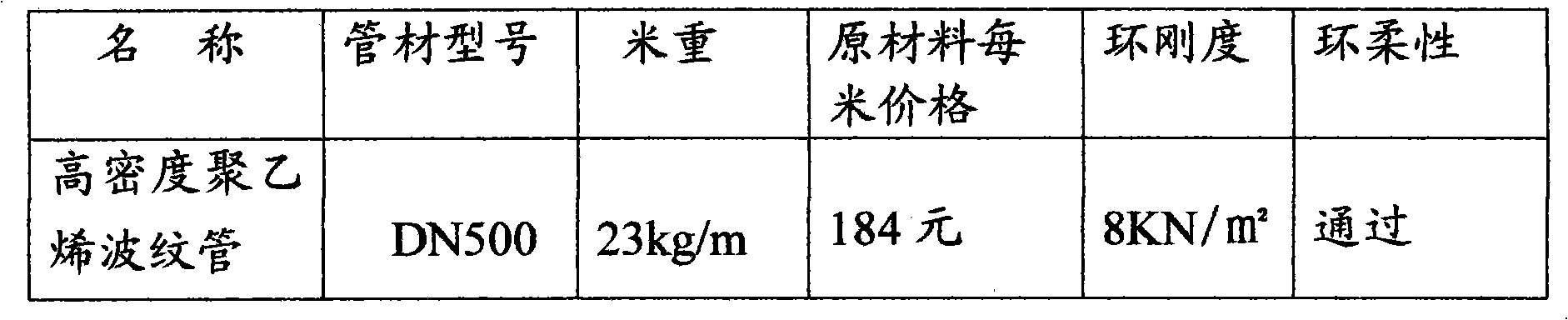

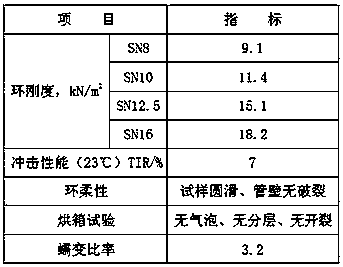

High-density polyethylene double-wall corrugated pipe

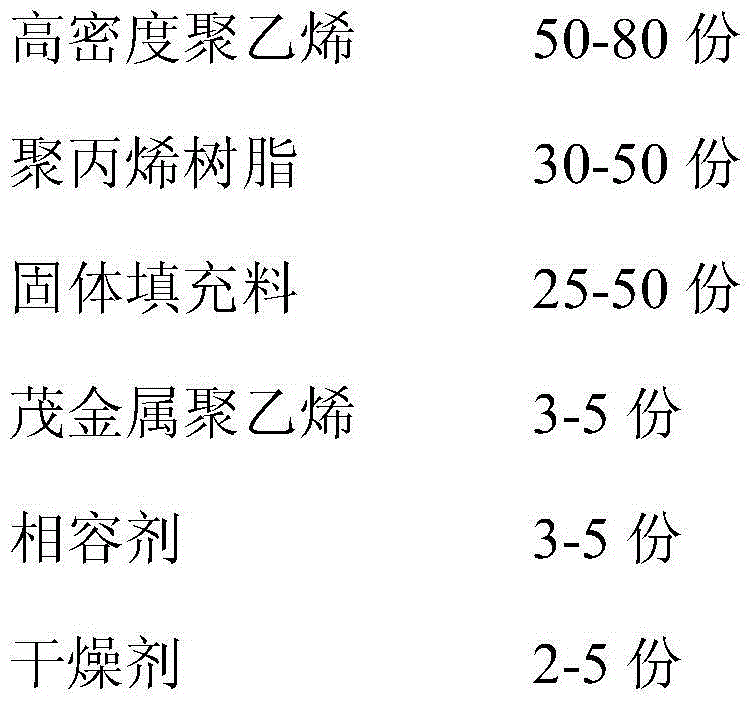

InactiveCN104910483AHigh melt strength and rigidityGood impact resistanceFlexible pipesLight pipePolypropylene

The present invention relates to the field of engineering plastic processing manufacturing, and discloses a high-density polyethylene double-wall corrugated pipe, which comprises an outer pipe and an inner pipe, wherein the materials of the outer pipe comprise 50-80 parts of high-density polyethylene, 30-50 parts of a polypropylene resin, 25-50 parts of a solid filling material, 3-5 parts of metallocene polyethylene, 3-5 parts of a compatibilizing agent, and 2-5 parts of a drying agent, and the materials of the inner pipe comprise 50-80 parts of high-density polyethylene, 30-50 parts of a solid filling material, and 2-5 parts of a drying agent. According to the modified high-density polyethylene double-wall corrugated pipe of the present invention, the inner pipe and the outer pipe have characteristics of high melt strength, high rigidity and good impact resistance, such that the double-wall corrugated pipe has characteristics of high ring rigidity, good compression resistance, and light pipe weight; the metallocene polyethylene is added to the materials of the outer pipe, such that the ring flexibility of the outer pipe is increased, and the toughness is good; and the high-density polyethylene double-wall corrugated pipe can be widely used in non-pressure plastic underground drainage and sewage drain pipelines, and has good application prospects and market competitiveness in the fields of plastic pipelines.

Owner:浙江中财管道科技股份有限公司

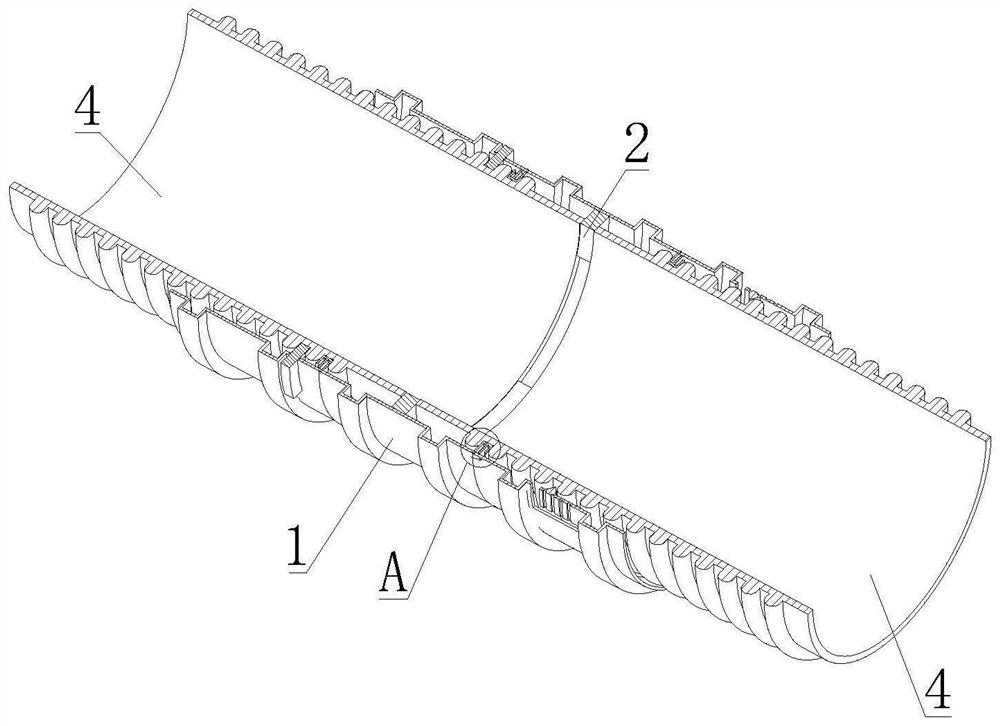

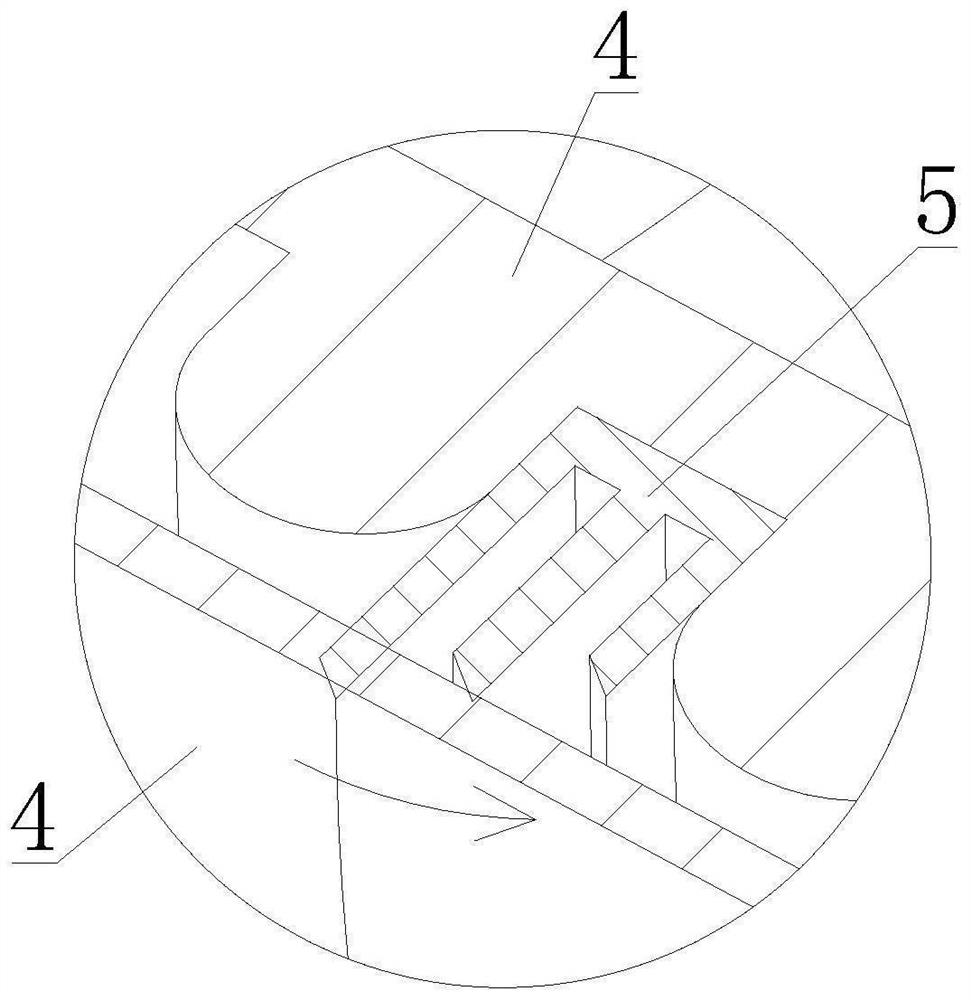

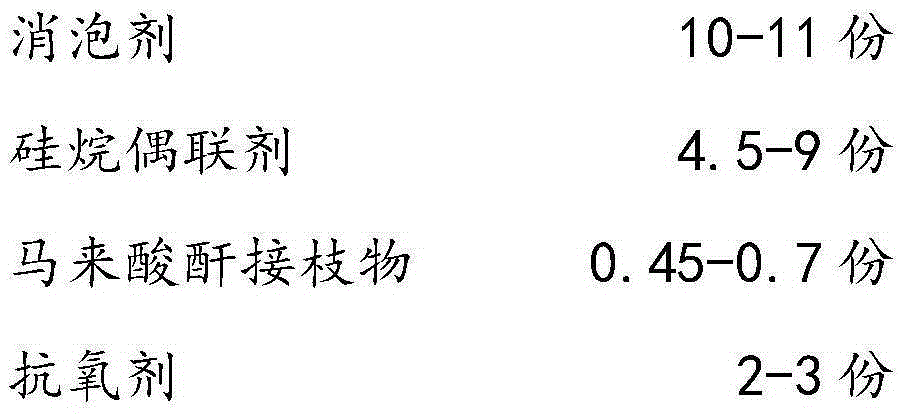

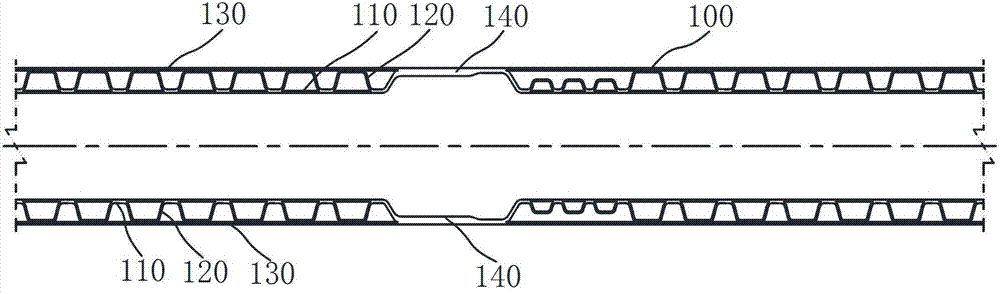

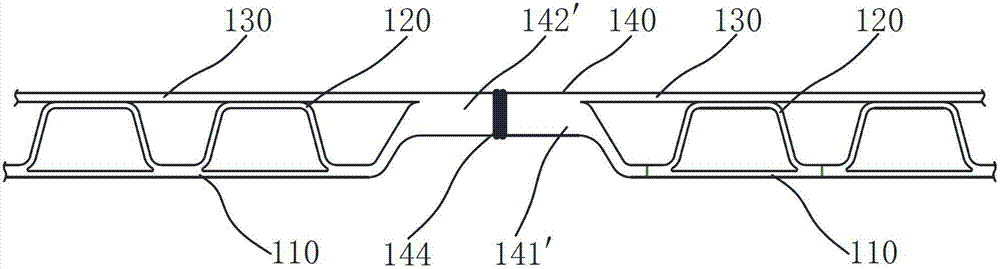

Three-wall corrugated pipe and manufacturing equipment thereof

The invention discloses a three-wall corrugated pipe and manufacturing equipment thereof. The pipe includes a pipe body, which includes a smooth inner wall layer, a corrugated intermediate layer and a smooth outer wall layer. The inner wall layer and the outer wall layer are closely connected with the crests or troughs of the intermediate layer, and the pipe body is provided with connection ports for mutual connection. Compared with prior arts, the inventive corrugated pipe has a smooth outer wall, which facilitates dragging and rolling during transportation and construction processes and avoids outer wall corrugation breakage and recess to further influence pipe use. Meanwhile, the outer wall layer is covered, in a molten state, on the outer wall of a double-wall corrugated pipe, which increases the pipe wave height and the moment of inertia to realize higher ring stiffness of the pipe and production of pipes with higher strength requirements on one hand, and increases the longitudinal bending strength of the pipe and improves the ring flexibility of the pipe on the other hand, thus realizing the purpose of the invention.

Owner:公元管道(上海)有限公司

Composite mixture and preparation method thereof

InactiveCN102153800AImprove mechanical propertiesMacrocyclic flexibilityRigid pipesLow-density polyethylenePolyethylene terephthalate glycol

The invention provides a composite mixture and a preparation method thereof. The composite mixture comprises the following components in parts by weight: 60-80 parts of polyethylene (PE), 20-40 parts of polyethylene terephthalate (PET), 0.1-0.5 part of tackifier, 4-8 parts of impact modifier and 5-10 parts of compatilizer. Because the new compatilizer is adopted to make the PE and the PET compatible with each other, the problem that interfaces are incompatible is solved, and the mechanical properties of the prepared composite mixture are far better than those of the PE and the PET; in addition, the tensile strength of the prepared composite mixture is improved by 40%, the flexural modulus is improved by 200%, and the impact performance is kept unchanged compared with those of the high-density polyethylene (HDPE) pipe material; and moreover, the developed material specially used for making the drain pipe has lower cost than the original formula for making the drain pipe, and the ring stiffness of the product is improved by 40%.

Owner:QINGDAO ZHIYUAN PAKE PLASTICS

Polythene glass fiber winding structure wall tube stock and production method thereof

ActiveCN103925431AEnhanced centroid heightReduce consumptionFlexible pipesFiberglass meshGlass fiber

The invention relates to a polythene glass fiber winding structure wall tube stock which is composed of an inner wall layer and an outer wall layer. The inner wall layer is characterized in that a composite material strip formed by adding a glass fiber material strip between an upper flaky polyethylene strip and a lower flaky polyethylene strip winds a roller mold, and edges of the neighboring composite strips are sequentially mutually lapped to form a continuous solid wall tube; the outer wall layer is characterized by being formed by outer protruding reinforcing ribs formed by the fact that another glass fiber material strip covering between an outer tubular polyethylene strip and an inner tubular polyethylene strip winds the outer surface of the inner wall layer, and the outer protruding reinforcing ribs spirally strides a lapping fusion joint of edges of the neighboring composite strips of the inner wall layer. The tubular pitch height of the reinforcing ribs can be guaranteed by adopting the glass fiber strips, good alkali resistance, flexibility and tensile resistance in the longitude and latitude height are achieved by the aid of fiberglass mesh fabric, the weight of the product is reduced, raw material consumption is reduced, cost of the product is low, internal stress of the tube stock is greatly reduced, consumption is reduced, and ring stiffness, ring flexibility and crack resistance are improved.

Owner:天津业和科技有限公司

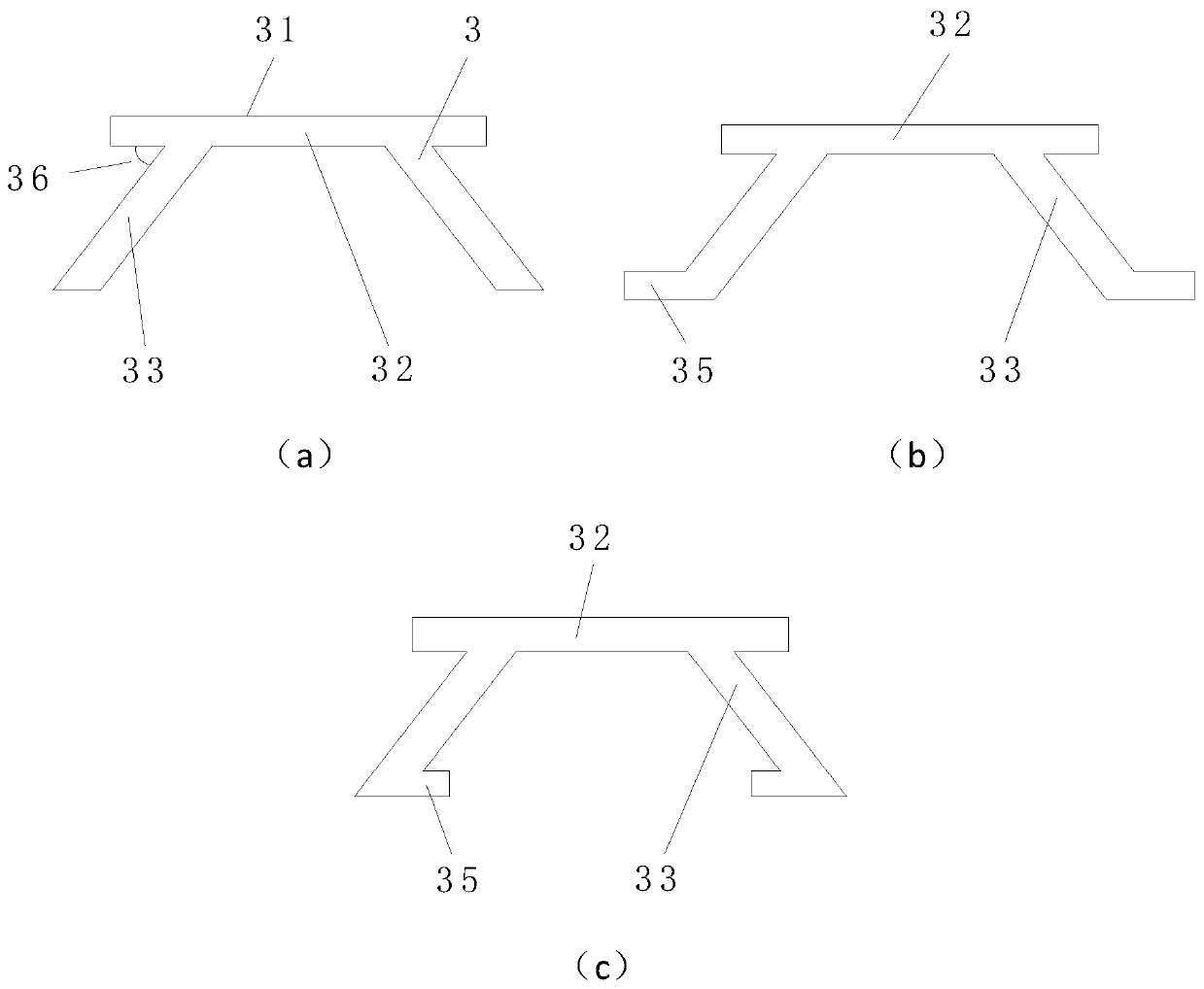

Preparation method of double-layer ribbed bi-color reinforced composite pipe

InactiveCN106182679AIncreased ring flexibilityIncreased ring stiffnessTubular articlesEngineeringColor structure

The invention discloses a preparation method of a double-layer ribbed bi-color reinforced composite pipe. Plastic ribbed special-shaped strips are extruded through a first extruding machine and a second extruding machine together, then the strips are wound through a molding roller, then molten plastisol is extruded into the strips through a third extruding machine and a fourth extruding machine, and the double-layer ribbed bi-color reinforced composite pipe is obtained through extrusion. The double-layer ribbed bi-color reinforced composite pipe is of a double-layer bi-color structure, so that the double-layer ribbed bi-color reinforced composite pipe is more attractive, and the characteristic of conveniently recognizing the product is achieved at the same time; and meanwhile, ribs corresponding to hollow cavities in the two sides of a wave trough can improve the ring flexibility and ring stiffness of the pipe.

Owner:SICHUAN AVIATION TUBE IND CO LTD

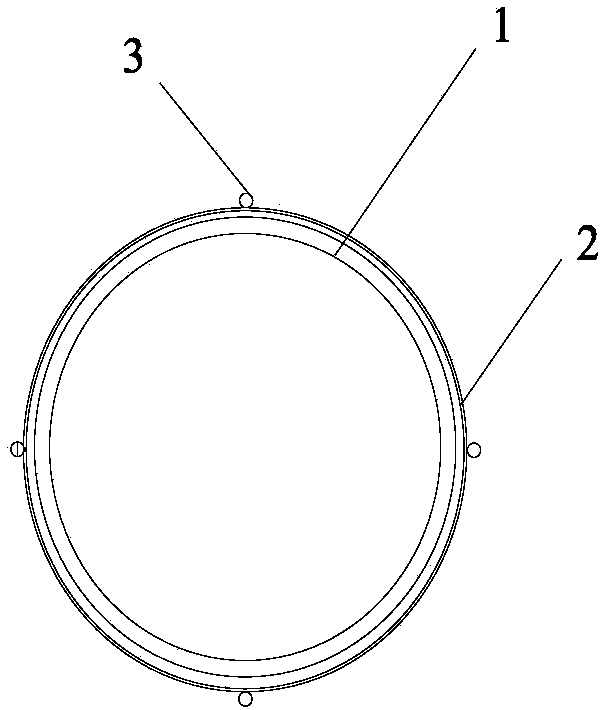

MUPO double-layer double-wave structure wall pipe

PendingCN114033897AIncreased ring stiffnessIncreased ring flexibilityRigid pipesElastomerWave structure

The invention relates to the technical field of polymer composite materials, in particular to an MUPO double-layer double-wave structure wall pipe which is formed by an inner layer and an outer layer through hot melting compounding, and the inner layer and the outer layer are both made of nano modified polyolefin materials. Each nano modified polyolefin material comprises the following raw materials in parts by weight: 60-70 parts of polyolefin, 5-10 parts of a composite cold-resistant elastomer toughening agent and 35-20 parts of an inorganic nano composite toughening and reinforcing material, the nano modified polyolefin material comprises the following raw materials in parts by weight: 60-70 parts of polyolefin, 5-10 parts of a composite cold-resistant elastomer toughening agent and 35-20 parts of an inorganic nano composite toughening and reinforcing material, and he composite cold-resistant elastomer toughening agent is prepared from the following ingredients in parts by weight: 80 parts of ethylene-octylene copolymer, 20 parts of EVA (Ethylene Vinyl Acetate), 3-6 parts of styrene, 3-6 parts of maleic anhydride and 1-3 parts of dicumyl peroxide. The ring stiffness, the ring flexibility, the cold resistance, the impact resistance and the like are obviously improved, and the performance requirements of the buried blow-off pipe can be met.

Owner:安徽国天成科技有限公司

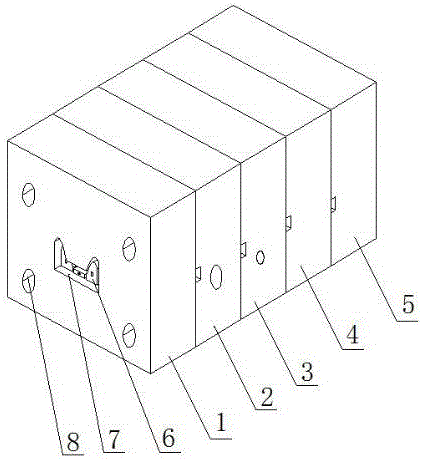

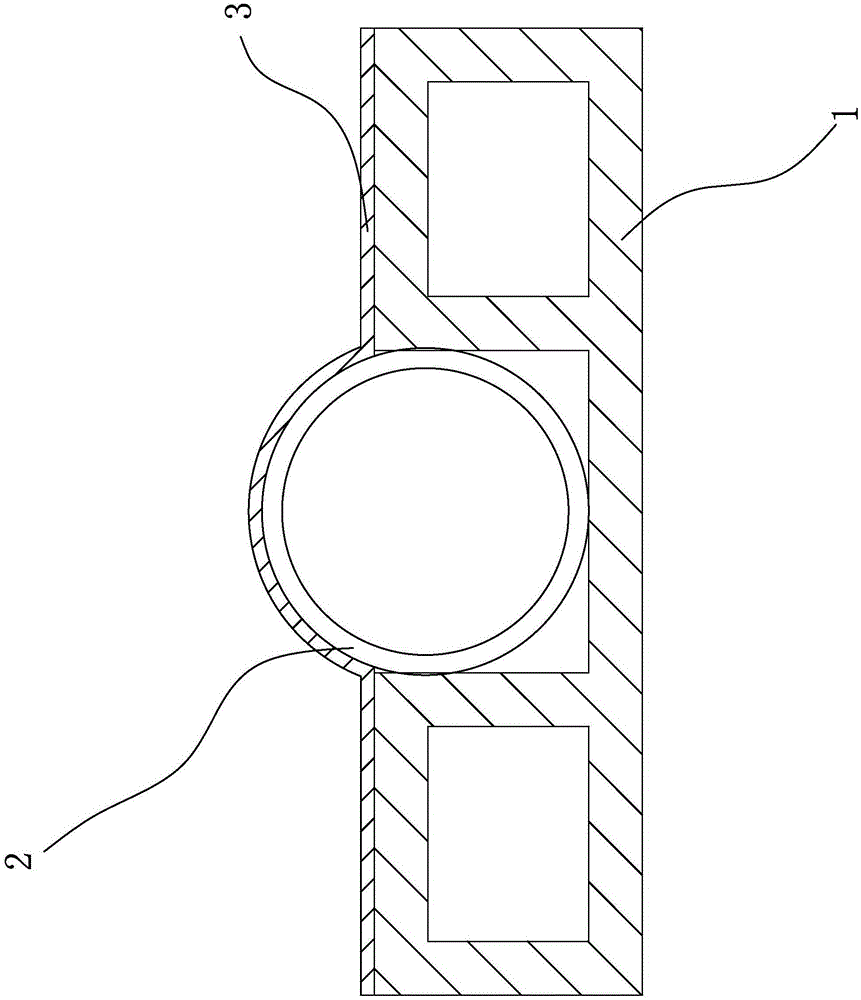

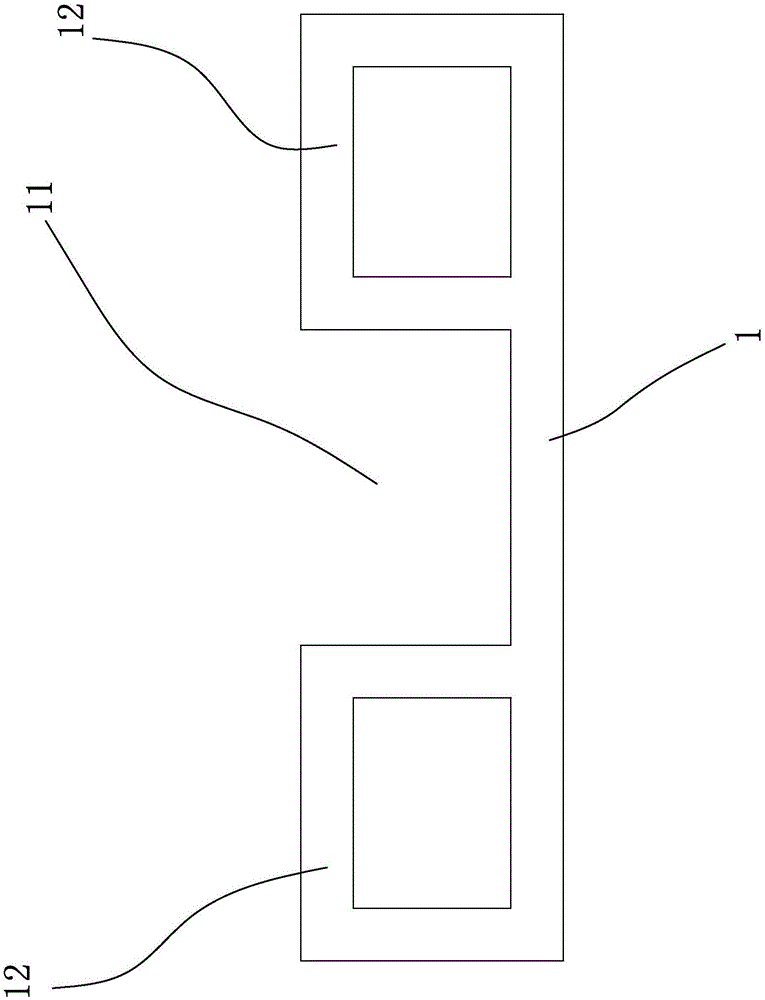

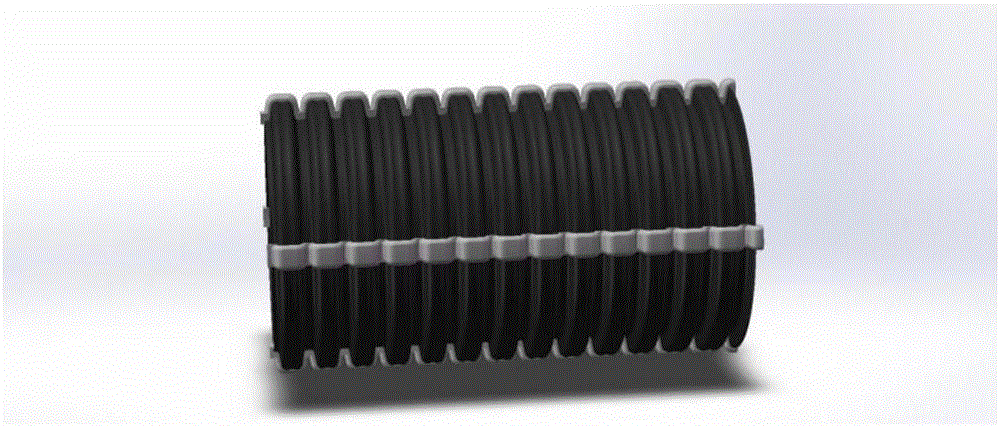

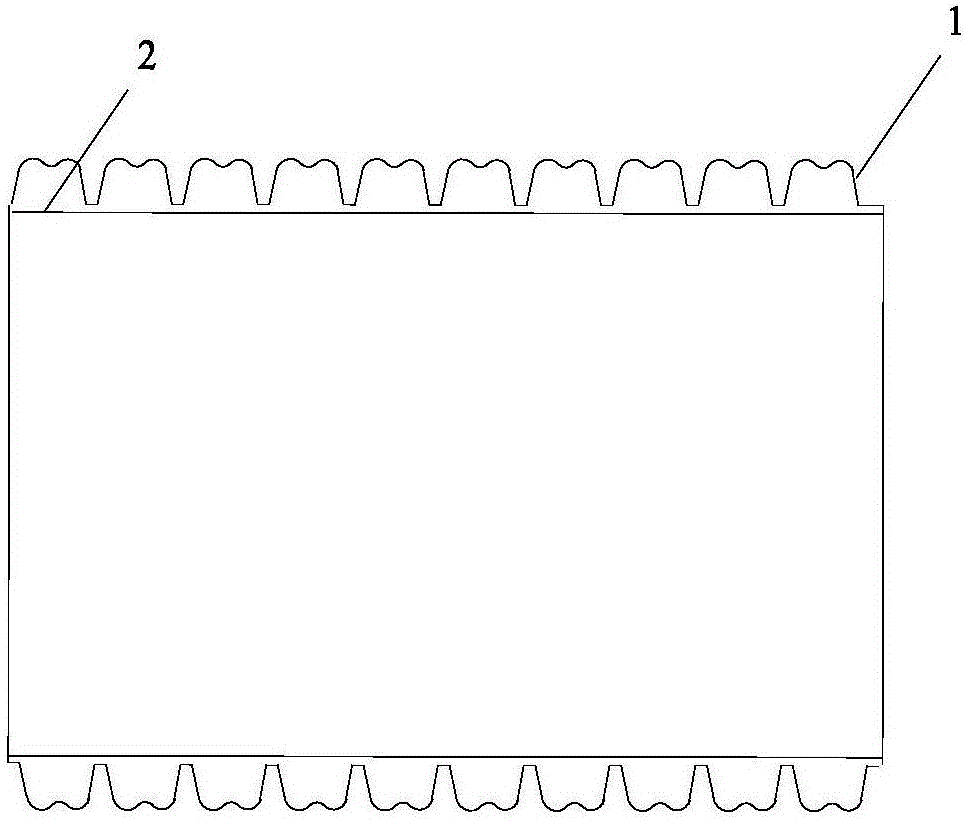

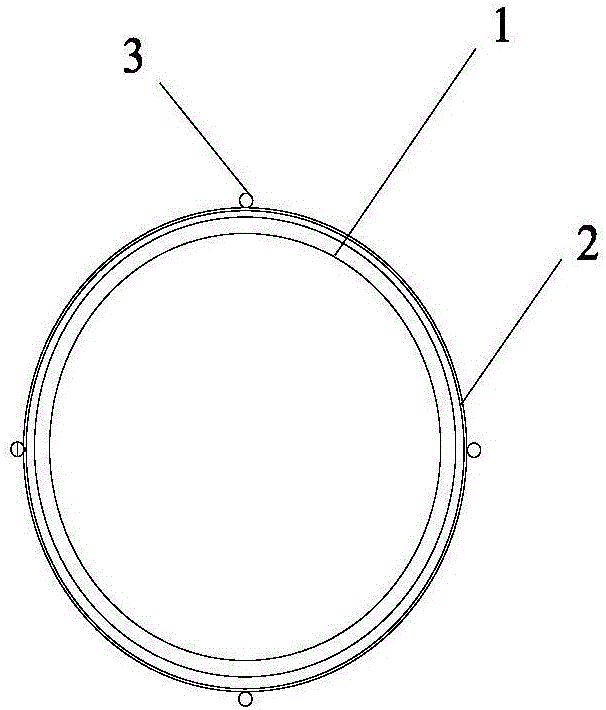

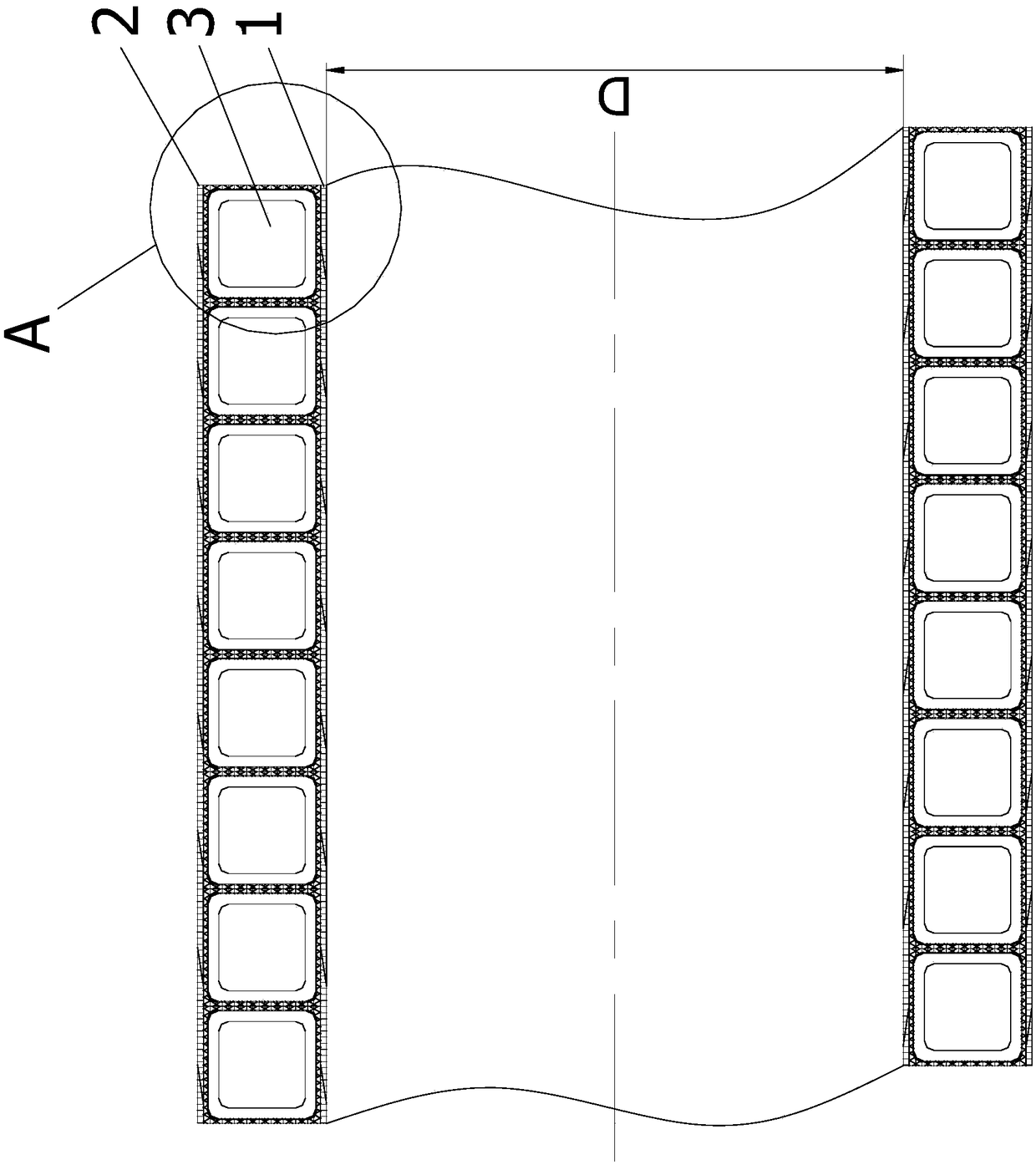

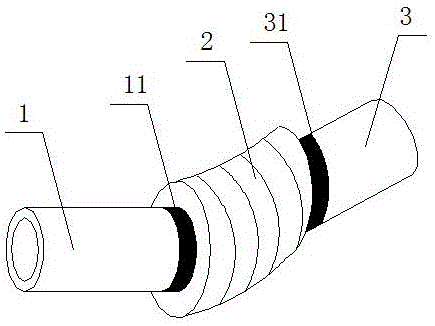

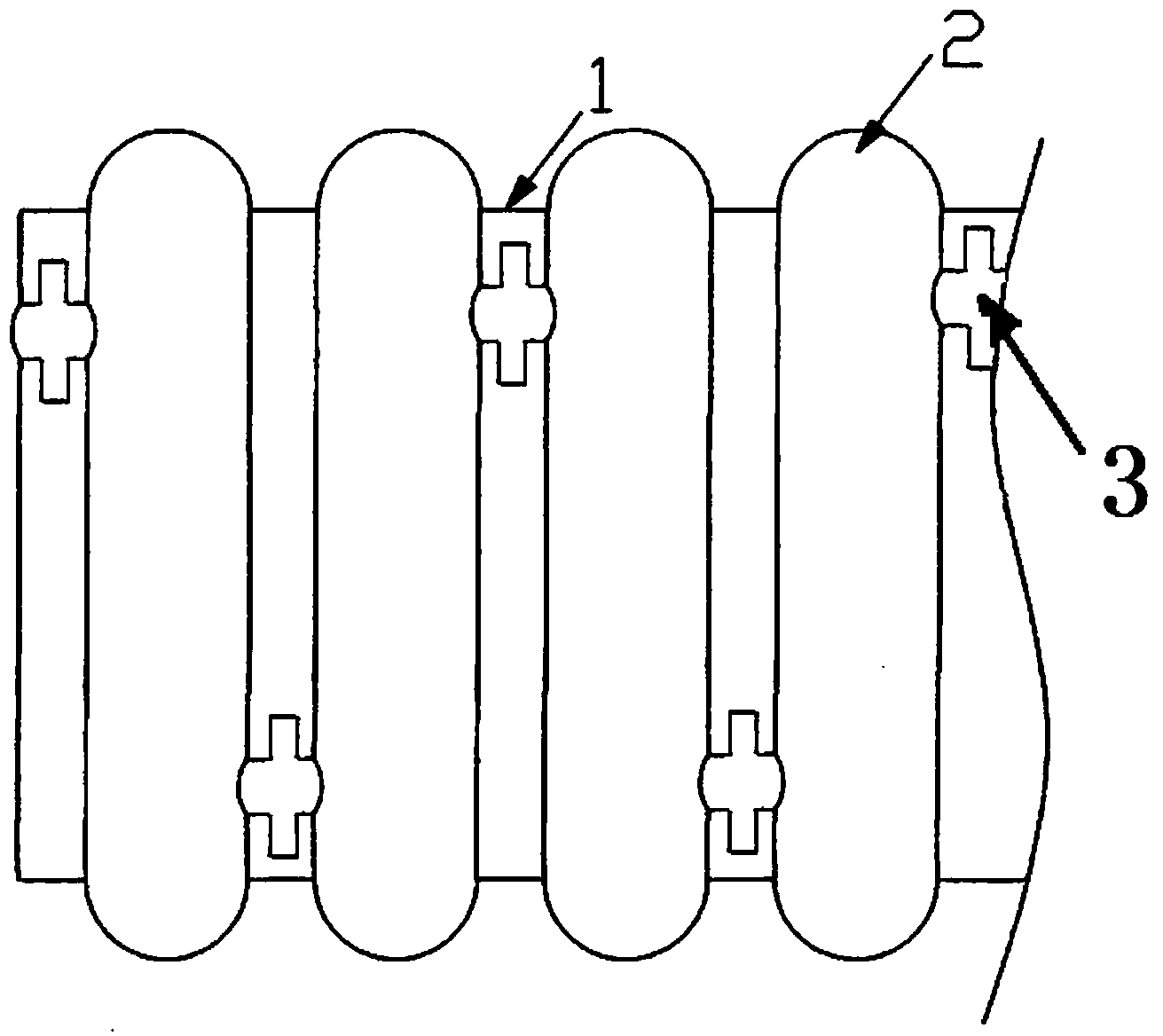

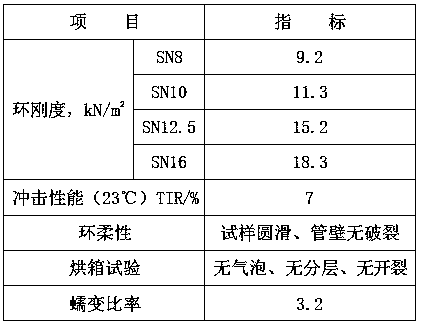

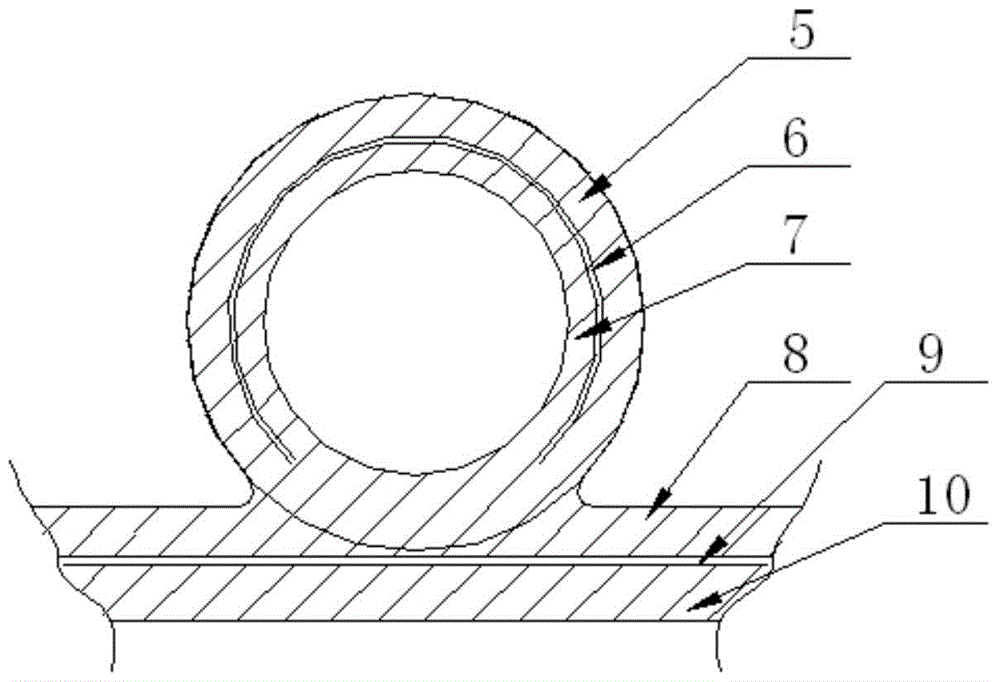

Composite reinforced winding pipe and preparation method thereof

ActiveCN109944984AIncreased ring stiffness and ring flexibilityImprove the safety of useRigid pipesEngineeringConductor Coil

The invention relates to a composite reinforced winding pipe. The composite reinforced winding pipe comprises a hollow pipe wall and a reinforced framework, the reinforced framework is arranged in thehollow pipe wall, a through hole is formed in the outer wall of the hollow pipe wall, the top of the reinforced framework is aligned with the outer wall, and a gap is formed between the top of the reinforced framework and the outer walls of the two sides of the reinforced framework, the hollow pipe wall is made of HDPE material, the reinforced framework is made of a PVC material, and an HDPE material layer is hot-coated on the outer surface of the hollow pipe wall. The invention further relates to a preparation method of the composite reinforced winding pipe. The preparation method comprisesthe following steps that the PVC reinforced framework is produced by using an extruder, and double-screw-rod extruding, shaping, cooling and winding rolling are conducted for using; an HDPE hollow strip is produced by using the extruder, single-screw-rod extruding, shaping, cooling and winding rolling are conducted for using; and the HDPE hollow strip and the PVC reinforced framework are wound, composited and molded on the extruder, and a layer of HDPE material is hot-coated on the outer surface to form the composite reinforced winding pipe. The composite reinforced winding pipe has the higherring stiffness and ring flexibility simultaneously.

Owner:ZIBO JINYANGDA PLASTIC CO LTD +1

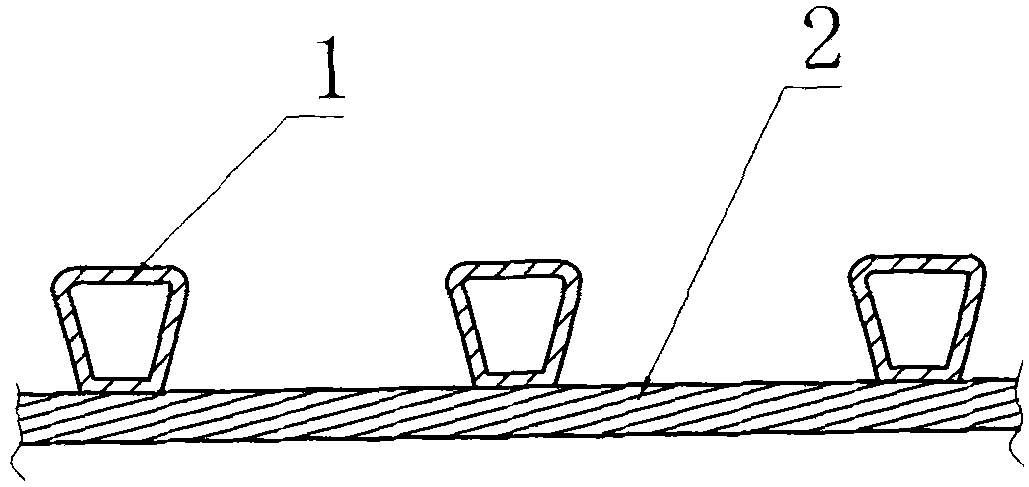

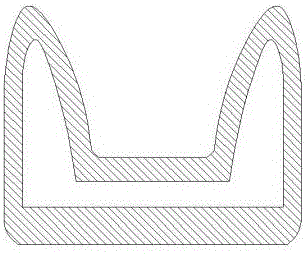

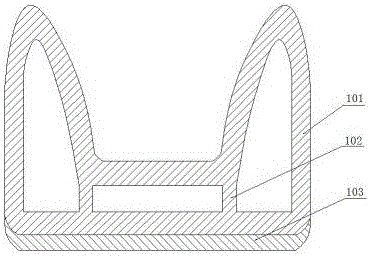

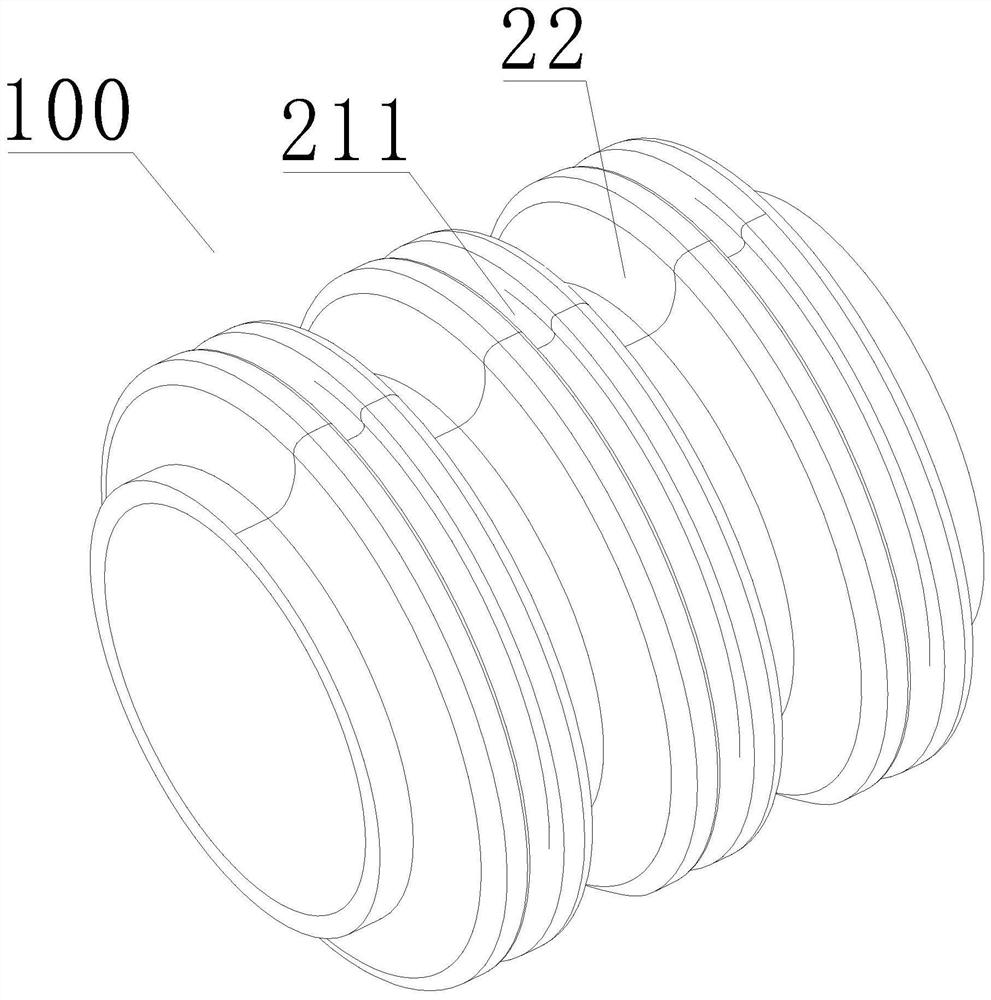

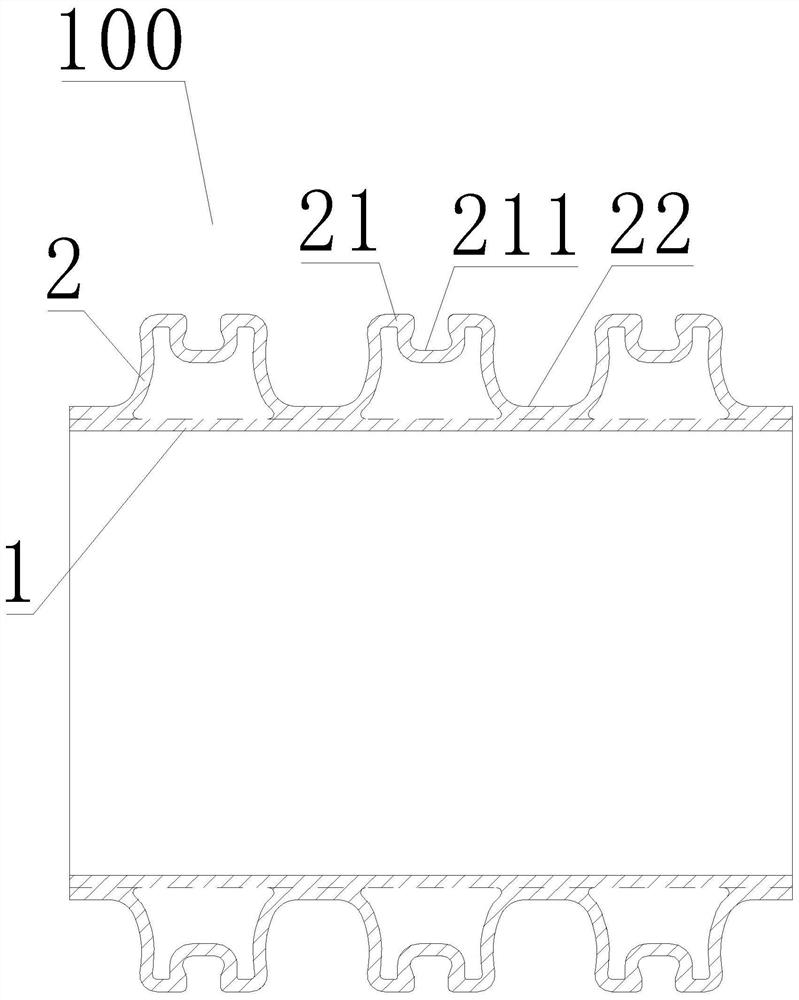

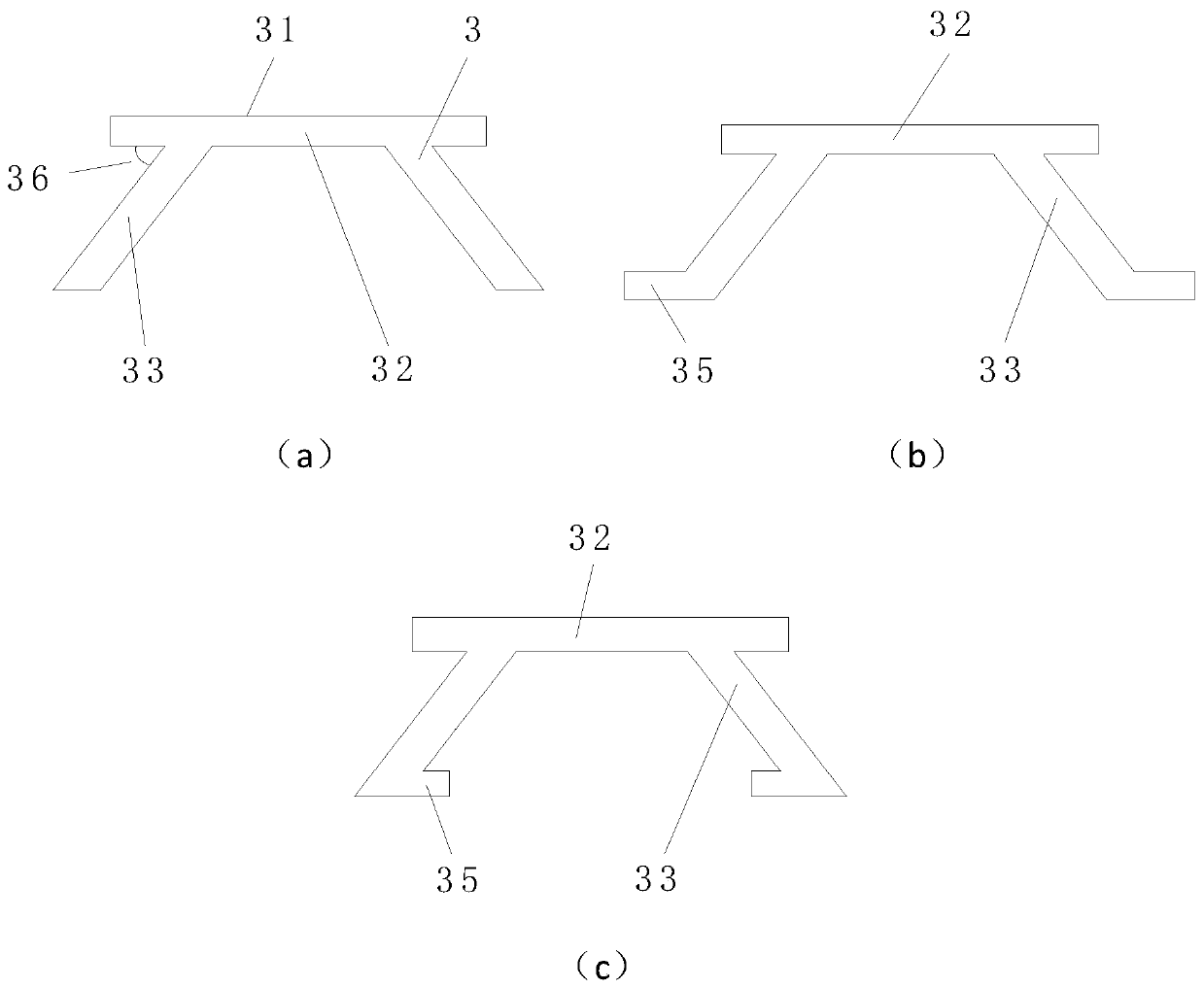

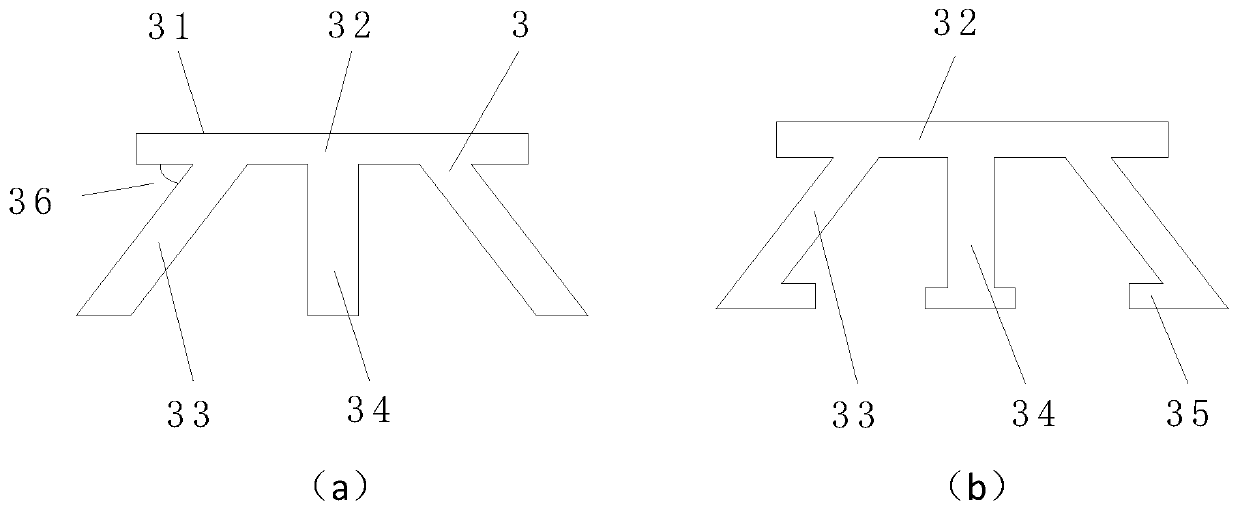

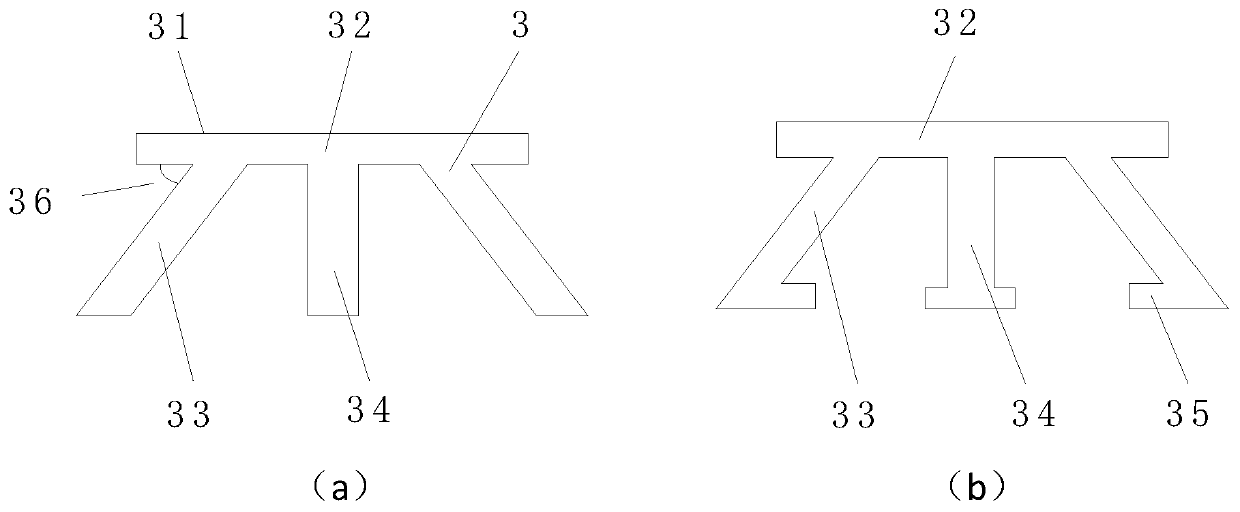

PP skeleton reinforced PE spiral corrugated pipe

InactiveCN105114709AClosely connectedSmall outer diameterCoatingsRigid pipesEngineeringMechanical engineering

The invention discloses a PP skeleton reinforced PE spiral corrugated pipe which includes a base body which is formed by winding of a squeezing unit. A reinforcing pipe is wound around the base body. The squeezing unit includes a recessed cavity and two pipe bodies. Each pipe body is in hollow arrangement. The two pipe bodies are connected and are respectively arranged on two sides of the recessed cavity. The reinforcing pipe is nested inside the recessed cavity. The squeezing unit is made of a HDPE material, and the reinforcing pipe is made of a PP material. According to the invention, a closer connection between the reinforcing pipe and the base body is achieved when the reinforcing body is wound around the base body by improving the structure of a basic unit, and the outer diameter of the whole pipe is much smaller when the same ring stiffness and inner diameter of the pipe are ensured. Furthermore, the hollow arrangement of the basic unit enables the whole pipe to have an inner pipe wall and an outer pipe wall, so that the ring flexibility of the pipe is increased and the relative density of the whole pipe is reduced. The PP skeleton reinforced PE spiral corrugated pipe is applicable to municipal pipelines.

Owner:潘小雄

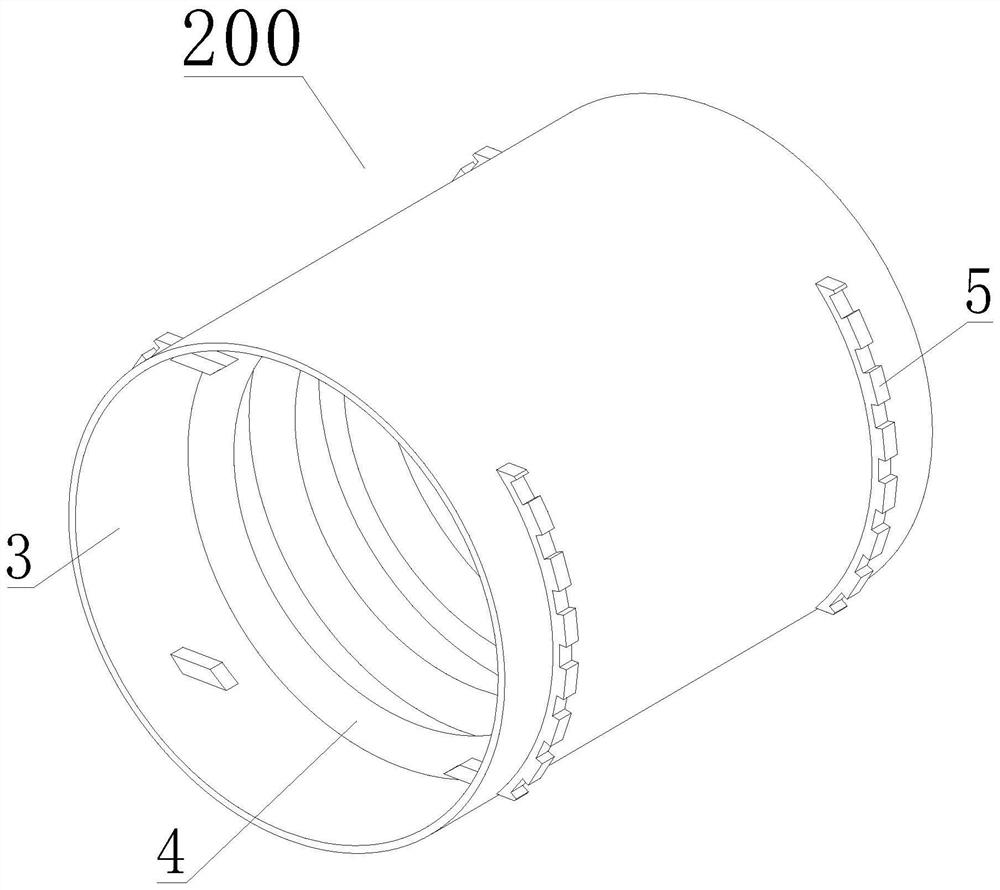

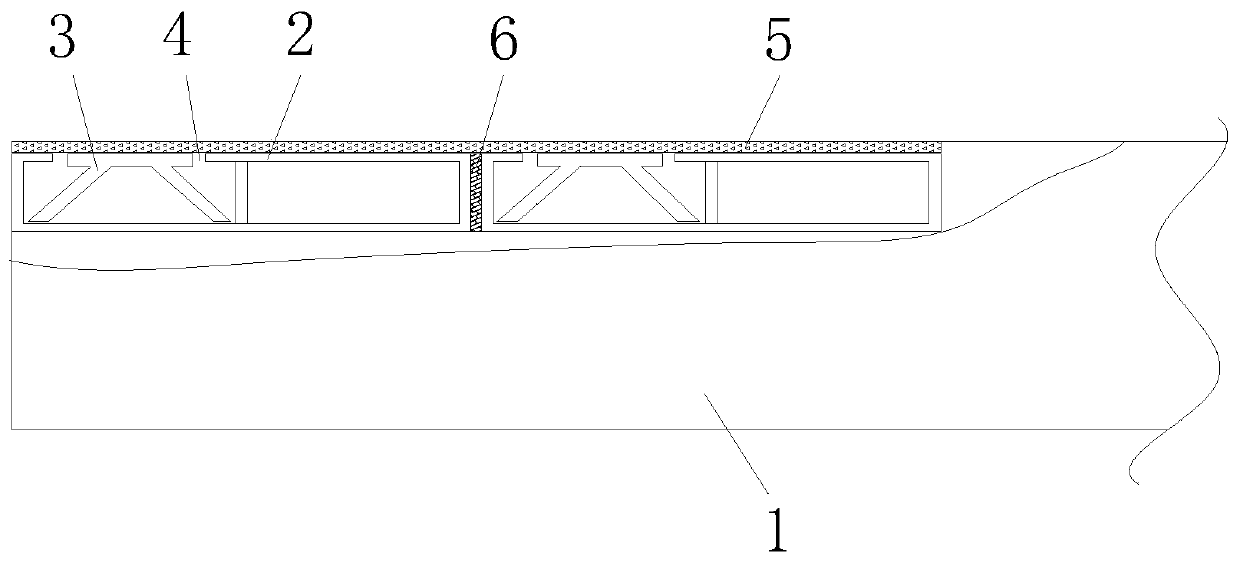

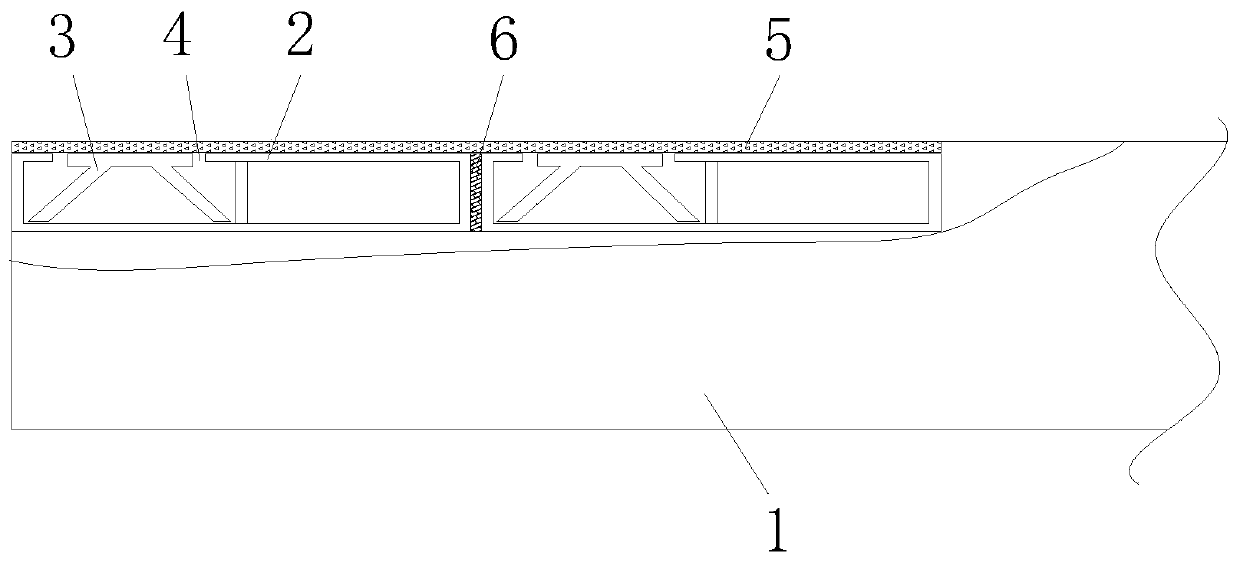

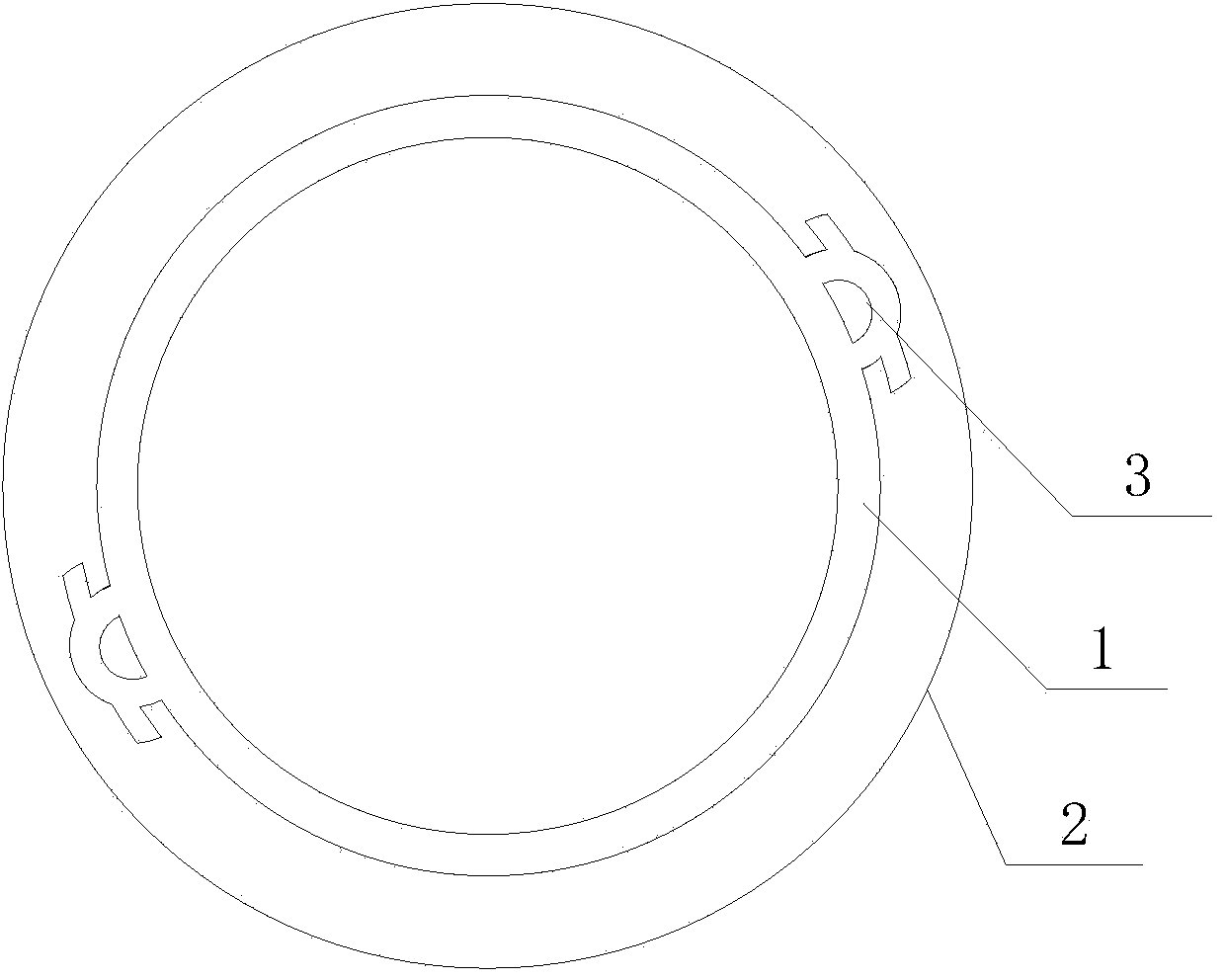

Drainage blind pipe and assembly thereof

ActiveCN106704733AIncreased ring stiffnessIncreased ring flexibilityPipe elementsFlexible pipesWeather resistanceEngineering

The invention provides a drainage blind pipe and an assembly thereof. The drainage blind pipe is of a multilayer structure composed of an anti-crystallization coating, an inner wall drainage layer, an outer wall structure layer and a filtering layer from inside to outside. The interiors of the drainage blind pipe are connected through the assembly. According to the provided drainage blind pipe of the four-layer structure, the anti-crystallization coating can effectively prevent calcium carbonate and other crystals from being attached to the pipe wall, and pipe crystallization plugging is prevented; the inner wall and the outer wall adopt materials with different components and ratios, the material formula of the inner wall can enable the pipe wall smoothness to be high, the drainage capacity is improved, in addition, the stability is high, the acid resistance and the corrosion resistance are higher, and the weather resistance is also greatly improved; crystal whiskers, various solid fillers and multiple additives are added into the formula of the outer wall, the ring stiffness, the ring flexibility and other mechanical properties of the pipe can be effectively improved, and the flame resistance of the pipe is also improved; and the filtering layer can effectively prevent silt and other particles from entering the pipe, so that pipe silting is prevented.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

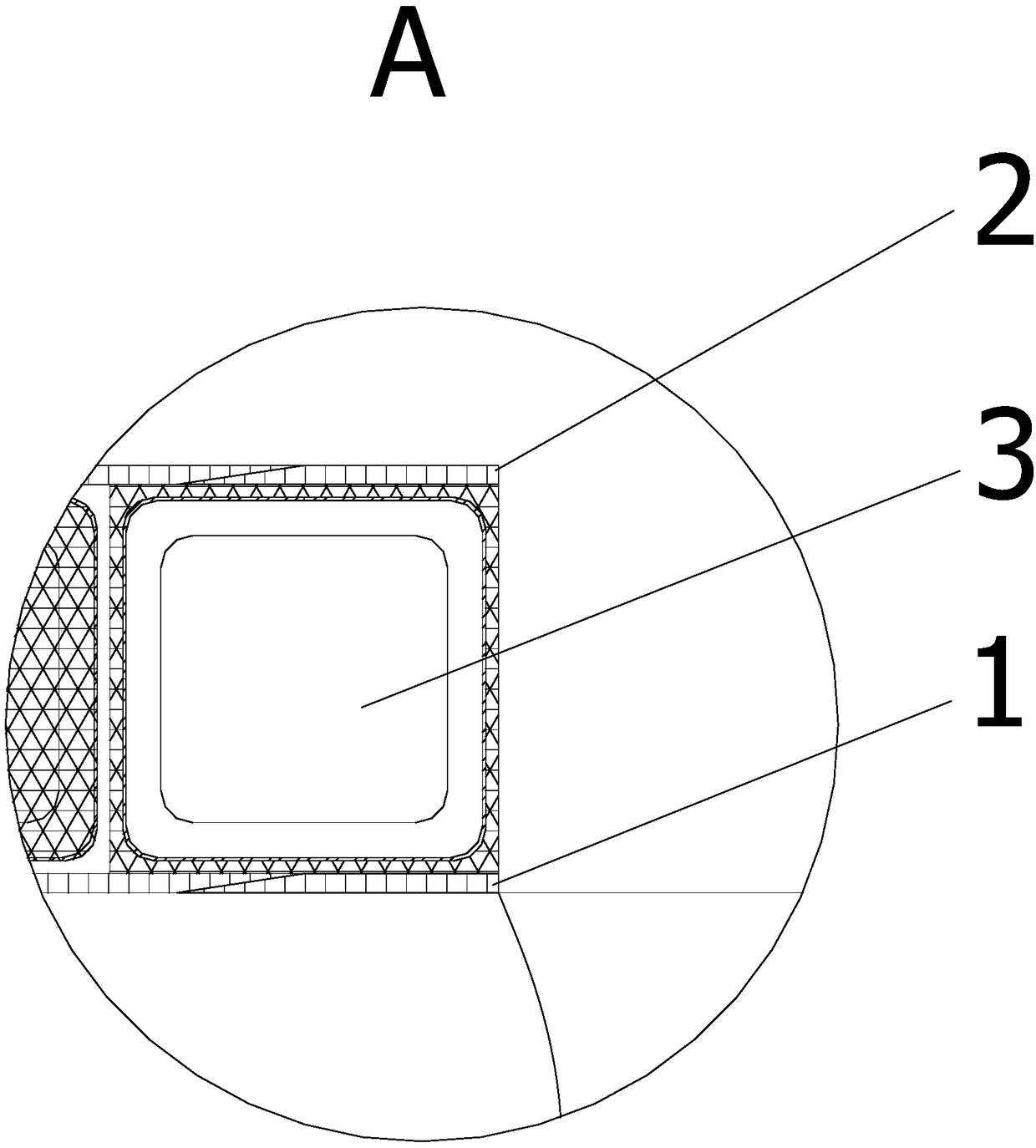

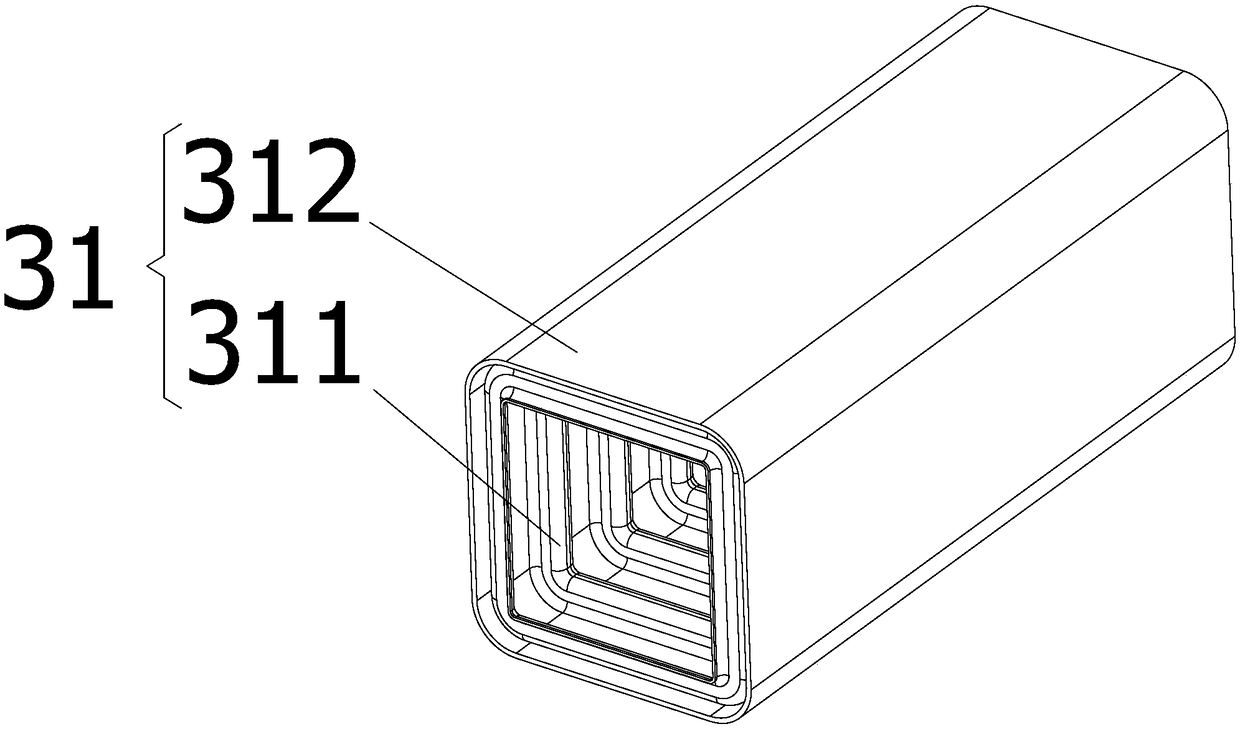

Hollow-wall pipe and manufacturing method thereof

PendingCN109140059AAvoid deformationHigh compressive strengthHollow wall articlesRigid pipesEngineeringCompressive strength

The invention relates to the field of pipes, in particular to a hollow-wall pipe and a manufacturing method thereof. The hollow-wall pipe comprises an inner layer, an outer layer and a hollow reinforcement layer, wherein the hollow reinforcement layer is formed by spirally winding a straight profile between the inner layer and the outer layer; the straight profile comprises a square single-wall corrugated pipe and a wrapping layer; four walls of the square single-wall corrugated pipe are of a corrugated structure with crests and troughs alternating in sequence in the axial direction; the crestpositions and the trough positions of the four walls of the square single-wall corrugated pipe correspond to one another; the junctions of the four walls of the square single-wall corrugated pipe adopt round corners for transition connection; and the junction of each crest and the corresponding trough adopts a round corner for transition connection. The pipe is not prone to deforming under external force and high temperature, has more excellent pressure resistant strength and damage resistance as well as high rigidity; and according to the manufacturing method, the fusion strength is high, the phenomenon that a cold-state winding pipe is extremely prone to fracture is avoided, operation is simple and convenient, the process is stable and pipes with ultrahigh diameters can be produced at will.

Owner:KANGMINGYUAN GUIZHOU SCI & TECH DEV CO LTD

PP corrugated pipe modified by ethylene propylene rubber (EPR)

InactiveCN105860267AReduce low temperature brittlenessImprove toughnessFlexible pipesUltimate tensile strengthPolypropylene

The invention discloses a PP corrugated pipe modified by ethylene propylene rubber (EPR). The PP corrugated pipe modified by the ethylene propylene rubber (EPR) comprises an outer wall pipe body and an inner wall pipe body, and the outer wall pipe body is composed of, by mass, 40-60 parts of polypropylene resin, 20-30 parts of nano calcium carbonate, 10-15 parts of ethylene propylene rubber (EPR) compound modifier, 1-3 parts of a colouring agent and 1-3 parts of a defoaming agent; the inner wall pipe body is composed of, by mass, 40-60 parts of polypropylene resin, 20-30 parts of nano calcium carbonate, 10-15 parts of ethylene propylene rubber (EPR) compound modifier, 1-3 parts of the colouring agent and 1-3 parts of the defoaming agent. By means of the PP corrugated pipe modified by the ethylene propylene rubber (EPR), low-temperature brittleness of the PP corrugated pipe can be lowered, toughness of an FRPP corrugated pipe in a low-temperature environment is improved, and non-notched impact strength, elongation at break and melt flowability of the PP corrugated pipe are all remarkably improved.

Owner:TAIZHOU YAMEIYUHE NEW MATERIAL

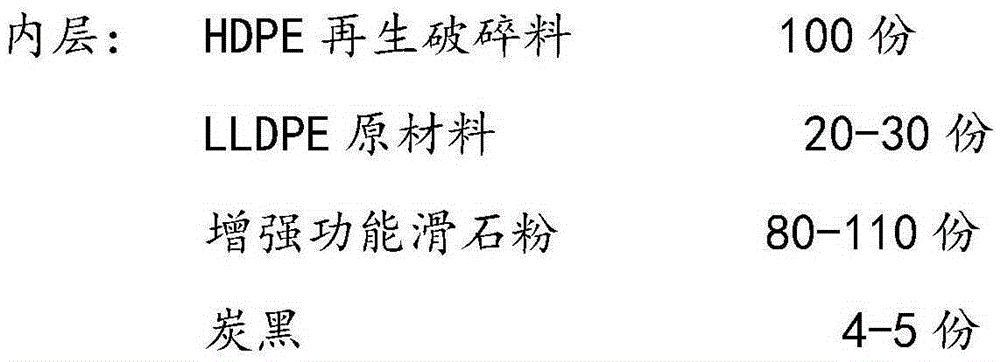

Method for processing draining corrugated pipe using waste and old mulch film

InactiveCN105131392AReduce manufacturing costIncreased ring stiffness and ring compliancePlastic recyclingCorrosionSewage

Owner:定西华冠农牧业开发有限公司

Polyethylene corrugated pipe for automobile emission flexible hose

InactiveCN106220974AIncreased ring stiffnessIncreased ring flexibilityFlexible pipesSilane couplingPolypropylene

The invention provides a polyethylene corrugated pipe for an automobile emission flexible hose. The polyethylene corrugated pipe comprises the following raw materials: 45% of polyethylene, 5% of bisphenol A polycarbonate, 5% of polypropylene, 5% of bulking agent, 3% of rigid master batch, 2% of antioxygen, 5% of light stabilizer, 5% of graphene, 5% of silane coupling agent, 2% of 3-acetamido-5-methyl isoxazole, 3% of light screener and 15% of engineering plastics. Compared with the present polyethylene corrugated pipe, the polyethylene corrugated pipe has the advantages that the ring stiffness can be increased by 20% under normal temperature condition and increased by 30% at 45-70 DEG C, the ring softness can be increased by 15% under normal temperature condition and the service life is obviously prolonged.

Owner:WUHU EVERSHINE AUTOMOTIVE COMPONENT

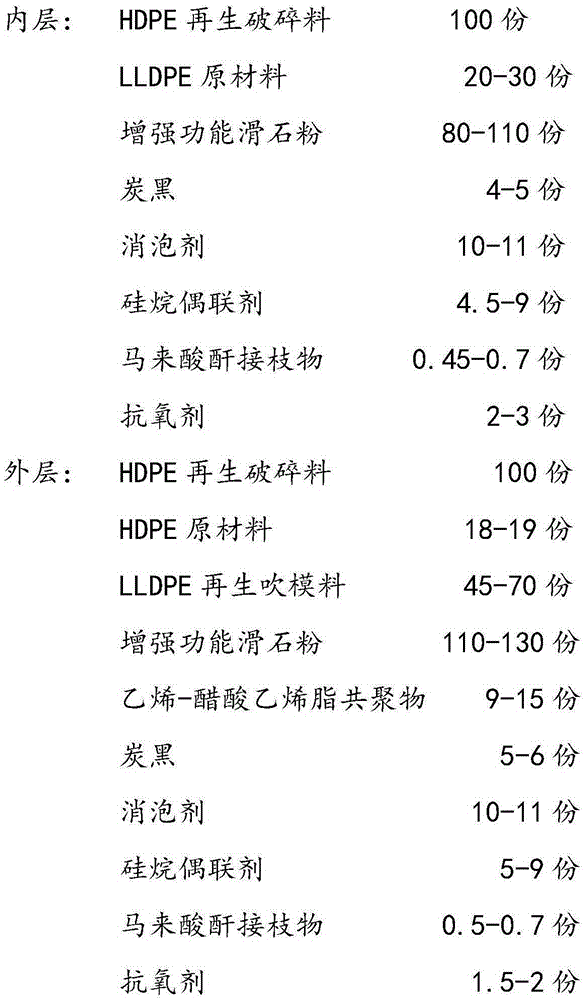

HDPE hollow wall composite reinforced winding pipe and its preparation method

ActiveCN109944984BIncrease stiffnessImprove mechanical propertiesRigid pipesMolding machineEngineering

Owner:ZIBO JINYANGDA PLASTIC CO LTD +1

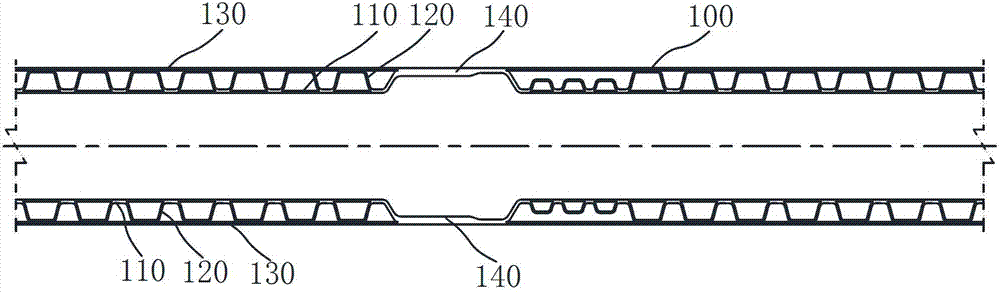

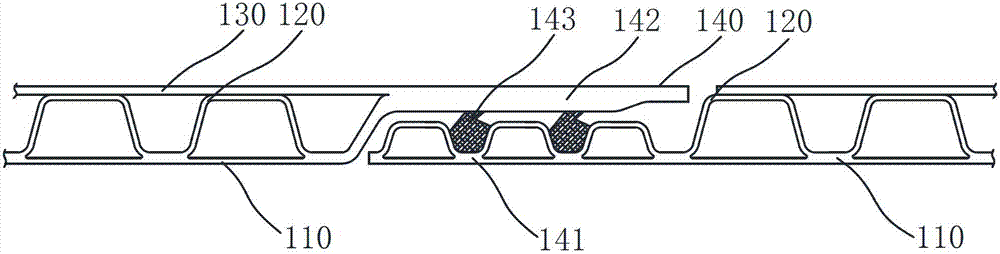

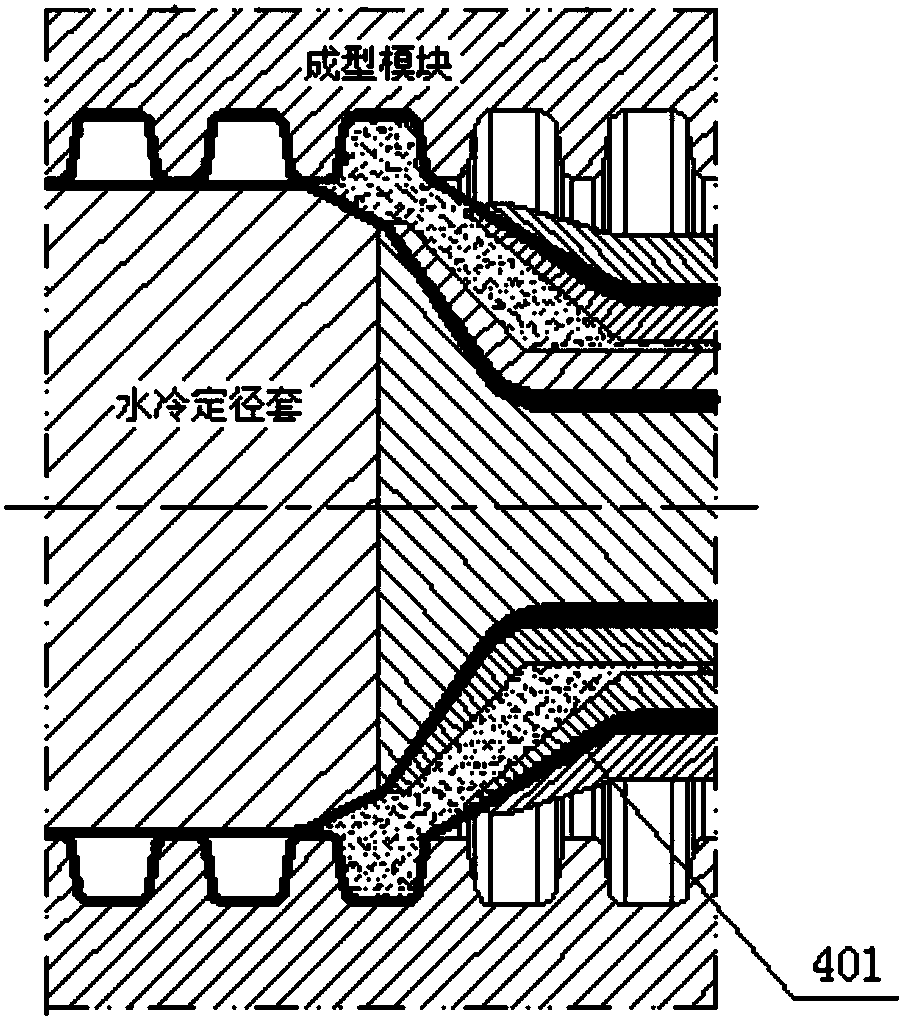

High-performance polyethylene double-wall corrugated pipe

InactiveCN104373709AEliminate internal stressIncreased ring stiffnessRigid pipesDouble wallEngineering

Provided is a high-performance polyethylene double-wall corrugated pipe. The high-performance polyethylene double-wall corrugated pipe comprises a smooth polyethylene pipe basal body and a polyethylene corrugated pipe layer attached to the outer surface of the pipe basal body. A plurality of discontinuous reinforcing ribs are arranged at the axial trough positions of the corrugated pipe layer. By means of the structural design of the reinforcing ribs of a forming module of the polyethylene double-wall corrugated pipe, the reinforcing ribs are distributed symmetrically and discontinuously along the troughs in the axial direction of the pipe with one mould as a distribution cycle. Through improvement on the structural design of the reinforcing ribs, inner stress generated in the extrusion molding process of the polyethylene double-wall corrugated pipe can be eliminated, so that the ring stiffness, ring flexibility and impact performance of the pipe are improved.

Owner:ANHUI YONGGAO PLASTIC IND DEV CO LTD

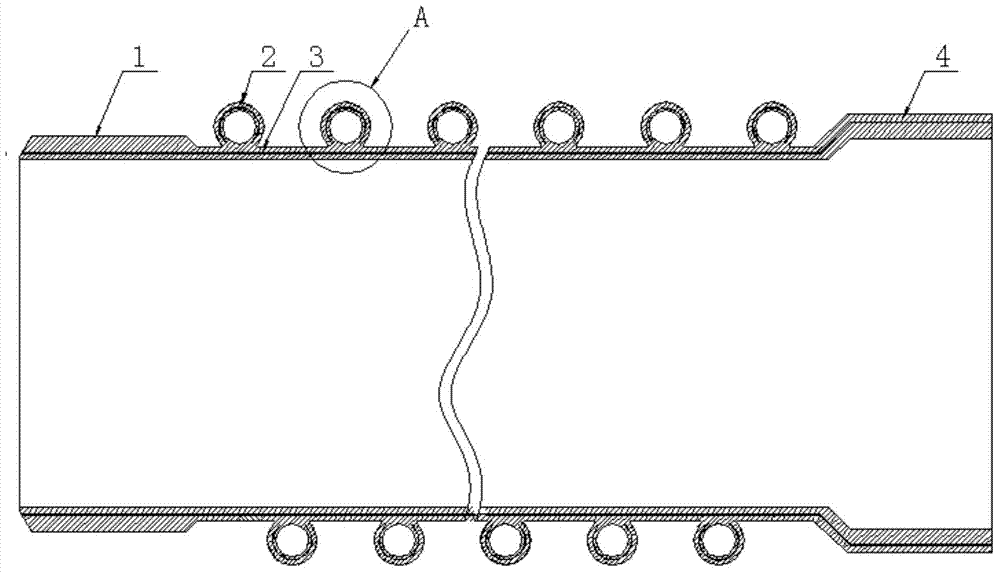

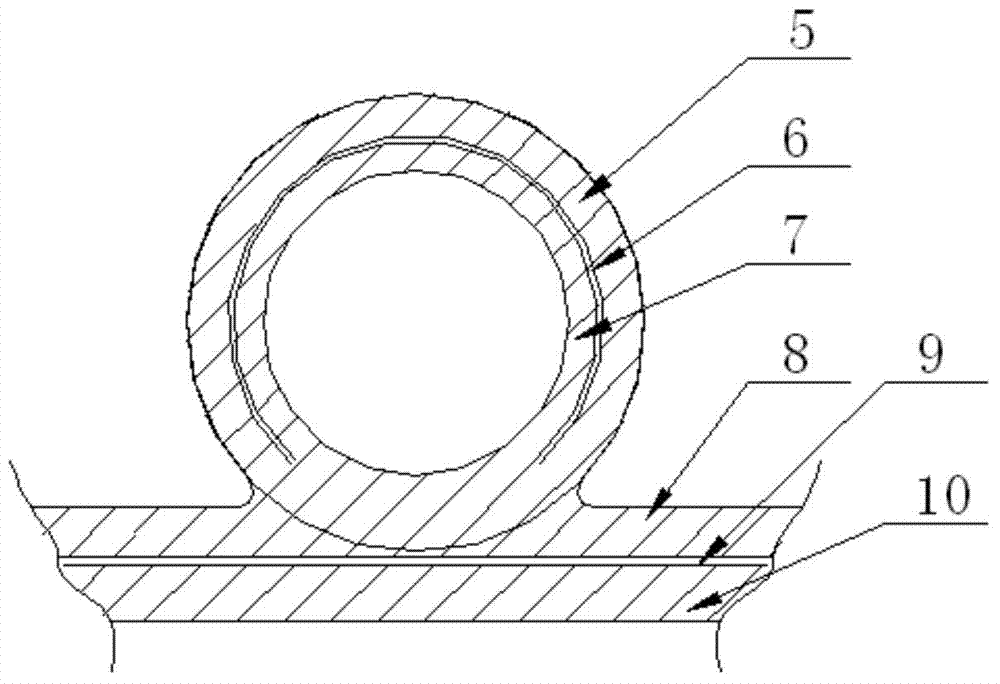

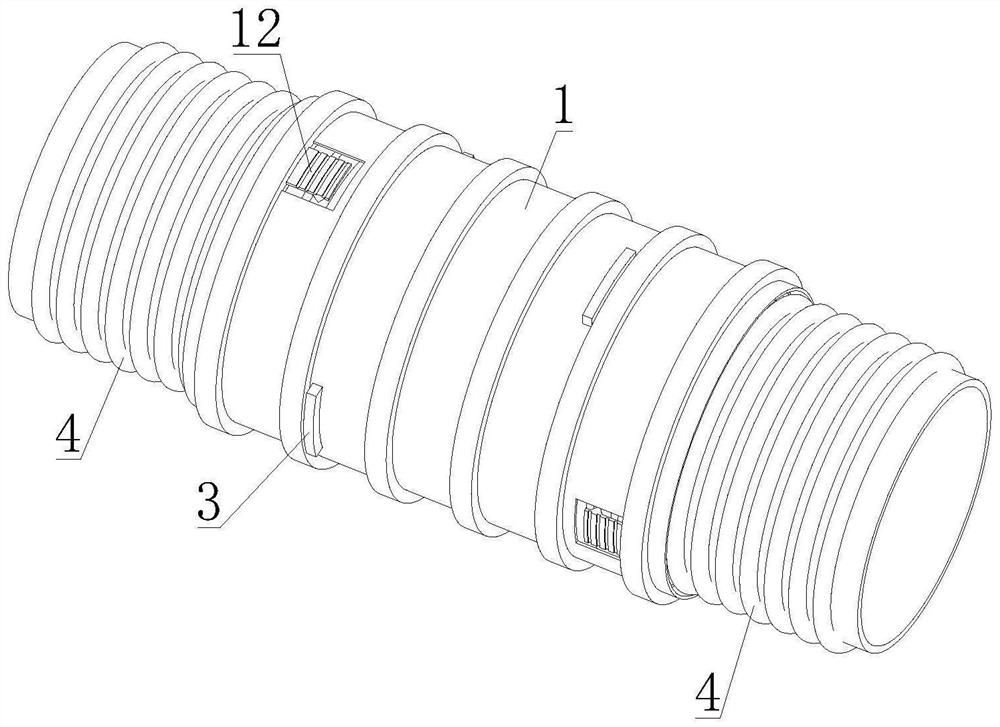

Production process of HDPE socket electric hot melting vertical plastic steel coating film winding pipe

The invention provides a production process of an HDPE socket electric hot melting vertical plastic steel coating film winding pipe, and relates to the technical field of municipal sewage systems. According to the production process of the HDPE socket electric hot melting vertical plastic steel coating film winding pipe, the plastic steel coating film winding pipe comprises the following production processes that S1, polyethylene plastic is heated and melted, the granular polyethylene plastic is made to be in a molten state, and heat preservation treatment is conducted in a heating container; S2, the steel belt is placed in the mold, the steel belt is fixed between the inner wall and the outer wall of the plastic-steel film-coated winding pipe after the plastic-steel film-coated winding pipe is subjected to injection molding; S3, molten polyethylene plastic is poured into a mold, and the molten polyethylene plastic is evenly distributed at all corners of the mold through vibration equipment. And by using the HDPE coating, external vertical ribs are protected, water is prevented from seeping into the pipeline to cause rusting of the steel belt, and the pipeline can have higher ring stiffness and ring flexibility.

Owner:重庆东搏科技有限公司

UHMWPE composite double-wall corrugated pipe

PendingCN113402801AHigh strength wear resistanceImprove wear resistanceRigid pipesHigh-density polyethylenePolymer chemistry

The invention relates to the field of plastic pipes, and provides a UHMWPE composite double-wall corrugated pipe, which comprises an inner wall and an outer wall. The inner wall is prepared from the following raw materials in parts by weight: 100 to 120 parts of low-density polyethylene, 3 to 5 parts of color master batch, 4 to 6 parts of a moisture absorbent and 4 to 6 parts of antioxidant master batch. The outer wall is prepared from the following raw materials in parts by weight: 30 to 40 parts of ultra-high molecular weight polyethylene, 70 to 80 parts of high-density polyethylene, 10 to 20 parts of reinforced master batch, 1 to 2 parts of a nucleating agent, 3 to 5 parts of black color master batch, 4 to 6 parts of antioxidant master batch and 4 to 6 parts of a moisture absorbent. According to the UHMWPE composite double-wall corrugated pipe, the ring stiffness and the wear resistance are improved, and the application field of the pipe is expanded.

Owner:福建亚通新材料科技股份有限公司

Ultrahigh molecular weight polyethylene reinforced modified polypropylene straight-wall pipe

PendingCN114801342AIncreased ring stiffnessIncreased ring flexibilitySynthetic resin layered productsFlexible pipesPolypropylene compositesPolymer science

The invention relates to the field of polymer composite materials, in particular to an ultra-high molecular weight polyethylene reinforced modified polypropylene straight-wall pipe which is formed by an inner layer and an outer layer through hot melting compounding, corrugations of the outer layer are of a polygonal n-shaped waveform structure, and the outer layer and the inner layer are both made of ultra-high molecular weight polyethylene reinforced modified polypropylene composite materials. The ultra-high molecular weight polyethylene reinforced modified polypropylene composite material comprises the following raw materials: PPR, PPB, ultra-high molecular weight polyethylene, linear polyethylene LLDPE, a compatible flexibilizer, a beta nucleating agent, a molten fat regulator, nanoscale talcum powder, 1250-mesh talcum powder, white carbon black, diffusion oil, a silane coupling agent, a light stabilizer, an antioxidant 1010 and an antioxidant 168. The ring stiffness, the ring flexibility, the impact resistance and the high and low temperature performance are improved.

Owner:安徽国天成科技有限公司

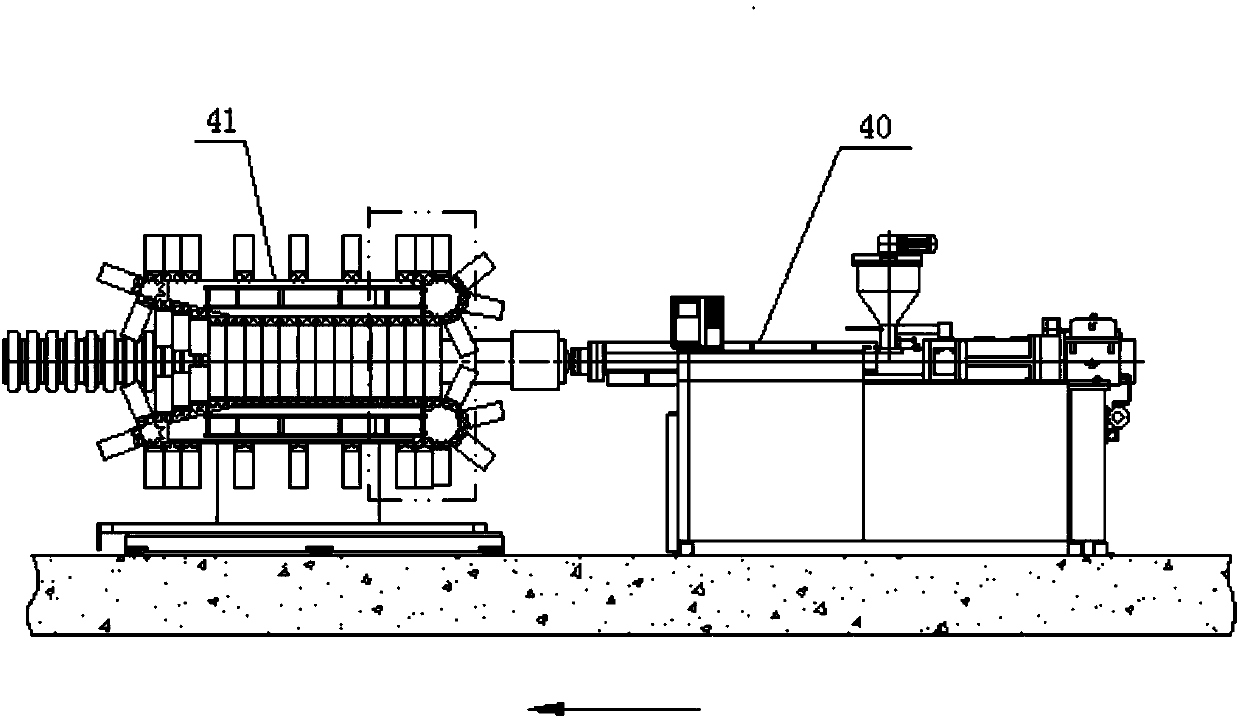

PE double-wall corrugated pipe and machining equipment

PendingCN107825685APlay a covering roleIncreased ring flexibilityFlexible pipesPipe protection against damage/wearDouble wallUltimate tensile strength

The invention discloses a PE double-wall corrugated pipe. The PE double-wall corrugated pipe comprises a corrugated pipe body; a flexible reinforcing layer is arranged at a mould-closing seam on the outer side of the outer wall of the corrugated pipe body and embedded into the outer wall of the corrugated pipe body, and the flexible reinforcing layer and the outer wall of the corrugated pipe bodyare formed integrally; and the flexible reinforcing layer has the formula of materials of, by weight, 80%-85% of PE100 pipe raw materials, 10%-15% of EVA resin and 3%-5% of color masterbatch. The invention further discloses machining equipment of the corrugated pipe. The machining equipment comprises a plastic extrusion machine and a forming module and further comprises a flexible reinforcing layer extrusion machine and a flexible reinforcing layer mould. According to the PE double-wall corrugated pipe, the flexible reinforcing layer is arranged at the mould-closing seam on the outer side of the outer wall of the corrugated pipe, and the flexible reinforcing layer and the outer wall are bonded into a whole, so that on the one hand, the wall thickness of the position is increased and the strength of the position is improved, and on the other hand, the ring flexibility performance of the mould-closing seam of the pipe is improved.

Owner:公元管道(上海)有限公司

Drain pipe fittings and their application in railway construction

ActiveCN106704733BIncreased ring stiffnessIncreased ring flexibilityPipe elementsFlexible pipesWeather resistancePipe fitting

The invention provides a drainage blind pipe and an assembly thereof. The drainage blind pipe is of a multilayer structure composed of an anti-crystallization coating, an inner wall drainage layer, an outer wall structure layer and a filtering layer from inside to outside. The interiors of the drainage blind pipe are connected through the assembly. According to the provided drainage blind pipe of the four-layer structure, the anti-crystallization coating can effectively prevent calcium carbonate and other crystals from being attached to the pipe wall, and pipe crystallization plugging is prevented; the inner wall and the outer wall adopt materials with different components and ratios, the material formula of the inner wall can enable the pipe wall smoothness to be high, the drainage capacity is improved, in addition, the stability is high, the acid resistance and the corrosion resistance are higher, and the weather resistance is also greatly improved; crystal whiskers, various solid fillers and multiple additives are added into the formula of the outer wall, the ring stiffness, the ring flexibility and other mechanical properties of the pipe can be effectively improved, and the flame resistance of the pipe is also improved; and the filtering layer can effectively prevent silt and other particles from entering the pipe, so that pipe silting is prevented.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Double-layer reinforced modified polyolefin drpo corrugated pipe for buried drainage and sewage

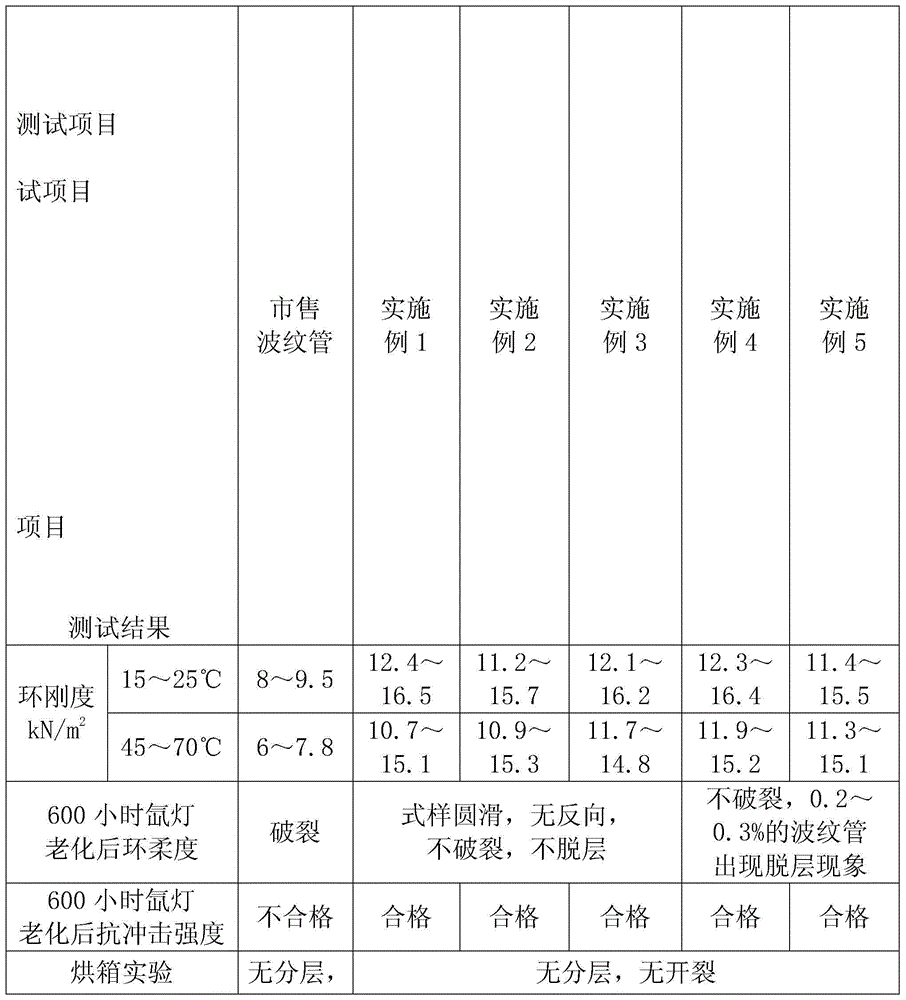

ActiveCN104989890BIncreased ring stiffnessIncreased ring flexibilityFlexible pipesRigid pipesElastomerPolyolefin

The invention discloses an underground double-layer reinforced and modified polyolefin (DRPO) corrugated pipe for water draining and sewage discharging. The pipe is formed by bonding an inner wall and an outer wall through hot melting, wherein the outer wall and the inner wall are both made of modified polyolefin materials. The modified polyolefin materials comprise, by weight, 50-75 parts of polyolefin, 5-10 parts of modified polyolefin elastomer (BPOE) and 20-40 parts of activated talcum powder. The DRPO corrugated pipe is mainly used for underground water draining and sewage discharging pipes.

Owner:源单新材料科技成都有限责任公司

UPE-T material and preparation method thereof and UPE-T double-wall reinforced winding pipe

PendingCN113801392AIncreased ring stiffnessIncreased ring flexibilityRigid pipesTubular articlesAdhesive cementPolymer science

The invention provides a UPE-T material and a preparation method thereof and a UPE-T double-wall reinforced winding pipe. The preparation method comprises the following steps: including ultra high molecular weight polyolefin UPE, modified PET and 25-40 parts of active sliding powder; and mixing the raw materials, and performing melt granulation through a double-screw extruder to obtain the UPE-T material composite material, wherein the temperatures of charging barrels are 190 DEG C, 205 DEG C, 215 DEG C, 220 DEG C and 220 DEG C respectively, and the temperature of a mouth mold is 215 DEG C. Modified PET, talcum powder and polyolefin are adopted to form a composite material UPE-T, the composite material UPE-T is used for producing the inner wall and the outer wall of the UPE-T double-wall reinforced winding pipe, a high-strength bonding material is formed by mixing resin HMCRP100N special for a high-density polyethylene pipe and a polyethylene copolymer adhesive GS101, the ring stiffness and the ring flexibility of a prepared pipe lining are obviously improved by 40%-60%, and the performance requirement of a large-caliber underground drainage blow-off pipe can be met.

Owner:四川亚塑新材料有限公司

UPP-T material, preparation method and UPP-T high-strength inspection well

PendingCN113789010AIncreased ring stiffnessIncreased ring flexibilityPolymer sciencePolyethylene terephthalate glycol

The invention provides a UPP-T material, a preparation method and a UPP-T high-strength inspection well. The preparation method of the UPP-T material comprises the following steps: mixing ultra-high molecular weight polyolefin, modified polyethylene glycol terephthalate and active talc powder, and then conducting melting and granulating through a double-screw extruder to obtain the UPP-T material. According to the invention, the modified UPP-T, talcum powder and polyolefin are adopted to form the composite material, the ring stiffness and the ring flexibility of the inspection well prepared from the composite material are obviously improved compared with those of the conventional common PP plastic modification and can be improved by 30-40%, and the performance requirements of the large-caliber underground drainage and pollution discharge inspection well can be met.

Owner:四川亚塑新材料有限公司

A manufacturing process of double-wall corrugated pipe modified by using waste hdpe

Owner:福建省高品科技管材有限公司

Manufacturing equipment of three-wall corrugated pipe

ActiveCN102767651BIncreased ring stiffnessIncreased longitudinal bending strengthRigid pipesMolten stateArchitectural engineering

The invention discloses a three-wall corrugated pipe and manufacturing equipment thereof. The pipe includes a pipe body, which includes a smooth inner wall layer, a corrugated intermediate layer and a smooth outer wall layer. The inner wall layer and the outer wall layer are closely connected with the crests or troughs of the intermediate layer, and the pipe body is provided with connection ports for mutual connection. Compared with prior arts, the inventive corrugated pipe has a smooth outer wall, which facilitates dragging and rolling during transportation and construction processes and avoids outer wall corrugation breakage and recess to further influence pipe use. Meanwhile, the outer wall layer is covered, in a molten state, on the outer wall of a double-wall corrugated pipe, which increases the pipe wave height and the moment of inertia to realize higher ring stiffness of the pipe and production of pipes with higher strength requirements on one hand, and increases the longitudinal bending strength of the pipe and improves the ring flexibility of the pipe on the other hand, thus realizing the purpose of the invention.

Owner:公元管道(上海)有限公司

Modified polyolefin drpo steel plastic reinforced winding drainage and sewage pipe

The invention discloses a modified polyolefin DRPO steel-plastic reinforced wrapped drainage blow-off pipe. The pipe is composed of an inner wall layer and an outer wall layer, the two of which are fitted and then twisted, wherein the outer wall is formed by use of a modified polyolefin material covered steel strip; the modified polyolefin material is prepared from the following raw materials in parts by weight: 50-75 parts of polyolefin, 5-10 parts of modified polyolefin elastomer BPOE and 20-40 parts of active talcum powder; the inner wall material is HDPE or PPR added with 15-25% of ultra-high molecular weight polyethylene UHMW-PE. The modified polyolefin DRPO steel-plastic reinforced wrapped drainage blow-off pipe is mainly used as a buried drainage blow-off pipe.

Owner:贵州省源单新材料科技有限公司

Polyethylene glass fiber wound structure wall pipe and its production method

ActiveCN103925431BEnhanced centroid heightReduce consumptionFlexible pipesFiberglass meshGlass fiber

The invention relates to a polythene glass fiber winding structure wall tube stock which is composed of an inner wall layer and an outer wall layer. The inner wall layer is characterized in that a composite material strip formed by adding a glass fiber material strip between an upper flaky polyethylene strip and a lower flaky polyethylene strip winds a roller mold, and edges of the neighboring composite strips are sequentially mutually lapped to form a continuous solid wall tube; the outer wall layer is characterized by being formed by outer protruding reinforcing ribs formed by the fact that another glass fiber material strip covering between an outer tubular polyethylene strip and an inner tubular polyethylene strip winds the outer surface of the inner wall layer, and the outer protruding reinforcing ribs spirally strides a lapping fusion joint of edges of the neighboring composite strips of the inner wall layer. The tubular pitch height of the reinforcing ribs can be guaranteed by adopting the glass fiber strips, good alkali resistance, flexibility and tensile resistance in the longitude and latitude height are achieved by the aid of fiberglass mesh fabric, the weight of the product is reduced, raw material consumption is reduced, cost of the product is low, internal stress of the tube stock is greatly reduced, consumption is reduced, and ring stiffness, ring flexibility and crack resistance are improved.

Owner:天津业和科技有限公司

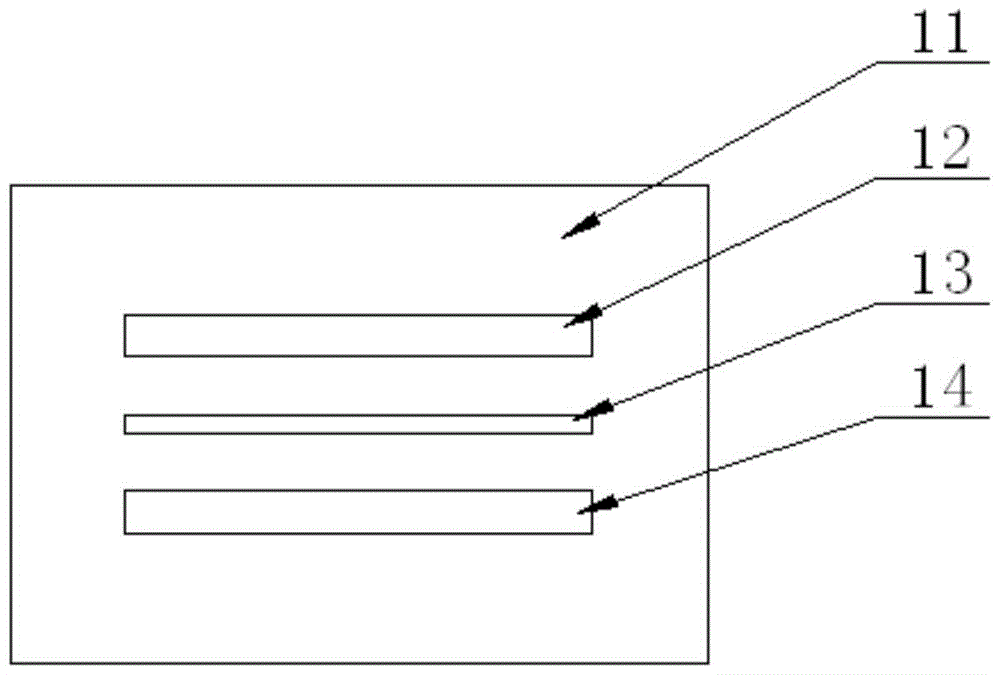

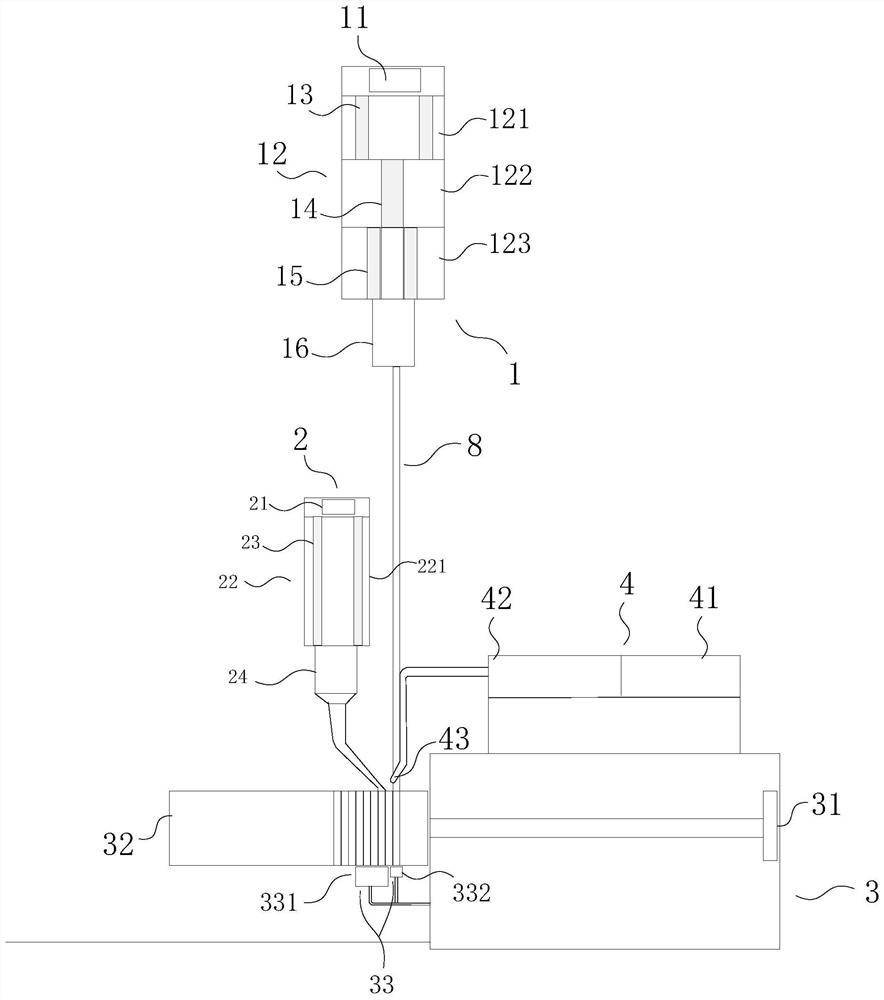

Preparation device and preparation method of multi-layer winding reinforced pipeline

PendingCN111634019AEliminates the spring effectIncreased ring stiffnessTubular articlesMoulding deviceEngineering

The invention discloses a preparation device and a preparation method of a multi-layer winding reinforced pipeline. The preparation device comprises a first heating plasticizing device, a second heating plasticizing device, a forming device and a gluing device, wherein the first heating plasticizing device comprises a first discharging mechanism, a first pipeline, a first heating plasticizing mechanism, a first forming mechanism, a first cooling mechanism and a first extruding mechanism; the second heating plasticizing device comprises a second discharging mechanism, a second container, a second heating plasticizing mechanism and a second extruding mechanism; the forming device comprises a winding driving device, a winding roller and a material pressing mechanism; and the gluing device comprises a glue melting mechanism, a glue extruding mechanism and a gluing head. According to the preparation device and the preparation method of the multi-layer winding reinforced pipeline, the springeffect of the prepared winding pipe can be eliminated, the ring stiffness, the ring flexibility and the impact resistance of the winding pipe are improved, and the service life of the pipeline is prolonged.

Owner:顾顺昌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com